1

Instruction Sheet #51-1160

04-28-04

Copyright®, 2003

by S&S Cycle, Inc.

All rights reserved. Printed in the U.S.A.

Because every industry has a leader

S&S Twin Cam Style Engine

Assembly and Installation Instructions

S&S Cycle, Inc.

14025 County Highway G Box 215

Viola, Wisconsin 54664

Phone: 608-627-2080 • Fax: 608-627-1488

Technical Service Phone: 608-627-TECH (8324)

Technical Service Email: sstech@sscycle.com

Website: www.sscycle.com

For all S&S Twin Cam style Engine Assemblies with Twin Cam style or

optional Evolution style engine mounting.

All S&S Twin Cam style Engine Assemblies are

Type "A" style (non-counterbalanced).

2

SAFE INSTALLATION AND OPERATION RULES:

Before installing any S&S engine part, it is your responsibility

to read and follow all instructions. The rules below are for

your personal safety, and must be kept in mind at all times.

● Gasoline is extremely flammable and explosive under

certain conditions, and toxic when inhaled. Do not smoke

around gasoline. Perform the installation in a well-ventilated

area away from sparks or open flame.

● After installation, be sure all fuel lines are routed correctly

with clamps in place and tightened securely. Even with

protective cover, gas lines must not contact extremely hot

surfaces where they could melt or leak and catch fire.

● Compressed air and particles dislodged by

compressed air are potentially harmful. Wear protective

goggles when using compressed air and always direct

the air stream away from yourself and others nearby.

● Some solvents, degreasers and other chemicals are

harmful, especially to skin and eyes. Many chemical

compounds such as lacquer thinner are also flammable and

present a fire hazard. Read the manufacturer’s instruction

label for precautions and proper use. Use in a well ventilated

area and wear protective clothing to avoid personal injury.

● If the motorcycle has been running, wait until the engine

and exhaust pipes have cooled before performing any

mechanical work.

● Before beginning the installation, disconnect and remove

the battery to eliminate potential sparks and possible

inadvertent engagement of the electric starter while working

on the motorcycle.

● Read instructions thoroughly and carefully so all

procedures are completely understood before beginning

installation. Contact S&S if you have questions, if any steps

are unclear, or if any abnormalities occur during final

assembly, installation, or operation.

● Consult an authorized H-D service manual for correct

disassembly , reassembly, and installation procedures for any

parts that need to be removed or disassembled to facilitate

the installation.

● Use good judgment during assembly, installation, and

when operating the motorcycle. Good judgment begins with

a clear head. Don’t let alcohol, drugs, or fatigue impair

judgment. Perform installation when fresh and alert.

● For optimum performance and safety and to minimize

potential damage to the cylinder heads or other components,

use correct hardware and follow procedures outlined in S&S

instructions and authorized H-D service manual.

● Motorcycle exhaust fumes are toxic and must not be

inhaled. Run motorcycle only in a well ventilated area where

fumes can dissipate.

WARRANTY :

All S&S parts are guaranteed to the original purchaser to be

free of manufacturing defects in materials and workmanship

for a period of twelve (12) months from the date of purchase.

Merchandise that fails to conform to these conditions will be

repaired or replaced at S&S’s option if the parts are returned

to S&S by the purchaser within the 12 month warranty period

or within 10 days thereafter.

In the event warranty service is required, the original

purchaser must notify S&S of the problem immediately.

Some problems can be rectified by a telephone call and need

no further action. Apart that is suspected of being defective

must not be replaced without prior authorization from S&S. If

it is deemed necessary for S&S to make an evaluation to

determine whether the part was defective, it must be

packaged properly to avoid further damage, and be returned

prepaid to S&S with a copy of the original invoice of purchase

and a detailed letter outlining the nature of the problem, how

the part was used, and the circumstances at the time of

failure. If after an evaluation was made by S&S and the part

was found to be defective, repair, replacement, or refund will

be granted.

ADDITIONAL W ARRANTY PROVISIONS:

(1) No part shall be returned to S&S without first contacting

the company and obtaining a Return Authorization (RA)

number.

(2) S&S shall have no obligation in the event an S&S part is

modified by any other person or organization, or if another

manufacturer’s part is substituted for one provided by S&S.

(3) S&S shall have no obligation if an S&S part becomes

defective in whole or in part as a result of improper

installation, improper break-in or maintenance, improper use,

abnormal operation, or any other misuse or mistreatment.

(4) S&S shall not be liable for any consequential or incidental

damages resulting from the failure of an S&S part, the breech

of any warranties, the failure to deliver, delay in delivery,

delivery in non-conforming condition, or for any other breach

of contract or duty between S&S and a customer.

(5) S&S parts are designed exclusively for use on

motorcycles with Harley-Davidson style V-twin engines. S&S

shall have no warranty or liability obligation if an S&S part is

used in any other application.

IMPORTANT NOTICE:

Statements in this instruction sheet preceded by the

following words are of special significance:

WARNING

Means there is the possibility of injury to yourself or

others.

CAUTION

Means there is the possibility of damage to the

motorcycle or a component.

NOTE

Other information of particular importance has been

placed in italic type.

S&S urges you to take special notice of these advisories.

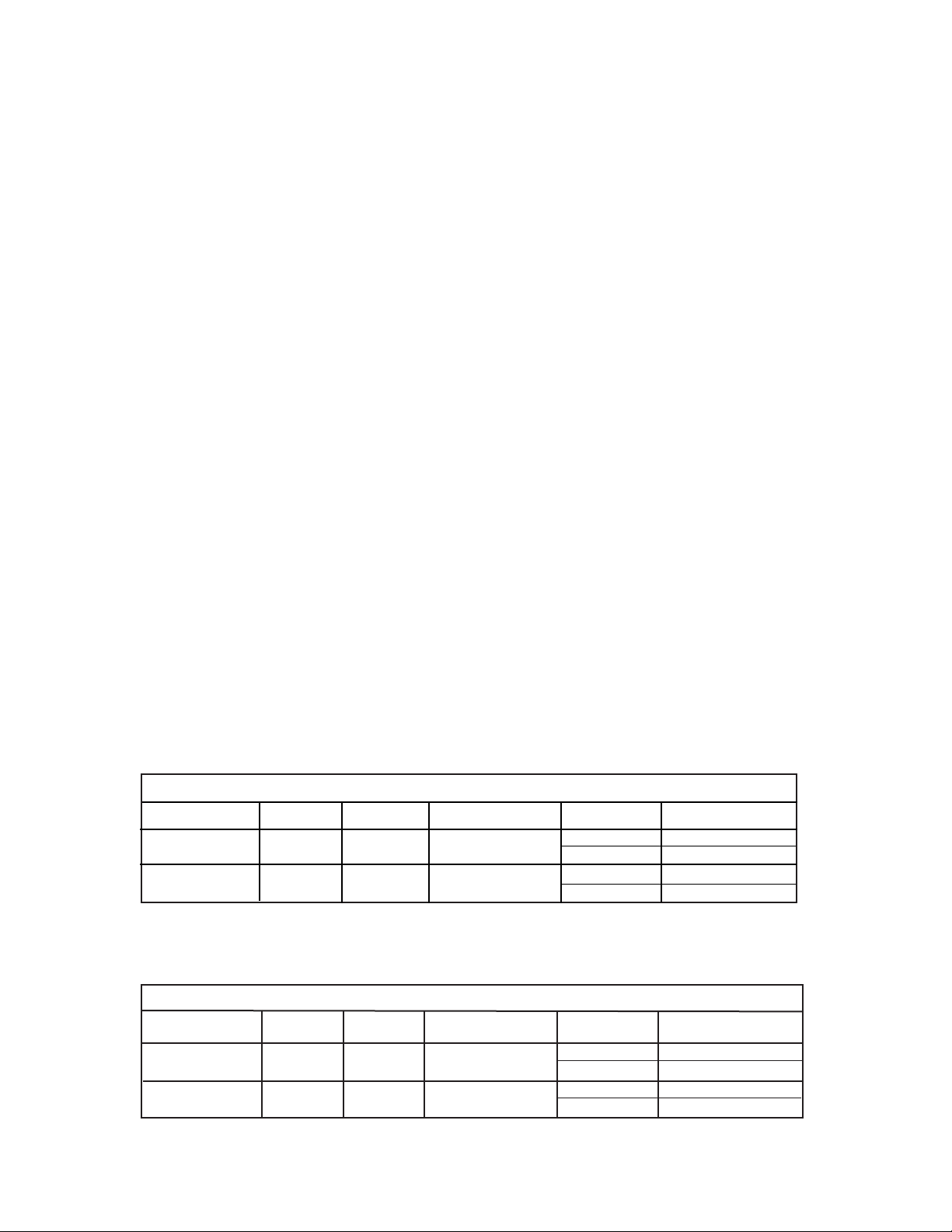

S&S Basic Twin Cam Style Engines for Evolution Style Chassis *

Displacement Bore Stroke Fuel System Finish

Assembled

Part Number

Natural 31-9340

124" 41⁄8"45⁄8" Carburetor

1

Black 31-9341

Natural 31-9343

124" 41⁄8"45⁄8" S&S VFI

2

Black 31-9344

S&S Basic Twin Cam Style Engines for Twin Cam Style Chassis*

Displacement Bore Stroke Fuel System Finish

Assembled

Part Number

Natural 31-9330

124" 41⁄8"45⁄8" Carburetor

1

Black 31-9331

Natural 31-9333

124" 41⁄8"45⁄8" S&S VFI

2

Black 31-9334

* For installation in Stock Harley-Davidson Twin Cam Chassis only. Balanced version unavailable.

1 Carbureted engines include an S&S IST ignition system and an S&S Super G or D carb.

2 Fuel injected Engines include S&S Variable Fuel Injection (VFI) system with your choice of S&S tuned or teardrop induction, and either

Magnetti-Marelli or Delphi style S&S VFI Module

A. Introduction

S&S 124 Twin Cam Engines are available in two

versions The first version is designed and intended for

installation in a stock Harley-Davidson Twin Cam

Chassis. It will bolt directly to the stock transmission

and engine mounts of chassis designed for stock

unbalanced Twin Cam engines. The second version of

Twin Cam style Engine is machined with an Evolution

style rear motor mount. It may be installed in a stock or

aftermarket Evolution style chassis. Both versions are

available in natural aluminum or black powder coat

finish.

S&S 124" T win Cam style Engines are available only in

a Basic version, meaning that some stock HarleyDavidson or aftermarket Twin Cam style parts will be

needed to complete the engine. The extra parts

needed include: oil pump, oil pressure switch, cam

support plate, cam cover, tappets, tappet covers, and

oil filter bracket.

Installation can be performed by any Harley-Davidson

repair shop equipped to do complete engine overhauls.

No special tools other than those used in normal

engine building operations are required.

NOTES

●

Installation of a fuel injected engine in a motorcycle that

was originally equipped with a carburetor is fairly difficult

and expensive. This conversion requires a fuel pump

equipped gas tank as well as wiring harness.

●

All S&S Twin Cam Style engine assemblies are for Twin

Cam “A” (non-counterbalanced) engine applications, and

are not for use in Twin Cam “B” (counterbalanced)

applications.

●

A balanced Twin Cam style Engine is not available from

S&S Cycle at this time.

3

* For installation in Stock Harley-Davidson Twin Cam Chassis only. Balanced version unavailable.

1 Carbureted Long Blocks include an S&S IST ignition system and an S&S Super G or D carb.

2 Fuel injected Long Blocks include S&S Variable Fuel Injection (VFI) system with your choice of S&S tuned or teardrop induction, and either

Magnetti-Marelli or Delphi style S&S VFI Module

I.Oil Tank, Fittings and Oil LIne

J. Exhaust System

K. Initial Start-up and Engine Break-In

L.Tuning Guidelines

M. Engine Specs and Torque Values

N. Service Intervals

O. Replacement Parts

Instruction Contents:

A. Introduction

B. Additional Features

C. Modification Notes

D. Engine to Frame Test Fit

E. Engine Assembly

F. Engine to Frame Assembly

G. Ignition System

H. Fuel System

Please read these instructions carefully before starting work. Proceed with the installation only after the instructions

are completely understood. These instructions should be supplemented by the appropriate OEM service manual for

your motorcycle. Follow all safety information.

B. Additional Features:

● Greater overall strength than stock crankcases,

especially in the front motor mount, an important

consideration in high performance applications.

● All oil passages between the crankcase and cam

support plate are o-ring sealed.

● Compatible with stock components. Use stock oil

pump, cam support plate, gear cover, etc.

● Uses 1999-2002 Timken style sprocket shaft bearing.

● Uses 2003-up pinion shaft bearing

S&S Twin Cam Style Engine Instructions often

refer to procedures described in other S&S

instructions or a Harley-Davidson Service Manual.

These materials should be cross-referenced as

necessary.

IMPORTANT

Before proceeding, verify that serial numbers on

crankcases match numbers on packing carton and

certificate of origin. Contact S&S immediately if

numbers do not match.

NOTE - Valid certificate of origin is required for any transfer

or sale of longblock assemblies. Certificate of origin is

required to title and license any motorcycle which is to be

driven on public streets and highways.

4

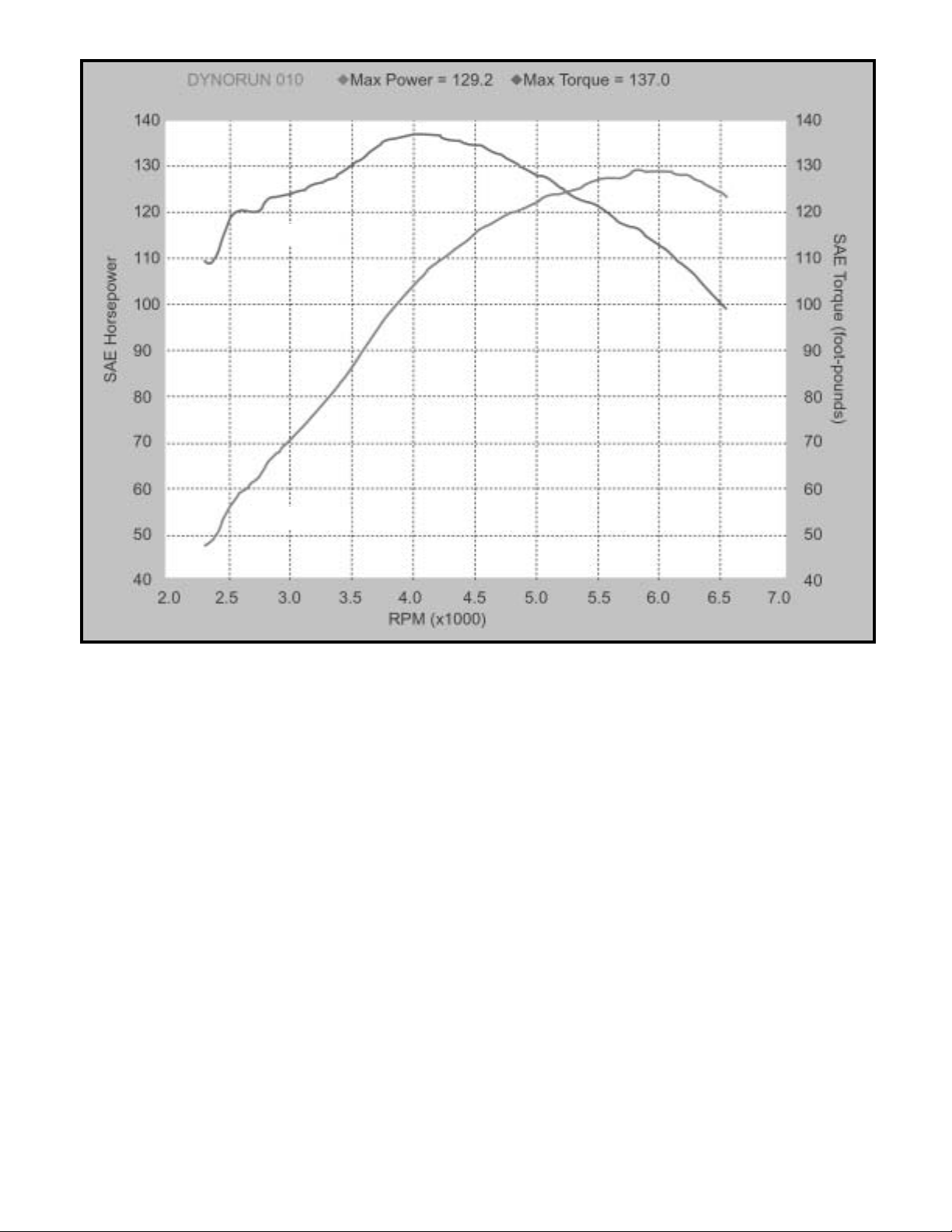

Dynomometer chart showing typical horsepower and torque curves for S&S 124” Twin Cam style engine.

Horsepower and torque curves will vary, dependant on the engines state of tune, and the ignition and fuel

systems used on the completed engine.

Torque

Horsepower

5

C. Modification Notes

S&S Cycle cautions against modifying these

crankcases due to the possibility of damaging or

weakening them. Modifying S&S crankcases in any

fashion voids all manufacturer warranties. Should the

customer elect to modify the crankcases regardless, it

is imperative that they and the information tag attached

to them be inspected beforehand to confirm that the

correct model, style, bore size, etc. have been

provided. The customer must confirm that crankcases

and related parts are correct before assembling them

or having them modified in any manner, and assumes

all liability for modifications.

Under no circumstance will S&S be held responsible

for expenses related to the modification of any S&S

part in the event warranty service is required. Modified

parts will not be accepted for credit or exchange. This

will apply regardless of cause or fault: customer,

retailer, manufacturer, or other.

For further information, contact S&S Technical Services

at 608-627-8324, FAX 608-627-0766 or e-mail

sstech@sscycle.com

NOTE - “Modification” includes but is not limited to

appearance changes such as painting, powdercoating,

plating, and polishing. Proper preparation for these

procedures as well as the processes themselves may

require the use of polishing compounds, chemicals or

procedures that are potentially harmful to crankcases.

CAUTION - Passages and internal cavities may become

obstructed by residues from materials used to polish,

paint, plate or powdercoat surfaces. Additionally,

surface finishing processes can damage critical

machined surfaces. Any of the above may cause

premature wear, damage or failure of other engine

components as well as the crankcases themselves.

Glass bead and polishing residues are abrasive and

can be difficult to remove from recesses and small

passages. Abrasive residues can cause oil

contamination and extensive engine damage. Engine

damage caused by powder coating, polishing, glass

bead blasting, or other modification will not be covered

under warranty.

Powder Coating - Subjecting heat-treated alloys such

as those used in S&S crankcases to excessive heat

can drastically alter their strength and their critical

properties. The degree of change depends upon the

temperatures reached and the duration of exposure.

When powder coating or otherwise processing alloy

parts, S&S exposes them to a maximum temperature

of 370°F for no longer than 20 minutes. Under no

circumstances should parts be heated past 400°F!

S&S strongly recommends trial-fitting every engine

before frame is painted or powder coated.

D. Engine to Frame Test Fit

NOTE - The engine must be fitted to the frame it is installed

into. It must rest squarely on its attachment points, and

bolted solidly to the frame without stressing the engine

case at any point. If possible, crankcase should be

positioned in motorcycle frame before assembly to check

alignment and clearances. The same clearancing and

alignment steps must be taken for assembled engines.

Performing the clearance alignment checks with a bare

case is convenient due to the reduced weight.

CAUTION - Failure to correctly mount the engine can

cause problems not covered under warranty including

but not limited to, excessive vibration, driveline misalignment, and broken castings.

CAUTION - Do not carry crankcase by the studs. It

stresses the crankcase and studs in ways they are not

designed to handle. Also, it is easy to drop and damage

the case when it is carried by the studs.

1. Test-fit instructions for Twin Cam style cases

with stock Twin Cam style engine mounts.

1. Assemble case halves using case bolts.

Tighten to snug. Torquing bolts to final

specification is not necessary.

2. Clean frame engine mounts and carefully

remove any irregularities from mounting

surfaces. Also inspect crankcase mounting

bosses for burrs.

3. Position case in frame, check for clearance at

frame, and alignment to transmission. It is a

good idea to replace rubber engine mounts at

this time. Old mounts deform over time and

can induce unwanted stresses on the engine

case.

6

CAUTION - Improper alignment of engine and frame

mounts may cause abnormal stresses resulting in

damage to crankcases or other parts.

2. Test-fit instructions for Twin Cam style cases

with Evo Style motor mounts.

1. Assemble case halves using case bolts.

Tighten to snug. Torquing bolts to final

specification is not necessary.

2. Clean frame engine mounts and carefully

remove any irregularities from mounting

surfaces. Also inspect crankcase mounting

bosses for burrs.

3. Position case assembly in frame.

4. Install engine mounting bolts in motor mounts,

and check clearance between mounting

bosses on cases and frame and any other

areas where frame and cases may contact

each other. Bolts may be difficult to install if

contact is severe.

5. If cases contact frame, remove them and

relieve just enough material in offending area

to provide clearance.

6. Place cases in frame, install one rear mounting

bolt and snug nut.

7. Measure gap between crankcase mounting

bosses and frame motor mounts with feeler

gauge to determine if shimming is required.

8. If gap exists, fabricate shim just thick enough

to fill gap

9. Install opposite corner shim and mounting bolt

and nut, and tighten identical to other bolt.

10. Check other corners with feeler gauge to

confirm thickness required is same as before.

If not, determine cause and correct.

NOTE - S&S Twin Cam style crankcase installation in

Evolution style motorcycle frame is essentially the same as

stock, although additional clearancing and shimming may

occasionally be required. When this style of case is solid

mounted instead of rubber mounted, additional care must

be taken in installing the case. Main areas of concern are

between cases and frame motor mounts. Checking

clearance around and between case mounting bosses and

frame is necessary to insure that crankcase rests squarely

on motor mount pad and no stress is applied to crankcases

when mounting bolts are tightened. Shimming may be

required to compensate for variances between frames.

E. Engine Assembly

NOTES:

●

S&S supplies Torco Engine Assembly Lube with each

Engine. It should be used as specified in following

instructions. While other brands of assembly lube are

acceptable, other lubricants are not. In no instance should

an aerosol lubricant be substituted for assembly lube.

●

While S&S has made every effort to insure that parts are

correct, it is the engine builder’s responsibility to confirm fit

and finish of all parts provided with Engines prior to

assembly. Parts are deburred at S&S and usually require

no further preparation, but must also be inspected by

installer. Individual parts should not be removed from

protective plastic wrappers until needed. After removal

from plastic, it is imperative that parts be thoroughly

cleaned and dried, preferably with compressed air. When

present, rust preventative must be completely removed.

Additionally , gaskets must be closely inspected for particles

that could become dislodged and damage engine. If

assembly of Engine must be interrupted, seal openings and

cover engine with plastic to protect from destructive

contaminants.

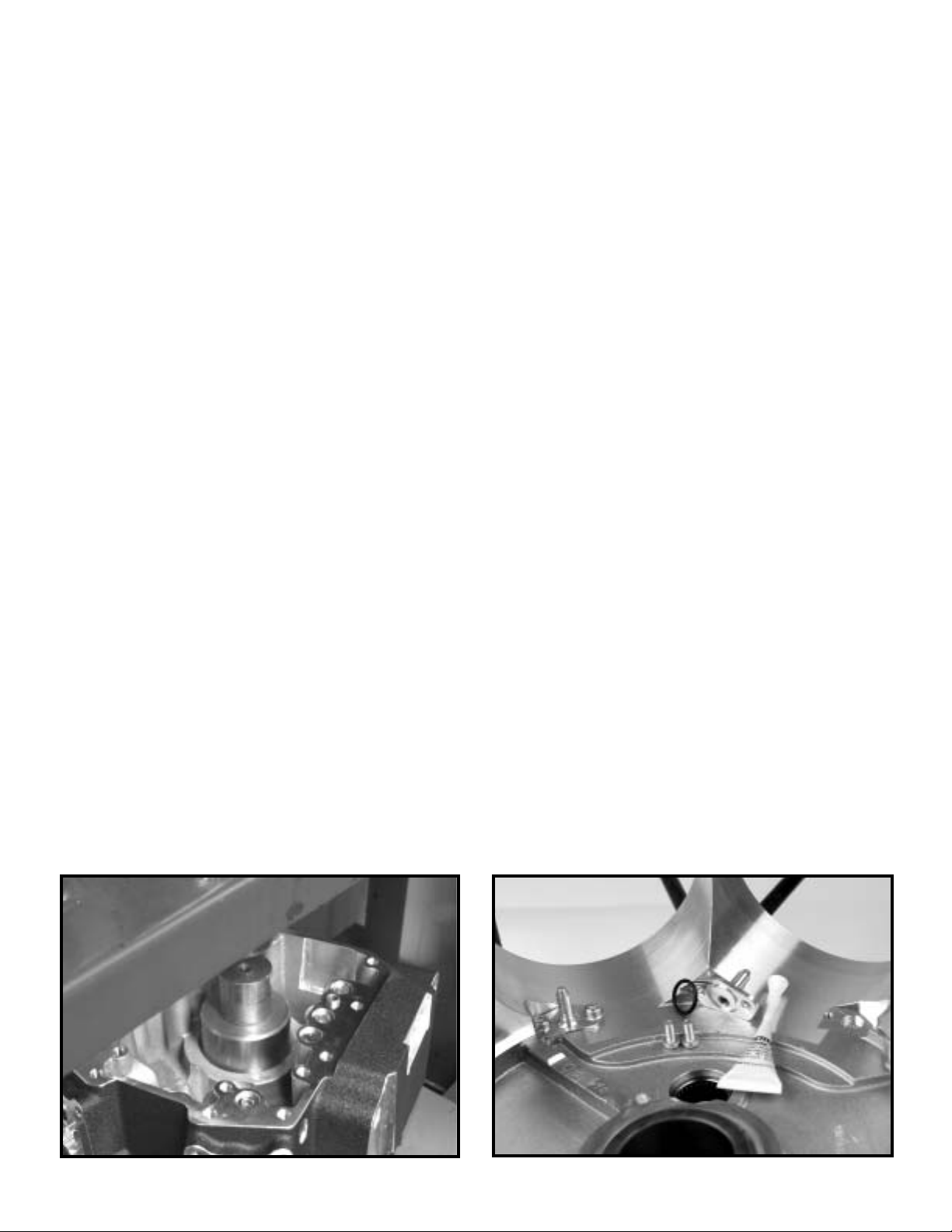

Picture E2

Picture E1

Loading...

Loading...