Page 1

A BATTERY CHARGER USING TSM101

This te ch n i ca l no t e s h ows ho w t o us e t h e TS M 10 1

integrated circuit with a switching mode power

supply (SMPS) to realize a battery charger.

An example of realization of a 12V

Nickel-Cadmium battery charger is given.

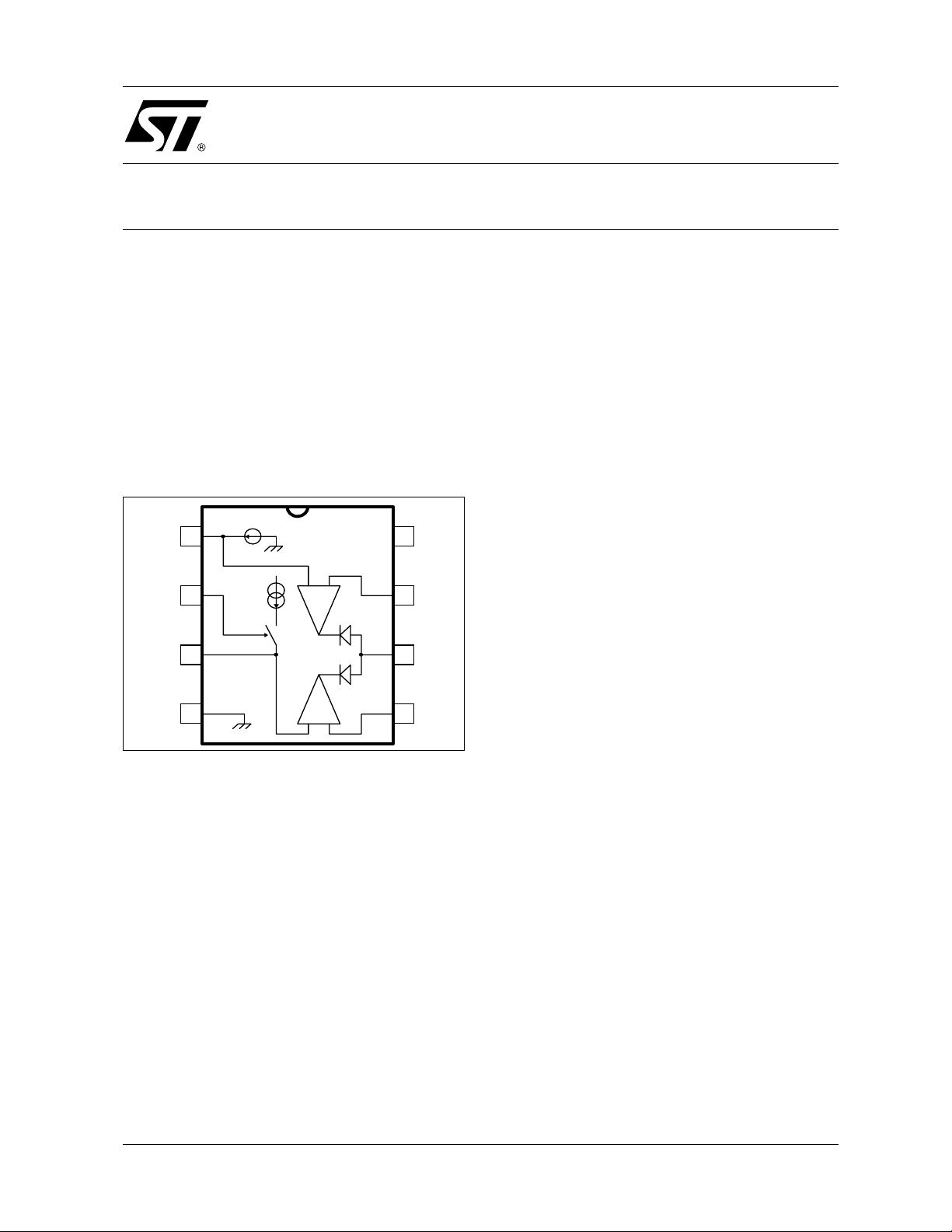

1 - TSM101 PRESENTATION

The TSM101 integrated circuit incorporates a high

stability series band gap voltage reference, two

ORed operational amplifiers and a current source

(Figure 1).

AN1283

APPLICATION NOTE

by S. LAFFONT and R. LIOU

A current limitation is used to prot ect the power

supply against short circuits, but lacks precision.

This limitation is generally realized by sensing the

current of the power transistor, in the primary side

of th e SMPS.

The role of the TSM101 is to make a fine

regulation of the output current of the SMPS and a

precise voltage limitation.

The primary current limitation is conserved and

acts as a security for a fail-safe operation if a

short-circuit occurs at the output of the charger.

Figure 1 : TSM101 Schematic Diagram

1.24V

1

CSEN

2

3

45

1.4mA

CRREF

GND CRIN

+

-

VCCVREF

8

-

VRIN

7

OUT

6

+

This IC compares the DC voltage and the current

level at the output of a switching power supply to

an internal reference. It provides a feedback

through an optocoupler to the PWM controller IC

in the primary side.

The controlled current generator can be used to

modify the level of current limitation by offsetting

the information comi ng from the cu rrent sensing

resistor.

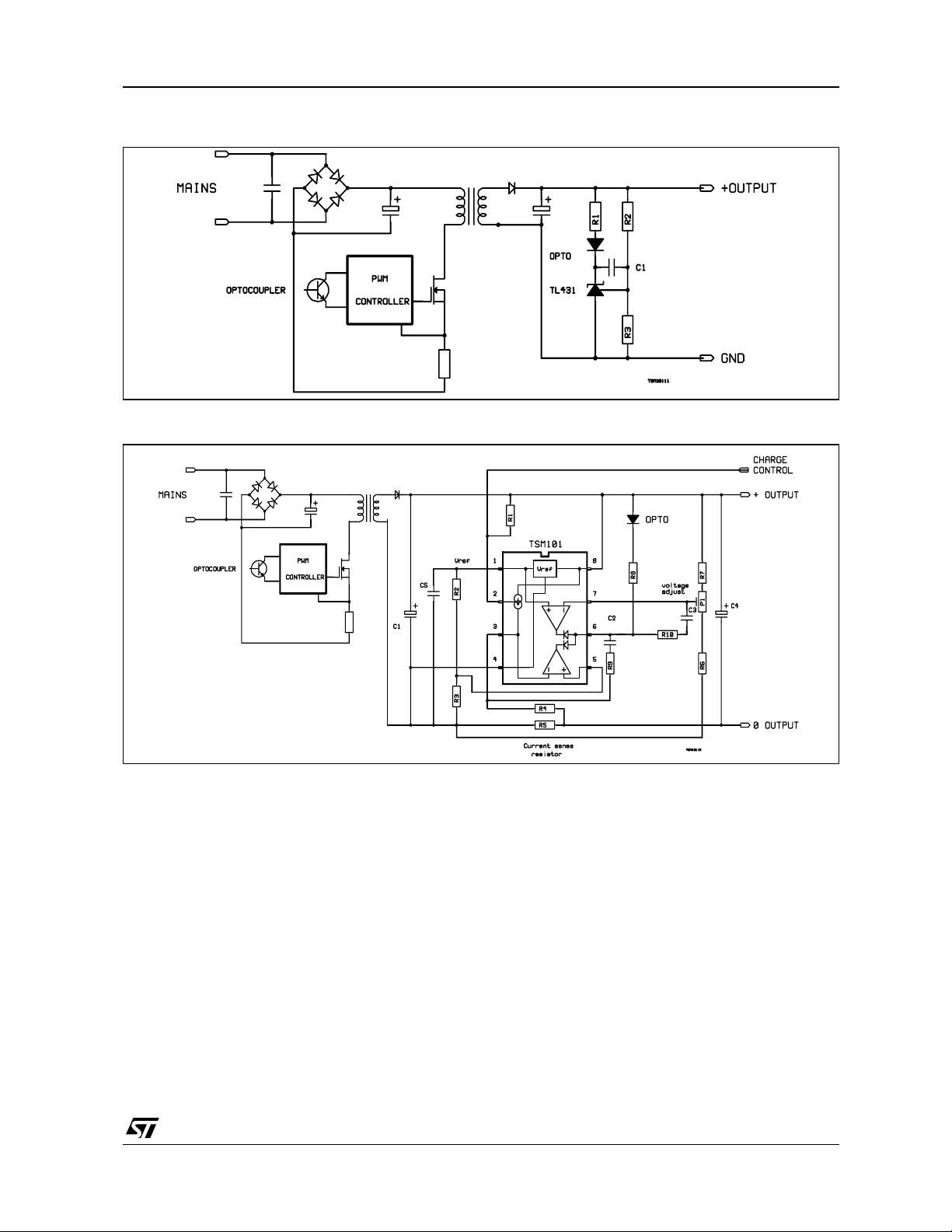

A great majority of low or medium end power

supplies is voltage regulated by using shunt

programmable voltage references like the TL431

(Figure 2).

The galvanic insulat ion of the control information

is done by using an optocoupler in linear mode

with a variable photo current depending on the

difference between the actual output voltage and

the desired one.

2 - PRINCIPLE OF OPERATION

The current regulation loop and the voltage

limitation loop use an internal 1.24V band-gap

voltage reference. This voltage reference has a

good precision (better than 1.5%) and e xhibits a

very stable temperature behavior.

The current limitation is performed by sens i ng the

voltage across the low ohmic value resistor R

and comparing it to a fixed value set by the bridge

composed by R

When the voltage on R

on R

the output of the current loop operational

3

and R3 (Figure 3).

2

is higher than the voltage

5

amplifier decreases. The optocoupler current

increases and t ends t o reduc e the out put voltage

by the way of the PWM controller.

The voltage regulation is done by comparing a

part of the output voltage (resistor bridge R

6

, R

and P1) to the voltage reference (1.24V).

If this part is higher than 1. 24V, the output of the

voltage loop operational amplifier decreases.

The optocoupler current increases and tends to

reduce the output v oltage b y the way of the P WM

controller.

By enabling the TSM10 1 current source (pin 2) it

is possible to offset the current sensing by a

voltage equal to :

with I

= 1.4mA

0

V

OFF

R4I0⋅=

This offset lowers the output charge current and

this function can be used to charge two types of

batteries having different capacities. The current

source is enabled by connecting pin 2 to ground.

5

7

May 2001

1/7

Page 2

AN1283 - APPLICATION NOTE

V

V

3 - CALCULATION OF THE ELEMENTS

The charge current i s regulated at 700mA (if the

charge control input is left open) or 200mA (if the

charge control input is put to ground ), allowing the

charge of two different types of batteries.

3.1 Voltage limitation

The end-of-charge voltage is limited at 1.45V/c ell,

this is the recommended vol tage for an am bient

temperature at 25°C.

A diode is gene rally inserted at the output of the

charger to avoid the discharge of the battery if the

charger is not powered. This diode is sometimes

directly integrated in the battery pack. The

influence of this diode on the charge is negligible if

the voltage drop (0.7V) is taken into account

during the design of the charger.

The voltage at the output of the charger is :

R6R7+

V

OUT

and regarding R

R

which is a part of R6 and R7 is not considered

(P

1

-------------------- -

and R7 :

6

V

-----------------------------

6

V

outVref

V

⋅=

⋅=

ref

R

7

R

6

ref

+

in this equation)

The following values are used on the application

board :

❑ R

= 12kΩ

7

❑ R

= 1kΩ

6

❑ P

= 220Ω adjust for V

1

battery replaced by a 1kΩ resistor

❑ R

❑ C

= short circuit

10

= 100nF

3

= 15.2V with the

output

3.2 Current regulation

R

is the sense resistor used for current

5

measurement.

The current regulation is effective when the

voltage drop acros s R

is equal to the voltage on

5

pin 5 of the T SM101 (assuming that the interna l

current source is disabled).

For medium currents (<1A), a voltage drop across

R

of 200mV = VR5 is a good value, R5 can be

5

realized with standard low c ost 0.5W resistors in

parallel .

R

5

I

0.285Ω==

ch

R

5

----------

(four 1.2Ω resistor in parallel)

R

and R3 can be chosen using the following

2

formula :

–

R

6

refVR

---------------------------

⋅=

R

3

5

V

R

5

3.3 Charge control

If the pin 2 is left open, the charge current is

nominal at 700mA.

If pin 2 is connected to ground, the internal current

source is enabled, the current measurement is

offset by a voltage equal to :

I0R4⋅=

R

4

with I

= 1.4mA

0

V

This can be used to lower the charging current or

eventually to stop the charge, if V

> VR5.

R4

In our example, the current offset is equal to 700 200mA = 500mA, representing a voltage offset

V

= 140mV across R4.

R4

The following values are used on the application

board :

❑ R

= 300mΩ (four 1.2Ω-0.5W resistors in

5

parallel )

❑ R

= 100 Ω

4

❑ R

= 1.2k Ω

2

❑ R

= 220 Ω

3

❑ R

= short circuit

9

❑ R

= 10kΩ

1

❑ C

= 100nF

2

❑ C

= 100nF

5

❑ C

= output capacitor of the SMPS

1

❑ C

= 10µF

4

4 - SCHEMATIC DIAGRAM

Figure 2 represents a schematic of the output

circuit of a “classical” SMPS using a TL431 for

voltage regulation. This circuit is modified to use

the TSM101 and the final circuit is represented in

Figure 3.

2/7

Page 3

Figure 2 : SMPS Using a TL431 as Voltage Controller

Figure 3 : SMPS Using the TSM101

AN1283 - APPLICAT ION NOTE

5 - IMPROVEMENT

5.1. High frequency compensati on

Two R-C devices (R

, C2 and R10, C3) are used to

9

stabilize the regulation at high frequencies.

The calculation of these values is not easy and is

a function of the transfer function of the SMPS.

A guess value for the capacitors C

and C3 is

2

100nF.

5.2. Power supply for TSM101

In applications requiring low voltage battery

charge or when the charger is in current regulation

mode, the output voltage can be too low to supply

correctly the TSM101. The s ame problem occurs

when the output is short-circuited.

A solution to provide a quasi constant supply

voltage to th e TSM101 is s hown at Fig ure 4 : an

auxiliary winding is added at the secondary side of

the transformer.

This winding is forward coupled to the primary

winding, the voltage across it is directly

proportional to the mains rectified voltage, even if

the flyback voltage is close to zero.

As this auxiliar y winding is a voltage s ource, it is

necessary to add a resistor (R

of the rectifier (D

A low cost regulator (Q

) to limit the current.

3

and Zener diode D4) is

2

) on the cathode

11

used to power the TSM101. This is necessary with

autoranging SMPS with wide input voltages, for

example 90 to 240V without switching. In standard

SMPS with voltage range from 200 to 240V AC or

100 to 130VAC, this regulator can be removed

and replaced by the small power supply shown on

Figure 5 (R

aux

, C

aux

, D2).

3/7

Page 4

AN1283 - APPLICATION NOTE

Figure 4 : An Auxilia ry Win ding fo r TSM 101 P o wer Su pply

5.3 Higher Precision for the Voltage Control

The voltage drop through the sense resistor R

offsets the voltage measurement. In most battery

charging application s, this offset is not t aken into

account because the error is negligible compared

to the end-of-charge v oltage due to the fact that

the charging current value decreases drastically

during the final phase of the battery charging.

But in other applications needing highest possibl e

precision in voltage control, another connecting

schematic is possible for TSM101 as shown on

Figure 5.

In this schematic, the 0V reference is defined as

the common point between the sense resistor, the

0V Output Volt age, the foot of the res istor bridge

R

, and the ground (pin 4) of the TSM101.

6/R7

TSM101A (1% internal voltage reference

precision) is required in such applications.

5.4 An example of application where the

charging current is different according to the

charging phase.

The following application includes a specific

recommendation which requires that the charging

current should be fixed to I

charging conditions, and I

cell voltage is below V

low

= 800mA in normal

ch1

= 200mA when the

ch2

=2.5V to optimize the cell

life-time.

Moreover, a Charging Status LED should be

switched off when the cell voltage is above

V

=6.5V.

high

Figure 6 shows how this can ea sily be achieved

using an additional dual comparator (type LM393)

where the first operator (C

) is used to activate the

1

TSM101 internal current generator to offset the

current measurement thanks to R

5

second (C

) is used to switch the status LED off.

2

On Figure 6, the status signal is determined by

voltage measurement, this could as well be

achieved by current measurement.

If V

= 100mV is the maximum t olerable voltage

5

drop through the sense resistor R

during normal

5

charging conditions, then the following

calculations apply :

Current Control :

R

5

V

5

with R

R

+ R3 ~ 12kΩ and V

2

= 1kΩ, R2 = 11.4kΩ

3

V

5

V

---------- -

I

ch1

V

0.1V

5

------------

0.8A

R

3

-------------------- -

⋅=

ref

R2R3+

= 1.24V

ref

R4I0⋅ R5I

125mΩ== =

⋅+=

ch2

therefore,

with I

with V

R

0

low

= R14 = 10kΩ

15

V5R5I

----------------------------------- -

R

=

4

= 1.4mA, R4 = 53.6Ω

V

ref

V

low

= 2.5V and R14 + R15 ~ 20kΩ

⋅–

ch2

I

0

R

15

-------------------------- -

⋅=

R

+

14R15

, and the

4

4/7

Page 5

Figure 5 : Precise Output Voltage Control

AN1283 - APPLICAT ION NOTE

Figure 6 : Optimized Charging Conditions

5/7

Page 6

AN1283 - APPLICATION NOTE

EVALUATION BOARD - TECHNICAL NOTE

TSM101 integrates in the same 8 pin DIP or SO

package

❑ one 1.24V precision voltage reference

❑ two operational amplifiers

❑ two diodes which impose a NOR function

on the outputs of the operational amplifiers

❑ one current source which can be activated/

inhibited thanks to an external pin.

An immediate way to take ad vantage of the high

integration and reliability of TSM101 is to use it as

a voltage and current controller on power supplies

secondary. The application note AN1283

describes precisely how to use TSM101 in an

SMPS battery charger.

The TSM101 Evaluation Board is adaptable to any

power supply or battery charger (SMPS or linear)

as a voltage and current controller with minimal

constraints from the user.

HOW TO USE THE TSM101 EVALUA TION

BOARD ?

The generic Electrical Schematic is shown on

Figure 7. It represents an incomplete SMPS

power supply where the primary side is simplified.

The “IN+”and “IN-” power inputs of the

evaluation board shoul d be connected directly to

the power lines of the power supply secondary.

The “Vcc” input of the evaluation board should

be connected to the auxiliary supply line.

In the case of an SMPS power supply, the “Reg”

output of the evaluation board should be

connected to the Optocoupler input to regulate the

PWM block in the prim ary side. In the case of a

linear power supply, the “Reg” output should be

connected to the base of the darlington to regulate

the power output.

A diode might be needed on the output of the

evaluation board i n the case of a bat tery charger

application to avoid the discharge of the battery

when the charger is not connected.

COMPONENTS CALCULATIONS

The voltage co ntrol is given by the choice of the

resistor bridge R

(and the trimmer P1) due to

6/R7

equation 1 :

❑ V

where V

= R6/(R6+R7)xV

ref

= 1.24V

ref

eq1

out

The curren t control is given by the choice of the

voltage drop through the sense resistor R

(to be

5

linked to the nominal current of the application)

and by the value of the sense resistor itself.

Figure 7: Evaluation board schematic

6/7

Page 7

AN1283 - APPLICAT ION NOTE

For medium currents (< 1A ), a good value for t he

voltage drop through R

can be V

5

sense

= 200mV

(dissipation < 200mW).

The resistor bridge R

should be chosen

2/R3

following equation 2 :

❑ V

= R3 / (R2+R3) x V

sense

eq2

ref

The total value of t he resistor bridg e should be i n

the range of the kW in order to ensure a proper

charge for the voltage reference (in the range of

the mA).

To set the current limit, the sense resistor R

should be chosen following equation 3 :

❑ I

= V

lim

The internal current generator (I

/ R5 eq3

sense

) can be used

sce

to offset the current limitation with a lower value.

This current generator is activated by connecting

pin 2 to ground. It is inhibited if pin 2 is connected

to the positive rail via the pull up resistor R

.

1

The current offset is given by the choice of the

resistor R

If I

lim1

paragraph, and I

set when pin 2 is co nnecte d to ground, R

.

4

is the current limit calculated in the previous

is the current limit that is to be

lim2

should

4

be chosen following equation 4 :

❑ R

= (V

4

where I

C

and C5 are bypass capacitors used to

4

= 1.4mA

sce

sense

- I

lim2

x R5) / I

sce

eq4

smoothen the regulated outputs.

C

and C3 are capacitors used for high f requency

2

compensation.

5

Table 1

Voltage/

Current

Control

R1 10k

R2 1.2k

R3 220

R4 100

R5 1.2Ωx4 0.8Ωx4 1Ωx4

R6 1k

R7 12k

P1 100

2 straps 0

C2 100nF 100nF 100nF

C3 100nF 100nF 100nF

C4 10µF22

C5 100nF 100nF 100nF

15V

700mA

200mA

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

12V

1A

500mA

10k

Ω

1.2k

Ω

220

Ω

68

Ω

1k

Ω

8.2k

Ω

100

Ω

0

Ω

F 4.7µF

µ

8.2V

200mA

100mA

10k

1.2k

220

68

1k

5.6k

100

Figure 8

Ω

Ω

Ω

Ω

Ω

Ω

Ω

0

Ω

EXAMPLES OF COMPONENT LISTS

Table 1 summarizes a few examples of

component lists t o generate quickly 15V/700mA/

200mA, 12V/1A/500mA or 8.2V/200mA/100mA

voltage and current regulations.

Information furnished is bel ieved to be accurate and reliable. However, STMicroe lectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from

its use. No li cense is granted by implica tion or otherwise under any patent or patent righ ts of S TMic roelec tronics. Specifications

mentioned in this publication ar e subject to change without notice. This publication supersedes and replaces all information

previously supplied. S TMicroelectronics products are not authorized for use as critica l components in life suppo rt devices or

systems without express written approval of STMicroelectronics.

Australi a - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malay sia - Malta - Morocco

© The ST logo is a registered trademark of STMicroelectronics

© 2001 STM icroelectronics - Prin ted in Italy - All Rights Reserved

STMicr o el ectronics GROU P OF COMPANIE S

Singapo re - Spain - Swe den - Switzerl and - United K i ngdom

© http://www.st.com

7/7

Loading...

Loading...