Page 1

AN1353

Application note

ASD

ST62000C software description for cooling thermostat applicatons

1 Introduction

In this document, we explain the software of an Electronic thermostat bread board. The

demonstration kit has been developped by STMicroelectronics and is available under

THERM01EVAL reference.

This board illustrates the operation of a low cost electronic thermostat for 220-240V 50Hz

cold appliances, including STMicroelectronics ACS102-5TA, ACST6-7ST and ST62 devices.

The microcontroller will ensure four functions:

● Temperature regulation (temperature capture through NTC resistor + Hysteresis

regulation).

● Compressor monitoring: the motor is controlled depending on fridge temperature. To

start it, the starting triac Ts and the run triac Tr are triggered simultaneously for 500ms.

Then, only the run triac will continue to conduct.

● Overcurrent detection: this is based on the measure of the peak current using a shunt

resistor. During the one second (500 ms+500 ms) of starting transient, this routine

does not run.

● Internal light bulb control.

2 Hardware configuration

2.1 General information

The power supply of the microcontroller is a capacitive one. Its particularity is that the VSS

is 5V less than the Neutral. This power supply can be called a “negative supply”. This

generates flowing out current from the ACS/ACST gates (ACS are triggered only with a

negative gate current). This feature must also be kept in mind when the overcurrent

detection is implemented. It will define in which polarity the current can be sensed.

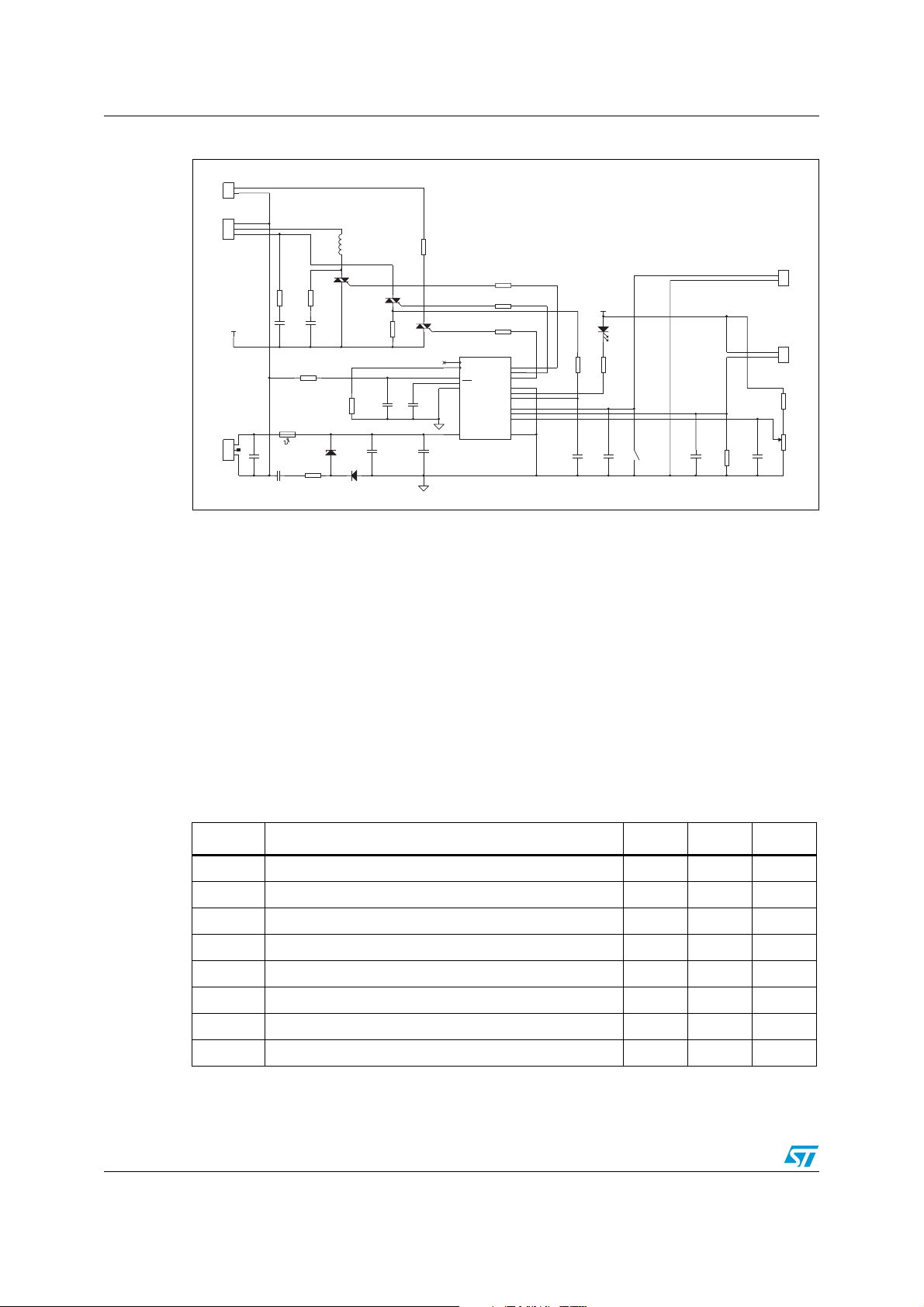

Figure 1 illustrates the board electrical circuit.

January 2006 Rev 2 1/17

www.st.com

Page 2

Hardware configuration AN1353

Figure 1. Bread-board schematic

J1

1

BULB

2

J4

L

Run

N

L

C4

10 nF X2

Start

R13

51R

C5

1nF

FUSE 6 A / 250 V

F1

C1

470nF X2

R6

470K

R11

47R 1/2 W

L_PCB

6µH

Tr

Start ACST6

R14

51R

C6

1nF

R10

50m 1/2 W

R9

47K

VDD

+

D2

6V2 1.3W

D3

C11

680pF

C3

2200µF / 10 V

Ts

Run ACST6

C2

100nF

R1

33R 1/2W

C12

1 µF

Tb

Bulb ACS102

2

3

4

6

5

1

U1

OSCIN

OSCOUT

NMI

RST

VPP/TEST

VDD

ST62T00C

PB0/AIN

PB1/AIN

PB3/AIN

PB6/AIN

PB7/AIN

PB5/AIN

J3

R2

160R

R3

160R

R4

360R

15

PA1

14

PA2

13

PA3

12

11

10

8

7

9

16

VSS

VDD

D1

LED

R5

R7

33k

1.5K

C10

2.2nF

doorswitch

2.2nF

S2

C9

R8

C8

62K

2.2nF

1

DOOR

2

J2

1

NTC

2

R12

1K

POT A

100K

C7

2.2nF

MOTOR

MAINS

1

2

3

VDD

J5

1

2

3

Note the following features on the MCU hardware environment:

● The clock is achieved by the internal oscillator

● No external reset circuit is used, thanks to the Low Voltage Detector option of the MCU

● The Zero Voltage Crossing (ZVC) event is sensed through R6 by the NMI pin.

2.2 I/O port configuration

The following table explains what the I/O ports are used for, and how they are configured,

beginning with the Port B which is configured in Input (except for PB1 which is configured as

a push pull output).

All the inputs are configured with a pull up resistor, except for when they are used as an

ADC input. No In-terrupt is active on any of these pins.

Table 1. Port B configuration registers

Pin Name USE DDR OR DR

PB0 Not used 0 0 0

PB1 Switch ON the LED / Switch OFF the LED 1 1 0/1

PB2 Not existing for ST6200 0 0 0

PB3 SHUNT voltage Analog Input / Input with pull up 0 1/0 1/0

PB4 Not existing for ST6200 0 0 0

PB5 Temperature order Analog Input / Input with pull up 0 1/0 1/0

PB6 Door switch information 0 0 0

PB7 Cabinet temperature Analog Input / Input with pull up 0/0 1/0 1/0

All port A pins are configured as push pull outputs. Table 2 details the option choices and

configuration reg-isters.

2/17 Rev 2

Page 3

AN1353 Main program

Table 2. Port A configuration registers

Pin Name USE DDR OR DR

PA1 START ACST6 ON / START ACST6 OFF 1 1 0/1

PA2 RUN ACST6 ON / RUN ACST6 OFF 1 1 0/1

PA3 LIGHT BULB ON / LIGHT BULB OFF 1 1 0/1

3 Main program

3.1 Mains period measurement

As the board does not embed an oscillator or resonator, the internal resonator of the MCU is

used to achieve the clock. But, in this case, the running frequency is given within a range of

20%. This is not enough to ensure an optimum pulse gate current control with a power

consumption as little as possible.

To increase the timer accuracy, the MCU uses the Zero Voltage Crossing (ZVC) events to

have time infor-mation. The LINE voltage is connected to the NMI pin through a high

impedance resistor. An interruption will then occur at each ZVC event. The MCU has just to

launch the timer decrementation between two NMI interrupts to calculate how much one

must load the TCR register to count down 20 ms.

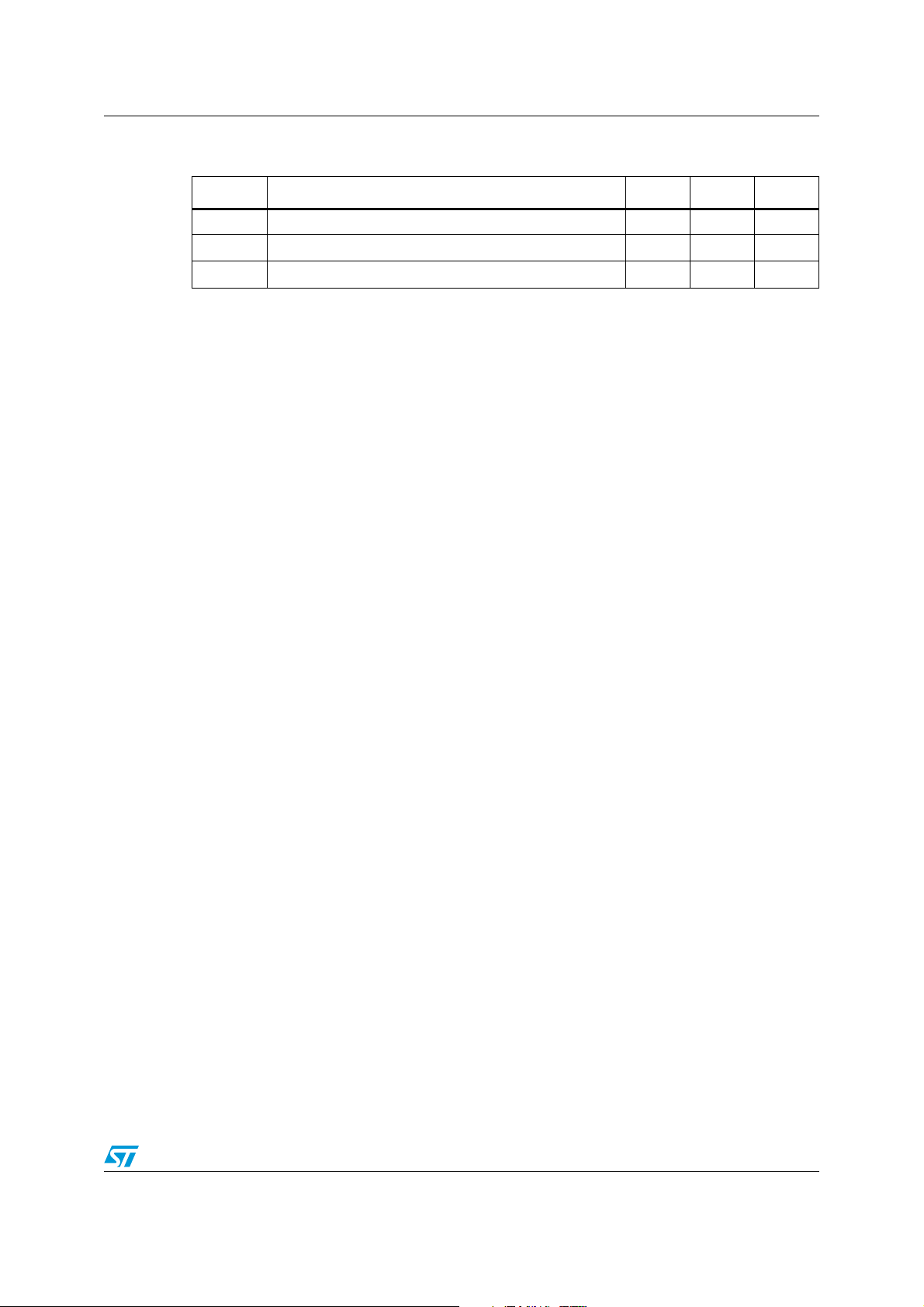

Of course, in normal operation, the timer can be used for other tasks than counting the

mains period. The period measurement will then be based on the rest of time from the last

timer utilization and the next NMI interrupt. This measured time is saved as DELTAT (see

Figure 2) by the software. The 20 ms will then equal the DELTAT, plus the sum of times T1 to

T3, plus the time lost due to calculator operations between each timer stop and launch (see

Section 4.3).

Note: Such a method is only valid when the mains frequency is know in advance; i.e. for a board

dedicated to one range of AC mains voltage. In our case, the software and hardware are

dedicated to 220/240 V 50 Hz applications.

Rev 2 3/17

Page 4

Main program AN1353

Figure 2. Timing definition

NMI

Mains Voltage

PA3

PA1 / PA2

Subroutines

Calcul

Delay 1

Current

Measure

Motor

Status

T1 T2 T3 T4 T5

3.2 Subroutines execution time checking

In order not to miss the timer interrupt events, the CPU must be completely free and ready

to check the timer interrupt flag. This means that all subroutines must be completed before

the expected end of the timer decrementation.

Figure 2 shows that the subroutines are placed at different moments, depending on their

length. For exam-ple, the longest CPU action is when the MCU calculates the T1 to T5

delays. This action can last up to more than 7.2 ms for a 4 MHz MCU clock frequency. Then,

there is not enough time available between two timer interrupts to calculate these five

values. This is the reason why the delay calculation subroutine has been split into two parts

(Calcul-Delay_1 and Calcul-Delay_2). These two parts are respectively placed during T4

and DELTAT decounts

Ta bl e 3 gives the maximum duration of each subroutine (for a 4 MHz clock frequency, and

the for the lon-gest software loops).

Table 3. Subroutines maximum durations

Calcul

Delay 2

Loads

Control

DELTAT

SUBROUTINE NAME MAXIMUM TIME

Loads_Control 0.93 ms

Motor_Status 0.26 ms

Current_Measure 0.92 ms

Calcul_Delay_1 1.75 ms

Calcul_Delay_2 5.49 ms

Ta bl e 4 gives the code execution maximum times for all the instructions written in the

software, before each subroutine (“code execution time” column). Then, according to the

implemented durations, the time, still available for the CPU, is given with a 0.2 ms safety

margin.

4/17 Rev 2

Page 5

AN1353 Main program

Table 4. CPU available time

Name

T1 0.45 0.25 0 0

T2 1.05 0.13 0 0.72

T3 1.75 0.13 0 1.42

T4 3.95 0.85 (T50 Hz average) 1.75 1.15

T5 2.80 0.09 0.26 + 0.92 1.33

DELTAT 6.75 0.08 5.49 + 0.93 0

TOTAL 4.62

Duration

(ms)

Code execution time

(ms)

3.3 Start-up and smart reset

At each RESET interrupt, the program first checks if the data stored in the RAM are as

scheduled or not. In-deed, a RESET can occur without the supply voltage having fallen

below VRM (Data retention parameter: 0.7 V). In this case, a whole start-up is not

necessary, and the program can keep working with the previous RAM data. This is helpful in

order to avoid missing loads control when a RESET occurs, due to an EMI problem for

example.

If the checked RAM registers are not as expected, then a complete initialization procedure is

launched (see Appendix B). This routine, among other things, configures the A and B ports,

waits 100 ms before go on (wait-ing for the stabilization of the supply), and measures the

mains period for the first time.

Subroutines time sum

(ms)

Available time (ms)

If the RAM area is adequate, then a “Smart Reset” can be performed. Only the registers

which are used to store internal sub-routines variables are cleared. Only the main registers

keep their previous values (motor status, etc.).

It is important to note that this start-up procedure can miss firing some loads during one

mains cycle. This is why, if the motor was at start-up state before a “Smart Reset”, it is better

to stop the motor. This avoids switching both the Tr and Ts devices ON together when the

split phase capacitor can be charged (refer to AN1354). This is done by simply setting to

high level the overcurrent detection flag.

Rev 2 5/17

Page 6

Gate current pulses AN1353

4 Gate current pulses

4.1 General description

The gate current pulses are generated during the main program (refer to Appendix A and

also to Figure 2). The Port A pins are set or reset depending on the information defined by

the sub-routines described in para-graph 5.

Annex 1 gives the flowchart of the main program. The ZVC events are sensed thanks to bit

0 of the FLAG register, which is only set during the NMI interrupt. The end of timer

decrementations are also sensed by bit 1 of the FLAG register, which is set during timer

interrupt.

First, as soon as the ZVC is detected, the T1 decrementation is launched and the light bulb

is switched on, if requested, by pulling PA3 down to VSS. After the timer interrupt, PA2 and

PA3 are set, or not, depending on the process status. After T2 decrementation, PA3 is set

and a new decrementation is launched (T3) to wait to turn off both Tr and Ts.

After this pulse generation, the timer counts down T4 to synchronize the current measure to

the moment at which it reaches its peak value. After the “Current_Measure” sub-routine, T5

is decremented in order to reach the beginning of the next half cycle. Gate current pulses

are then generated as in the previous cycle.

4.2 How to change the pulse duration?

All the pulse durations are based on a one half-cycle time reference basis. Indeed, in order

to count the pe-riod time, the timer is launched after the last current pulse, when VLN is

positive. DELTAT will then always represent a time shorter than 10 ms. To be sure that the

timer overflow will never occur before the next NMI interrupt, we must ensure that the time to

decrement 256 will be always higher than 10 ms.

This condition can be reached with a 32 prescalar ratio. With such a value, even with the

maximum allowed MCU clock frequency, the overflow will happen in 12.28 ms.

T50Hz = DELTAT + T1 +T2 +T3, then represents the value to load in the TSCR register to

achieve a 10 ms overflow period.

To define an “n” ms duration, consider the following relation:

10 ms T50Hz→

n

(ms)

Tx→

So, Tx must be loaded in the TSCR to have a timer interrupt after “n” ms. However, as a

division by ten is not easy to implement, and in order to increase the register accuracy, it is

better to use variables in the range of 256. The variable “Dx” is used and defined as

explained below:

Dx =

⎫

Tx =

⎬

⎭

n x 256

10

T50Hz x n

10

(ms)

6/17 Rev 2

Page 7

AN1353 Gate current pulses

When, Tx can be calculated as follows:

T50Hz x Dx

Tx =

256

Dividing by 256 is thus easily achieved simply by considering the Most Significant Byte of

the multiplication result of T50Hz and Dx.The Dx variables are defined in the Constants list

at the beginning of the software. To implement new pulse timings, only the values in this list

have to be changed.

For 60 Hz applications, the “10ms” used in the calculation should be replaced by 8.33.

4.3 Influence of the code time

In fact, the timer is not launched exactly when it has to be. This is due to the time required by

the MCU to perform some instructions between the last interrupt and the effective

decrementation beginning.

For example, before the launch of the first T1 decrementation, the program must run the

NMI interrupt, save the DELTAT result, write PORT A and the start the timer. These 47

instructions all in all last 200 µs for a 4 MHz MCU clock frequency. Then, to ensure that the

gate current will be applied on the Tr and Ts de-vices at the right time, it is better to cut off

this delay from T1.

Furthermore, this delay will vary depending on the MCU clock frequency (fcpu), which will

vary according to the junction temperature and the supply voltage level. So, a method is

required to remove the code delay whatever fcpu is.

First, we know that the oscillator frequency is divided by 13 to drive the CPU core.

Therefore, “N” CPU cy-cles last 13xN/fcpu seconds.

Secondly, the CPU oscillator frequency is divided by 12 to drive the Timer, and then divided

by the division factor programmed in the TSCR register. In our case, the division factor is 32

during the main program loop. Therefore, one unit timer counter equals 12x32/fcpu. Based

on the previous formula, we can easily convert N cycles code execution time to the timer

counter value (Tcode), as shown below.

f

Tcode = = N x

N x 13

f

cpu

x

12 x 13

cpu

13

384

For example, the length of the code time for 47 cycles approximately equals one unit of the

timer counter. Then, one must be subtracted from T1 in order to rectify the gate current

pulse delay from the code execution delay.

For T2 and T3, it does not matter if the code execution delay is removed or not. Indeed, it is

not a problem that the gate current pulses last longer.

For T4, it is important to begin the current measure at the right time. The 98 cycles must

then be subtracted from T4. This leads to subtract 3 from the TSCR register value.

When the half-cycle duration is calculated, the code execution time must also be added to

T50Hz. As 110 cycles are performed, 4 must be added to the T50Hz value.

Rev 2 7/17

Page 8

Sub-routines AN1353

4.4 Timing example

Ta bl e 5 gives the values which must be loaded into the TSCR register to implement a 1.5 ms

pulse (to trig-ger the light) and a 0.45 ms delayed pulse of 2.8 ms length (to trigger the both

windings of the motor). These are the values programmed by default in the THERM01EVAL

board microcontroller.

Table 5. TSCR values to implement the required pulses

NAME DELAY (ms) TSCR value (decimal)

T1 0.45 (-code delay) 12 -1

T2 1.05 27

T3 1.75 45

T4 3.95 (-code delay) 101 -3

5 Sub-routines

5.1 Load control

This sub-routine defines which load has to be turned on (refer to Appendix C). The light bulb

is then controlled de-pending on the door switch information. It is the sensed temperature,

the order set by the external potenti-ometer and the Hysteresis law, described in Figure 3,

that instructs the motor to be ON.

Order 1, the upper limit, equals the temperature order set by an external potentiometer plus

a threshold value (which can be changed, refer to “THRES” in the constants list). Order 2

equals the same order minus this threshold.

Figure 3. Temperature Hysteresis control

MOTOR ON

Temperature

MOTOR OFF

ORDER 2 ORDER 1

8/17 Rev 2

Page 9

AN1353 Sub-routines

This sub-routine also defines if the motor must be started up. If the temperature becomes

higher than ORDER 1, the compressor should be started. But, care must be taken not to

start the motor if it is already ON. Otherwise, Ts could be switched on when Tr is already

ON, resulting in a capacitor discharge through the two devices.

Note that each evaporator temperature and potentiometer voltage measurements are

refreshed every 256 cycles (by the average value of the previous 256 cycles). This means

that the temperature control is acti-vated every 5 seconds.

5.2 Motor status

This sub-routine defines which ACST must be triggered depending on the motor state and

the order asked by the “LOADS_CONTROL” routine. This flowchart is shown on annex 4.

When the motor is required to be ON, both Tr and Ts are switched on 500 ms. After that,

only Tr is fired, if the motor must still be ON. In this case, the MOTOR_STATUS routine

claims that the motor is in a transient state again for 500 ms. This state is used by the

“CURRENT_MEASURE” sub-routine. Indeed, the current must not be measured during the

first one second of operation, during which the current is high. On the other hand, if the

current remains high after this one second, that means that an abnormal condition has

occurred (stall rotor for example) and it is better to stop the motor.

5.3 Current measure

The current measure is only performed when the motor should be ON, and if it is not at

start-up transient state. At each overcurrent detection, the motor is stopped, a LED is

switched on during 5 s, and, of course, the current measure is no longer performed.

The overcurrent detection is, in fact, based on an average of four measures. This is done to

reduce EMI noise. The over current therefore always acts with at least an 80 ms delay,

because only one measure by cycle is done.

The measured value is compared to the “VLIMIT” constant. A 242 value equals a voltage of

5.22 V at the in-put of the Analog to Digital Converter (for a 5.5 V supply). As the measure is

achieved thanks to a 50 mOhm shunt, referenced to the Vdd, this value is similar to a 5.6 A

current. Such a current means that the rotor is stalled because, in steady state, a 100-300

W compressor always sinks a current lower than 3 A.

Rev 2 9/17

Page 10

Conclusion AN1353

6 Conclusion

This paper has presented how a software for ST6200C MCUs has been developed for

thermostat applica-tions. The main goals of this software are:

● Low cost: no external resonator is used even if good accuracy for time control is

required. This is achieved thanks to a mains period based calculation method. No

external RESET circuit is needed thanks the MCU LVD option.

● Low consumption: all ACS and ACST devices are triggered by pulsed gate currents in

order to reduce the average current consumption.

● Noise immunity: the noise immunity has been increased by several software

techniques (smart reset, ADC results averaging). The hardware watch-dog option must

also be activated and unused program memory space can be filled as described in the

AN435 Application Note.

This paper will help users to adapt the software to their own requirements. The following

data in particular must be checked:

● Peak current measure moment (T5 register)

● Gate current pulses delay & duration

● Maximum peak current value to detect an over current (VLIMIT constant)

● Temperature control Hysteresis threshold.

10/17 Rev 2

Page 11

AN1353 Main program flowchart

Appendix A Main program flowchart

Figure 4. Main program flowchart

MAIN PROG

NEXT

Wait for ZVC event

Reset NMI flag

Save TCR in DELTAT

Starts T1 decrementation

Writes PA3 output data

Wait for timer

interrupt

Start T4 decrementation

First cycle

passed ?

no

Starts T2 decrementation

Set PA3 output

Wait for timer

interrupt

Starts T3 decrementation

Set PA3 output

Wait for timer

interrupt

Set PA1 output

Set PA2 output

Negative

Cycle

passed ?

no

yes

Start timer decrementation

Call Calcul_delay_2

Call LOADS_Control

yes

Decrementation COUNT5

SUM(T50Hz) < - SUM(T50Hz)

+ T50Hz + T1 + T2 + T3 +

DELTAT + 4

COUNT5 = 0?

yes

SUM(T50Hz) < -SUM(T50Hz) / 4

no

Call Calcul_delay_1

Wait for timer

interrupt

Start T5 decrementation

Call CURRENT_MEASURE

Call MOTOR_STATUS

NEXT

COUNT5 < -2

MAIN PROG

Rev 2 11/17

Page 12

Start-up procedure AN1353

Appendix B Start-up procedure

Figure 5. Start-up procedure

RESET

Sub-routines Internal

Variables Initialization

Ram data

OK ?

yes

no

Registers Initialization

PORT A&B Configuration

Write “Check-Ram” registers

Wait 100 ms

Measure Mains Period

(T50Hz)

MAIN_PROG

Start-up = 1 ?

yes

no

PORT A&B configuration

Outputs writing

Over-Current < -1

Switch OFF Tr&Ts

12/17 Rev 2

Page 13

AN1353 Loads_Control sub-routine

Appendix C Loads_Control sub-routine

Figure 6. Loads_Control flowchart

LOADS_CONTROL

Fridge door

open ?

yes

no

Switch OFF the light

Read Temperature order

ORDER 1 < - Order + THRES

ORDER 2 < - Order - THRES

Temperature

> ORDER 1?

Motor start-up not allowed

yes

Switch ON the light

yes

Motor ON ?

no

Motor start-up allowed

Switch ON the motor

Temperature

> ORDER 2?

yes

Switch OFF the motor

no

Motor start-up not allowed

RET

Rev 2 13/17

Page 14

Motor_Status procedure AN1353

Appendix D Motor_Status procedure

Figure 7. Motor_Status flowchart

MOTOR_STATUS

Motor should

be ON ?

no

yes

Over Current

= 1 ?

yes

no

Start-up in

progress ?

no

yes

Decrement COUNTER 1

COUNTER 1

< 0 ?

yes

COUNTER 1 < -25

COUNTER 2 < -25

Switch OFF the motor

(Ts & Tr)

Motor start-up not allowed

Transient state < -1

Switch ON Ts

Switch ON Tr

no

Switch ON Ts

Switch ON Tr

14/17 Rev 2

Transient

state = 1 ?

no

yes

Decrement COUNTER 2

COUNTER 2

< 0 ?

yes

no

RET

Transient state < - 0

COUNTER 2 < - 25

Page 15

AN1353 Current_Measure procedure

Appendix E Current_Measure procedure

Figure 8. Current_Measure flowchart

Current_Measure

Over Current

= 1 ?

yes

no

Motor should

be ON ?

no

yes

Transient

state = 1 ?

yes

no

Decrement COUNTER 4

Measure SHUNT Voltage

VSHUNT < - VSHUNT +

measure

BACK

COUNTER 3 < - 250

COUNTER 4 < - 4

VSHUNT < - 0

Decrement COUNTER 3

COUNTER 3

< 0 ?

no

yes

Over-Current < - 0

Switch OFF the LED

COUNTER 3 < - 250

COUNTER 4

< 0 ?

no

yes

VSHUNT < - VSHUNT / 4

COUNTER 4 < - 4

VSHUNT

>

VLIMIT ?

no

yes

BACK

Over_Current < - 1

Switch ON the LED

RET

Rev 2 15/17

Page 16

Revision history AN1353

Revision history

Table 6. Document revision history

Date Revision Changes

Apr-2001 1 Initial release.

24-Jan-2006 2

Reformatted to current standard. Minor changes to Figures 1, 2,

7, and 8.

16/17 Rev 2

Page 17

AN1353

The present note which is for guidance only, aims at providing customers with information regarding their products in order for them to save

time. As a result, STMicroelectronics shall not be held liable for any direct, indirect or consequential damages with respect to any claims

arising from the content of such a note and/or the use made by customers of the information contained herein in connection with their

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

products.

www.st.com

Rev 2 17/17

Loading...

Loading...