ACS™

AN1172

Application note

A logic-level transient-voltage protected AC switch

Introduction

Home appliances such as washing machines, refrigerators and dishwashers employ a lot of

low power loads such as valves, door lock systems, dispensers or drain pumps. Since these

loads are powered by the mains in ON / OFF mode, they were initially controlled by relays.

Recently, relays have been replaced by triacs, due to their smaller size and lower driving

energy. Nevertheless triacs don't fulfill alone the new requirements that users now need and

are used with others components.

Power switches must now be directly driven by a microcontroller unit (MCU) and must be

robust to withstand the A.C. line transients so that systems may fall into line with

electromagnetic compatibility (EMC) standards. ACSs (for Alternating Current Switches)

have been designed with this goal mind, i.e. to offer logic level and more robust

semiconductor devices.

On the other hand, ACSs have been developed adopting a functional integration approach.

They can be used directly between a MCU and the load. An external protection or a buffer

circuit are not required since these are already integrated on the die. This considerably

reduces the overall electronic board size. Moreover, the array of ACSs allows one device to

control the various loads typically required in a washer appliance.

Table 1. gives the RMS current of loads that can be controlled by ACS402-5SB4 or

ACS108-5SA/N, in ON / OFF control mode.

Table 1. ACS108 and ACS402 targeted loads

(dI

I

Load

Door Lock <0.3 1 0.15 0.15 <10

Lamp <0.8 1 0.4 0.15 <20

Relay, Valve,

Dispenser,

Micromotor

Pump <0.2 >0.2 <0.1 <10 <10

Fan <0.6 >0.2 <0.3 <10 <20

RMS

(A)

<0.1 >0.7 <0.05 <2 <10

Power

Factor

/dt)c

out

(A/ms)

(dV

/dt)c

out

(V/µs)

Turn-off delay

(ms)

May 2006 Rev 2 1/23

www.st.com

Contents AN1172

Contents

1 ACS triggering mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Negative gate current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 New layout possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Inductive loads on/off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Valves and relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Pumps and Fans ON / OFF control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Resistive loads on/off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Inrush current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Transient junction temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Light bulb flashover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Electromagnetic compatibility standards . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 IEC 61000-4-5 standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 IEC 61000-4-4 standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/23

AN1172 ACS triggering mode

1 ACS triggering mode

1.1 Negative gate current

The ACS silicon structure is different from the triac one. For instance, the gate embeds a

diode junction. Then the gate current can only circulate in one direction, from the COM pin

to the Gate one. A peak reverse voltage (VGM) of this junction is also defined in the ACS

data sheet.

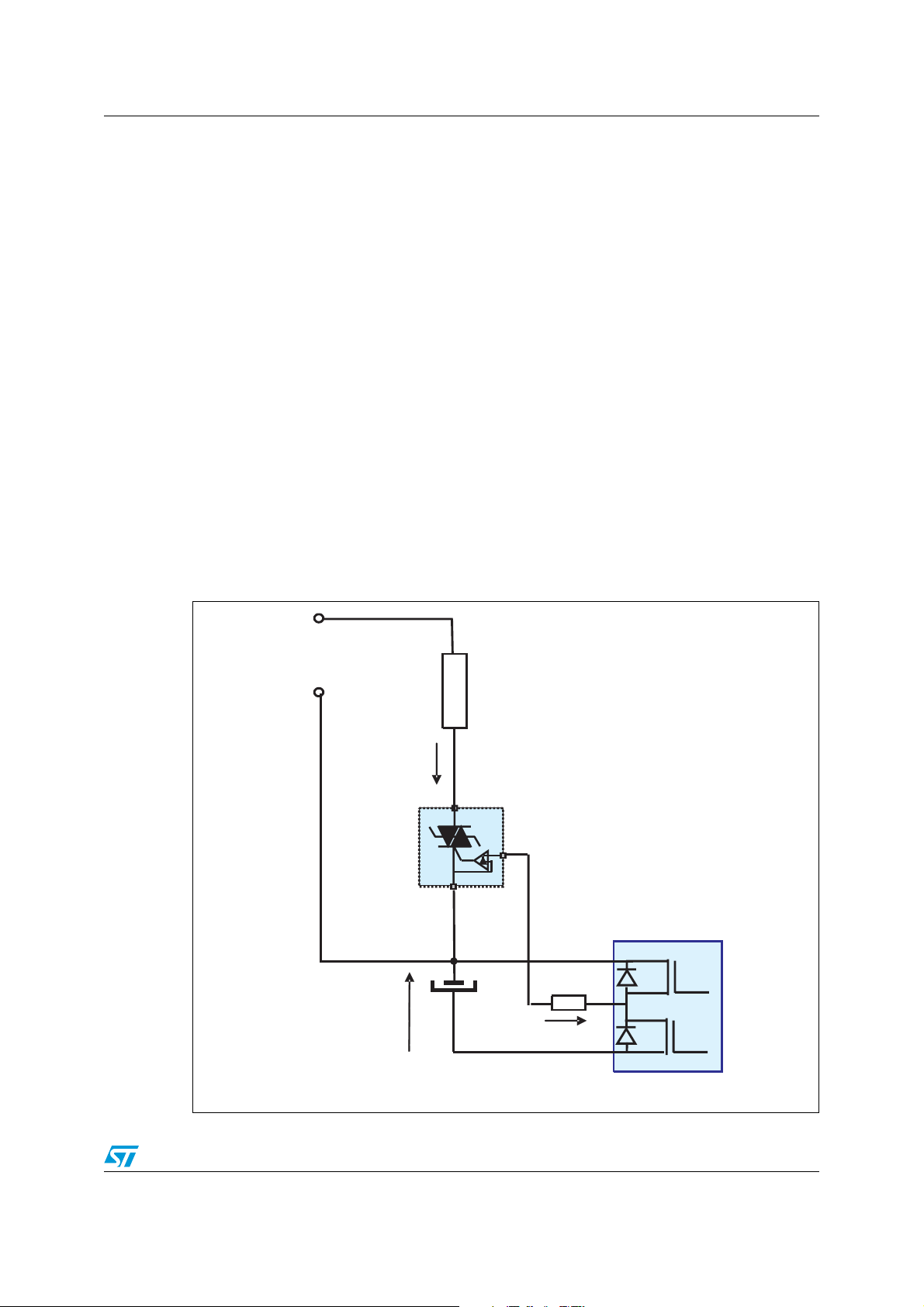

In order to sink a current from the gate by a microcontroller output port, the supply voltage

positive terminal must be connected to the drive reference, i.e. the COM pin of ACSs (see

Figure 1.).

An interesting benefit of such a connection is that the ACS is not fired when the MCU is at

reset state. Indeed, in this case, all the MCU port pins are at high level. This means that the

gate resistors are all connected to the COM terminal. No spurious triggering can then occur.

It should be noticed that for a direct switch / MCU connection, the MCU current capability is

not the only point to check to decide if the buffer circuit can be removed. Actually, the

transistor, used to amplify the MCU current in order to control the gate, also play an

overvoltage protection role. Annex B gives the gate voltage limits between which the MCU

output port will be not stressed. It is also shown that with ACSs, the gate voltage remains

inside these limits even with worst cases of dI/dt gradients at turn-on.

Figure 1. Gate / MCU connection

L

AC MAINS

N

Iout

Com

Vs

Valve / PUMP

etc.

Vg

G

R

I

R

Vdd

D1

D2

M1

M2

Vss

MCU

3/23

ACS triggering mode AN1172

1.2 New layout possibilities

It has already been said that ACS silicon structure is different from the triac, according to the

gate operation. A second difference is that ACS have been developed in an integration goal.

To allow different cells to be associated in one single package or controlled by one single

drive die, the common drive reference voltage must be connected to the back of the die.

Indeed, each die bottom is electrically linked to the other ones by the frame. This is achieved

by the ACS silicon structure, where an integrated level shifter allows both thyristors to be

controlled by means of a gate voltage referenced at the back of the die (COM pin). (See

References, 1.).

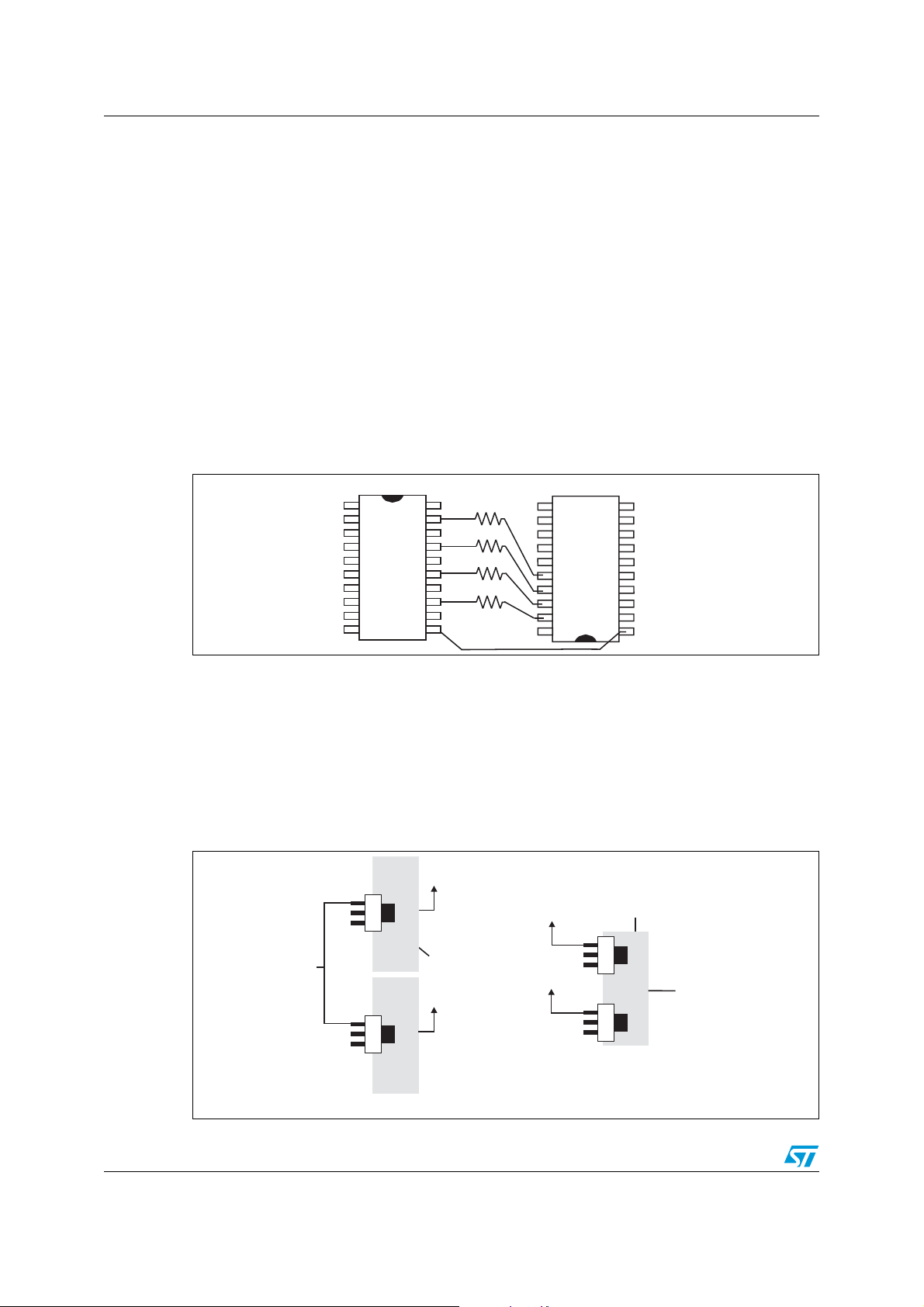

Thanks to ACSs arrays, the copper tracks count is reduced since the different COM pins are

connected together inside the package. This also allows smaller gate / MCU copper tracks

loop areas, and so increases the EMI immunity of the overall electronic board. Figure 2.

shows an example of connection between an ACS402-5SB4 and an ST62xx, both in DIL20

packages.

Figure 2. Reduction of gate / MCU loop areas

1

ACS402

OUT1

OUT2

OUT3

OUT4

G1

Rg

G2

G3

G4

COM

PA3

PA2

PA1

PA0

ST6

Vdd

1

A particular benefit of such a pin out appears with Surface Mount Devices (SMD). In this

case, the tab pin is the COM one. The copper surface used to perform a heat-sink can then

be used as a supply voltage bus. It allows new layout possibilities and, above all, a

miniaturization of the Printed Circuit Board (PCB). Indeed, unlike triacs, the heat-sink areas

are at the same voltage and so can be regrouped (see Figure 3.). The heatsink area

therefore depends on the maximum amount of dissipated power at the same time, by all the

switches put on it. So, the number of switches which will conduct at the same time and their

conduction time should be known.

Figure 3. Printed circuit area reduction thanks to ACSs in SOT223 packages

LOAD

A1

A2

G

MCU

Ref.

A1

A2

G

PCB required for TriacsPCB required for Triacs

A2

A2

A2

A2

Copper heatsink

LOAD

LOAD

LOAD

COPPER HEATSINK

OUT

COM

G

OUT

COM

G

PCB required for ACSs

MCU

Ref.

4/23

AN1172 Inductive loads on/off control

2 Inductive loads on/off control

2.1 Valves and relays

2.1.1 Turn-off overvoltages are clamped by ACSs

Valves and relays are both electromagnetic systems. In the case of AC high voltage

operation, their windings present a high series resistance (a few kΩ) and a high series

inductance (tens of Henry). Hence, they absorb a low RMS current (typically, 10 to 50 mA).

In this case, the current rate of decrease is low and an automatic switch turn-off may result,

when its current becomes lower than the holding level (see References, 2.). There may be

an over-voltage due to the fact that there is still some current through the inductive load. The

inductive energy thus creates a back electromotive voltage which tends to force the switch to

conduct. If this over-voltage is not clamped, it can exceed the device breakdown level and

damage it.

ACSs are over-voltage self-protected. They can sustain their holding current in such an

operating mode, as shown in Figure 4.

Figure 4. ACS voltage and current waveforms at turn-off (230 V 35 mA RMS valve)

Iout (10 mA/div)

Vout (200 V/div)

During clamping periods, the inductive energy is dissipated both in the silicon die and the

series resistance of the load. The worst case appears when the load inductance is the

highest, i.e. for electromagnet loads.

In annex C, a theoretical analysis is performed with a 0.1 power factor load and an RMS

current lower than 40 mA (value which never appears in practice where, for such RMS

currents, the power factor is always higher than 0.7). Then, it is demonstrated that, even in

this worst case scenario, the transient junction temperature remains below 160°C. And the

clamping period time (t

ACSs dies thanks to their reliable planar technology.

) always lasts less than 1 ms. Such a thermal stress is suitable for

cl

5/23

Inductive loads on/off control AN1172

2.1.2 Maximum switching frequency

As far as thermal management involving clamping phases is concerned, a maximum load

commutation frequency must be defined to avoid excessive device heating. Figure 5. gives

the maximum supplementary temperature rise due to recurrent clampings, versus the ACS

switching period (see Appendix C). This value is given for a 230 V - 50 Hz mains voltage

(110 V mains is less stressing), for the worst case of load (power factor = 0.1, peak load

current = i

this case, the energy absorbed by the die equals 25 mJ.

The chosen package is the TO92 one (ACS108-5SA device) because it presents the highest

Rth value, among ACS packages on offer (DIL20, TO92, SOT223, DIL8).

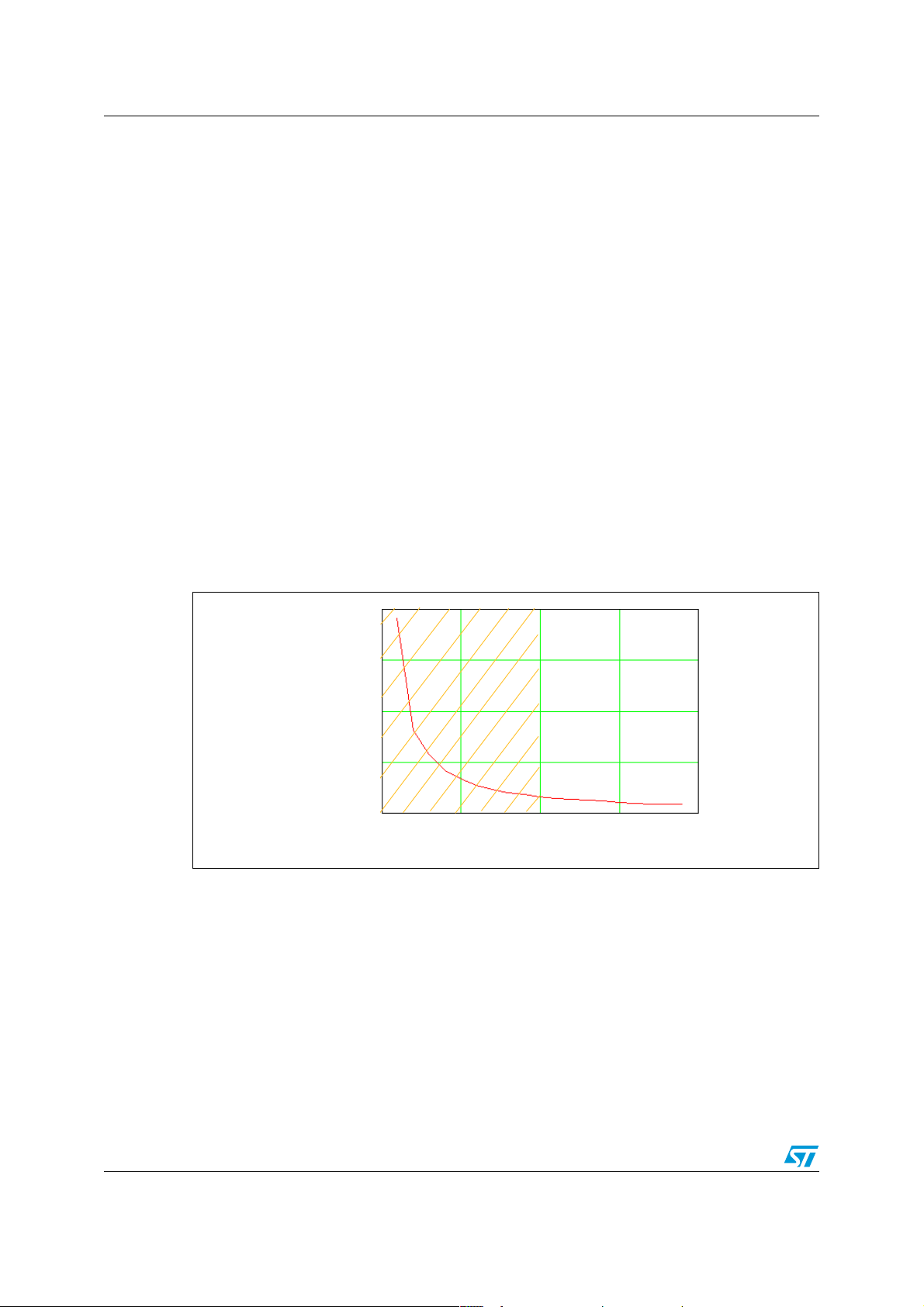

It can be seen that this temperature elevation can be neglected (< 4° C) as long as the

control frequency is less than one Hertz. Such a value is suitable for most appliance

applications where loads are at most controlled once per second. For that reason, in ACS

data-sheets, the maximum allowed current is given for a 1 Hertz maximum frequency 0.1

minimum load power factor. Turn-off dissipated power is then reviewed for a wide range of

application needs.

This enables us to conclude that no varistor is needed across ACSs to clamp the loads

inductive energy at turn-off, even with electromagnets which are the highest inductive loads

in Appliances.

max) and for the maximum VCL and iH values (800 V and 60 mA respectively). In

H

Figure 5. Supplementary temperature elevation due to repetitive clampings (@

clamping energy = 25 mJ, package: TO92)

40

30

Appliances

∆ T

rep

(° C)

20

10

0

0 0.5 1.0 1.5 2.0

ACS switching period (T) (s)

operation field

2.2 Pumps and Fans ON / OFF control

2.2.1 Application requirements for (dI/dt)c and (dV/dt)c

There is a higher risk that a triac or an ACS will fail to turn-off when both the load current

rate of decrease and the reapplied voltage rate across the device are steep (see

References, 3.). This risk increases as the junction temperature increases. The maximum

current decreasing rate that ACS can switch off, called (dI/dt)c is defined for a maximum

reapplied voltage rate, called (dV/dt)c, and for its maximum T

.

j

6/23

AN1172 Inductive loads on/off control

Pumps and Fans are, for the most part, induction or permanent magnet motors. Their series

inductance is in the range of one Henry, and their winding resistance equals a few hundred

Ohm. Their power factor is low. Hence, after switch turn-off, the reapplied voltage across it is

high and appears with a high rate of increase (as described in Equation 1 where L and cosϕ

are the inductance and power factor of the load, V the mains RMS voltage and C is the ACS

capacitance value).

Equation 1

6

−

()

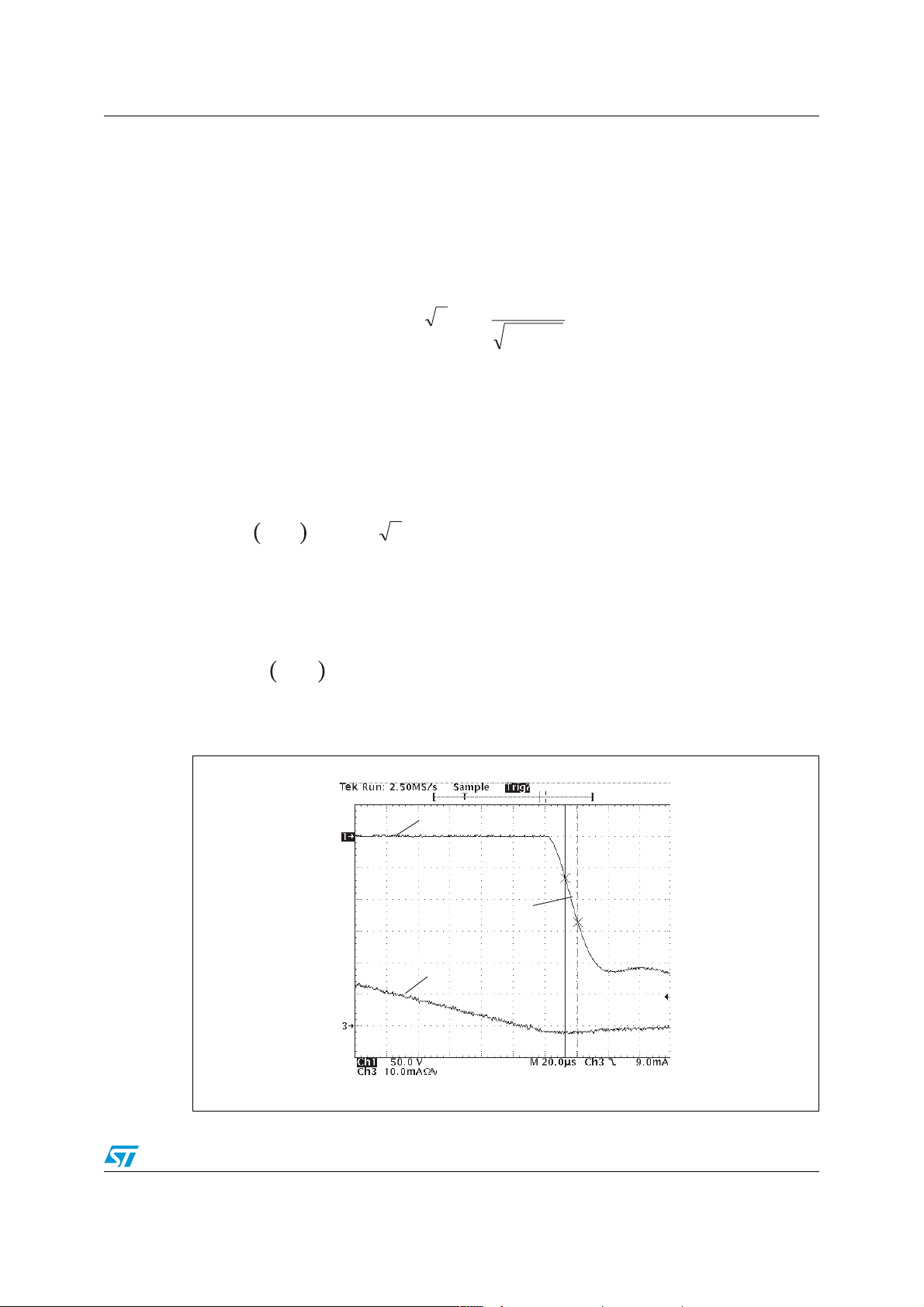

Figure 6. shows that the (dV/dt)c rate for an ACS402-5 die without any snubber, controlling a

230 V 220 mA pump, is lower than 10 V/µs. The measure will be similar with an ACS108-5

die because it presents the same capacitance value as an ACS402-5.

Equation 2 shows that the current rate of decrease is almost half the RMS current (0.44 ratio

for a 50 Hz mains frequency and 0.53 for 60 Hz).

≅ϕ

sin2Vcdt/dV

)V()µs/V(

10

CL

)F()H(

Equation 2

3

-

≅π

10f2I2cdt/dI

)Hz()A(RMS)ms/A(

To summarize, it can be said that the worst case commutation appears with pumps or fans.

In this case, the stress that ACSs must withstand is:

Equation 3

≅

⎧

⎨

()

⎩

Figure 6. 230 V 220 mA RMS pump switch-off

≤

I5.0cdt/dI

)A(RMS)ms/A(

µs/V10cdt/dV

Vout (50 V/div)

dV/dt = 8,7 V/µs

Iout (10 mA/div)

7/23

Inductive loads on/off control AN1172

2.2.2 ACS asymmetrical turn-off behavior

As shown in Figure 7., ACSxxx-5 behaves differently depending on the current direction

before switch-off. This asymmetrical behavior is very lower for ACSxxx-6 and

ACS110/ACS120 devices where the (dI/dt)c parameter is quite similar for both polarities.

Figure 7. ACS402-5 and ACS108-5 (dI/dt)c typical ability versus reapplied (dV/dt)c

rate @ Tj = 110°C

(dI/dt)c (A/ms)

800

700

600

500

400

300

200

100

(mA/ms)

Iout>0 Iout<0

2

1

024681012

(dVdt)c (V/µs)

For a 200 mA RMS current pump (see case 1 in Figure 7.), the turn-off will be performed

whatever the current sign is. The maximum turn-off delay is then one half-cycle (10 ms for

50 Hz mains frequency).

On the other hand, for a 200 - 600 mA RMS pump (see case 2 in Figure 7.) and for a 110° C

junction temperature, the switch-off will only be achieved when the current reaches zero with

a negative sign. Therefore, in this case, the turn-off delay time can reach up to 20 ms for

50 Hz line frequency (Figure 8.).

Figure 8. Turn-off delay for two different pump or fan RMS current

1

VOUT

IOUT

ig

Turn-off delay

8/23

2

IOUT

VOUT

t

t

ig

Turn-off delay

AN1172 Resistive loads on/off control

3 Resistive loads on/off control

3.1 Inrush current

In most systems, resistive loads are thermal effective. For example, light bulbs emit light

when their filament is hot enough. New types of door-lock actuators have emerged in which

the bolt move is due to a thermal expansion of a metallic part or a wax.

All these loads can be characterized by a very low resistance value in cold state.

Consequently, when the switch is turned on, there is a high inrush current. For low power

light bulbs, the inrush current lasts on average 10 ms. The worst scenario is in the case of

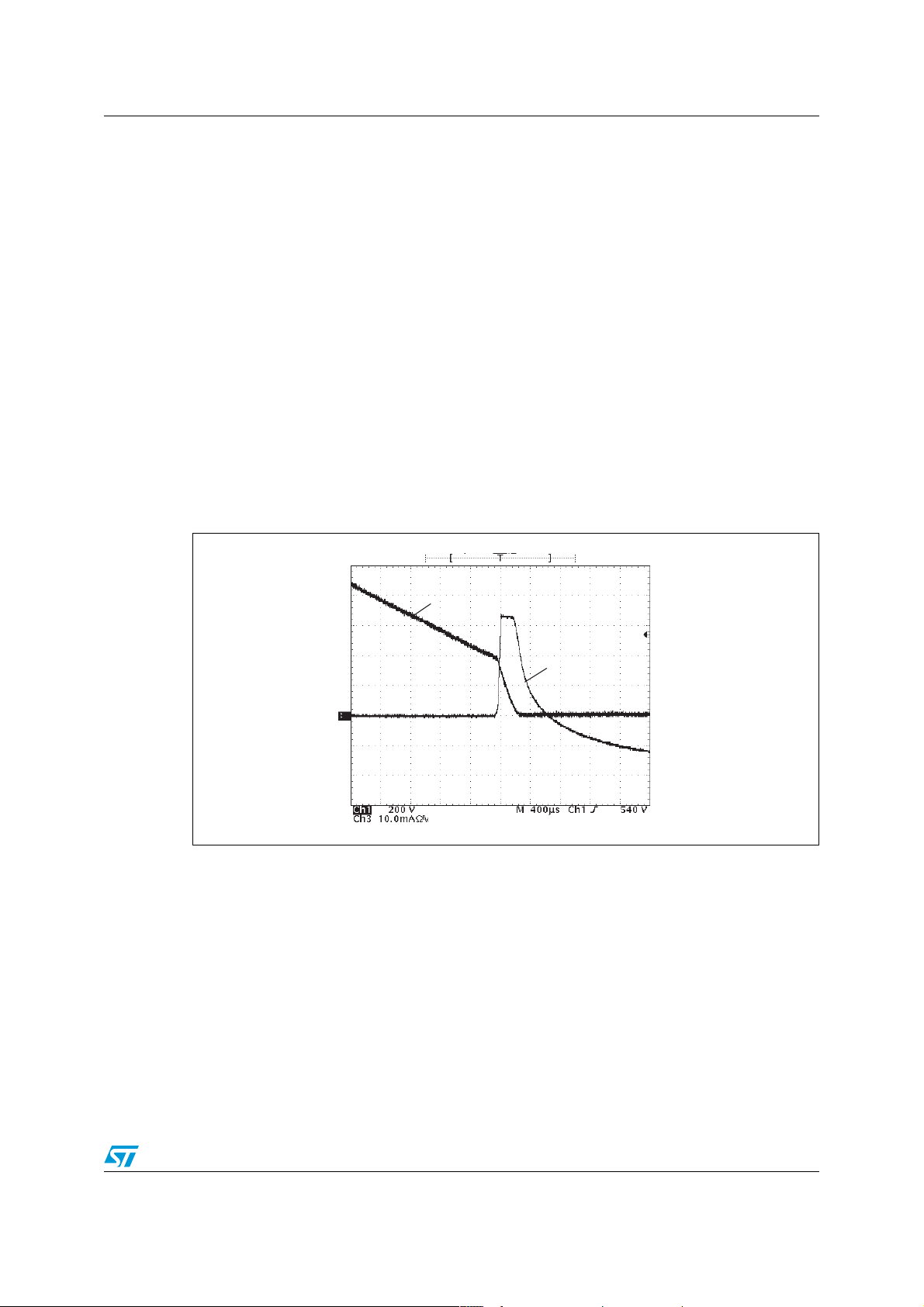

thermal door-locks. Figure 9. shows a typical inrush current in such loads.

Figure 9. Inrush current in a 230 V thermal effective door-lock

Vout (200 V/div)

3.2 Transient junction temperature

With such current shapes at turn-on, thermal calculation must be carried out in order to

choose the right package or heat-sink so as to avoid exceeding the maximal junction

temperature (110° C).

To perform the calculus, the current shape must be simplified. Let us work on the hypothesis

that the current average waveform of Figure 9. is similar to a 2 A peak 0.18 s time long sinus

shape.

Iout (1 A/div)

9/23

Resistive loads on/off control AN1172

Then, the average conduction and gate current losses in the ACS are given by the following

relationship:

Equation 4

2

RMSdav

IVIrP++=

22

π

IV

ggtRMS0t

Then, according to ACS108-5 or ACS402-5 specifications, we find: Pav = 1.76 W.

For a t

Equation 5, where T

long dissipated power pulse, the peak junction temperature (T

p

is the initial Tj value.

jo

) is given by

j peak

Equation 5

PtZthTT ⋅+=

avpjopeakj

Since the thermal impedance values at 0.18 s for TO92 and DIL20 packages are 22.5 and

8° C/W respectively, it can be said that the junction temperature elevation, at the end of the

inrush current period, is 40° C for a TO92 package and 14° C for a DIL20 package.

So, the maximal junction temperature before door lock switch-on should be at most 96° C for

ACS402-5SB4 (DIL20) and 70° C for ACS108-5SA (TO92), in order to keep T

T

(110 °C).

j max

For washing systems, as the door lock start may appear at the beginning of a washing cycle,

we suppose that T

equals at worst the maximal ambient temperature, i.e. 70° C. So, in this

jo

respect, both ACS devices are convenient for door lock operation.

j peak

below

3.3 Light bulb flashover

Another point should be highlighted when driving a light bulb with a silicon switch. Indeed, at

the lamp life time end, the filament breaks itself. This results on a flashover across the gas,

included in the bulb. Then, the overall filament can be can short circuited by the flashover,

and the load current is not limited. Figure 10. gives the typical overcurrent measured when a

25 W lamp fails. This current can exceed the i

Figure 10. 25 W light bulb flashover current

250 Amp !

²

.t capability of the ACS and destroy it.

I lamp (50A/div)

t = 500 µs/div

10/23

AN1172 Resistive loads on/off control

To avoid destroying the ACSs at each lamp flashover, a power resistor can be added in

series with the light.

This resistor (R) is rated in order to limit the ACS current to its I

half sinus conduction). R is calculated as following:

value (10 A for a 10 ms

TSM

Equation 6

R

2230

Ω==33

10

The power dissipated by the resistor is linked on the load RMS current, and so on the load

power (P

Equation 7

A 33 Ω 1/2 W resistor is sufficient.

Figure 11. gives the overcurrent measured with such a resistor during the flashover of a

25 W light bulb.

Figure 11. Flashover current limited by a 33 Ω 1/2 W resistor

). Here we have :

L

L

22

=×=⋅=

W39.0230/2533V/PRP

Iout (2 A/div)

11/23

Electromagnetic compatibility standards AN1172

4 Electromagnetic compatibility standards

4.1 IEC 61000-4-5 standard

4.1.1 Standard requirements

The IEC 61000-4-5 standard has been established to check if systems can always work

after there has been a voltage surge super-imposed to the mains. A standard voltage

waveform has been chosen which embodies typical over-voltages due to thunder or

disconnection of running inductive loads from the line.

Two kinds of surges must be applied:

1. Line to Ground surge: in this case the maximum voltage surge is 4 kV (for aerial

power network), but the energy is absorbed by the Y2 capacitors (connected between

lines and ground) of the mains filter.

2. Line to Neutral surge: in this case the maximum voltage surge is 2 kV (for aerial

power network, N.B: 1 kV is required for public power network) and is applied across

the power device and the load controlled by this one.

A Line to Neutral over-voltage is then:

1. entirely absorbed by the load if the power switch is ON;

2. entirely held by the semiconductor device if it appears while the switch is at off-state.

As the Line to Neutral surge can appear at peak mains voltage, the overall amount of

voltage can reach 2.4 kV. This will be higher than the break-down level of the silicon devices

used in appliances. Then, in order to prevent components destruction, designers use a

varistor connected across silicon devices. The overvoltage is limited below the breakdown

level of the power semiconductor and the surge energy is absorbed by the metal-oxyde

component.

4.1.2 ACS behavior during IEC 61000-4-5 test

When a surge appears when an ACS is OFF, the mains over-voltage is first clamped by the

device. But an excessive energy surge can raise the ACS current above its breakover level.

Then, the switch turns on in break over mode. Such an event is particularly stressful on the

semiconductor especially so if the current and its rate of increase are both high. The worst

case occurs for ACS driving low resistance, non inductive loads.

For example, Figure 12. and Figure 13. have been recorded with a thermal active door lock

system at low temperature. The 2 kV surge is super-imposed to the 230 V - 50 Hz mains

and synchronized with its peak value, as shown on Figure 12. Figure 13. highlights the

device turn-on in this mode. As the load was previously off, its resistance is cold and equals

150 Ω. In this case, the current rises at a rate of 100 A/µs and reaches 15 A. Such transient

surges would damage triacs, but not ACSs which are designed to turn-on in breakover

mode. No more varistor is then needed in parallel across ACSs unlike triacs. The difference

between ACS and Triac + Varistor is that, with the ACS, the load is switched on during a half

or one mains cycle. This can be accepted as such events happen a few times in the

system's life.

Reliability tests are carried out on production batches to check the ACS robustness towards

IEC 61000-4-5. A standard surge generator is used directly across a load and an ACS. The

load is a 150 Ω resistor, including a 3 µH parasitic inductance, to simulate a cold door-lock.

12/23

AN1172 Electromagnetic compatibility standards

The applied surge is fixed at +/- 2,4 kV in order to be equivalent to a 2 kV over-voltage

applied at the peak mains voltage, with the same bias.

Figure 12. 2 kV surge on the mains

(IEC 61000-4-5 test)

Figure 13. ACS breakdown zoom

(IEC 61000-4-5 test)

4.2 IEC 61000-4-4 standard

4.2.1 2.1: Standard requirements

For IEC 61000-4-4 tests, two different stressing ways are demanded. One is to apply the

bursts to the Line, Neutral or Ground through 33 nF capacitors. In this case, the bursts are

entirely absorbed by the mains filter, which is always present at the input of electronic

systems. The second IEC 61000-4-4 stressing mode is to apply the bursts through a typical

100 pF capacitor (realized by an aluminum sheet), directly to the I/O ports of the system.

The I/O port test is in fact required for systems where there are control wires, as for

computers (wires between keyboard and central unit). But appliance manufacturers apply

similar test to check if their products can withstand fast voltage transients.

The standard requires that for burst voltages up to 2 kV, the system must operate without

problem. However, triacs can then turn-on due to high dV/dt rates. In this case, a snubber

must be added to smooth these rates. Designers must then manage with the following

trade-off:

1. Reduce dV/dt rates: the snubber capacitance must be high and the snubber

resistance must be low;

2. Reduce the dI/dt rate at turn-on: the snubber capacitance must be low and the

snubber resistance must be high.

4.2.2 Snubber removal thanks to ACSs

I/O tests have been carried out on an electronic board including an ACS402, where the

gates are short-circuited to the COM in order to avoid parasitic turn-on due to MCU bad

operations. The system under test is embodied by this board. The I/O wires are then the

OUT pins of each ACS cell (which are connected to the loads), plus the Line and Neutral

wires. The trial diagram is shown in Figure 14.

13/23

Electromagnetic compatibility standards AN1172

Figure 14. IEC 61000-4-4 test synopsis

Filter

Y2

Mains

10 cm

25 W light bulb

Ground Reference

IEC1000-4-4

Generator

100 pF

High Voltage

Output

10 cm

Test board

COM

220

Ω

220

Ω

220

Ω

220

Ω

ACS 402

Figure 15. shows the OUT-COM voltage measured during a 2 kV IEC 61000-4-4 test (N.B.:

1 kV is required for public power network). We see that in spite of capacitive current due to

high dV/dt rates, the ACS does not turn-on. The semiconductor switch withstanding to IEC

61000-4-4 depends on its dV/dt capability. ACS devices present dV/dt characteristics ten

times greater than both same current and sensibility ratings triacs. For example, a 10 mA

maximum 0.2A i

ACS has a minimum dV/dt capability of 500 V/µs (@ Tj = 110 °C).

gt

It can also be seen that the ACS voltage overflows its breakdown value given for a 50 Hz

sine wave (810 V is reached in spite of 650 V breakdown value). In fact, the voltage rate of

increase is so high that the silicon device has not enough time to begin to clamp. A higher

value than its V

value can then be reached.

CL

Figure 15. IEC 61000-4-4 test on ACS402-5 cell for a 2 kV burst

Iout (1 A/div)

Vout (250 V/div)

To sum up, it can be said that ACSs, thanks to their high dV/dt capability, improve the overall

electronic board robustness towards fast line transients without any snubber. But it must be

kept in mind that the mains filter Y2 capacitors play also a role in sustaining IEC 61000-4-4

tests, by derivating some part of the bursts energy. The typical values of these capacitors

are 2.2 nF.

14/23

AN1172 Conclusion

Conclusion

ACS retains the well-known advantages of the triac (high AC voltage blocking capability,

current bidirectionality) and adds high over-voltage robustness and the increased reliability

and compactness that appliance manufacturers now need.

Thanks to the clamping capability and robust break-over characteristics of the ACS

structure, the protection circuits that are usually connected in parallel with the triacs, are no

longer required. The varistor removal increases automatically the reliability of the electronic

board. And the snubber removal allows designers to be free with the dV/dt at off state and

dI/dt at turn-on trade-off when choosing an R-C circuit.

In addition, the triac gate-drive transistor and its associated resistors are also redundant

because ACS devices have built-in logic level drive circuits that allow the power switch to be

safely driven from any MCU output pin capable of sinking 20 mA without over-stressing the

micro-controller output.

Hence, the typical component count falls from eight with triacs, down to two with ACSs (see

Figure 16.).

The new ACS devices represent a real breakthrough in the design of power switches for

home appliances. The enhanced performance, for example their robust off-state and logic

level drive, allied to their inherent compactness will open new perspectives in the design of

compact and reliable electronic power controllers.

Figure 16. Component count reduction thanks to ACS

MCU

References

1. P.Rault, "Triacs for Home Appliances: present and future", PCIM forum, Honk Kong, pp.

57-65, 1998.

2. E.Leblanc, "Thyristors and Triacs, an Important Parameter: the Holding Current",

Application Note n°302, STMicroelectronics, February 1989.

3. P.Rault, "Improvement in the Triac commutation", Application Note n°439,

STMicroelectronics, May 1992.

4. SCR Manual, General Electric, 6th Edition, 1979.

Vcc

Vcc

ACS

MCU

15/23

ACS402 demonstration Board AN1172

Appendix A ACS402 demonstration Board

Figure 17. shows the electronic diagram of a demonstration board used to illustrate ACS402

/ ST6 compatibility. Note that the reset, power supply and oscillator circuits are given as

examples. Other solutions are also possible. For instance, ST6 and ST7 microcontrollers

with integrated reset circuits can be used.

The main features are:

● V

● V

● each ACS402 cell is driven directly from a Port A I/O pin, which can sink up to 20 mA.

Figure 17. Demonstration board diagram

is connected to the Neutral;

DD

is the reference voltage of each ACS402 cell, which are all connected together in

DD

the DIL20 package;

D1

BRIDGE

-+

T1

TRANSFORMER 1.5VA 230V/6V

VDD

F1

FUSE 2A

MAINS CONNECTOR

L

N

J2

100µF/25V

VDD

C3

22n

C4

22n

IN

TS831

OUT

+C1

VIN

VOUT

GND

U2

LM7905

U3

GND

X1

8MHz

ST6220B

U4

2

5

6

7

3

4

TIMER

NMI

TEST

RST

OSCIN

OSCOUT

VDD

+C2

100µF/16V

1

PB0/AIN

PB1/AIN

VDD

PB2/AIN

PB3/AIN

PB4/AIN

PB5/AIN

PB6/AIN

PB7/AIN

GND

20

R5

2Meg

15

14

13

12

11

10

9

8

19

PA0

18

PA1

17

PA2

16

PA3

RG4 220

RG3 220

RG2 220

RG1 220

SW1

SW2

SW3

SW4

SW5

SW6

Figure 18. Demonstration board printed circuit

VDD

U5

ACS402

13

G4

15

G3

17

G2

19

G1

10

8

OUT4

6

OUT3

4

OUT2

2

OUT1COM

J1

LOADS CONNECTOR

1

L

2

3

4

5

16/23

AN1172 ESD diode conduction due to kick-back

Appendix B ESD diode conduction due to kick-back

An over-voltage can appear across the gate and COM (or A1 for triacs) terminals at high

turn-on di/dt rates. This effect is called the "kick-back". It is due to the high density current at

turn-on which causes high conduction voltage drop. Since the conduction begins around the

gate area, the forward voltage is in part applied to the gate.

This gate spike is clamped by the micro-controller internal electrostatic discharge (ESD)

diodes, which can be damaged if conduction lasts for too long.

In order to prevent ESD diodes conduction, their voltage must remain negative. When

considering Figure 1. at ACS turn-on, i.e. when the push transistor M1 is off and the pull

transistor M2 is on, a circulating current will never occur through D2 if the current i

positive. This yields Equation B1.

Equation B1

0VVViR

>++-=⋅

gS2MR

As M2 is conducting, its voltage drop can be neglected. Thus, the previous relation gives:

remains

R

Equation B2

VV->

Sg

If D1 conducts, this means that the supply voltage is held by M2, neglecting D1 drop

voltage. This MOS transistor is thus in a linear mode. Its current equals its saturating level,

called i

Now, since i

controller operation), we can write the following relationship :

sat

.

current is necessarily higher than the Vs/R ratio (in order to secure the micro-

sat

Equation B3

VViRVV-<⋅-=

Sgsatg1D

A sufficient condition to ensure that VD1 remains below zero is that Vg remains below Vs.

This condition, plus Equation B2, gives the following safety rule for no ESD diode

conduction:

Equation B4

VVV+<<-

SgS

17/23

ESD diode conduction due to kick-back AN1172

Figure 19. Kick-back test with ACS402 Figure 20. Kick-back test with Z0109

triac

13,5 V

Vg (5 V/div)

Vg (5 V/div)

dI/dt = 110 A/µs

1,5 V

Iout (5 A/div)

+5 V

-5 V

dI/dt = 65 A/µs

IA2 (5 A/div)

+5 V

-5 V

To compare the kick-back effect of triacs and ACSs, a special test circuit has been defined.

It consists on turning on the switch with a 10nF capacitor connected directly across the A1A2 or OUT-COM terminals. The capacitor is charged at 300 V. Figure 19. and Figure 20.

show the experimental results obtained with such a testing method, for a positive bias

voltage.

A Z0109 (0.8 A IRMS 10 mA igt ST triac) doesn't fulfill with Equation B4, for V

GA1

voltage

reaches 13.5 V with a 65 A/µs dI/dt rate. This is largely above the supply voltage. With the

ACS402, the maximum V

voltage is 1.5 V, and is still within the limits of Equation B4

g

despite a dI/dt which is twice as big as with the Z0109.

ACS / MCU interface would then be secured even at turn-on at peak mains voltage or on a

short-circuit.

18/23

AN1172 How to calculate the junction temperature during clamping periods

Appendix C How to calculate the junction temperature

during clamping periods

C.1 Dissipated power evaluation

It should be kept in mind that the load inductive energy is not entirely absorbed by the die at

clamping. Another part is dissipated by the Joule effect in the load resistor or absorbed by

the mains. A way to accurately evaluate the clamping energy is then to estimate the ACS

current waveform, versus the time. The energy is then calculated by integrating this

waveform and the product of the clamping voltage along the turn-off period.

Figure 21. Electric equivalent circuit at clamping

E

I

R

L

Vac

Let us consider a typical AC load equivalent circuit shown in Figure 21. The load current

during the clamping time is given by the following relationship.

Vcl

Equation C1

R

() ()

tt

cl

)t(i

=

R

It is difficult to evaluate the influence of E in a general way. Its sign depends on its phase

towards the current and the value of the holding current. But, it can be said that the back

electromotive force has little influence for most universal and synchronous motors in which

impedances are high and E is close to zero. Furthermore, for all other loads, such as

passive loads or asynchronous motors, the b.e.m.f E is null. For this reason, let us neglect

its value. Let cosϕ be the load power factor and V the RMS mains voltage. Since the

clamping occurs near the zero crossing current, the value of the main voltage at t

positive current, is given by the relationship C.2.

L

⎜

⎜

⎝

⎛

VacEV

-+

⎞

⎟

-

⎟

⎠

R

tt

----

00

L

e)t(i1e

⋅+

0

, for a

0

Equation C2

ϕ²cos12VVac -⋅-=

Figure 22. shows the current waveforms calculated with such an hypothesis, and assuming

that the holding current does not depend on the current rate of decrease. The junction

temperature influence on the i

C1, is equal to the i

ACS402-5 or an ACS108-5). The ACS clamping voltage is taken equal to 700 V.

Calculations are carried out for 100 mA RMS loads with different power factors, and for a

230 V 50 Hz mains voltage.

value given for a 25°C junction temperature (ex: around 30 mA for an

H

and Vcl levels is also not considered. Then, i(t0), in Equation

H

19/23

How to calculate the junction temperature during clamping periods AN1172

Figure 22. Current waveform during clamping phase for 100mA / 230V RMS loads

50

40

I

30

H

cos = 0.1ϕ

20

10

Load current (mA)

0

9 9.1 9.2

cos = 0.9ϕ

9.3 9.4

t

0

Time (ms)

t

ZC

cos = 0.7ϕ

9.5

9.6

Considering Figure 22., we can see that the load current is always inferior to a linearly

decreasing current beginning at (i

, t0) point and ending at (0, tZC). Furthermore, the

H

temperature elevation due to a rectangular power pulse is always superior to the one due to

a decreasing triangular power pulse of same average value (see References, 3.).

So, a pessimistic way to calculate the junction temperature is to simplify the clamping losses

shape by a constant power pulse of V

by the die during a clamping event (E

/2 value and tZC-t0 time long. The energy absorbed

cl.IH

) depends on two ACS parameters (Vcl and IH) and

CL

on the clamping duration:

Equation C3

E-=

1

2

()

ttIV

0ZCHclCL

C.2 Transient maximum junction temperature

The clamping time is given by Equation C1, which gives way to the following one.

Equation C4

⎡

L

R

1ln

+-

⎢

⎣

tt

0ZC

R

VacEV

-+

cl

Neglecting the on-state dissipated power in front of clamping dissipated power, the junction

temperature rise at the end of the clamping phase is:

Equation C5

1

)tt(ZthT ⋅-=∆

20/23

IV

Hcl0ZCj

2

⎤

i

H

⎥

⎦

AN1172 How to calculate the junction temperature during clamping periods

Figure 23. shows the maximum ∆Tj reached for different load RMS currents and power

factors. Calculations are similar whatever the package is (TO92, DIL20, SOT223), because

in such a range of times, the Zth is only due to the die area.

Note that ∆Tj first increases. On this curve part, the load peak current is lower than the i

H

level (taken equal to its worst value: 60 mA). So, when the load RMS current increases, the

turned-off current increases too. When the load peak current becomes higher than i

, ∆Tj

H

decreases because of the load series inductance decrease (here the turn-off current is

constant and equals i

).

H

Figure 23. Supplementary temperature rise at clamping depending on load nature

(for ACS402-5SB4 or ACS108-5SX)

60

45

cos =0.1ϕ

30

∆Tj (°C)

15

cos =0.98ϕ

0 0.1 0.2 0.3 0.4 0.5

cos =0.7ϕ

cos =0.9ϕ

I

RMS

(A)

It can be concluded that, if the junction temperature was 110° C before turn-off, the

maximum transient temperature can reach 160° C. As these events last less than one ms

(refer to Figure 22.), such junction temperatures can be permitted.

C.3 Repetitive clampings

To evaluate heating due to repetitive clampings, Equation C6 can be used, assuming that

the clampings occur at a constant period T and that the conduction losses can be neglected

in front of the previous ones.

Equation C6

⎡

1

T

IV

Hclrep

2

In practice T (above 1s) is very much higher than the clamping duration. Equation C6 can

then be simplified to the following one.

Equation C7

T

1

2

-

⋅=∆ )tt(Zth)T(Zth)ttT(Zth

⎢

T

⎣

⋅=∆

IV

Hclrep

-

tt

⎛

1Rth

⎜

⎝

-

tt

0ZC

Rth

tt

⎞

-+

0ZC0ZC

⎟

T

⎠

⎤

-+--+

0ZC0ZC

⎥

⎦

T

21/23

Revision history AN1172

Revision history

Table 2. Document revision history

Date Revision Changes

10-Jun-1999 1 Initial release.

11-May-2006 2

Reformatted to current standard. Figure 1., Figure 6., Figure 17., and

Figure 18. updated.

22/23

AN1172

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

23/23

Loading...

Loading...