Page 1

AN1105

APPLICATION NOTE

ST7 pCAN PERIPHERAL DRIVER

by Central European MCU Supp ort

INTRODU CT I ON

The Controller Area Network (CAN) norm defines a fast and robust serial bus protocol, suited

for local networking of intelligent devices such as microcontrollers, sensors and actuators. It is

now widely used, mostly in the automoti ve dom ain, but also for hom e automation and i ndustrial equipment control.

Several members of the ST7 MCU family have a built-in CAN peripheral named pCAN, which

allows them to be used as nodes in a CAN network. A software driver provided is by ST to help

you start designing and writing applications using the ST7 pCAN cell.

The purpose o f t he follow ing ap plicati on note is to ex plain to y ou how t o u se the dri ver, and

how it works. Thus, you can either build your software from the provided files, or modify them

to meet specific needs.

You will find in this application note:

– a brief description of the CAN protocol

– an overview of the pCAN peripheral

– the complete description of the user interface

– the step-by-step development of an example application using the driver features

– a technical report including a description of algorithms and internal data types

Version 1.3

AN1105/0801 1/100

1

Page 2

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 CAN COMMUNICATION PROTOCOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 GENERAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Protocol properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.2 CAN in the OSI reference model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 CAN FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.1 CAN Data Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.2 CAN Remote Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.3 CAN Error Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.4 CAN Overload Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 PHYSICAL REPRESENTATION OF DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.1 Bit Stuffing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 Bit timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 ARBITRATION PHASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.1 Arbitration Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.2 Message Acknowledge men t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 ERROR MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6 ST7 PCAN PERIPHERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.6.1 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.6.2 Cell Behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 CAN DRIVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 USER INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.1 Files Furnished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.2 Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.3 Principle of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.4 Interrupts (IT s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.5 User Interface Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 HO W TO USE THE CAN DRIVER: A DEMO APPLICATION . . . . . . . . . . . . . . 27

2.2.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2.2 Cell Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.3 Implementing the Notification Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.4 Transmissions outside the CAN Interru pt Function . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.2.5 IMPORTANT: Reentrant Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3 DETAILED DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1 USER INTERFACE FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2 INTERNAL FUNCTIONS AND DATA TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.2.1 Internal Data Types and Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.2.2 Internal Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.3 A FEW WORDS ABOUT DRIVER PERFORMANCE . . . . . . . . . . . . . . . . . . . . 55

3.3.1 CPU Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.3.2 Code Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2/100

2

100

Page 3

Table of Contents

4 DRIVER COD E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.1 CAN.C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.2 CAN.H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4.3 CAN_CUSTOM.C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.4 CAN_CUSTOM.H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.5 CAN_HR.H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3/100

1

Page 4

ST7 pCAN PERIPHERAL DRIVER

1 CAN COMMUNICATION PROTOCOL

In the early 80s, electronic appl icati ons appeared i n the automotive world. The need gradually

arose to establish real-time communications between various types of on-board equipment.

In 1986, the CAN bus protocol, designed by Robert Bosch GmbH, was presented to the public

for the first time. In 1989, the first silicon implementing the protocol was issued and in 1991,

the first car equipped with a CAN network was produced.

Today, the protocol is an international norm (ISO 11898). Its relative simplicity, the wide availability of products and services in terms of chips, softwar e libraries, starter kits, cour ses and

training makes the development of applications relatively fast and cheap.

The CAN p rotocol prov ides t he user with very r eliabl e comm unicati on, with a po werful e rror

detection/confinement m echanism. It allows baud rates up to 1Mbaud (for networks o f up to

40m) which makes it able to support real time applications. The bus can of course be configured with lower speeds for larger networks (50kbaud for networks up to 1km long for example).

There were more than 150 million CAN nodes installed at the beginning of 1999.

1.1 GENERAL CHARACTERISTICS

1.1.1 Prot oc ol pr ope r ties

■ Asynchronous serial bus (See “Bit timing” on page 9)

– No clock signal is transmitted, allowing a tw o-wires (high speed CAN see ISO 11898) or

even one-wire communication (low speed CAN, see ISO 11519)

– Each node resynchronizes itself on every falling edge occurring on the bus.

■ CSMA/CA (Carrier Sense Multiple Access/Collision Avoidance)

– Several nodes can request the bus simultaneously (CSMA).

– When such a situation occurs, there is no loss of data and the mes sage with the highest

priority is immediately sent (CA).

■ Multimaster capability (See “Arbitration Phase” on page 10)

– Every CAN node in the network is able to transmit data.

– The arbitration mechanism is decentralized.

■ Object oriented communication

– Each message on the bus carries its own identifier which is an 11-bit (or 29-bit) number.

This field describes the content of the message. It is not an address.

– Consequently, a transmitter doesn’t address data to a peer but simply broadcasts its data.

Each node in the network picks off data from the bus when it recogn izes an identifier that

concerns it.

4/100

Page 5

ST7 pCAN PERIPHERAL DRIVER

■ Message prioritization

– The identifier of a message also indicates the priority of its carrier. During the arbitration

phase, a bitwise comparison of the different identifiers is performed. The message with the

higher identifier being the more urgent, it wins the arbitration and is immediately transmitted.

■ Error management system (See “Error Mana gem ent” on page 11)

– Detection: every node continuously monitors the bus, even if it is not concerned by the cur-

rent transmission, to detect potential violations of the protocol.

– Signalization: any node detecting an error, signals it to its peers and aborts the current

transmission meanwhile. The sender automatically retries transmission within a certain

amount of time. Thus, the consistency of data throughout the network is preserved.

– Confinement: each node implements counters which are incremented (or decremented)

after each detection of an error (or successful operation). A defective station can then

switch itself off when its counters reach a certain value, and thus stop disturbing the bus

operations.

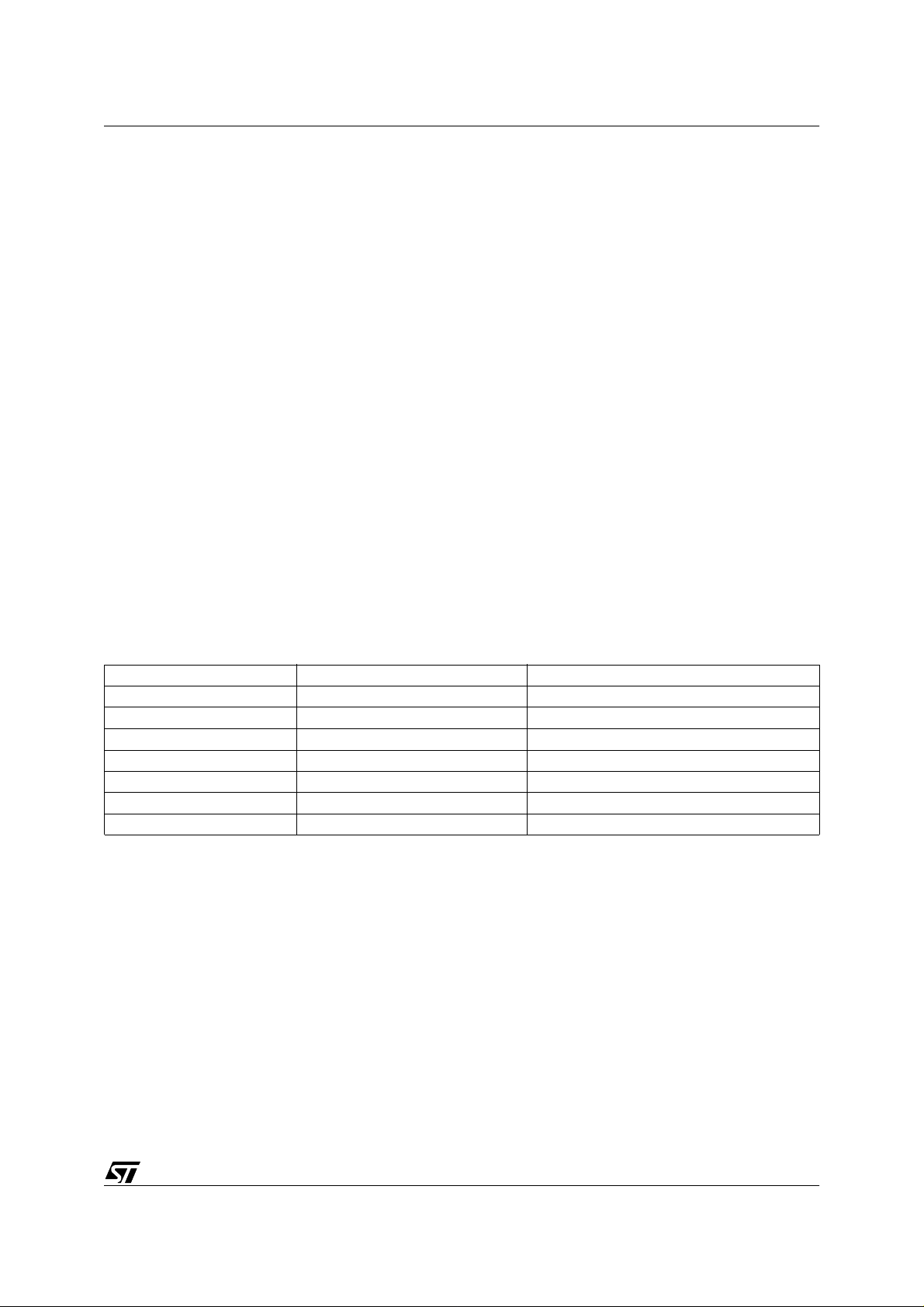

1.1.2 CAN in the OSI reference mo del

The protocol occupies parts of the two lowest lev els (t he physical and data link layers) of t he

7-level ISO/OSI (Open System Interconnection) telecommunications reference model.

Table 1. ISO/OSI Standard Telecommunication Layers

OSI Layer OSI Model CAN Protocol

7 Application No (User defined)

6 Presentation No (User defined)

5 Session No (User defined)

4 Transport No (User defined)

3 Network No (User defined)

2 Data Link Yes

1 Physical Partly

In this reference model, the data link layer deals with physically passing data from one node to

another. It define s arbitrati on, me ssage f raming, er ror m anagem ent a nd tr ansmission timing

for example.

The physical layer deals with putting data on the physical network, and with taking it off. Consequently, it defines signal levels and timings, as well as the transmission support (wire types,

connectors, etc.).

The CAN protoc ol splits the Data L ink lay er into Object and Transfer sublayers, corre-

sponding to the ISO/OSI Logical Link Co nt rol and Medium Access Control sublayers. The

Transfer l ayer is the interf ace betw een the user ap plic ation an d the CA N. The Objec t layer

5/100

1

Page 6

ST7 pCAN PERIPHERAL DRIVER

manages frame s ha ping and a ckno wle dgm ent m e chani sms, b us a rbit ration an d check s t he

formal correctness of the data transmitted and received.

The physical layer is only partly defined, and the user is free to choose the transmission medium for example.

Figure 1. Layered architecture of CAN (ISO 11898 definition)

Data Link Layer

Logical Link Control

Acceptance filtering

Overload Notification

Recovery manageme nt

Medium Access Control

Data encapsulation/decapsulation

Frame coding (stuff/destuff)

Medium access management

Error detection

Error signaling

Acknowledgement

Serialization/Deserialization

Fault confinement

(MAC-Layer Management

Entity)

Physical Layer

Physical Layer Signaling

Bit encoding/decoding

Bit timing

Synchronization

Physical Medium Attachment

Driver/Receiver characteristics

Medium Dependent Interface

Connector

Bus Failure Management

(PLS-Layer Management

Entity)

1.2 CAN FRAME

There are four different CAN frame types: Data frame, Error frame , Remote frame and

Overload frame

There are also two versions of the CAN protocol: 2.0A (or base format) and 2.0B (or extended

format). The 2.0B standa rd introduc es a n ex ten ded data fr ame with a longe r identifi er. B oth

frame types coexist on a CAN 2.0B bus, and its nodes must be at least able to recognize and

acknowledge both.

We will only describe here the 2.0A format, or base format.

1.2.1 CAN Data Frame

The CAN Data frame is used for data transmission and contains the following fields:

■ A start of frame field, consisting of one bit.

■ A 12-bit arbitration field, including:

– An 11-bit identifier

6/100

Page 7

ST7 pCAN PERIPHERAL DRIVER

–A RTR bit used to differentiate data and remote frames. It is dominant in a data frame.

■ A 6-bit control field, including:

– A 4-bit data length code bits giving the size (in bytes) of the data field

–1 IDentifier Extension (IDE) bit ( dom inant for CAN 2.0A frame) and 1 bit reserved for fur-

ther development.

■ A data field of up to 8 bytes.

■ A 16-bit long CRC field. The Cycli c Redundancy Check (CRC) is based on a BCH encoding.

■ A 2-bit acknowledgment field. The transmitters sends it as all recessive. (See “Message

Acknowledgement” on page 11)

■ A 7-bit end-of-frame field.

The interframe space (or Intermission) is the minimum amount of time between two consecutive transmissions.

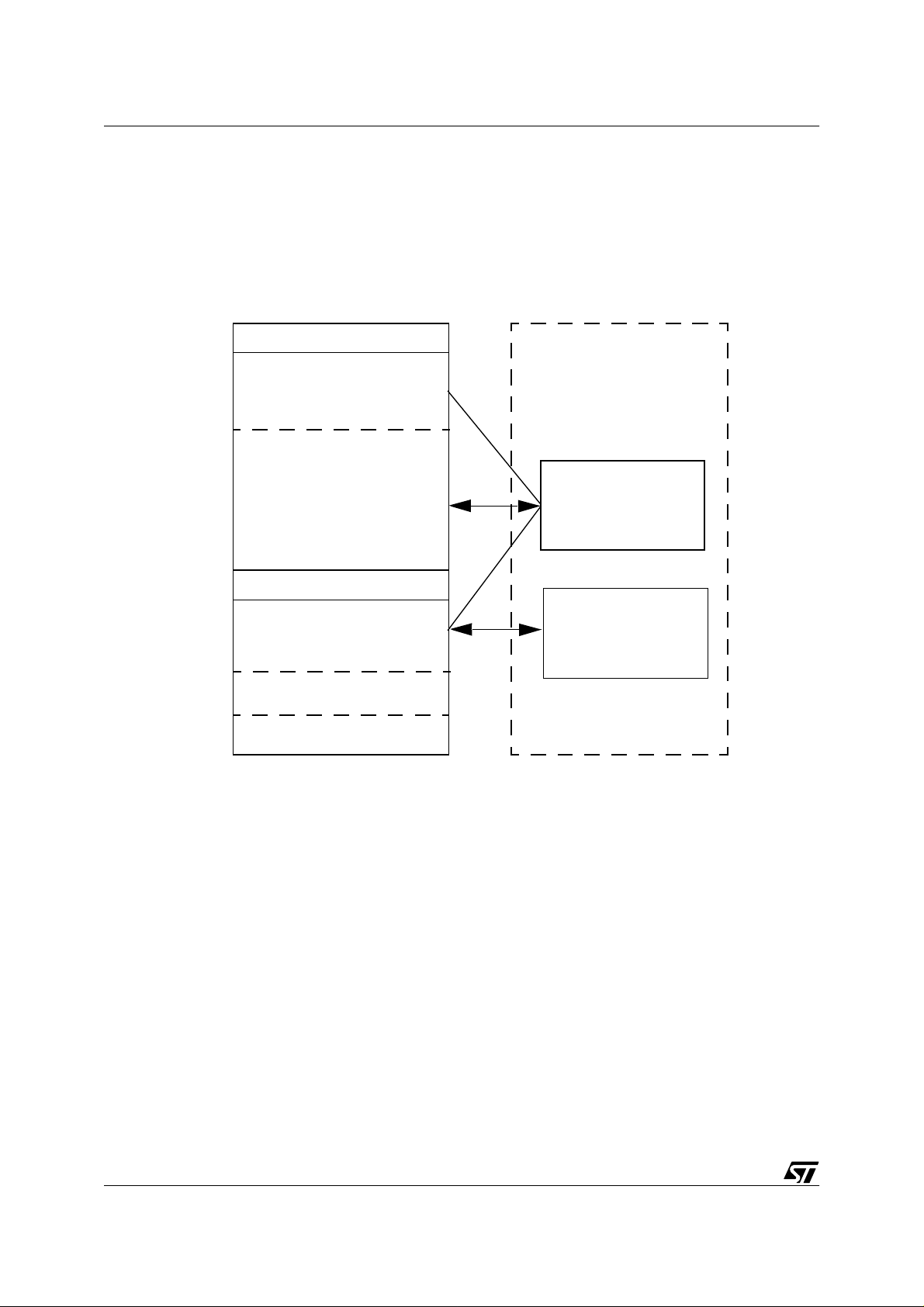

Figure 2. CAN Data Frame

19 bits

Arbitration Field

Control

Field

0..64 bits

Data Field

CRC Field

25 bits

EOFACK

Interframe

Space

R

11-bit Identifier

DLC

Data

15 bits

7 bits

3 bits

Bus Idle

D

CRC

ACK Delimiter

ACK Slot

SOF

RTR = 0

Delimiter

IDE = 0

1.2.2 CAN Remote Frame

The CAN Remote frame is used to request data. This frame has the same overall constitution

as the data frame. However, in this case, the Rem ote bit (RTR) i s recessive and there is no

data field.

7/100

Page 8

ST7 pCAN PERIPHERAL DRIVER

Figure 3. CAN Remote Frame

19 bits 25 bits

Arbitration Field

IDE = 0

Field

DLC

15 bits Bus Idle3 bits7 bits

CRC

Delimiter

R

11-bit Identifier

D

RTR = 1

SOF

EOFACKCRC FieldControl

ACK Delimiter

ACK Slot

Interframe

Space

1.2.3 CAN Error Frame

The CAN Error frame is sent by a node as soon as it detects a protocol violation in the current

operations on the bus. This frame is composed of 6 successive dominant bits (active error

flag) or recessive (passive error flag), followed by 8 recessive Frame Delimiter bits. The cur-

rent error state of the node sending the error frame (See Section 1.5 "Error Management") will

determine whether it is an acti ve frame (node i n error active state) or a passive frame (node in

error passive state).

1.2.4 CAN Overload Frame

The CAN Overload Frame can be sent during the interframe space to delay the next transmission on the bus. This frame has the same constitution as the active Error frame.

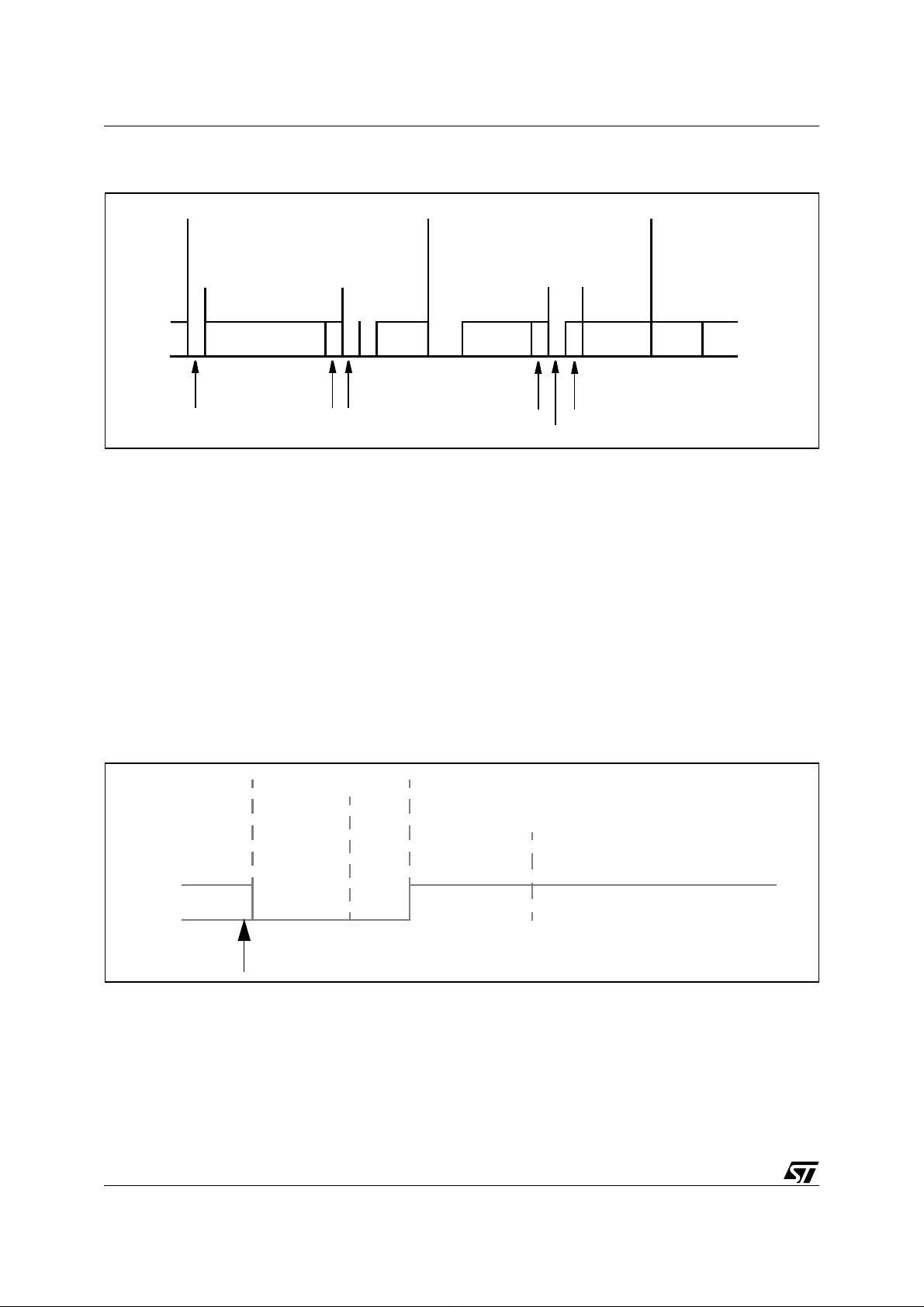

Figure 4. CAN Error/Overload Fram e

Max. 12 bits

Data Frame

R

D

Error/Overload

Flag

6 bits

Error Detection

Error/Overload

Delimiter

8 bits

Interframe

Space

3 bits

Bus Idle or Data Frames

1.3 PHYSICAL REPRESENTATION OF DATA

The CAN data is enco ded w ith NRZ (Non Re turn to Z ero) c ode. The tw o logical l evels us ed

are named dominant ( 0) and recessive (1). Because the CAN cells are connected on the bus

according to the wired-AND principle, it follows that the default bus state is recessive, and that

8/100

Page 9

ST7 pCAN PERIPHERAL DRIVER

transmission of a dominant bit forces this state to dominant, no matter how many other nodes

are transmitting recessive bits.

1.3.1 Bit Stuffing

Once built, a frame is passed t o the T ransfer sub-layer, where the CRC is calculated. Then,

Stuffing Bits are inserted in the frame . Each time fiv e conse cutiv e bits of th e same logical

level are detected, a bit of the opposite value is inserted. This is used to generate a minimum

edge rate on the bus for resynchronisation purpose (See “Bit timing” on page 9).

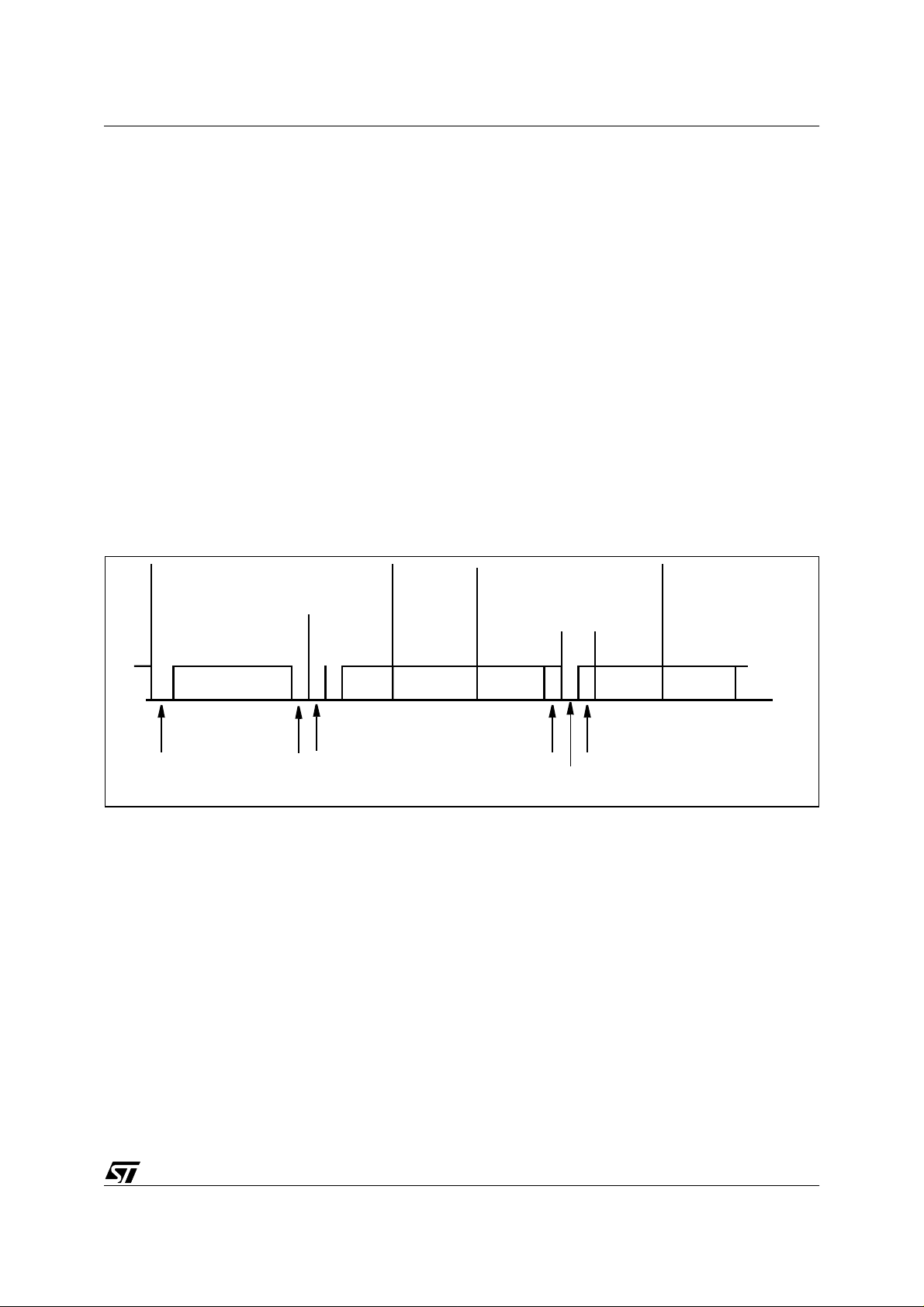

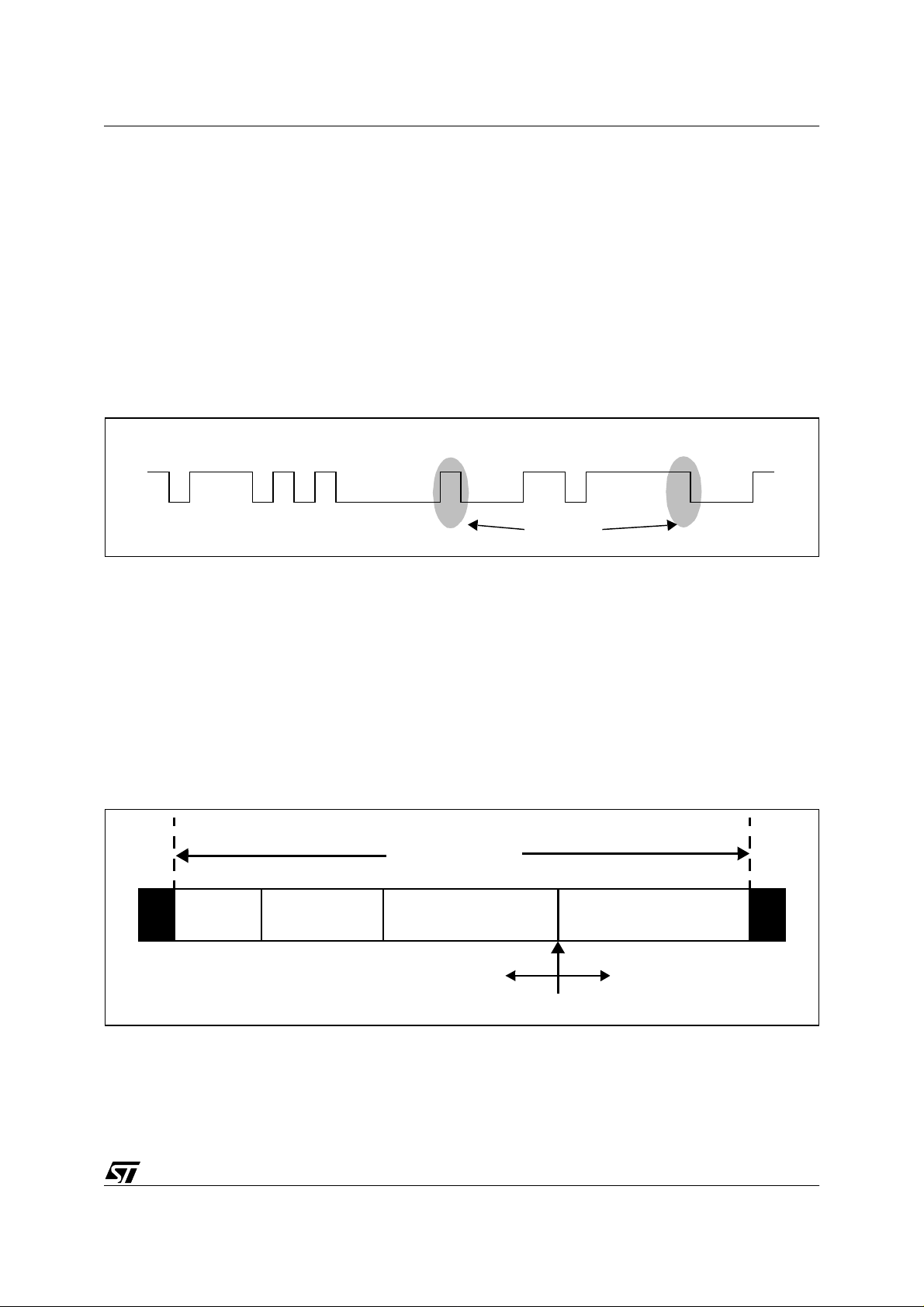

Figure 5. Bit-stream NRZ Code & Bit Stuffing

1 0 1 1 1 0 1 0 1 0 0 0 0 0 1 0 0 0 1 1 0 1 1 1 1 1 0 0 0 1

Stuff bits

1.3.2 Bit timing

The CAN standard divides the bit time into four segments:

– A synchronisation segment (SYNC),

– A propagation segment (PROP),

– A phase buffer 1 segment (TSEG1),

– A phase buffer 2 segment (TSEG2),

– Each segment is divided into time quanta. The synchronisation segment lasts, by defini-

tion, 1 time quantum.

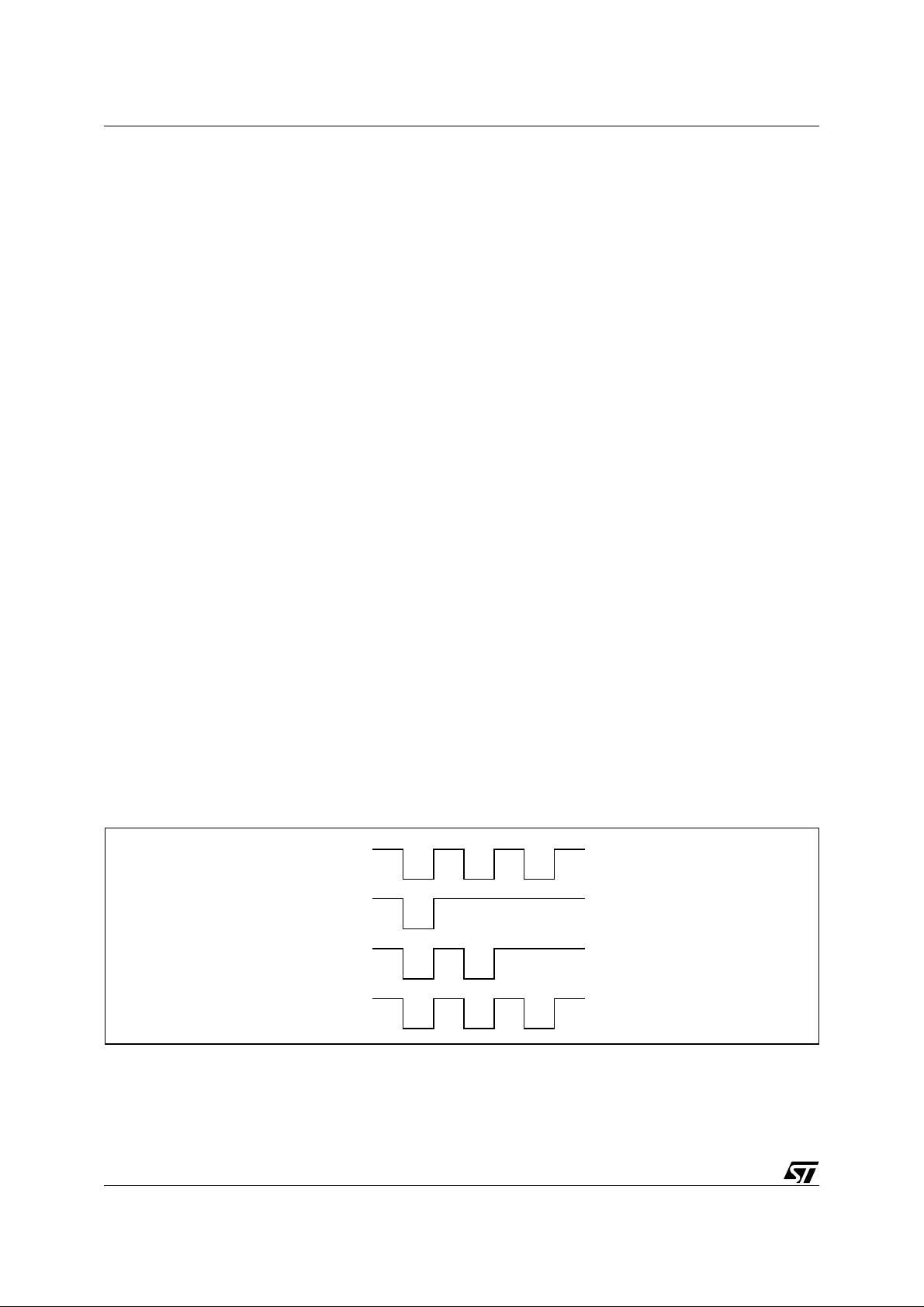

Figure 6. CAN Bit Segm ents

Previous

Bit

Bit Time

SYNC PROP TSEG1

TSEG2

Sample Point

Next Bit

The CAN communication is asynchronous, i.e. no clock signal is sent together with data. Each

node in the network maintains its own bit timing calculated from the internal clock of the device.

9/100

Page 10

ST7 pCAN PERIPHERAL DRIVER

To deal with signal phase variations on the transmission line due mostly to desynchronization

between clocks of bus participants, TSEG1 and TSEG2 are of variable length. A resynchronization of the local clock occurs on every r ecessive-to-dominant state change. If such a change

arises before (or after) the SYNC segment expected by the cell, TSEG1 (or TSEG2) is lengthened (or shortened) to correct the detected variation. If the edges occur during the SYNC segment, the node assumes that it is synchronized.

The PROP segmen t takes into accoun t the m axim um propag ation ti me of the si gnal on the

network, ensuring that all the nodes sample the same bit at the same ti m e .

The sampling point of the bit takes place between TSEG1 and TSEG2.

1.4 ARBITRATION PHASE

1.4.1 Arbitration Phase

All the cells connected on the CAN network are likely to transmit a message at any time. A cell

can initiate a transmission only when the bus is idle. On transmission of a message, a cell simultaneously monitors the state of the bus to detect potential problems.

If the bus is idle, any cell that is ready for transmission begins to send its data. The other

nodes listen.

If the bus is already in use when a cel l requests i t, the cell waits u ntil the end of the curr ent

transmission. Then, all the nodes that are ready to transmit begin their transmission. If a dom-

inant and a recessive bit are sent in the meantime, the first one erases the second. This

causes the cell that is sending the recessive bit to lose the arbitration and switch to Reception

mode. This way, messages with the highest identifiers are sent before the others. This mechanism also prevents collisions occurring on the bus, which saves bandwidth. This is referred to

as non-destructive bitwise arbitration.

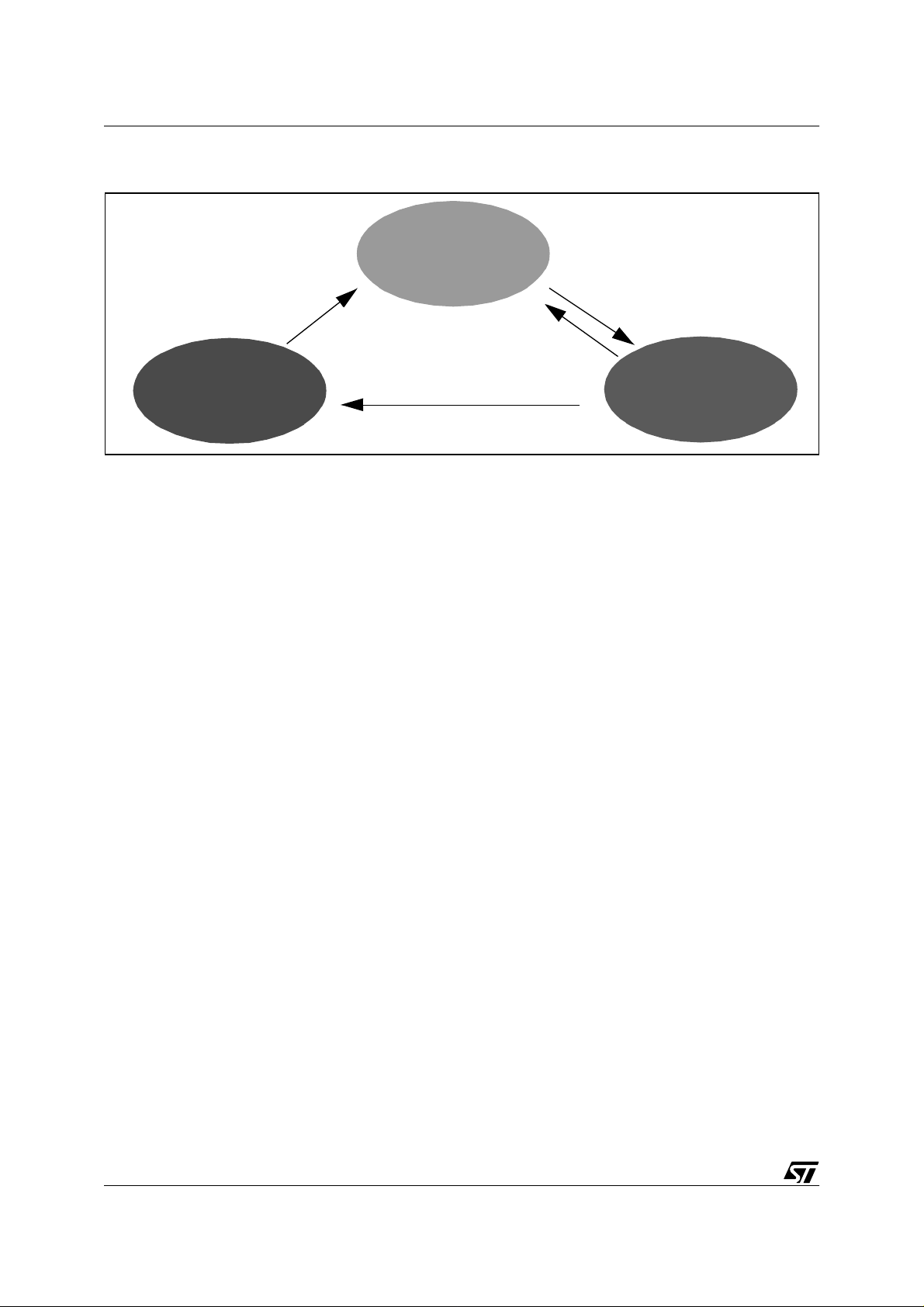

Figure 7. Arbitration example: node 1 win s

Node 1

Node 2

Node n

CAN Bus

Recessive

Dominant

10/100

Page 11

ST7 pCAN PERIPHERAL DRIVER

1.4.2 Message Acknowledgement

Any cell having received a message correctly, regardless of the result of the acceptance test,

must acknowledge it by sending a dominant bit during the ACK slot of the current frame, thus

overwriting the recessive bit sent by the current transmitter.

1.5 ERROR MANAGEMENT

The Error Management System of the CAN protocol i s proof of the protocol’ s robustness. T his

system provides a way to automatically distinguish permanent failures from sporadic errors. It

can lead to self-disconnection of a failing node from the bus. This feature i s named Error Con-

finement. An error is defined as a violation of one of the protocol’s rules. It can happen after

one of following events:

Bit error:

–

A transmitter detects a difference between the actual bus state and what it

sends.

–

Acknowledgement error:

Stuffing e rror:

–

–

CRC error:

–

Format error:

More than five identical bits were received consecutively.

The CRC received does not match the calculated CRC.

One of the f ixed -format fi elds ( CRC delimi ter, ACK delimi ter, End Of Frame )

A frame is not acknowledged (ACK slot recessive).

does not have the expected format.

An Error frame is immediately sent by all the cells that have detected an error on the bus. Note

that the Error frame does not yield to the Stuffing r ule. Upon reception of this frame, al l cells in

the network detect a Stuffing error and react by sending an Error frame. The dominant state of

the bus caused by the occurrence of an error can last at most 12 bits (case when a node detects the error only at the end of the error flag).

The Error Confinement system is based on two counters:

– A TransmissionError counter (TEC)

– A ReceptionError Counter (REC)

The rules handling the counters are basically the following:

– When an emitting node detects an error, it increments its TEC and sends an error frame.

– When a receiving node detects an error it increments its REC and sends an error frame.

– When a transmission is successful, the TEC counter is decremented.

– When a reception is successful, the REC counter is decremented.

Note: The complete set of rules is quite complicated taking into account the possibility of receiving over-

load frames, etc. Consequently, it’s beyond the scope of this document. This docume nt describes

the basic reactions of the cell. For more information, refer to the original Robert Bosch GmBH document or to the ISO 11898 norm.

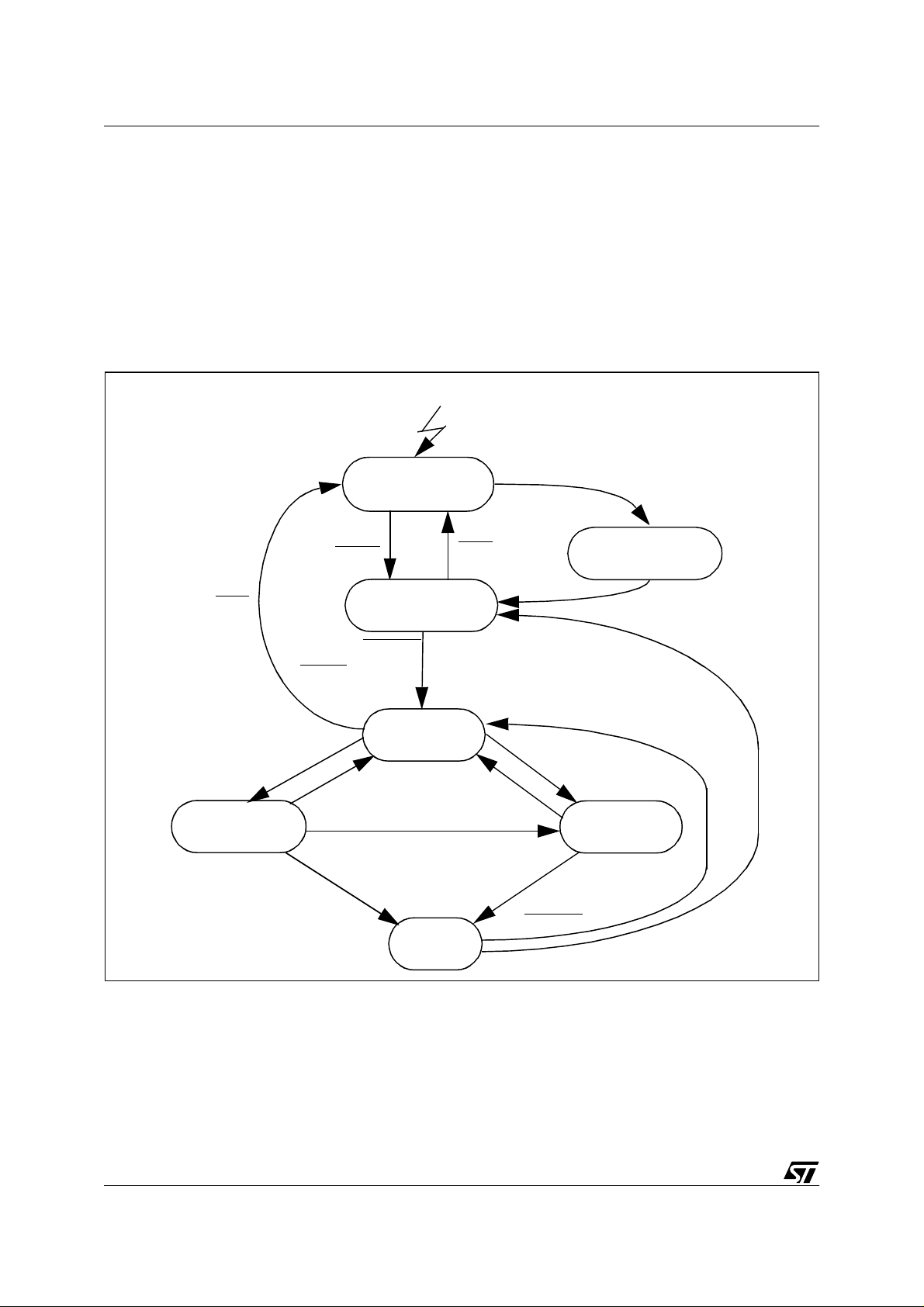

The behaviour of the cell con cerning the sta te of the counters is sho wn in the following dia gram.

11/100

Page 12

ST7 pCAN PERIPHERAL DRIVER

Figure 8. CAN Error States

Error Active

128 blocks of 11 successive recessive b its

TEC<127 and REC<127

Bus Off

When both counters contain values between 0 and 127, the CAN node is in Error Active

state, which means that it can send and receive normally. If it detects an error, it will send Active Error flags.

When one of the two c ount ers rea ches a value bet ween 12 8 and 2 55, th e node is in Error

Passive state. It will go on receiving and sending normally but will only be authorized to send

Passive Error flags. Therefore, if this node causes trouble by sending unjustified Error frames,

it will not disturb the network for too long.

When one of the counters reaches a value over 255 ( i.e. it overf lows), the CAN node enters

Bus Off state. It is then physically disconnected from the bus. It can go back to Active mode

if it successfully detects 128x11 consecutive recessive bits on the bus.

TEC >255

TEC>127 or REC>127

Error Passive

1.6 ST7 PCAN PERIPHERAL

1.6.1 Main Features

The ST7 pCAN peripheral implements a CAN 2.0B passive protocol. This means that extended frames are recognized and acknowledged, but cannot be saved nor processed by the

microcontroller.

– The pCAN peripheral is based on three 10-byte hardware buffers that can be used either

for transmission or reception. They are prioritized in the increasing priority order 1 to 3 for

transmission and 3 to 1 for reception. Each buffer has a control register indicating if a job is

pending, if new data has been received or if the buffer is currently being written/read. A bit

in this register is used to lock the buffer for transmission (See ST72511 datasheet p.116).

– The baud rate is programmable up to 1 Mbps. The length of the bit synchronisation fields is

also programmable. The baud rate is configured by setting three values: the size of time

quanta (in clock ticks) and the length of the two synchronization segments (in time quanta).

See ST72511 datasheet p.114, Baud Rate Prescaler Register and Bit Timing Reg ister.

12/100

Page 13

ST7 pCAN PERIPHERAL DRIVER

– Two 11-bit filters and two 11-bit masks are used for hardware filtering with identifier/iden-

tifier-range definition. The masks define which bits of the filters are to be ignored and which

are to be tested. Any message whose identifier does not match will not be saved in the buffers.

– The cell automatically enters Low Power mode after the reception of 20 recessive bits, or

Standby state on command.

– The pCAN peripheral can wake-up the ST7 microcontroller from HALT mo de. See Section

2.1.3.2 "Waking-up from HALT Mode" to learn how.

– The CAN Erro r Confinement feature, as defined by the CAN protocol, is fully implement-

ed, with read-only access to the counters and maskable interrupts on state changes. Once

in Bus Off state, the cell automatically returns to Bus Ac tiv e state if it has detected 128x11

recessive bits on the bus (see Section 2.1.3.1 "Controlling Status Changes"). See note on

Section 2.1.3.2 "Waking-up from HALT Mode" to see how the driver can provide you with full

control over the bus-off to bus-active transition.

– The three Send/Receive buffers, filters, masks and counters are mapped at a unique ad-

dress space, allowing efficient software access.

1.6.2 Cell Behaviour

In Standby state, the node monitors the bus in order to detect a dominant pulse that could generate an interrupt (See ST72511 datasheet p.112, Interrupt Control Register, SCIE bit).

When the RUN bit of the Co ntrol Status Regi ster is set (See ST 72511 datasheet p.113), the

cell leaves

standby

mode. It then enters

resynchronization

mode before it r eally starts running.

If the WKPS bit of the Control/Status Register is set, then the cell will send a dominant pulse

when it wak es up . You c an choos e bet ween two resyn chron ization duration s: 11 recessiv e

bits if the FSYN bit of the C SR is set or 128*11 recessive bi ts if not (See ST72511 datasheet

p.113).

If the cell resynchronizes after leaving bus-off st ate, it will wait 128*11 recessi ve bits, whatever

the value of FSYN may be.

To send data, a buffer has to be selected first by writing to the Page Selection Register (See

datasheet p. 114). Then it has to be locked for transmission by setting the LOCK bit in the

Buffer Control/Status Register (See datasheet p.116: LOCK bit and RDY bit). Then data can

be written in the buffer registers: identifier, data length code, data bytes. Writing in the seventh

data register starts transmission.

Received data is automatically stored in one of the buffers configured for reception (LOCK bit

reset) each time a message identifier matches the hardware filters of the pCAN cell, and provided th at thi s b uff er is m ark ed as fre e (R DY b it res et. Se e dat ashe et p .116: L O CK bit a nd

RDY bit). The masks/filters can be configured through the Filter/Mask High/Low Registers

(See datasheet p.117).

13/100

Page 14

ST7 pCAN PERIPHERAL DRIVER

Any event (succ essfu l transm ission , data recep tion, er ror, s tate ch ange , overru n) can generate a maskable interrupt. The Interrupt C ontrol Regis ter (see datasheet p.112) al lows you to

set/reset these masks. Note that each buffer has its own reception interrupt, allowing the data

to be saved rapidly.

Note: For further, more detailed explanations, please read the ST72511R/ST72512R/ST72532R Datash-

eet, downloadable from the ST web site, http://mcu.st.com.

Figure 9. ST7 pCAN State Diagram

RESET

RUN

Transmission

RUN

& WKPS

FSYN & BusOFF

(FSYN

TX Error

| BusOFF) & 128*11 Recessive bits

TX OK

Standby

RUN

Resynchronisation

& 11 Recessive bits or...

Idle

RX OK

Arbitration lost

RUN & WKPS

Wake-up Pulse

Generation

Start of frame

Reception

RX Error

14/100

BusOFF

Error

BusOFF

Page 15

ST7 pCAN PERIPHERAL DRIVER

2 CAN DRIVER

To quickly start developing your own CAN applications using the ST7 pCAN peripheral, STMicroelectronics provides you with a driver. The source code (can.h and can.c) is given as an example, and can therefore be used as provided or be modified to fit specific needs.

There are two customizatio n files which make the dr iver’s f unctionality flexib le a nd able to

meet a wide range of needs.

The entire processing is interrupt driven, so no polling is required. The application is notified of

CAN events through function calls from the interrupt routine.

To immediately use the driver, without modifying its structure, see Section 2.2 "How to Use the

CAN Driver: A Dem o Applicat ion" .

The following sections will explain the details of the driver architecture and describe all the

functions and data types implemented in the software.

2.1 USER INTERFACE

2.1.1 Files Furnished

The driver consists of five files:

– can.c. Driver function definitions and internal data types. This file may not be modified.

– can.h. Header file of can.c. This file may not be modi fied.

– can_hr.h. Hardware description (register mapping of the ST7 MCU memory space). This file

is hardware dependent and must not be modified.

– can_custom.c. Frames of customization functions. They are called (some optionally) by the

driver to notify the application of events when some user-specific processing is required (for

example on reception of data). This file has to be completed by the user.

– can_custom.h. Contains a pre-processor directive list (

#define

types) which allows user

customizations to be taken into account at compilation time. T his file has to be m odified by

the user.

2.1.2 Architecture

The cell is statically configured with one transmi ssion buffer and two reception buffers, which

reduces the need for processor responsiveness in reception.

For the same purpose, a 3-message deep transmission FIFO is implemented. It is not accessible by the user, and is automatically managed by the software.

The entire processing is interrupt driven. The user can choose which interrupts are to be taken

into account and which are not, due to the compilation options in can_custom.h. Some interrupts request an immediate answer from the application, e.g. a reception event. To avoid

having the user modify the interrupt routine (in can.c), the routine calls one of the notification

15/100

Page 16

ST7 pCAN PERIPHERAL DRIVER

functions defined in can _custom. c on c ertain ev ents . Th e user only has t o enter these func tions according to his needs before compiling the software.

2.1.3 Principle of Use

During compilation, the values of the hardware control registers are calculated by the preprocessor according to the compilation options selected in can_custom.h.

If the software filtering feature is enabled, the values of accepted identifiers hav e to be entered

by the user as a list in can_custom.h (See “Filtering” on page 29)

The functions in can.c are compiled or not, according to the selected

unwanted ones are simply left as comments).

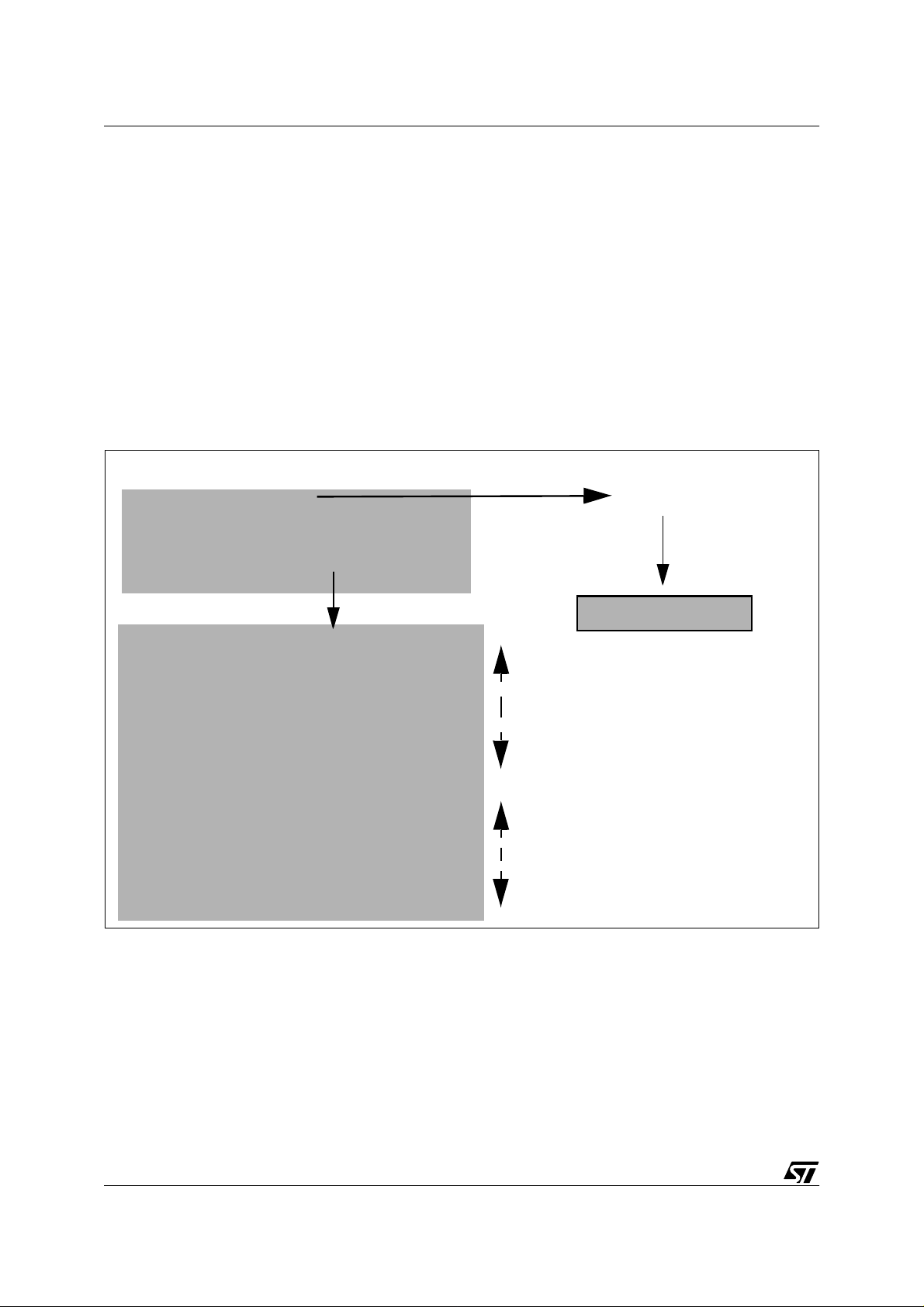

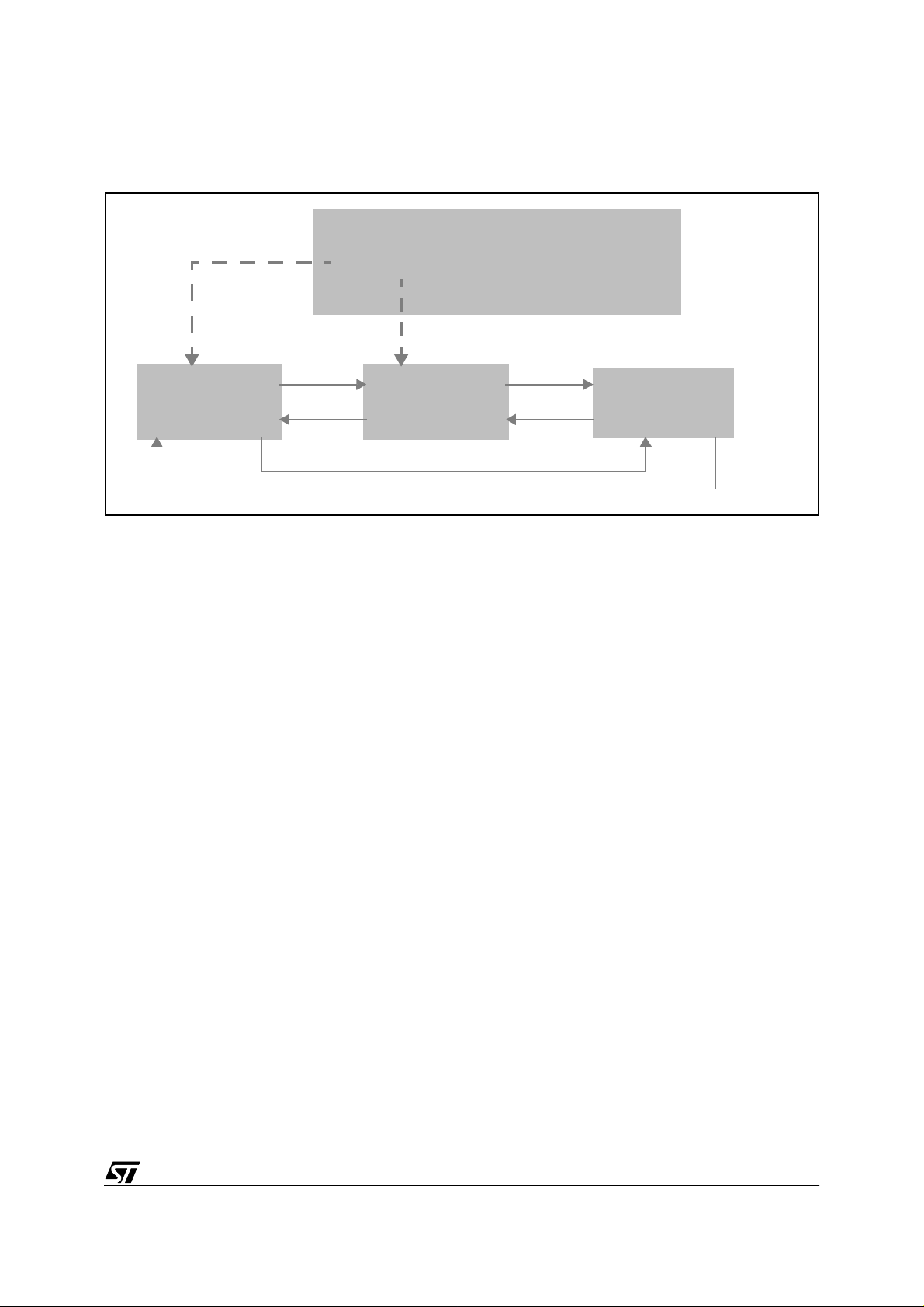

Figure 10. Driver Customization System

CAN_CUSTOM.H FILE

#define INIT_BRPR 0x11

...

#define STATUS_CHANGE_NOTIFICATION

...

//#define DEBUG

CAN_CUSTOM.C FILE

#ifdef STATUS_CHANGE_NOTIFICATION

void CAN_Bus_Passive_Notification(void)

{

//To implement if defined

}

#endif

...

...

#ifdef DEBUG

void CAN_Overrun_Notification(void)

{

//To implement if defined

}

#endif

Compilation

Compiled

Not Compiled

BRPR Reg ister

ST7 Registers

#define

0x11

directives. (The

Compilation

During the first initialization (performed using the CAN_First_Init function), the periph eral’s

registers are written with the values defined at compilation time, the transmission FIFO is initialized and the cell starts (a wake up by bus can be chosen).

Then:

– The

CAN_Transmit_Request

function initiates a transmission which begins with an in-queuing of the message to be sent. Then, hardware buffer no.1 (the static transmission buffer ) is

filled according to hardware requirements. (See Section 1.6.2 "Cell Behaviour").

16/100

Page 17

ST7 pCAN PERIPHERAL DRIVER

– The

CAN_Switch_Off

and

CAN_Sleep

functions are used to switch the cell to Standby mode.

The first function kills any pending jobs and erases all data in the reception buffers, even if

the data is unread. The second function is executed the same way as long as no work is in

progress, the transmission FIFO is empty and all reception buffers have already been read.

These two functions also define the way the cell will be woken-up: either by bus or by software (by enabling or disabling the corresponding interrupt). They can help you to manage

status changes by controlling the transition between Bus Off and Bus Active states (See Sec-

tion 2.1.3.1 "Controlling Status Changes").

–

CAN_Switch_On

resets the cell and returns to RUN mode. It can also place the cell in a state

waiting for a dominant pulse to be woken-up.

–

CAN_Get_Status

–

CAN_Get_TEC

–

CAN_Get_REC

returns the current status of the peripheral (run, standby, error passive...)

returns the current content of the transmission error counter.

returns the current content of the reception error counter.

2.1.3.1 Controlling Status Changes

Your application can be notified by the dri ver when the error state of the cell changes . (See

“Compilation Options” on page 25). If you don’t want the microcontroller to directly resynchro-

nize after leaving bus-off state for example, you can call the CAN_Switch_Off function from inside o f the C AN _Bu s _Off_Notifica ti on fu nc tion ( Se e “C an_cus tom.c Fil e” on page 26), then

perform any operations you want before calling the CAN_Switch_On function to restart the peripheral.

2.1.3.2 Waking-up from HALT Mode

If you want to switch the ST7 to HALT mode and have it woken-up by the CAN, the correct interrupt routine must be enabled. Before switching to HALT mode, call the CAN_Sleep or

CAN_Switch_Off function with the BUS_WAKEUP parameter that is used to enable the CAN

interrupt on the bus dominant state while in Standby state.

Then, enter the CAN_Dominant_Bit_Reception_Notification function to customize the waking

up of the microcontroller.

Note: See ST72511 datasheet p.37 for more information about HALT mode.

2.1.4 Interrupts (ITs)

Once the interrup t r outin e is enter ed, th e f irst thi ng you wan t t o kno w is “Wha t t rigger ed the

event?” Priority is then given to reception if more than one IT has occurred simult aneously, unless the DEBUG compilation option was set. In this case, the Error ITs are processed first.

– In the event of a Transmission IT, the driver tries to send the following message in the queue,

if it’s not empty. The driver then notifies the application of the event before leaving the routine.

17/100

Page 18

ST7 pCAN PERIPHERAL DRIVER

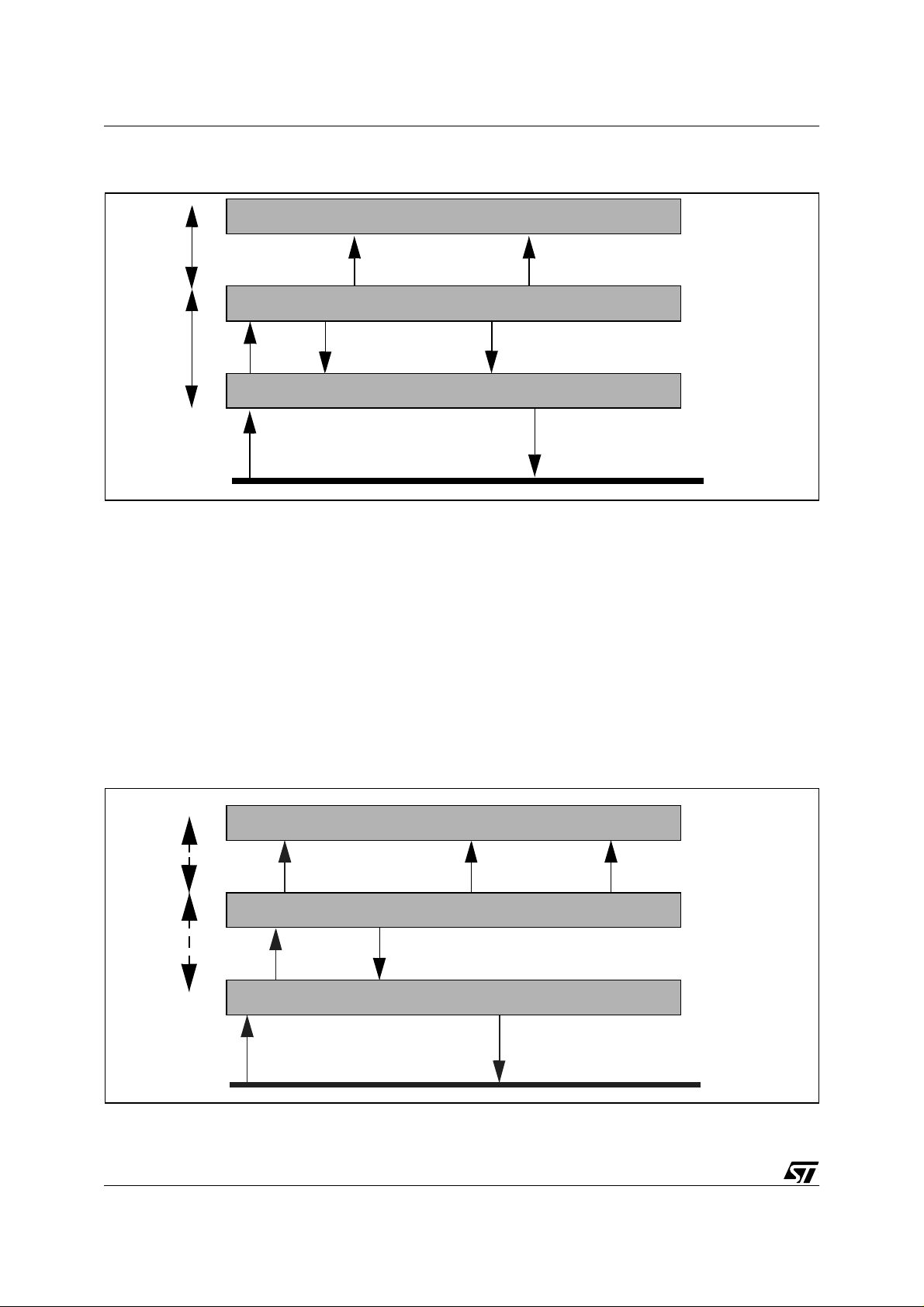

Figure 11. Transmission IT Proced ure

What

you

see

Application

3

Notification

Error notification, only

5

if DEBUG defined

ST Driver

4

Fills buffer

with next data

Driver

Processing

1

IT

2

Clears flags

ST7 Hardware

Successful

Transmission

CAN Bus

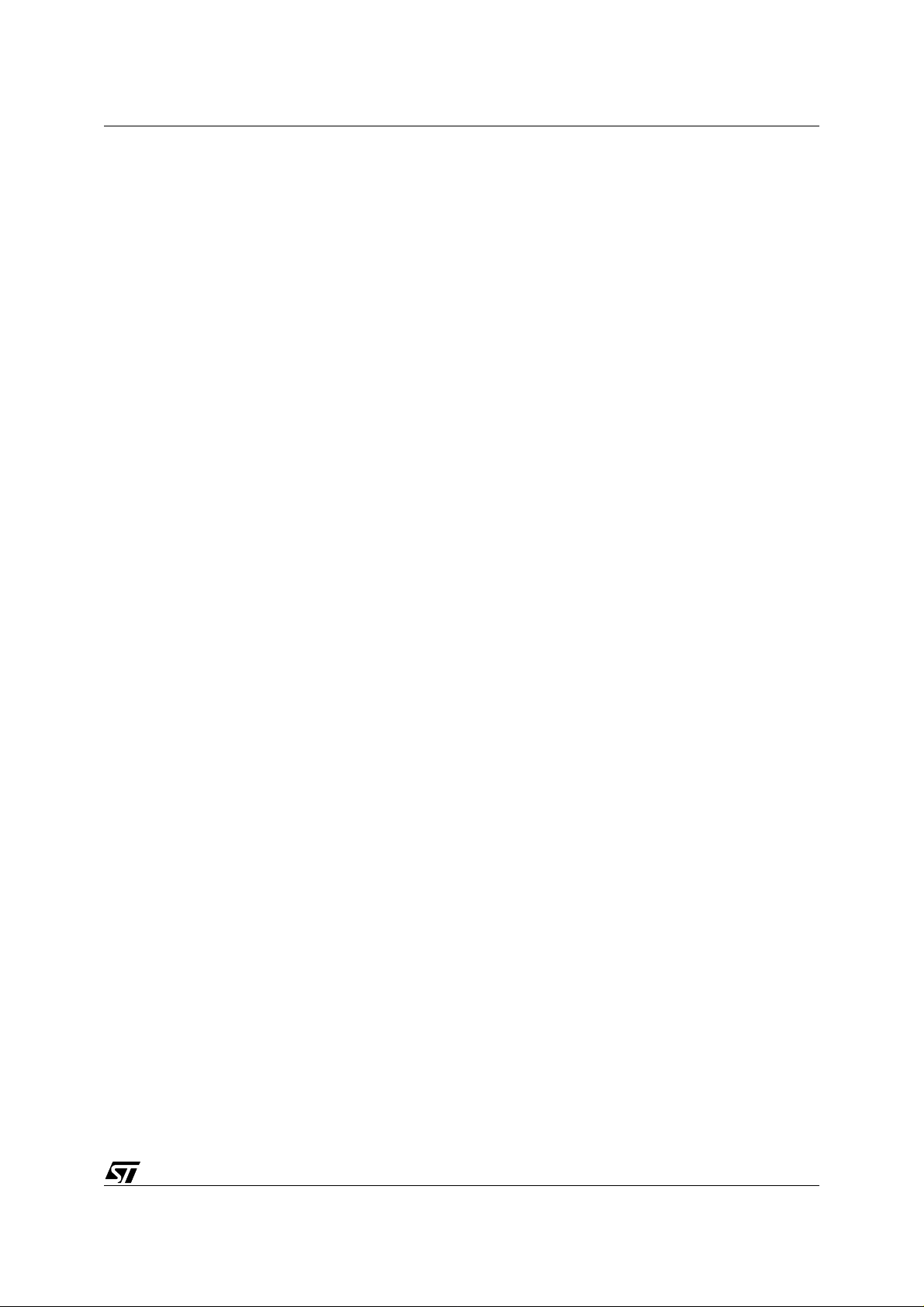

– In the event of a reception IT, after having found which buffer is i nvolved, the dri ver performs

an optional software filtering, then noti fies the application. If the cell r eceived a remote frame,

the CAN_Remote_Reception_Notification function is called. Otherwise, if the cell received

data, the CAN_Request_Buffer function is called to request a buffer from your application.

After the buffer is filled, the dr iver calls the CAN_Data_Reception_Notification function to notify you that the data is ready. If the DEBUG option is set, the CAN_Reception_Status function is called just before leaving the IT routine, which passes the status of the reception

processing procedure (Error, Success...) as a parameter. This is used to detect the causes

of any problems. See “Can_custom.h File” on page 24 for more information about notification

routines.

Next

Transmission attempt

Figure 12. Reception IT Procedure

What

you

see

Driver

Processing

18/100

1

Notification:

2

Data or Remote

IT

Successful

Reception

3

Application

Notification

4

(case data)

5

ST Driver

Save data in software buffer

(case data) + clears flags

ST7 Hardware

CAN Bus

Buffer free for

reception

next

Error notification

Only if DEBUG defined

Page 19

ST7 pCAN PERIPHERAL DRIVER

– Error ITs are only processed if the DEBUG option was chosen in can_custom.h. Then, the

application is notified of any other events through function calls. (Functions entered in

can_custom.c).

2.1.5 User Interface Description

This section describes the user interface in a “black-box” way. The parameters and the return

values of the function declared in can.h and can_custom.h are described in this section. For a

complete description of the algorithms and internal data type variables, please see Section 3

"Detailed Description".

2.1.5.1 Data-type Variables

CAN_Buffer -type variables

typedef struct CAN_Buffer{

u16msg_identifier;

CAN_Data_Size data_size;

u8 CAN_msg_data[CAN_MAX_DATA_SIZE];

CAN_Bool buffer_rw;

CAN_Bool buffer_free;

}CAN_Buffer;

Software repres enta tion of C AN data . The trans latio n into hardwar e buffers is pe rform ed b y

the driver.

A variable of this data-type must be passed to the driver each time it is requested by the

CAN_Request_Buffer notification function (See “Functions called unconditionally” on

page 26). Otherwise, data in the hardware buffer will be lost.

A pointer to this structure i s also us ed as param eter of the CAN_Trans mit_Req uest function

(See “Functions” on page 21).

–

msg_identifier:

2 bytes field containing the identifier of the CAN message. The identifier is

stored in the 12 most significant bits. The 4 least significant bits MUST be zero. The u16

type means 2 bytes unsigned variable and is defined in lib.h.

–

data_size:

1 byte field containing the length of the data in the m essage (in bytes). The

CAN_Data_Size type is an enum type (See below for its description).

–

CAN_msg_data

: array of 8 bytes containing the data to be sent. The u8u16 type means 1

byte unsigned variable and is defined in lib.h.

–

buffer_rw

: this boolean variable is to be us ed as a flag to prevent simultaneous writing/

reading on the structure. It is checked and modified by the driver each time an operation

is being performed on the buffer. If CTRUE, the structure will not be read or written. If

CFALSE, it can be used. Always check/modify this variable in your application for this purpose.

–

buffer_free

: boolean variable used to mark if the data in the buffer can be overwritten or

not. It has to be used as the s ecurity by the user’s application. If C FALSE , the driver will

refuse to perform any write operation on the data in the structure and return an error code.

19/100

Page 20

ST7 pCAN PERIPHERAL DRIVER

If CTRUE, the data can be modified. Take care to check and/or initialize it before passing

a buffer to the driver.

Init_Data -type variables

typedef struct {

u8 brpr_init;

u8 btr_init;

u8 fhr1_init;

u8 flr1_init;

u8 mhr1_init;

u8 mlr1_init;

u8 fhr0_init;

u8 flr0_init;

u8 mhr0_init;

u8 mlr0_init;

u8 }Init_Data;

This structure contains the value of registers tha t can be reinitialized when switching on the

cell after a passage in Standby state (see Section 2.1.5.2 "Functions", CAN_Switch_On).

It is used for hardware initialization.

–

brpr_init

: value of the CANBRPR register (set length of a CAN time quantum in number of

CPU clock ticks). S ee “Bit timing” on page 9.

btr_init

–

: value of the CANBTR register (length of both time segments 1 and 2 in number of

time quanta). See “Bit timing” on page 9.

fhr1_init

–

–

flr1_init

–

mhr1_init

mlr1_init

–

–

fhr0_init

–

flr0_init

–

mhr0_init

mlr0_init

–

: value of Filter 1 High Register.

: value of the Filter1 Low Register.

: value of the Mask 1 High Register.

: value of the Mask 1 Low Register.

: value of Filter 0High Register.

: value of the Filter 0 Low Register.

: value of the Mask 0High Register.

: value of the Mask 0Low Register.

Enum -type variables

The names of the variables are in principle self-explanatory.

typedef enum

{DLC0,DLC1,DLC2,DLC3,DLC4,DLC5,DLC6,DLC7,DLC8,REMOTE_FRAME}CAN_Data_Size;

Possible values of the CAN _Mess age data_size fiel d (See “CAN_Buffer -type variables” on

page 19)

typedef enum

20/100

Page 21

ST7 pCAN PERIPHERAL DRIVER

{CAN_RUN,CAN_STANDBY,CAN_BUS_ACTIVE,CAN_BUS_PASSIVE,CAN_BUS_OFF}CAN_Status;

Describes the different states of the cell.

typedef enum {CFALSE=0,CTRUE=1}CAN_Bool;

Custom Boolean type variable.

typedef enum {BUS_WAKEUP,SOFT_WAKEUP}WakeUp_Cause;

Possible parameters of the CAN_Sleep and CAN_Switch_Off functions. (See Section 2.1.5.2

"Functions".)

typedef

enum{CAN_SLEEP_ERROR,CAN_SLEEP_SUCCESS,CAN_SWITCH_ON_SUCCES,CAN_SWITCH_ON_FA

ILURE}CAN_Switch_Error;

Possibl e val ues r etu rned by CA N_S leep , CAN _Sw itc h_Off and C AN _Swit ch_ On fun cti ons

(See Section 2.1.5.2 "Functions")

typedef enum {CAN_INIT_SUCCESS,CAN_INIT_FAILURE}CAN_Init_Error;

Possible values returned by CAN_First_Init function (See Section 2.1.5.2 "Functions")

typedef enum

{CAN_TRANSMIT_SUCCESS,CAN_TRANSMIT_FAILURE,CAN_TRANSMIT_NO_MSG,CAN_FIFO_FULL

,CAN_TRANSMIT_BUFFER_FULL,CAN_TRANSMISSION_ERROR_IT}CAN_Transmit_Error;

Error codes used in Transmission functions.(See Section 2.1.5.2 "Functions")

typedef enum

{CAN_RECEIVE_SUCCESS,CAN_RECEIVE_REMOTE,CAN_ILLEGAL_IDENTIFIER,CAN_FILTERING

_FAILURE,CAN_RECEIVE_FAILURE,CAN_BUFFER_IN_USE,CAN_NO_BUFFER,CAN_RCV_BUFFER_

NOT_READY}CAN_Receive_Error;

Error codes used in Reception functions. (See Section 3.2.2 "Internal Routines").

Note: With some compilers, an option is used to define the size, in bytes, of enum-type variables. We rec-

ommend selecting 1 byte, if possible, to save memory space.

You can see in which case the different error codes are returned by the functions by studying

the flow charts in Section 3.2.2 "Internal Routines" for internal functions and Section 3.1 "User

interface functions" for user interface functions.

You als o fin d th is info r ma tion i n t he a rr ays o f Section 2.1.5.2 "Functions" for user-interface

routines and Section 3.2.2 "Internal Routines" for internal routines.

2.1.5.2 Functions

CAN_Init_Error CAN_First_Init(void):

Input -Output Error status

21/100

Page 22

ST7 pCAN PERIPHERAL DRIVER

CAN Cell Power-on initialization routine.

During its execution, all registers are initialized with values entered in can_custom.h

Description

Comments Calls CAN_Init() (See Section 3.2.2 "Internal Routines")

or calculated from the compilation options chosen

It initializes the transmission queue.

This function must be called in the main routine prior to any use of the CAN cell.

Possible return values: CAN_INIT_FAILURE and CAN_INIT_SUCCESS.

void CAN_It_Dis(void):

Input -Output -Description Disables all CAN interrupts.

Comments --

CAN_Status CAN_Get_Status (void):

Input -Output Current status of the cell

Retrieves the current status of the CAN cell.

Description

Comments Useful if the STATUS_CHANGE_NOTIFICATION option is enabled in can_custom.h

Possible return values: CAN_STANDBY, CAN_BUS_PASSIVE, CAN_BUS_OFF

and CAN_BUS_ACTIVE following the current state of the cell.

u8 CAN_Get_TEC(void):

Input -Output Value of the TECR register (Transmission Error Counter)

Description Returns the value of the TECR

Comments --

u8 CAN_Get_REC(void):

Input -Output Value of the RECR register (Reception Error Counter)

Description Returns the value of the RECR

Comments --

CAN_Switch_Error CAN_Switch_Off(WakeUp_Cause):

Input Chip Wake-up function: BUS_WAKEUP or SOFT_WAKEUP

Output Error status

22/100

Page 23

ST7 pCAN PERIPHERAL DRIVER

Puts the CAN node into Standby state.

This function aborts any pending transmissions and does not wait for the reception

buffers to be read. Then, it resets the driver in the same state as after power-on initialization.

If BUS_WAKEUP is selected, the next dominant bit detected on the bus will restart

Description

Comments Calls CAN_Clean (See Section 3.2.2 "Internal Routines".)

the cell. If SOFT_WAKEUP is selected, the cell will not take the bus state int o account. It can only be woken up by the CAN_Switch_On function.

Possible return value: CAN_SLEEP_SUCCESS or CAN_FATAL_ERROR (if the

RUN bit fails to reset after a time out or if the CAN_Clean function fails).

There is a time out mechanism implemented in this function (about 30ms), waiting for

the RUN bit to be actually reset. So if your application uses the watchdog REFRESH

IT BEFORE calling the function

CAN_Switch_Error CAN_Sleep (WakeUp_Cause):

Input Chip Wake-up function: BUS_WAKEUP or SOFT_WAKEUP

Output Error status

Puts the CAN node into Standby state.

Returns CAN_SLEEP_ ERROR if a tra nsmiss ion r equest is pending, or i f a hardware

receptio n bu ff er is still un s av e d.

Description

Comments This function will not reset the CAN node.

Possible return values:

CAN_SLEEP_ERROR if there are jobs pending in the hardware registers,

CAN_FATAL_ERROR if the RUN bit fails to reset after a time out,

or CAN_SLEEP_SUCCESS

CAN_Switch_Error CAN_Switch_On(Init_Data_Ptr,CAN_Bool):

Input

Output Error status

Description

Comments Calls CAN_Init (See Section 3.2.2 "Internal Routines").

Pointer on an Init_Data structure (See Section 2.1.5.1 "Data-type Variables"),

Boolean (CTRUE, CFALSE)

Puts the CAN node into Active state

The Boolean is used to transmit a dominant pulse (CTRUE) or not (CFALSE) upon

wake-up.

The bit timing and the mask/filter parameters can be reinitialized in this function. In

most cases, the cell will be initialized the same way as in the Power-on sequence.

So, you can re-use the first_init_data structure is declared in can.h.

Possible return values: SWITCH_ON_SUCCES and SWITCH_ON_FAILURE.

CAN_Transmit_Error CAN_Transmit_Request(CAN_Buffer*):

Input Pointer to the CAN message to be sent

Output Error status

23/100

Page 24

ST7 pCAN PERIPHERAL DRIVER

Puts a buffer into the transmission queue, and may request an immediate transmission if the queue is empty.

The buffer_rw field has to be CFALSE before passing it to the function. It is immediately marked as CTRUE after entering the routine. In case of an error, during the execution, this parameter is reset to CFALSE before exiting. Else it is only reset by

Description

Comments

CAN_Fill_Transmission_Buffer (See Sec tion 3.2.2 "Internal Routines").

Possible return values:

CAN_TRANSMIT_FAILURE if the cell is in stand-by,

CAN_FIFO_FULL if the 3 messages deep FIFO is full,

CAN_TRANSMIT_FATAL if CAN_Fill_Transmission_Buffer fails,

or CAN_TRANSMIT _ SUC CESS o th e r wise.

This function MUST NOT be interrupted, so protect it with SIM and RIM statements

when used OUTSIDE the notification functions of CAN_custom.c!

Calls CAN_Init_Queue and CAN_Fill_Transmission_Buffer (See Section 3.2.2 "Inter-

nal Routines")

2.1.5.3 Constants

Those constants are defined internally, but are made visible to the user because they may be

useful.

extern const Init_Data first_init_data

This is the initialization data structure that is used on power-on. It is made visible to allow you

to pass it to the CA N_Switch_On function when you do no t want to modi fy the param eters it

contains. (See Section 2.1.5.1 "Data-type Variables")

extern const u16 i_filters[];

This is the array of filters used to perform software filtering on incoming messages. The maximum number of identifiers stored is 127 (See “Filtering” on page 29). It is made visible in case

you would like to link the behaviour of your application upon reception of a message with the

offset of the id entifier in the array (ma naging an arr ay of pointe rs to func tions fo r example) .

One can of course imagine other applications.

2.1.5.4 Can_custom.h File

The preprocessor directive s used to configure the har dware an d to customize the driver are

located in this file .

Cell Configuration Values

#define INIT_BRPR 0x00

#define INIT_BTR 0x00

These values are used to initialize bit timing registers. (See Section 2.2.2.1 "Bit Timing").

/*Masks & filters*/

#define INIT_FHR0 0x00

24/100

Page 25

ST7 pCAN PERIPHERAL DRIVER

#define INIT_FLR0 0x00

#define INIT_MHR0 0x00

#define INIT_MLR0 0x00

#define INIT_FHR1 0x00

#define INIT_FLR1 0x00

#define INIT_MHR1 0x00

#define INIT_MLR1 0x00

These values are used to initialize hardware filters and masks. (See “Filtering” on page 29).

Compilation Options

//Start options

//#define WAKE_UP_PULSE

#define RUN_ON_START_UP

You may decide whether or not to include these options in the code.

If enabled:

– WAKE_UP_PULSE enables the cell to send a domi nant bit when leaving Standby mode.

– RUN_ON_START_UP starts the cell in the Initialization function CAN_First_Init. If not en-

abled, make sure that a dominant bit detected on the bus can make the cell start. To do

this, complete the

CAN_Dominant_Bit_Reception_Notification()

function in can_custom.c

in calling CAN_Switch_On.

//#define FILTERS_ENABLED

//#define INIT_FILTERS {}

These options are used for software filtering.

Select both of them if you want to use the feature.

If selected, en ter the li st of ide ntifi ers to b e accep ted b etwee n the c urly brac es as s hown i n

“Software Filter Configuration” on page 30.

Enabling one of the following options implies modifying the corresponding function in the

can_custom.c file:

//#define STATUS_CHANGE_NOTIFICATION

This option is used to monitor status changes (active/passive/bus-off). Setting this option will

change th e pri ority ord er in w hic h the i n terru pt s are t ak en i nt o ac c ount. T he i nte rrupts con cerning status change will be checked first, before considering reception and transmission interrupts. It will also allow compilation of the cor responding notificatio n function s

(CAN_Bus_Passive_Notification, CAN_Bus_Acti ve_Notification, CAN_Bus_Off_Notification).

To use the Error Notification functions (called when an Error IT is received), enable:

//#define DEBUG

25/100

Page 26

ST7 pCAN PERIPHERAL DRIVER

If DEBUG is defined, you can then chose to add the following options:

//#define GENERAL_RECEPTION_ERROR

All reception errors trigger an interrupt. You CANNO T us e this option and the

Notification

function together because both use the same IT flag. This option does not exclude

Status Change

the bus Wake-Up feature.

//#define SIMULTANEOUS_EMISSION_RECEPTION

Only if Debug is also defined.

This function is used for forcing the cell to simultaneously send and receive any message it is

ordered to transmit to check the hardware integrity of the CAN transceiver and controller.

2.1.5.5 Can_custom.c File

This is a source file you have to complete, to allow your applicati on to react on hardware

events as they happen. An example of implementation is given in Section 2.2.3 "Implementing

the Notification Functions".

Functions called unconditionally

CAN_Buffer* CAN_Request_Buffer(u16 ident_of_message)

This function is called unconditionally when a new data message is available in the hardware

buffer of the cell. This function has to be completed to return a pointer on a buffer structure. To

ignore it, return NULL. To help you to manage your reception buffer(s), the ID of the message

is passed as a parameter.

void CAN_Remote_Reception_Notification(u16 ident_of_remote)

This function is called unconditionally when a r emote message has been saved in a hardw are

buffer. Its ID is passed as a parameter for a quick answer.

void CAN_Data_Reception_Notification(u16 message_ident)

This function is called unconditi onally when a data message has been successfully saved i n a

software buffer supplied by the application. Its ID is passed as a parameter.

void CAN_Transmission_Notification(void)

This function is called unconditionally upon the successful transmission of a message.

Functions called conditionally

The following functions are called only if the corresponding option is set in can_custom.h.

void CAN_Dominant_Bit_Reception_Notification(void)

This function is called upon reception of a dominant bit while in Standby mode, if the

RUN_ON_STARTUP option was not defined in can_custom.h. The corresponding interrupt

will be accepted only once. Then its acceptance flag will be cleared.

void CAN_Bus_Passive_Notification(void)

void CAN_Bus_Active_Notification(void)

26/100

Page 27

ST7 pCAN PERIPHERAL DRIVER

void CAN_Bus_Off_Notification(void)

These functions are called after a status change.

Option: #define STATUS_CHANG E_NOTIFICATION

void CAN_General_Reception_Error_Notification(void)

This function notifies the application of any hardware reception errors.

Option: #define DEBUG and #define GENERAL_R ECEPTION_ERROR

void CAN_Reception_Status(CAN_Receive_Error status)

This function is called after a reception attempt and returns the status of the software

processing (See “Enum -type variables” on page 20).

Option: #define DEBUG

void CAN_Overrun_Notification(void)

This function notifies the application of any overruns.

Option: #define DEBUG

void CAN_Transmission_Error_Notification(CAN_Transmit_Error status)

This function notifies the application of any hardware transmission errors.

Option: #define DEBUG

2.2 HOW TO USE THE CAN DRIVER: A DEMO APPLICATION

In this section, we will des cribe step-b y-step the c onfigurati on and pr ogrammi ng of a s imple

test application using the ST7 CAN driver.

2.2.1 Application

First of all, we mus t define how th e applicati on will lo ok, i.e. w hich m essages our cell w ill be

able to send, which ones it will accept to receive, and how it will behave when sp ecific messages are received.

Let’s imagine the following:

– The cell has to run immediately after power-on, and does not have to send a dominant pulse.

– Every 15 ms the cell must send the contents of the ST7 A/D Converter data register. The

identifier (ID) of this message could be, for example, 0x402.

– Upon reception of a remote frame (see Section 1.2 "CAN Frame") it must reply with the trans-

mission of a given message. The ID of the remote frame could be, for example, 0x500 (consequently, the ID of the answer will also be 0x500).

– Upon reception of a given data item, the CAN cell must shut down. This ID of the message

could be 0x600, and the data item 0xFF, in its first data byte.

– The cell is supposed to receive 3 other data messages coming from other nodes. Let’s im-

agine they are identified by 0x127, 0x311, 0x3A5.

27/100

Page 28

ST7 pCAN PERIPHERAL DRIVER

– Identifiers may exist on the bus that do not concern our cell.

2.2.2 Cell Configuration

Open then the can_custom.h file. You can see the two first lines of code:

//#define WAKE_UP_PULSE

//#define RUN_ON_START_UP

According to ou r requi reme nts (Se e Sec tion 2 .2.1 "Ap plica tion"), w e only want to define the

RUN_ON_STARTUP option.

So modify the code the following way:

//#define WAKE_UP_PULSE

#define RUN_ON_START_UP

2.2.2.1 Bit Timing

First of all, we have to decide the speed of our network. Let’s say, for example, 250 kilobaud.

Look in your can_custom.h file. You see the following code:

#define INIT_BRPR 0x00

#define INIT_BTR 0x00

The following two registers define the bit timing in the cell.

The BRPR regi ster c onta ins the size o f t ime qu antum , i n num b er of clo ck tic ks, in a bit f ield

named BRP (See Section 1.3.2 "Bit timing").This field ranges from 0 to 63. The true value for

a time quanta is then BRPR+1.

The BTR register contains the size of the two synchronization segments in time quanta, in two

different bit fields: BS1 and BS2(“). BS1 ranges from 0 to 7and BS2 from 0 to 3. The actual

length of bit segments in time quanta is then BS1+1 and BS2+1.

You must always chose BS1>BS2, so that the sampling point takes place in the second half of

the bit.

Use the following formula:

fbus Bauds()

------------------------------------------------------------------------ -=

1BRP+()3BS1 BS2++()×

fcpu Hz()

For example, in our case, fcpu = 8 MHz.

So, fbus = fcpu/32.

We have then the following possibilities:

28/100

BTR+1 BS1+BS2+3

216

Page 29

ST7 pCAN PERIPHERAL DRIVER

BTR+1 BS1+BS2+3

48

84

Let’s choose, for example, BTR = 3, BS1 = 3, BS2 = 2 (second row).

We have to complete the code:

#define INIT_BRPR 0x03

#define INIT_BTR 0x23

2.2.2.2 Filtering

The driver is able to filter out all messages not needed by the application. First by using hardware filters, and second by using software filters.

Use the hardware filters to eliminate as many identifiers as possible and to avoid further

processing. Use the software filters to elimi nate IDs that are unwanted, but that can not

stopped by the hardware.

Hardware Filter Config uration

Let’s define the values of hardware masks and filters. To do this, we must split the IDs into two

groups:

– 0x127, 0x311 and 0x3A5, on one hand; and,

– 0x500 and 0x600 on the other.

Note: When grouping the IDs, try to maximize the number of identical bits inside the same group, thus

minimizing the width of the ID ranges accepted by the cell.

Then let’s find the first filter/mask pair (12 bits to be determined):

– 0x500 is written in binary: 101 0000 0000

– 0x600 is written in binary: 110 0000 0000

In the first three bits, only the most significant bit (MSB) of both identifiers is the same, the following two bein g d ifferent. S o, the thr ee MS Bs of the mas k wi ll b e 1 0 0 (m atch, don ’t c are,

don’t care) and the three MSBs of the filter will be 1 and then either 1 or 0.

The following eight bits are identically null. So the last eight bits of the filter will be 0, and the

last eight bits of the mask will be 1 (match required).

The least signi ficant bit (LSB) of t he filter/ma sk is used to s epa rate rem o te fr ames a nd d ata

frames. Here we have a data frame and a remote frame, so it does not have to be checked (1

or 0 into the filter, 0 into the mask).

So we have:

– Filter 1000 0000 0000

– Mask 1001 1111 1110

29/100

Page 30

ST7 pCAN PERIPHERAL DRIVER

Now look at the can_custom.h file:

There are several #define statements, including:

#define INIT_FHRi 0x00

#define INIT_FLRi 0x00

where i is either 0 or 1.

These are the two registers containing hardware filters. In the FHRi register, the 8 MSBs for

the filters are given, and in the second register the 4 LSBs are given followed by 4 zeros.

We have to do the same thing for the mask. First, let’s write 0 for the filter.

Finally we have:

#define INIT_FHR0 0x80

#define INIT_FLR0 0x00

#define INIT_MHR0 0x9F

#define INIT_MLR0 0xE0

Doing the same thing with the other group of identifiers leads to:

#define INIT_FHR1 0x20

#define INIT_FLR1 0x20

#define INIT_MHR1 0xA9

#define INIT_MLR1 0x30

Software Filter Configuration

You need to use software filtering feature if the hardware cannot stop all the undesired identifiers. Look at the following code in can_custom.h:

//SOFTWARE ACCEPTANCE MASKS

//#define FILTERS_ENABLED

//#define INIT_FILTERS {}

To allow software filtering, remove the “//” comment signs, and enter the identifiers between

the parentheses. Please note that the filters must be given in h exadecimal format with four

digits, always terminated by zero, and in increasin g order.

That is to say in our case:

SOFTWARE ACCEPTANCE MASKS: optional choice

#define FILTERS_ENABLED

#define INIT_FILTERS {0x1270,0x3110,0x3a50,0x5000,0x6000}

Note: There can not be more than 127 identifiers in the array.

2.2.3 Implementing the Notification Functions

The cell is now configured, we no longer need to worry about hardware.

30/100

Page 31

ST7 pCAN PERIPHERAL DRIVER

We have then to write our code. Look at the last lines of can_custom.h. There is a set of #define options. As we want to be notified neither of status changes, n or of errors, we will leave

them as comments. Please see Section 2.1. 5.5 "C an_cus tom.c File" for more details about

notification functions.

We must then open can_custom.c, and learn how to use the notification functions that are always compiled.

If your application uses the watchdog timer, you have to write on top of the file:

#include “wdg.h”

to be able to use the refresh function in this module.

The CAN_Request_Buffer function

To retrieve data stored in the ST7 buffers after reception, the application must pass a software

buffer when requested. The following prototype is given in the code:

CAN_Buffer* CAN_Request_Buffer(u16 ident_of_message)

{

//The application must here return a pointer to a physical structure CAN_Buffer

}

This routine is called each time a message has been successfully filtered and is ready to be

used. The pa rame ter pass ed (i.e . the ID of th e recove red me ssage) m ay hel p you mana ge

your buffer(s) more easily.

You then have to create a buffer that will be used to save all data messages.

At the top of the file, add:

////////////////////////////////////////

//VARIABLES/////////////////////////////

////////////////////////////////////////

CAN_Buffer reception_buffer;

And then in the function body:

CAN_Buffer* CAN_Request_Buffer(u16 ident_of_message)

{

reception_buffer.buffer_rw=CTRUE;

return &reception_buffer;

}

The two first lines are used as a s afety device: the driver wil l then be sure that the buffer is not

currently in us e and the da ta in that bu ffer can be overwr itten. In yo ur progr ams, use thes e

fields as keys to know whether the data in a buffer can be accessed and whether it has already

been processed.

Note 1: There is only ONE buffer here that will be used to save all the receive messages. This is only an

31/100

Page 32

ST7 pCAN PERIPHERAL DRIVER

example! You can implement a buffer for each message type, a FIFO of standardized buffers etc.

Note 2: For safe programming, you should systematically verify whether the buffer is not currently being

read/written, and whether the buffer is really free before further processing.

(For specific information concerning the buffer data type, see Section 2.1.5.1 "Data-type Var-

iables").

Remember that one of the received messages may switch off the cell. Once a message is received, we have to check to see if it is this one. This is done using the

CAN_Data_Reception_Notification function.

CAN_Data_Reception_Notification F unction

The CAN_Da ta_R eception_ Notifi cation function is the followi ng protot ype in can_c ustom .c.

The routine is called once the data in a data frame has been saved in the buffer passed in the

CAN_Re ques t_Bu ffer f uncti on. Be fore calli ng the C AN_Sw itc h_on functi on, refres h t he

watchdog (See “Func tions” on pag e 21, CAN_Switch_Off for further explanation). Let’s add

the following code:

void CAN_Data_Reception_Notification(u16 message_ident)

{

if (message_ident==0x6000)//checks the id of message

{

if (reception_buffer.CAN_msg_data[0]==0xFF)//Checks the content of data

{

CAN_Switch_Off(BUS_WAKEUP);

}

}

}

So, if the first data byte of the mes sage whos e identifier is 0x600 contains 0x FF, the cell w ill

switch off and wait for a bus Wake-Up command (a dominant bit).

CAN_Remote_Reception_Notification Function

When a remote frame is received, we must send a message with a 0x500 ID. Let’s do i t i nside

this routine which is called each time a remote frame is received.

The message does not exist yet. As for the buffer, we have to create a variable

message

, by

adding the following code in the file:

////////////////////////////////////////

//VARIABLES/////////////////////////////

////////////////////////////////////////

CAN_Buffer message_to_send_on_request= /

{0x5000,DLC5,{0x00,0x01,0x02,0x03,0x04},CFALSE,CFALSE};

32/100

Page 33

ST7 pCAN PERIPHERAL DRIVER

The structure is initialized here with 0x500 ID, which has a length of five and five data items.

Note: In a real network, the message would not be statically initialized, but would be filled with the content

of one or several variables. The aim here is only to show the way the function can be used.

Then we fill the function with a transmission request:

void CAN_Remote_Reception_Notification(u16 ident_of_remote)

{

if (ident_of_remote==0x5000)

{

CAN_Transmit_Request(&message_to_send_on_request);

}

}

CAN_Transmission_Notification Function

This function is called after each successful transmission. It is not requir ed for our application,

so let’s leave it blank.

CAN_Dominant_Bit_Reception_Notification Function

This function is called each time a dominant bit is received while in Standby mode. Here, we

want to be able to wake up the cell when this happens. So we add the following code:

void CAN_Dominant_Bit_Reception_Notification(void)

{

CAN_Switch_On(&first_init_data,CFALSE);

}

The cell will be woken-up with the same configuration as when first initialized and a dominant

pulse will not be sent at wake-up.

Note: For the exact meaning of the data parameters, see Section 2.1.5.2 "Functions"

All other notification functions can be used in the same way. They are compiled only if the corresponding options are chosen in can_custom.h.

2.2.4 Transmissions outside the CAN Interrupt Fun ction

As part of the user interface, the CAN_Transmit_Request routine can be used outside the interrupt function of the CAN driver. Below is an example of a message transmission on a timer

event. The content of the A/D converter of the ST7 microcontroller will be sent every 15 ms.

First of all, we must configure the timer by modifying the existing code.

At the top of the tima.c file, add:

#include “can.h”

#include “lib.h”

#include “adc.h”

Then declare a CAN_Message -type variable:

33/100

Page 34

ST7 pCAN PERIPHERAL DRIVER

CAN_Buffer periodic_transmission;

In the TIMA_Init() function, make sure the following lines are included:

TACR1=0x40

TACR2=0x08

TAOC1HR=0x3A

TAOC1LR=0x98

and finally,

#asm

LD _TAOC2HR,A; /* Write the Output Compare 2 high register to disable the OC2 */

LD A,_TASR /* Clear the flags in case it is already set. To Clear */

LD A,_TAOC1LR /* OC1F flag: Read Status Register and Access OC1R low byte,

clearing OC1F flag */

LD A,_TAOC2LR /* OC2F flag: Read Status Register and Access OC2R low

byte,clearing OC2F flag*/

LD _TAOC2HR,A//No access to low byte: OutputCompare 2 ITs disabled

#endasm

Note: The explanation of the code written here concerns timer programming and is beyond the scope of

this document. Its purpose is to configure timer A to trigger a timer interrupt every 15 ms. Further

explanations of timer functions can be found in the microcontroller datasheet.

Then we have to fill in the IT function of the timer:

void TIMA_Interrupt(void)

{

u16 output_value;

if (ValBit(TASR,OCF1))

{

TASR;

output_value = ((unsigned int)TAOC1HR << 8)| TAOC1LR;

}

output_value += 0x3A98;

TAOC1HR = output_value >>8;

TAOC1LR = (unsigned char) output_value;

//Note: The code above is only meant to update the value for the next IT

//Now comes the code that interests us

if (!periodic_transmission.message_in_queue) //Checks if the message is already

//in the transmission queue

{

periodic_transmission.msg_identifier=0x4020;

periodic_transmission.data_size=DLC1;

periodic_transmission.CAN_Msg_data[0]=ADC_Get(0x00);

34/100

Page 35

ST7 pCAN PERIPHERAL DRIVER

CAN_Transmit_Request(&periodic_transmission);

}

//We have given a transmission order here, that will be called on every

//timer IT if the message is not already in the transmission queue.

//The data is filled each time with the value of the A/D converter data

//register. For info. about the ADC, please see the datasheet.

}

IMPORTANT: Please note that WHEN USED OUTSID E AN INTERRUPT ROUTINE, AND

ONLY T HE N, the t ransm is sion r eques t MUS T NO T BE I NTER R UPT ED . So , dis able al l I Ts

before a function call (SIM) and re-enable them afterwards (RIM) in the last step of the main.c

file.

In the adc.c file, enter also the following code:

In the ADC_Init routine:

ADCCSR=0x20;//Starts the ADC peripheral

and write a function:

u8 ADC_Get(u8 channel)

{

ADCCSR |= channel;

return ADCDR;

}

Our application is almost entirely written now. Our last step is to fill the main.c file, to allow the

entire program to run.

At the beginning of the file add:

#include “lib.h“

#include “adc.h“

#include “tima.h“

#include “can.h“

#include “can_custom.h”

Then complete the main function as follows:

void main(void)

{

_asm(“SIM”); //Disable interrupts

/* ----------------------------- */

/*------------------- I N I T I A L I S A T I O N -------------------------*/

/* ----------------------------- */

35/100

Page 36

ST7 pCAN PERIPHERAL DRIVER

ADC_Init(); //Initializes the ADC

if ((CAN_First_Init())==CAN_INIT_FAILURE) //Initializes the CAN peripheral

{

return;

}

TIMA_Init();//Initializes the timer

_asm(“RIM”);// EnableInterrupts;

/* ------------------- */

/*---------------------------- LOOP --------------------------*/

while (1) /* ------------------- */

{

}

}

Finished! Now co mpile th e entir e code and r un the soft ware . Onc e the

while {1}

loop is entered, the microcontroller will r un non-stop unti l it is shut down, reacti ng to every ev ent, saving

data in our buffer, sending data periodically and answering remote requests.

If you own a CAN bus simulation tool, you can monitor messages being received and sent by

the ST7.

The next section of this application note w ill explain in detail the driver architecture and all software functions (including internal functions).

2.2.5 IMPORTANT: Reentran t Func tions

If the memory model you chose for compiling your application does not use the physical stack

but simulates it in RAM, you CANNOT allow functions to be reentrant.

The COSMIC compiler will generate an error if it finds some code that could be reentrant. For

example, this may occur if you use a subroutine inside both an initialization function and an interrupt routine.

This is, of course, not a real error, but the compiler does not know this and prevents you from

going further.

To fix this problem with the COSMIC compi ler, use the following trick:

– Change the name of the function in your code, in the call that makes the error appear.

36/100

Page 37

ST7 pCAN PERIPHERAL DRIVER

– For example, rename function to function_init_call.

– In the link file (extension .lkf), define an alias the following way:

+def _function=_function_init_call //!!

Note the underscore as first character.

– If the function takes parameters, add also:

+def _function$L=_function_init_call$L//!!

This is the way the parameters names are generated by the compiler

– Save the file and compile.

IN ANY CAS E, ALWAYS MAKE SUR E THAT YOUR CODE IS NO T ACTUA LLY REEN-

TRANT, If IT IS, IT WON’T RUN THE WAY YOU EXPECT, EVEN IF YOU HAVE COMPILED

IT SUCESSFULLY!

37/100

Page 38

ST7 pCAN PERIPHERAL DRIVER

3 DETAILED DESCRIPTION

In the following section we w ill give a detailed description of function algorithms. We will also

look at the internal aspects of the driver.

3.1 USER INTERFACE FUNCTIONS

As described above in the routine parameters and return values, the algorithm will only be

shown on flowcharts. For more information, refer to Section 2.1.5.2 " Functions".

void CAN_It_Dis(void):

Simply clears the CAN Interrupt control register.

u8 CAN_Get_TEC(void):

Simply returns the value of TEC.

u8 CAN_Get_REC(void):

Simply returns the value of REC.

CAN_Init_Error CAN_First_Init(void)

Figure 13. CAN_First_Init Flowchart

Begin

RUN=0

Y

Returns

CAN_INIT_FAILURE

Initializes

Transmission

Queue

Locks Buffer 1 Calls CAN_Init

N

Success?

Y

Returns

CAN_INIT_SUCCESS

38/100

Page 39

CAN_Status CAN_Get_Status (void)

Figure 14. CAN_Get_Status Flowchart

Begin

ST7 pCAN PERIPHERAL DRIVER

NNN

RUN=0 EPSV=1 BOFF=1

YYY

Returns

CAN_STANDBY

Returns

CAN_BUS_PASSIVE

Returns

CAN_BUS_OFF

CAN_Switch_Error CAN_Switch_Off(WakeUp_Cause)

Figure 15. CAN_Switch_Off Flowch art

Begin