Page 1

Modbus RTU/TCP/IoT Protocol Gateway

IOT600-TWX-TS

User Manual

V1.0 REV A

SST Automation

E-mail: SUPPORT@SSTCOMM.COM

WWW.SSTCOMM.COM

Page 2

WWW.SSTCOMM.COM

1

Catalog

1 Introduction................................................................................................................................................................2

1.1 About This Document.....................................................................................................................................2

1.2 Copyright information.................................................................................................................................... 2

1.3 Related Products............................................................................................................................................. 2

2 Product Overview...................................................................................................................................................... 3

2.1 Product Function.............................................................................................................................................3

2.2 Product Features............................................................................................................................................. 3

3 Hardware Description................................................................................................................................................5

3.1 Appearance......................................................................................................................................................5

3.2 Indicators.........................................................................................................................................................6

3.3 Configuration Switch......................................................................................................................................6

3.4 Interface.......................................................................................................................................................... 7

3.4.1 Power Interface....................................................................................................................................7

3.4.2 Ethernet Interface.................................................................................................................................8

3.4.3 Serial Interface.....................................................................................................................................8

4 Instructions of Configuration Software................................................................................................................... 11

4.1 Notes before Configuring............................................................................................................................. 11

4.2 Rapid Configuration......................................................................................................................................11

4.3 Search Equipment.........................................................................................................................................12

4.3.1 Search All Equipment in Ethernet..................................................................................................... 12

4.3.2 IP Search............................................................................................................................................ 12

4.4 Configuration................................................................................................................................................14

4.4.1 Configuring Ethernet Parameters...................................................................................................... 15

4.4.2 Configuring Modbus Serial Port Parameters.................................................................................... 16

4.4.3 Configuring Modbus TCP Master Parameters.................................................................................. 17

4.4.4 Configuring Modbus Command........................................................................................................18

4.4.5 Configuring Modbus TCP Slave Parameters.................................................................................... 21

4.5 Locate............................................................................................................................................................21

4.6 Remote Reset................................................................................................................................................ 22

4.7 Open/Save/Export EXCEL...........................................................................................................................23

4.8 Auto Assign Property Name/Download....................................................................................................... 26

4.9 New...............................................................................................................................................................27

5 Typical Application..................................................................................................................................................29

6 Installation................................................................................................................................................................30

6.1 Machine Dimension......................................................................................................................................30

6.2 Installation Method.......................................................................................................................................31

Page 3

WWW.SSTCOMM.COM

2

1 Introduction

1.1 About This Document

This document describes the parameters, use methods and considerations of IOT600-TWX-TS,providing a

detailed technical implementation guide for developers. Please read this manual carefully before using the

gateway.

1.2 Copyright information

The data and examples in this document cannot be copied without authorization.

is the registered trade mark of SST Automation.

1.3 Related Products

If you want to get more information about related products, please visit SSTCOMM website:

http://www.sstcomm.com or Call the technical support hotline: +1-626-569-7107.

Page 4

WWW.SSTCOMM.COM

3

2 Product Overview

Support connecting 15 Modbus slaves

Each serial port supports up to 100 Modbus commands

Support baud rate:1200, 2400, 4800, 9600, 19200, 38400, 57600 and 115200bps

Support 01H, 02H, 03H, 04H, 05H, 06H 0FH and 10H function codes

Support up to 100 Modbus commands and up to 36 Modbus TCP devices

Support 01H, 02H, 03H, 04H, 05H, 06H 0FH and 10H function codes

Support 01H, 02H, 03H, 04H, 05H, 06H 0FH and 10H function codes and up to 36 Modbus TCP master

Register supports int16, uint16, int32, int32 inverse, uint32, uint32 inverse, float, float inverse, double,

Support coil status block, input status block, hold register block and input register block, each block

2.1 Product Function

IOT600-TWX-TS is designed to get ThingWorx users connected to their Modbus RTU slave, Modbus TCP

slave and Modbus TCP Master devices with just a few minutes of configuration time. The gateway could be edge

gateways that securely connect industrial Modbus equipment over Ethernet networks to ThingWorx.

2.2 Product Features

[1] Support maximum number of properties:1000 (Encrypted communication:860);

[2] The communication mode adopts the WebSocket mode and support TLS encrypted transmission;

[3] Modbus RTU master

[4] Modbus TCP master

[5] Modbus TCP slave

double inverse, int64, int64 inverse, uint64, uint64 inverse

supports the maximum 1024 registers or bits

[6] Power supply: 24VDC (9V ~ 30V), 90mA (24VDC);

[7] Working temperature: -4℉~140℉(-20℃~60℃), relative humidity: 5% ~ 95% (non-condensing);

[8] External Dimensions (W*H*D): 1.57 in*4.92 in*4.33 in (40mm*125mm*110mm);

Page 5

WWW.SSTCOMM.COM

4

[9] Installation: 35mm rail;

[10] Protection class: IP20;

Page 6

WWW.SSTCOMM.COM

5

3 Hardware Description

serial port I indicators

Ethernet RJ45 interface

Configuration switch

Dual power interface

serial port II indicators

RS-485 serial port I

Modbus TCP indicators

RS-485 serial port II

3.1 Appearance

Page 7

WWW.SSTCOMM.COM

6

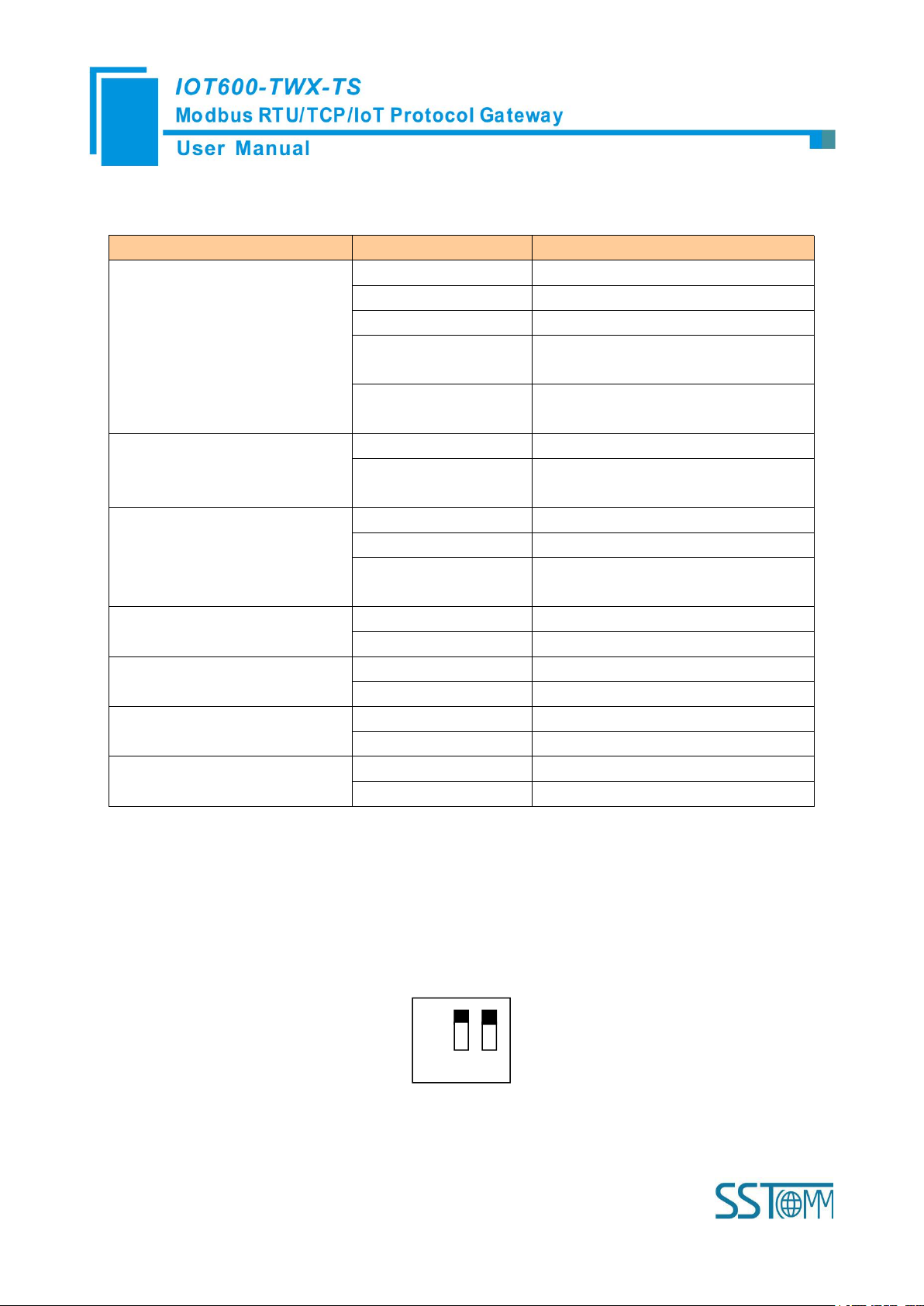

3.2 Indicators

Indicators

Status

Descriptions

ENS

Green on

IP address has not conflict

Red on

IP address has conflict

Blinking(Red)

DHCP,IP address conflict detection

Green on

Modbus TCP interface has data to

receive or send.

Blinking(Green)

Modbus TCP interface has not data to

receive or send.

SNS

Green on

Connect to the cloud platform

Blinking(Green)/Blinkin

g(Red)/Red on

Unconnected to the cloud platform

ENS (Orange) and SNS (Orange)

(Orange: Red and green light on at

the same time)

Simultaneously on

Start-up state

Blink alternately

Configuration mode or Retained mode

Blink alternately

(lasts 3 seconds)

Using locate function

serial port I TX

Blinking(Green)

serial port I is sending data

Close(Green)

serial port I isn't sending data.

serial port I RX

Blinking(Green)

serial port I is receiving data.

Close(Green)

serial port I isn't receiving data.

serial port II TX

Blinking(Green)

serial port II is sending data

Close(Green)

serial port II isn't sending data.

serial port II RX

Blinking(Green)

serial port II is receiving data.

Close(Green)

serial port II isn't receiving data.

Off

On 1 2

3.3 Configuration Switch

The DIP switch is located at the bottom of the gateway, bit 1 is mode bit and bit 2 is function bit.

Page 8

WWW.SSTCOMM.COM

7

Mode (bit 1)

Function (bit 2)

Description

Off

Off

Run mode, allowing reading and writing of configuration

Off

On

Run mode, forbidding reading and writing configuration

On

Off

Configuration mode, IP address is 192.168.0.10 (fixed),

On

On

Reserved

Notes:Restart IOT600-TWX-TS (power off and power on) or remote reset after resetting the

Pin

Function

1

GND

2

NC, not connected

3

24V+ , DC 24V

configuration to make the configuration take effect!

3.4 Interface

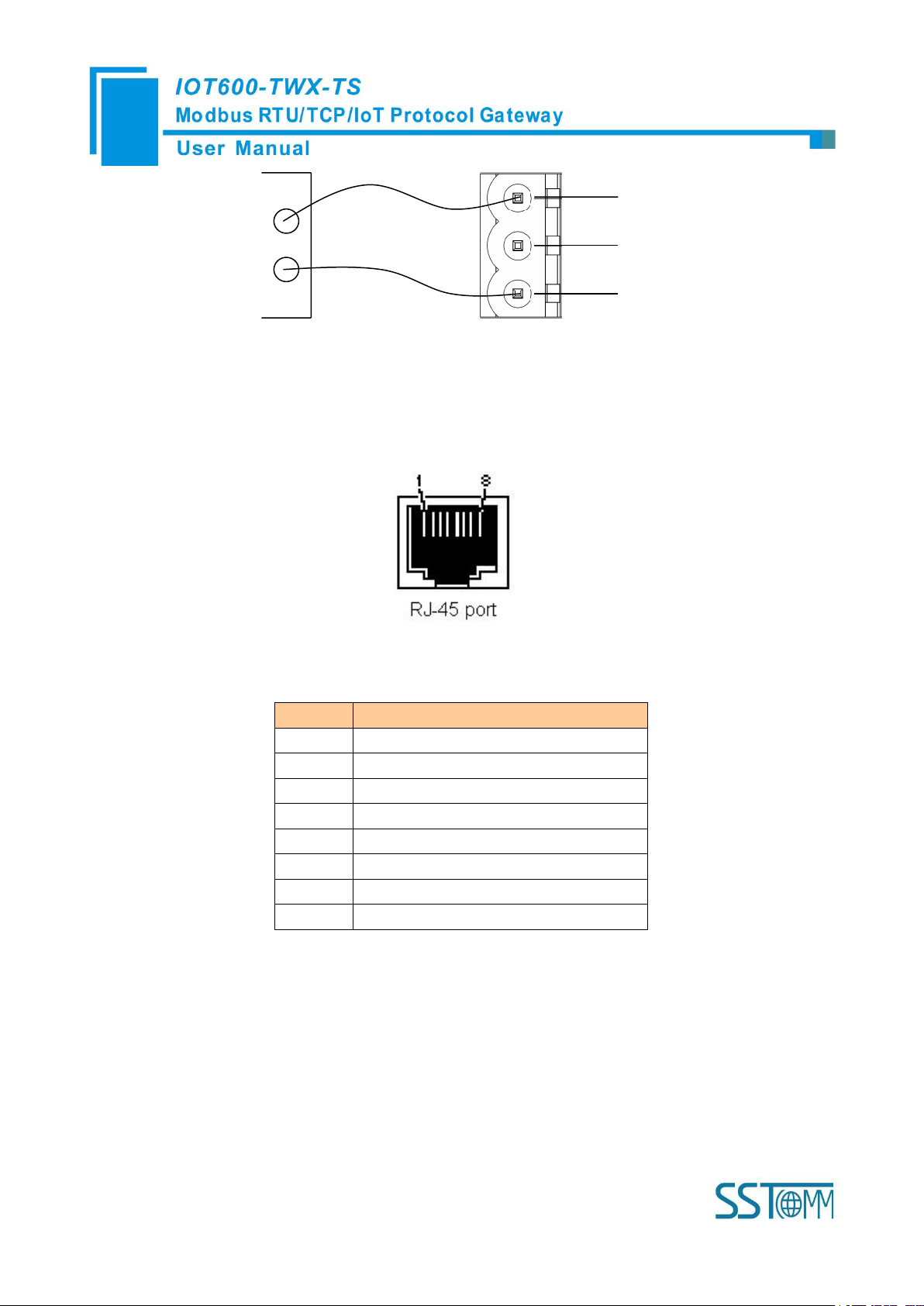

3.4.1 Power Interface

IOT600TWX-TS uses a 24V DC power supply which has two power interfaces and power redundant

function. When one power fails, another power can keep supplying power.

Power supply wiring is shown as below:

Page 9

WWW.SSTCOMM.COM

8

GND

NC

24V+

1

23GND

24V+

DC power: +24V

Power interface

3.4.2 Ethernet Interface

Pin

Signal Description

S1

TXD+, Tranceive Data+, Output

S2

TXD-, Tranceive Data-, Output

S3

RXD+, Receive Data+, Input

S4

Bi-directional Data+

S5

Bi-directional Data-

S6

RXD-, Receive Data-, Input

S7

Bi-directional Data+

S8

Bi-directional Data-

Ethernet interface uses RJ-45 connector; its pin (standard Ethernet signal) is defined as below:

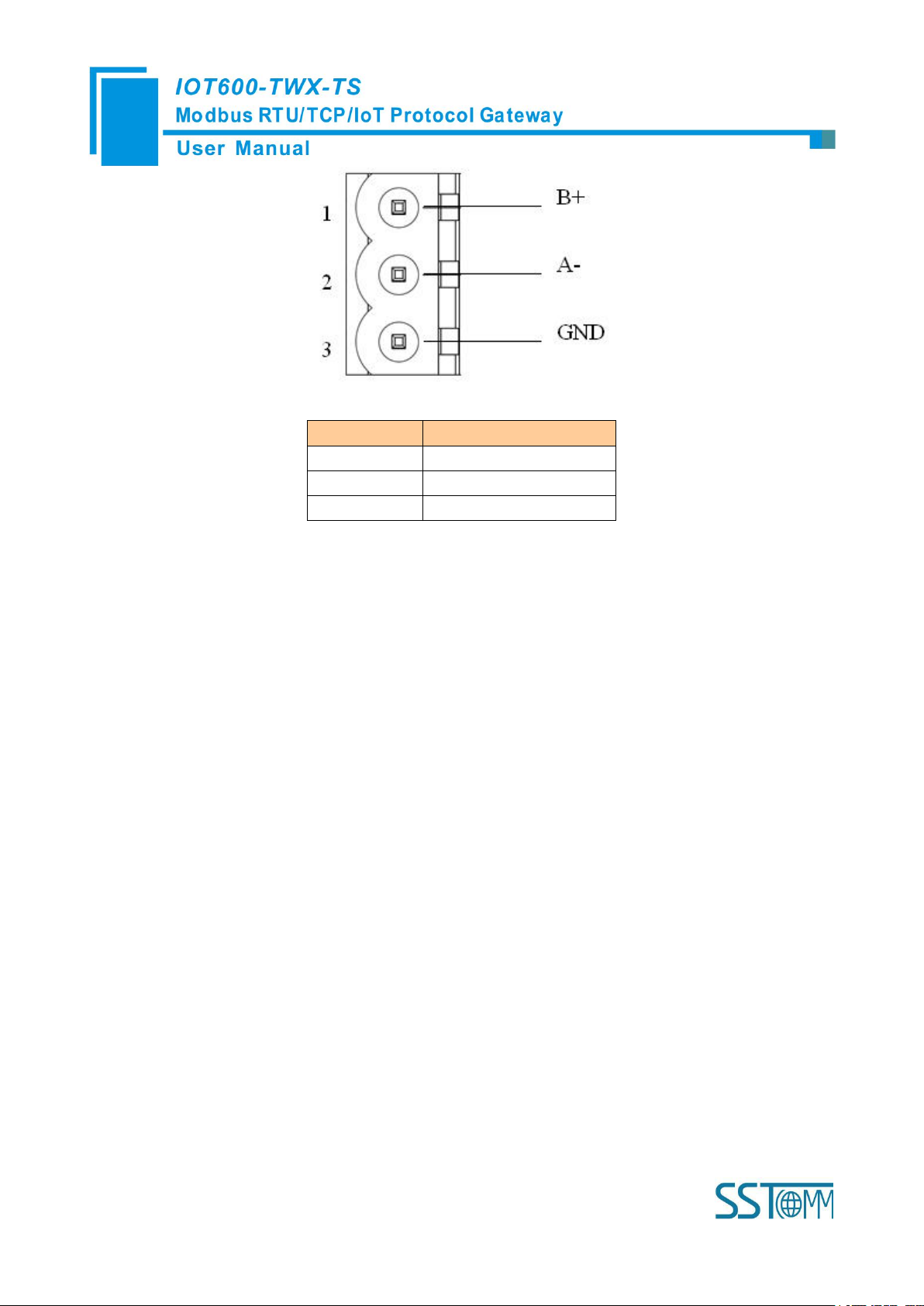

3.4.3 Serial Interface

Pin of RS485 interface is defined as below:

Page 10

WWW.SSTCOMM.COM

9

Pin

Description

1

B+, RS485

2

A-, RS485

3

GND

The RS485 interface of the IOT600-TWX-TS is a standard one, and the RS485 characteristics of the

product are shown as follows:

1. The basic characteristics of RS485 transmission technology

① Network topology: Linear bus, there are active bus terminal resistors at both sides.

② Transmission rate: 1200 bps~115.2Kbps.

③ Media: Shielded twisted-pair cable and also can cancel the shielding, depending on environmental

conditions (EMC).

④Site numbers: 32 stations per subsection (without repeater), and can up to 127 stations (with RS485

repeater).

⑤Plug connection: 3-pin pluggable terminal.

2. The main points on RS485 transmission equipment installation

①All the equipment are connected with RS485 bus;

②Subsection can be connected up to 32 sites;

③The farthest end of each bus has a termination resistor—120Ω 1/2W to ensure reliable operation of the

network.

Page 11

WWW.SSTCOMM.COM

10

D+D-GND

1

2

3

485+

485-

RS485 device

RS485 interface

RS485 device

RS485 device

485+

485-

485+

485-

…

When RS485 is in point to multipoint communication, in order to prevent the reflection and interference of

the signal, each of a terminal resistance is required at the farthest ends of the line, with a parameter of 120Ω 1/2W.

IOT600-TWX-TS serial port side has no parallel terminal resistance.

Page 12

WWW.SSTCOMM.COM

11

4 Instructions of Configuration Software

Connect the power lines, network lines and RS485 lines correctly;

Double click the configuration software (SST-IOT-CFG) and finish the configuration of IOT600-TWX-TS

Notes: The factory setting of IOT600-TWX-TS is 192.168.0.44, If you need to change, set the mode of the

configuration switch (bit 1) to the configuration (On) and restart the IOT600-TWX-TS.at this time the IP address

of IOT600-TWX-TS is 192.168.0.10(fixed), subnet mask is 255.255.255.0, and gateway address is 192.168.0.1.

Change the relevant parameters to the gateway as required, adjust the position of the dial switch to the factory

setting, and restart the gateway.

4.1 Notes before Configuring

SST-IOT-CFG is a software based on Windows platform,Before running the software, make sure the user’s

computer and IOT600-TWX-TS need to be in the same local network.

Double-click the icon to enter configuration interface:

4.2 Rapid Configuration

Page 13

WWW.SSTCOMM.COM

12

Power on IOT600-TWX-TS;

According to the actual situation of Modbus slave equipment, modify the IOT600-TWX-TS

configuration according to this specification, and download the configuration to IOT600-TWX-TS;

Connect Modbus slave equipment;

4.3 Search Equipment

Before configuring parameters of IOT600-TWX-TS, users need to search the gateway using the software.

The software provides two ways to search the gateway.

4.3.1 Search All Equipment in Ethernet

Click "Search Equipment" button of the main interface, the software will search all the available

IOT600-TWX-TS equipment and list them in the main interface.

4.3.2 IP Search

Click "IP Search" button of the main interface will pop up a dialog box which demands you to input IP

address.

Page 14

WWW.SSTCOMM.COM

13

After entering the correct IP address, the software will search IOT600-TWX-TS with this IP address in

the network, and list the information of the equipment in the main interface.

Page 15

WWW.SSTCOMM.COM

14

Notes:If users select the "IP Search", users need to enter correct IP address or it will not search equipment.

4.4 Configuration

Select the equipment to be configured in the list, and the "Locate", "Configuration", "Remote Reset", "New",

"Open" and "Save" buttons will become available:

Click "Configuration" button,The following window is popped out:

Page 16

WWW.SSTCOMM.COM

15

4.4.1 Configuring Ethernet Parameters

Ethernet parameters include: "Name", "Assign IP Mode", "IP Address", "Subnet Mask", "Default Gateway",

"DNS1" and "DNS2".

IOT Protocol Type: Web Socket

Device name: When connecting multiple IOT600-TWX-TS device, that is used to identify different

devices

Notes: The name can not have space, up to 32 characters.

Assign IP Mode: Manual Assign and DHCP

IP address: IP Address of IOT600-TWX-TS

Subnet Mask: set subnet mask of the equipment;

Default Gateway: set gateway address of the equipment;

DNS1: Preferred domain name server (LAN can not be set)

DNS2: Standby domain name server

URL and port:URL and Port should separate with ":", and can not exceed 100 characters. Such as:

iot.bokaiyun.cn:443. Note: The port number is related to the "TLS Enable", and the port number can

only be 443 when "TLS Enable" is selected as Enable.

TLS Enable: Whether to use TLS encryption transmission. You can choose: Disable, Enalbe. Note:

The TLS enable is related to the port.

Retries: the connection to the cloud server failed and the number of reconnects. Default: 10

Page 17

WWW.SSTCOMM.COM

16

Connection timed out: Send a connection request to the cloud server, waiting for the server to respond

to the time. Default: 10

AppKey: Connecting to ThingWorx requires AppKey, and can not exceed 64 characters.

Push Data Cycle: After the connection is established with ThingWorx, This parameter is the cycle of

the data pushed to the ThingWorx cloud. Range 100 ~ 60000ms, default: 300ms.

4.4.2 Configuring Modbus Serial Port Parameters

Serial parameters include: "Baud Rate", " check bit", "Stop bits" and "Data Bits".

Baud rate: 1200,2400,4800,9600,19200,38400,57600,115200

Data Bits: 8 (currently only support 8 data bits)

check bit: Odd, Even, None, Space and Mark

Stop bits: 1, 2

Transmission mode: RTU

Response timeout: After the gateway sends request, it waits the Modbus slave's response for max time which

Page 18

WWW.SSTCOMM.COM

17

is in ms. The range of the parameter value is 300 to 60000ms.

Delay between polls: Delay between polls means delay between a response has been received and sending

next request. The range of the parameter value is 0 to 2500ms

Output mode: There are two types of output: Cycle: the write command will be sent periodically; Change of

Value: when the output data change, the write command will be sent;

Scan rate: Scan Rate is ratio of fast scan to slow scan

Enable Auto Demotion: When Enable Auto Demotion and a command is a fast scan command without

correct response for N times, then the command will demote a slow scan command.

Auto Demotion: Setting Modbus command does not respond to resending the times

Auto Demotion time: When the Demotion Time timeout the command will promote a fast command. How to

Action after N successive Response Timeout: Clear Data; Hold Data

Note: the shadow’s parameter can not be changed.

4.4.3 Configuring Modbus TCP Master Parameters

Protocol Type selection: Modbus TCP Master, Modbus TCP Slave

Response timeout: After the gateway sends request, it waits the Modbus slave’s response for max time

Which is in ms. the range of the parameter value is 300 to 60000ms.Default value is

1000ms

Delay between polls: Delay between polls means delay between a response has been received and

Page 19

WWW.SSTCOMM.COM

18

sending next request. The range of the parameter value is 0 to 2500ms.Default value is 3ms

Output mode: Cycle, Change of Value

Cycle: the write command will be sent periodically;

Change of Value: when the output data change, the write command will be sent;

4.4.4 Configuring Modbus Command

1.Add nodes and Delete nodes

Right click "Modbus Master I"and select "Add Node"

Right click on the node to be deletedand select "Delete Node"

2.Add commands

Right click "Node ()" and select "Add command"

Page 20

WWW.SSTCOMM.COM

19

Select the command: Double click the command

For each Modbus command setting, the SST-IOT-CFG software automatically maps the Modbus command to

the corresponding attributes after the completion.

Page 21

WWW.SSTCOMM.COM

20

"Property type": Number, Boolean;

Read Input Register: Mapping to Number object;

Read Holding Register: Mapping to Number object;

Read Coil Status: Mapping to Boolean object;

Read Input Status: Mapping to Boolean object;

Force Single Coil: Mapping to Boolean object;

Force Multiple Coils: Mapping to Boolean object;

Preset Single Register: Mapping to Number object;

Preset Multiple Registers: Mapping to Number object;

Property name": you can edit and modify, the maximum data length is 20

"

"Register Count ":The Register Count can be selected as "1","2"and"4",Default value is 1

"Data type": BOOL, UINT16, INT16, UINT32, Float, INT32, UINT32V, INT32V, FloatV, Double, DoubleV,

INT64, NT64V, UINT64, UINT64V

"scale": you can edit and modify, The range of the parameter value is 0.001~1000, Default value is 1.0

Page 22

WWW.SSTCOMM.COM

21

4.4.5 Configuring Modbus TCP Slave Parameters

The Starting Address of Coil:Range 0~65535. Default 0.

The size of Coil: is the length which Modbus TCP master can access from the Starting Address of Coil in

IOT600-TWX-TS.

The Starting Address of Input Bit:Range 0~65535. Default 0.

The Size of Input Bit: is the length which Modbus TCP master can access from the Starting Address of Input

Bit in IOT600-TWX-TS

The Starting Address of Holding Register:Range 0~65535. Default 0.

The Size of Holding Register: is the length which Modbus TCP master can access from the Starting Address

of Holding Register in IOT600-TWX-TS

The Starting Address of Input Register:Range 0~65535. Default 0.

The Size of Input Register: is the length which Modbus TCP master can access from the Starting Address of

Input Register in IOT600-TWX-TS

4.5 Locate

When users manage multiple IOT600-TWX-TA, you can use "Locate" function to determine equipment that

you want to configure.

Users click on the "Locate" button, and the equipment is in Ethernet, the ENS and SNS orange indicator of

Page 23

WWW.SSTCOMM.COM

22

the equipment will flash alternately then the users can find it.

4.6 Remote Reset

The function of "remote reset" is restarting the selected equipment. Select the equipment in the list first, click

"Remote reset" button, it will pop up a confirmation dialog, then click "OK" to complete the operation.

Page 24

WWW.SSTCOMM.COM

23

4.7 Open/Save/Export EXCEL

Open: open and display the saved to the configuration data in a computer;

Page 25

WWW.SSTCOMM.COM

24

Export EXCEL: Excel document helps users to examine the configuration related

Page 26

WWW.SSTCOMM.COM

25

Save: Save the configuration parameters to the computer (.Chg) for later view, and pay attention to

saving the file.Select the device in the list, click "save", select the path to complete the operation.

Page 27

WWW.SSTCOMM.COM

26

4.8 Auto Assign Property Name/Download

Auto Assign Property Name: Naming the properties of thing automatically

Download: download the configuration information to IOT600-TWX-TS

Page 28

WWW.SSTCOMM.COM

27

4.9 New

Page 29

WWW.SSTCOMM.COM

28

Page 30

WWW.SSTCOMM.COM

29

5 Typical Application

IOT600-TWX-TS can connect Modbus slave devices to Ethernet in order to realize the communication

between Ethernet and serial devices.IOT600-TWX-TS plays a bridging role in communication.

The following is some typical application of .IOT600-TWX-TS:Ethernet master connects multiple serial port

Slave.

IOT600-TWX-TS collects Modbus RTU/TCP slave equipment data to the cloud, and exchange data

Page 31

WWW.SSTCOMM.COM

30

6 Installation

6.1 Machine Dimension

Size: 1.57 in (width)*4.92 in (height)*4.33 in (depth)

Page 32

WWW.SSTCOMM.COM

31

6.2 Installation Method

35mm DIN rail mounting

Loading...

Loading...