®

ASD™

AC Switch Family

MAIN APPLICATIONS

AC static switching in appliance control systems

■

Drive of low power high inductive or resistive

■

loads like

- relay, valve, solenoid, dispenser

- pump, fan, micro-motor

- defrost heater

FEATURES

Blocking voltage : V

■

Avalanche controlled : VCLtyp = 1100 V

■

Nominal conducting current : I

■

Gate triggering current : IGT<10mA

■

■ Switch integrated driver

■ High noise immunity : static dV/dt >500V/µs

DRM/VRRM

= +/-700V

T(RMS)

=2A

ACS120-7SB/SFP/ST

AC LINE SWITCH

COM

G

OUT

DPAK

ACS120-7SB

G

COM

OUT

TO-220FPAB

ACS120-7SFP

BENEFITS

■ Needs no more external protection snubber or

varistor

■

Enables equipment to meet IEC 61000-4-5

■

Reduces component count up to 80 %

■

Interfaces directly with the microcontroller

■

Eliminates any gate kick back on the

microcontroller

■

Allows straightforward connection of several

ACS™ on same cooling pad.

DESCRIPTION

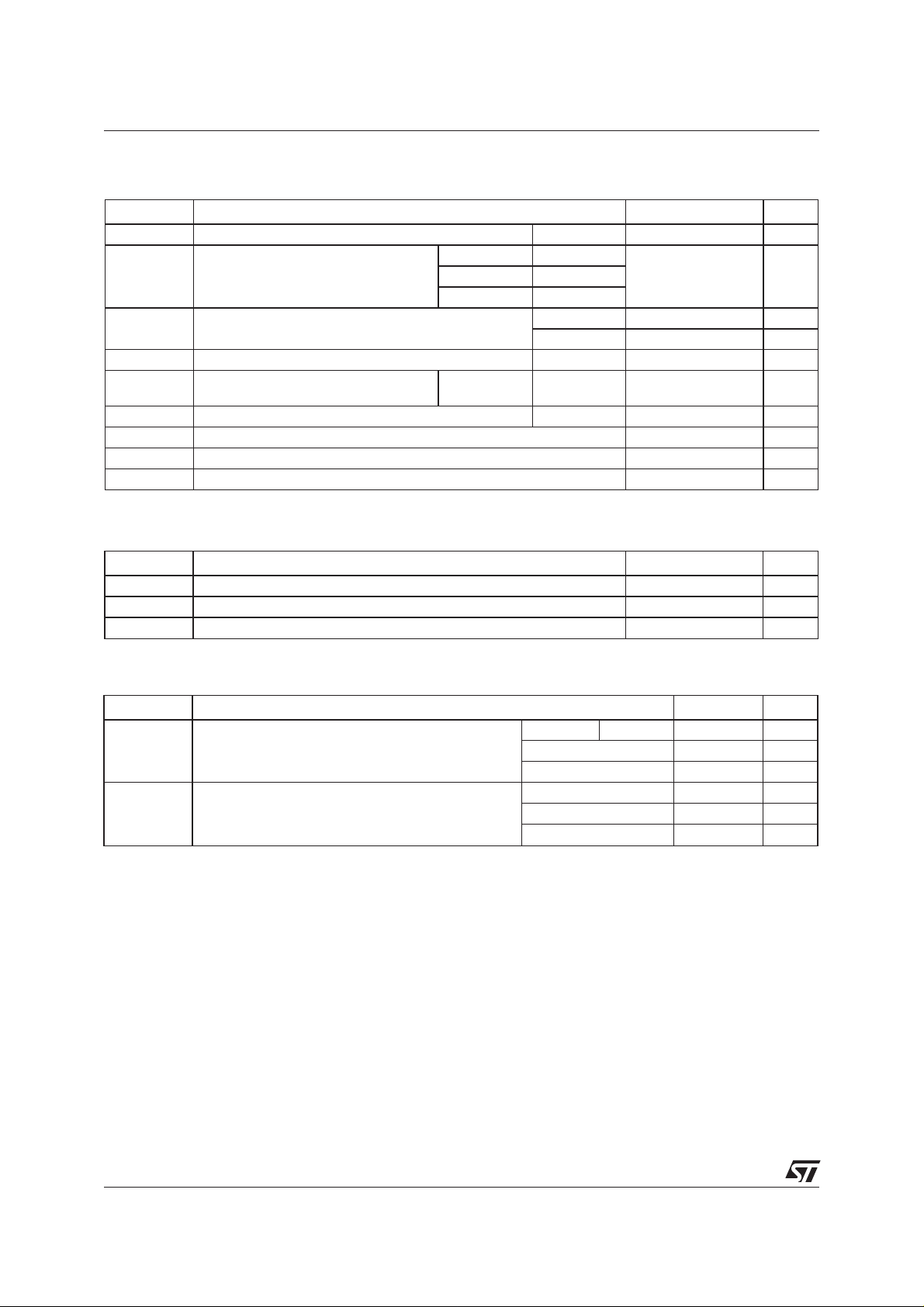

The ACS120 belongs to the AC line switch family

built around the ASD™ concept. This high performanceswitchcircuitisableto control a loadup to 2

A.

The ACS™ switch embeds a high voltage clampingstructure to absorb the inductiveturnoff energy

anda gate level shifterdriver to separate thedigital

controller from the main switch. It is triggered with

a negative gate current flowing out of the gate pin.

G

COM

OUT

TO-220AB

ACS120-7ST

FUNCTIONAL DIAGRAM

OUT

S

ON

D

April 2003 - Ed: 2A

COM

G

1/11

ACS120-7SB/SFP/ST

ABSOLUTE RATINGS (limiting values)

For either positive or negative polarity of pin OUT voltage in respect to pin COM voltage

Symbol Parameter Value Unit

V

DRM/VRRM

I

T(RMS)

I

TSM

2

I

t Fusing capability tp = 10ms 2.2 A²s

dI/dt Repetitiveon-state current critical rate

V

PP

Tstg Storagetemperature range - 40 to + 150 °C

Tj Operating junction temperature range - 30 to + 125 °C

Tl Maximum lead soldering temperature during 10s 260 °C

Note 1: according to test described by IEC61000-4-5 standard & Figure 3.

GATE CHARACTERISTICS (maximum values)

Symbol Parameter Value Unit

P

G (AV)

I

GM

V

GM

Repetitive peak off-state voltage Tj = -10 °C 700 V

RMS on-state current full cycle sine

wave 50 to 60 Hz

DPAK Tc = 115 °C 2 A

TO-220FPAB Tc = °C

TO-220AB Tc = 115 °C

Non repetitive surge peak on-state current

Tj initial = 25°C, full cycle sine wave

of rise I

= 10mA (tr < 100ns)

G

Non repetitive line peak pulse voltage

Tj = 125°C

F =50 Hz 20 A

F =60 Hz 11 A

F = 120 Hz 50 A/µs

note 1

2kV

Average gate power dissipation 0.1 W

Peak gate current (tp = 20µs) 1 A

Peak positive gate voltage (in respect to pin COM) 5 V

THERMAL RESISTANCES

Symbol Parameter Value Unit

Rth (j-a) Junctionto ambient S = 0.5cm² DPAK 70 °C/W

TO-220FPAB 60 °C/W

TO-220AB 60 °C/W

Rth (j-l) Junction to tab/lead for full cycle sine wave

conduction

S = Copper surface under Tab

DPAK 2.6 °C/W

TO-220FPAB 3.5 °C/W

TO-220AB 2.6 °C/W

2/11

PARAMETER DESCRIPTION

Parameter Symbol Parameter description

ACS120-7SB/SFP/ST

I

GT

V

GT

V

GD

I

H

I

L

V

TM

V

TO

Triggering gate current

Triggering gate voltage

Non-triggering gate voltage

Holding current

Latching current

Peak on-state voltage drop

On state threshold voltage

Rd On state dynamic resistance

I

DRM/IRRM

Maximum forward or reverse leakage current

dV/dt Critical rate of rise of off-state voltage

(dV/dt)c Critical rate of rise of commutating off-state voltage

(dI/dt)c Critical rate of decrease of commutating on-state current

V

CL

I

CL

Clamping voltage

Clamping current

ELECTRICAL CHARACTERISTICS

For either positive or negative polarity of pin OUT voltage in respect to pin COM voltage.

Symbol Test Conditions Values Unit

I

GT

V

GT

V

GD

I

H

I

L

V

TM

V

TO

Rd Tj=125°C MAX 200 mΩ

I

DRM

I

RRM

dV/dt V

(dI/dt)c (dV/dt)c = 20V/µs Tj=125°C MIN 1 A/ms

V

CL

V

=12V (DC) RL=140Ω QII - QIII Tj=25°C MAX 10 mA

OUT

V

=12V (DC) RL=140Ω QII - QIII Tj=25°C MAX 1 V

OUT

V

OUT=VDRMRL

I

= 100mA gate open Tj=25°C MAX 45 mA

OUT

=3.3kΩ Tj=125°C MIN 0.15 V

IG= 20mA Tj=25°C MAX 65 mA

I

= 2.8A tp=380µs Tj=25°C MAX 1.3 V

OUT

Tj=125°C MAX 0.85 V

/

V

= 700V Tj=25°C MAX 2 µA

OUT

Tj=125°C MAX 200

=460V gate open Tj=110°C MIN 500 V/µs

OUT

ICL= 1mA tp=1ms Tj=25°C TYP 1100 V

3/11

ACS120-7SB/SFP/ST

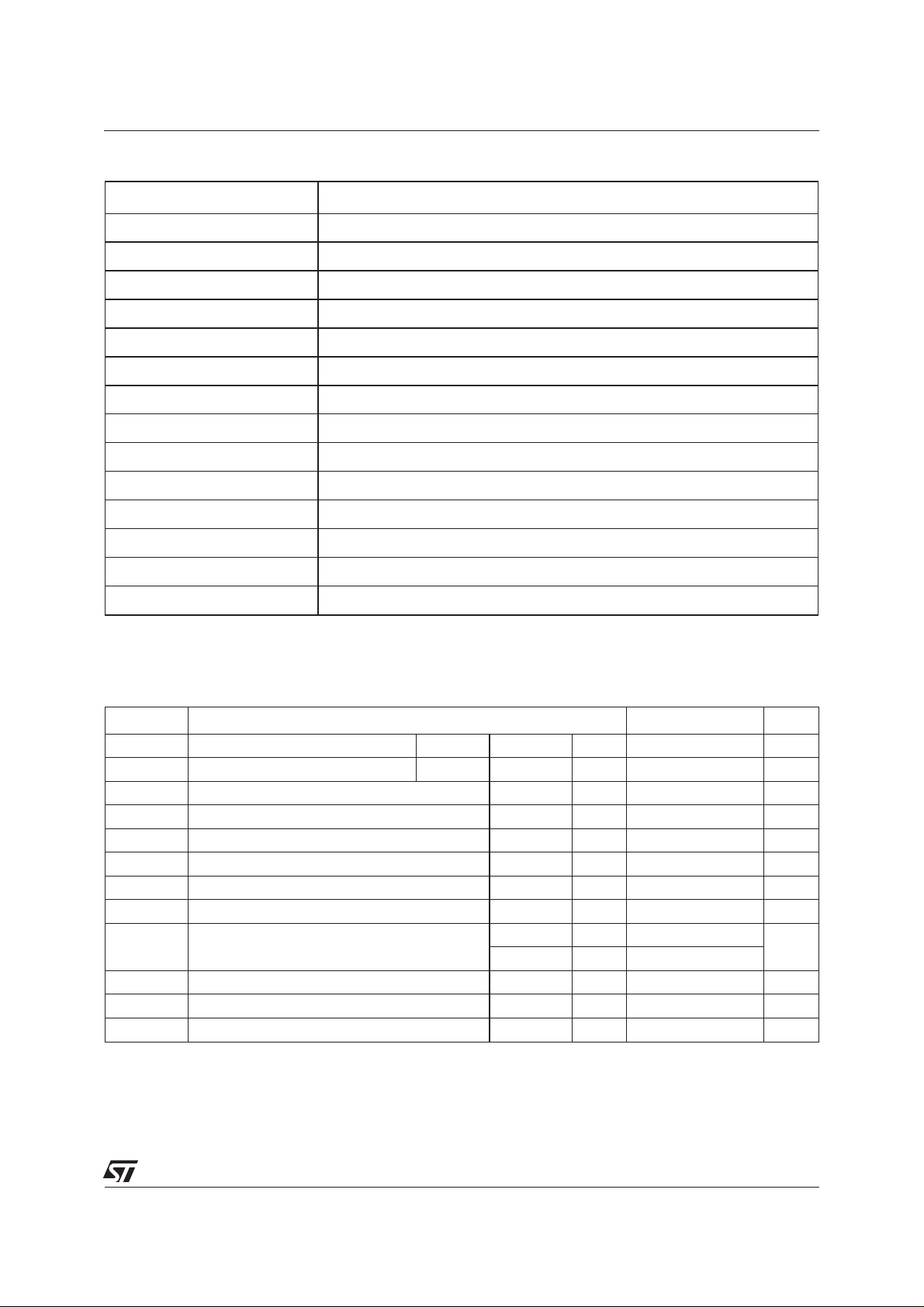

AC LINE SWITCH BASIC APPLICATION

The ACS120 device is well adapted to Washing machine, dishwasher, tumble drier, refrigerator,

air-conditioningsystems, and cookware.Ithas been designedespecially to switchon & off lowpower loads

such as solenoid, valve, relay, dispenser, micro-motor, pump, fan and defrost heaters.

Pin COM: Common drive reference to connect to the power line neutral

Pin G: Switch Gate input to connect to the digital controller

Pin OUT: Switch Output to connect to the load

ThisACS™switch is triggered with anegative gate current flowing outofthe gate pin G. Itcan be driven directly by the digital controller through a resistor as shown on the typical application diagram.

Thanks to its thermal and turn off commutation performances, the ACS120 switch is able to drive with no

turn off additional snubber an inductive load up to 2 A.

TYPICAL APPLICATION DIAGRAM

L

AC

MAINS

N

-Vcc

D

COM

LOAD

L

M

R

OUT

ACS120

S

ON

G

ST72 MCU

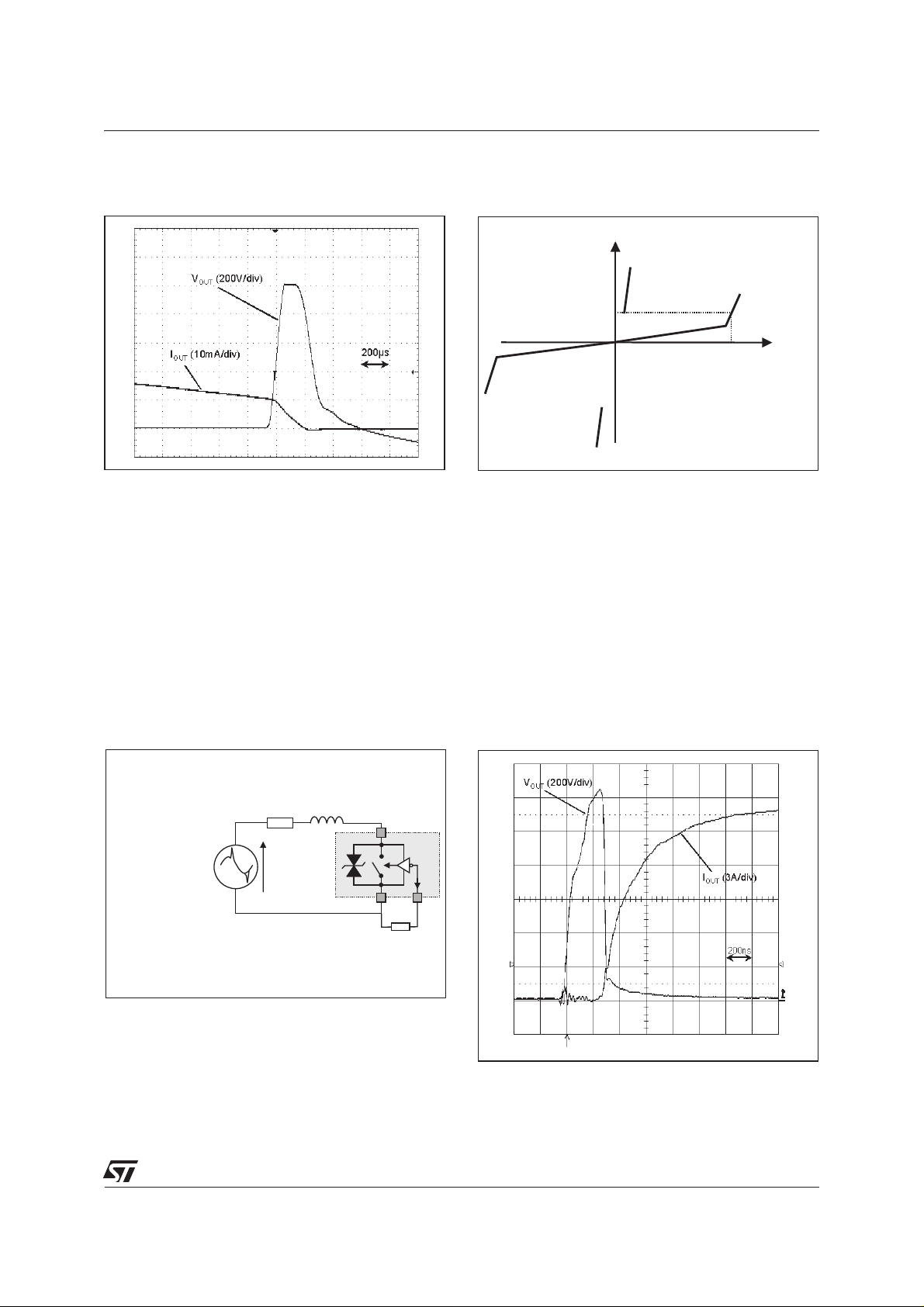

HIGH INDUCTIVE SWITCH-OFF OPERATION

At the end of the last conduction half-cycle, the load current reaches the holding current level I

, and the

H

ACS™ switch turns off. Because of the inductance L of the load, the current flows then through the avalanche diode D and decreases linearly to zero. During this time, the voltage across the switch is limited to

the clamping voltage V

The energy stored in the inductance of the load depends on the holding current I

CL

.

and the inductance (up

H

to10 H); it canreach about 10 mJandis dissipated intheclamping diode section.TheACS switch sustains

the turn off energy because its clamping section is designed for that purpose.

4/11

ACS120-7SB/SFP/ST

Fig. A: Turn-off operation of the ACS120 switch

Fig. B: ACS120 switch static characteristic.

with an electro-valve: waveform of the pin OUT

current I

and voltage V

OUT

OUT

.

IOUT

IH

VCL

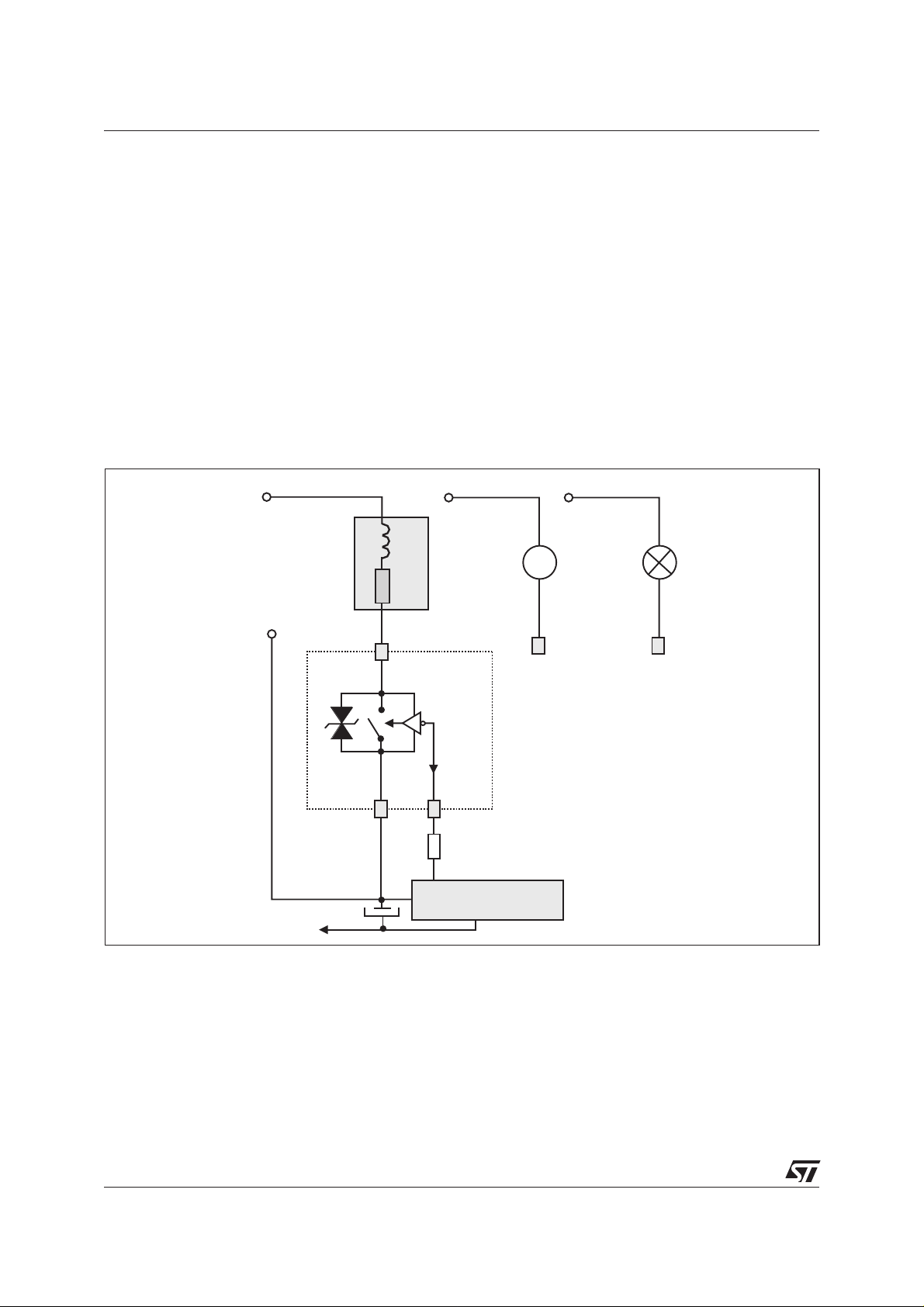

AC LINE TRANSIENT VOLTAGE RUGGEDNESS

The ACS120 switch is able to sustain safely the AC line transient voltages either by clamping the low energy spikes or by breaking over under high energy shocks, even with high turn-on current rises.

The test circuit of the figure C is representative of the final ACS application and is also used to stress the

ACS switch according to the IEC 61000-4-5 standard conditions. Thanks to the load, the ACS switch sustains the voltage spikes up to 2 kV above the peak line voltage. It will break over safely even on resistive

load where the turn on current rise is high as shown on figure D. Such non repetitive test can be done 10

times on each AC line voltage polarity.

VOUT

Fig. C: Overvoltage ruggedness test circuit

for resistive and inductive loads according to

IEC61000-4-5 standards.

R = 150Ω, L = 10µH, V

SURGEVOLTAGE

AC LINE & GENERATOR

PP

= 2kV.

R

V

+V

AC

L

OUT

ACSxx

S

PP

ON

D

COM

G

RG = 220Ω

Fig. D: Current and Voltage of the ACS120 dur-

ing IEC61000-4-5 standard test with R,L&V

PP

.

5/11

ACS120-7SB/SFP/ST

OTHER FIGURES

Maximum power dissipation vs RMS on state current.

RMS on-state current vs ambient temperature, case temperature

Relative variation of thermal impedance junction to ambient vs pulse duration and package

Relative variation of gate trigger current vs junction temperature

Relative variation of holding, latching and gate current vs junction

Relative variation of dV/dt vs Tj

Relative variation of (dV/dt)

Surge peak on-state current vs number of cycles

Non repetitive surge peak on-state current for a sinusoidal pulse with tp<10ms, and corresponding of I²t.

On-state characteristics (maximal values)

Thermal resistance junction to ambient vs copper surface under tab (DPAK)

Relative variation of critical (di/dt)c vs junction temperature

vs (di/dt)

c

c

Fig. 1: Maximum power dissipation versus RMS

on-state current.

P(W)

2.4

α=180°

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

I (A)

T(RMS)

180°

α

α

Fig. 2-2: RMS on-state current versus ambient

temperature.

I (A)

T(RMS)

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 25 50 75 100 125

T (°C)

amb

α=180°

Printed circuitboardFR4

Natural convection

S=0.5cm²

Fig. 2-1: RMS on-state current versus case

temperature.

I (A)

T(RMS)

2.4

α=180°

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 25 50 75 100 125

Tc(°C)

TO-220AB/DPAK

TO-220FPAB

Fig. 3: Relative variation of thermal impedance

versus pulse duration.

K=[Zth/Rth]

1.E+00

DPAK

1.E-01

1.E-02

1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

Zth

(j-c)

TO-220FPAB

DPAK

Zth

(j-a)

t (s)

p

TO-220FPAB

6/11

ACS120-7SB/SFP/ST

Fig. 4: Relative variation of gate trigger current,

holding current and latching versus junction

temperature (typical values).

I , I , I [T ] / I , I , I [T = 25°C]

GTHLj GTHL j

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

I

GT

I& I

LH

T (°C)

j

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

Fig. 6: Relative variation of critical rate of decrease of main current versus reapplied dV/dt

(typical values).

(dI/dt) [(dV/dt) ] / Specified (dI/dt)

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

cc c

V

=400V

OUT

(dV/dt) (V/µs)

c

0 5 10 15 20 25 30 35 40 45 50

Fig. 5: Relative variation of static dV/dt versus

junction temperature.

dV/dt [T ] / dV/dt [T = 125°C]

8

7

6

5

4

3

2

1

0

jj

V

=460V

OUT

T (°C)

j

25 50 75 100 125

Fig. 7: Relative variation of critical rate of decrease

of main current versus junction temperature.

(dI/dt) [Tj] / (dI/dt) [T = 125°C]

ccj

20

18

16

14

12

10

8

6

4

2

0

25 50 75 100 125

T (°C)

j

V

=400V

OUT

Fig. 8: Surge peak on-statecurrentversus number

of cycles.

I (A)

TSM

22

20

18

16

14

12

10

8

6

4

2

0

1 10 100 1000

Repetitive

T =105°C

ab

Non repetitive

T initial=25°C

j

Number of cycles

t=20ms

Fig. 9: Non repetitive surgepeak on-state current

for a sinusoidal pulse with width tp < 10ms, and

corresponding value of I²t.

I (A),I²t (A²s)

TSM

1000

dI/dt limitation:

50A/µS

100

10

t (ms)

p

1

0.01 0.10 1.00 10.00

T initial=25°C

j

I

TSM

I²t

7/11

ACS120-7SB/SFP/ST

Fig. 10: On-state characteristics (maximum

values).

I (A)

TM

10.00

T max. :

j

V =0.85V

to

Ω

R =200m

d

1.00

Tj=125°C

0.10

0.01

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

Tj=25°C

V (V)

TM

ORDERING INFORMATION

ACS 1 20 - 7 S X

AC Switch

Number of switches

Fig. 11: Thermal resistance junction to ambient

versus copper surface under tab (printed circuit

board FR4, copper thickness: 35µm)

Rth (°C/W)

(j-a)

100

90

80

70

60

50

40

30

20

10

0

0 5 10 15 20 25 30 35 40

S(cm²)

Package

V

DRM

7 = 700V

B = DPAK

FP = TO-220FPAB

T = TO-220AB

DPAK

T(RMS)

I

20 = 2.0A

Gate Sensitivity

S= 10mA

8/11

PACKAGE OUTLINE MECHANICAL DATA

DPAK

ACS120-7SB/SFP/ST

DIMENSIONS

REF.

A 2.20 2.40 0.086 0.094

A1 0.90 1.10 0.035 0.043

A2 0.03 0.23 0.001 0.009

B 0.64 0.90 0.025 0.035

B2 5.20 5.40 0.204 0.212

C 0.45 0.60 0.017 0.023

C2 0.48 0.60 0.018 0.023

D 6.00 6.20 0.236 0.244

E 6.40 6.60 0.251 0.259

G 4.40 4.60 0.173 0.181

H 9.35 10.10 0.368 0.397

L2 0.80 typ. 0.031 typ.

L4 0.60 1.00 0.023 0.039

V2 0° 8° 0° 8°

Millimeters Inches

Min. Max Min. Max.

FOOT PRINT

DPAK

6.7

6.7

3

3

1.61.6

2.32.3

9/11

ACS120-7SB/SFP/ST

PACKAGE OUTLINE MECHANICAL DATA

TO-220FPAB

DIMENSIONS

L3

L4

L2

G1

REF.

A

H

B

A 4.4 4.6 0.173 0.181

Millimeters Inches

Min. Max. Min. Max.

B 2.5 2.7 0.098 0.106

Dia

D 2.5 2.75 0.098 0.108

E 0.45 0.70 0.018 0.027

L6

L7

F 0.75 1 0.030 0.039

F1 1.15 1.70 0.045 0.067

F2 1.15 1.70 0.045 0.067

L5

D

F1

F2

G 4.95 5.20 0.195 0.205

G1 2.4 2.7 0.094 0.106

H 10 10.4 0.393 0.409

L2 16 Typ. 0.63 Typ.

L3 28.6 30.6 1.126 1.205

F

E

L4 9.8 10.6 0.386 0.417

L5 2.9 3.6 0.114 0.142

G

L6 15.9 16.4 0.626 0.646

L7 9.00 9.30 0.354 0.366

10/11

PACKAGE OUTLINE MECHANICAL DATA

TO-220AB

H2

L2

F1

Dia

L5

L6

F2

L9

L4

F

G1

G

C

D

M

ACS120-7SB/SFP/ST

DIMENSIONS

REF.

A

L7

E

A 4.40 4.60 0.173 0.181

C 1.23 1.32 0.048 0.051

D 2.40 2.72 0.094 0.107

E 0.49 0.70 0.019 0.027

F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.066

F2 1.14 1.70 0.044 0.066

G 4.95 5.15 0.194 0.202

G1 2.40 2.70 0.094 0.106

H2 10 10.40 0.393 0.409

L2 16.4 typ. 0.645 typ.

L4 13 14 0.511 0.551

L5 2.65 2.95 0.104 0.116

L6 15.25 15.75 0.600 0.620

L7 6.20 6.60 0.244 0.259

L9 3.50 3.93 0.137 0.154

M 2.6 typ. 0.102 typ.

Diam. 3.75 3.85 0.147 0.151

Millimeters Inches

Min. Max. Min. Max.

OTHER INFORMATION

Ordering type Marking Package Weight Base qty Delivery mode

ACS120-7SB ACS1207S DPAK 0.3 g 75 Tube

ACS120-7SB-TR ACS1207S DPAK 0.3 g 2500 Tape & reel

ACS120-7SFP ACS1207S TO-220FPAB 2.4 g 50 Tube

ACS120-7ST ACS1207S TO-220AB 2.3 g 250 Bulk

■

Epoxy meets UL94,V0

Informationfurnished is believed to beaccurate and reliable. However, STMicroelectronicsassumesno responsibility for theconsequencesof

useof such information norfor any infringement of patentsor other rights ofthirdparties which may resultfrom its use. No licenseis granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

11/11

Loading...

Loading...