AN1060

®

APPLICATION NOTE

FLYBACK CONVERTERS WITH THE L6561 PFC

CONTROLLER

by C. Adragna & G. Gattavari

The L6561, controller specifically designed for Power Factor Correction (PFC) circuits, may be successfully used in flyback converters as well.

The excellent performance of the device, along with its characteristics in terms of low current consumption, makes L6561-based flyback converters really attractive in medium-low power applications.

There are basically three different configurations that an L6561- bas ed flyback converter can assume,

each of them with its own characteristics, bene fits and peculiarities. This paper describes these configurations and highlights advantages/drawbacks with the aim of identifying the most suitable applications they can fit.

INTRODUCTION

Common practice bounds their use in conventional boost PFC stages, yet Transition Mode (TM) Power

Factor Corrector IC’s can be used in applications different from those they are primarily intended for.

This is particularly true for the L6561, PFC controller for medium-low power applications, because of its

peculiar characteristics.

Reference [2] presents a special example showing how to extend the use of this device to Mag Amp applications.

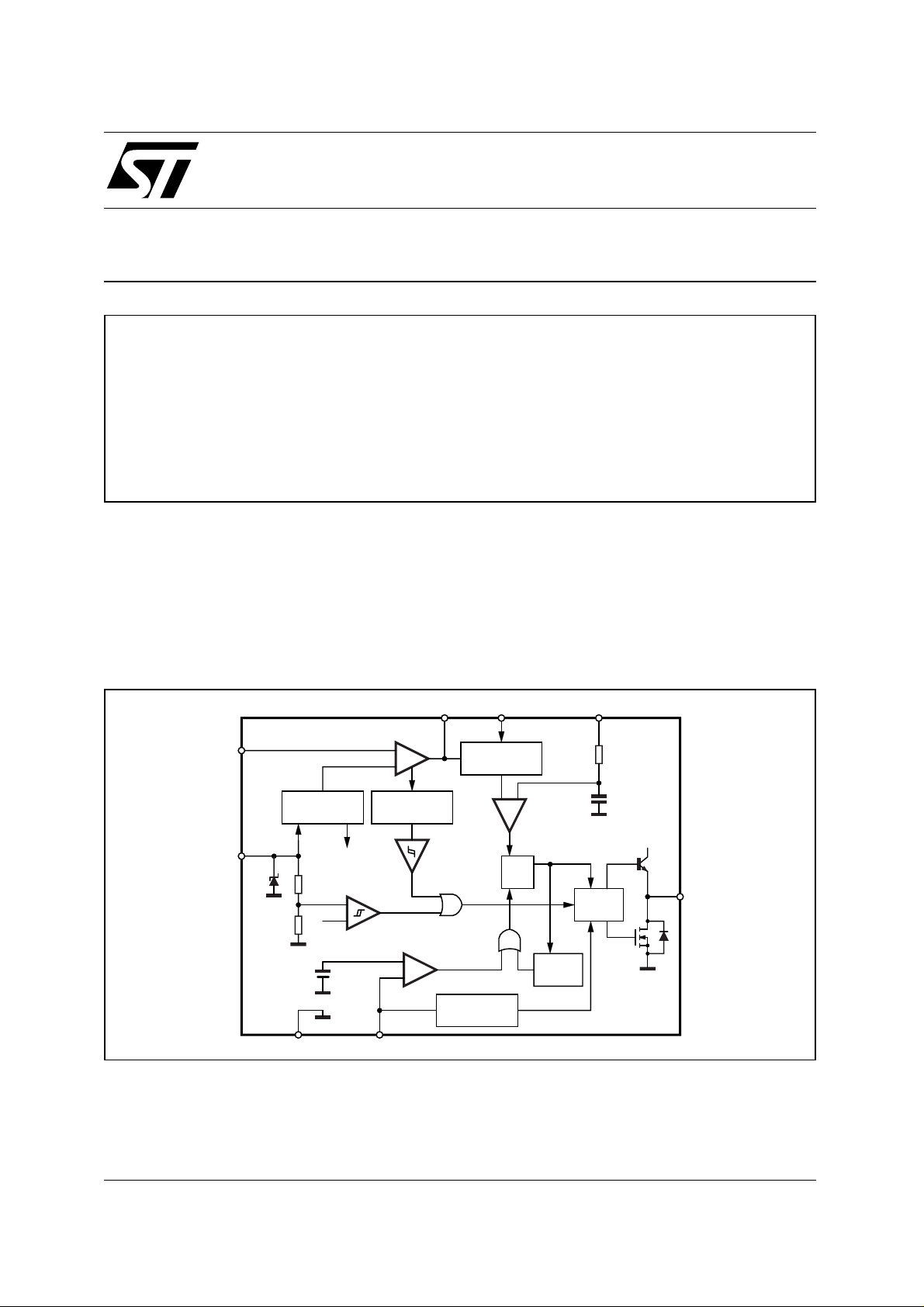

Figure 1 - L6561 Internal Block Diagram

COMP MULT CS

23 4

1

INV

V

-

2.5V

+

VOLTAGE

REGULATOR

8

CC

20V

R2

2.1V

1.6V

6

GND

INTERNAL

SUPPLY 7V

R1

V

REF2

OVER-VOLTAGE

+

-

5

ZCD

DETECTION

UVLO

ZERO CURRENT

+

-

DETECTOR

MULTIPLIER

+-

RSQ

DISABLE

5pF

STARTER

40K

DRIVER

D97IN547D

V

CC

7

GD

The outperforming L6561 offers a number of unique advantages that make the device an interesting alternative to the t raditionally used PWM controllers where quite a good performance is required at low

cost:

January 2003

1/11

AN1060 APPLICATION NOTE

disable function for power management and/or protection schemes;

•

true micropower start-up current, 50µA typ., for cost-effective start-up circuits;

•

very low quiescent current, 3mA typ., for high efficiency at light load;

•

two-level (static and dynamic) overvoltage protection (OVP);

•

on-chip RC filter on current sense pin for improved noise immunity;

•

pulse-by-pulse current limiting. In conjunction with TM operation, this ensures a safe operation under

•

short circuit conditions.

Refer to [1] for a detailed explanation of the internal architecture (shown in fig. 1) and the functionality of

the device.

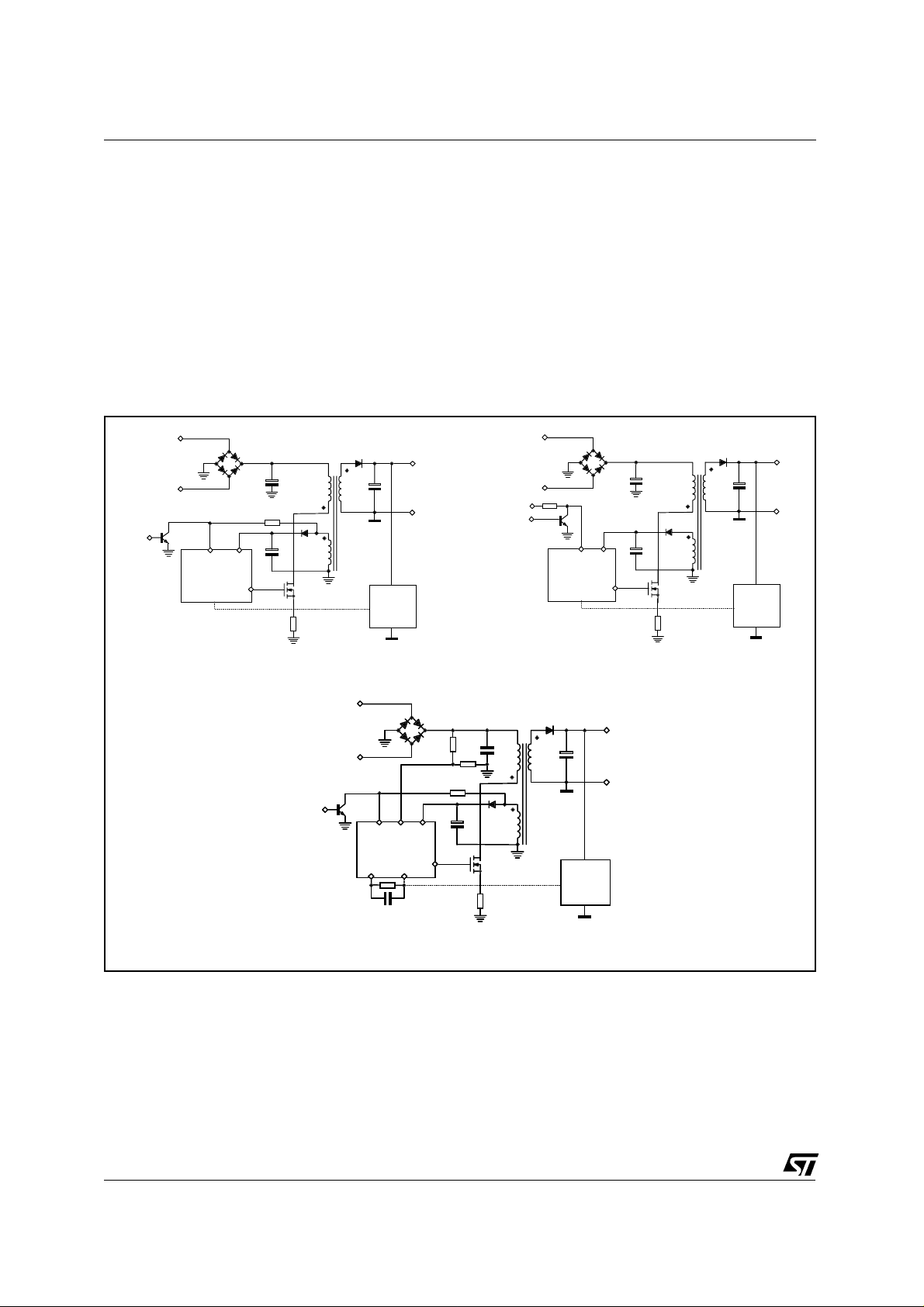

L6561-based flyback converters can be realised as schematically illustrated in fig. 2a, 2b, 2c, and which

will be referred to as "TM", "Synchronised" and "High-PF" respectively.

Figure 2. L6561-based flyback converter configurations

DISABLE

OPTO

TL431

Vout

+

Vac

VCCZCD

L6561

GD

BULK

C

a) TM Flyback

Vac

DISABLE

VCCZCD

MULT

IN

C

SYNCH

DISABLE

Vac

C

VCCZCD

L6561

GD

b) Sy nchronised Flyb ack

Vout

BULK

OPTO

TL431

Vout

+

L6561

GD

INV

COMP

OPTO

+

TL431

(BW<100 Hz)

c) High-PF Flyback

Each of them has its own peculiarities but they all share some key points:

low parts count, which helps reduce total cost and space;

•

high efficiency at very light load: an L6561-based flyback can be easily compliant with Blue Angel

•

standards;

standby function: the internal start-up timer may be used to make the system work at a (fixed) low

•

frequency under light load conditions, so as to minimise losses;

disable function: pin ZCD, if grounded, turns off the L6561 and reduces its consumption at a couple

•

of mA; this can be used either for power management or protection.

2/11

AN1060 APPLICATION NOTE

In the following, the three basic configurations will be taken into consideration and their advantages,

benefits and drawbacks will be highlighted so as to identify their most appr opriate field of application.

This will be made easier by some application examples.

TM Flyback

This configuration, very similar to a free-running flyback, always works on (actually, very close to) the

boundary between Continuous and Discontinuous Mode (i.e. Transition Mode, or TM), t heref ore at a frequency dependent on the input voltage and on the output current.

This type of operation requires a low induc tance and therefore a small-size magnetics but on t he other

hand, involves high peak current. Therefore it can be reasonably used for power levels up to 50-60 W in

110 V or wide-range mains applications, and up to 100 W with 220/240 V mains.

At high input voltage and especially at light load, the switch ON-time becomes very short and the switching frequency tends to become quite high. There is, however, a minimum ON-time (0.4-0.5µs) below

which it is not possible to go. This is due to the internal delay of the L6561 as well as the turn-off delay of

the MOSFET.

When this minimum is reached, TM operation can no longer be kept. The energy drawn each cycle exceeds the short-term demand from the load and the control loop delays MOSFET’s turn-on so as to

maintain the long-term energy balance. Switching becomes asynchronous, and this can be seen as a

"ghosting" of the waveform on the scope.

If the load is decreased furt her on, so many cycles need to be skipped that the amplitude of the drain

voltage ringing becomes very small, and the ZCD can no longer be triggered. In this case the internal

starter of the IC will start a new switching cycles sequence. Under this condition, the system will operate

in "burst" mode: there will be short periods of switching spaced out by long intervals where L6561’s OVP

keeps the switch in OFF state.

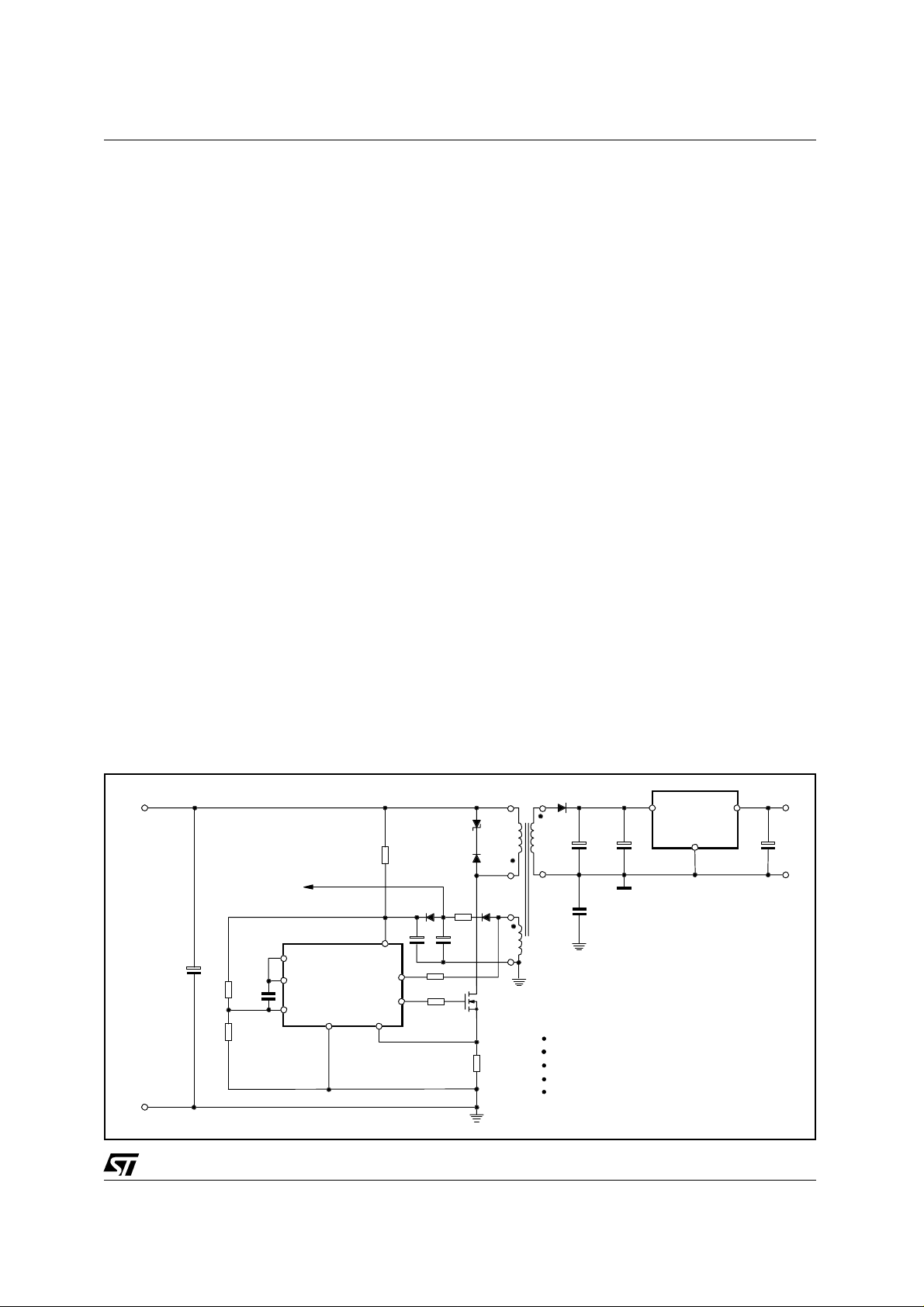

Fig. 3 shows a 7W power s upply, r ealis ed in TM flyback. It is intended as an auxiliary power supply suitable for systems provided with power management, such as monitor displays, printers, servers, photocopiers, fax machines, etc.

According to an approach that is becoming mor e and more popular, when the system is requested to go

into some low-consumption mode, a µP switches off the main SMPS. A small auxiliary supply, optimised

for a low power level, keeps alive the µP itself and the circuits needed for waking up the system again.

This approach allows to minimise the power consumption from the mains, in compliance with regulations

coming into force (such as Blue Angel and others).

Figure 3. 7W, Wide-range, Auxiliary Power Supply.

Vin=90 to 400 Vdc

BZW04- 154

Ω

Inpu t bulk capacitor

of the mai n S M PS

to L4990 A or L5991A

UC3843A/B or UC3 845A/B

or L4981A

100 nF

Ω

33 k

Ω

7.5 k

470 k

3

L6561

2

1

6

8

4

47 µF

5

7

1N4148

STD1NB60

STTA106

47 µF

47 k

Ω

22

22

Ω

Ω

1N4148

Ω

2

STPS360B

N1 N2

N3

TRANSFORMER SPECS:

CORE: E20x10x6, 3C85 material or equivalent

≈

0.5 mm air gap for a primary inductance of 1.7 mH

N1: 2 series windings 66 T each, AWG32

N2: 11 T, AWG24

N3: 21 T, AWG32

2x330

4.7 nF

µF

13

L4955V5.1

2

(∅0.57 mm)

5 Vdc / 1A

100

µF

(∅0.24 mm)

3/11

AN1060 APPLICATION NOTE

The converter is powered by the high-voltage DC bus, rangin g from 90 to 400 VDC, generated by the

front-end AC-DC stage (bridge rectifier + input capacitor) shared with the main SMPS (power factor corrected or not).

The output is post-regulated in order to provide a better regulation and supplies the µP as well as the

logic circuit needed to wake up the system.

The auxiliary winding will be properly designed so as to supply the controller(s) of the main SMPS besides powering the L6561. To minimise component count, a primary sensing feedback technique is

used.

The auxiliary winding is used also by the ZCD circuit for detecting transformer’s full demagnetisation and

turning on the MOSFET to start a new switching cycle (TM operation). The resistor driving the ZCD pin

is in the ten kΩ but can be optimised so as to achieve a "quasi zero-voltage turn-on" as described in Ref.

[1]. The optimum value depends mainly on the inductance of transformer’s primary winding and on the

of the power MOSFET, thus it can be found empirically after bench tests.

C

oss

With the component values shown in fig. 3 the wake-up time of the converter, that is the time the system

takes to start operating after being powered, does not exceed 3 s at 90 V

In fig. 4, the circuit of f ig. 3 is proposed with a different power rating: 15W output power so as to be able

to support USB function in computer equipment. The modifications concern the MOSFET, the transformer and the sense resistor on the primary side, the catch diode and the filter capacitors on the secondary side. They all have been increased in size.

Figure 4. 15W, Wide-range, Auxiliary Power Supply supporting USB function

supply and 1 s at 400 VDC.

DC

Vin=90 t o 400 Vd c

Input bulk capacitor

of the main SMPS

to L4990A or L5 991A

UC3843A/B or UC3845A/B

100 nF

Ω

33 k

Ω

7.5 k

or L4981A

BZW04-154

Ω

470 k

3

L6561

2

1

6

8

4

47 µF

5

7

STTA106

1N4148

22

STP3NB60FP

Ω

47 µF

47 k

Ω

22

1N4148

Ω

Ω

1

STPS560B

N1 N2

N3

TRANSFORMER SPECS:

CORE: E20x10x6, 3C85 material or equivalent

0.5 mm air gap for a primary inductance of 0.8 mH

≈

N1: 2 series windings 48 T each, AWG30

N2: 8 T, 2xAWG22

N3: 15 T, AWG32

2x1000

4.7 nF

µF

(∅0.24 mm)

13

L4955V5.1

2

(∅0.71 mm)

5 Vdc / 3A

220

µF

(∅0.30 mm)

Fig. 5 shows another example of low-power TM flyback application, an AC-DC adapter for battery

charger of cellular phones. The system looks very simple and very few parts are required.

The feedback uses a popular arrangement making use of a TL431 as secondary reference/error amplifier and of an optocoupler for transferring the control sign al to the primary side. This provides very good

regulation of the output voltage and galvanic isolation from the primary side at the same time.

The self-supply winding both powers the L6561and provides transformer’s demagnetisation signal to the

ZCD pin. The start-up cir cuit arrangement and its component values ensures that the wake-up time of

the converter does not exceed 3 s at 90 VAC supply (it will be less than 1 s at 270 V

AC

).

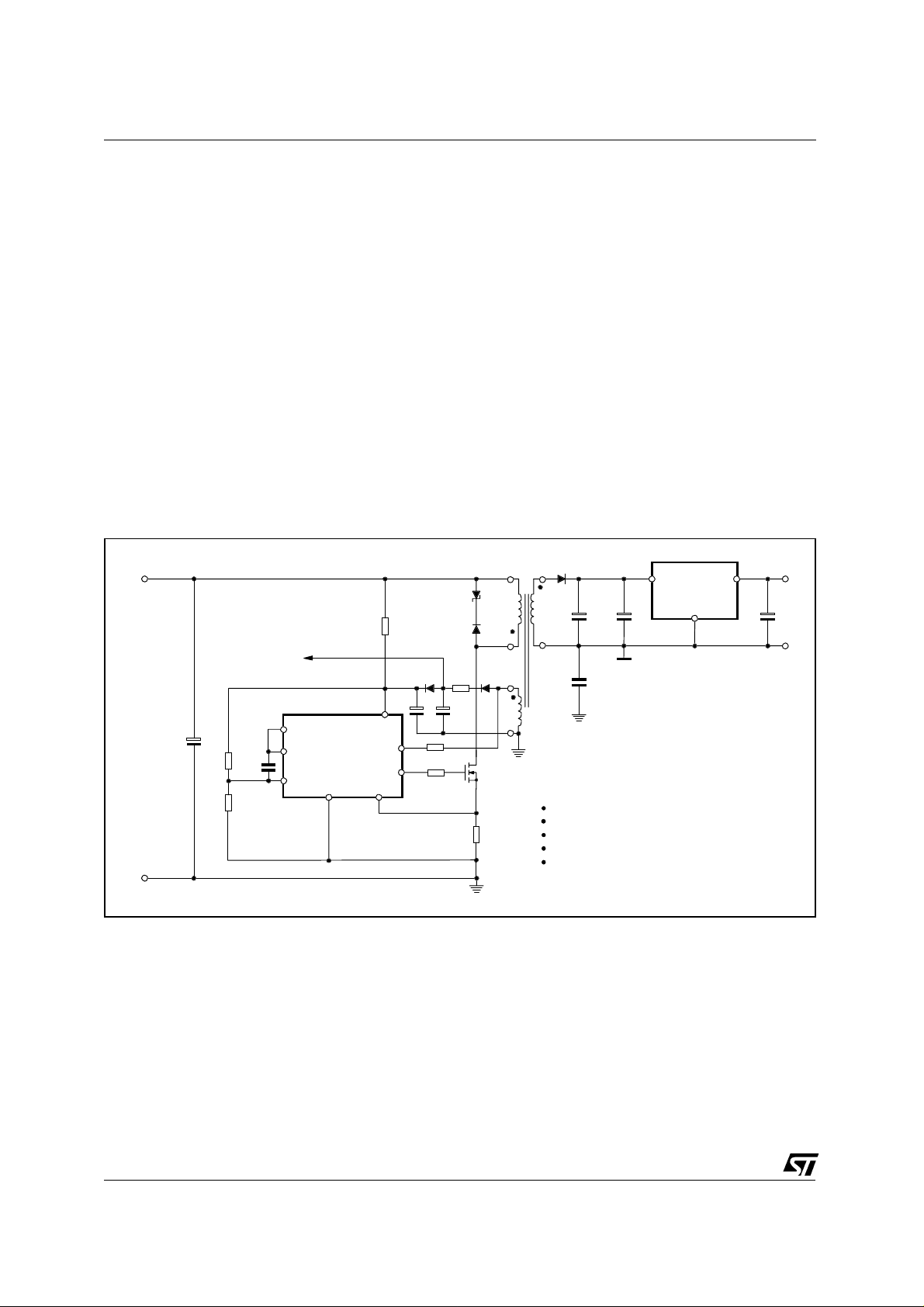

In fig. 6 an example of multi-output SMPS for inkjet printer is presented. The converter accepts input

voltages from 85 to 270 Vac and is rated for 40W output power. T he 28V output is used f or motors, the

12V output for the printhead and the 5V bus supplies the logic circuitry.

4/11

t

AN1060 APPLICATION NOTE

Figure 5. 7.5 W, Wide-range Mains AC-DC Adapter for cellular phones.

2200pF 2KV

2A fuse

N2

BYW98-100

2 x 470µF

85 to 270 Vac

4x1N40 07

10 µF

400V

110 k

BZW04-154

Ω

STTA106

Ω

47 k

N1

9V / 0.85A

16V

GND

4N35

3.3 nF

5

100 k

L6561

Ω

Ω

10 k

1N4148

F

µ

33

8

Ω

10

7

4

6

132

2

1/2 W

Ω

1 k

N3

STD1N B6 0

Ω

TRANSFORMER SPECS:

CORE: E19x8x5, 3C85 material or equivalent

≈

0.6 mm air gap for a primary inductance of

1.8mH

N1:170 T, AWG34 (∅0.20 mm)

N2: 15 T , 3x AWG34

N3: 19 T , AWG 34

4N35

TL431

Ω

1 k

0.022µF

1.8 k

Ω

4.7 k

Ω

The isolated feedback is realised with the configuration TL431 + optocoupler. Output cr oss-regulation is

improved by multiple sensing technique.

The system works in TM but can be forced to work at fixed frequency (that of L6561’s internal timer) for

minimum consumption at light load by the STANDBY signal (see fig. 6). This signal can be generated by

either the µP or a current sense circuit that enables low (fixed) frequency operation when t he load current falls below a defined threshold. To achieve this functionality, the ZCD pin is connected to ground

through a 4.3 kΩ resistor.

Figure 6. 40W, Wide-range Mains SMPS for Inkjet Printer.

STANDBY

DISABLE

47 k

47 k

85 to 270 Vac

Ω

Ω

2A fuse

5

3.3 nF

4.3 k

L6561

100 k

Ω

Ω

10 k

KBU4G

Ω

100

400V

132

4700pF 4KV

F

µ

110 k

8

7

4

6

1 k

Ω

Ω

56 k

Ω

2 W

STTA106

Ω

43 k

47µF

1N4148

STP4NA60FP

Ω

10

Ω

0.39

1/2 W

4N35

22 nF

250V

4.7M

N1

TL431

220

Ω

Ω

4700pF 4KV

4.7M

Ω

N2

N3

N4N5

4N35

2.7 k

BYW100-200

2 x 470µF

BYW98-100

2 x

1000µF

16V

BYW100-50

470µF

100 nF

Ω

TRANSFORMER SPECS:

CORE: ETD29x16x10, 3C85 material or equivalen

≈

N1: 6 9 T, AWG25

N2: 11 T, AWG25

N3: 9 T, AWG20

N4: 4 T, AWG25

N5: 1 1 T, AWG32

35V

16V

Ω

3.9 k

Ω

5.1 k

1 mm air gap for a primary inductance of 530 µH

(∅0.51 mm)

(∅0.89 mm)

(∅0.24 mm)

270 k

28V / 0.7A

12V / 1.5A

GND

5V / 0.5A

Ω

5/11

AN1060 APPLICATION NOTE

By directly grounding the Z CD pin, the converter will instead be shut down (DISABLE signal). This can

be used for either power m anagement ( an auxiliary supply like the one of fig. 3 will keep the µP alive) or

for protection, for example in case of overcurrent.

Pulse-by-pulse current limitation, inherent in the L6561, prevents input peak current from reaching too

high values. TM operation keeps pulse-by-pulse current limiting effective even under short circuit conditions and ensures that the transformer will never saturate.

Synchronis e d Fly back

L6561’s ZCD pin is intended for triggering MOSFET’s turn-on as the transformer is demagnetised, so as

to achieve TM operation. In this configuration the ZCD pin is used instead as a synchronisation input

and is driven by an external signal at a fixed frequency. This converter will then be exactly equal to a

synchronised flyback based on available standard current mode controllers.

A typical application of such a configuration is in multisynch monitors, where a synchronisation signal

coming from the horizontal deflection circuits of the display locks SMPS’ switching frequency so as to improve noise immunity.

An example of 17" multisynch monitor SMPS with the L6561 is shown in fig. 7. Capable of working with

wide-range mains, it is sized for 90W output power and can be synchronised from 31 to 82 kHz.

The primary side is extremely simple, yet the system features a number of functions needed in these

systems, such, overcurrent protection and synchronisation. There is also a protection against feedback

disconnection (the zener diode between the supply voltage and L6561’s pin 1).

Figure 7. 90W, Wide-range Mains SMPS for Multisynch Monitors.

85 to 270 Vac

SYNCH

(31 to 82 kH z)

DISABLE

47 k

47 k

5A fuse

Ω

Ω

KBU4G

220µF

400V

5

L6561

3

2

3.3 nF

1

Ω

100 k

Ω

10 k

TRANSFORM ER SPECS:

ETD44 core, 3C85 grade or equivalent

≈

1 mm air gap for a primary inductance of 38 0 µH

Ω

110 k

8

10

7

4

6

15 V

Ω

1 k

4N35

Ω

56 k

3W

STTA106

Ω

10

1N4148

47µF

Ω

Ω

Ω

1 k

1 k

1N4148

Ω

82 k

Ω

9.1 k

2.2 nF

N1 : 38 T, 2 series windings, 19T each, 4x AWG29 (∅0.29 mm)

N2 : 48 T, AWG25 (∅0.45 mm)

N3 : 32 T, AWG25

N4 : 3 T, AWG25

N5, N6 : 6 T, AWG25

N7 : 6 T, AWG32 (∅0.24 mm)

4700pF 4KV

4.7M

47 nF

250V

N1

N7

STP7NB60FP

0.47 Ω0.47

Ω

Ω

4700pF 4KV

Ω

4.7M

N2

N3

BYW100 - 100

N4

BYW100-100

N5

N6

BYW100-100

2.7 k

TL431

BYT11-800

STTA106

470µF 25V

470µF 25V

Ω

220µF

100V

4N35

330 pF

1000µF

16V

470 k

4.7 k

47

47µF 25V

1 nF

Ω

100µF

250V

Ω

Ω

100 k

200V

65W

80V

22µF

100V

Ω

330 k

10W

GND

6.3V

5W

+15V

5W

-15V

5W

Ω

6/11

AN1060 APPLICATION NOTE

In addition, a disable f unction is always available, which can be used f or any purpose the designer may

require.

Since the system works in Continuous Conduction Mode, especially at high switching frequency, a slope

compensation circuit has been added to prevent subharmonic oscillation at duty cycles greater than

50%.

Compared to the circuitry needed for a standard controller, the synchronisation interface is much simpler: just one resistor. Furthermore, when the synchronisation signal is missing, the system will run at the

frequency of the internal start-up timer (<15 kHz), which is lower than the minimum horizontal frequency.

Under this conditions the power demanded by the monitor circuits is usually very low, and the system

will go on working properly. This automatic functionality is extremely useful for minimising power consumption from the mains, again with the aim of meeting the relevant regulations.

High-PF Flyback.

This configuration works in Transition Mode t oo, but quite different ly from the TM flyback previously discussed. The input capacitance is here so small that t he input voltage is very close to a rectified sinewave. Besides, the control loop has a narrow bandwidth so as to be little sensitive to the twice mains frequency ripple appearing at the output. Ultimately, it is a PFC stage realised in f lyback topology, rather

than in boost topology as usual.

Actually, the high power factor (PF) exhibited by this topology can be considered just as an additional

benefit but not the main reason that makes this configuration attractive. In fact, despite a PF greater then

0.9 can be easily achieved, it is a real challenge to comply with EMC norms regarding THD of line current, especially in universal mains applications. There are, however, several applications in the lowpower range (to which EMC norms do not apply) that can benefit from the advantages offered by a highPF flyback converter.

For a given power rating, the input capacitance can be 200 times less, compared to a conventional flyback. The bulky and costly high voltage electrolytic capacitor located after the bridge rectifier is replaced

by a smaller low-cost film capacitor, with a considerable cut of cost and space.

Efficiency is high at heavy load, more than 90% is achievable: TM operation ensures low turn-on losses

in the MOSFET and the high PF reduces dissipation in the bridge rectifier. This, in turn, minimises the

requirements on the heatsink.

A few drawbacks, however, limit the applications that the high-PF flyback can fit (AC-DC adapters, battery chargers, low-power SMPS, etc.) and which one has to be aware of.

Because of the small input capacitance, the system is unable to cope with line missing cycles at heavy

load. Like in boost PFC stages, the transient response to step-load changes is poor: as to this point,

speeding up the control loop may lead to a compromise between an acceptable t ransient response and

a reasonably high PF.

The output voltage exhibits a considerable twice-mains-frequency ripple, unavoidable if a high PF is desired. Speeding up the control loop may lead to a compromise between a reasonably low output ripple

and a reasonably high PF. To keep the ripple low, a large output capacitance (in the thousand µF) is

anyway required: however, cheap standar d capacitors and not costly high-quality par ts are needed. In

fact, a low ESR and an adequate AC current capability are automatically achieved with so large a capacitance. Besides, in conventional flyback converters there is usually plenty of output capacitance too,

thus this is not so dramatic as it may seem.

As a result, secondary post-regulation will be required where tight specifications on the output ripple

and/or on the transient behaviour are given. This is true but is also what happens in numerous applications with a conventional flyback.

Please refer to Ref. [3] for a detailed explanation of the design of this kind of converter.

Fig. 8 shows the electrical schematic of a 30W AC-DC adapter based on high-PF flyback concept. It ac-

cepts universal mains and delivers 15V DC, 2A max. with a peak-to-peak twice mains frequency ripple

below 1V.

The multiplier is biased with a part ition of t he input voltage and provides a quasi-sinusoidal reference to

the current sense comparator. The feedback network uses a TL431+optocoupler configuration. Unlike

the previously considered ones, in this case opto’s transistor is connected as an emitter follower and

drives the input of L6561’s error amplifier. This aims at keeping the gain of the feedback and of the overall loop at twice mains frequency low, so as to achieve a high power factor.

7/11

AN1060 APPLICATION NOTE

Figure 8. 30W, Wide-range Mains, High-PF, AC-DC Adapter.

2A fuse

85 to 270

Vac

2.2 nF

DF06M

470 nF

20 k

4N35

P6KE170A

Ω

3 M

2

Ω

9.1 k

Ω

39 k

220 nF

Ω

20 k

2.4 k

3

L6561

1

6

Ω

Ω

470 k

Ω

STTA106

47 µF

8

5

10

Ω

7

4

STP4NA60

0.5

Ω

STPS8H100D 3x2200 µF

N1 N2

1N4148

N3

Ω

47 k

4.7 nF

DISABLE

TRANSFORMER SPECS:

Core: ETD29, 3C85 grade or equivalent

≈

1 mm airgap for 1 mH primary inductance.

N1: 2 series windings, 45 T each, AWG27 (∅0.41 mm)

N2: 14 T,5xAWG27

N3: 14T, AWG32 (∅0.24 mm).

5.1 k

4N35

1 µF

TL431

The optional 2.2µF capacitor connected in parallel to the upper resistor of the feedback divider acts as a

soft-start circuit. The diode between the capacitor and TL431’s control pin decouple the capacitor during

steady-state operation so that it does not interfere with t he loop gain. The other diode provides a discharge path when the converter is turned off, so that the system is always soft-started at power-up.

15 Vdc / 2A

Ω

Ω

12 k

2.2 µF

Ω

2.2 k

1N4148

Ω

2.4 k

1N4148

Figure 9. 30W, offline, High-PF battery charger with secondary post-regulation

2A fuse

85 to 270

Vac

220 nF 3 M

1 nF

DF06M

30 k

20 k

2xBZW0485

Ω

3

Ω

Ω

1 µF

5.1 k

2

1

Ω

220 k

5

L6561

6

Ω

47 k

47 µF

8

7

4

STTA10 6

Ω

Ω

22

Ω

10

STP5NA60

Ω

0.5

N1

1N4148

N3

STPS8H100D

N2

2200 µF

2200 µF

TRANSFORMER SPEC:

Core E25/13/7, 3C85 grade or equivalent

≈

0.7 mm air gap for a primary inductance of 720 µH

N1 : 2 series winding, 39 T each, AWG28 (∅ 0.37 mm)

N2 : 12T, 3xAWG26 (∅ 0.40mm)

N3 : 14T, AWG31 (∅ 0.23 mm)

Ω

20 k

1

2

22 k

4.7 nF

6

L4955

Ω

43

220

BAT46

7

5

Ω

2.7 k

1W

BAT46

Ω

15 Vdc / 2A

Ω

20 k

22 µF

Fig. 9 presents a 30W off-line, universal mains battery charger suitable for lead-acid batteries. Compared to the previous circuit, the primary side do es not change so much. The basic difference concerns

the feedback that here is based on sensing the voltage developed by the auxiliary winding.

This technique ensures a high PF in such flyback configuration because of t he poor coupling between

secondary and auxiliary winding at low frequency. It is then quite easy to get a gain low enough at twice

8/11

AN1060 APPLICATION NOTE

mains frequency. The drawback of primary sensing t ec hnique is its poor load regulation, but this is of no

concern in this case.

The post regulation on the secondary side with the L4955 linear regulator (see Ref. [4] for information)

ensures a high accuracy of the end-of-charge output voltage, as well as a precise constant current characteristic during battery charge. Additionally, the charge current can be adjusted from 1 to 2 A by means

of the 22 kΩ trimmer. The schottky diode in series to t he output prevents battery discharge when t his is

connected and the charger is off. The diode connected between pin 4 and pin 7 of the L4955 and the

220Ω resistor limit the current flowing in case of reverse battery connection.

Figure 10. 30W, High-PF battery charger with secondary voltage/current regulation

2A FUSE

85 to 270

Vac

20 k

1 nF

Ω

DF06M

470 nF

4N35

Ω

39 k

2.4 k

220 nF

Ω

9.1 k

20 k

Ω

2xBZW0485

100-200

10µF

50V

N1

BYW

N3

Ω

3 M

3

2

1

Ω

470 k

5

L6561

6

Ω

47 k

1N4148

47 µF

8

7

4

Ω

1

L78L12

2

10

Ω

STTA106

3

STP5NA60

Ω

0.5

STPS8H100D

560 µF

N2

2.2

15 Vdc / 2A

560 µF

4N35

Ω

10 k

Ω

k

100 nF

Ω

11 k

4.7 µF

0.1

2200

Ω

5.1 k

µF

Ω

2

8

1

5

100 nF

2200

2.2 µF

2.2 k

6

TSM

101

µF

Ω

12 k

Ω

130

1 µF

1.1 k

2.2 µF

1N4148

1N4148

Ω

Ω

3

7

4

TRANSFORMER SPE C:

Core E25/13 / 7, 3C 85 gra de or equi valent

≈

0.7 mm air gap for a primary inductance of 720 µH

N1 : 2 series winding, 39 T each, AWG28 (∅ 0.37 mm)

N2 : 12T, 3xAWG26 (∅ 0.40mm)

N3 : 25T, AWG31 (∅ 0.23 mm)

4.7 nF

The same battery charger can be realised without a post-regulator. Such a system is shown in fig. 10. It

uses again an isolated feedback with an optocoupler and a secondary side reference/error amplifier, the

TSM101, for voltage and current regulation.

This device basically incorporates a TL431 and two op-amps with or-ed outputs. One op-amp will be

used for constant voltage control and the other one for constant current control. A precise internal current generator, available at pin 3, can be used to offset the intervention threshold of the constant current

regulation. For more details, please refer to Ref. [5].

The voltage generated by the self-supply winding tracks the output voltage, which can be quite low (<9V)

when the battery is nearly exhausted. To let the system work even under this condition the self-supply

will deliver a voltage above L6561’s UVLO when the output voltage falls to its minimum. As a result,

however, when the charger is in voltage regulat ion (battery disconnected or end-of-charge) t he self-s upply voltage will exceed the maximum rating of the L6561. This requires the use of a linear regulator

(L78L12 in the present case) to limit the excursion of the voltage. The diode in series to the output of the

L78L12 prevents current diversion through the regulator at start-up.

The switch connected between TSM101’s pin 2 and ground enables/disables the above mentioned internal current reference. If t he switch is open, pin 2 is pulled up through the 10 kΩ resistor, the internal current generator is disabled and the constant current characteristic is set at 2A. If the switch is closed, pin

2 is grounded and t he internal current reference will be enabled. Pin 3 will be offset by about 160 mV

and the constant current threshold will be set at 0.3A.

9/11

AN1060 APPLICATION NOTE

Conclusions

The three basic configurations of L6561-based flyback converters have been presented. The common

characteristics, as well as the ones peculiar of each configuration have been analised.

A number of application examples has been presented for each category. They highlight how simple and

cheap but, this notwithstanding, well-performing L6561-based systems are.

It does not sound out of place, therefore, to say that the L6561 can be considered as a really inter esting

alternative to today’s high-runner current mode controllers, especially where quite good performance

and robustness are required at low cost.

References

[1] "L6561, Enhanced Transition Mode Power Factor Corrector", (AN966)

[2] "L6561-based Switcher Replaces Mag Amps in Silver Boxes", (AN1007)

[3] "Design Equations of High-Power Factor Flyback Converters Based on the L6561", (AN1059)

[4] "L4955 Family Application Guide", (AN932)

[5] "TSM101 Voltage and Current Controller", Datasheet

10/11

AN1060 APPLICATION NOTE

Information furnished is bel i eved to be accurat e and reliable. However, STMicroelec tronics assumes no responsibility for the consequences

of use of such inform ation nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherw ise under any patent or patent rights of STMic roelectronics . Specification mentioned in this publi cation are

subject to c hange without notice. Thi s publication supersedes and replac es all information previously su ppl ie d. S TMicroelectroni cs products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroel ec tr on i c s GRO U P OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Moro cco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

11/11

Loading...

Loading...