Page 1

AN1320

APPLICATION NOTE

L6574 & MICROCONTROLLER

IN BALLAST APPLICATIONS

by Francesca Sandrini and Luca Rodeschini

There is an increasing demand for flexibility in ballast applications. This means a request for having

ballast that can be used for different tubes without changing the soldered components. The aim is to

save money by using less parts (resistors, capacitors and so on) and less ballast models to be stored

and managed.

A way that is going to be investigated is the use of micr ocontroller which can “supervise” the application

in such a way that the key parameters of the application can be modi fied accordi ng to the tube char acteristics just by changing the micro-code.

In this application note we will exploit a way to interface a microcontroller with our integrated ballast

controller: the L6574.

1.0 INTRODUCTION

Roughly speaking a HF-TL ballast converts the 50-60Hz input to a high frequency output, usually in the range

of 25-125KHz.

A rectifier block and a DC to high frequency inverter usually make up a ballast. The half bridge of the inverter

can be driven in different ways with different ICs.

We will focus on a specific driver: the L6574. We will see first how the L6574 can drive and control a ballast,

then how it can communicate and be supervised by a

The aim of this paper is to examine if there are advantages in having a

this “cooperation”, and a practical example.

2.0 L6574

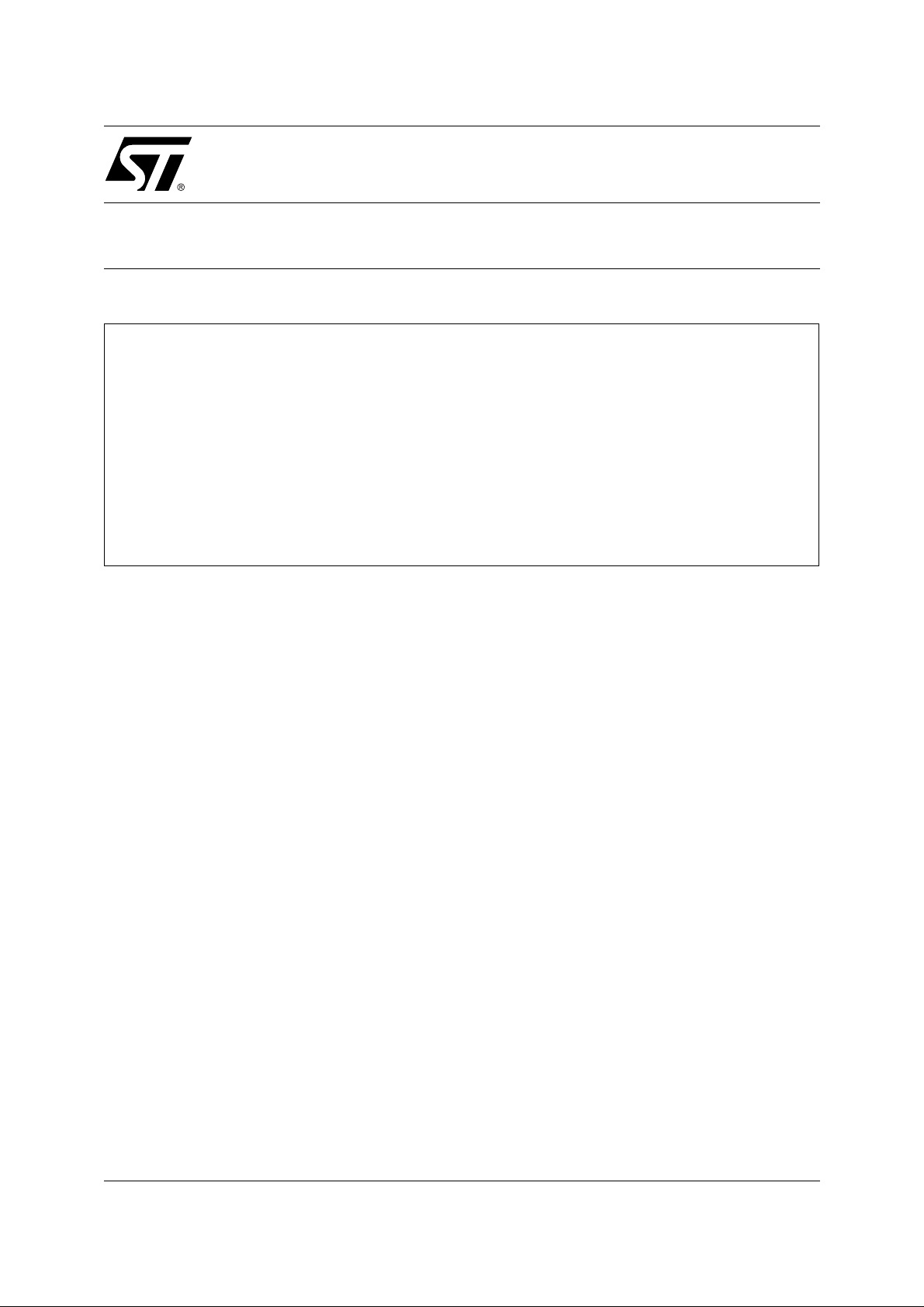

L6574 is a BCD off line 16 pin IC specifically designed for ballast applications [r ef.1](see fig.1). It has both driver

functions and controller functions on board.

The most useful characteristics to control the lamp are:

■

Preheat and frequency shifting timing

■

Cmos shut down input

■

Sense op-amp for closed loop control or protection failures

The parameters of the application are set by external components (resistors and capacitors) connected to the

IC. L6574 allows the user to set all the parameters according to the lamp characteristics, and the ballast wi ll be

a high performance one. There is a specific application note on this IC (ref. [2]) : here you find the description of

58W TL ballast with PFC section. Please refer to this application note and to the L6574 datasheet for the IC

details. In the following paragraphs we will focus our attention on a way to interface the L6574 with the microcontroller rather than on “L6574 - stand alone” perfor mances. The aim of this “supervision” is to control the three

points mentioned above.

µ

C.

µ

C work with L6574, the feasibility of

December 2000

1/20

Page 2

AN1320 APPLICATION NOTE

Figure 1. L6574 Block Diagram

V

S

OP AMP

5

OPOUT

6

OPIN-

7

OPIN+

4

R

IGN

2

R

PRE

3

Cf

Imin

Imax

VCO

+

-

V

REF

V

REF

12

CONTROL

LOGIC

UV

DETECTION

DEAD

TIME

Ifs

+

Vthpre

-

+

-

Ipre

BOOTSTRAP

1

C

PRE

DRIVER

DRIVING

LOGIC

HVG

DRIVER

LEVEL

SHIFTER

LVG DRIVER

+

-

+

-

V

V

THE

V

THE

D97IN493B

V

16

BOOT

HVG

15

OUT

14

S

LVG

11

GND

10

8

EN1

9

EN2

H.V.

C

BOOT

LOAD

3.0 L6574: HOW TO SET FREQUENCIES, TIMING, FAULT SIGNALS IN AN “ANALOG APPLICATION”

In this paragraph we will have a snap shot of the L6574 working, just as far as the characteristics important for

the micro interface are concerned. For further details please refer to [1] and [2].

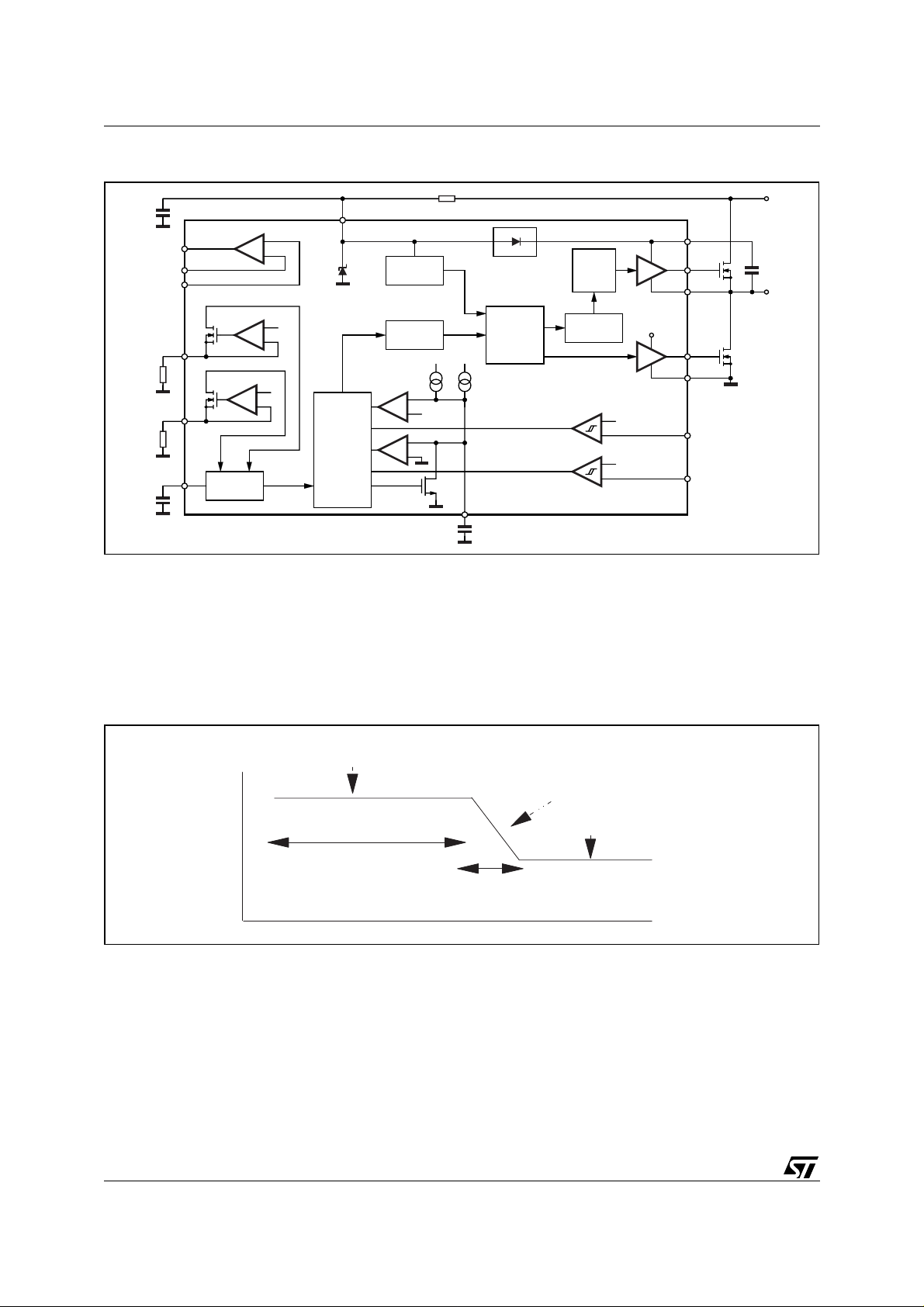

The L6574 typical behavior is shown in fig. 2: there is a starting frequency (f

set preheat time T

, than there is a frequency shift towards f

PRE

that last 0.1 of T

min

MAX

or f

PRE

) that is constant for a

PRE

and is called T

IGN

or TSH.

Figure 2. Frequency shift

freq

preheating phase

fmax

Tpre

ignition phase

normal operation

fmin

Tsh

time

Leads 1, 2, 3, 4 are used to set frequencies and timing.

The capacitor connected to pin 1[CPRE] sets the preheat time:

T

= K1 · C

PRE

The ignition time, or better, the time to let frequency shift from preheat value to the min. value is one tenth of T

PRE

PRE

.

The current that charges and discharges the capacitor connected to pin 3 (CF) sets the half bridge oscillating

frequency.

The current that charges C

2/20

is set by the current that flows out from pin 2 and 4 during preheat and from pin 4

F

Page 3

AN1320 APPLICATION NOTE

alone during the on phase. As pin 2 and 4 are at 2V, the currents that flow out of them is inversely proportional

to the resistance connected between gnd and pin 2 (R

There are some useful formula:

1.41 R

ƒ

---------------------------------------------------=

min

ƒ

max

Choosing properly the resistor and the c apacitor values the designer can set the desired fr equencies and timing.

When the designer has to do another application for another lamp type, he has to change the resistors and capacitors in order to have another range of frequencies.

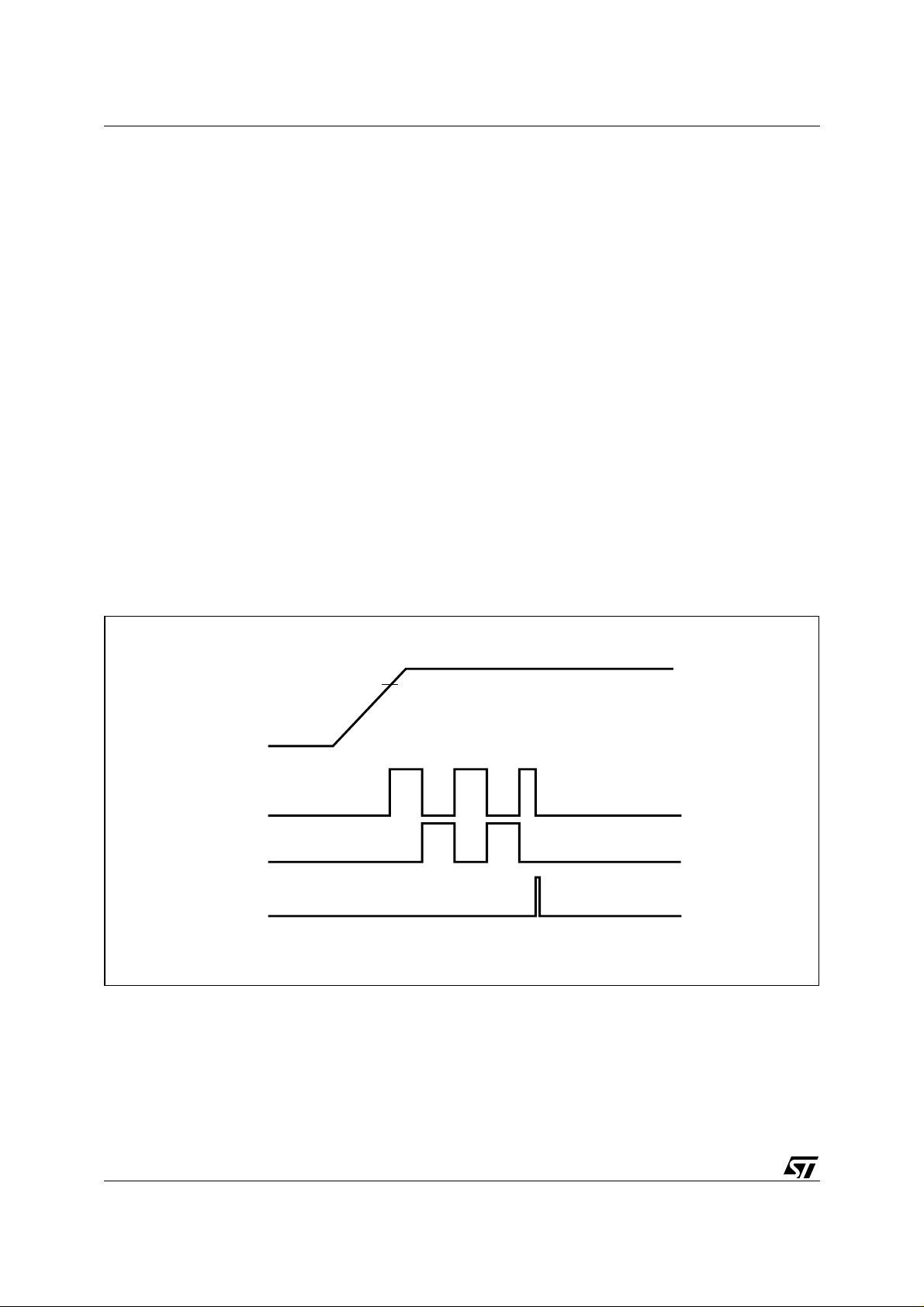

For protection in case of lamp failure two logic input are provided: pin8 [EN1] and pin9 [EN2]. Both are active

high, but they have different functions: when EN2 is activated it forces the IC to start again the preheat sequence. When EN1 is activated it shut down the IC until V

EN2 is usually used as “ignition fault”: if the lamp is not ignited, the preheat sequence starts again.

EN1 can be used to sense lamp removal / replacement or disconnection.

) and between gnd and pin 4 (R

PRE

+()⋅

preRign

⋅⋅

R

preRign

1.41

----------------------- -=

R

ign

Cƒ

⋅

Cƒ

is removed or until EN2 is pulled high.

CC

IGN

).

Figure 3. EN1

V

CC

LVG

HVG

EN1

V

SUVP

D97IN490

3/20

Page 4

AN1320 APPLICATION NOTE

Figure 4. EN2

V

CC

V

SUVP

f

OUT

f

PRE

f

ING

EN2

D97IN491B

t

PRE

t

SH

t

PREtSH

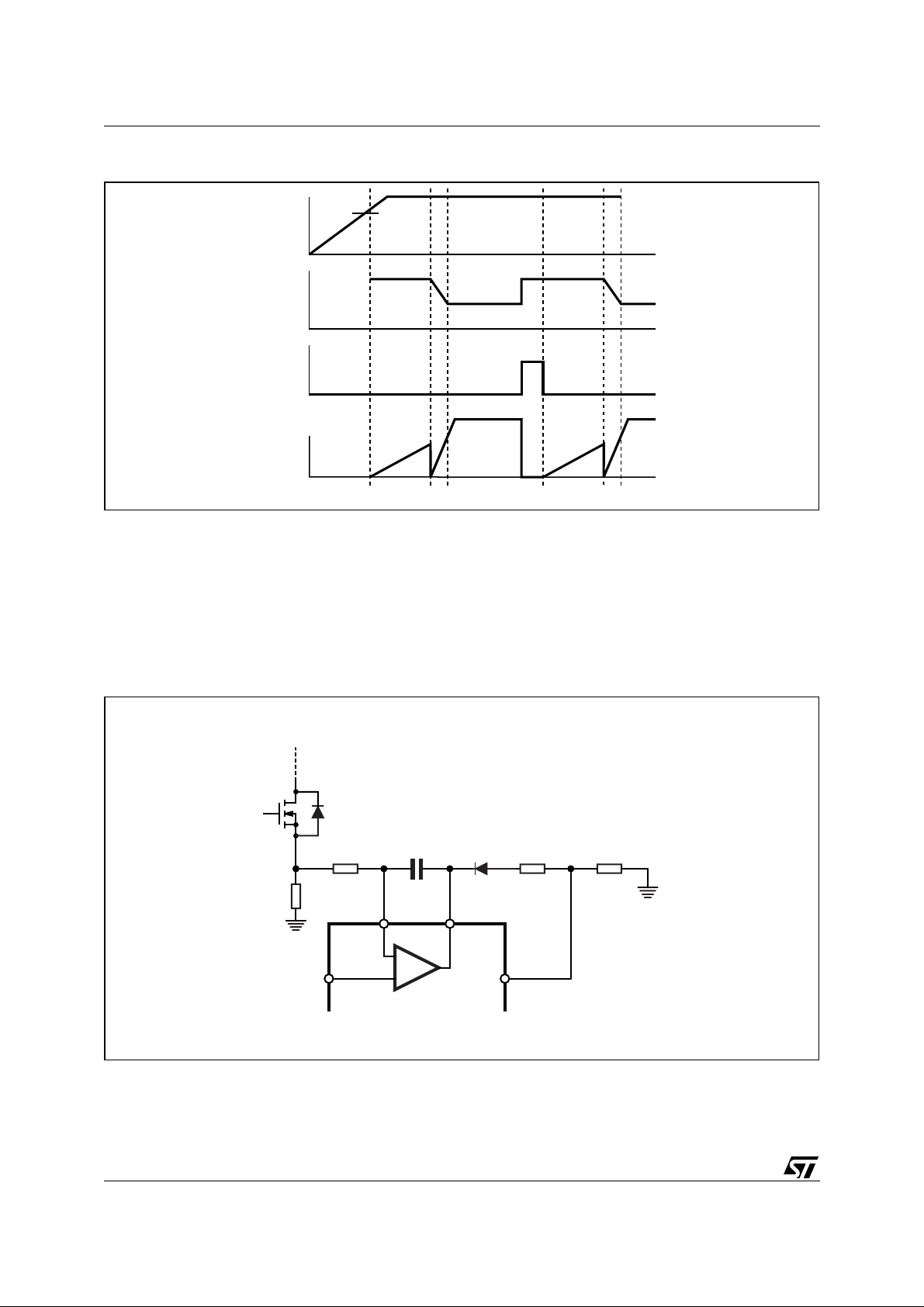

L6574 has also a sense op-amp th at can be used to have a closed loop contr ol of the lam p. We can give a voltage reference to the non-inverting input, a signal proportional to the load current to the inverting input, and we

can connect the op amp output pin to pin #4. In this way if the current in the load exceeds the reference the op

amp will sink from pin 4 an additional amount of current that has to be added to the current that flows through

R

. So the current charging CF will increase, that means a higher half bridge osci llation frequency, that m eans

IGN

a lower current in the load. C hanging the reference v oltage on the non- in verting input of the op amp we change

the frequency of the oscillator, that means we change the current in the load, and this allows lamp dimming.

Figure 5. Cl osed Loop

4/20

R25

0.68

Q3

STP4NB50/

STP6NB50

R33 9.1K

7+

C9 8.2nF

D3

1N4148

65

-

R18 100K R19 100K

RIGN

4

D98IN818A

Page 5

Figure 6. AN993 Demo Application Circuit

47K

R16 47

R20

C12

100nF

C11

680pF 630V

C20

R21

100nF

22

15

1612

2

C18

C17

L1 2.1mH

STP6NB50

Q2 STP4NB50/

R22 22

14

7

R17 9.1K

100nF 250V

R28

750K

100nF 250V

R26

390K

STP6NB50

47K

R23

11

L6574

6

C9

8.2nF

C19

8.2nF

1500V

R29

750K

Q3 STP4NB50/

D4

9

8

5

D3

1N4148

AN1320 APPLICATION NOTE

R27

6.8K

LAMP

R30

3.9K

C16 1µF

R32 20K

1N4148

R25

0.68

C15

330nF

R24

R18

100K

C14

C13

R19

6.8K

1µF

R33 9.1K

470pF

100K

10

1

3

4

D1 BYT11600

R5

T1 1.24mH (E25*13*7)

10 Turns 1.3mm gapped

R1

Bridge

Fuse

C1

220nF

DZ1

68K

1.5M

630V

D2

14V

1N4148

4.7K

RSENSE

C4 680nF

C8

R15

R12

R9

R8

C3

R2

100nF

1.5K

9.53K

0.68

0.68

10nF

10.1K

D99IN1064

R13

100K

C6

25V

R4

R3

C5

4.7µF

120K

120K

NTC

100nF

Q1

R6 22

7

8

5

6

STP6NB50

R7

47K

L6561

C2

220nF

C7

R10

400V

22µF

750K

450V

4

3

R11

12

R14

750K

5/20

Page 6

AN1320 APPLICATION NOTE

4.0 L6574: HOW TO SET FREQUENCIES, TIMING, FAULT SIGNALS IN A “MICROCONTROLLED

APPLICATION”

We have seen that the frequencies in L6574 are set by fixing the current that flows out from pin 2 and 4 and

fixing the value of the C

A microcontroller output pin can give us a high logic level (5V) a low logic one (0V) or a PWM output at fixed

frequency and variable duty cycle.

capacitor.

F

We can not use the P WM to act directly on C

pin, because the rising edge on CF is the low side mosfet “on

F

time” and the falling edge is the high side mosfet one. The half bridge would oscillate in asymmetrical way at

fixed frequency instead of at 50% duty cycle and variable frequency. So we have to interface the

pins that set the current that charges C

. A push pull output that gives us just 0V or 5V can not be used to in-

F

µ

C with th e

terface pin 2 and 4 because they have a maximum voltage level up to 2V. We have to use the integrated value

of a PWM signal to set a voltage level between 0V and 2V.

We can use a PWM output also to gi ve the op amp the vo ltage reference to c hange the load c urrent (and so the

lamp power to perform dimming)

Acting on L6574 pin 4 and (or) on pin 7 (opamp+) we can control the inverter working frequency.

If we want to control the preheat timing and frequency we have to act on pins 2 and 1. First we have to avoid

that the L6574 fixes the preheat time by itself. If we connect to pin 1 a ver y small cap (e.g. 1nF), the L6574 “analog T

” will be so small to be “invisible” to the lamp (i.e. less than 2ms). During these 2 ms, the oscillating

PRE

frequency has to be high enough to avoid lamp filaments preheat (> 150KHz). The resistor connected to pin 2

has to be sized properly.

After these 2 ms L6574 is in “working mode”: it means that pin 4 is no more involved in fixing the frequency.

Only C

Now the effective preheat time can be decided by the

and R

F

(pin 3 and 4) set it.

IGN

µ

C just acting on the PWM that gives the voltage reference

to pin 4. For example, it can have a certain duty cycle (appropriate for the preheat freq.) for a fixed time, than it

can change the duty cycle (i.e. the voltage reference) to set the ignition profile and the final working frequency.

Now we are able to change all the frequencie s and the tim ing invo lved in lamp tur ning on a nd dimming with two

connections between L6574 and the

µ

C.

The fault management can al so be d one by the

µ

C: all the fault si gnals will be br ought to it, and then it will react

according to the code. A connection that can be useful is the one to pin 8 (shut down pin) that can be direct

because the ICs levels are compatible. In this way the

µ

C can react to a signal either by stopping the inverter

or by changing the frequency (i.e. r epeating a preheat sequ ence if there is the no-i gnition al arm, or brin ging the

frequency to a very high value…).

Just with these 3 connection between the L6574 and the

µ

C we can set nearly all the parameters of the appli-

cation by software.

The number of

We need another input pin to give the

µ

C inputs we need for fault signals depends only on what we want to control.

µ

C the information about the dimming level: this is the interface between

the ballast and the “final user”. We can use either switches or an AD input. The first solution is more expensive

in terms of number of pin, the AD input requires some attention for the co de part but allows a much larger number of levels.

5.0 HOW TO APPLY THIS INTERFACE TO A BALLAST

We started from AN993 demo boar d to build a µC application with the s ame performances and s ome additi onal

degrees of freedom.

We will now apply all the concepts already discussed and put them into a working board.

6/20

Page 7

AN1320 APPLICATION NOTE

The hardware and software development can not be separated: it is a very interactive process. Starting from

the basic point there are different way to act on the L6574, depending on what we want to be softw are dependent and what we want to be hardware dependent in the final application.

We will describe the two sections separately just for ease of understanding.

5.1 HARDWARE CHOICES

First we have to choose the µC. We have chosen the ST62E62C, a 16 pin µC belonging to the ST6 family.

This device is able to perform all the functions we need with pins left over.

In this microcontroller we have just an auto reload timer, this means that we have just one PWM available. We

can call this PWM the HARDWARE PWM in the following pages, just to differentiate it from the second one we

need and that is obtained by software from a standard output pin. We will call this second PWM the “SOFTWARE PWM”

We have discussed in the previous chapters how to interface the

µ

C and the L6574; the remaining problem is

how to supply the ICs.

We have chosen a cheap way to supply the

µ

C: we use a L7805, which is a linear regulator (5V output). It has

been connected to the L6574 supply. This choice (mainly based on economical reasons) has many consequences:

■

As L6574 supply is given by a charge pump connected to the middle point of the half bridge,

the L6574 has to work (to oscillate) to give the supply to the micro

■

The ICs are not supplied at the same time, but as a sequence: the micro (the supervisor)

has to be told when everything is OK to start the preheat sequence

■

If the L6574 is disabled (after a fault condition for example) the micro no longer has a voltage

supply. When the circuit starts again the micro is reset and the program starts from the very

beginning

It can happen that the micro mus t alw ays be sup plied, even when L657 4 is off. In this case another s olution has

to be used, e.g. a regulator connected to the rectified mains.

The board start up sequence management takes into account the above mentioned point 1 and 2. Using the

start up resistors we let the L6574 start, so its oscillation allows the charge pump work. Then the L6561 is supplied and the L7805 feeds the

µ

C. This sequence is an inheritance of L6561+L6574 demo board. The co-ordination between the L6574 and the L6561 is done by choosing the start up resistors and the charge pump

components. The co-ordination between the micro and the analog part is a mix of hardware and software. By

software we let the micro w ait for a “po wer OK” signal from the L 6574, that in the meanw hile keeps on oscill ating

at a very high frequency, so as to let the filament not to be preheated. The L6574 can provide this “power OK”

signal for free. The internal sequence of the L6574 charges the preheat cap connected to pin 1 to 5V after the

preheat and the ignition sweep has ended. We can deliver this 5V signal to a

µ

C input, and hereafter the µC will

start to set all the application parameter s: in this way we are sure that everything is correctly supplied. Moreover

by choosing properly C

value (i.e. very small ~1nF) this “waiting time” is around 2 ms, so it does not influence

PRE

the overall timing: it is hundreds of time shorter than a typical preheat time.

To be sure that the third condition does not happen and that there are no out of control situations in which we

do not know which part of the code the micro is running we have added additional safety circuitry. After the alarm

for open load or disconnection, the micro sets an output pin to the high logic level in order to activate an SCR

to disconnect the VCC from all the ICs, PFC included. In this way the

µ

C can supervise not only the L6574 but

also the L6561.

7/20

Page 8

AN1320 APPLICATION NOTE

5.2 SOFTWARE CHOICES

We have already done some software choose choosing the microcontroller. When we chose a microcontroller

with only one PWM output we have already decided to devote a certain amount of microcontroller resources to

build the PWM software (see appendix for software details).

A logic sequence of actions could be:

1) to check that everything is ok - i.e. all the ICs are supplied in the right way;

2) check the presence of the load

3) do the preheat sequence

4) check lamp ignition

5) set the current in the load according to the user input

This is a basic set of functions typical of nearly any ballast application (see fig. 7)

Figure 7. Flow Chart

N

L6574 OK?

ST6 start up

Y

N

open load?

N

set Fpre

t>Tpre?

Y

set IGN freq.

profile

lamp on?

Y

set working

freq.

(freq.&loop

ref.)

Y

wait for reset

and/or pow er

off

L6574 and

L6561 disable

N

N

Y

Y

fault cd.?

N

#fail<MAX?

Y

dimming?

8/20

N

Page 9

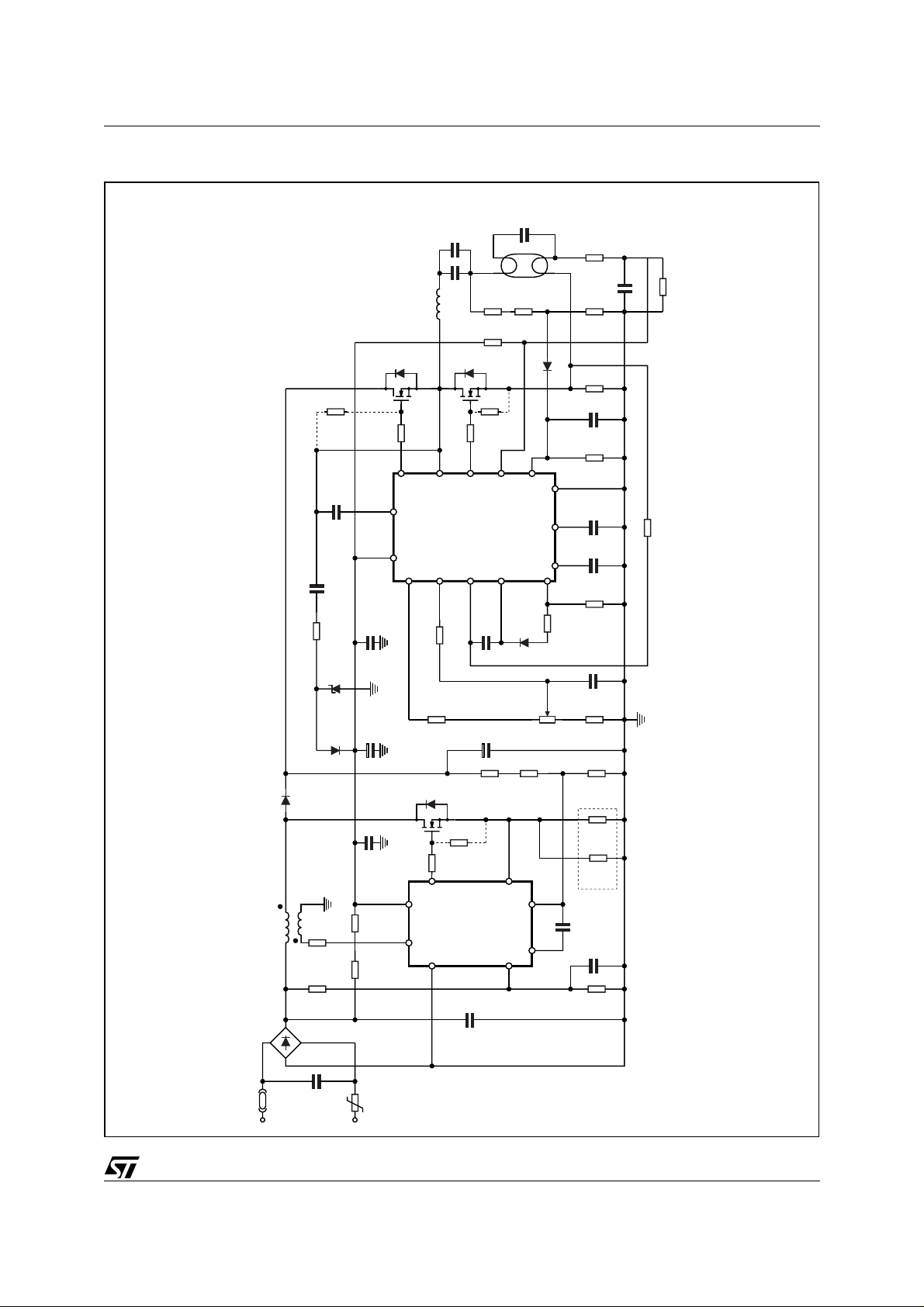

6.0 BOARD

We have implemented the board whose schematic is shown in fig.8.

Figure 8. Schematic

PC3 (DISCONNECTED LAMP)

PC2 (NOT IGNITED LAMP)

D11

5V

R32

10K

C18

330nF

R36

6.8K

D10

1N4148

SW

S5

PB3 PO WER O K

SW

S4

S6

SW

PB2

C17

2uF

R31

20K

R33

1.2K

D9

1N4148

R35

100

IN L7805PORTR IGHT -R

R1

50

D1

D2

BRID GE

C2

R2

D4

D3

STTA106

T1

1.24mH (E25*13*7)1.3mm gapped

DIODE

-+

R17

1.2K

R10

390K

C13

1uF

R20

6.8K

8.2nF

R[*]

50K

Q2

STP6N B50

L1

2.1mH

R8

22

14

15

C3

1.34nF 600V

36

D5

14V

1N4148

D6

1N4148

R4

68K

R3

1.5M

HVG

100nF

16

VBOOT

U2

L6574

12

VS

RPRE

2

7

S1

SW

R9

81.5K

C6

100nF

C5

47uF 2 5V

Q1

R7

22

C4

10uF

7

8

VCC

GD

R6

120K

5

ZCD

U1

L6561

GND

6

R5

120K

C7

C10

100nF 2 50V

C8B1

R13

1.5M

C8

OUT

OPIN+

STP6N B50

R15

100nF 2 50V

R11

1.5M

Q3

STP6N B50

DISABLE PB0

22

11

6

S2

SW

8

9

EN1

EN2

LVG

OPOUT

OPIN-

RIGN

5

4

C9

8.2n

D7

1N4148

R16

R19

C11

47uF

R14

650K

R12

650K

4

3

1

CS

INV

2

C12

MULT

220nF 4 00V

200K

R29

R24

3.9K

R23

0.68

R28

1.2K

C16

100nF

13

NC

10

GND

1

CPRE

3

CF

C15

470pF

100K

R26

9.1K

S3

SW

9.1K

R22

8.2K

R21

0.22

R21A

0.22

R18

9.1K

R25

510K

1uF

COMP

C14

10nF

R27

10.1K

AN1320 APPLICATION NOTE

R48

100K

R46

C20

C19

1uF

321

PNP CB E

1nF

Q4

R39

R37

10K

R38

123

Q5

20K

100K

NPN CBE

R42

4.7K

R41

4.7K

NOT IGNITED LAMP

DISCONNECTED L AMP

16

PC315PC2

U3

PB01VPP2PB23PB34PB65PB7

PB7

DISABLE L6574

C22

2uF

R40

20K

R43

100K

C21

R44

2.2K

100nF

1K

C25

S7

SW

C23

20pF

C26

Y1

8MHz

10

11

12

13

14

NMI

RESET

OSC_ IN

ST62 E6 2C

OSC_ OUT

6

RIF PIN 4

PFC DISABLE

L6574 POW ER OK

RIF OP AMP (PIN 7)

C24

100nF

R47

1.5K

R45

POT 4.7K

R

10K

100nF

C27

100nF

20pF

PA49PA5

8

VSS

7

C28

VDD

2

VOUT

L7805

VIN

U4

1

C29

D13

1N4148

IN L780 5

PB6 L6561 DIS

100nF

3

GND

10uF

2A 250 V

NTC1

10

1 2

220nF 6 30V

PORTR IGHT -R

[*]: 4 resistors 200K 0.6W each

t

C1

F1

9/20

Page 10

AN1320 APPLICATION NOTE

This is a “double board”: it can be used with the micro or without it according to the position of six switches (S1

to S6) that are on board. The microcontroller, the L7805 and some parts related to the micro (the oscillator, the

reset switch and so on) are mounted on a small separated board that can be connected with a 9 pin connector

to the main board. As a result the board looks huge, but we have two di fferent applicati on on it. It is a “ modular”

board: the six switches and the small insertion PCB let the user choose between a “analog ballast” and a “microcontrolled one”.

The larger board includes the “analog ballast controller” (that is the L6561-L6574 demo board) and some additional parts that allows the use of the PCB with the microcontroller and the L7805 regulator. You can choose the

control system setting by the proper position of 6 switches:

Analog version Sw nr. Function vs. L6574

### ### SW1 Pin 2 – R

### ### SW2 Pin 8 – EN1- shut down

### ### SW3 Pin 7 – op amp ref. – PWM SW

### ### SW4 Pin 1 C

### ### SW5 Pin 9 – EN2

### ### SW6 Pin 4 – R

PRE

– power OK

PRE

- PWM HW

IGN

Changing all the switch positions the micro can take the control of the board (the control system cannot be

changed while the application is running).

The connector that allows the communication between the two boards has 9 signals:

Ref. # function Analog ↔ micro

0 Void: there is the hole but it is not connected

1GND ↔

2 PB3 (L6574 power OK) →

3 L7805 input voltage →

4 PB2 (ref. Op-amp) SW PWM ←

5 PB6 PFC disable ←

6 PB7 ref. Pin 4 = HW PWM ←

7 PC3 disconnected lamp →

8 PC2 not ignited lamp →

9 PB0 disable L6574 - EN1 ←

The two control system have the same performances, but the microcontrolled application can change its characteristics just changi ng the code of the micro. If we wish to have a counted number of re-s trike of the lamp after

ignition failure we can choose any number we want (2, 8 or 23), just chan ging a parameter of the software. The

same can be done if we connect another lamp that needs a different T

10/20

or a different range of frequencies.

PRE

Page 11

AN1320 APPLICATION NOTE

This is an added value of the micro.

An important feature of the overall ap plicati on is its modularity: we can have a boar d with th e micr o and a board

without it changing very few parts, we can also put all the parts on the same PCB and then decide which connection to do.

7.0 COMMENTS:

The lamp disconnection fault is managed as an interrupt not only for fast acting, but also for the characteristics

of the application we have chosen. The ST62E62C has just a PWM output, while the application needs two

PWM. We have solved the problem using the software PWM. This is something very “heavy” for the micro to

perform, and it influences all the other choices: e.g. a polling sequence is to expensive as time consuming and

it influences the SW PWM duty cycle dy namic. It cons umes ~25%-30% of the cycl e, and this, added to 20% due

to the 4 instructions to do the PWM itself was too large. That is the main reason why the disconnection fault is

managed as an interrupt.

Of course there ar e different solutions. A feasible choice could be to use the hardware PWM to set the reference

of the non inverting input and not to use the software PWM. But we should relay on the L6574 preheat and ignition sequence, where T

supervise less items.

PRE

, f

PRE

and T

are set by capacitors and resist ors. This means that the µC has to

IGN

A third choice might be to choose a

teristics and the

µ

C has an easier code to run.

µ

C with two PWM output: in this way the application has the same charac-

8.0 REFERENCES:

1] L6574 datasheet

2] AN993: electronic ballast with PFC using L6574 and L6561

3] ST62E62C datasheet

9.0 APPENDIX:

1) Flow Chart

2) Vardef.inc

3) Ballast.asm

11/20

Page 12

AN1320 APPLICATION NOTE

9.1 APPENDIX 1: Flow Chart

Figure 9. Appendix 1: Flow Chart

N

PB3 H?

["check

power"]

Y

check PC3:

N

["start up

sequence"]

set pwm on

PB7=duty_pre

t>Tpre?

["call tpre"]

N

set IGN freq. profile

["load duty cycle

values from look up

table"]

ST6 start up

Y

H?

wait for reset

and/or power

off

Y

PB0 & PB5 high

N

12/20

check PC2: H?

N

enable pwm1

on PB7 and

pwm2[software]

on PB2

Y

nr tent = max

Y

check PA4

voltage<>

5V

tent ?

N

Y

Y

interrupt s on

PC3?

N

Page 13

9.2 Appendix 2 - Vardef.inc

;****************** ****************** *****************************************

;

; MODULE Name: VarDef.Inc

;

;*****************************************************************************

; *** Default duty cycle value for preheating

DUTY_PRE .EQU 0BEh

; *** Maximum start-up sequence retrials

MAX_TENT .EQU 3h

; *** Default Sw PWM Duty Cycle

DEF_SW_DUTY.EQU 0BCh

; *** Gen waiting timer parameters

; Gen Waiting = 2ms

; GenTick = 11 -> 11*192us = 2.112 ms

; GenRep = 1

GenTick .equ 0Bh

GenRepeat .equ 01h

; *** Tpre waiting timer parameters

; Tpre [0.5 ./. 2 sec] = 1 sec

; TpreTick = 256 -> 256*192us = 49.152 ms

; TpreRep = 21 -> 21*49.152ms = 1.032 s

TpreTick .equ 0FFh

TpreRepeat .equ 015h

AN1320 APPLICATION NOTE

; *** Tign waiting timer parameters

; Tign [(100 ./. 200)/64 msec] = 150/64 msec = 2.34 ms

; TignTick = 12 -> 12*192us = 2.3 ms

; TignRep = 1

TignTick .equ 0Ch

TignRepeat .equ 01h

; *** Tad waiting timer parameters

; Tad = c.a 500 ms

; TadTick = 256 -> 256*192us = 49.152 ms

; TadRep = 10 -> 10*49.152ms = 491 ms

TadTick .equ 0FFh

TadRepeat .equ 0Ah

.ORG 0F00H

; Look-up table for PWM

; *HW* *SW*

.BYTE 0BCH,0B4H ; Samp = 0

.BYTE 0C1H,0C8H

.BYTE 0C2H,0CBH

.BYTE 0C4H,0CEH

.BYTE 0C6H,0D2H

.BYTE 0CBH,0DBH

.BYTE 0D0H,0E6H

.BYTE 0D5H,0FEH ; Samp = 7

13/20

Page 14

AN1320 APPLICATION NOTE

9.3 Appendix 3 - ballast.asm

;****************** ****************** ************************************** ***

;

; MODULE Name: Ballast.asm

;

;*****************************************************************************

.romsize 4

.vers "st6262"

.input "ST626x.INI"; ST626x data space & registers declaration

.input "VarDef.inc"

;==========================================================

; Data Variables

;==========================================================

Step .DEF 084H,0FFH,0FFH,M

Repeat .DEF 085H,0FFH,0FFH,M

NrTent .DEF 086H,0FFH,0FFH,M

Media .DEF 087H,0FFH,0FFH,M

Count .DEF 088H,0FFH,0FFH,M

Sample .DEF 089H,0FFH,0FFH,M

;==========================================================

; Ignition Sweep PWM Parameters

;==========================================================

.ORG 0F40H

.BYTE 0BEH,0BEH,0BEH,0BFH,0BFH,0BFH,0C0H,0C0H

.BYTE 0C0H,0C1H,0C1H,0C1H,0C2H,0C2H,0C2H,0C3H

.BYTE 0C3H,0C3H,0C4H,0C4H,0C4H,0C5H,0C5H,0C5H

.BYTE 0C6H,0C6H,0C6H,0C7H,0C7H,0C7H,0C8H,0C8H

.BYTE 0C8H,0C9H,0C9H,0C9H,0CAH,0CAH,0CAH,0CBH

.BYTE 0CBH,0CBH,0CCH,0CCH,0CCH,0CDH,0CDH,0CDH

.BYTE 0CEH,0CEH,0CFH,0CFH,0D0H,0D0H,0D1H,0D1H

.BYTE 0D1H,0D2H,0D2H,0D2H,0D3H,0D3H,0D3H,0D3H

;==========================================================

; Inizialisation

;==========================================================

.org 880h

Init

; *** Oscillator and internal Timer

; *** Port configuration

; Port A: All Input, No Interrupt, Pulled up, except PA4 Analog - PA4 = A/D (in), PA5 = N/C

; Port B: port 2,6 and 7 output 0, push pull, value 1; port 3 input

; PB0 = 6574 Disable PB2 = SW PWM (out), PB3 = POWER OK (in),

; PB6 = PFC Disable (out), PB7 = HW PWM - AutoReload Timer (out)

14/20

reti

clr IOR ; Disable Interrupts (Confirm Reset Value)

ldi OSCR,08h ; Set Prescaler ratio @ 1

ldi TSCR,27h ; Timer1 no int, presc 128, lock

ldi DRA,10h

clr DDRA

ldi OPRA,10h

clr DRB

ldi DDRB,0C5H

ldi OPRB,0C5H

Page 15

AN1320 APPLICATION NOTE

; Port C: All Input, No Interrupt, Pulled up (PC2 = NO IGN(in), PC3 = DISC LAMP (in))

; Data Rom Window Configuration

; Default Duty Cycle value on SwPWM

; A/D Converter setup

; AR-TIMER Configuration (HwPWM)

;==============================================

; Startup Sequences

;==============================================

CheckPower

; "Power Ok" test twice

clr DRC

clr DDRC

clr OPRC

ldi DRWR,3DH ; = (0F40H >> 6)

ldi V,DEF_SW_DUTY ; V = Duty Cycle

set 2,DRB ; SwPWM Port Set

ldi ADCR,10h ; AD w/out Interrupt, Turned On

ldi ARMC,20h ; Autoreload mode, enabled, stopped, no int enabled

ldi ARLR,00h ; LOAD REGISTER

ldi ARRC,80h ; RELOAD REGISTER

ldi ARCP,DUTY_PRE ; COMPARE REGISTER

set 7,ARMC ; Load ARRC and RESET ARSC1

res 7,ARMC ; STOP Load phase

ldi ARSC1,60h ; Fint, prescaler /8 Fpwm =7.8125KHz

set 6,ARMC ; Start Timer

jrr 3,DRB,CheckPower ; wait for pin = 1

ldi a,GenTick ; Load tick counter

ld x,a

ldi a,GenRepeat ; Load repetition time

ld y,a

call Wait

jrr 3,DRB,CheckPower ; test for pin data steady

LampOK ; *** Test if Lamp is connected

jrr 3,DRC,StartHeat ; if connected, go ahead

ldi a,GenTick ; Load tick counter

ld x,a

ldi a,GenRepeat ; Load repetition time

ld y,a

call Wait ; Wait

jrr 3,DRC,StartHeat ; test twice for steady

jp StopIt ; unconnected lamp: RIP

StartHeat

clr NrTent ; Reset Tentative counter

PreHeat

; *** Preheating waiting time

ldi A,DUTY_PRE ; Set preheating Duty-Cycle

ld ARCP,A

ldi a,TpreTick ; Load tick counter

ld x,a

ldi a,TpreRepeat ; Load repetition time

ld y,a

call Wait

15/20

Page 16

AN1320 APPLICATION NOTE

IgnStart

; *** Ignition sequence

clr Step ; Reset lookup table index

Ignition

Ignited

GotoStop

ldi A,40H ; Load Duty-Cycle value from look-up table

add A,Step

ld X,A

ld A,(X)

ld ARCP,A ; on comparator value

ldi a,TignTick ; Load tick counter

ld x,a

ldi a,TignRepeat ; Load repetition time

ld y,a

call Wait

inc Step ; Update step counter

ld A,Step

cpi A,40h ; if last value in table

jrz Ignited ; exit

nop ; else next value

nop

jp Ignition

inc NrTent

ldi a,GenTick ; Load tick counter

ld x,a

ldi a,GenRepeat ; Load repetition time

ld y,a

call Wait

jrr 2,DRC,LampOn ; if lamp ignited (PC2=0) go ahead

ld A,NrTent

cpi A,MAX_TENT ; if trial number overflows, stop

jrz GotoStop

jp PreHeat ; else retry

jp StopIt

LampOn

; *** System working, set interrupt on PortC, pin 2 and 3

clr IOR

clr DDRC

ldi OPRC,08H ; PC3 (No Lamp) INT pull-up

clr DRC

ldi IOR,30h ; enable global int, rising edge

; *** Internal timer activation for A/D tracking

; New Data Rom Window Configuration

16/20

res 3,TSCR ; Stop Timer 1

set 6,TSCR ; Enable interrupt

ldi a,TadTick ; Load tick counter

ld TCR,a

ldi a,TadRepeat ; Load repetition time

ld Repeat,a

set 3,TSCR ; Start Timer

ldi DRWR,3CH ; = (0F00H >> 6)

Page 17

;==============================================

; Main loop

;==============================================

res 0,ARSC0

nop

Main

jrr 0,ARSC0,Main

res 0,ARSC0

set 2,DRB ; Set SwPWM output

AN1320 APPLICATION NOTE

SwPWMLoop

;==============================================

; Routines

;==============================================

;==============================================

; Stop all operations and disables chips

;==============================================

StopIt

RIP

; =============================================

; Wait: holds for a time:=x*y*192us

; x = 192us Ticks number to hold

; y = Repeat Times

; =============================================

Wait

WaitRestart

WaitTimerExp

ld A,ARLR

cp A,V

jrc SwPWMLoop

res 2,DRB ; Reset SwPWM output

jp Main

set 0,DRB ; Disable 6574

set 6,DRB ; Disable PFC

jp RIP ; Do nothing

ld a,y ; Load repeat time nr.

ld Repeat,a

ld a,x ; Load Counter Value

ld TCR,a

set 3,TSCR ; Timer start

jrr 7,TSCR,WaitTimerExp

res 7,TSCR ; Timer expired, reset flag

dec Repeat

ld a,Repeat

jrnz WaitTimerExp ; WaitAgain

res 3,TSCR ; Repetition Timer expired, reset

ret

;==========================================================

; Setup A/D Converter

;==========================================================

SADC

clr Media; Reset Media register

ldi Count,04h ; Init counter

set 5,ADCR ; start a/d conversion

nop

nop

set 7,ADCR ; Enable Interrupt

ret

17/20

Page 18

AN1320 APPLICATION NOTE

;==========================================================

; Interrupt routines

;==========================================================

; *** Port A ; Unused

IPA

reti

; *** Port C ; Test if some signal went up

IPC

PC2End

PC3End

ld W,A ; save accumulator

jrs 2,DRC,PC2 ; Test port C, pin 2

jrs 3,DRC,PC3 ; Test port C, pin 3

ld A,W ; restore accumulator

reti

PC2 ; PC2 issued

PC3

;==========================================================

; DispatchIRQ4: test if timer or AD interrupt

;==========================================================

DispatchIRQ4

;==========================================================

IADC

nop

nop

jrr 2,DRC,PC2End ; Confirm steady on pin

jp StopIt ; Stop operations

nop

nop

jrr 3,DRC,PC3End ; Confirm steady on pin

jp StopIt ; Stop operations

jrs 7,TSCR,ITIM ; Test for timer interrupt

jrs 6,ADCR,IADC ; Test for AD interrupt

reti

res 7,ADCR ; Disable Interrupt

ld a,ADR ; Load Sample

ld Sample,a

ld a,Count ; Test for maximum sample

jrnz Conversion ; maximum reached

reti

Conversion

18/20

ld a,Sample ; a = Sample

rlc a ; a = a >> 4

rlc a

rlc a

rlc a

andi a,07h ; 8 levels

add a,Media

ld Media,a

dec Count

ld a,Count

jrz SetSamp

set 5,ADCR ; Enable A/D converter

nop

Page 19

nop

set 7,ADCR ; Enable Interrupt

reti ; Restart fo new sample

SetSamp

ld a,Media ; Media=+last 4 conversion

andi a,01Ch

rlc a

rlc a

rlc a

rlc a

rlc a

rlc a

rlc a ; sample=media/4 (media >> 2)

ld Sample,a

rlc a ; offset for table look-up (@ 0x40)

addi a,040h

ld x,a

ld a,(x)

ld ARCP,a ; hw pwm

inc x

ld a,(x)

ld v,a ; sw pwm

reti

;==========================================================

ITIM

ldi a,TadTick ; Load tick counter

ld TCR,a

res 7 ,TSC R ; Reset Tout Flag

dec Repeat

ld a,Repe at

jrnz GetOut ; WaitAgain

res 3,TSCR ; Repetition Timer expired, reset

call SADC

ldi a,TadRepeat ; Load repetition time

ld Repeat,a

set 3,TSCR ; Start Timer

GetOut

reti

AN1320 APPLICATION NOTE

;==========================================================

ARTInt reti ; Autoreload Timer interrupt

INMI RETI ; not used

.org 0FF0H

irq4

jp DispatchIRQ4

irq3

jp ARTInt

irq2

jp IPC

irq1

jp IPA

.block 4

nmi

jp INMI

vrst

jp Init

.END

19/20

Page 20

AN1320 APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent r i ght s of STMi croelectr oni cs. Specifications menti oned in thi s publication are s ubj ect

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical components in li f e support dev i ces or systems without express writ t en approval of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMi croelectronics - All Ri ghts Rese rved

Australi a - Brazil - China - Finland - Fr ance - Germany - Hong Kong - India - Italy - Japan - Malaysia - Mal ta - Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Sw itzerland - United Kingdom - U. S .A .

http://www.s t. com

20/20

Loading...

Loading...