AN1048

Application note

ST7 software LCD driver

Introduction

This note describes a technique for driving Liquid Crystal Displays (LCD) with any standard

ST7 Microcontroller (MCU) i.e without any specific on-chip LCD driver hardware. This

technique offers a solution for applications which require a display at low cost together with

the versatile capabilities of the standard ST7 MCUs. This note also provides a technique to

control the LCD contrast through software.

After an introduction on LCDs in Section 1, Section 2 & 3 of this note describes the typical

waveforms required to drive an LCD with a multiplexing rate of 1 or 2 (duplex) and 4

(quadruplex). Section 3 presents a solution based on a standard ST7 MCU directly driving a

quadruplex LCD. This solution can be implemented with any ST7 MCU as it only requires

the standard I/O ports and one timer, both of which are standard features on all ST7 MCUs.

Section 4 describes how to control the contrast through software. Finally, Section 5 gives a

brief overview of the LCD demo board including the board schematics. The demo board,

based on a ST72F321B microcontroller, allows the user to develop and test applications

using an LCD device.

The program size (~300 bytes), the CPU load required for controlling the LCD (0.2%), and

the number of external components is kept to the minimum (two external resistors per COM

line). The number of I/O’s is the same as a solution using an on-chip LCD hardware driver or

an external hardware LCD driver. With software contrast control, it is a very flexible solution

that can be adapted easily to a range of applications.

May 2006 Rev 5 1/21

www.st.com

Contents AN1048

Contents

1 LCD requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 LCD drive signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Single backplane LCD drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Duplexed LCD drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Quadruplex LCD drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 LCD mean voltage calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 Contrast calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Example of a quadruplex LCD with ST72F321B . . . . . . . . . . . . . . . . . . 11

4 Software contrast control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Contrast calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 LCD demo board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5 Oscillation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21

AN1048 LCD requirements

1 LCD requirements

With a low Root Mean Square (RMS i.e.: ) voltage applied to it, an LCD is

Mean Signal

2

()

practically transparent. The LCD segment is inactive(OFF) if the RMS voltage is below the

LCD threshold voltage and is active(ON) if the LCD RMS voltage is above the threshold

voltage. The LCD threshold voltage depends on the quality of the liquid used in the LCD and

the temperature. The optical contrast is defined by the difference in transparency of a LCD

segment ON (dark) and a LCD segment OFF (transparent). The optical contrast depends on

the difference between the RMS voltage on an ON segment (V

an OFF segment (V

). The higher the difference between VON(rms) and V

OFF

higher the optical contrast. The optical contrast also depends on the level of V

LCD threshold voltage. If V

completely or almost transparent. If V

is below or close to the threshold voltage, the LCD is

ON

is close or above the threshold voltage, the LCD is

OFF

) and the RMS voltage on

ON

(rms), the

OFF

versus the

ON

completely dark.

In this document, contrast is defined as D = V

(rms) / V

ON

OFF

(rms).

The applied LCD voltage must alternate to give a zero DC value in order to ensure a long

LCD life time.

The higher the multiplexing rates, the lower the contrast. The signal period has also to be

short enough to avoid visible flickering on the display.

The LCD voltage for each segment is equal to the difference between the S and COM

voltages (see Figure 1).

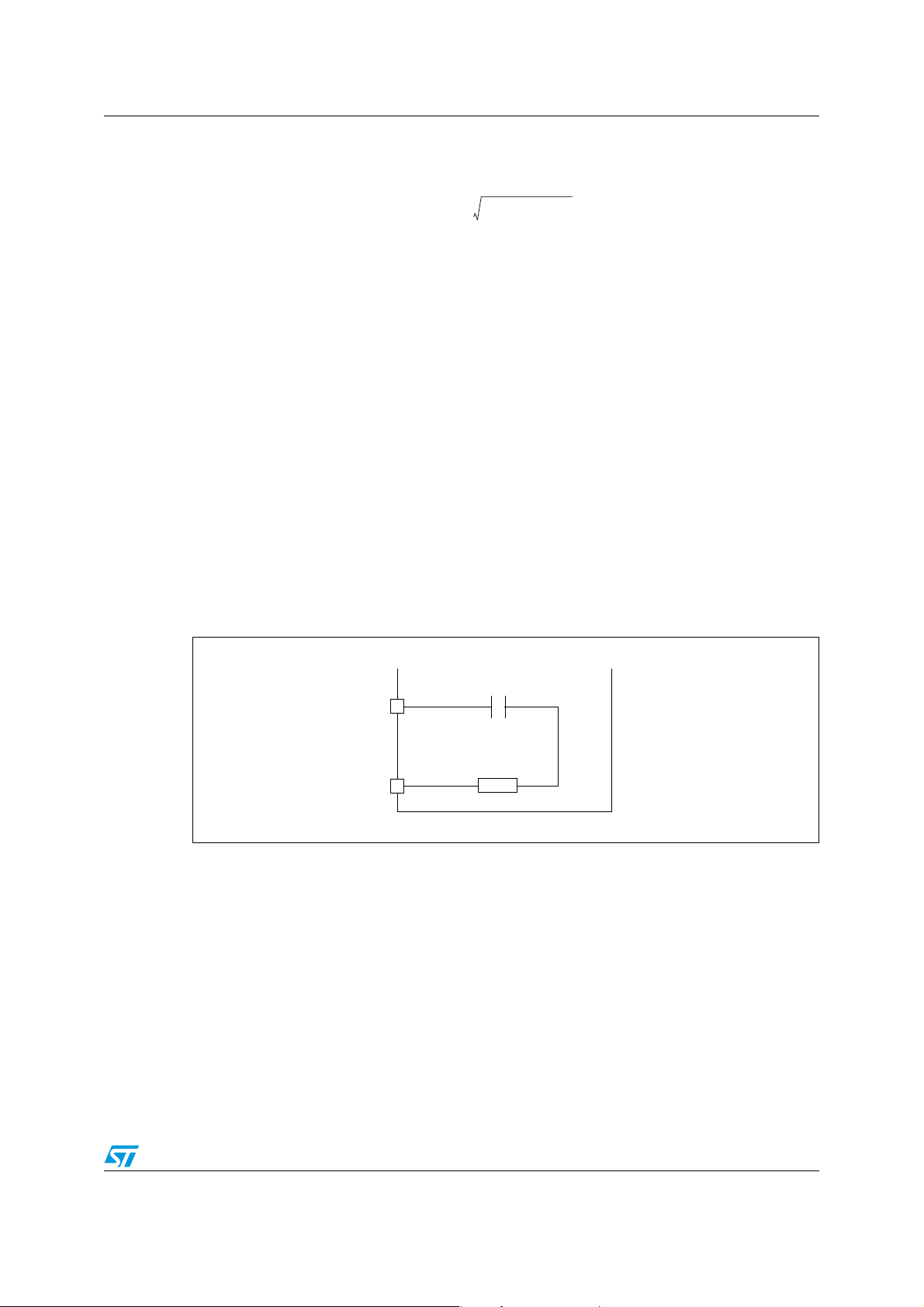

Figure 1. Equivalent Electrical Schematic of an LCD Segment

C

S

Rs

COM

Note: The DC Value should never be more than 100mV (refer to the LCD manufacturer’s

datasheet). Otherwise the life time can be shortened. The frequency range is 30 - 200Hz

typically. If it is less, it flickers; if it is more, the power consumption increases.

3/21

LCD drive signals AN1048

2 LCD drive signals

2.1 Single backplane LCD drive

In a single backplane drive, each LCD segment is connected to a segment line(Sx) and to

one backplane(common line) common to all the segments. A display using S segments is

driven with S+1 MCU output lines. The backplane is driven with a “COM” signal controlled

between 0 and V

When switching a segment “ON”, a signal with opposite polarity to “COM” is sent to the

corresponding “Segment” pin. When the non-inverted signal “COM” is sent to the “Segment”

pin, the segment is “OFF”. Using an MCU, the I/O operates in output mode either at logic 0

or 1.

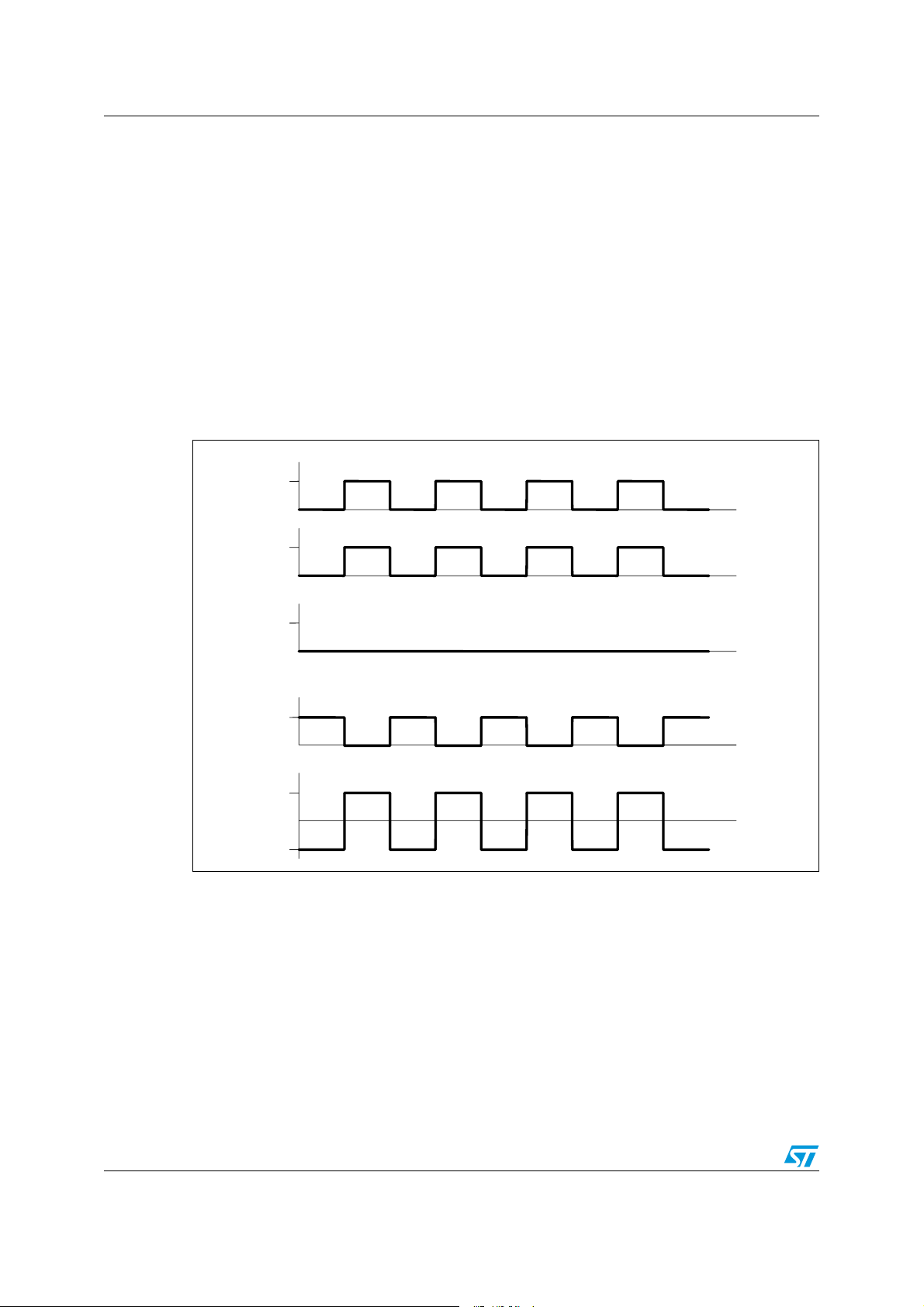

Figure 2. LCD signals for direct drive

COM

+Vdd

S

+Vdd

with a duty cycle of 50%.

DD

S1=COM-S

+Vdd

S

+Vdd

S1=COM-S

+Vdd

-Vdd

2.2 Duplexed LCD drive

In a duplexed drive, two backplanes are used instead of one. Each LCD segment line(Sx) is

connected to two LCD segments, each one connected on the other side to one of the two

backplanes or common lines(refer to Figure 3). Thus, only (S/2)+2 MCU pins are necessary

to drive an LCD with S segments.

Three different voltage levels have to be generated on the backplanes: 0, V

“Segment” voltage levels are 0 and V

and LCD waveforms. The intermediate voltage V

voltages. The ST7 I/O pins selected as “Backplanes” are set by software to output mode for

O

F

F

O

N

/2 and VDD. The

DD

only. Figure 4 shows typical Backplane, Segment

DD

DD/2 is only required for the Backplane

4/21

AN1048 LCD drive signals

0 or VDD levels and to high impedance input mode for VDD/2. When one backplane is active,

the other one is neutralised by applying V

/2 to it. This VDD/2 voltage is defined by two

DD

resistors of equal value, externally connected to the I/O pin. By using an MCU with flexible

I/O pin configuration, a duplexed LCD drive can be implemented with only 2 external

resistors bridge (each on two com lines).

Figure 3. Basic LCD Segment Connection in duplexed mode

S1

S2 S3

S11 S12

COM1

COM2

Figure 4. LCD signals for duplexed mode (used in the ST7 example)

COM1

+Vdd

+Vdd/2

COM2

+Vdd

+Vdd/2

S1

+Vdd

CASE1 CASE2 CASE3 CASE4

S11=COM1-S1

+Vdd

+Vdd/2

-Vdd/2

-Vdd

SEGMENT1

S12=COM2-S1

+Vdd

+Vdd/2

-Vdd/2

-Vdd

SEGMENT2

OFF ON ONOFF

OFFOFFONON

5/21

LCD drive signals AN1048

2.3 Quadruplex LCD drive

In a quadruplex LCD drive, four backplanes are used. Each LCD pin is connected to four

LCD segments, with each segment connected on the other side to one of the four

backplanes. Thus, only (S/4)+4 MCU pins are necessary to drive an LCD with S segments.

For example: to drive an LCD with 128 segments (32 x4), only 36 I/O ports are required (32

I/O ports to drive the segments, 4 I/O ports to drive the backplanes).

Three different voltage levels have to be generated on the common lines: 0, V

The Segment line voltage levels are 0 and V

only. The LCD segment is inactive if the

DD

/2, VDD.

DD

RMS voltage is below the LCD threshold voltage and is active if the LCD RMS voltage is

above the threshold. Figure 6 shows typical Backplane, Segment and LCD waveforms. The

intermediate voltage V

selected as “Backplanes” are set by software to output mode for 0 or V

high impedence input mode for V

/2 is only required for Backplane voltages. The MCU I/O pins

DD

/2. The VDD/2 voltage is defined by two resistors of

DD

levels and to the

DD

equal value, externally connected to the I/O pins. When one backplane or COM is active, the

other ones are neutralized by applying V

/2 to them.

DD

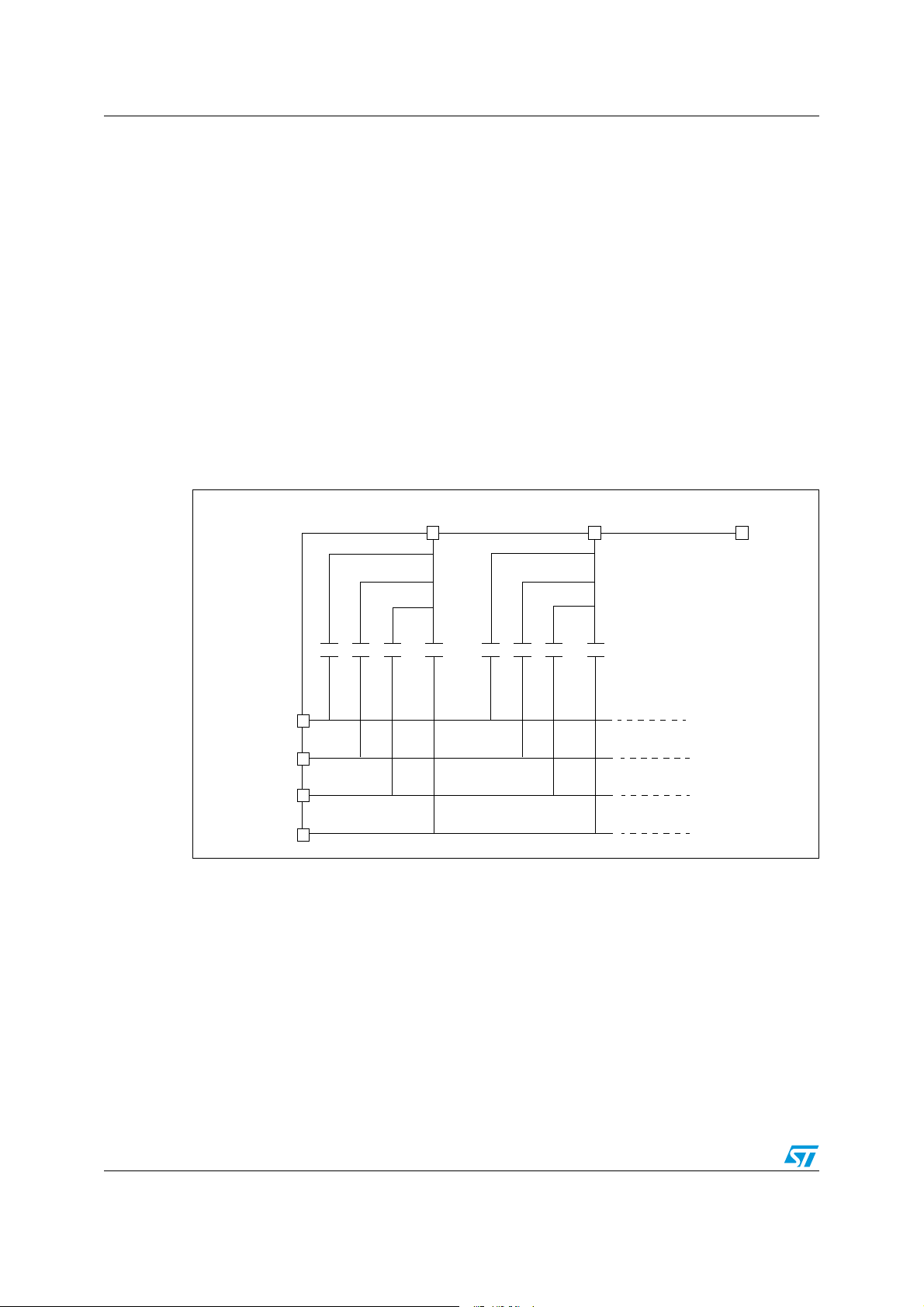

Figure 5. Basic LCD Segment Connection in Quadruplexed Mode

COM1

S11

S12

S13

S14

S1

S2

S3

COM2

COM3

COM4

6/21

AN1048 LCD drive signals

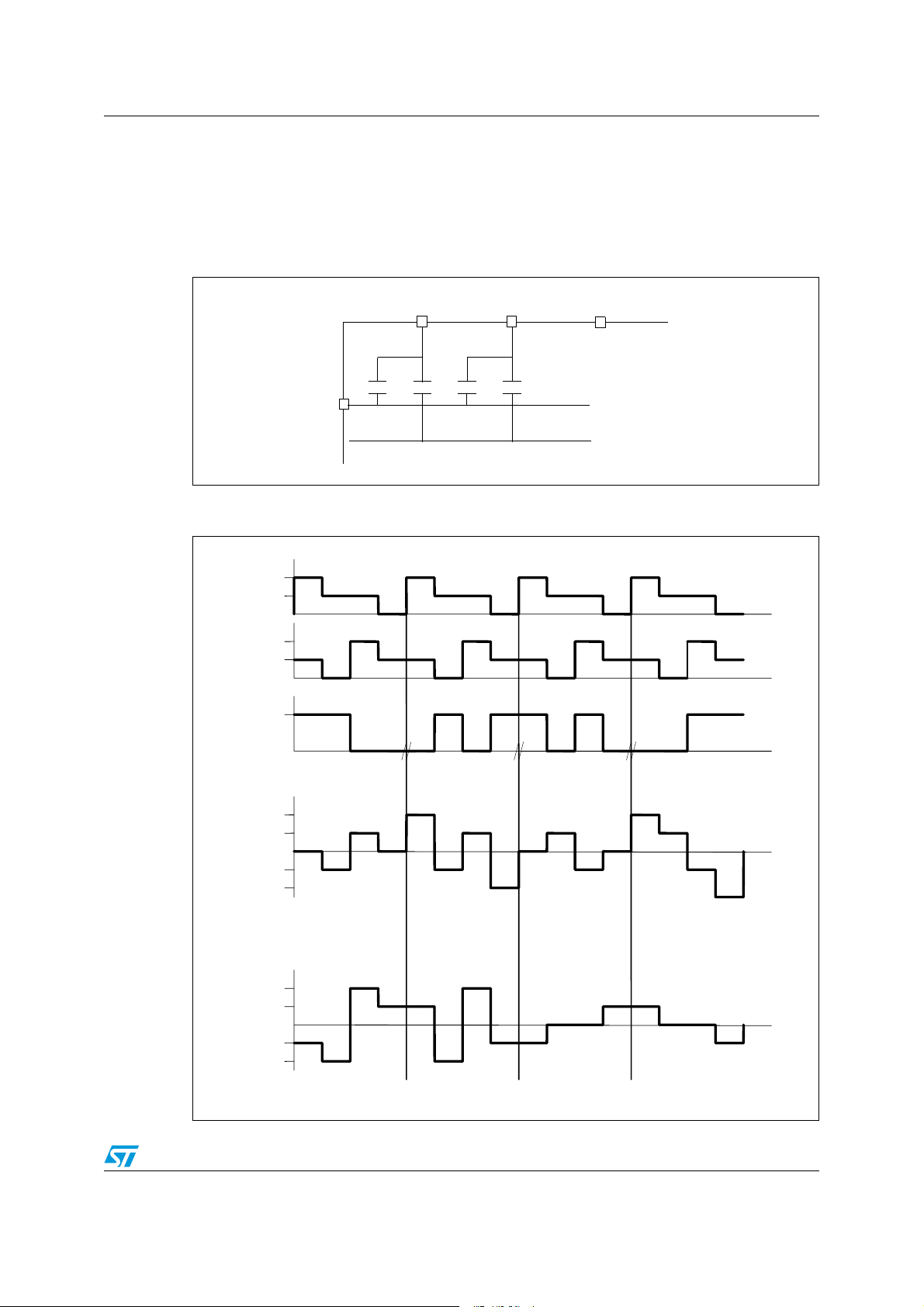

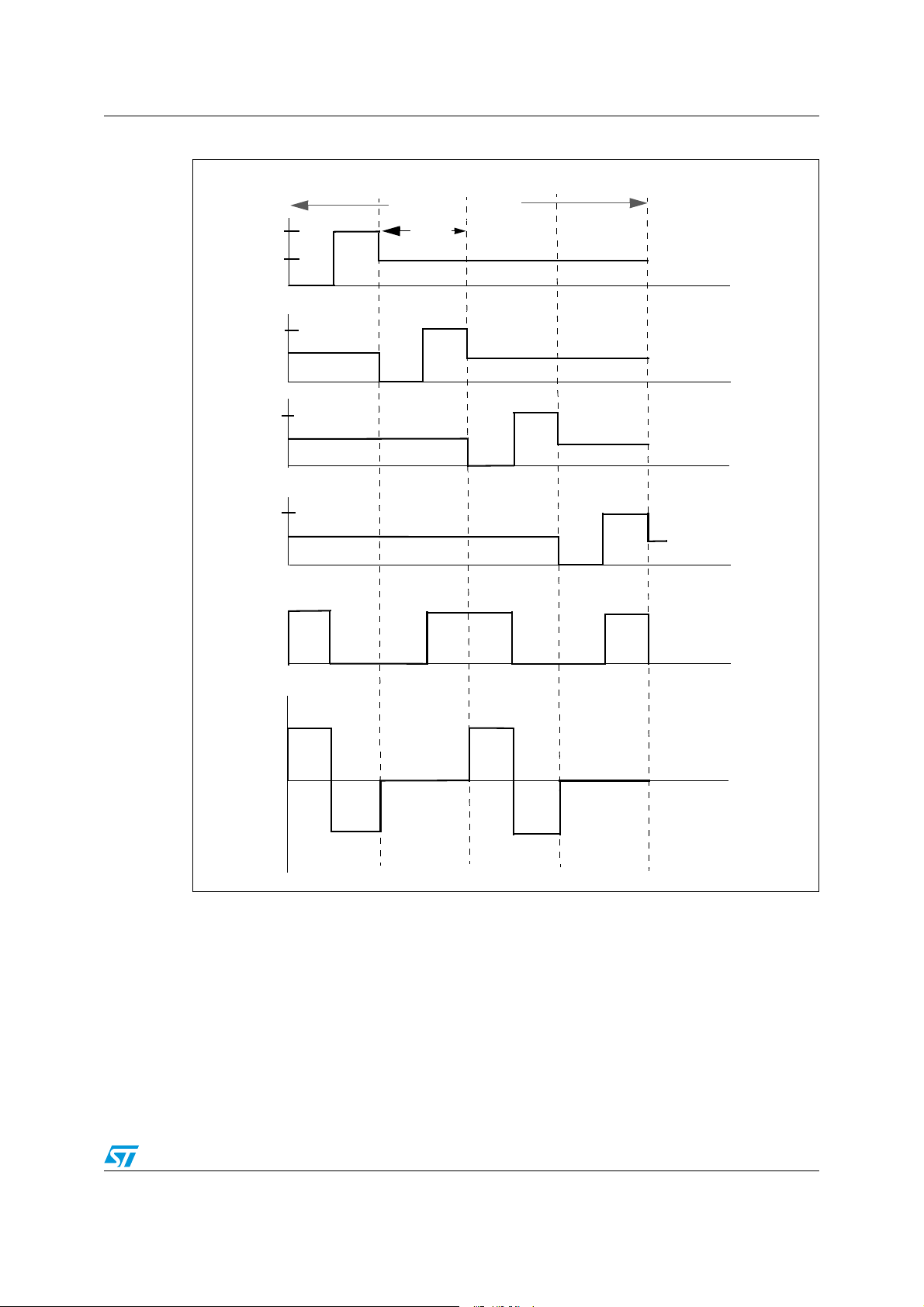

Figure 6. LCD timing diagram for Quadruplex Mode

Single Frame Period

T/4

Control

Period

T/2

3T/8

T

Vcom

Vdd/2

COM1

T/8

COM2

COM3

COM4

Vsegx

Vseg-Vcom

Seg x_1 ON

Vsegx-Vcom1

Segx_2 Off

Segx_3 ON Segx_4 Off

Vsegx-Vcom4

7/21

LCD drive signals AN1048

Figure 7. LCD Timing Diagram for a single segment

Vsegx

Segx

Vsegx

Segx_1 (ON)

Vcom1

Segx_1(off)

2.3.1 LCD mean voltage calculation

The LCD mean voltage must be very close to zero to guarantee long life to the LCD. The LCD mean

voltage for ON and OFF periods can be calculated as:

Vmean(ON) = 1/8 Vseg + 1/8 (-Vcom) + 3(Vseg - Vr/2) + 3(-Vr/2) ----(1)

Vmean(Off) = 3(Vseg/2) + 3(-Vr/2) -----(2)

Vmean(ON) and Vmean(Off) assume identical periods for each phase.

From eqn (1) & (2), to get Vmean(ON) and Vmean(Off) = zero

Vseg = Vcom = Vr = Vcc

Where:

Vcom = Max voltage on COM line

Vr/2 = Voltage in the middle of the resistor bridge applied on the COM line

Vseg = Max voltage on Segx line

Vcc = Microcontroller power supply

8/21

AN1048 LCD drive signals

2.3.2 Contrast calculation

The performance of an LCD driving system is defined by the contrast:

Contrast(D) = Vrms(ON) / Vrms(Off)

For the quadruplex signal as described on the previous page:

T

Vrms ON()

=

1

--- f t()2td

∫

T

0

Vrms ON()

Vrms ON()

Vrms ON()

Vrms ON()0.661Vcc=

Vrms OFF()

=

T

--8

1

---

Vcc()2td

∫

T

0

⎛⎞

1

Vcc()

=

---

⎜⎟

T

⎝⎠

7

Vcc()

-----16

T

--8

1

--- 0()td

∫

T

0

2

2

2T

-------

++=

2T

------8

Vcc()2td

++=

∫

T

--8

2

T

--- Vcc()

8

8

0()td

∫

T

--8

Vcc()

T

-------------------

---

8

T

Vcc

⎛⎞

----------

∫

⎝⎠

2T

------8

T

∫

2T

------8

2

4

2

2

2

Vcc

⎛⎞

----------

⎝⎠

2

6T()8⁄⋅+⋅+⋅

td

td

Vrms OFF()

Vrms OFF()0.43Vcc=

=

Contrast(D) = Vrms(ON) / Vrms(OFF) = 0.661Vcc / 0.43Vcc = 1.52

3

Vcc()

-----16

2

9/21

LCD drive signals AN1048

For comparison, a hardware LCD drive uses 1/3 bias voltage. With 1/3 bias control, the

contrast value (D) is 1.73. Therefore, 1/3 bias gives only a small advantage of contrast

versus temperature. This advantage is reduced to zero when using software contrast

control.

10/21

AN1048 Example of a quadruplex LCD with ST72F321B

3 Example of a quadruplex LCD with ST72F321B

The following example describes a drive for a quadruplex mode (4COM) LCD using the

ST72F321B (TQFP64 pin package 10 x 10). Refer to Figure 8. The only external

components needed for driving the LCD are eight resistors. The resistor value of 56K is

used to reduce the DC voltage on the LCD(~7.5 mV). This value can be further decreased

to get the better DC voltage on the LCD but this will result in an increase of the current

consumption. One I/O port per segment and one I/O port for each COM line are needed to

drive the LCD. For example: To drive a quadruplex LCD that has 128 segments (with 32

segment lines and 4 COM lines) requires only a total of 36 I/O ports.

In the example program, the Port PA0-A5, PB0-B7, PD0-D7, PF7-F0, PE7-E6 pins are

connected to the 32 segment lines and are used to generate the segment signals. Ports

PC3...PC0 are connected to the 4 COM lines and used to generate the COM signals. The

LCD driver consists of two initialization routines (port init, timer init) and a TimerA interrupt

routine “timer_rt”. To activate the LCD, these two initialization routines have to be called.

After these routines are called, the ST7 gets the timer Output Compare 1 & Output Compare

2 interrupts.

11/21

Example of a quadruplex LCD with ST72F321B AN1048

Figure 8. Hardware Connection Diagram

Vcc

PC0-C3

PA0-A5

PB0-B7

PD0-D7

56K

56K

Network Resistors

Common Lines

LCD GLASS

Segment Lines

6

8

8

PF0-F7

PE6-E7

ST72F321B

The LCD Timing is generated by the TimerA output compare interrupt. Each cycle consists

of four phases, one for each backplane. Each COM line generates its waveform during the

corresponding phase e.g. COM1 line during phase1. During other phases it remains at level

V

/2. Each phase consists of two parts:

DD

1. Active time

2. Dead time

During the Active time, the segment lines and COM lines are used to drive the LCD. During

dead time Segment and COM lines are used to tune the contrast.

12/21

8

2

AN1048 Example of a quadruplex LCD with ST72F321B

Active time starts after the Output Compare 1 interrupt and dead time starts after the Output

Compare 2 interrupt. A total of 16 interrupts are generated in each frame period with four

interrupts per control period. There are 2 Output Compare 1 events (OC1_1 and OC1_2)

and 2 Output Compare 2 events in each phase.These are explained as follows:

During OC1_1, V

is applied to the segments which have to be turned ON and 0 for the

DD

segments which have to be turned OFF. The COM line which corresponds to this phase is

set to low level. Other COM lines are set to level V

DD

/2.

During OC2, all segments and COM lines are inactive (set to low level) if we want to

decrease the Vrms (see Figure 9) and COM lines are set low, segments are set high if we

want to increase the Vrms (see Figure 10).

During OC1_2, Segment Lines are supplied with voltage levels which are inverted to the one

applied during OC1_1.COM line which corresponds to this phase is set to high level.Other

COM lines are set to level V

DD

/2.

Again during OC2, all segments and COM lines are inactive(set to low level) if we want to

decrease the Vrms and COM lines are set high, segments are set low if we want to increase

the Vrms (see Figure 10).

13/21

Example of a quadruplex LCD with ST72F321B AN1048

Figure 9. LCD timing diagram with Dead & Active Time (to decrease Vrms)

dead time

control

period

Vcom

Vdd/2

COM1

Vcom

Vdd/2

COM2

Vcom

Vdd/2

COM3

Vcom

Vdd/2

COM4

Vseg

Segx

(ON)

active

time

T/4 T/2 3T/4 T

Vseg

Vdd/2

Segx_1

On

Vcom

Vdd/2

Segx_1

Off

oc1_1

OC2

OC1_2

OC2

oc1_1

14/21

AN1048 Example of a quadruplex LCD with ST72F321B

Figure 10. LCD timing diagram with Active and dead time (to increase Vrms)

Dead time

Period

COM1

ActiveControl

time

COM2

COM3

COM4

Vseg

Segx

(ON)

Vseg

Vdd/2

Segx_1

(ON)

T/ 4

T/2

3T/4

T

Vseg

Vdd/2

Segx_1

(Off)

oc1_1

oc2

oc1_2

oc2

15/21

Software contrast control AN1048

4 Software contrast control

The software contrast control is under pending patent from STMicroelectronics. The use of

this technique with a non-STMicroelectronics' Microcontroller has to be agreed by

STMicroelectronics.

The LCD contrast is controlled entirely by software without the use of any external

components. LCD contrast can be adjusted to the optimal value depending on the operating

voltage of the LCD used. The LCD contrast is controlled by varying the timing of dead phase

as shown in the LCD timing diagram.

Deadtime can be used to decrease as well as to increase the Vrms of the LCD. Deadtime is

the voltage compensation time to regulate rms voltage up and down. Dead time can be

implemented either after each control period or at the end of the frame. To avoid flickering,

the duration of the dead time must be adjusted depending on the quality of LCD and the

frequency of the frame.

In the example in Figure 9, the Rms value of the LCD decreases if the duration of dead time

is increased and Rms value increases if the duration of dead time decreases. In Figure 10,

this works the opposite way.

4.1 Contrast calculations

Let the frame period = T + xT

where T - Active Time, xT- Dead Time

x- Proportion of dead time, Vx - Voltage during the dead time

TXT+()

1

Vrms ON()

Vrms ON()

Vrms ON()

=

=

=

---------------- TxT+

---------------- -

TxT+

1

---------------- TxT+

∫

1

ft()2td

0

T

⎛⎞

---

⎜⎟

8

Vcc()2tVcc–()2tVcc()2⁄()2tVx

⎜⎟

∫

⎜⎟

0

⎝⎠

⎛⎞

2

Vcc()

⎜⎟

⎝⎠

T

--- Vcc()

8

2T

-------

8

+d

∫

T

---

8

2

T

---

8

T

+d

∫

2T

------ -

8

Vcc()

------------------ -

4

2

2T

------ - Vx

8

xT

------ -

8

2

()t8⋅d

+d

∫

0

2

xT

⎛⎞

------ -

⋅

⎝⎠

8⋅+⋅+⋅+⋅

8

16/21

AN1048 Software contrast control

Vrms ON()

=

⎛⎞

()

1

------------

------------------------- - Vx()2x⋅+

⎜⎟

1x+

⎝⎠

14V cc

32

2

Since Vx = 0 (incase of a decrease in Vrms)

2

14V cc

()

1

------------

Vrms ON()

=

Vrms ON()

Vrms OFF()

1x+

1

-----------1x+

=

-------------------------32

0.661V cc=

T

---

⎛⎞

1

8

⎜⎟

---------------- -

TxT+

0()t0()tVcc()2⁄()

∫

⎜⎟

0

⎝⎠

2T

-------

8

+d

∫

T

---

8

T

+d

∫

2T

-------

8

xT

------ -

8

2

tVx

()t8⋅d

+d

∫

0

2

2

6Vcc

()

---------------------- Vx2x⋅+

32

Vrms OFF()

=

⎛⎞

1

------------

⎜⎟

1x+

⎝⎠

Since Vx = 0 (incase of a decrease in Vrms)

Vrms OFF()

Contrast Dx()

1

0.18Vcc=

-----------1x+

1

⎛⎞

⎝⎠

-------------------------------------------------=

0.661V cc

-----------1x+

1

⎛⎞

⎝⎠

-----------1x+

0.18Vcc

Where Dx = Contrast calculation with contrast control method

17/21

LCD demo board AN1048

The contrast D, between VON and V

optical contrast by tuning V

ON

5 LCD demo board

5.1 Schematic

PF7

PF5

PF3

PD1

PB7

PB5

PB3

PB1

PF6

PD0

PB6

PB4

PB2

PB0

S1

SW-PB

7k

R5

4.

RESET

C12

22pf

hz

16M

C11

22pf

OSCINOSC2

10µ F

+5

2

1

HEADER

PF1

PE7

PA5

PA3

PA1

VIM878-DP6.35-RH-W-HV

101112131415161718 19

PF4

PF2

PF0

PE6

PA4

PA2

PA0

C13

100nF

GND

PA4

4

9

PA5

5

0

5

1

5

2

VPP

5

3

RESET

5

4

5

5

5

6

7

5

OSC2

5

8

OSC1

5

9

6

0

6

1

6

2

6

3

6

4

PC0

PC1

2021222324252627282930313233343536

PC3

PC2

U1

PD7

PD5

PD3

U2

123456789

PD6

PD4

PD2

+5

Y1

C6

C1 100nF

+5

JP1

2

is constant (quality of contrast). We only change the

OFF

close to the threshold value of the LCD.

+5

123

4

J1

SO

I

PC5

M

SS

SCK

OSI

M

100nF

C3

10µ F+5 +5

F

10µ

C2

100nF

100nF

C4

F

C9

10µ

PA4

PA5

VPP

RESET

EVD

TLI

VSS2

OSC2

OSC1

VDD2

PE2

PE3

+5

48

VSS1

PA6/ SD A

PA7 / SCL I

PE0/ TD O

PE1/R DI

4

PE

1

3

2

1

J2

PA3

PA2

PA1

PA0

PC7

42

46

47

PA043PA144PA245PA3

VDD1

SS/AIN15

PC7/

ST72321B

PE52PE63PE74PB0/PWM35PB1/PWM26PB2/PWM17PB3/PWM08PB4/ARTCLK9PB5/ARTIC1

PE6

PE7

PB0

PB1

PB2

OSCIN

PC6

41

PC6/SCK/ICCCLK

PB3

OSC1

R6

R1

R2

PC5

PC4

39

40

/AIN14

OSI

M

PC5/

10

PB4

PB5

JP2

10K

R7

+5

10k

10K

+5

7K

4.

PC3

PC2

PC1

36

37

38

CAP2-B

CAP1-B

I

I

ICCDATA

PC2/

PC3/

PC4/M ISO/

PB6/ARTIC211PB712PD0/AINO13PD1/AIN114PD2/AIN215PD3/AIN3

PB6

PB7

PD0

1234

5678910

CC

I

R4

4.7K

7K

R3

VPP

RESET

PC6

PC4

R11

56K

R10

56K

56K

R9

56K

R8

PC3

+5

100nF

C5

F

C10

10µ

PC0

33

34

VSS0

VDD0

PC0/OCMP2-B/AIN1235PC1/OCMP1-B/AIN13

A

16

PD1

PD2

PD3

4.

56K

PORT C

R15

56K

R14

56K

56K

R13

R12

56K

PC0

PC1

PC2

PF7/E X TC L K -A

7

PF

2

3

PF6/IC AP1-A

PF6

3

1

PF5/AI N11/ ICA P2-A

PF5

0

3

PF4/AI N10/ OCMP1-

PF4

9

2

PF3/A I N 9/ OC M P2- A

PF3

2

8

PF2

PF2

7

2

PF1/B EE P

PF0/A I N 8/ M CO

VSS3

VDD3

VSSA

VAREF

PD7/ A I N7

PD6/ A I N6

PD5/ A I N5

PD4/ A I N4

C8

1

PF

6

2

PF0

2

5

24

3

2

2

2

1

2

PD7

2

0

PD6

9

1

C7

PD5

1

8

PD4

7

1

SPI

18/21

AN1048 LCD demo board

5.2 Power supply

The LCD demo board should be supplied by a maximum DC voltage of 5V. The board is

provided with the connector JP1 for this board supply.

Note: For the demo software loaded inside the micro, the board should be supplied with 5V. The

software attached to this application note displays the word “EMBEDDED” and tunes

automatically its contrast from transparent to dark with the ST software pattented method.

The Vrms increase is performed by putting the segment voltage once at Vdd, once at -Vdd

during the dead times, the Vrms decrease is performed by putting at 0 the segment voltage

during the same dead times. The voltage average is then kept. Refer to the software

attached to this application note for more details.

5.3 Programming

The demo board uses the ST72F321B microcontroller and can be programmed using the

ICC protocol. The board is provided with the ICC connnector JP2. By default, OSC_TYP is

programmed as a resonator oscillator in the option bytes. You can disable the option bytes

when you want to use the ICC clock to program the micro.

5.4 Reset

The device can be reset by pressing the switch s1 on the demo board.

5.5 Oscillation system

The demo board is mounted with a 16 MHz crystal with 8 MHz fcpu. You can change this

clock value but need to modify the timer setting inside the software accordingly.

19/21

Revision history AN1048

6 Revision history

Table 1. Document revision history

Date Revision Changes

Document reformatted

References to ST72F321 changed to ST72F321B

09-May-2006 5

Formulae for VRMS(ON) and VRMS(OFF) corrected, Section 4.1 on

page 16

Note updated, Section 5.2 on page 19

20/21

AN1048

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

21/21

Loading...

Loading...