Page 1

Industrial Ethernet Serial Gateway

(Modbus RTU/ASCII / Modbus TCP)

Modbus Serial/TCP Series

User Manual

REV 1.4

SST Automation

E-mail: support@sstcomm.com

WWW.SSTCOMM.COM

Page 2

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

2

Catalog

1 Product Overview...................................................................................................................................................... 4

1.1 Product Function.............................................................................................................................................4

1.2 Product Features............................................................................................................................................. 4

1.3 Technical specifications..................................................................................................................................5

2 Hardware Description................................................................................................................................................ 6

2.1 Appearance......................................................................................................................................................6

2.2 Indicators.........................................................................................................................................................7

2.3 DIP switch.......................................................................................................................................................7

2.4 Interface.......................................................................................................................................................... 8

2.4.1 Power interface.................................................................................................................................... 8

2.4.2 Ethernet interface.................................................................................................................................9

2.4.3 Serial interface...................................................................................................................................10

3 Instructions of Configuration Software...................................................................................................................12

3.1 Notes before configuration........................................................................................................................... 12

3.2 Search equipment..........................................................................................................................................13

3.2.1 Search all equipment in Ethernet.......................................................................................................13

3.2.2 IP search.............................................................................................................................................14

3.3 Configuration................................................................................................................................................ 16

3.3.1 Mode selection...................................................................................................................................17

3.3.2 Ethernet parameters........................................................................................................................... 18

3.3.3 Serial parameters............................................................................................................................... 18

3.3.4 ID mapping (Advanced parameters)................................................................................................. 20

3.3.5 Modbus parameters (Advanced parameters).....................................................................................21

3.3.6 Priority control (Advanced parameters)............................................................................................22

3.3.7 Advanced (Advanced parameters).....................................................................................................23

3.3.8 OK, Cancel and Help.........................................................................................................................24

3.4 Locate............................................................................................................................................................25

3.5 Remote reset................................................................................................................................................. 26

3.6 New (offline configuration)..........................................................................................................................26

3.7 Open..............................................................................................................................................................27

3.8 Save...............................................................................................................................................................28

3.9 Communication test......................................................................................................................................30

4 Typical Application..................................................................................................................................................31

4.1 Multiple Ethernet master connect with multiple serial slave.......................................................................31

4.2 Multiport serial master connect with multiple Ethernet slave..................................................................... 32

4.3 Serial master connect with serial slave via Ethernet.................................................................................... 33

5 Installation................................................................................................................................................................34

5.1 Machine Dimension......................................................................................................................................34

Page 3

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

3

5.2 Installation Method.......................................................................................................................................34

Page 4

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

4

1 Product Overview

Product Type

Ethernet end protocol

Serial protocol

Serial number

GT200-MT-RS

Modbus TCP

Modbus RTU/ASCII

Single serial port

GT200-MT-2RS

Modbus TCP

Modbus RTU/ASCII

Dual serial port

Operating mode:

Dual Ethernet interface , built-in switch, support cascade , can be used in a ring network ,save field

GT200-MT-RS: One RS485 interface or RS232 interface, 1KV electromagnetic isolation;

Ethernet 10/100M self-adaptive;

Slave ID mapping function;

1.1 Product Function

Modbus Serial/TCP series gateway can achieve the interconnection between Ethernet (Modbus TCP protocol)

devices and serial (Modbus RTU/ASCII) devices. The Modbus Serial/TCP series gateway supports dual Ethernet

ports, built-in switch; the serial side supports single/dual/four serial port. Each port supports both RS485 and

RS232, but the same product can only achieve one type of port, users can specify the port according to actual

needs when ordering.

Modbus Serial/TCP series gateway products type list:

1.2 Product Features

Modbus RTU/ASCII slave mode: Modbus TCP masters communicate with Modbus RTU/ASCII slaves

through the gateway;

Modbus RTU/ASCII master mode: Modbus RTU/ASCII masters communicate with Modbus TCP salves

through the gateway.

connection cables and switches;

GT200-MT-2RS: Two RS485 interfaces or RS232 interfaces, 1KV electromagnetic isolation;

Page 5

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

5

Packet request is automatically routed to the serial port;

Network security settings;

Limit the IP address range of clients’ communication machine;

Debugging function;

Provide easy-to-use configuration software SST-MT-CFG.

Login password can be set;

1.3 Technical specifications

[1] Slave mode: Support 4 Modbus TCP master communication simultaneously, and can support 32

command request simultaneously;

[2] Master mode: Support visiting 4 different IPs or Modbus TCP slaves of different ports;

[3] Every serial interface is all RS485 or RS232, half-duplex, and baud rate support: 1200, 2400, 4800, 9600,

19200, 38400, 57600, 115200 and 230400bps optional; parity: none, odd and even optional; 1 or 2 stop bits;

[4] Power supply: 24VDC (11V ~ 30V), 130mA (24VDC);

[5] Working temperature: -4℉~140℉(-20℃~60℃), relative humidity: 5% ~ 95% (non-condensing);

[6] External Dimensions (W*H*D): 1.57 in*4.92 in*4.33 in (40mm*125mm*110mm);

[7] Installation: 35mm rail;

[8] Protection class: IP20;

[9] Test standard: EMC test standards.

Page 6

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

6

2 Hardware Description

1. The picture above shows the appearance of GT200-MT-2RS;

2. GT200-MT-2RS , two serial ports : serial I and serial II;

3. GT200-MT-RS, one serial port: serial I.

Dual Ethernet interface

Serial interfaceⅠ

Serial interface Ⅱ

Configuration switch

Power interface

Indicators

2.1 Appearance

Notes:

Page 7

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

7

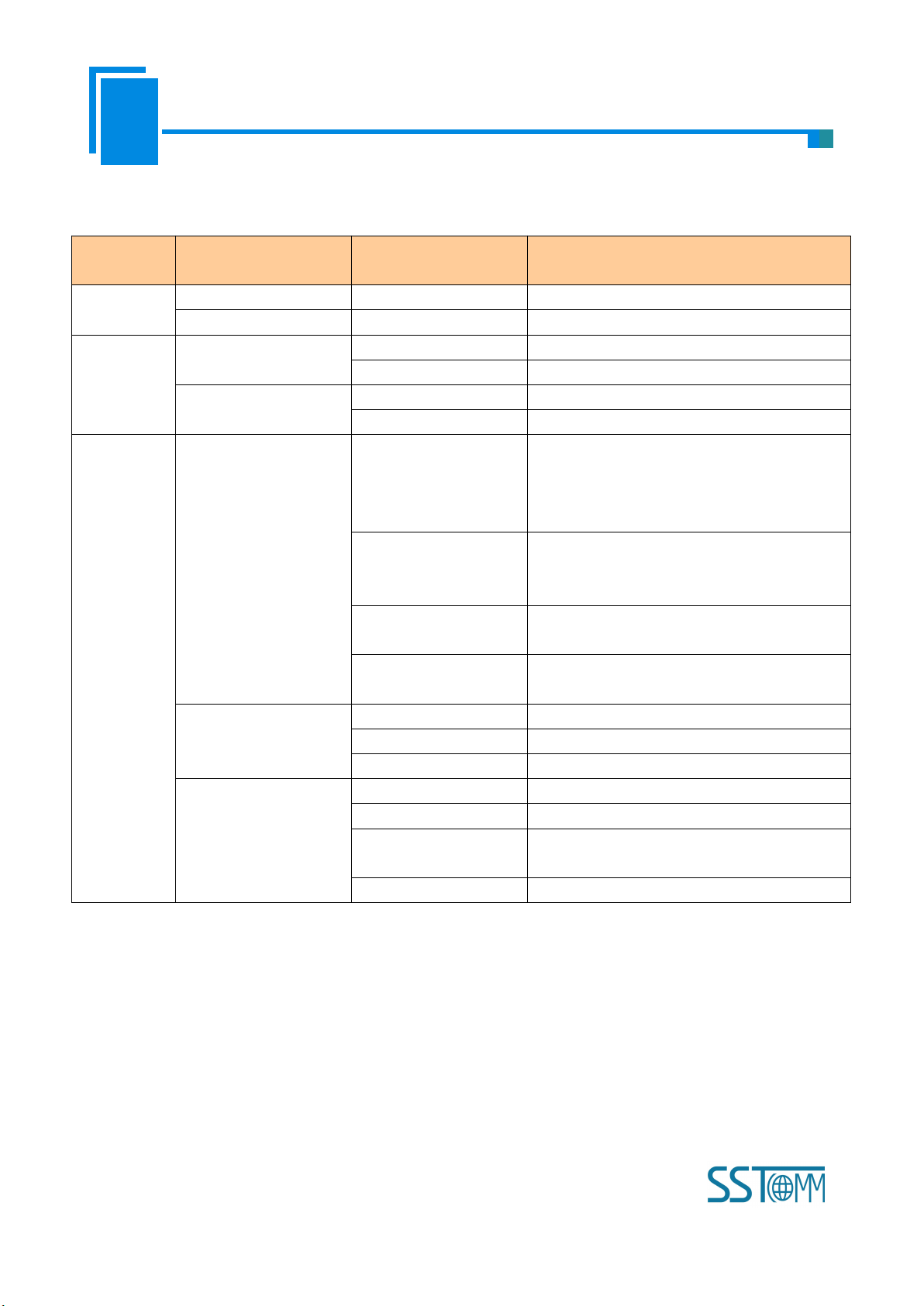

2.2 Indicators

product

model

Indicators

Status

Descriptions

GT200-MT-

RS

RX

Blinking(Green)

Serial port is receiving data

TX

Blinking (Green)

Serial port is transmitting data

GT200-MT-

2RS

Ⅰ

RX blinking(Green)

Serial portⅠis receiving data

TX blinking (Green)

Serial portⅠis transmitting data

Ⅱ

RX blinking (Green)

Serial portⅡis receiving data

TX Blinking(Green)

Serial portⅡis transmitting data

Modbus

Serial/TCP

series

ENS

Green on

Slave mode: At least one Modbus TCP

connection has been established;

Master mode: Modbus TCP connection has

been established

Blinking(Green)

Slave mode: Modbus TCP no connection;

Master mode: Modbus TCP connection has

not been established

Blinking(Red)

Modbus TCP connection is disconnected and

no longer exists; Obtain IP config via DHCP

Blinking(Red)

(lasts 3 seconds)

Modbus TCP connection is disconnected

SNS

Green on

Serial port ready to transmit and receive data

Blinking(Red)

Automatic routing conflict

Red on

Equipment failure or firmware update failed

ENS (Orange) and

SNS (Orange)

(Orange: Red and

green light on at the

same time)

Simultaneously on

Start status

Blink alternately

Configuration Mode

Blink alternately

(lasts 3 seconds)

Using locate function

ENS on, SNS off

Firmware update mode

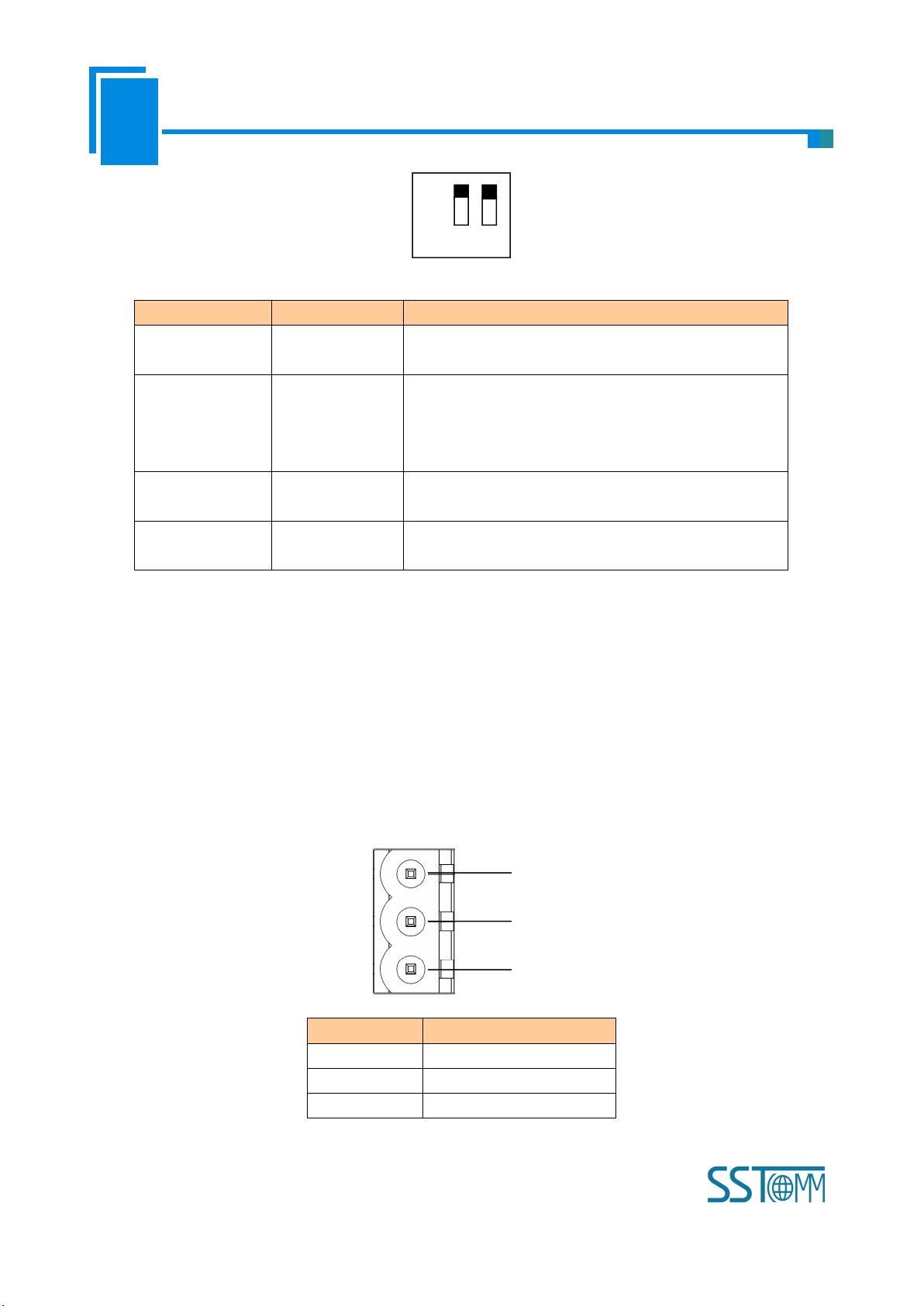

2.3 DIP switch

The DIP switch is located at the bottom of the gateway, bit 1 is mode bit and bit 2 is function bit.

Page 8

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

8

Off

On 1 2

Mode (bit 1)

Function (bit 2)

Description

Off

Off

Run mode, allowing reading and writing of configuration

data

Off

On

Configuration mode, IP address is 192.168.0.10 (fixed),

this mode can read and write configuration data but cannot

finish communication between Modbus TCP and Modbus

RTU devices

On

Off

Run mode, forbidding reading and writing of configuration

data (configuration data protection switch )

On

On

Firmware update mode, IP address is 192.168.0.10, this

mode can only update firmware

Notes:

GND

NC

24V+

1

2

3

Pin

Function

1

GND

2

NC, not connected

3

24V+ , DC 24V

Restart Modbus Serial/TCP series gateway (power off and power on) after resetting the configuration

to make the configuration take effect!

2.4 Interface

2.4.1 Power interface

Modbus Serial/TCP series gateway uses a 24V DC power supply. The power interface uses a 3-pin 7.62mm both

ends of the closed-end terminals, defined as follows:

Page 9

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

9

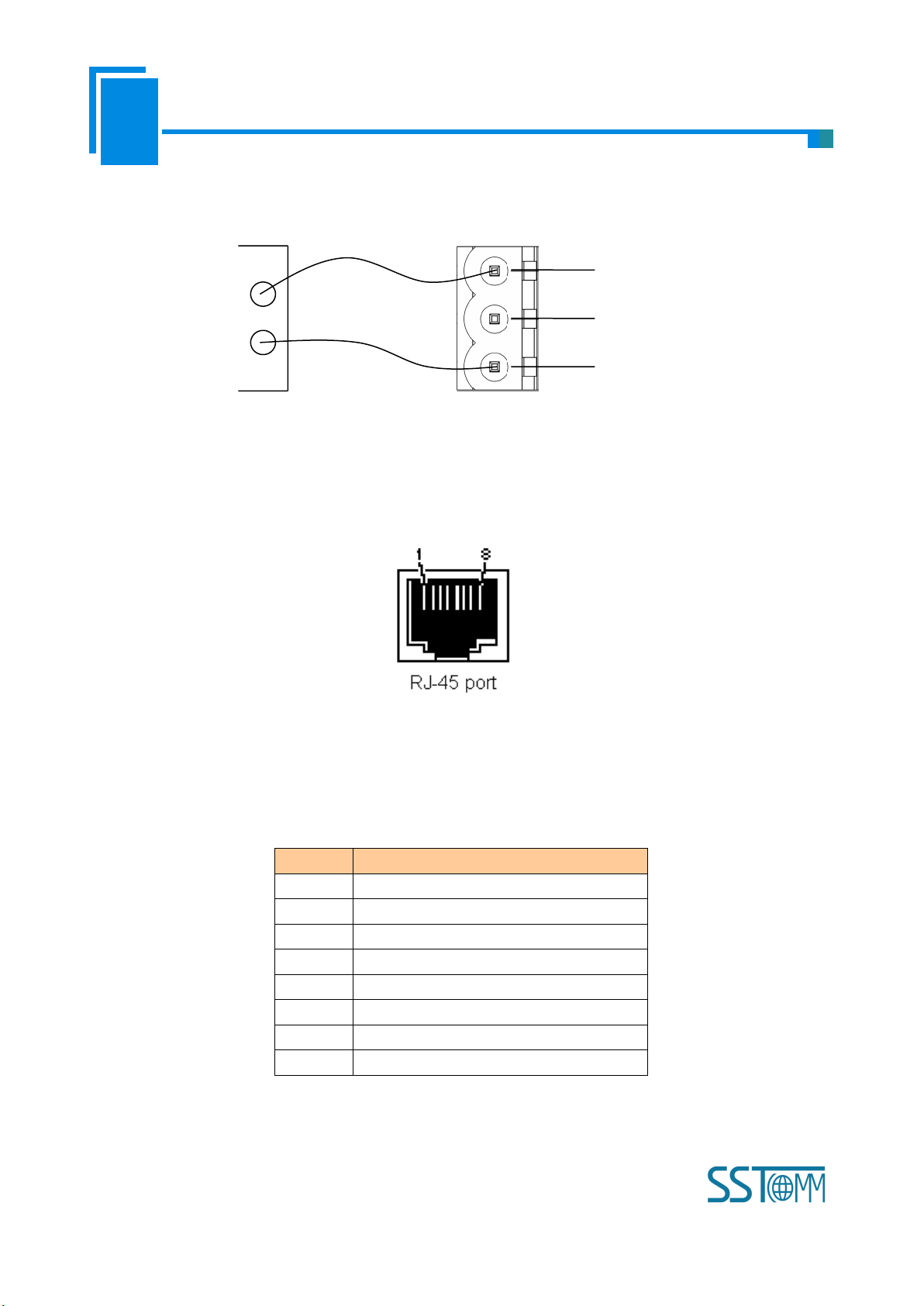

Power supply wiring is shown as below:

GND

NC

24V+

1

2

3

GND

24V+

DC power: +24V

Power interface

Pin

Signal Description

S1

TXD+, Tranceive Data+, Output

S2

TXD-, Tranceive Data-, Output

S3

RXD+, Receive Data+, Input

S4

Bi-directional Data+

S5

Bi-directional Data-

S6

RXD-, Receive Data-, Input

S7

Bi-directional Data+

S8

Bi-directional Data-

2.4.2 Ethernet interface

Ethernet interface uses RJ-45 connector; its pin (standard Ethernet signal) is defined as below:

Page 10

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

10

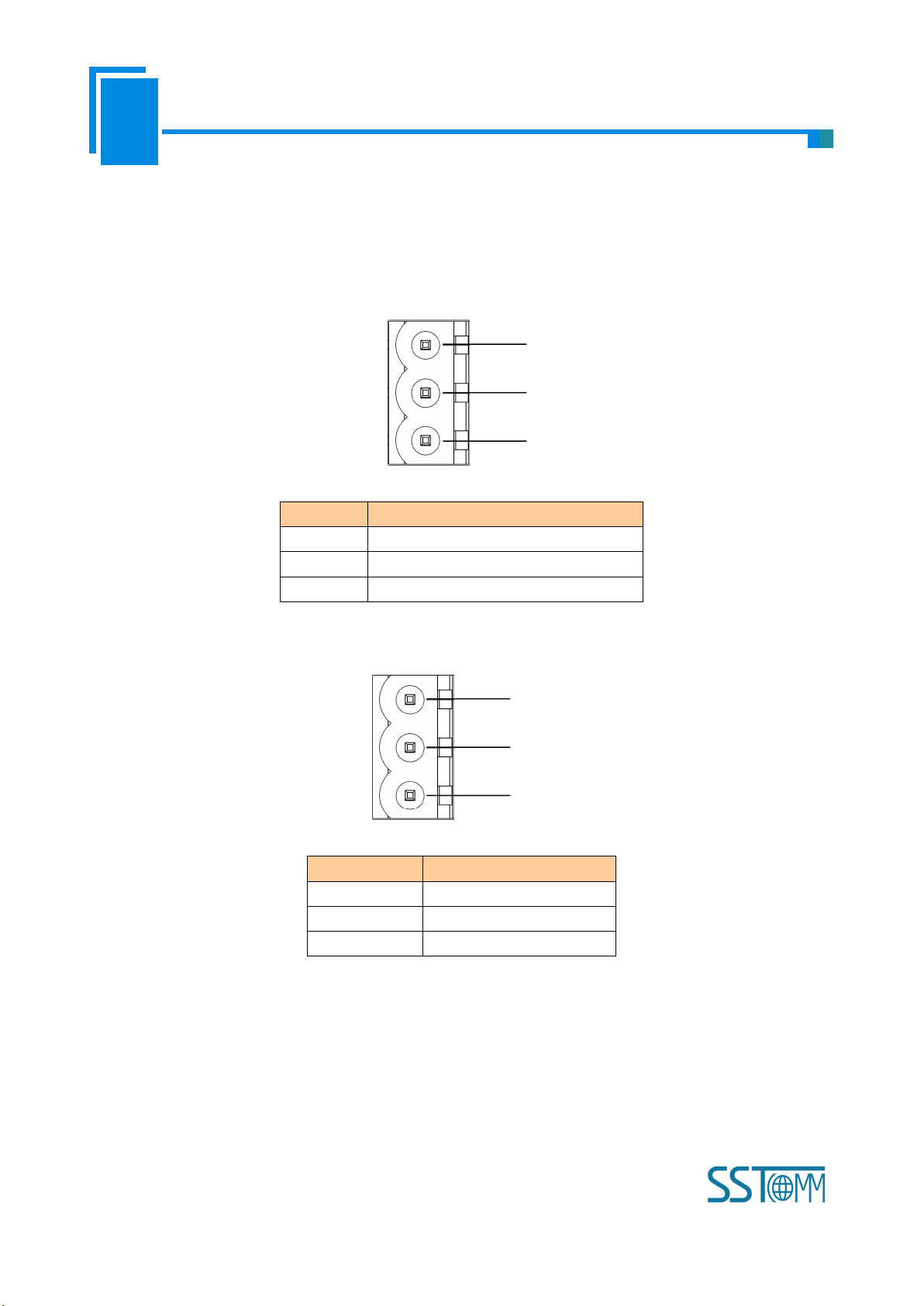

2.4.3 Serial interface

TXRXGND

1

2

3

Pin

Signal Description

1

TX, connect with RX of user device

2

RX, connect with TX of user device

3

GND

D+D-GND

1

2

3

Pin

Signal Description

1

D+, RS485

2

D-, RS485

3

GND

Modbus Serial/TCP series gateway uses a 3-pin 5.08mm closed terminal of two ends. Ports support RS485 or

RS232.

Pin of RS232 interface is defined as below:

Pin of RS485 interface is defined as below:

The RS485 interface of the Modbus Serial/TCP series gateway is a standard one, and the RS485

characteristics of the product are shown as follows:

1. The basic characteristics of RS485 transmission technology

① Network topology: Linear bus, there are active bus terminal resistors at both sides.

Page 11

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

11

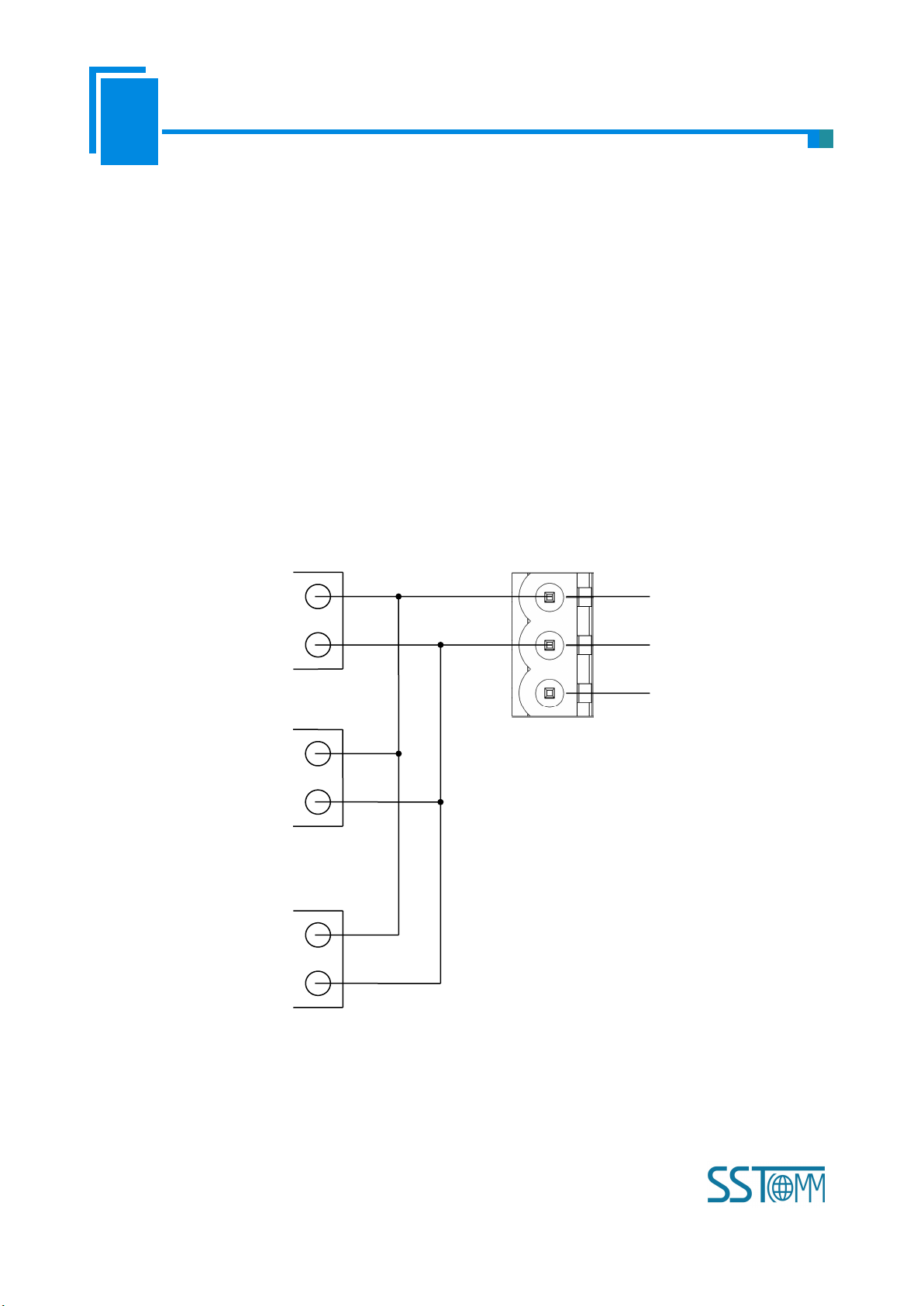

② Transmission rate: 1200 bps~115.2Kbps.

D+D-GND

1

2

3

485+

485-

RS485 device

RS485 interface

RS485 device

RS485 device

485+

485-

485+

485-

…

③ Media: Shielded twisted-pair cable and also can cancel the shielding, depending on environmental

conditions (EMC).

④Site numbers: 32 stations per subsection (without repeater), and can up to 127 stations (with RS485

repeater).

⑤Plug connection: 3-pin pluggable terminal.

2. The main points on RS485 transmission equipment installation

①All the equipment are connected with RS485 bus;

②Subsection can be connected up to 32 sites;

③The farthest end of each bus has a termination resistor—120Ω 1/2W to ensure reliable operation of the

network.

Page 12

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

12

3 Instructions of Configuration Software

Double click the configuration software and finish the configuration of Modbus Serial/TCP series gateway.

(GT200-MT-2RS as an example below)

Notes:

The factory setting of Modbus Serial/TCP series gateway is 192.168.0.10, subnet mask is 255.255.255.0, and

gateway address is 192.168.0.1.

(When users click the “Advanced” tab in the “Restore Factory Settings ", the default IP address configuration

is DHCP.)

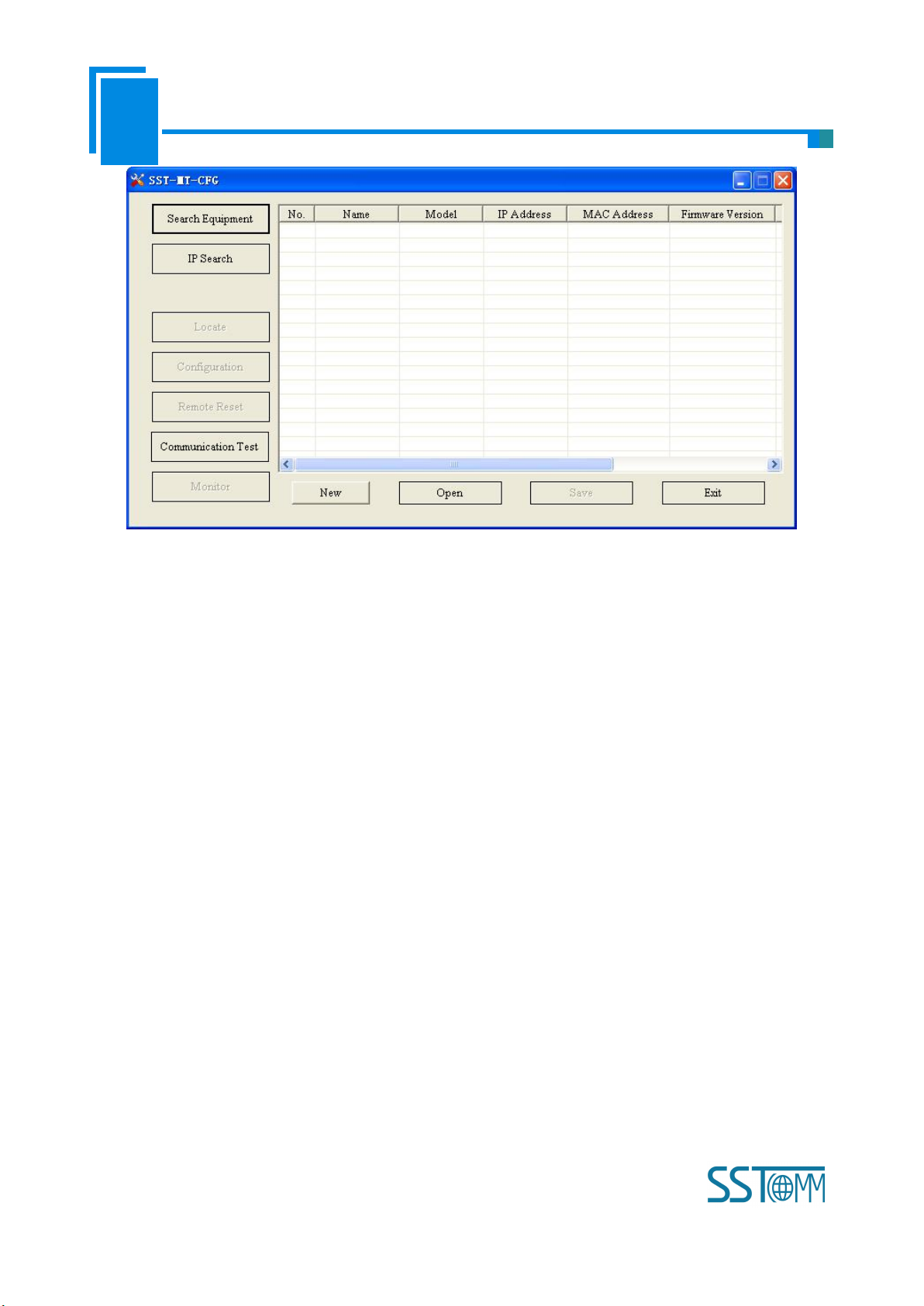

3.1 Notes before configuration

SST-MT-CFG is a product based on Windows platform, and used to configure parameters of Modbus

Serial/TCP series gateway.

Before running the software, make sure the user’s computer and Modbus Serial/TCP series need to be in the

same network.

Double-click the icon to access the main interface:

Page 13

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

13

3.2 Search equipment

Before configuring parameters of Modbus Serial/TCP, users need to search the gateway using the software.

The software provides two ways to search the gateway.

3.2.1 Search all equipment in Ethernet

Click “Search Equipment” button of the main interface, the software will search all the available Modbus

Serial/TCP series gateway equipment and list them in the main interface.

Page 14

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

14

3.2.2 IP search

Click “IP Search” button of the main interface will pop up a dialog box which demands you to input IP

address.

Page 15

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

15

After entering the correct IP address, the software will search Modbus Serial/TCP series gateway with this IP

address in the network, and list the information of the equipment in the main interface.

Notes:

Page 16

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

16

If users select the “IP Search”, users need to enter correct IP address or it will not search equipment.

3.3 Configuration

Select the equipment to be configured in the list, and the “Locate”, “Configuration”, “Remote Reset”, “New”,

“Open” and “Save” buttons will become available:

Click “Configuration” button, a password authentication dialog box will pop up if the equipment has been set

with a password:

Pass the password authentication or then enter configuration interface with no password:

Page 17

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

17

3.3.1 Mode selection

Now Modbus Serial/TCP series gateway supports four operating modes:

Modbus RTU slave mode——Modbus TCP master communicate with Modbus RTU slave through the

gateway;

Modbus RTU master mode——Modbus RTU master communicate with Modbus TCP salve through the

gateway.

Modbus ASCII slave mode——Modbus TCP master communicate with Modbus ASCII slave through the

gateway;

Modbus ASCII master mode——Modbus ASCII master communicate with Modbus TCP salve through the

gateway.

Operating mode of Modbus Serial/TCP series gateway is defined by the role of master or slave of serial

equipment, for example, when you want to achieve the communication between Modbus TCP master devices and

Modbus RTU/ASCII slave devices, users need to select “RTU/ASCII slave mode” of Modbus Serial/TCP series

gateway.

Page 18

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

18

3.3.2 Ethernet parameters

Ethernet parameters include: “Name”, “Assign IP Mode”, “IP Address”, “Subnet Mask”, “Default Gateway”,

“DNS1” and “DNS2”.

Name——enter a name to identify the device in order to distinguish from other equipment;

Assign IP Mode——set the IP address configuration mode of the equipment;

IP address——set IP address of the equipment;

Subnet Mask——set subnet mask of the equipment;

Default Gateway——set gateway address of the equipment;

DNS1——0.0.0.0 (currently only support 0.0.0.0)

DNS2——0.0.0.0 (currently only support 0.0.0.0)

Notes:

The name cannot have spaces, up to 20 characters.

3.3.3 Serial parameters

Serial parameters include: “Baud Rate”, “Parity”, “Stop bits” and “Data Bits”.

Page 19

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

19

Baud rate——1200、2400、4800、9600、19200、38400、57600、115200、230400bps;

Parity——None, Odd, Even;

Stop bit——1, 2;

Data bit——8 (currently only support 8 data bits)

Notes:

GT200-MT-2RS gateway: You only need to set one serial port, if all serial port parameters are consistent, and

then click "Apply to All Serial Ports”, all serial port parameters can be configured to the current display serial port

parameters. Click “Display Serial Information” will pop up:

Page 20

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

20

3.3.4 ID mapping (Advanced parameters)

When you select RTU slave or ASCII slave mode, and only configure the basic configuration, this cannot be

configured.

When you select RTU master or ASCII master mode, please indicate which server the request packets are

sent to.

Virtual Slave ID Range——enter an ID range, the left is minimum, the right is maximum (no more than

247);

Offset of Slave ID——D-value of virtual ID and actual ID (can be negative);

Actual Salve ID——by clicking “Set” button to calculate;

When selecting “RTU/ASCII slave mode”, users need to specify the serial port to be mapped.

When selecting “RTU/ASCII master mode”, users need to set “IP of Target TCP server”, that is the IP

address of the server to be connected.

After setting “Virtual slave ID Range” and “Offset of Slave ID”, click “Set” button, “Actual Salve ID” value

is automatically calculated.

When users click “Add” button, users can add a message in “Slave ID Mapping Table”.

When users want to modify the added information, users fist select the information you want to modify, and

Page 21

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

21

then set “Virtual Slave ID Range” and “Offset of Slave ID”, click “Modify” button.

When users want to delete the added information, users need to select the information you want to delete, and

click “Delete” button.

Tips:

1. “Add” and “Modify” button both have “Set” function, users do not need to click “Set” then click “Add”

or “Modify”.

2. Support up to 4 group ID mapping.

3.3.5 Modbus parameters (Advanced parameters)

When you select RTU slave or ASCII slave mode, and only configure the basic parameters, the item does not

need to be configured.

Set "Time Interval between Characters", "Response Timeout" and "Delay between Polls" of Modbus

RTU/ASCII in the following interface:

Notes:

When users use GT200-MT-2RS gateway, you only need to set one serial port if all serial port parameters are

consistent, and then click "Apply to All Serial Ports”, all serial port parameters can be configured to the current

display serial port parameters. Click “Display Serial Information” will pop up:

Page 22

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

22

3.3.6 Priority control (Advanced parameters)

Conditions

Priority

Comply with specified master, and comply with specified request

High

Comply with specified master, or comply with specified request

General

Not comply with priority conditions

Low

When users select RTU slave or ASCII slave mode, and only configure the basic configuration, this does not

need to be configured. (Modbus Serial/TCP series gateway does not support this feature temporarily)

Ethernet speed is faster than serial port, and it will cause queuing of frame, then you can set priority of

frames.

After enabling “Priority Control”, users can set the parameters they want and only “RTU/ASCII salve mode”

supports the function:

Specify the master——the requests of specified master are prior to transmit.

Specify the request——the requests of specified slave ID (virtual ID) or function codes are prior to transmit.

Priority of requests:

Use method of “Add”, “Modify” and “Delete” is the same with “ID mapping”.

Page 23

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

23

3.3.7 Advanced (Advanced parameters)

When you select RTU slave or ASCII slave mode, and only configure the basic configuration, this cannot be

configured.

Advanced parameters include: "Password", "Confirm Password", "Use default port", "Port Number",

"Start-up Delay of Serial Port", "Restore Factory Settings", "TCP Connect Idle Time", and "Limitation of

communication IP Range".

Password——after setting the password, users need to enter the password when logging in the equipment

Page 24

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

24

again. If users want to delete the password, just set your password to empty.

(1) OK:

Restore Factory Settings——when users click the button, the previous configuration information will be lost.

TCP Connect Idle Time and Keep-Alive——When a TCP connection idle time reaches the set value, if

“Keep-Alive” is selected, then transmit keep-alive message; If not, then disconnect the TCP connection.

Limitation of communication IP range——Set the range of communication IP to limit the client to connect to

Modbus Serial/TCP.

3.3.8 OK, Cancel and Help

After configuring parameters, users need to click “OK” button to write the configuration to the equipment. If

you do not want to write to the configuration, click “Cancel” button.

Page 25

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

25

Save: Save the configuration as ". inf " format to the local disk;

(2) Cancel:

(3) Help:

Download: Download the configuration to the equipment;

Save and Download: Save to the hard disk and download to the equipment.

Yes: Save to the hard drive and close;

No: No save and direct close.

Open the software manual.

3.4 Locate

When users manage multiple Modbus Serial/TCP gateways, you can use “Locate” function to determine

equipment that you want to configure.

Users click on the “Locate” button, and the equipment is in Ethernet, the ENS and SNS red indicator of the

equipment will flash alternately 3 seconds then the users can find it.

Page 26

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

26

3.5 Remote reset

The function of “remote reset” is restarting the selected equipment. Click remote reset, ENS and SNS red

indicators will be on at the same time

Select the equipment in the list first, click “Remote reset” button, it will pop up a confirmation dialog, then

click “OK” to complete the operation.

3.6 New (offline configuration)

Click “New” and select an equipment message dialog box:

Page 27

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

27

Enter into the new configuration interface; all of the data is the factory defaults.

3.7 Open

Open: Including open online and open offline;

Open online (as shown below ) : is equivalent to import, select the device from the list , click the " Open " , if

the equipment type of the gateway is the same with the opened configuration file type , and the equipment allows

remote configuration , open successfully ; otherwise , it will show the appropriate error message.

Open offline (as shown below): Open directly without choosing the equipment (One of the off-line

configuration functionality)

Page 28

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

28

3.8 Save

Save: is equivalent to export, select a device and click “Save, save the parameters of the device as “.inf”

format on the hard disk

Page 29

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

29

Notes:

The configuration file can be opened with notepad, you can modify the data inside; make sure the accuracy

of the modified data;

Please don’t modify keywords, don’t add a space.

Page 30

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

30

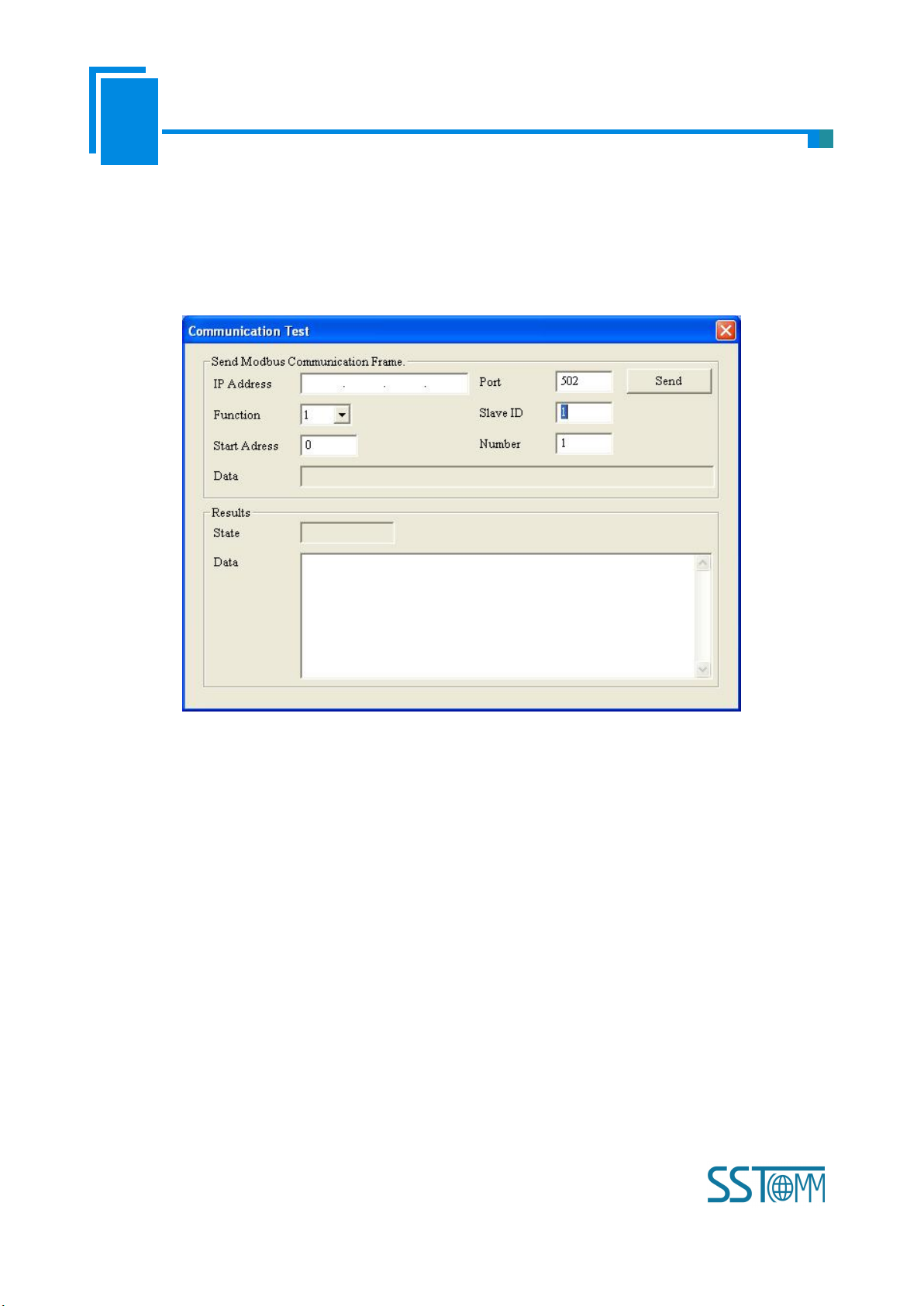

3.9 Communication test

"Communication Test" can send Modbus TCP request manually, it is convenient for user's debugging serial

equipment, click "Communication Test" to enter:

IP Address: the IP address of equipment needs to be connected;

Port: the port number of equipment needs to be connected; the default value is 502;

Function: support function code: 1, 2, 3, 4, 5, 6, 15 and 16;

Slave ID: the slave address (virtual ID);

Start Address: the start address of registers or coils, decimal;

Number: the number of registers or coils, decimal;

Data (up): the data needs to be sent, hex;

State: the response state, "No response", "Right response", "Wrong response";

Data (down): show the content of response message.

Note: the input data is HEX data, it must comply with data format like "12 ff 0c". The data format is this one too.

Page 31

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

31

4 Typical Application

Modbus Serial/TCP series gateway can connect Modbus master/slave devices to Ethernet in order to realize

the communication between Ethernet and serial devices.

The following is some typical application of Modbus Serial/TCP series gateway. (Take GT200-MT-2RS as an

example)

4.1 Multiple Ethernet master connect with multiple serial slave

GT200-MT-2RS supports dual Ethernet ports, built-in switch function. Support more than one independent

serial port. When serial is RS485, it can connect nearly 100 Modbus slave devices to the Ethernet.

Page 32

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

32

4.2 Multiport serial master connect with multiple Ethernet slave

Page 33

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

33

4.3 Serial master connect with serial slave via Ethernet

Serial devices communicate via Ethernet, not subject to the limitation of the transmission distance.

Page 34

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

34

5 Installation

5.1 Machine Dimension

Size: 1.57 in (width)*4.92 in (height)*4.33 in (depth)

5.2 Installation Method

35mm DIN rail mounting

Page 35

User Manual

Industrial Ethernet Serial Gateway

Mod bus Serial/TCP Series

WWW.SSTCOMM.COM

35

Loading...

Loading...