Up to 1 A step down switching regulator

Features

■ Qualified following the AEC-Q100

requirements (see PPAP for more details)

■ 1 A DC output current

■ Operating input voltage from 4 V to 36 V

■ 3.3 V / (±2%) reference voltage

■ Output voltage adjustable from 1.235 V to V

■

Low dropout operation: 100% duty cycle

■ 250 kHz Internally fixed frequency

■ Voltage feedforward

■ Zero load current operation

■ Internal current limiting

■ Inhibit for zero current consumption

■ Synchronization

■ Protection against feedback disconnection

■ Thermal shutdown

Application

■ Dedicated to automotive applications

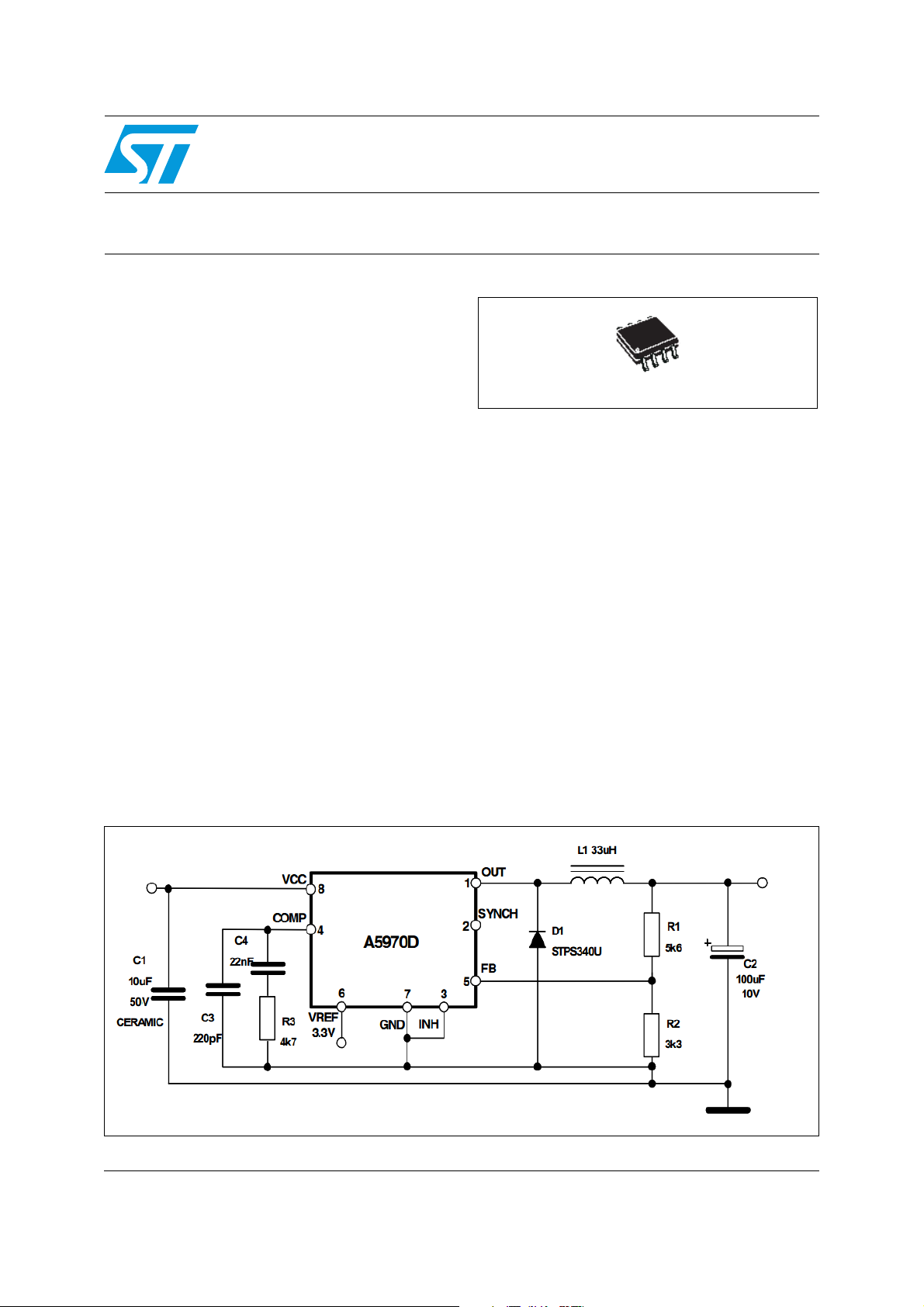

Figure 1. Application schematic

VIN=4 to 36V

A5970D

for automotive applications

SO8

IN

Description

The A5970D is a step down monolithic power

switching regulator with a minimum switch current

limit of 1.35 A so it is able to deliver up to 1 A DC

current to the load depending on the application

conditions. The output voltage can be set from

1.235 V to V

The device uses an internal p-channel DMOS

transistor (with a typical R

switching element to minimize the size of the

external components.

An internal oscillator fixes the switching frequency

at 250 kHz. Having a minimum input voltage of

4 V only it fits the automotive applications

requiring the device operation even in cold crank

conditions. Pulse by pulse current limit with the

internal frequency modulation offers an effective

constant current short circuit protection.

.

IN

of 250 mΩ) as

DS(on)

=3.3V

V

OUT

November 2009 Doc ID 13955 Rev 6 1/41

www.st.com

41

Contents A5970D

Contents

1 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Datasheet parameters over the temperature range . . . . . . . . . . . . . . . . 8

5 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Power supply and voltage reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Voltages monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.3 Oscillator and synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.4 Current protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.5 Error amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.6 PWM comparator and power stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.7 Inhibit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.8 Thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Additional features and protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Feedback disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Output overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 Zero load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Closing the loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.1 Error amplifier and compensation network . . . . . . . . . . . . . . . . . . . . . . . . 17

7.2 LC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 PWM comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/41 Doc ID 13955 Rev 6

A5970D Contents

8.1 Component selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.2 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.3 Thermal considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.4 Short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.5 Application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.6 Positive buck-boost regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.7 Negative buck-boost regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.8 Synchronization example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.9 Compensation network with MLCC at the output . . . . . . . . . . . . . . . . . . . 33

8.10 External SOFT_START network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 Typical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Doc ID 13955 Rev 6 3/41

Pin settings A5970D

1 Pin settings

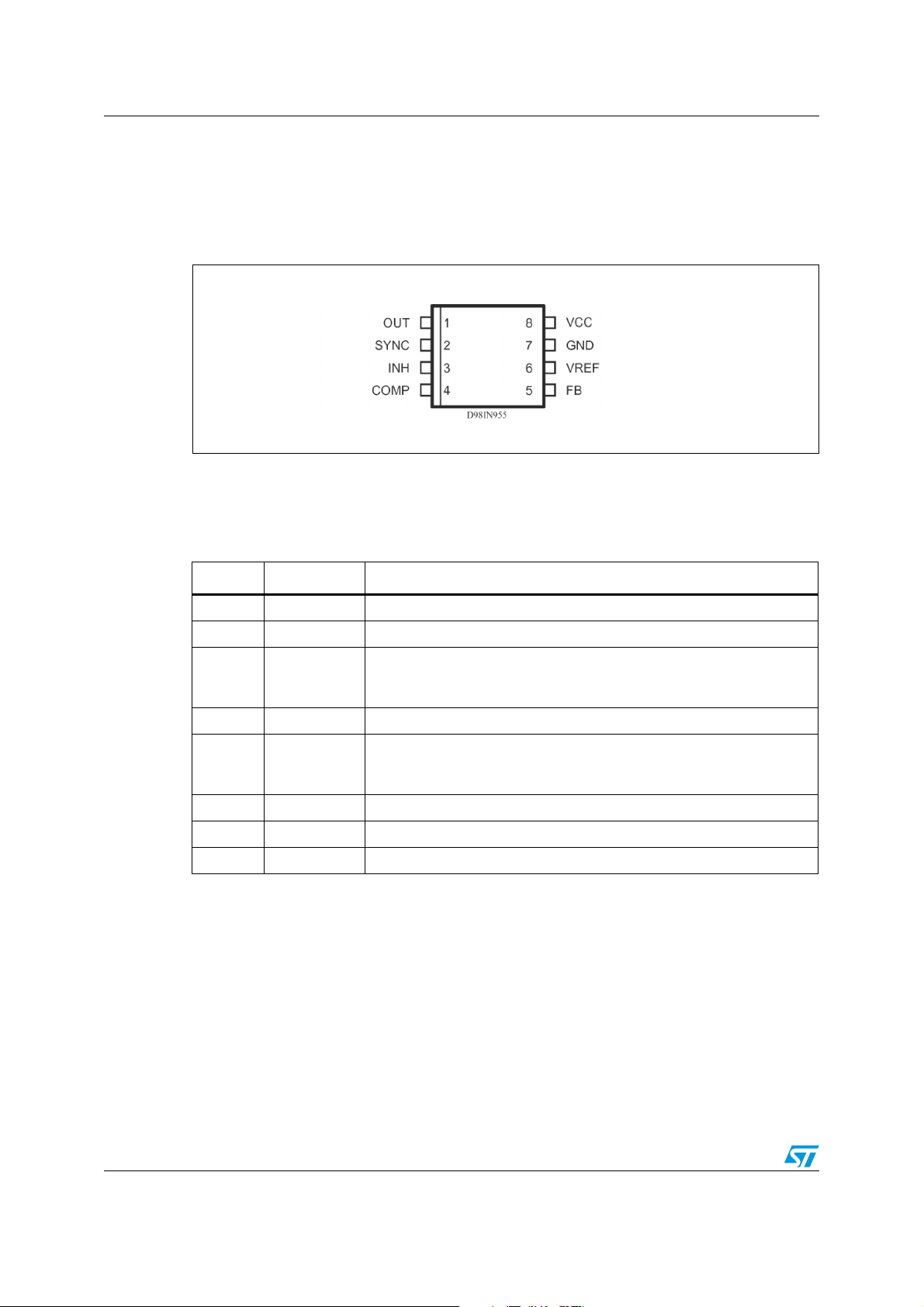

1.1 Pin connection

Figure 2. Pin connection (top view)

1.2 Pin description

Table 1. Pin description

N Pin Description

1 OUT Regulator output.

2 SYNCH Master/slave synchronization.

A logical signal (active high) disables the device. If INH not used the pin

3INH

4 COMP E/A output for frequency compensation.

5FB

6 VREF 3.3 V V

7 GND Ground.

8 VCC Unregulated DC input voltage.

must be grounded. When it is open an internal pull-up disable the

device.

Feedback input. Connecting directly to this pin results in an output

voltage of 1.23 V. An external resistive divider is required for higher

output voltages.

REF. No cap is requested for stability.

4/41 Doc ID 13955 Rev 6

A5970D Electrical data

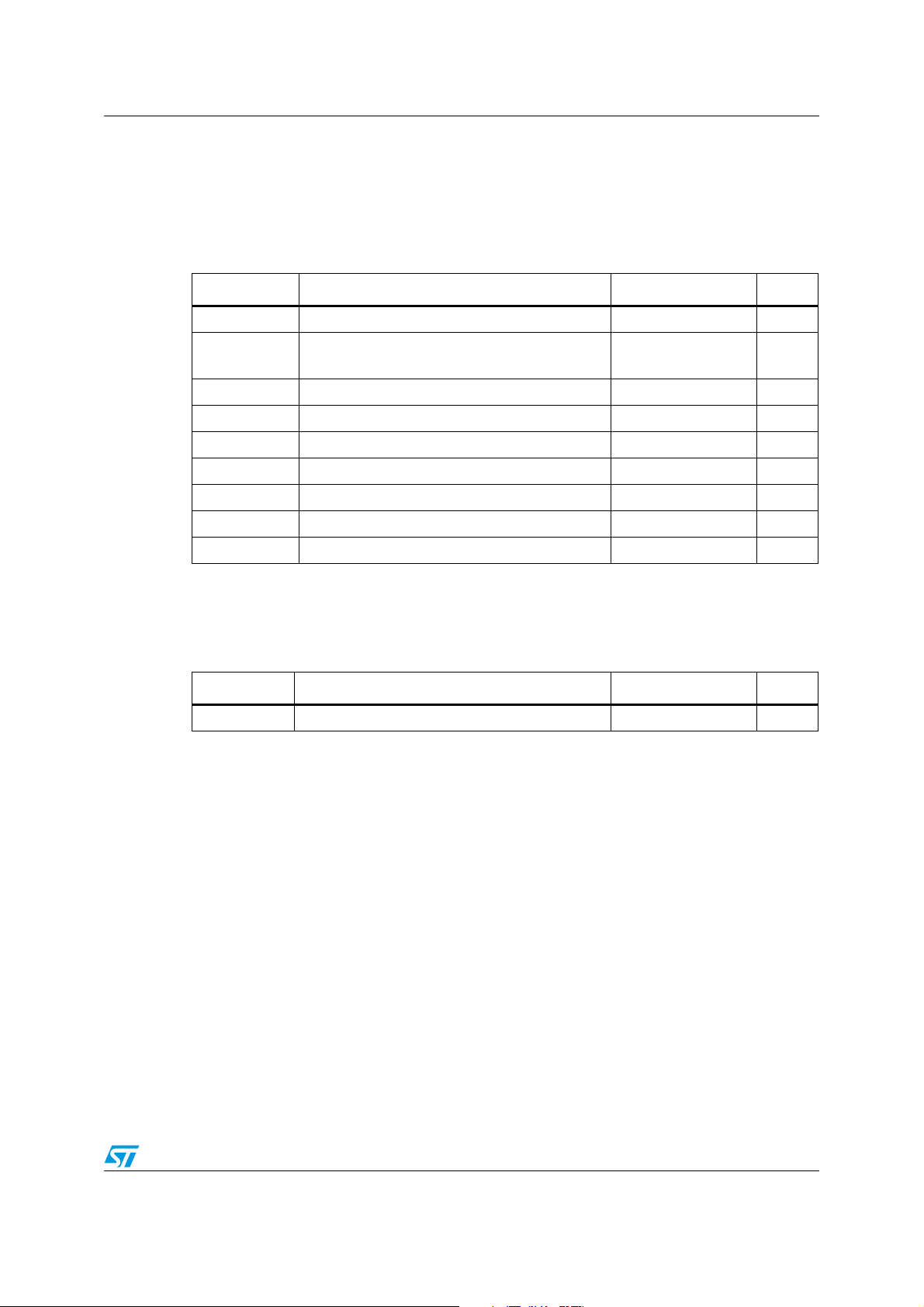

2 Electrical data

2.1 Maximum ratings

Table 2. Absolute maximum ratings

Symbol Parameter Value Unit

V

8

V

1

I

1

V

, V

4

V

3

V

2

P

TOT

T

J

T

STG

Input voltage 40 V

OUT pin DC voltage

OUT pin peak voltage at Δt = 0.1 μs

Maximum output current int. limit.

Analog pins 4 V

5

INH -0.3 to V

SYNCH -0.3 to 4 V

Power dissipation at T

Operating junction temperature range -40 to 150 °C

Storage temperature range -55 to 150 °C

2.2 Thermal data

Table 3. Thermal data

Symbol Parameter Value Unit

R

thJA

1. Package mounted on evaluation board

Maximum thermal resistance junction-ambient 120

-1 to 40

-5 to 40

CC

≤ 70 °C 0.6 W

A

(1)

V

V

V

°C/W

Doc ID 13955 Rev 6 5/41

Electrical characteristics A5970D

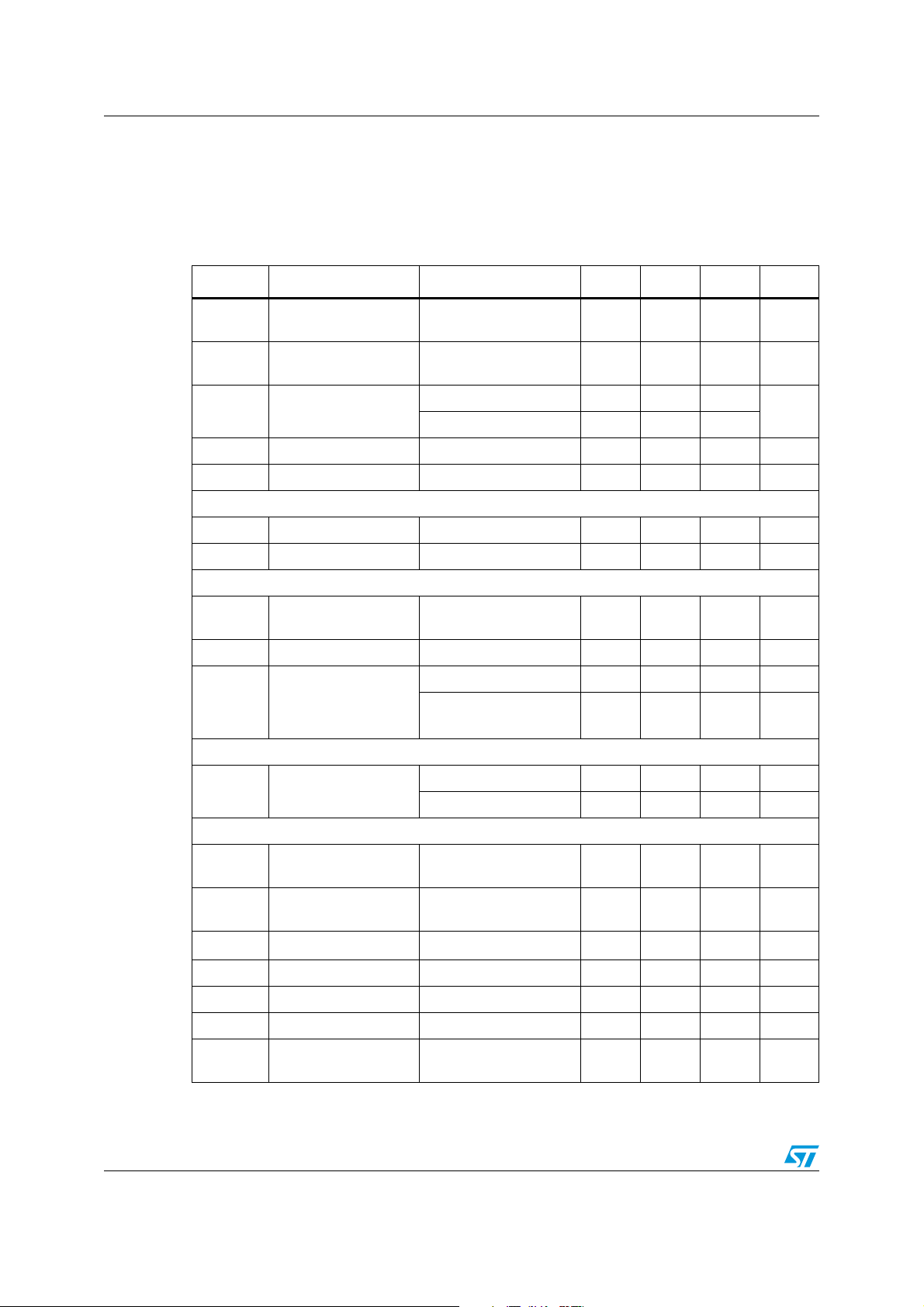

3 Electrical characteristics

TJ = -40 °C to 125 °C, VCC = 12 V, unless otherwise specified.

Table 4. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

V

R

DS(on)

f

CC

I

SW

Operating input

voltage range

MOSFET on

resistance

Maximum limiting

L

current

(1)

V

CC

= 5 V, TJ = 25 °C 1.5 1.87 2.25

V

CC

Switching frequency 212 250 280 kHz

Duty cycle 0 100 %

Dynamic characteristics (see test circuit).

V

η Efficiency V

Voltage feedback 4.4 V < V

5

= 5 V, V

0

DC characteristics

I

qop

I

qst-by

I

Total operating

quiescent current

Quiescent current Duty cycle=0; VFB=1.5 V 2.5 mA

q

> 2.2 V 50 100 μA

V

Total stand-by

quiescent current

inh

V

CC

V

inh

> 2.2 V

Inhibit

436V

0.250 0.5 Ω

= 5 V 1.35 1.87 2.25

< 36 V, 1.198 1.235 1.272 V

CC

= 12 V 90 %

CC

35mA

= 36 V;

80 150 μA

A

INH threshold voltage

Device ON 0.8 V

Device OFF 2.2 V

Error amplifier

V

OH

V

Io source

o sink Sink output current

I

I

High level output

voltage

Low level output

OL

voltage

Source output current

b Source bias current 2.5 4 μA

DC open loop gain R

gm Transconductance

= 1 V 3.5 V

V

FB

= 1.5 V 0.4 V

V

FB

V

= 1.9 V; VFB = 1 V

COMP

V

= 1.9 V; VFB=1.5 V

COMP

L=5065dB

I

= -0.1 mA to 0.1

COMP

mA; V

COMP

= 1.9 V

6/41 Doc ID 13955 Rev 6

190 300 μA

11.5 mA

2.3 mS

A5970D Electrical characteristics

Table 4. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Synch function

High input voltage V

Low input voltage V

Slave synch current

Master output

amplitude

Output pulse width no load, V

Reference section

Reference voltage

Line regulation

Load regulation I

Short circuit current 5 18 35 mA

1. With TJ = 85 °C, I

2. Guaranteed by design

lim_min

= 4.4 to 36 V; 2.5 V

CC

= 4.4 to 36 V; 0.74 V

CC

V

= 0.74 V

synch

V

= 2.33 V

synch

= 3 mA 2.75 3 V

I

source

I

= 0 to 5 mA

REF

VCC = 4.4 V to 36 V

I

= 0mA

REF

= 4.4 V to 36 V

V

CC

= 0 mA 8 15 mV

REF

= 1.5 A, assured by design, characterization and statistical correlation.

(2)

= 1.65 V 0.20 0.35 μs

synch

0.11

0.21

0.25

0.45

3.2 3.3 3.399 V

510mV

REF

V

mA

Doc ID 13955 Rev 6 7/41

Datasheet parameters over the temperature range A5970D

4 Datasheet parameters over the temperature range

The 100% of the population in the production flow is tested at three different ambient

temperatures (-40 °C; +25 °C, +125 °C) to guarantee the datasheet parameters inside the

junction temperature range (-40 °C; +125 °C).

The device operation is so guaranteed when the junction temperature is inside the (-40 °C;

+150 °C) temperature range. The designer can estimate the silicon temperature increase

respect to the ambient temperature evaluating the internal power losses generated during

the device operation (please refer to the Chapter 2.2).

However the embedded thermal protection disables the switching activity to protect the

device in case the junction temperature reaches the T

temperature.

All the datasheet parameters can be guaranteed to a maximum junction temperature of

+125 °C to avoid triggering the thermal shutdown protection during the testing phase

because of self heating.

SHTDWN

(+150 °C±10 °C)

8/41 Doc ID 13955 Rev 6

A5970D Functional description

5 Functional description

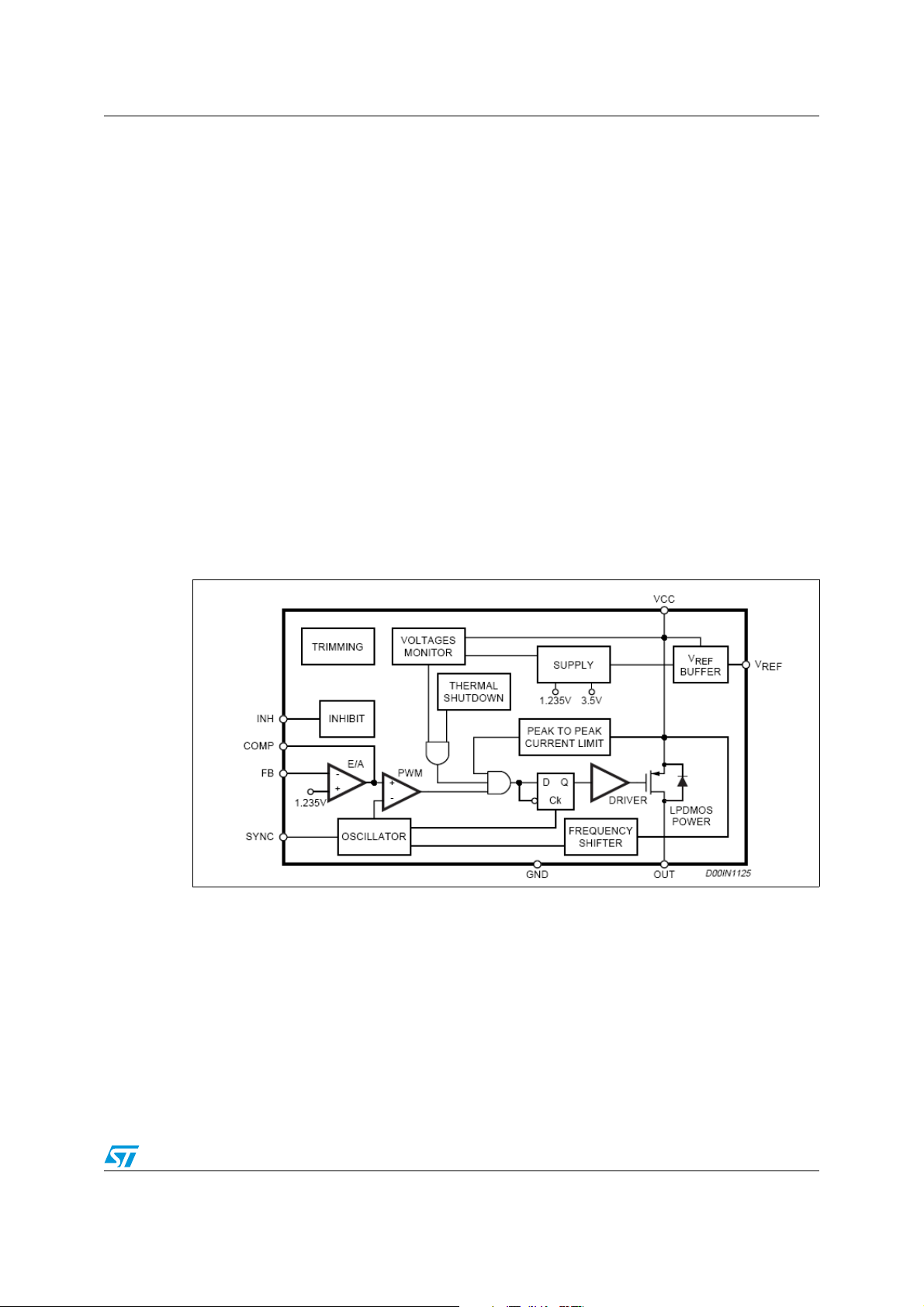

The main internal blocks are shown in the device block diagram in Figure 3. They are:

● A voltage regulator supplying the internal circuitry. From this regulator, a 3.3 V

reference voltage is externally available.

● A voltage monitor circuit which checks the input and the internal voltages.

● A fully integrated sawtooth oscillator with a frequency of 250 kHz ± 15%, including also

the voltage feed forward function and an input/output synchronization pin.

● Two embedded current limitation circuits which control the current that flows through

the power switch. The pulse-by-pulse current limit forces the power switch OFF cycle

by cycle if the current reaches an internal threshold, while the frequency shifter reduces

the switching frequency in order to significantly reduce the duty cycle.

● A transconductance error amplifier.

● A pulse width modulator (PWM) comparator and the relative logic circuitry necessary to

drive the internal power.

● A high side driver for the internal P-MOS switch.

● An inhibit block for stand-by operation.

● A circuit to implement the thermal protection function.

Figure 3. Block diagram

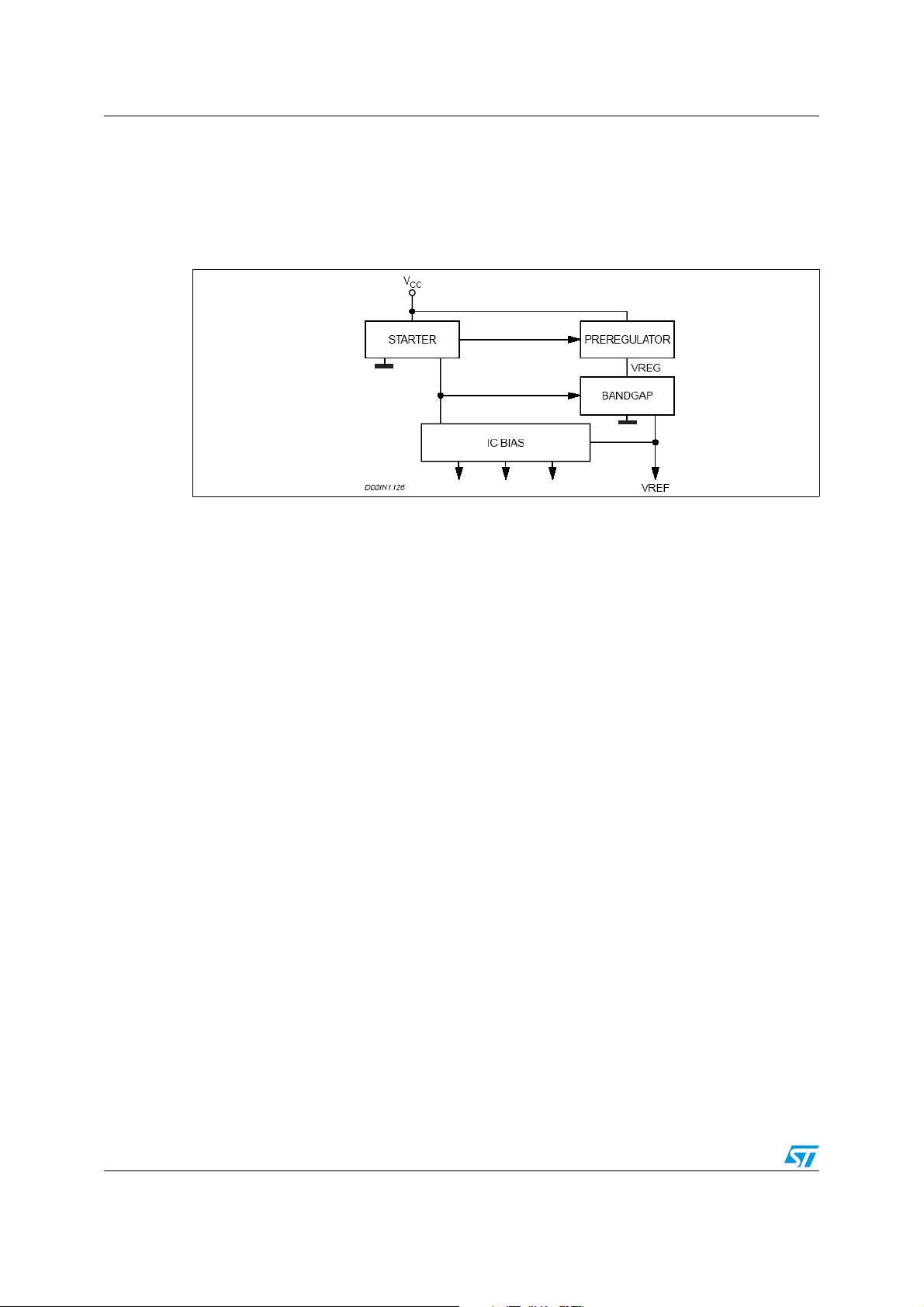

5.1 Power supply and voltage reference

The internal regulator circuit (shown in Figure 4) consists of a start-up circuit, an internal

voltage pre-regulator, the Bandgap voltage reference and the Bias block that provides

current to all the blocks. The Starter supplies the start-up currents to the entire device when

the input voltage goes high and the device is enabled (inhibit pin connected to ground). The

pre-regulator block supplies the Bandgap cell with a pre-regulated voltage V

very low supply voltage noise sensitivity.

that has a

REG

Doc ID 13955 Rev 6 9/41

Functional description A5970D

5.2 Voltages monitor

An internal block continuously senses the Vcc, V

their thresholds, the regulator begins operating. There is also a hysteresis on the V

(UVLO).

Figure 4. Internal circuit

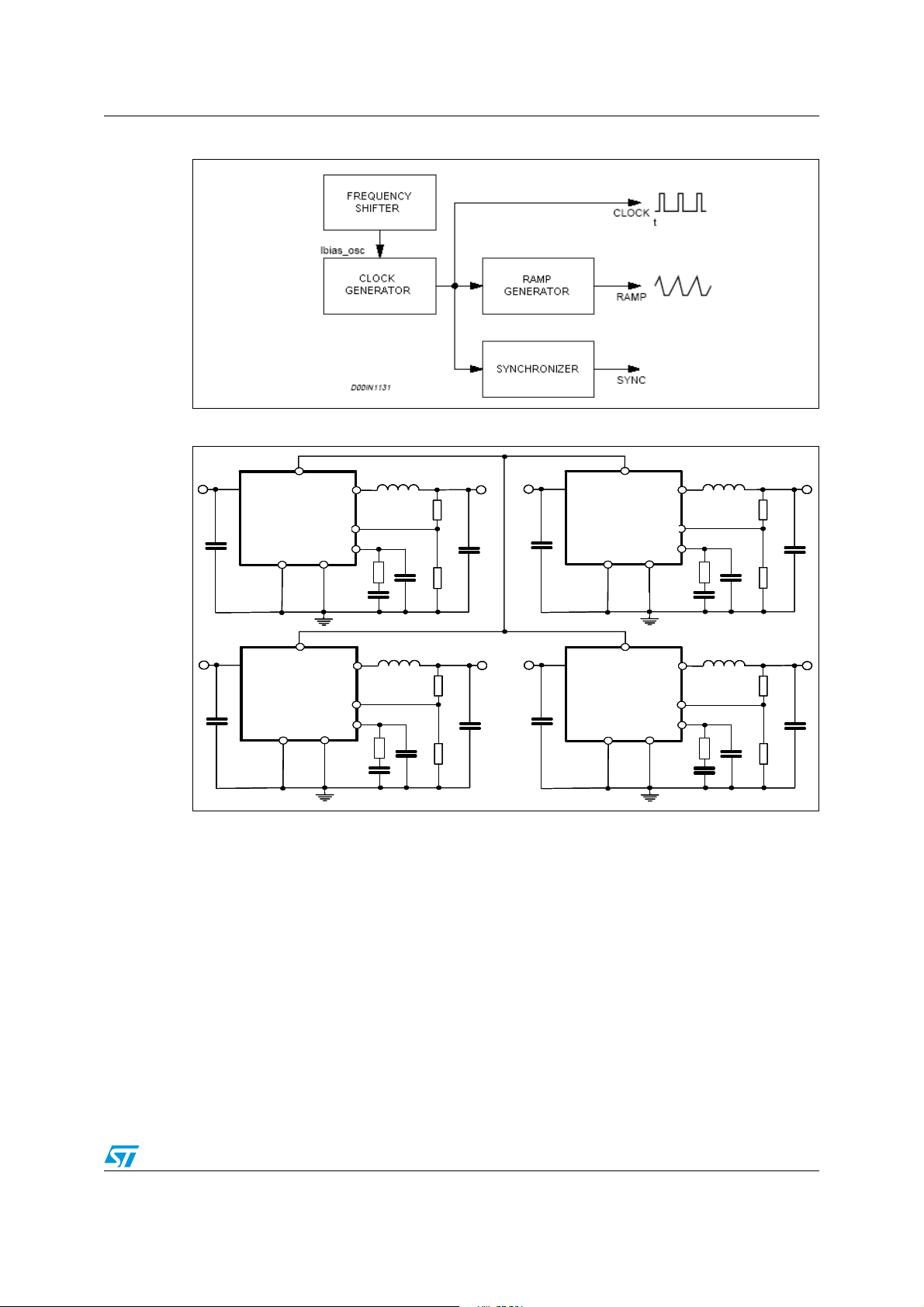

5.3 Oscillator and synchronization

Figure 5 shows the block diagram of the oscillator circuit.

The clock generator provides the switching frequency of the device, which is internally fixed

at 250 kHz. The frequency shifter block acts to reduce the switching frequency in case of

strong overcurrent or short circuit. The clock signal is then used in the internal logic circuitry

and is the input of the ramp generator and synchronizer blocks.

and Vbg. If the voltages go higher than

ref

CC

The ramp generator circuit provides the sawtooth signal, used for PWM control and the

internal voltage feed-forward, while the synchronizer circuit generates the synchronization

signal. The device also has a synchronization pin which can work both as master and slave.

Beating frequency noise is an issue when more than one voltage rail is on the same board.

A simple way to avoid this issue is to operate all the regulators at the same switching

frequency.

The synchronization feature of a set of the A5970D is simply get connecting together their

SYNCH pin. The device with highest switching frequency will be the MASTER and it

provides the synchronization signal to the others. Therefore the SYNCH is a I/O pin to

deliver or recognize a frequency signal. The synchronization circuitry is powered by the

internal reference (V

) so a small filtering capacitor (≥ 100 nF) connected between V

REF

REF

pin and the signal ground of the Master device is suggested for its proper operation.

However when a set of synchronized devices populates a board it is not possible to know in

advance the one working as Master, so the filtering capacitor have to be designed for whole

set of devices.

When one or more devices are synchronized to an external signal, its amplitude have to be

in comply with specifications given in the Tab l e 4 . The frequency of the synchronization

signal must be, at a minimum, higher than the maximum guaranteed natural switching

frequency of the device (275 kHz, see Tab le 4 ) while the duty cycle of the synchronization

signal can vary from approximately 10% to 90%. The small capacitor under V

REF

pin is

required for this operation.

10/41 Doc ID 13955 Rev 6

A5970D Functional description

Figure 5. Oscillator circuit block diagram

Figure 6. Synchronization example

OUT

OUT

SYNCH

SYNCH

SYNCH

A5970D

A5973D

A5973D

A5973D

OUT

OUT

OUT

FB

FB

FB

COMP

COMP

COMP

SYNCH

SYNCH

SYNCH

A5970D

A5973D

A5973D

A5973D

OUT

FB

FB

FB

COMP

COMP

COMP

SS/INH

SS/INH

SS/INH

SYNCH

SYNCH

SYNCH

A5970D

A5973D

A5973D

A5973D

SS/INH

SS/INH

SS/INH

GND

GND

GND

GND

GND

GND

OUT

OUT

OUT

FB

FB

FB

COMP

COMP

COMP

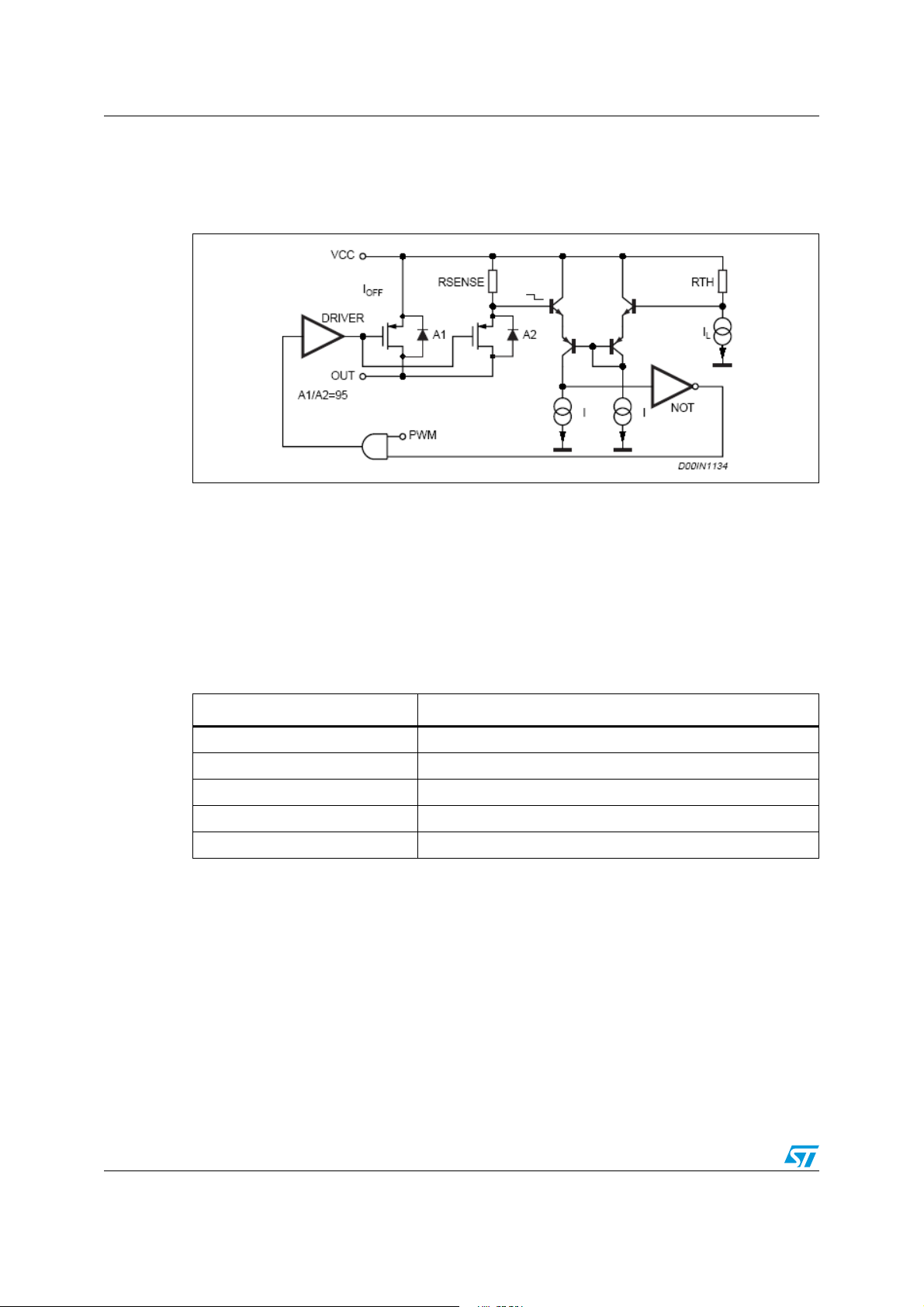

5.4 Current protection

The A5970D features two types of current limit protection: pulse-by-pulse and frequency

foldback.

The schematic of the current limitation circuitry for the pulse-by-pulse protection is shown in

Figure 7. The output power PDMOS transistor is split into two parallel PDMOS transistors.

The smallest one includes a resistor in series, R

R

switched off until the next falling edge of the internal clock pulse. Due to this reduction of the

ON time, the output voltage decreases. Since the minimum switch ON time necessary to

sense the current in order to avoid a false overcurrent signal is too short to obtain a

sufficiently low duty cycle at 250 kHz (see Chapter 8.4), the output current in strong

overcurrent or short circuit conditions could be not properly limited. For this reason the

switching frequency is also reduced, thus keeping the inductor current under its maximum

and if it reaches the threshold, the mirror becomes unbalanced and the PDMOS is

SENSE

SS/INH

SS/INH

SS/INH

SYNCH

SYNCH

SYNCH

A5970D

A5973D

A5973D

A5973D

SS/INH

SS/INH

SS/INH

. The current is sensed through

SENSE

GND

GND

GND

GND

GND

GND

OUT

OUT

OUT

FB

FB

FB

COMP

COMP

COMP

Doc ID 13955 Rev 6 11/41

Functional description A5970D

threshold. The frequency shifter (Figure 5) functions based on the feedback voltage. As the

feedback voltage decreases (due to the reduced duty cycle), the switching frequency

decreases also.

Figure 7. Current limitation circuitry

5.5 Error amplifier

The voltage error amplifier is the core of the loop regulation. It is a transconductance

operational amplifier whose non inverting input is connected to the internal voltage

reference (1.235 V), while the inverting input (FB) is connected to the external divider or

directly to the output voltage. The output (COMP) is connected to the external compensation

network. The uncompensated error amplifier has the following characteristics:

Table 5. Uncompensated error amplifier characteristics

Description Values

Transconductance 2300 µS

Low frequency gain 65 dB

Minimum sink/source voltage 1500 µA/300 µA

Output voltage swing 0.4 V/3.65 V

Input bias current 2.5 µA

The error amplifier output is compared to the oscillator sawtooth to perform PWM control.

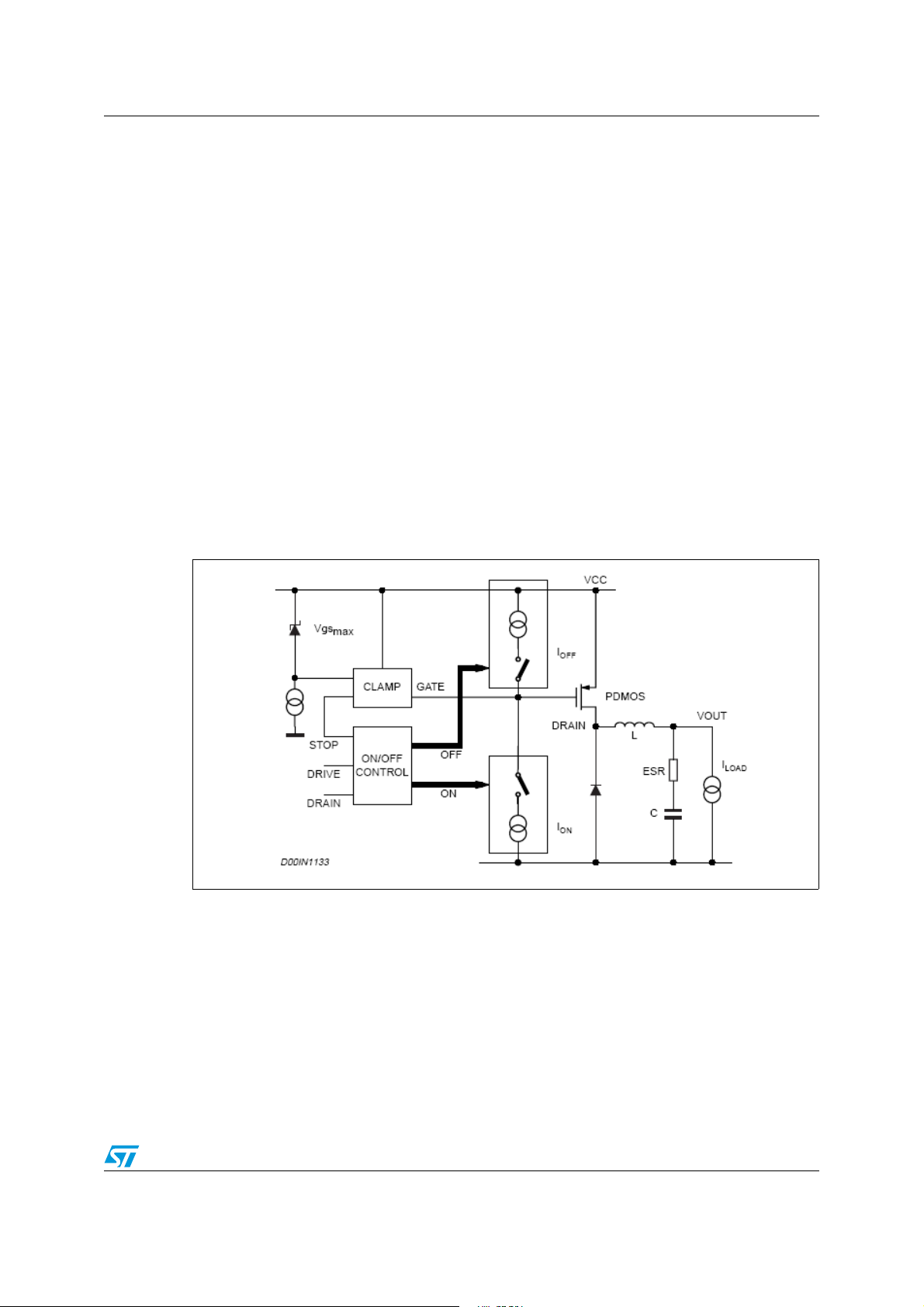

5.6 PWM comparator and power stage

This block compares the oscillator sawtooth and the error amplifier output signals to

generate the PWM signal for the driving stage.

The power stage is a highly critical block, as it functions to guarantee a correct turn ON and

turn OFF of the PDMOS. The turn ON of the power element, or more accurately, the rise

time of the current at turn ON, is a very critical parameter. At a first approach, it appears that

the faster the rise time, the lower the turn ON losses.

However, there is a limit introduced by the recovery time of the recirculation diode.

12/41 Doc ID 13955 Rev 6

A5970D Functional description

In fact, when the current of the power element is equal to the inductor current, the diode

turns OFF and the drain of the power is able to go high. But during its recovery time, the

diode can be considered a high value capacitor and this produces a very high peak current,

responsible for numerous problems:

● Spikes on the device supply voltage that cause oscillations (and thus noise) due to the

board parasites.

● Turn ON overcurrent leads to a decrease in the efficiency and system reliability.

● Major EMI problems.

● Shorter freewheeling diode life.

The fall time of the current during turn OFF is also critical, as it produces voltage spikes (due

to the parasites elements of the board) that increase the voltage drop across the PDMOS.

In order to minimize these problems, a new driving circuit topology has been used and the

block diagram is shown in Figure 8. The basic idea is to change the current levels used to

turn the power switch ON and OFF, based on the PDMOS and the gate clamp status.

This circuitry allows the power switch to be turned OFF and ON quickly and addresses the

freewheeling diode recovery time problem. The gate clamp is necessary to ensure that V

of the internal switch does not go higher than V

max. The ON/OFF Control block protects

GS

GS

against any cross conduction between the supply line and ground.

Figure 8. Driving circuitry

5.7 Inhibit function

The inhibit feature is used to put the device in standby mode. With the INH pin higher than

2.2 V the device is disabled and the power consumption is reduced to less than 100 µA.

With the INH pin lower than 0.8 V, the device is enabled. If the INH pin is left floating, an

internal pull up ensures that the voltage at the pin reaches the inhibit threshold and the

device is disabled. The pin is also V

compatible.

cc

Doc ID 13955 Rev 6 13/41

Loading...

Loading...