Page 1

AN1344

Application note

VIPower: 108 W power supply using VIPer100A-E

Introduction

The VIPer100A-E is designed to deliver 100 W for the upper voltage range or 50 W for

universal input. This application note describes a power supply that delivers over 100 W for

both voltage ranges using a voltage doubler in the front end. The VIPer100A-E combines a

state-of-the-art PWM circuit along with an optimized 700 V avalanche rugged Vertical Power

MOSFET. It is part of STMicroelectronics’ proprietary VIPower, (Vertical Intelligent Power). It

uses a fabrication process, which allows the integration of analog control circuits with

vertical power device on the same chip.

This document covers the implementation and results for achieving 18 V at 6 A power

supply that runs from both European and domestic mains. (90-132 V

47-63 Hz).

and 180- 264 Vac,

ac

October 2007 Rev 2 1/14

www.st.com

Page 2

Contents AN1344

Contents

1 Key features of the VIPer100A-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 General circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Transformer construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Burst mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Thermal consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Overcurrent limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Transient response 50% step change . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Output ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 EMI consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10 Performance and cost consideration . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14

Page 3

AN1344 Key features of the VIPer100A-E

1 Key features of the VIPer100A-E

■ Adjustable switching frequency up to 20 kHz

■ Current mode control

■ Burst mode operation in standby mode, meets "Blue Angel"

■ Undervoltage lock-out with hysteresis

■ Integrated start-up supply

■ Avalanche rugged

■ Overtemperature protection

■ Primary or secondary regulation

Figure 1. Board layout

The power supply has low ripple voltage, good transient response, and be able to current

limit by power limiting and cycling on and off during a hard short. One use of this application

is to replace a bulky 60 Hz transformer with a lighter, better regulated, more efficient

alternative for an audio or entertainment system.

3/14

Page 4

General circuit description AN1344

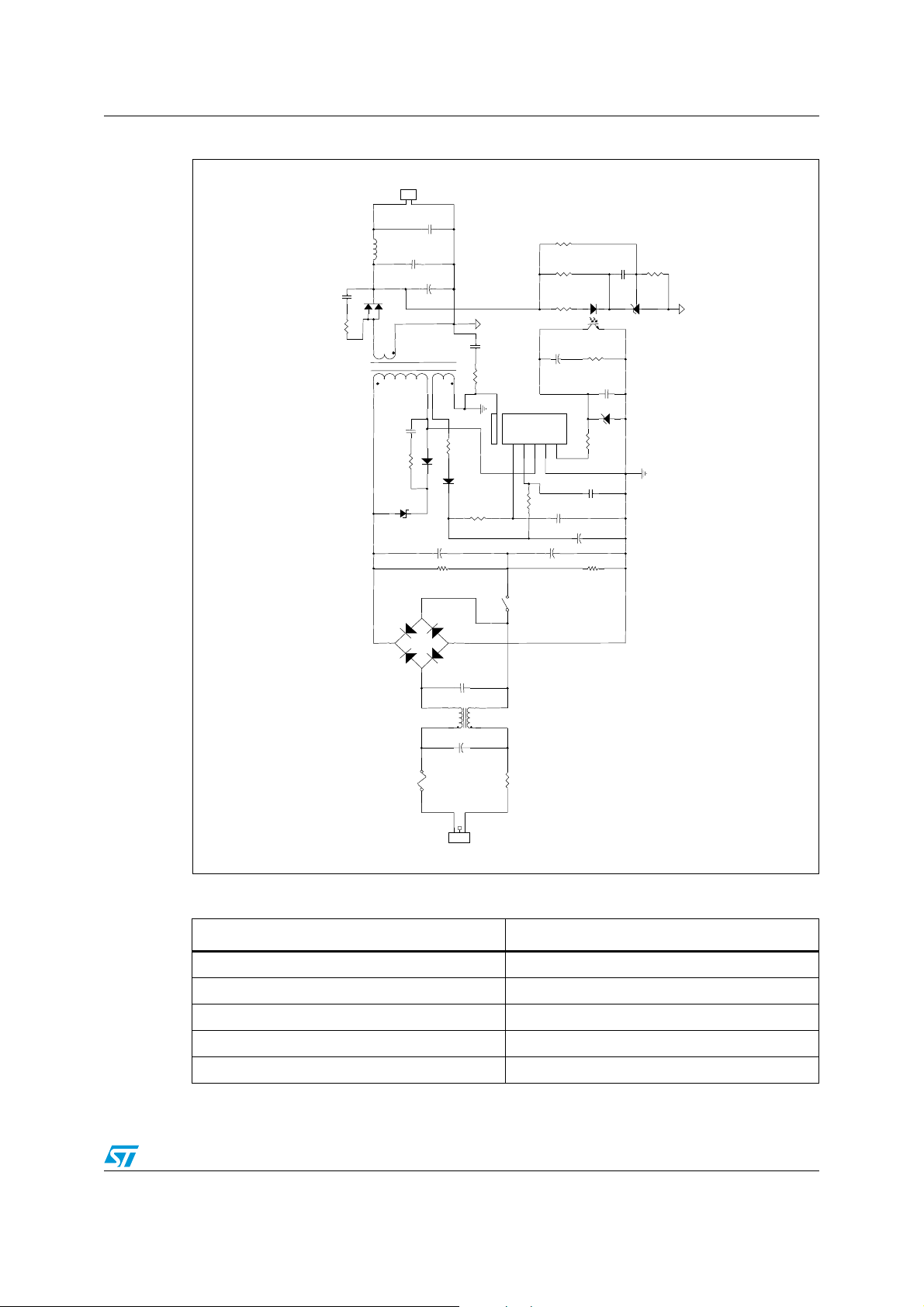

2 General circuit description

The power supply has been designed for the upper voltage range. The lower voltage range

utilizes a voltage doubler to raise the bulk voltage to 2 times the peak of the input line

voltage. In the doubling mode, the current charges one capacitor for each phase of the line,

therefore doubling the voltage. When SW1 is open, both capacitors are charged in series

resulting in a bulk voltage equal to the peak of the line input.

A wire jumper can be installed at production for units destined for countries using the lower

range. The switching frequency operates at 100 kHz. The output can deliver 18 V from no

load to 6 A continuous. The mode of operation ranges from discontinuous at high line

minimum load to continuous at low line max load. This mode of operation was chosen to

minimize the high peak currents of the discontinuous mode of operation.

The VIPer100A-E can be regulated in secondary mode with an optocoupler giving excellent

regulation or in the primary mode. Primary regulation works by regulating the V

output of the auxiliary winding. Depending on the coupling of the transformer, a 15%

regulation can be achieved. In this application, by taking advantage of the dual regulation, a

current limit scheme is obtained. This VIPer100A-E advantage, along with the transformer

design, constitutes the overcurrent circuit. The transformer is designed for a turn ratio of

operation for a universal input and an inductance to run in continuous conduction mode at

one-half the output load. The coupling between the secondary to auxiliary winding along

with the VIPer100A-E dual regulation plays an important part in the current limit.

pin at the

dd

Under typical operation, the output is tightly regulated through U2 and U3, the optocoupler

and TL431 respectively. As the output current increases, it causes the voltage at the

auxiliary output to increase. R4 is selected to trim the voltage at V

to reach 13 V when the

dd

output current exceeds the maximum limit. At this point, primary regulation takes over and

the output starts to fold-back.

The output uses an STMicroelectronics 100 V Schottky diode for better efficiency. C9 and

C10 are low ESR capacitors which manage the ripple current. U3 provides the reference

and the feedback to tightly regulate the output. C7, C8, and R6 form the feed back loop

compensation to optimize stability during transients.

Table 1. Electrical specification

Parameter Results

Input voltage 90-132 V

Output voltage J2

Load regulation (0.6 to 6 A) from set point +/- 0.6%

Line regulation (at max load) +/- 0.05%

Efficiency 86% @120 V

Output ripple voltage 15 mV max

Input power at no load 1.5 W typical

Transient response, 50% load step +/- 350 mV, +/- 1.9%, 200 µs settling time

with jumper in, 180 - 264 VAC no jumper

AC

and 87% @ 375 VDC

DC

EMI EN55022 and FCC class B

4/14

Page 5

AN1344 General circuit description

D3

STPS20H100C

T

C14

2.2nF

Y1 cap

R1

33

Thermistor

R14

470k

J2

CON2

1

2

D5

BZW50-180

C1

.1uF

X CAP

C4

100pF

1KV

Close for 120Vac

C2

330uF

200V

C20

330uf

200V

R9

1k

C6

4.7nF

50V

R8

10

R12

470k

C15

.1uF

50V

F2

FUSE

2.5A

5X20mm

J1

CON

123

123

C10

1800uF

25V

R5

4.22K

1%

R3

200

2W

BR1

600V 2A

BRIDGE

4 3

2

1

R11

20K

1%

C16

.001uf 1KV

R13

22 .5W

D1

STTA106

ST

600V

12

U2

H11A817A

1

2

4

3

D2

1N4148

12

SW1

SW SPST

1 2

18 V @ 6A

C7

22nF

50V

2 X 6mH

L1

2

1

4

3

R4

8.2

L4

10uH

C11

470uF

25V

R7

220

C12

.1uF

50V

C17

.1uF

X CAP

D4

NU

C8

1uF

50V

E34351E

TX1

Cramer Coil

2

394

7

5

.

...

.

.

C5

180uF

16V

U1

241

3

5

6

VDD

SOURCE

OSC

DRAIN

COMP

HS

U3

TL431

2

3

1

R10

3.16K

1%

R6

6.2K

C9

1800uF

25V

R0

0

R00

0 ohms

VIPer100A-E

Figure 2. Electrical schematic

Table 2. Transformer specification

Primary inductance 525 µH

Primary leakage inductance 7.9 µH

Inductance rating (al factor) 329 nH/T

Parameter Value

Core ETD34

Note Split primary - gapped core

5/14

Page 6

General circuit description AN1344

2.1 Transformer construction

Figure 3. Cross section of the transformer

The transformer is wound with a split primary to reduce leakage inductance and minimize

the snubbing needed. The auxiliary winding is placed on the outside to achieve the coupling

needed for the current limiting function.

Figure 4. PC board top legend and bottom foil (112 mm X 83 mm single sided)

6/14

Page 7

AN1344 General circuit description

Figure 5. Voltage and current waveforms

Figure 5 illustrates the voltage drain to source, and the current through the VIPer100A-E.

Vr3 is the V

across R3 to snub the diode. The maximum voltage drain to source

rms

measured 609 V out of the 700 V, specified maximum. The current shows the power supply

being in continuous conduction mode with a peak of 2 A. The snubber R3-C4 reduces

ringing thus lowering the maximum peak voltage on the Power MOSFET and reducing the

EMI. In these waveforms the transil, D3, was replaced by an RC clamp, (R2=39 K, 2 W and

C3=4700 pF). The clamp circuit worked the same under normal operation, but during start

up or during short circuit operation, the voltage on the drain of VIPer100A-E reached as high

as 750 V. The device is avalanche rugged and was able to withstand the momentary energy.

Using the Transil at this power level is preferred in order to reduce the stresses.

Table 3. Component list

Quantity Reference Value Part number

1 BR1 600 V, 1.5 A Bridge 2KBP06M

2 C1, C17 0.1 µF, X CAP P4610

2 C2, C20 330 µF, 200 V P6116

1 C4 100 pF, 1 KV P4116

1 C5 180 µF, 16 V P10245

1 C6 4.7 nF, 50 V P4793

1 C7 22 nF, 50 V P4517

1 C8 1 µF, 50 V P10312

1 C9 1800 µF, 25 V PANASONIC FC

1 C10 1800 µF, 25 V P10283

1 C11 470 µF, 25 V P6242C

2 C12, C15 0.1 µF, 50 V P4923

1 C14 2.2 nF, Y1 CAP P10463

7/14

Page 8

General circuit description AN1344

Table 3. Component list (continued)

Quantity Reference Value Part number

1 C16 0.001 µF, 1 KV P4128

1 D1 600 V STMicroelectronics STTA106

1 D2 1N4148

1 D3 2x10 A, 100 V STMicroelectronics STPS20H100CT

1 D4 3.3NZ NU

1 D5 STMicroelectronics BZW50-180

1 F2 2.5 A, 5x20 mm FUSE

1 J1 CON

1 J2 CON2

1 L1 2x6 mH PLK1084

1 L4 10 µH M6007

1 R0 0 WIRE

1 R00 0 Ω WIRE

1 R1 33 Ω Thermistor NW 96F3302

1 R3 200 Ω, 2 W

1 R4 8.2 Ω

1 R5 4.22 KΩ, 1%

1 R6 6.2 KΩ

1 R7 220 Ω

1 R8 10 Ω

1 R9 1 KΩ

1 R10 3.16 KΩ, 1%

1 R11 20 KΩ, 1%

2 R12, R14 470 KΩ, 1/4 W

1 R13 22 Ω, 1/2 W

1 SW1 SW SPST

1 TX1 Cramer Coil E34351E

1 U1 VIPer100A-E STMicroelectronics VIPer100A-E

1 U2 H11A817A

1 U3 TL431 STMicroelectronics TL431Z

8/14

Page 9

AN1344 Layout considerations

3 Layout considerations

Some simple rules to improve the performance and minimize noise should be followed:

1. Minimize power loops. Switched power current paths inner loop area must be as small

as possible. This can be achieved by careful layout of the printed circuit board. This

avoids radiated and conducted EMI noise, and improves efficiency by eliminating

parasitic inductance, thus reducing or eliminating the need for snubbers and EMI

filtering.

2. Use separate tracks for low level signal and power traces carrying fast switching pulses.

This can be seen on the VIPer100A-E pin 4. Ground is split between power and signal

traces on the printed circuit lay out. When signal paths share the same trace as a

power path, instabilities may result. The compensation components, C7, R6, and C9

are on a separate trace connected directly to the source of the device.

4 Burst mode

When the output current is too low, the minimum on time, fixed by the internal blanking time,

is too high to control the output voltage. In this case the burst mode operation takes over

automatically. The VIPer100A-E switch stays off when the voltage on the compensation pin

goes below 0.5 V. This results in missing cycles as shown in Figure 6. V

minimum output current is at 40 mA.

is 115 VAC,

in

Figure 6. Good burst mode

As can be seen, there is a burst of pulses followed by a pause of 600 ms. This repetitive

burst reduces power consumption while maintaining a negligible ripple on the output. The

V

voltage is stable, just above the low threshold of 8 V of the internal under voltage lock

dd

out. The under voltage lock out can be reached by further reducing the output current. As

the current decreases, the V

below the under voltage lock out of 8 V, another type of burst mode appears which is

controlled by the V

drawbacks, but the output voltage is still under control.

voltage. This is called “bad” burst mode (see Figure 7) because it has

dd

voltage on the primary side also decreases. When Vdd falls

dd

9/14

Page 10

Burst mode AN1344

Figure 7. Bad burst mode

At lighter load, the V

is reset, and the V

voltage drops below the under voltage threshold, the start up circuit

dd

capacitor charges back up to the high threshold of 11 V through the

dd

start up current source.

As shown in Figure 7 the reoccurrence of this cycle is about 300ms. The worst output

voltage swing is 2.4 V, which occurs at 20mA. At no-load condition, the output voltage swing

becomes negligible (45 mV).

This mode of operation leads to the following drawbacks:

1. Because the start up current source is turned on to supply the capacitor from a high

voltage rail, efficiency is dramatically reduced.

2. The recurring period leads to as much as 13% variation in the output voltage. For this

audio application it does not matter, but the designer should review all aspects of

operation.

3. Below the minimum current of 40 mA, the dynamic behavior is very poor which is

typical of all power supplies. If the demand of current occurs during the recharging

phase, the output capacitor is discharged and normal operation returns only at the next

starting phase.

In conclusion for this design a 40 mA minimum load is needed, 0.6% of maximum load, to

keep the unit in optimal performance. However, below this range, the output voltage is still

under control and no stresses are applied to the unit.

Table 4. Stand-by input power

Input voltage Input wattage at no-load Input wattage at 40 mA

90 V

0.85 W 1.77 W

ac

115 V

ac

132 V

1.3 W 1.86 W

ac

The transformer was optimized for the current scheme and not for Blue Angel.

10/14

1.1 W 1.8 W

Page 11

AN1344 Thermal consideration

5 Thermal consideration

Temperature measurement was taken at room ambient of 24 °C, convection air-cooled

resulted in the VIPer100A-E tab temperature of 91.1 °C at 115 V

input with a 6 A output.

ac

Results may vary depending on final application.

6 Overcurrent limiting

This power supply was designed for an audio application where music peaks can exceed

the maximum current of the power supply. In a sound entertainment system it is imperative

for the power supply to not shut down during such peaks. It is acceptable for the voltage to

decrease as the current increases. This maintains constant power for the unit. Under a short

circuit condition, this unit cycles on and off or "hiccup mode". In Figure 8 the output voltage

versus the output current is shown. Maximum output power reached is 163 W. The

VIPer100A-E also has thermal shutdown with hysteresis that is located close to the Power

MOSFET portion of the die, which protects it from exceeding the temperature limit of the I.C.

Figure 8. Output voltage versus the output

Figure 10. Output Ripple Figure 11. EMI measurement

current

Figure 9. Transient Response 50% step

change

11/14

Page 12

Transient response 50% step change AN1344

7 Transient response 50% step change

The output current is modulated from 3 A to 6 A, 50% duty cycle at a line input of 115 VAC.

The result is 322 mV or 1.8% dynamic regulation with a settling time of 500 microseconds.

8 Output ripple

The ripple was measured using an HP probe socket attached after the output connector.

This minimizes stray noise being picked up by the scope probe ground lead, which shows up

as high frequency noise.

The top trace shows the reduction in cost from eliminating L4 and C11. This gives a ripple,

at 6 A load, of 125 mV peak to peak. With the low pass filter the ripple is reduced to about

13 mV excluding voltage spikes.

9 EMI consideration

When dealing with EMI, it is always best to reduce noise at its source. Figure 11 shows FCC

class B plots comparing EMI at 6 amps load with snubber R3 and C4 in and out. The blue

trace, or lower trace, has the RC snubber across the diode. The EMI is reduced by 4 to 8 db.

Adding a 2W resistor and a capacitor here is much less expensive than adding across the

line capacitors and inductors in the EMI filter. This unit passed both EN55022 class B and

FCC class B.

10 Performance and cost consideration

This design has been optimized for performance. Cost can be reduced by substituting a 17V

zener for the TL431. The output regulation falls to the +/- 5% voltage set point, plus a

+0.084/°C temperature drift of the zener. The cost of the TL431 and 3 other passive

components can then be eliminated. If more output ripple voltage can be tolerated, than L4

and C11 can be eliminated.

11 Conclusion

This design delivers over 100 W for both voltage ranges by utilizing the VIPer100A-E with a

voltage doubler in the front end. The power supply has excellent regulation, current limiting,

short circuit protection, meets both EN55022 and FCC class B and best of all is from

STMicroelectronics.

12/14

Page 13

AN1344 Revision history

12 Revision history

Table 5. Document revision history

Date Revision Changes

04-Jan-2005 1 Minor text changes

18-Oct-2007 2

– Document reformatted no content change

– VIPer100A replaced by VIPer100A-E

13/14

Page 14

AN1344

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14

Loading...

Loading...