Page 1

AN1088

®

APPLICATION NOTE

L6234 THREE PHASE MOTOR DRIVER

by Domenico Arrigo

INTRODUCTION

The L6234 is a DMOSs triple half-bridge driver with input supply voltage up 52V and output current of

5A. It can be used in a very wide range of applications.

It has been realized in Multipower BCD60II technology which allows the combination of isolated DMOS

transistors with CMOS and Bipolar circuits on the same chip. It is available in Power DIP 20 (16+2+2)

and in Power SO 20 packages.

All the inputs are TTL/CMOS compatible and each half bridge can be driven by its own dedicated input

and enable.

The DMOS structure has an intrinsic free wheeling body diode so the use of external diodes, which are

necessary in the bipolar configuration, can be avoided. The DMOS structure allows a very low quiescent

current of 6.5 mA typ. at Vs=42V , irrespective of the load.

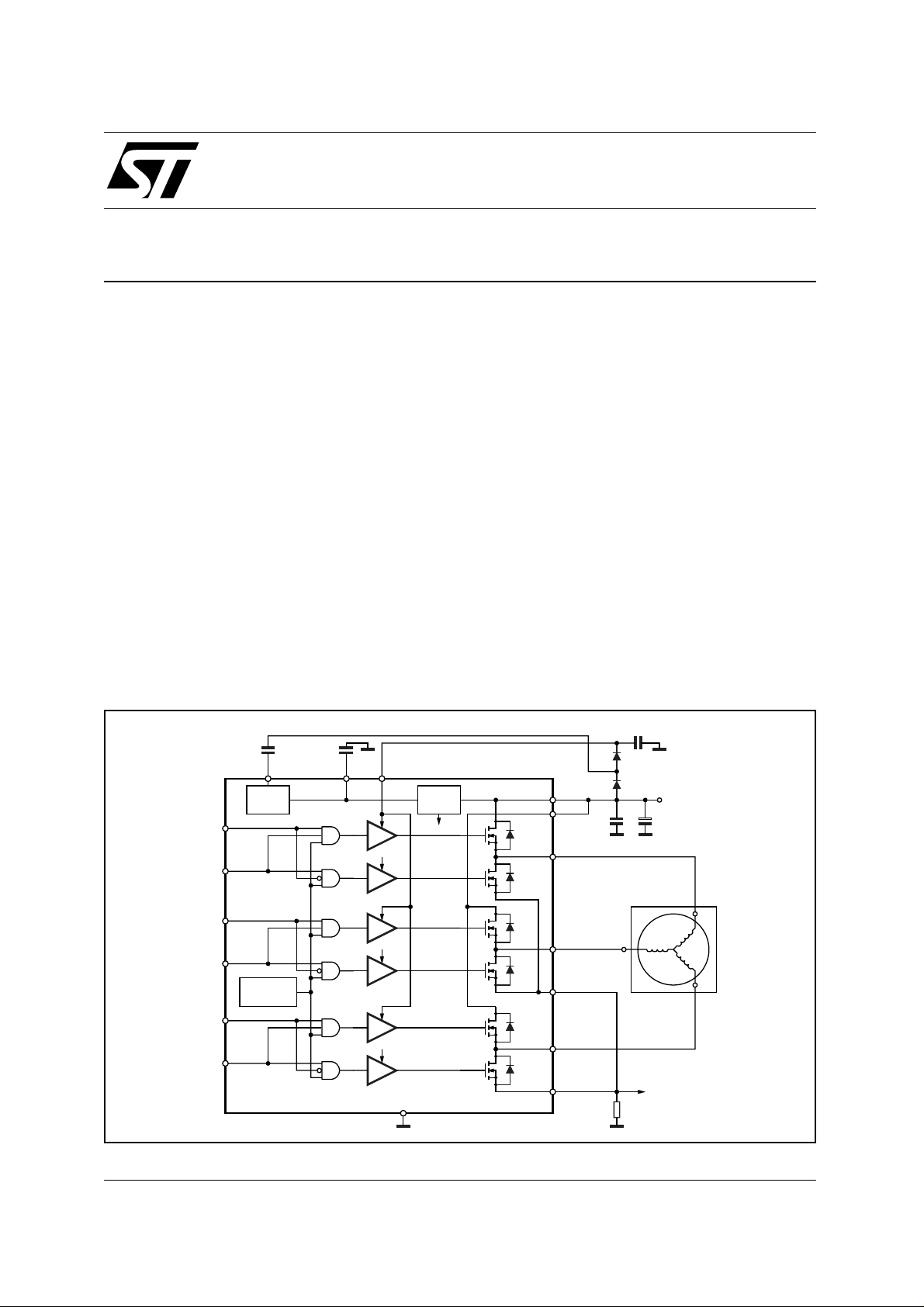

DEVICE DESCRIPTION

The device is composed of three channels. Each channel is composed of a half bridge with two power

DMOS switches ( typ. Rdson of 300mW @ 25°C) and intrinsic free wheeling diodes. Each channel includes two TTL/CMOS and uP compatible comparators, and a logic block to interface the inputs with the

drivers. The device includes an internal bandgap reference of 1.22V, a 10V voltage reference to supply

the internal circuitry of the device, a central charge pump to drive the upper DMOS switch, thermal shutdown protection and an internal hysteretic function which turns off the device when the junction temperature exceeds approximately 160 °C. Hysteresys is about 20 °C.

Figure 1. L6234 Block Diagram

April 2001

IN1

EN1

IN2

EN2

IN3

EN3

C3

10nF

CHARGE

PUMP

THERMAL

PROTECTION

1µF

VREFVCP

C4 220nF

C5

VBOOT

T1

T2

T3

T4

T5

T6

Vs

Vs C2

OUT1

OUT2

SENSE1

OUT3

SENSE2

D98IN940A

100nF

GND

V

10V

REF

D2

1N4148

D1

1N4148

100µF

BRUSHLESS

MOTOR

WINDINGS

R

SENSE

Vs

C1

1/14

Page 2

]

AN1088 APPLICATION NOTE

PIN DESCRIPTION.

Vs ( INPUT SUPPLY VOLTAGE PINS).

Figure 2.

V

S

These are the two input supply voltage pins. The unregulated

input DC voltage can range from 7V to 52V.

With inductive loads the recommended operating maximum

supply voltage is 42V to prevent overvoltage applied to the

DMosfets. In fact considering a full bridge configuration (see

ON/OFF

T1

L

B

-V

F

T3

C

(VS+VF)

ON

V

F

OFF

fig. 2), when the br idge is switched of f (ENABLE CHOPPING)

the current recirculation produces a negative voltage to the

source of the lower DMOS switches (point A). In this condition the drain-source voltage of T

Dinamically V

slope, dI/dt, and also V

can be same Volts depending on the current

F

sense

and T4 is VS + VF + V

1

sense

, depending on the parasitic in-

ductance and current slope can be some Volts. So the drain-

T2 T4

.

-V

A

SENSE

Rsense

ON/OFF

S

D98IN938A

source voltage of T1 and T4 DMOS switches can reach more

than 10V over the V

voltage. The input capacitors C1 and C2 are chosen in order to reduce overvoltage

S

due to current decay and to parasitic inductance. For this reason C2 has to be placed as closed as possible to V

and GND pins.

S

The device can sustain a 4A DC input current f or each of the two Vs pi ns, in accordance with the

power dissipation.

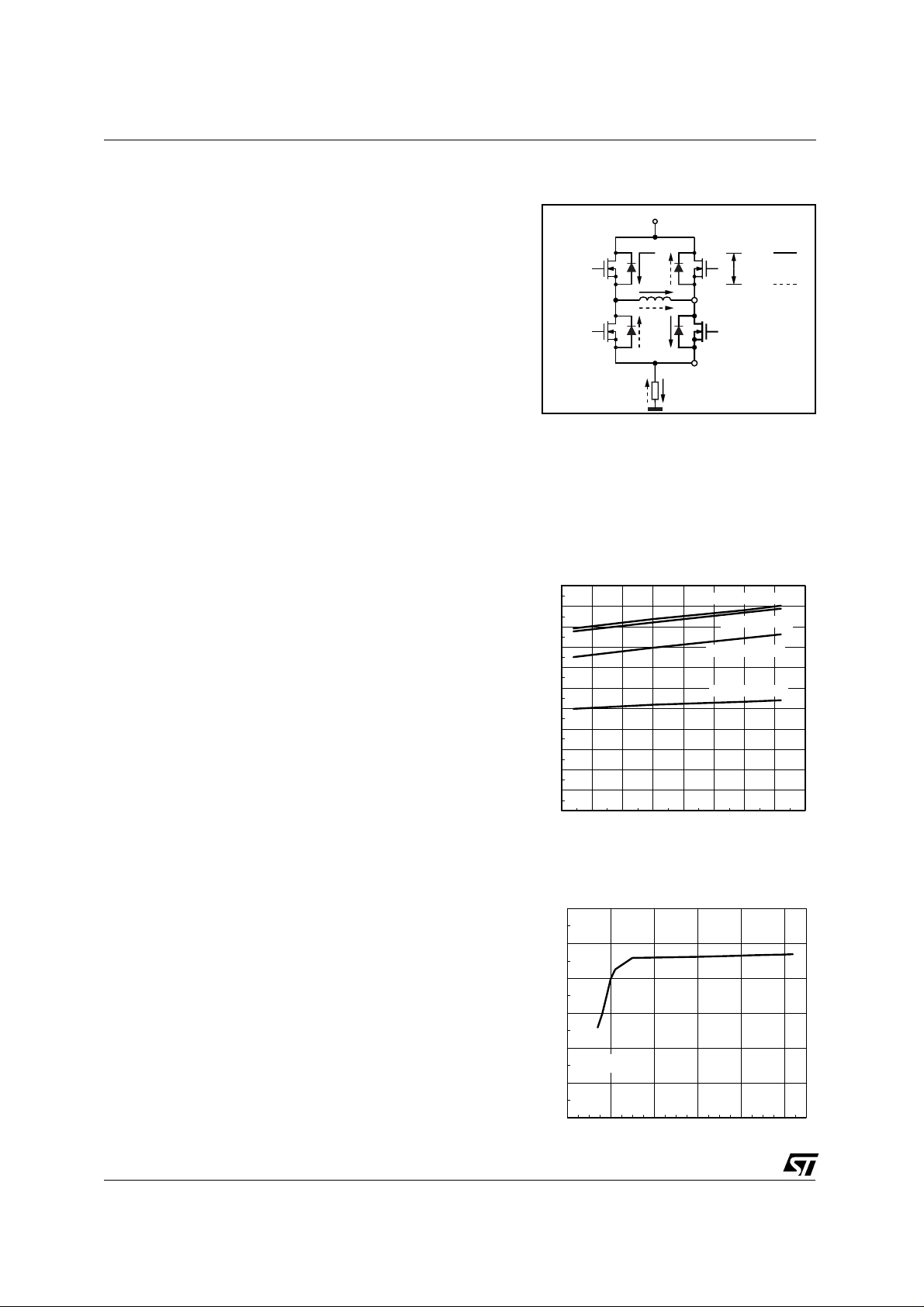

Figure 3. Reference Voltage vs.

OUT1, OUT2, OUT3 (OUTPUTS).

These are the output pins

that correspond to the mid point of each half bridge. They are

designed to sustain a DC current of 4A.

SENSE1, SENSE2.

SENSE1 is the common source of the lower DMOS of the half

bridge 1 and 2.

SENSE2 is the source of the lower DMOS of the half bridge

3.

Each of these pins can handle a current of 5A.

A resistance, Rsense, connected to these pins provides feed-

back for motor current control.

Care must be taken with the negative voltage applied to these

pins : negative DC voltage lower than -1V could damage the

device. For duration lower than 300ns the device can sustain

pulsed negative voltage up to -4V.

For example, if enable chopping current control method is

used, negative voltage pulses appear to these pins, due to the

current recirculation through the sensing resistor.

Vref ( Voltage Reference).

This is t he internal 10V voltag e reference pi n to bias the log ic

and the lo w volt a ge circu it ry of the d evic e. A 1µF electrolytic capacitor connected from this pin to GND ens ur es the s tability of the

Vref [V]

11

10

9

8

7

6

5

4

3

2

1

0

-50 -25 0 25 50 75 100 125 150

Figure 4. Reference Voltage vs.

Vref [V]

12

10

8

Junction Temperature.

Vs = 52V

Vs = 24V

Vs = 10V

Vs = 7V

Tj [°C]

Supply Voltage.

DMOS drive circuit. This pin can be externally loaded up to 5mA .

Figure 3 and 4 show the typical be havior of the Vref pin.

6

4

Vcp ( CHARGE PUMP ).

Tj = 25°C

2

This is the internal oscillator output pin for the charge pump.

The oscillator supplied by the 10V Voltage Reference

switches from GND to 10V with a typical frequency of

2/14

0

01020304050

Vs [V

Page 3

AN1088 APPLICATION NOTE

1.2MHz (see fig 4). When the oscillator output is at ground , C3 is charged by Vs through D1. When it

rises to 10V, D1 is reverse biased and the charge flows from C3 to C4 through D2, so the Vboot pin after a few cycles reaches the maximum voltage of Vs + 10V - VD1- VD2.

Vboot ( BOOTSTRAP).

This is the input bootstrap pin which gives the overvoltage nec essary to dr iv e all the upper DMOS of the

three half bridges (see fig 5).

Figure 5. Charge Pump Circuit.

Vs

C1

C2

100µF

0.1µF

Vs

Vs-VD1

Vs+Vref-VD1

f=1.2 MHz

VCP

D1

1N4148

C3

10nF

Vref

D2

1N4148

Vs+Vref-VD1-VD2

C4

0.22µF

VBOOT

CHARGE

PUMP

f=1.2 MHz

Vref

10V

HIGH

SIDE

DRIVER

OUT

SENSE

LOGIC INPUTS PINS.

EN1, EN2, EN3 (ENABLES).

These pins are TTL/CMOS and µP compatible. Each half bridge can be enabled by its own dedicated

pin with a logic HIGH. The logic LOW on these pins switches off the related half bridge (see Fig. 6). The

maximum switching frequency is 50kHz.

Figure 6. Control logic for each half bridge.

INPUT

ENABLE

UPPER

DMOS

LOWER

DMOS

low level

high level

DMOS OFF

DMOS ON

high level

high level

DMOS ON

DMOS OFF

low level

low level

DMOS OFF

DMOS OFF

high level

low level

DMOS OFF

DMOS OFF

time

time

time

time

Figure 7. Cross Conduction Protection.

DMOS ON

tdelay

DMOS OFF

high level

low level

tdelay

300ns

DMOS OFF

DMOS ON

INPUT

PIN

UPPER

DMOS

LOWER

DMOS

low level

DMOS OFF

300ns

DMOS ON

time

time

time

IN1, IN2, IN3 (INPUTS).

These pins are TTL/CMOS and µP compatible. They allow switching on the upper DMOS ( INPUT at

high logic level) or the lower Dmos (INPUT at low logic level) in each half bridge (see Fig. 6).

3/14

Page 4

AN1088 APPLICATION NOTE

Cross conduction protection (see Fig. 7) avoids simultaneously turning on both the upper and lower

DMOS of each half bridge. There is a fixed delay time of 300ns between the turn on and the turn off of

the two DMOS switches in each half bridge. The switching operating frequency is up 50kHz. High commutation frequency permits the r eduction of ripple of the output current but increa ses the device’s power

dissipation, however low commutation frequency causes high ripple of the output current. The switching

frequency should be higher than 16kHz to avoid acoustic noises.

The sink current at the INPUTS and ENABLES pins is approximately 30µA if the voltage to these pins is

at least 1V less than the Vref voltage (see Fig. 3 and Fig. 4). To avoid overload of the logic INPUTS and

ENABLES , voltage should be applied to Vs prior to the logic signal inputs.

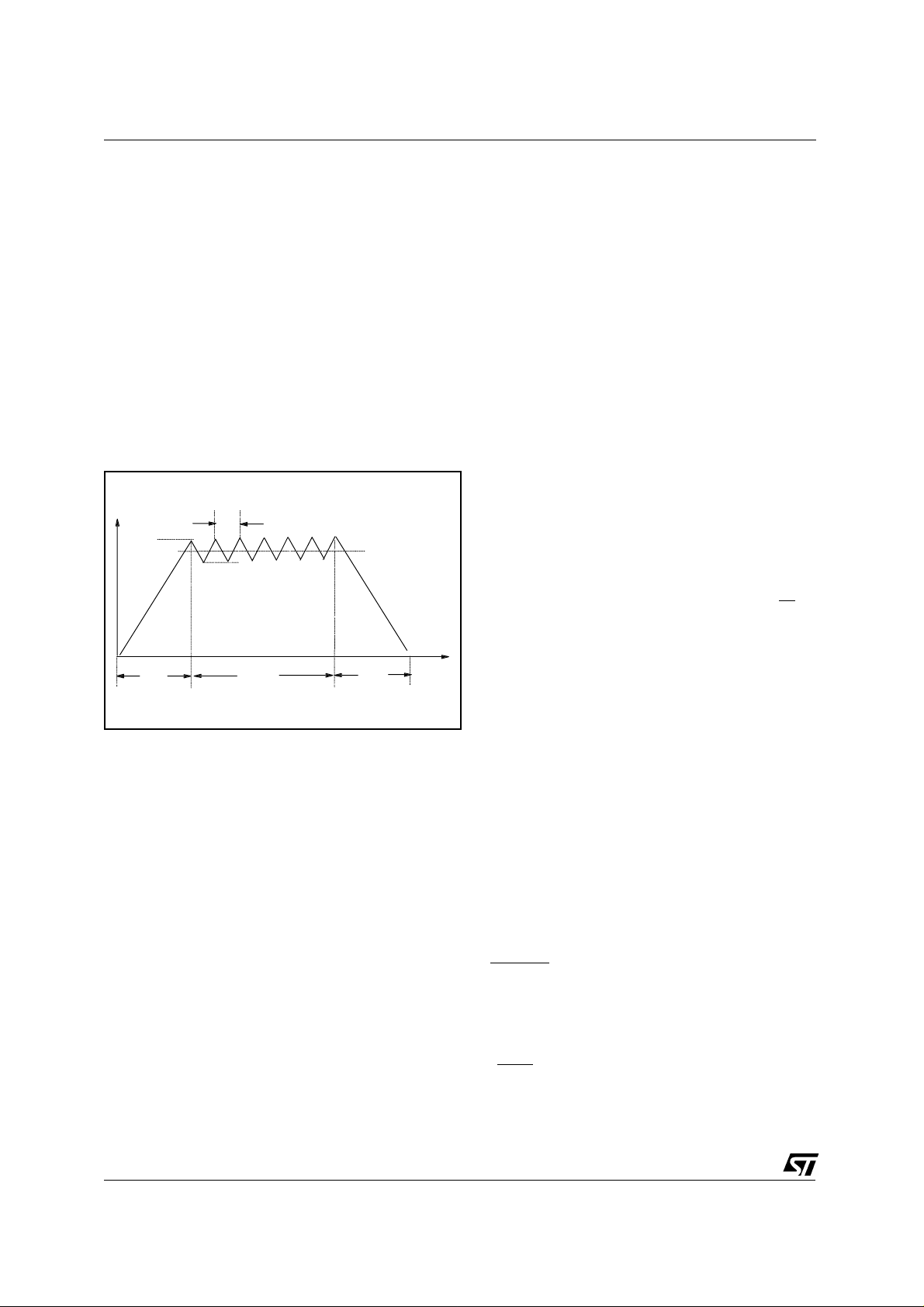

POWER DISSIPATION

An evaluation of the power dissipation of the I C driving a three phase motor in a chopping current control application follows.

With a simplified approach it can be distinguished three periods (see Fig. 8) :

Figure 8.

Rise Time, Tr, period.

This is the rise time period, Tr, in which the current switches from one winding to another. In this

Tchop

Ipk

Iload

Ival

time a DMOS is switched on and the current increases up to the peak value Ipk with the law i(t)

= (Ipk/Tr) t. T he energy lost for t he rise time in

the period T is :

Erise =

Tr

Rdson ⋅ i

∫

0

2

dt = Rdson ⋅ I

(t)

2

pk ⋅

Tr

3

Fall Time,Tf, period.

Trise

Tload

Tfall

When the current switches from one winding to

another, there is a fall time in which the current

that flows in the intrisic diode of the DMOS decreases from Ipk to zer o. If VD is t he voltage fall

of the diode, the energy lost is :

tf

Efall =

VD(t) ⋅ i(t)dt

∫

0

Tload

During this time the current that flows in the winding is limited by the chopping current control. The energy dissipated due to the ON resistance of the DMOS is :

Eload = Rdson ⋅ (I

rms

2

⋅ Tload

)

In the formula, Irms is the RMS load current, given by :

Irms =

Iload

(

2

+

)

√

I

pk

2

3

√

− Ival

and Iload is the average load current.

When the switch is ON, the energy dissipated due to the commutation of the chopping current control in

the DMOS can be assumed to be:

Eon = Vs ⋅ Ival ⋅

tcom

2

where tcom is the commutation time of the DMOS switch.

4/14

Page 5

AN1088 APPLICATION NOTE

When the switch is OFF :

Eoff = Vs ⋅ Ipk ⋅

tcom

2

The energy lost by commutation in a chopping period, given by Eon + Eoff, is :

Ecom = Vs ⋅ Iload ⋅ tcom

The energy lost by commutation during the Tload time is given by :

Ecom = Vs ⋅ Iload ⋅ tcom ⋅ Tload ⋅ fchop

Quiescent Power Dissipation, Pq.

The power dissipation due to the quiescent current is Pq = Vs ⋅ Iq , in which Iq is the quiescent current

at the chopping frequency, fchop = 1/Tchop.

Total Power Dissipation

.

Let’s evaluate the power dissipation of the device driving a three phase brushless motor in chopping current control. In the driving sequence only one upper DMOS and a lower one are on at the same time

(see fig. 9 and 10). The total power dissipation is given by :

2 ⋅ (Erise + Efall + Eload + Ecom

Ptot =

T

)

+ Pq

Figure 11 shows the total power dissi pation, Pd, of the L6234 driving a three phase brushless motor in

input chopping current control at different chopping frequency.

EVALUATION BOARD.

The L6234 Power SO20 board has been realized to evaluate the device driving, in closed loop control, a

three phase brushless motor with open collector Hall effect sensors.

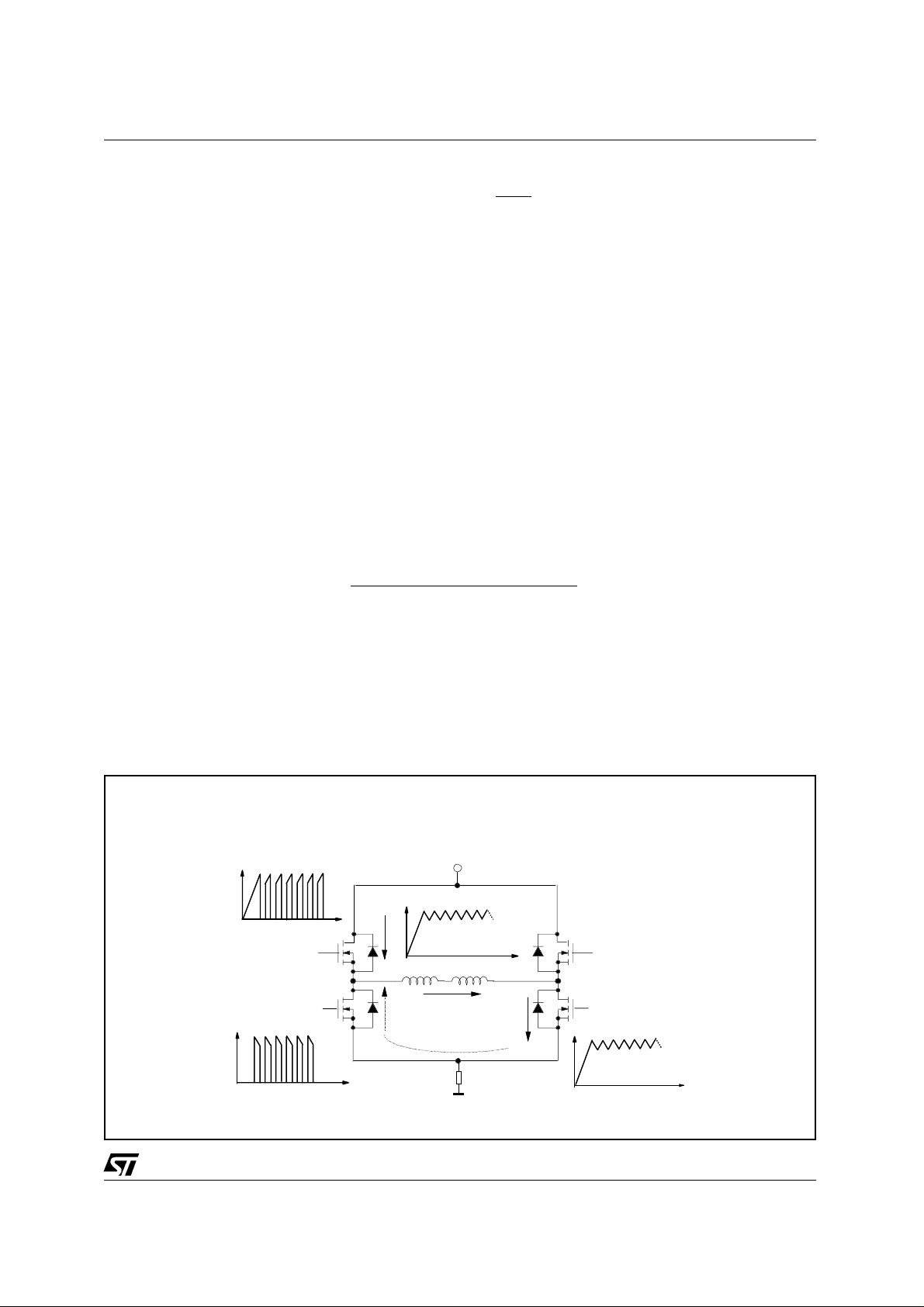

Figure 9. In put chopping curren t cir c ulation.

_

PHASE 12

CHOPPING INPUT

Vs

ILOAD

ILOAD

I1B

IOFF

half bri dge 2

I2B

OFF

ON

I2B

I1B

I1A

half bri dge 1

I1A

ON/OFF

OUT1 OUT2

OFF/ON

5/14

Page 6

AN1088 APPLICATION NOTE

Figure 10. Three Phase Brushless motor control sequence.

IOUT1

BRUSHLESS MOTOR

OUT1

OUT2

L6234

OUT3

IOUT2

IOUT3

T

The device soldered on the copper heat dissipating

area on the board ,without any additional heat sink,

can sustain a DC load current of 2.3 A at T

amb

approximately 40 °C.

The board provides a closed loop speed and torque

control, with a constant TOFF chopping current control method. It allows the user to change the direction and brake the motor.

Constant t

Chopping Current Control.

OFF

Figure 11. L6234 Power Dissipation in Three

of

Pd [W]

Phase Brushless Motor Control.

INPUT CHOPPING

Vs=36V

15

L=2mH

T=2ms

Tj=100C

10

fchop=50 k Hz

fchop=30 k Hz

DC

When the current through the motor exceeds the

threshold, fixed by the ratio between the control

voltage Vcontrol and the sensing resistor, Rsense,

5

an error signal is generated, the output of the

LM393 comparator switches to ground. This state is

maintained by the monostable (M74HC123) for a

constant delay time ( t

) generating a PWM sig-

OFF

nal that achieves the chopping current control. The

PWM signal is used for chopping the INPUT pat-

0

01

2

ILOAD [A ]

3

45

tern. During the toff in chopping current control, the

current flows in the low side loop ( see fig. 9 ) and does not flow through the sensing resistor.

The t

A suitable value of toff for the majority of applications is 30µs. The larger the t

rent ripple. If t he t

value can be set by the R9 and C11 to values shown in the table 1.

OFF

is too large the ripple current becomes excessive . On the other hand if the t

OFF

, the higher is the cur-

OFF

OFF

is

too small the winding current cannot decrease under the threshold and current regulation is not guaranteed.

6/14

Page 7

Figure 12. Application board Schematic Circuit.

AN1088 APPLICATION NOTE

+5V

HALL

EFFECT

SIGNALS

BRAKE

DIR

PWM

OUT

C7

10uF

3

PWM

L7805

2

GND

CONTROL

LOGIC

1

C6

220nF

CONSTANT toff

T1

IN

Z1

18V

IN1

IN2

IN3

EN1

EN2

EN3

CHOPPING

10k

R5

J7

CURRENT

CONTROL

Figure 13. Constant toff current control.

+5V

+5V

C9

100nF

1

LM393

4

PWM

+5V

C10

100nF

+5V

Vcontrol

_

Q

R9

100k

2316

M74HC123

monostable

4

15

B

14 8

C11

330pF

R11

10k

1

A

100uF

60V

Vsense

Vcontrol

8

+

Vs=8V to 42

C1

R1010K each

2

3

R8

1K

IN1

IN2

IN3

EN1

EN2

EN3

TORQUE &

1K

R6

C8

470pF

R7

11 k

C2

100nF

7

4

14

8

3

13

GND

+5V

SPEED

CONTRO L

Vsense

+5V

J1

1N4148 1N4148

D1 D2

912 17

L6234

POWER SO20

1

10 11 20

Vref

Table 1. toff selection

C3

10nF

18

16 19

C5

1uF

Hall effect signal

Reference

Speed

C4

220nF

VbootVcpVs

OUT1

6

OUT2

5

OUT3

15

2

SENSE

R1

Ω

1

BRUSHLESS MOTOR

R2 R3

Ω

1

Ω

1

REFERENCE

SPEED

1

toff R9 C11

20µs 100k 270pF

30µs 100k 330pF

45µs 100k 560pF

70µs 100k 1nF

HALL

EFFECT

SENSORS

R4

Ω

Torque & Speed Clos e d Loop C ontrol.

The motor’s rotational speed is determined by the frequency of the Hall effect signals. The speed control

loop has been achieved by comparing this f requency with a frequ ency of a reference os cillator (see f ig.

14) that corresponds to a desired speed limit.

Figure 14. PLL Motor Control.

REFERENCE

FEEDBACK

PHASE/

FREQUENCY

DETECTOR

Vcontrol

Amp.

COMPENSATION

NETWORK

D01IN1209

PWM

MOTOR

HALL

SENSORS

7/14

Page 8

AN1088 APPLICATION NOTE

Figure 15. Oscillator for Reference Speed.

Reference Speed

+5V

R26

C21

36K

8

3

NE555

1

R27

4

7

16K

6

2

5

C20

100nF

C19

100nF

100nF

Figure 16. Phase Locked Loop and filtering.

+5V

C12

100nF

Vcontrol

+5V

GND

HALL1 (Speed feedback)

Reference Speed

LM358

8

+

-

1

4

R12

47K

R14

47K

3

2

1uF

C13

R13

47K

+5V

BAT47

+5V

R15

P2

47K

1K

P1

5K

C14

100nF

+5V

R17

10M

R18

33K

R16

270K

810

9

Loop

Amplifier

+VIN

13

Phase/ Frequency

14

6

Figure 17. Control Logic Circ uit.

+5V

R29

10k

2

3

4

5

6

100nF

SW2

7

191

18

GAL 16V8

C18

17

16

15

14

10

20

DIRECTION CHANGE

DIR =0 GND : BACK ROTATION

DIR = 5V : FORWARD ROTATION

BRAKE FUNCTION

BRAKE = GND : BRAKE

BRAKE = 5V : GO

MOTOR

HALL

EFFECT

SIGNALS

+5V

GND

+5V

R22

10k

BRAKE DIR

R23

10k

R25

10k

SW1

R24

10k

HALL1

HALL2

HALL3

BRAKE

R26

10k

J1

DIR

PWM

100nF

R20

Aux.

OP-AMP

2.5V

Detector

EN1

EN2

EN3

IN1

IN2

IN3

C15

11

3635

2

TP8

C17

47nF

3

C16

220nF

12

R19

91K

15

EN1

EN2

EN3

IN1

IN2

IN3

PWM

When the hall effect signal frequency is lower than the reference

frequency, the control voltage is

maintained to a value that set s the

motor current limit and therefore the

torque control limit. The peak current limit is given by Ipeak = Vcontrol/Rsense.

When the frequency from the Hall

Effect sensors exceeds the reference frequency and an error signal

is generated by the PLL (see Fig.

14). An LM358 comparator, a loop

amplifier and an auxiliary OP-AMP

ensure the right gain and filtering to

guarantee the stability (see fig.16).

The error signal causes Vcontrol

decrease to a value that sets the

PWM chopping current control in order to reduce the torque and set

the desired speed. The motor

speed is regulated to within ± 0.02

% of the desired speed.

R21

91K

Output

4

Control Logic Ci r c uit.

The logic sequence to the motor is

generated by a GAL16V8, which

decodes the Hall Effect signals and

5

7

1

16

GND

generates the INPUT and ENABLE

pattern shown in Fig. 18.

The brake function is obtained by

setting the input pattern to logic low

and thus turning on the lower

DMOS switches of the enabled halfbridges.

The PWM signal is used for chopping the INPUT pattern.

The control logic circuit decodes

Hall effect sensors having different

phasing.

With the DIR jumper opened the

application achieves forward rotation for motors having 60° and 120°

Hall Effect sensor electrical phasing

and the reverse rotation for motors

having 300° and 240° Hall Effect

sensor phasing.

Connecting the DIR jumper to

ground sets the reverse rotation for

motors having 60° and 120° Hall

sensors phasing and the forward

rotation for motors having 300° and

240° Hall sensor phasing.

The SW2 switch performs the startstop function.

8/14

Page 9

Figure 17.

AN1088 APPLICATION NOTE

SENSOR

SIGNALS

ENABLE

FORWARD

ROTATION

HALL1

HALL2

HALL3

EN1

EN2

EN3

IN1

IN2

IN3

0˚

ELECTRICAL DEGREES

360˚

REVERSE

ROTATION

MOTOR

DRIVE

CURRENT

IN

FORWARD

ROTATION

IN1

IN2

IN3

IOUT1

IOUT2

IOUT3

0

0

0

NO PWM PWM CONSTANT t

OFF

D98IN912

9/14

Page 10

AN1088 APPLICATION NOTE

Layout Considerations.

Special attention must be taken to avoid overvoltages at Vs and additional negative voltages to the

SENSE pins and noise due to distributed inductance. Thus the input capacitor must be connected close

to the Vs pins with symmetrical paths. The paths between the SENSE pins and the input capacitor

ground have to be minimized and symmetrical . The sensing resistors must be non-inductive. The device GND has to be connected with a separate path to the input capacitor ground.

Figure 19. Application Board Layout.

Figure 20. Com pone nt side.

10/14

Page 11

AN1088 APPLICATION NOTE

Figure 21. Coppe r s ide.

APPLICATION ID EAS.

The L6234 can be used in many different applications. Typical examples are a half bridge driver using

one channel and a full bridge driver using two channels. In addition, the bridges can be paralleled to reduce the RDSon and the device dissipation.

The paralleled configuration can also be used to increase output current capability. Channel 1 can be

paralleled with Channel 3 or Channel 2 can be paralleled with Channel 3. Channel 1 should not be paralleled with Channel 2 because the sources of their low side DMOSs are connected to the same SENSE1

pin .

Application ideas for the L6234 follow.

Figure 22. Constant frequency current control

Vs

EN1

+5V

EN2

EN3

IN1

IN2

IN3

Reset

Q

S

R

S

R

Q

OSC

Rx

Cx

+5V

100nF

L6506

Vsense

Vcontrol

CONTROL

LOG IC

100uF

EN1

EN2

EN3

IN1

IN2

IN3

Constant frequency

+5V

Curren t Co n t ro l

1

Fchop= __________

0.69 Rx Cx

for Rx>10kOhm

100nF

GND

1N4148 1N4148

10nF

Vs

L6234

POWER SO20

Vref

SENSE1

1uF

220nF

VbootVcp

OUT1

OUT2

OUT3

SENSE2

RSENSE

11/14

Page 12

AN1088 APPLICATION NOTE

Low Cost Application with Speed and Torque Control Loops.

Figure 23. Complete three phase brushless motor application with speed and torque control.

V

S

HALL

EFFECT

BRUSHLESS MOTOR

V5

Vm

2

R1 100K

3

Vref

(Reference

SENSORS

+5V

1/fe

Ton

1Q

Rx1

100K

SPEED LOOP

163

1/2

M74HC123

MONOSTABLE

13

15 1 14 8

Cx1

V5=+5V

27

1B

HALL EFFECT SIGNAL

HALL

EFFECT

SIGNALS

PWM

+5V

V5=+5V

Q

Rx2

CONTROL

LOGIC

1/2

M74HC123

MONOSTABLE

12

IN1

IN2

IN3

EN1

EN2

EN3

1110

1

6

Cx2

912

L6234

POWER SO20

V

SENSE

6

5

+

17 18

16 2 19

R3 4KVCONTROL

R4

1K

7

4

14

8

3

13

1,10,11,20

GND SENSE

+5V

A

7

11

1/4

TSM221

D01IN1210

1/4

TSM221

6

5

15

C1 200nF

R2 1M

1

4

OUT1

OUT2

OUT3

R

SENSE

0.3W

+

Speed Voltage)

A low cost solution to obtain a complete three phase brushless motor control application with speed and

torque closed control loop is shown in Fig. 23. This simple low cost solution is useful when high dynamic

performances and accuracy of the speed loop are not required.

The current regulation limit, which determines the torque , is given by Vcontrol/Rsense. The constant

toff of the PWM is fixed by Rx2 and Cx2.

The speed loop is realised using a Hall effect signal, whose frequency is proportional to the motor

speed. At each positive transition of the Hall effect sensors the monostable maintains the pulse for a

constant time , Ton, with a fixed amplitude, V5. The average value of this signal is proportional to the frequency of the Hall effect signal and the motor speed . An OP-AMP configured as an integrator , filters

this signal and compares it with a reference voltage, Vref, which sets the speed . The generated error

signal is the control voltage, Vcontrol, of the currrent loop. Therefore the current loop modifies the produced torque in order to regulate the speed at the desired value.

The values of Cf and R2 should be chosen to obtain a nearly ripple free op-amp output, even at low motor speed. This constrain limits the system bandwidth and so limits the response time of the loop.

The regulated speed, for a rotor with n pairs of permanent magnetic poles , is given by :

R1

1 +

ωm =

V5 ⋅ Ton ⋅ n +

with KG =

R2

⋅ Vref ⋅ 60 [RPM]

1

KG

R4

R3 + R4

⋅ Kt ⋅

1

Rsense

⋅

1

B

R2

⋅

R1

in which Kt, expressed in [Nm/A] , is the Motor Torque constant and B, expressed in [Nms], is the Total

Viscous Friction.

In most cases 1/KG can be neglected.

12/14

Page 13

AN1088 APPLICATION NOTE

The Ton values, given by KCx1Rx1, must be less than the period of the Hall effect electrical signal at

the desired motor speed , so Ton must meet the requirement of 1.1 :

( 1.1 ) Ton <

For the motor and the load used in this application, which have the following parameters :

-4

Jt = 10

[Kg ⋅ m2] (Motor plus Load Inertia Moment); Kt = 10-2 [Nm/A] ; B = 10-5 [Nms]

n=4 ; R1=100k +/- 10% [kΩ] ; R2=1M ±1[kW] ; Cf=220n [F]

A regulated speed of 6000RPM can be obtained with an accuracy of around +/-3%, considering Ton accuracy of +/-1% , the V5 and Vref mismatch of +/-1% .

If the speed is 6000RPM, there are 100 rotor revolution for second, with n=4, the Hall effect frequency

is 400Hz. Therefore Ton has to be lower than 2.5ms (according to equation 1.1).

The phase margin is about 45° and the response time of the speed loop for a speed step variation is

around 200ms .

6X6 BRUSHLESS APPLICATION

Figure 24. 6x6 Three Phase Brushlees Application Circuit

60

n ⋅ ωm

SPEED AND POSITION

FEEDBACK

CONTROL

LOGIC

Constant Toff PWM

Current Control. Two M74HC124 plus an LM339

Compara tor & monostable

+5V

100nF

1

A

15

PWM3

+5V

100nF

_

4

Q

16

23

M74HC123

monostable

14 8

B

1

+5V

+5V

8

+

4

IN1A

IN1B

IN2A

EN1

IN3A

IN3B

IN2B

EN3

LM339

EN2

1K

470pF

Vs

100uF

Vs

100uF

Vsense3

Vcontrol

100nF

IN1

IN2

IN3

EN1

EN2

EN3

100nF

IN1

IN2

IN3

EN1

EN2

EN3

1N4148

Vs

GND

1N4148

Vs

GND

1N4148

10nF

Vcp

L6234

Vref

Vcp

L6234

Vref

Vboot

SENSE2

1uF

1N4148

10nF

OUT1

OUT2

OUT3

SENSE1

Vboot

OUT1

OUT2

OUT3

SENSE1

SENSE2

1uF

220nF

220nF

OUT1A

OUT1B

OUT2A

OUT2B

OUT3A

OUT3B

THREE PHASE

BRUSHLESS

MOTOR

PWM2

PWM1

Compar ator & monostable

Compara tor & monostable

Vsense2

Vsense1

13/14

Page 14

AN1088 APPLICATION NOTE

Information furnished is believ ed to be accurate and reliable. How ever, STMicroelect ronics assumes no responsibility for the consequences

of use of such informati on nor for any infringement of patents or other ri ghts of third parties which may result from its use. No license is

granted by implication or otherw ise under any patent or patent rights of STMic roelectronics . Specification mentioned in this publication are

subject to c hange without notice. Thi s publication supersedes and replac es all information previously su ppl ie d. S TMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelect roni cs

© 2001 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.co m

14/14

Loading...

Loading...