Page 1

HART/ Modbus Serial Gateway

GT200-HT-RS

User Manual

V 2.3 REV B

SST Automation

E-mail: SUPPORT@SSTCOMM.COM

WWW.SSTCOMM.COM

Page 2

WWW.SSTCOMM.COM 2

Catalog

1 Product Overview...................................................................................................................................................... 4

1.1 Product Function.............................................................................................................................................4

1.2 Product Features............................................................................................................................................. 4

1.3 Technical Specifications.................................................................................................................................4

1.4 Safety and Explosion-Proof Features............................................................................................................. 5

1.5 Related Products............................................................................................................................................. 5

1.6 Revision History............................................................................................................................................. 5

2 Quick Start Guide...................................................................................................................................................... 6

2.1 Configuration of Gateway Parameters........................................................................................................... 6

2.1.1 Pre-configured Settings....................................................................................................................... 6

2.1.2 Software Configuration....................................................................................................................... 6

2.2 Function Demo............................................................................................................................................... 9

3 Hardware Descriptions.............................................................................................................................................11

3.1 Product Appearance...................................................................................................................................... 11

3.2 Indicators.......................................................................................................................................................12

3.3 DIP Switch/Button........................................................................................................................................12

3.3.1 DIP Switch.........................................................................................................................................12

3.3.2 Modbus Address Setting Button........................................................................................................13

3.3.3 Internal/External Sampling Resistor Switch..................................................................................... 13

3.4 Interface........................................................................................................................................................ 14

3.4.1 Power Interface..................................................................................................................................14

3.4.2 RS-485/RS-422 Interface.................................................................................................................. 14

3.4.3 RS-232 Interface................................................................................................................................15

3.4.4 HART Interface..................................................................................................................................16

3.4.5 Mini B Type USB.............................................................................................................................. 16

3.5 Topology of GT200-HT-RS and Fieldbus Devices......................................................................................17

4 Software Instructions............................................................................................................................................... 19

4.1 Software Interface Description.....................................................................................................................19

4.2 Software Functional Specifications..............................................................................................................21

4.2.1 Connect with the Hardware............................................................................................................... 21

4.2.2 Upload configuration.........................................................................................................................22

4.2.3 Configure the Fieldbus...................................................................................................................... 22

4.2.4 Configure the HART Fieldbus...........................................................................................................25

4.2.5 Conflict Detection..............................................................................................................................32

4.2.6 AutoMap............................................................................................................................................ 33

4.2.7 Download Configuration................................................................................................................... 33

4.2.8 Memory Data Display....................................................................................................................... 33

4.2.9 Diagnose............................................................................................................................................ 34

Page 3

WWW.SSTCOMM.COM 3

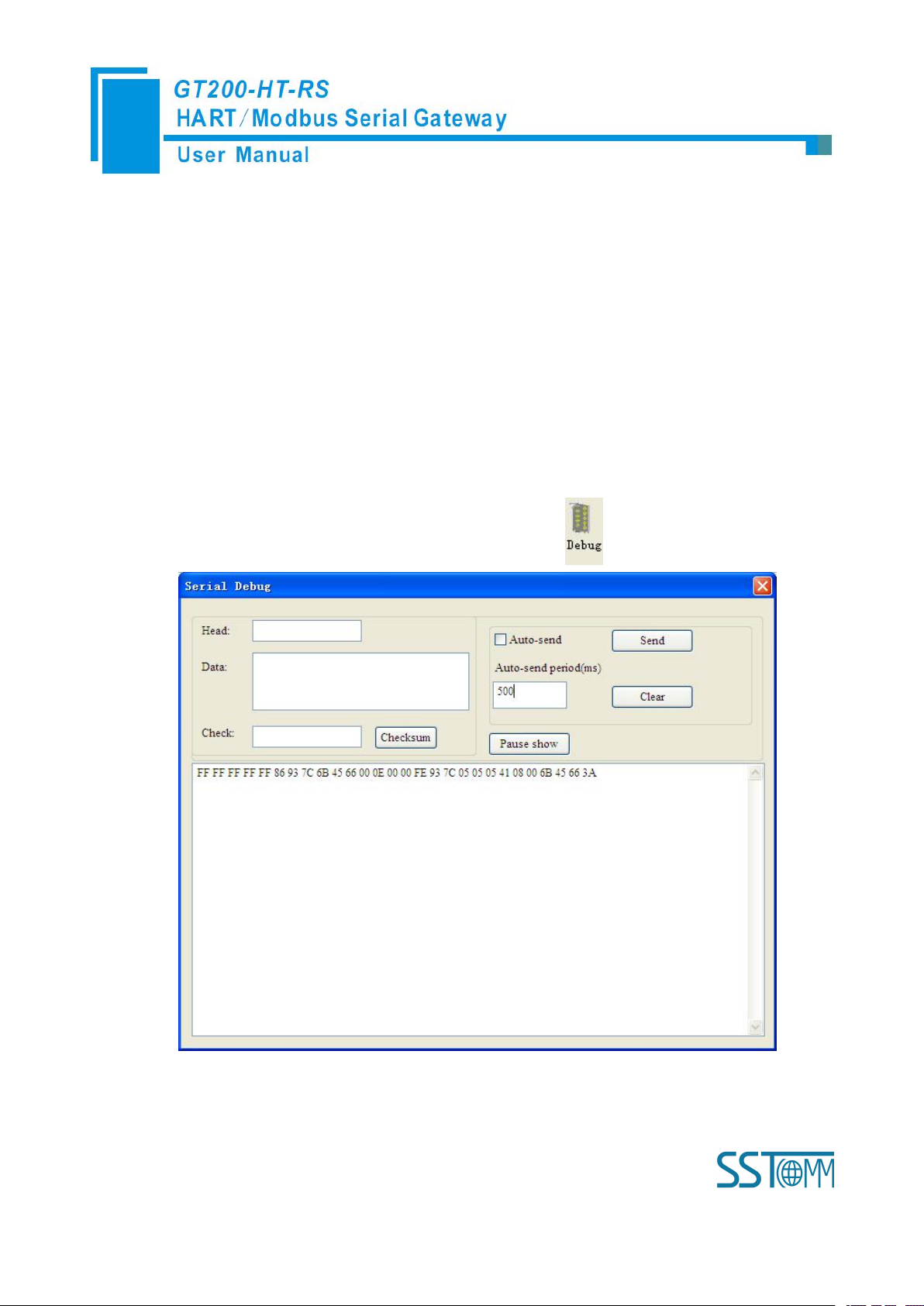

4.2.10 Serial Debug.................................................................................................................................... 38

4.2.11 Switching Tools............................................................................................................................... 39

4.2.12 Use USB Port...................................................................................................................................40

5 Working Principle.................................................................................................................................................... 45

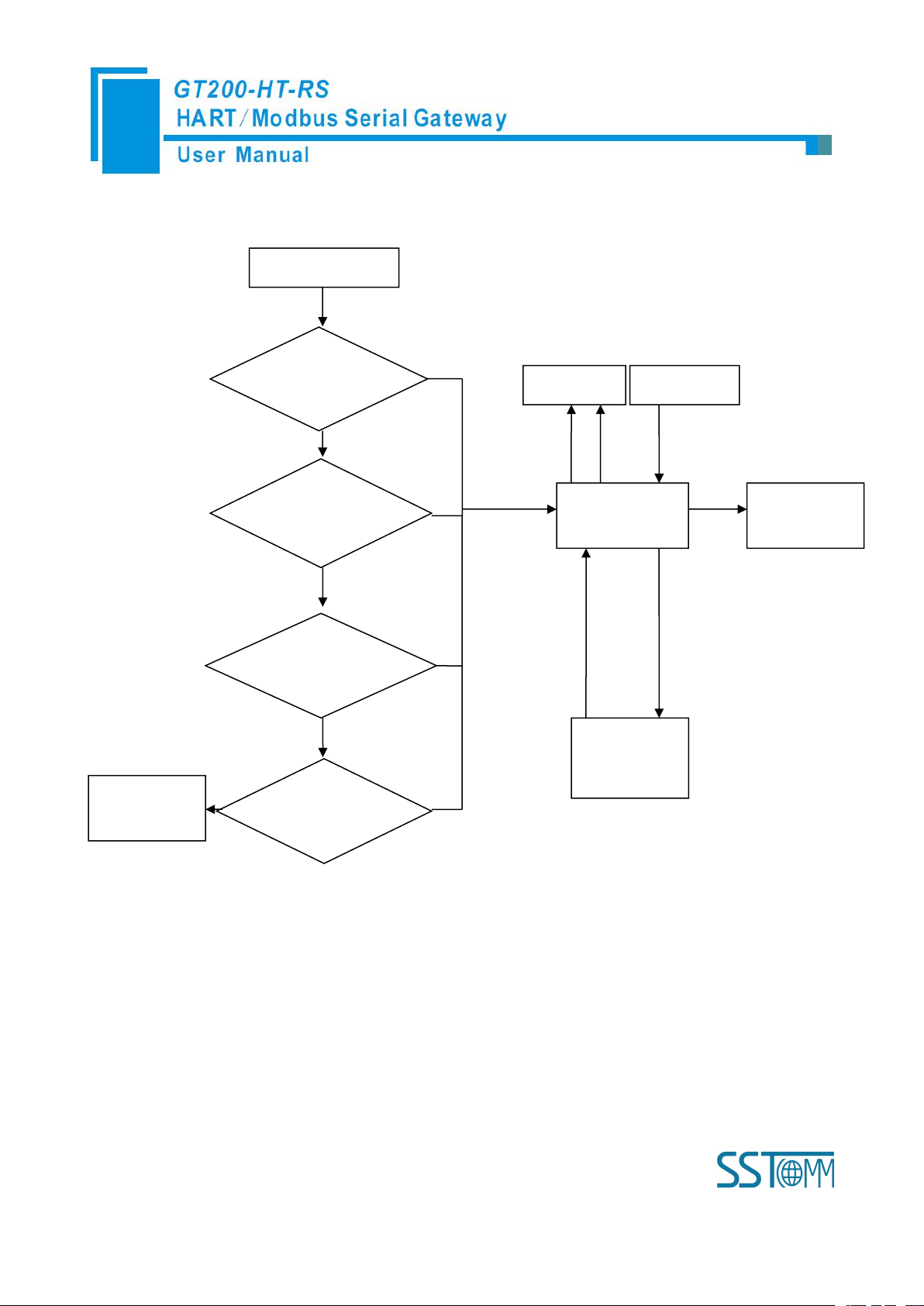

5.1 Flowchart of Executing One HART Command........................................................................................... 48

5.2 Universal Send and Receive Data................................................................................................................ 48

5.3 Trigger Command......................................................................................................................................... 49

5.4 Data Exchange with Modbus........................................................................................................................50

6 Installation................................................................................................................................................................51

6.1 Machine Dimension......................................................................................................................................51

6.2 Installation Method.......................................................................................................................................51

Page 4

WWW.SSTCOMM.COM 4

1 Product Overview

Powerful Serial function: Support the interconnection between HART and Modbus , also support transparent

Multi debugging functions: It can display the exchanging data, and diagnosis the HART command

[1] Used as a primary or a secondary HART master;

[2] Supports one HART-channel, under multi-point mode, support connecting at most 13 HART slaves with

[3] Supports single-point and multi-point mode at the HART side;

[4] Under single-point mode, support data burst operation;

[5] Supports all commands of the HART protocol;

[6] Each HART command can be configured for change-of-state output, polling output, initialization output or

[7] Supports up to 128 HART commands, HART output data buffer is up to 1000 bytes, and the input data buffer

[8] Supports an internal or external HART sampling resistor;

[9] Supports serial RS-232, RS-485 and RS-422, baud rate supports: 300, 600, 1200, 2400, 4800, 9600, 19.2K,

1.1 Product Function

GT200-HT-RS is a gateway that can provide a seamless connection between HART and Modbus. At HART

side it can be configured as a primary master or the secondary master, and acts as slave at the Modbus side.

1.2 Product Features

transmission between HART and serial port.

1.3 Technical Specifications

gateway internal resistor and support connecting 15 HART slaves with an external resistor (250Ω);

disable output;

is up to 1600 bytes;

Page 5

WWW.SSTCOMM.COM 5

38.4K, 57.6K, 115.2Kbps;

[10] The serial port can be configured as Modbus slave, supports modbus function code: 03H, 04H, 06H, 10H;

[11] Modbus slave supports RTU and ASCII communication;

[12] The serial port can be configured as universal mode, and achieve transparent data transmission with HART

[13] Power: 24VDC (9V~30V), 80mA (24VDC);

[14] Working circumstance temperature: -4℉~140℉(-20℃~60℃), Humidity: 5%~ 95%;

[15] External dimensions (W*H*D): 0.98 in*3.94 in *3.54 in (25mm*100mm*90mm);

[16] Installation: 1.38 in (35mm) DIN RAIL;

[17] Protection Level: IP20;

Revision

Date

Chapter

Description

REV A

21/9/2015

All

New software version

REV B

1/4/2016

All

Hardware Update

slave devices;

1.4 Safety and Explosion-Proof Features

GT200-HT-RS is not the product with the features of safety and explosion-proof, please put it in the control

room when using.

1.5 Related Products

The related products include: GT200-HT-DP, GT200-DP-RS etc.

If you want to get more information about these products, please visit SSTCOMM website:

http://www.sstcomm.com.

1.6 Revision History

Page 6

WWW.SSTCOMM.COM 6

2 Quick Start Guide

1. Turn gateway’s configuration bit of DIP switch(refer to chapter 3.3.1) to “ON”;

2. Connect the Gateway’s RS-232/USB interface and the serial port of the computer with a serial cable, wiring

3. Power on the gateway, the LED display shows “CF”, indicates that the gateway is in the configuration mode.

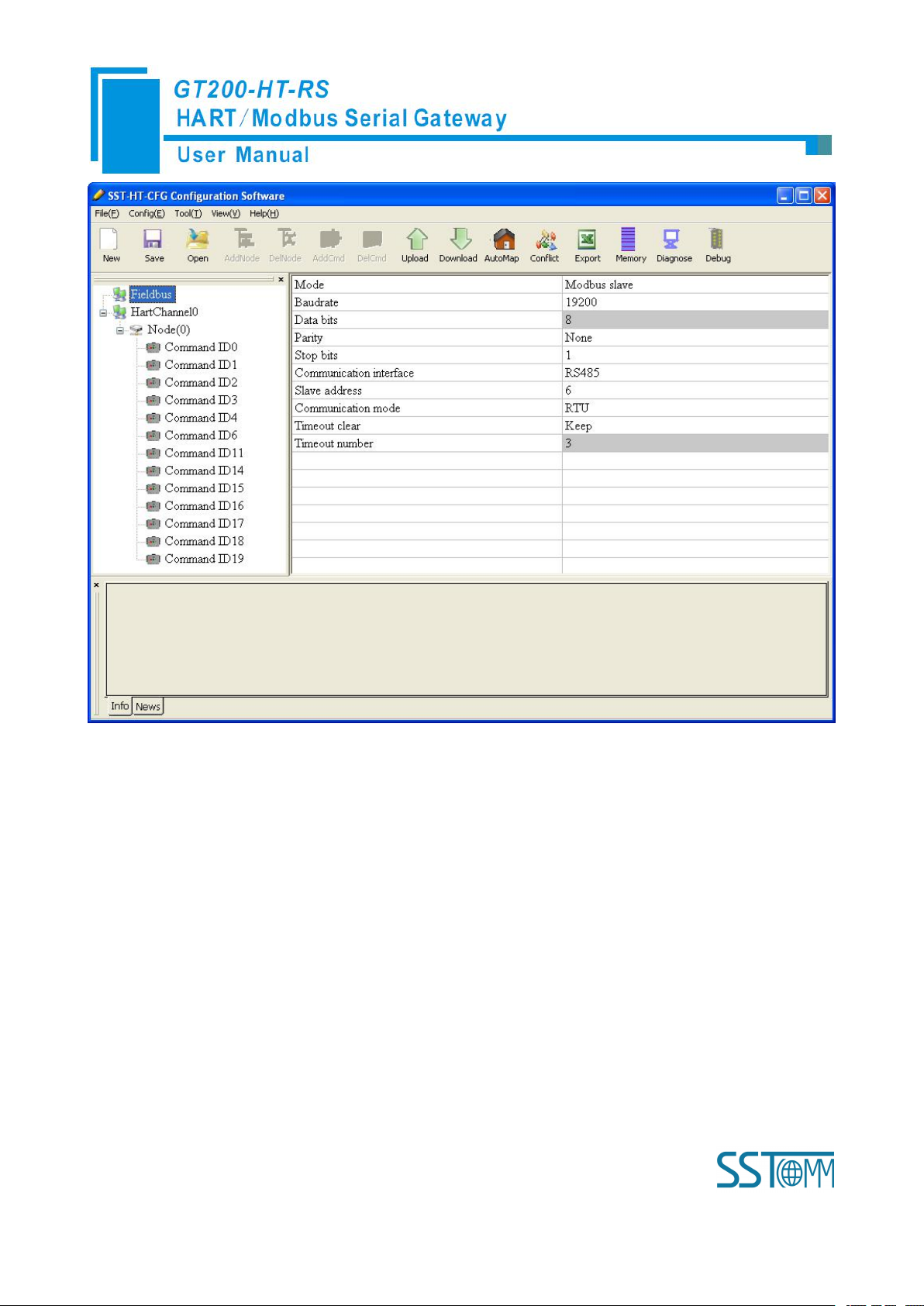

1. Run the SST-HT-CFG software installed on your computer.

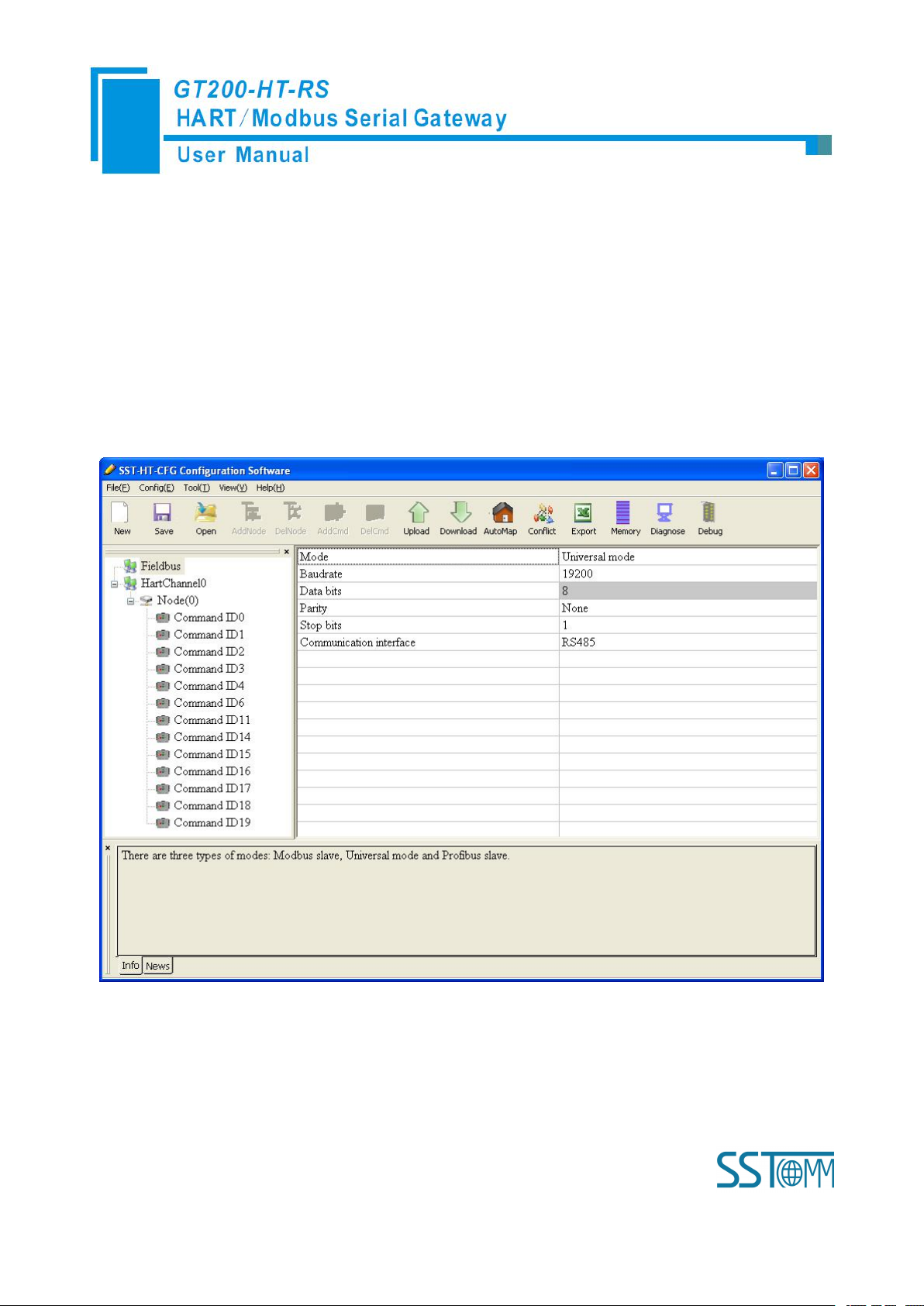

2. Click “Fieldbus” in the tree view on the left, the configuration table is shown on the right as below:

The following example introduces the use method of the Gateway.

2.1 Configuration of Gateway Parameters

2.1.1 Pre-configured Settings

methods see chapter 3.4.3 of this manual;

Run the SST-HT-CFG to start the gateway configuration.

2.1.2 Software Configuration

Page 7

WWW.SSTCOMM.COM 7

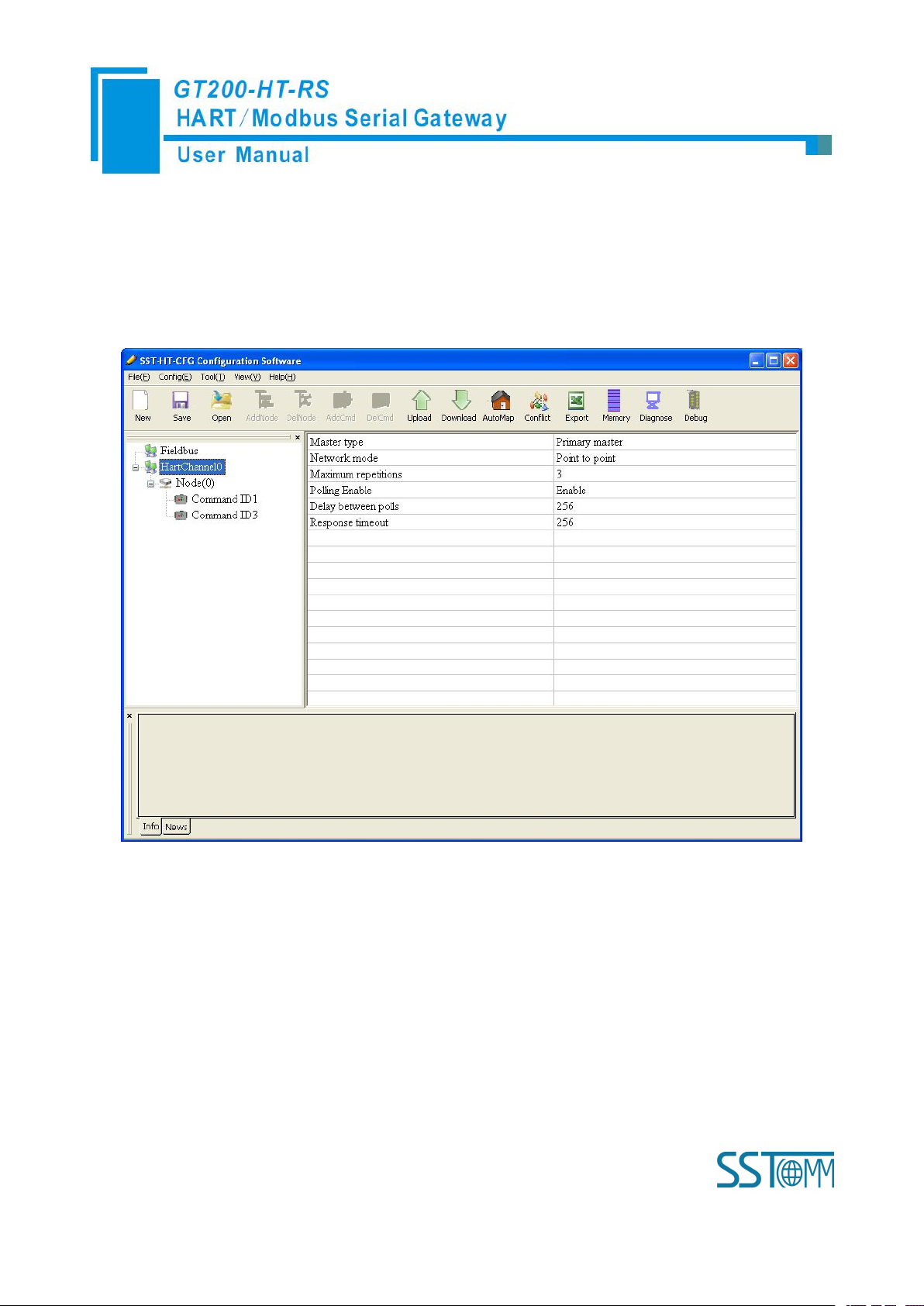

3. Click “HartChannel0” in the tree view on the left, the configuration table is shown on the right as below:

Note: HART protocol specifies that the slave device which address is 0 must work in single-point mode. In

single-point mode the digital communication and analog communication is allowed to exist at the same time. The

Slave with address 1~15 works in multi-point mode. In multi-point mode the analog output of the device is the

minimum value (e.g. 4mA), only allows digital communication. The protocol also specifies that the default factory

address of field device is 0.

4. Right-click HartChannel0, in the pop-up menu, select “Add Node”, as shown below:

5. Right-click “Node(0)”, in the pop-up menu selects “Add Command” to add a command (Command ID1) in

the dialog box, and then click OK to return.

Page 8

WWW.SSTCOMM.COM 8

6. Click the “Command ID1”, the configuration table on the right is configured as below:

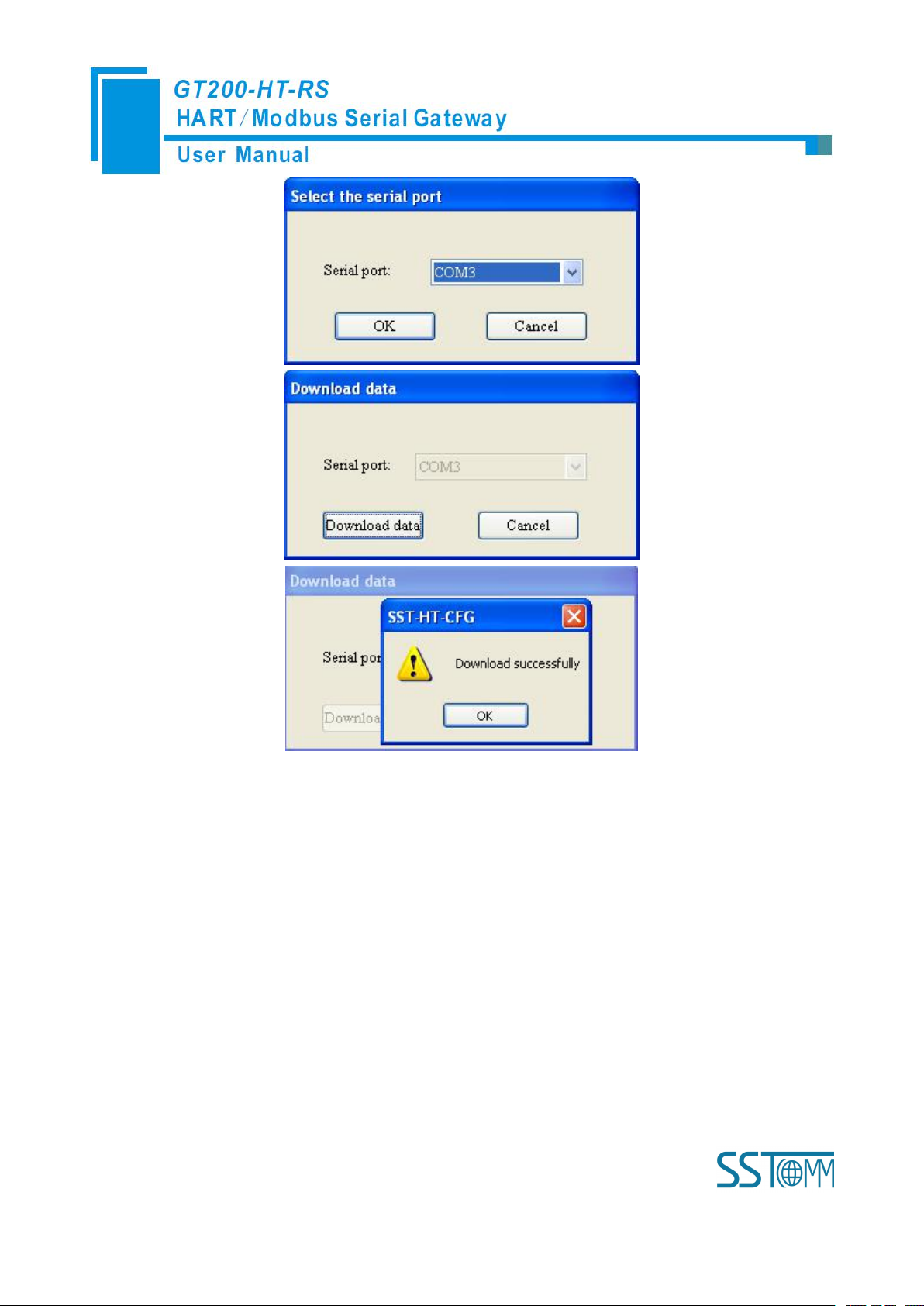

7.Click the tool , in the pop-up dialog box, select the serial port that gateway is connected to the computer,

click OK and then click Download data:

Page 9

WWW.SSTCOMM.COM 9

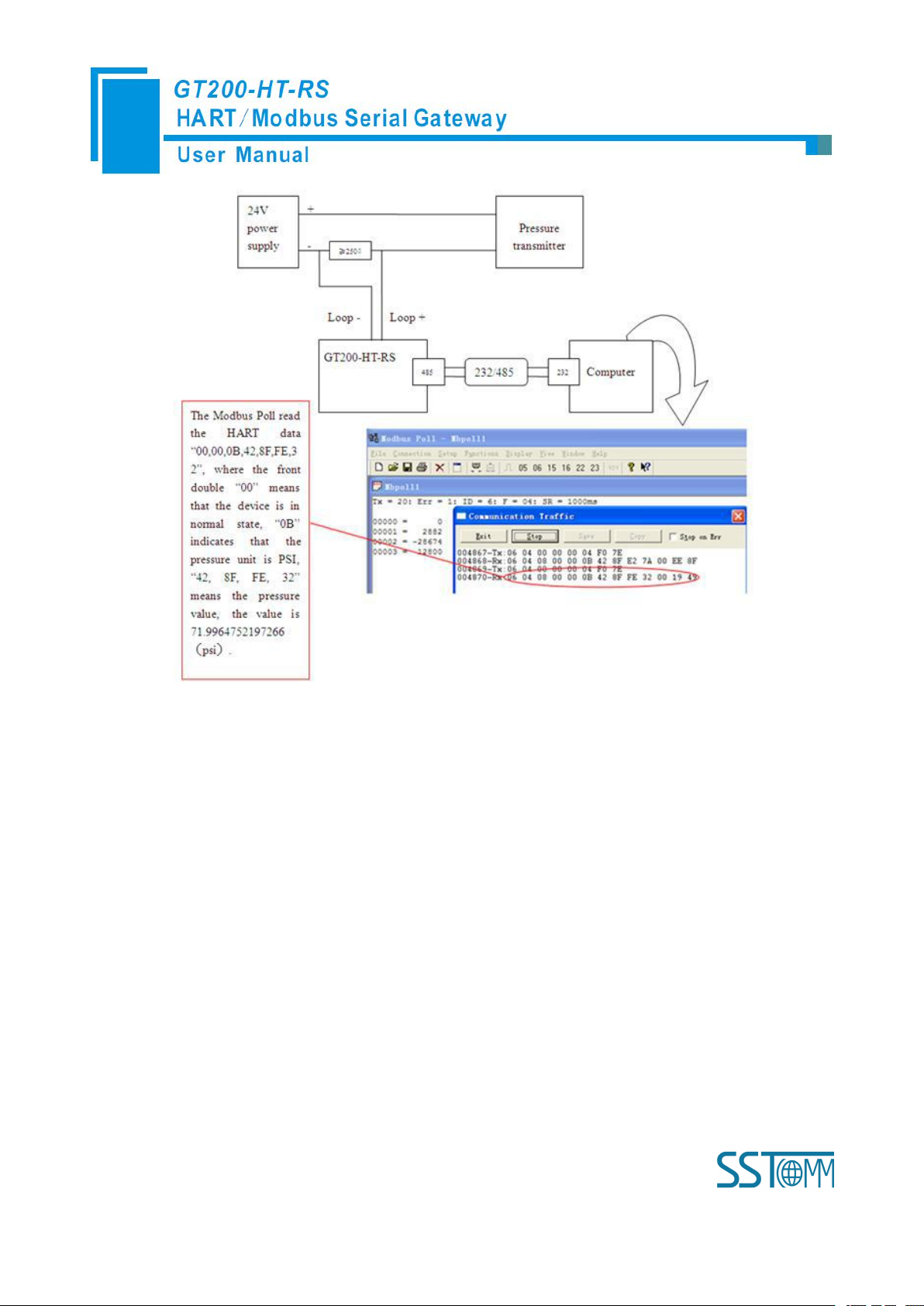

2.2 Function Demo

HART interface of the gateway connects with a 2-wire pressure transmitter with slave address 0, RS-485

interface is connected to the computer through RS-485/RS-232 converter, and computer with configured Modbus

POLL software can simulate to work as a Modbus master, then in data exchange window you can see the main

variable value of the pressure transmitter:

Page 10

WWW.SSTCOMM.COM 10

Page 11

WWW.SSTCOMM.COM 11

3 Hardware Descriptions

HART Interface

LED Display

Power Interface

RS-485/RS-422

RS-232 Interface

DIP Switch

Serial State Indicator

HART State Indicator

Internal/External Sampling

Resistor Switch

Modbus Address Setting Button

Mini USB

3.1 Product Appearance

Note: This picture is for reference only. Product appearance should refer to the real object.

Page 12

WWW.SSTCOMM.COM 12

3.2 Indicators

Indicator location

Indicator

State

State Description

Row 1

TX

Blinking

Serial port data sending

OFF

No data is sending

RX

Blinking

Serial port data receiving

OFF

No data is receiving

Row 2

TX

Blinking

HART Bus data sending

OFF

No data is sending

RX

Blinking

HART Bus data receiving

OFF

No data is receiving

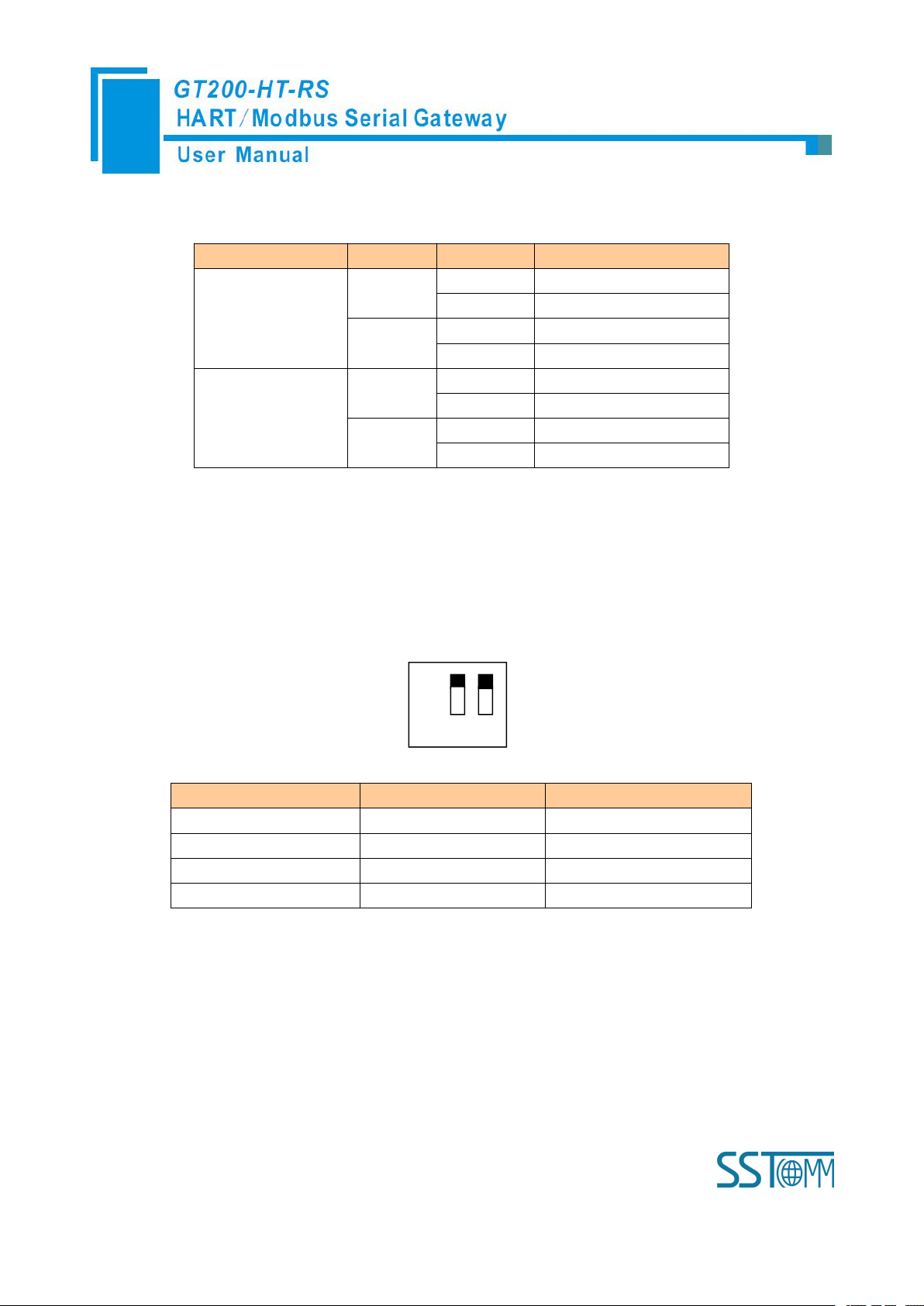

Debugging (bit 1)

Configuration (bit 2)

Description

Off

Off

Run Mode

Off

On

Configuration Mode

On

Off

Debug Mode

On

On

Configuration Mode

Off

On 1 2

3.3 DIP Switch/Button

3.3.1 DIP Switch

The DIP switch is located at the bottom of product, bit 1 is the debug bit and bit 2 is the configuration bit.

Note: ①After re-configuring the switch, you have to restart the GT200-HT-RS to make the settings take

effect! (Power off then Power On)

②Set to the debug mode, it will be compulsory to appoint RS-485 interface as communication

interface, RS-232/USB interface as debugging interface.

③Configuration interface uses the RS-232/USB interface.

Page 13

WWW.SSTCOMM.COM 13

3.3.2 Modbus Address Setting Button

Switch to ON, using the internal

sampling resistor

Switch to OFF, using the external

sampling resistor

Under run mode of the GT200-HT-RS, LED display always displays the address of the current Modbus

address. Quickly press (double-click) the button twice in succession, the high bit starts to flash, and the low bit is

always on, click the button to add 1 to start setting the high bit of Modbus address. Long-press the button for 3

seconds, the high bit is always on, and the low bit starts to flash. Click the button to add 1 to start setting the low

bit of Modbus address. At last, long-press the button again for 3 seconds, the address flashing three times shows

that the address is set successfully. If no button action within ten seconds, GT200-HT-RS exits the status of setting

address and continue to display the original address. The configurable range of Modbus address is 0 to 99

(Decimal).

3.3.3 Internal/External Sampling Resistor Switch

GT200-HT-RS can choose using the internal sampling resistor or external sampling resistor to get the HART

signal. The specification of the internal resistor is 270Ω, 2W. When the power of the sampling resistor is more

than 2W, you must use an external resistor.

Page 14

WWW.SSTCOMM.COM 14

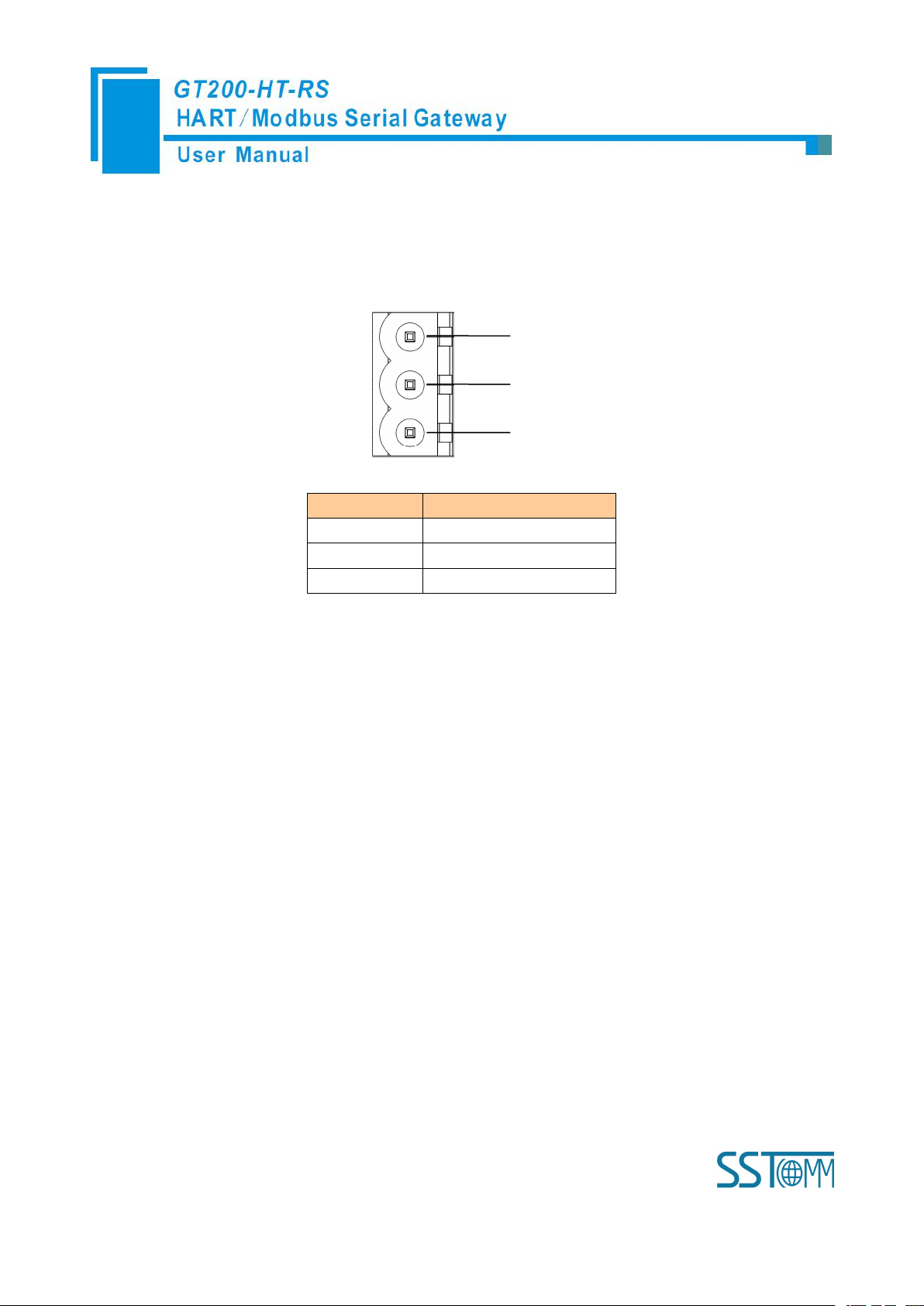

3.4 Interface

GND

NC

24V+

1

2

3

Pin

Function

1

Power GND

2

NC(Not Connected)

3

24V+, DC Positive 24V

3.4.1 Power Interface

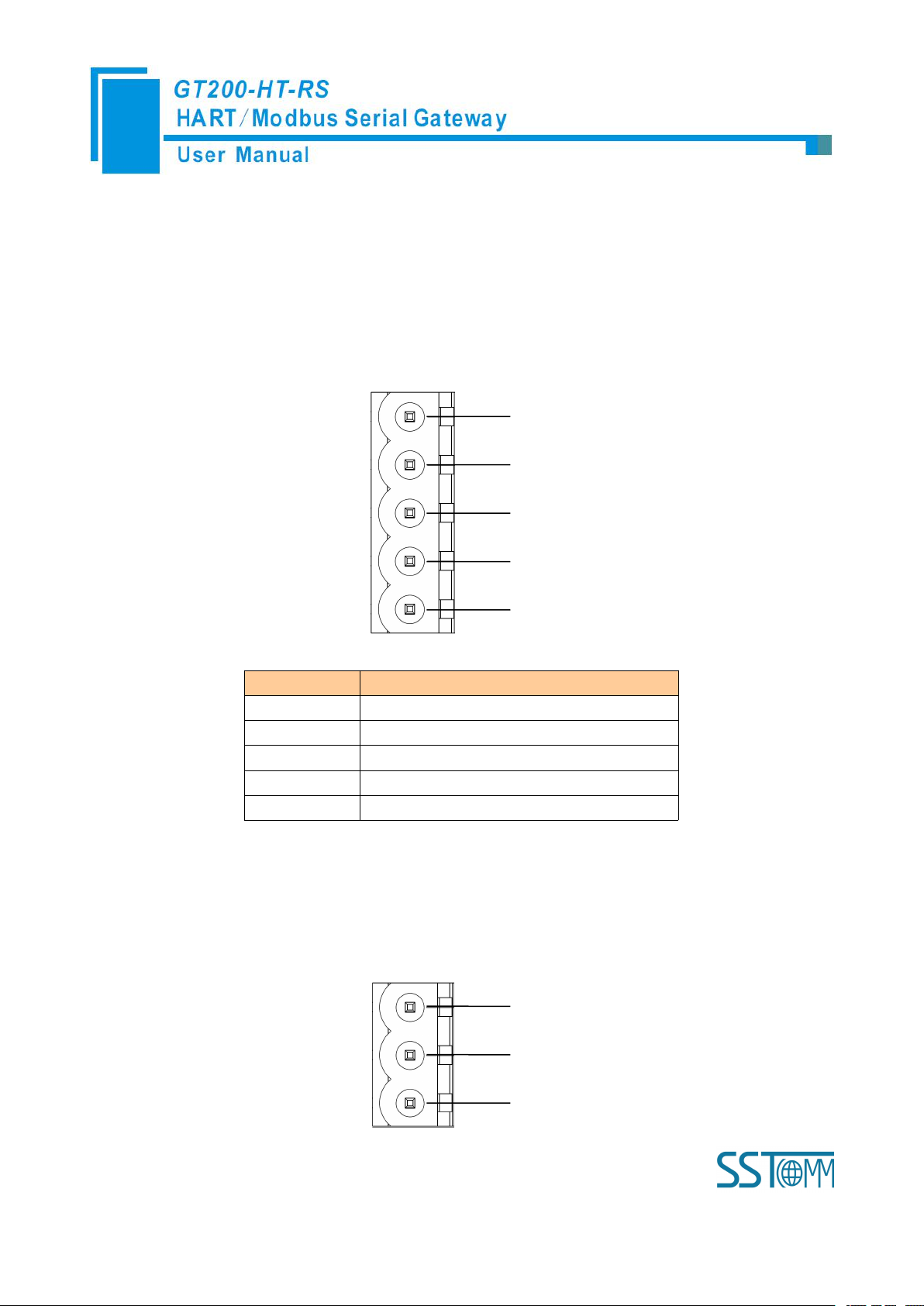

3.4.2 RS-485/RS-422 Interface

The RS-485 interface of GT200-HT-RS is a standard one, and the RS-485 characteristics of the product are

shown as follows:

1. The basic characteristics of RS-485 transmission technology

① Network topology: Linear bus, there are active bus terminal resistors at both sides.

② Transmission rate: 1200 bps~115.2Kbps.

③ Media: Shielded twisted-pair cable and also can cancel the shielding, depending on environmental

conditions (EMC).

④Site number: 32 stations per subsection (without repeater), and can increase up to 127 stations (with

repeater).

⑤Plug connection: 3/5-pin pluggable terminal.

2. The main points on the installation of RS-485 transmission equipment

①All the equipment are connected with RS-485 bus;

Page 15

WWW.SSTCOMM.COM 15

②Each subsection can be connected up to 32 sites;

GND

D-

D+

1

2

3

4

5R-R+

Pin

Function

1

R-, RS-422 Receive Negative

2

R+, RS-422 Receive Positive

3

GND

4

D-, RS-485/RS-422 Transmit Negative

5

D+, RS-485/RS-422Transmit Positive

RXTXGND

1

2

3

③The farthest two end of the bus has a terminal resistor—120Ω 1/2W to ensure reliable operation of the

network.

Serial interface uses 5-pin pluggable open terminal and user can wire it according to the wiring instructions

on the panel.

5-pin terminal:

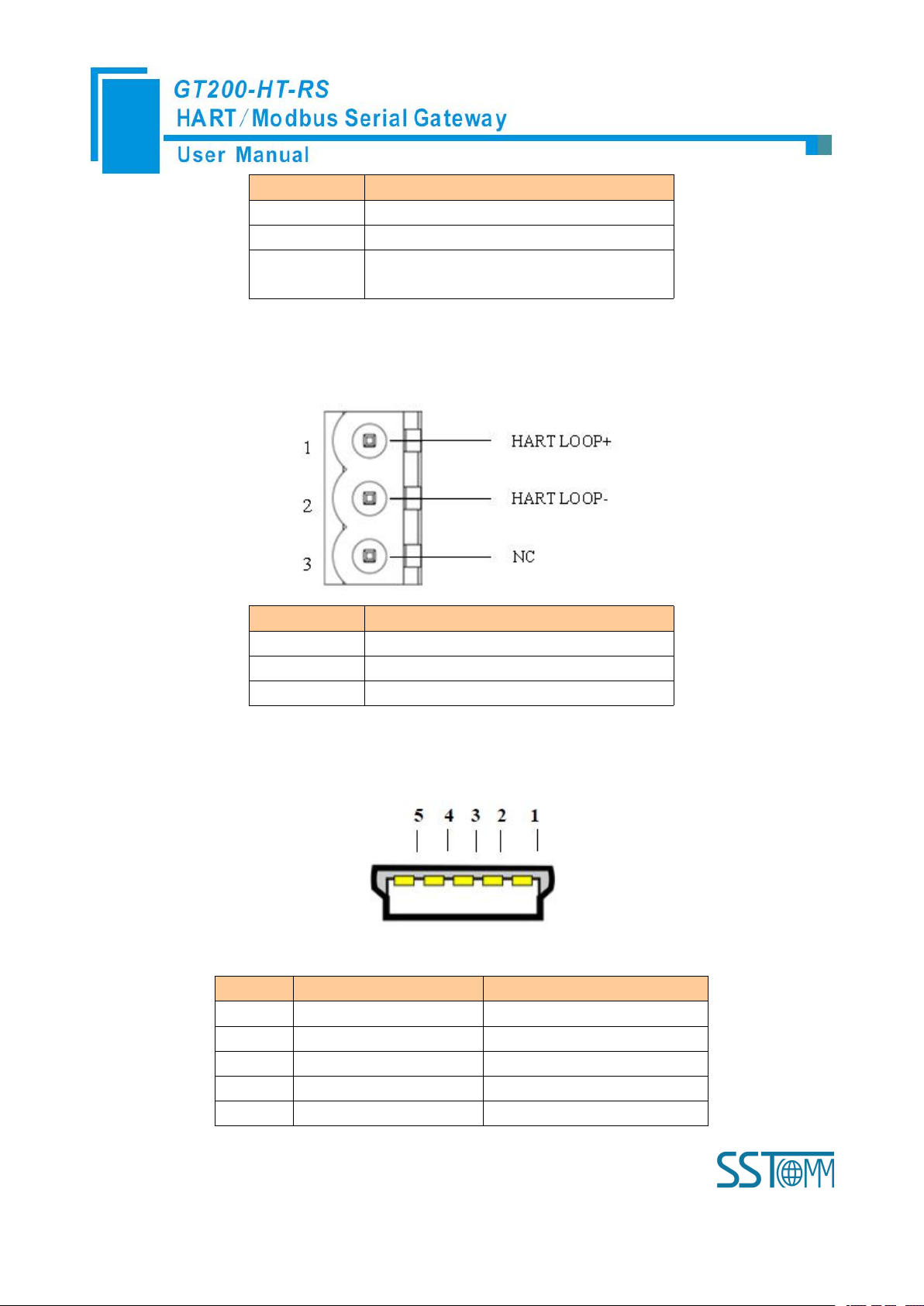

3.4.3 RS-232 Interface

RS-232 interface uses one 3-pin pluggable open terminal, and its pin description is shown as follows:

Page 16

WWW.SSTCOMM.COM 16

Pin

Function

1

RX, Connect RS-232's RX of user device

2

TX, Connect RS-232's TX of user device

3

GND, Connect RS-232's GND of user

device

3.4.4 HART Interface

Pin

Function

1

Connect HART signal positive

2

Connect HART signal negative

3

NC

Pin

Name

Function

1

VBUS

+5V

2D-Data negative

3D+Data positive

4

IN

NC

5

GND

Signal Ground

3.4.5 Mini B Type USB

Mini B type USB interface is defined as below:

Page 17

WWW.SSTCOMM.COM 17

3.5 Topology of GT200-HT-RS and Fieldbus Devices

Page 18

WWW.SSTCOMM.COM 18

Note: 1. Some HART slave instrument need to perform self-test and other internal work when power is on, they

may not start HART communication, then gateway cannot receive the response data of the instrument right now. It

is recommended the HART slave instrument and gateway uses separate power supply so that the gateway can

immediately establish communication with instrument.

2. When configuring HART commands in the software SST-HT-CFG, the commands need to be

configured according to the actual demands. To improve the speed of bus communication, it is recommended not

to configure the empty node (in fact, not connected to the node) and empty commands (the actual unnecessary

commands).

Page 19

WWW.SSTCOMM.COM 19

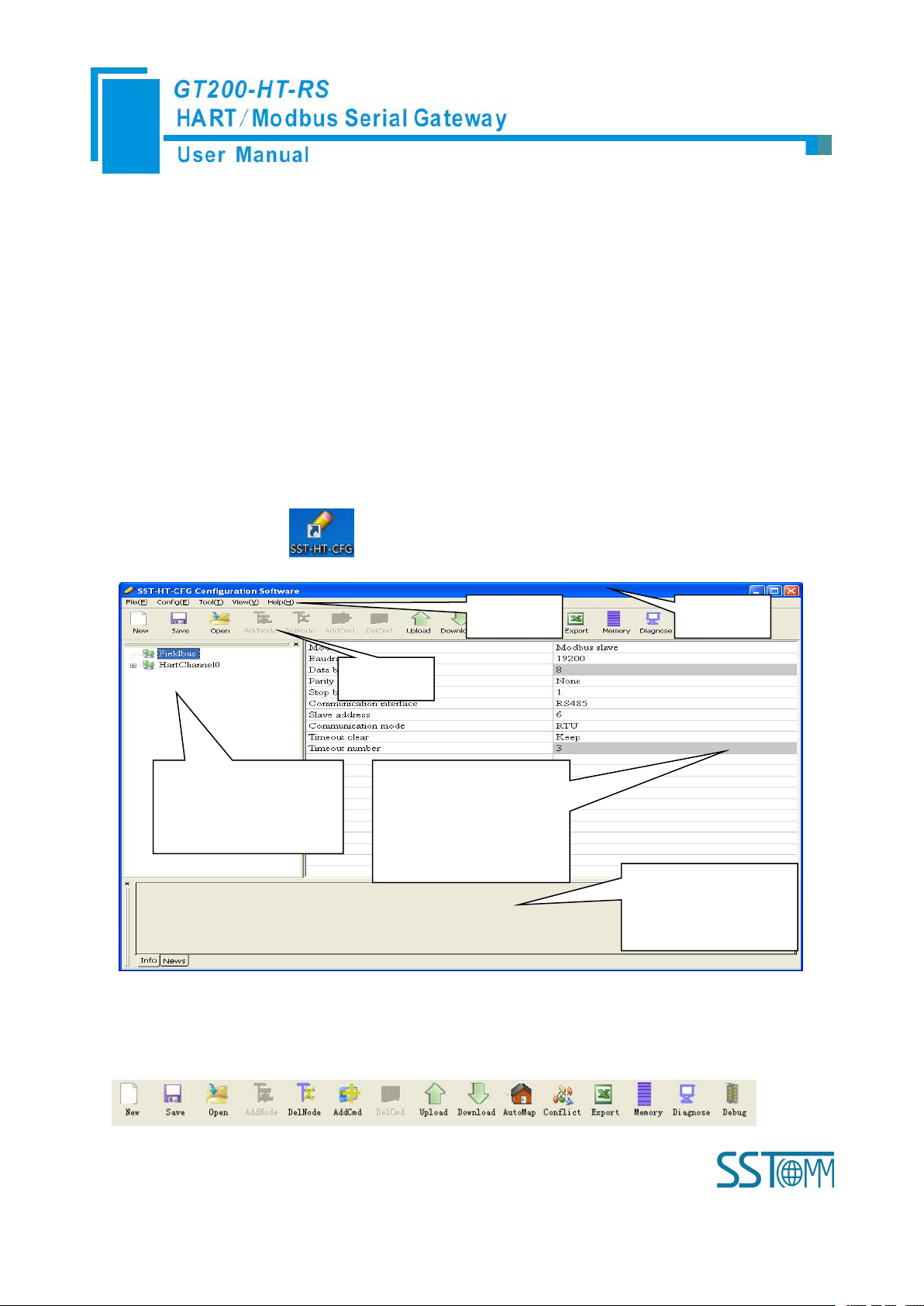

4 Software Instructions

Network Settings interface:

Contains Fieldbus and the

connection object

Menu Bar

Tool Bar

Title Bar

Parameter Settings interface:

Contains modifiable part

(white) and unmodifiable part

(grey)

Comment field: Explain

the function of the

configuration options

4.1 Software Interface Description

SST-HT-CFG is configuring software based on Windows platform, and used to configure HART series

products.

The following describes how to use the software SST-HT-CFG to configure the product GT200-HT-RS. You

may also check the software user manual to get detailed usage.

Double-click on the icon to enter the main interface of software:

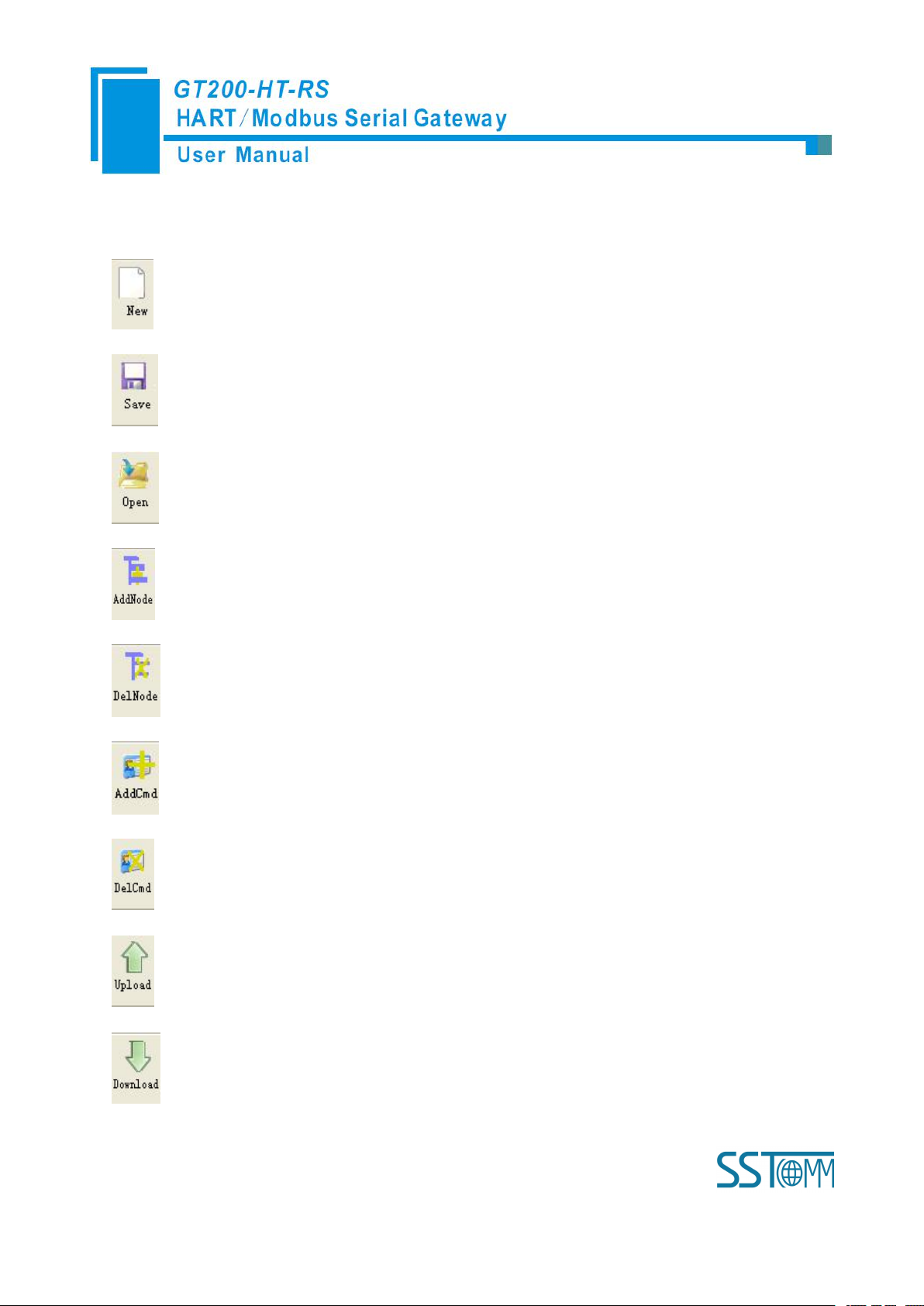

Tool Bar:

Toolbar interface shown as follow:

Page 20

WWW.SSTCOMM.COM 20

The function from left to right is: New, Save, Open, AddNode, DelNode, AddCmd, DelCmd, Upload,

Download, AutoMap, Conflict, Export, Memory, Diagnose and Debug.

New: Create a new configuration file

Save: Save the configuration file

Open: Open the configuration file

AddNode: Add a HART slave node

DelNode: Delete a HART slave node

AddCmd: Add a HART command

DelCmd: Delete a HART command

Upload: Read the configuration information from the module and shown in the software

Download: Download the configuration file to the gateway

Page 21

WWW.SSTCOMM.COM 21

AutoMap: Used to automatically calculate the mapped memory address without confliction by each

command

Conflict: To check whether there are some conflicts with configured commands in the gateway

memory data buffer

Export: Output current configuration to the local hard disk and saved as Excel spreadsheet form

Memory: Show the data exchange inside of the gateway

Diagnose: through this function could analyze operating condition of fieldbus device; also it can finish

some certain analysis

Debug: through this function could send any request frame to Hart fieldbus and show the response

information received in HART, convenient to debug

4.2 Software Functional Specifications

4.2.1 Connect with the Hardware

Put the gateway configuration switch to “ON”, use a serial port line to connect the gateway RS-232 port and

that of computer or use USB cable line to connect gateway’s USB port and computer . Power on the gateway and

its LED display displaying “CF” indicates it is in the configuration mode.

Page 22

WWW.SSTCOMM.COM 22

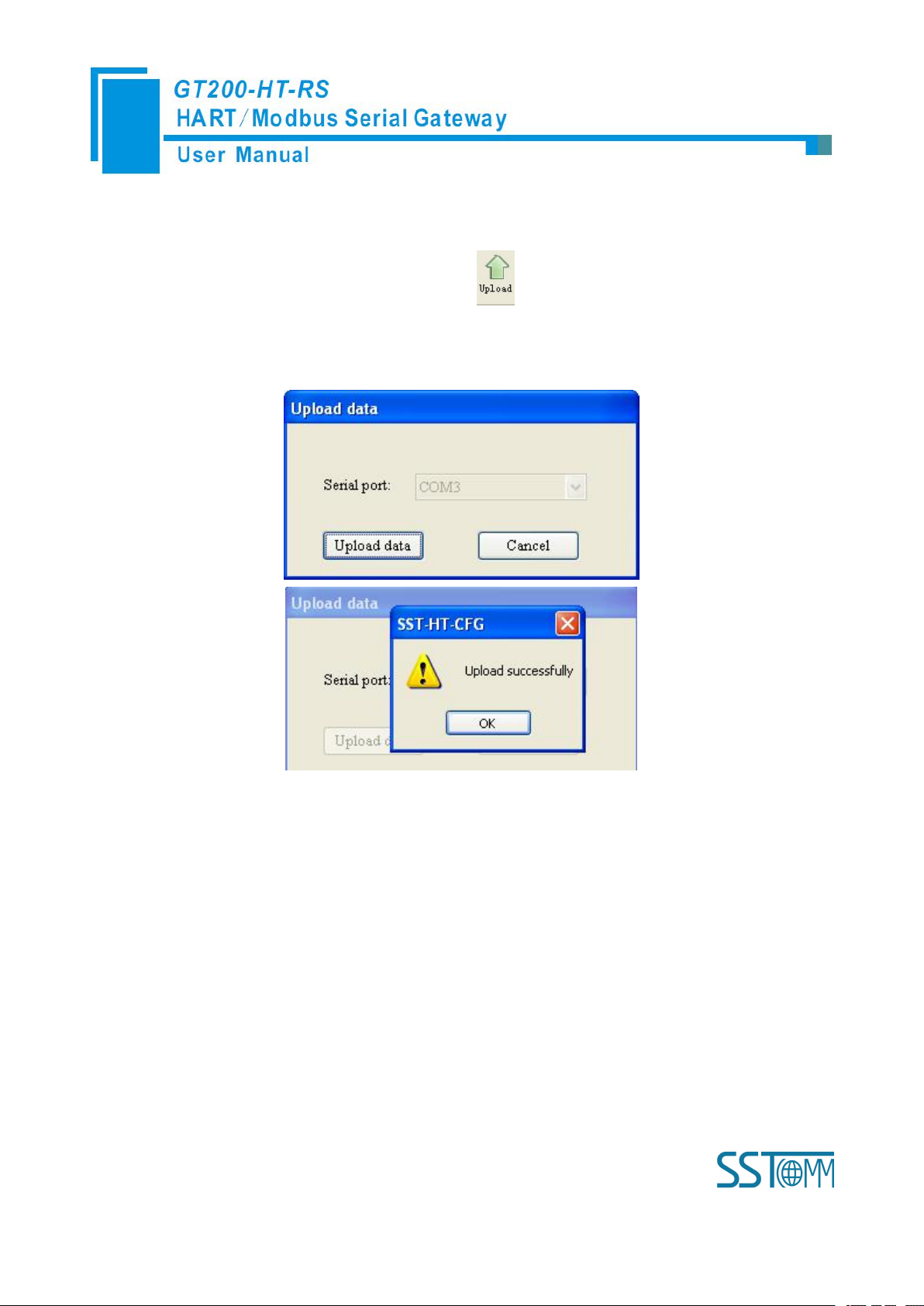

4.2.2 Upload configuration

Open the software “SST-HT-CFG”, Click on the icon , Select the computer port connected to the

gateway and then click “upload data”, If it shows “upload successfully”, which indicates that configuration file

had been uploaded to the SST-HT-CFG.

4.2.3 Configure the Fieldbus

4.2.3.1 Configure the fieldbus as Modbus slave

If you want to use the functionality of Modbus slave, click the “Fieldbus” in the tree view, select mode as

“Modbus slave” in the right configuration plate, and then press ENTER to confirm, you will see the interface as

below:

Page 23

WWW.SSTCOMM.COM 23

In this interface you can set the parameters as shown:

Baud rate: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200bps

Data bits: 8

Parity: None, Odd, Even, Mark, Space optional

Stop bits: 1, 2

Communication mode: RTU, ASCII

Slave address: 0~247

Communication interface: RS-485, RS-232 optional. When the serial need to communicate with RS-422,

please choose “RS-485”

Timeout clear: When the HART commands exceed the no-reply times, whether or not to clear the HART

input data buffer

Page 24

WWW.SSTCOMM.COM 24

Timeout number: set the timeout/clear times

4.2.3.2 Configure the fieldbus as universal mode

The universal mode (transparent transmission mode) means that we can send HART frame directly through

serial port (RS-232/RS-485/RS-422), meantime gateway also will send out the data received from HART bus

through serial port. In this process, the data don’t change.

Click the “Fieldbus” in the tree view, select mode “Universal mode” in the right configuration plate, and then

press ENTER to confirm, you will see the interface as below:

The range and meaning of general mode are the same as “Modbus Slave”.

Page 25

WWW.SSTCOMM.COM 25

4.2.4 Configure the HART Fieldbus

4.2.4.1 Set the Parameters of HART Channel

Click the HartChannel0 in the tree view, in the right place will show the configuration plate:

Master type: Primary master, Secondary master

Network mode: Select the networks link as single or multiple points, in the single point the gateway can only

communicate with the slave device whose address is 0;

Maximum repetitions: 0~5

Polling Enable: Enable, Disable

Delay between polls: 256~65535ms

Response timeout: 256~65535ms

Page 26

WWW.SSTCOMM.COM 26

4.2.4.2 Add Slave Nodes

Select the”HartChannel0”, Right click the mouse and click “Add Node”.

Click the added node, set slave address in the right configuration plate, and please notice that HART channel

can only be equipped with one slave node when configured in the single point mode.

Note: When configured node numbers are more than the actual connected devices, the redundant node will

lead to the longer time of polling circle; so, it is recommended that configured node numbers should be the same

as actual devices.

4.2.4.3 Add HART Commands

Select the “Node (x)”, Right click the mouse and click “Add Command”.

Page 27

WWW.SSTCOMM.COM 27

Choose the command you want in the popup menu, and then click “OK” to exit:

Note: the same command can only be configured once in one node.

4.2.4.4 Configure HART Commands

Click the command number in the tree view; you will see the configuration plate in the right place:

Page 28

WWW.SSTCOMM.COM 28

Configuration Mode: basic and advanced optional, “basic” is shown as above, “advanced” configuration can

Change-of-state output: Execute this command once s data buffer of HART changes

Polling output: This order is put in the polling list, executed periodically

Initialization output: Execute the command only once when power is on

Disable output: the command will not be sent.

refer to chapter 4.2.4.7;

Mode of outputting command: You can use the execution way of the command, change-of-state, polling

output, Initialization output and disable output optional;

Memory starting address of sending data: Set the memory starting address of output data by this command,

the range is 3000~3999;

Modbus register starting address of sending data: the property is automatically calculated by gateway, used

for register addressing;

Sending data length (BYTE): used to set the length of output data by this command;

Sending data length (WORD): the property is automatically calculated by gateway, used for user checking

output data length, 1 word=2 byte;

Memory starting address of receiving data: set the memory address of input data by this command. Response

Page 29

WWW.SSTCOMM.COM 29

data only includes data area of HART frame;

Modbus register starting address of receiving data: the property is automatically calculated by gateway, used

for register addressing;

Receiving data length (BYTE): set the length of input data by this command;

Receiving data length (WORD): the property is automatically calculated by gateway, used for user checking

output data length conveniently, 1 word=2 byte;

Command index: the property is automatically calculated by the configuration software, it indicates the index

in the configured command list this command belongs to.

4.2.4.5 Delete Commands

Select the command need to be deleted, Right click the mouse and click “Delete Command”. Through the

menu command can also be the same action.

4.2.4.6 Delete Nodes

Select the node needed to be deleted, Right click the mouse and click “Delete Node”. Through the menu

command can also be the same action.

4.2.4.7 Advanced Options to Configure Slave Commands

When using HART command configuration, sometimes users want to get one part data of one command. For

example, No.1 HART command. The float value of main variable is only needed, no need to get unit of main

variable, this is why advanced option exists. Advanced options is actually the execution of “segment mapping

function”, it cut the response data of HART command and get the segment data. Users can get any part data they

want. Below is the interface of Advanced Options:

Page 30

WWW.SSTCOMM.COM 30

This interface details is described in chapter 4.2.4.4, so here we don’t describe it. The below is the example

of No.3 HART command, to show how to use “Segment Mapping” function, we can see one “configuration”

button after the “receive data project configuration” option, click it:

There are many parts in “Bytes”. For example, “Command Status” means the communication status and

relevant code of HART response command, “Byte0-3” means byte 0 to 3 of data area of HART response

Page 31

WWW.SSTCOMM.COM 31

command, and so on.

In the above example, click “Byte5-8” will show the Primary Variable in the left bottom area. Other column

have the relevant explanation.

First to explain the “Mapped Address”:

Bytes: response bytes of “Response Data”;

Memory Address: assigned memory address which this byte is located in memory buffer area of

GT200-HT-EI;

Modbus register address: the relevant Modbus register address of “Memory Address”; Note: this address is

not a single address, that is the same memory area which it occupied.

Byte swap: there are two options, “no swap” and “register swap”, swap option is only valid to float type data.

When using “no swap”, the byte order is byte1, byte2, byte3 and byte4. After using “register swap”, the byte order

will be byte3, byte4, byte1 and byte2. For example, the original data is 0x12345678, it will be 0x56781234 after

using “register swap”.

Choose “Byte0-3” and “Byte5-8”, click auto mapping, as shown below:

Close the dialog box, download the configuration into GT200-HT-RS.

Others are the same with “Basic Mode”.

Page 32

WWW.SSTCOMM.COM 32

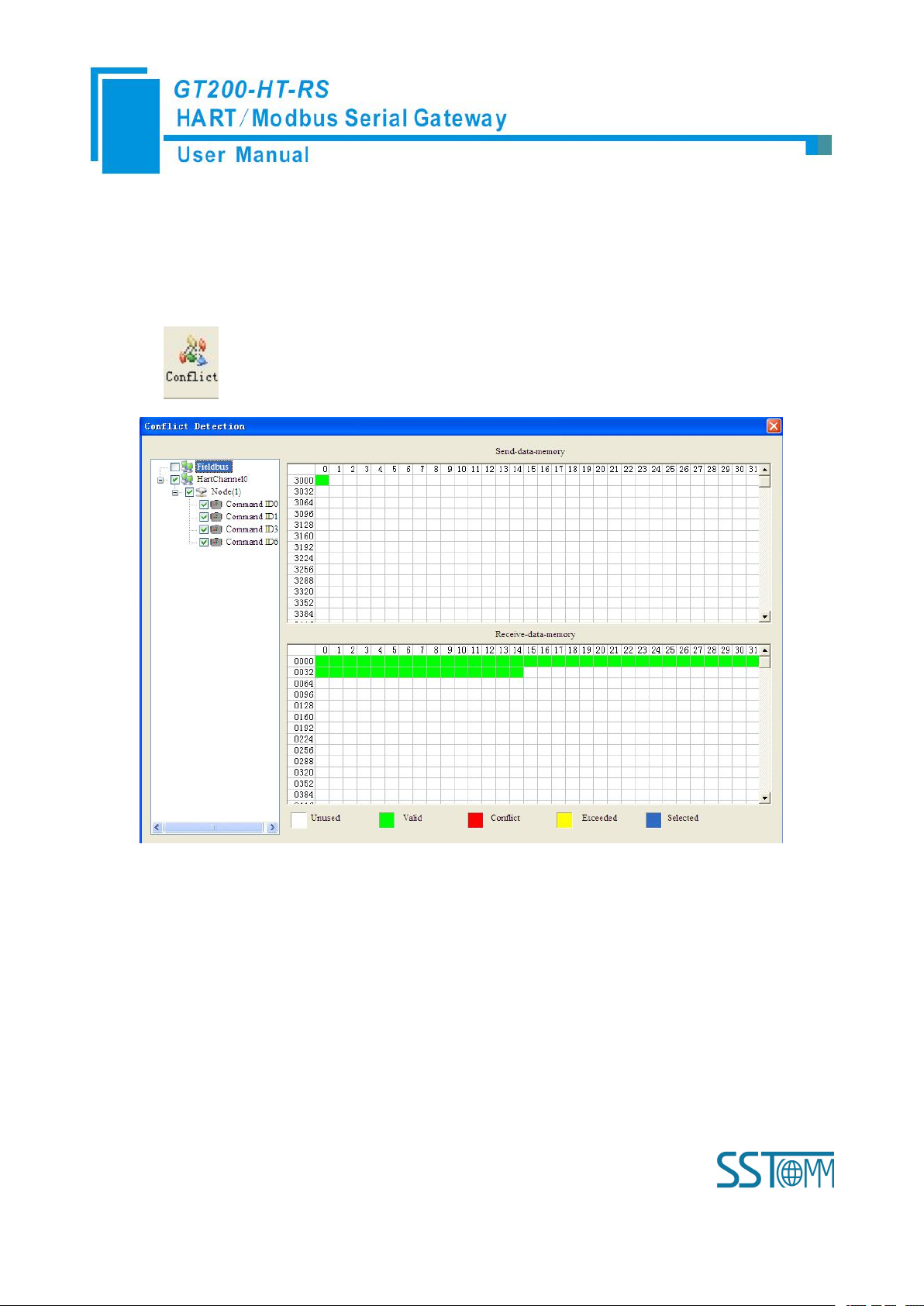

4.2.5 Conflict Detection

Conflict detection is used to check the distribution condition of the input and output data of all commands

stored in the memory.

Click icon will show the conflict detection interface as follow:

The left side is configuration commands, the right side is data memory address including receive data storage

address and send data storage. Upper side is memory distribution of the HART’s sending data; lower side is

memory distribution of the HART’s receiving data. When one memory unit is configured with two commands or

more, the memory unit will display red color. When the distributed memory exceeds the defined scale of gateway,

the exceeding part will display yellow color. White color area shows the usable memory. Green color area

indicates occupied memory. Clicking one command, the distribution chart shown in blue will show the storage

location of input/output data.

Page 33

WWW.SSTCOMM.COM 33

4.2.6 AutoMap

1. Set the DIP switch’s debug bit to ON state and the configuration bit to OFF state, restart the

2. Use a serial port line to connect the GT200-HT-RS’s RS-232 port and computer RS-232 serial port

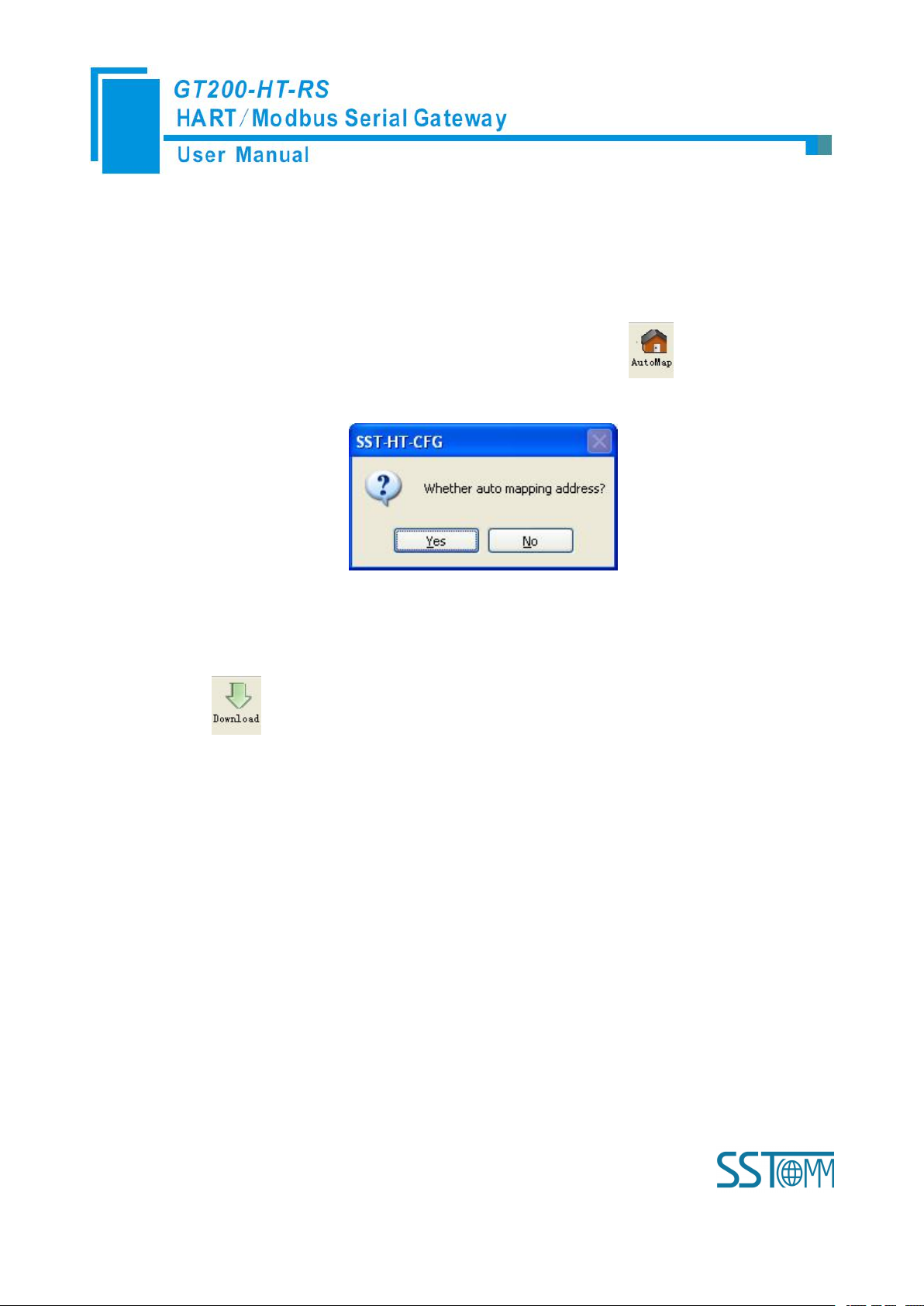

Automap will automatically distribute the memory with no conflict according to the input/output bytes

number by users’ commands.

You should set the correct input/output bytes for each commands, then click label, select “yes” in the

popup menu.

4.2.7 Download Configuration

Click the icon ; it will download the configuration into the gateway.

4.2.8 Memory Data Display

Show the data exchange inside of the gateway, users can use this function to debug the HART fieldbus in the

absence of the Modbus master station. Steps are as follows:

gateway. GT200-HT-RS is in the debug mode.

or use USB way to connect it, open the software “SST-HT-CFG”, Click “Config—Serial

Connection”, Select the correct serial port

Page 34

WWW.SSTCOMM.COM 34

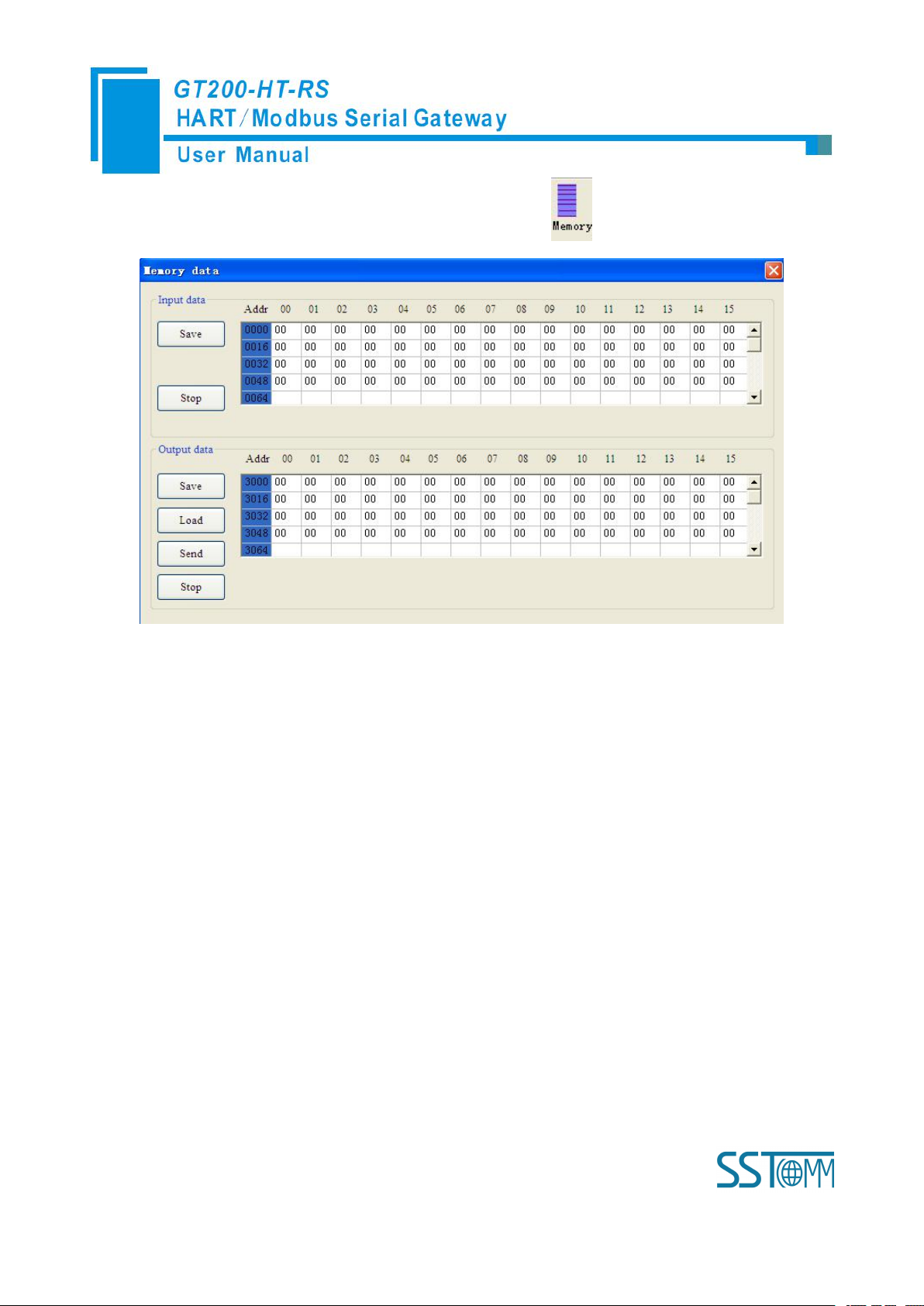

3. Click “Tool—Show Memory Data” or click on the icon , Interface is as follows:

As is shown in the table, upper table shows the memory distribution of HART input data, lower table shows

1. Set the DIP switch’s debug bit to ON state and the configuration bit to OFF state, back online.

2. Use a serial port line to connect the GT200-HT-RS’s RS-232 port and computer RS-232 serial port or

the output data. When you need to change the output data, click the “stop” button firstly, then change the related

data or load the already saved data table, at last, click the “sending data”.

4.2.9 Diagnose

Through this function users will know which device is not communicating, execution condition of configured

commands, data transmit of gateway and displays of certain command, operating steps are as follows:

GT200-HT-RS is in the debug mode.

use USB way to connect it, open the software “SST-HT-CFG”, Click “Config—Serial Connection”,

Select the correct serial port

Page 35

WWW.SSTCOMM.COM 35

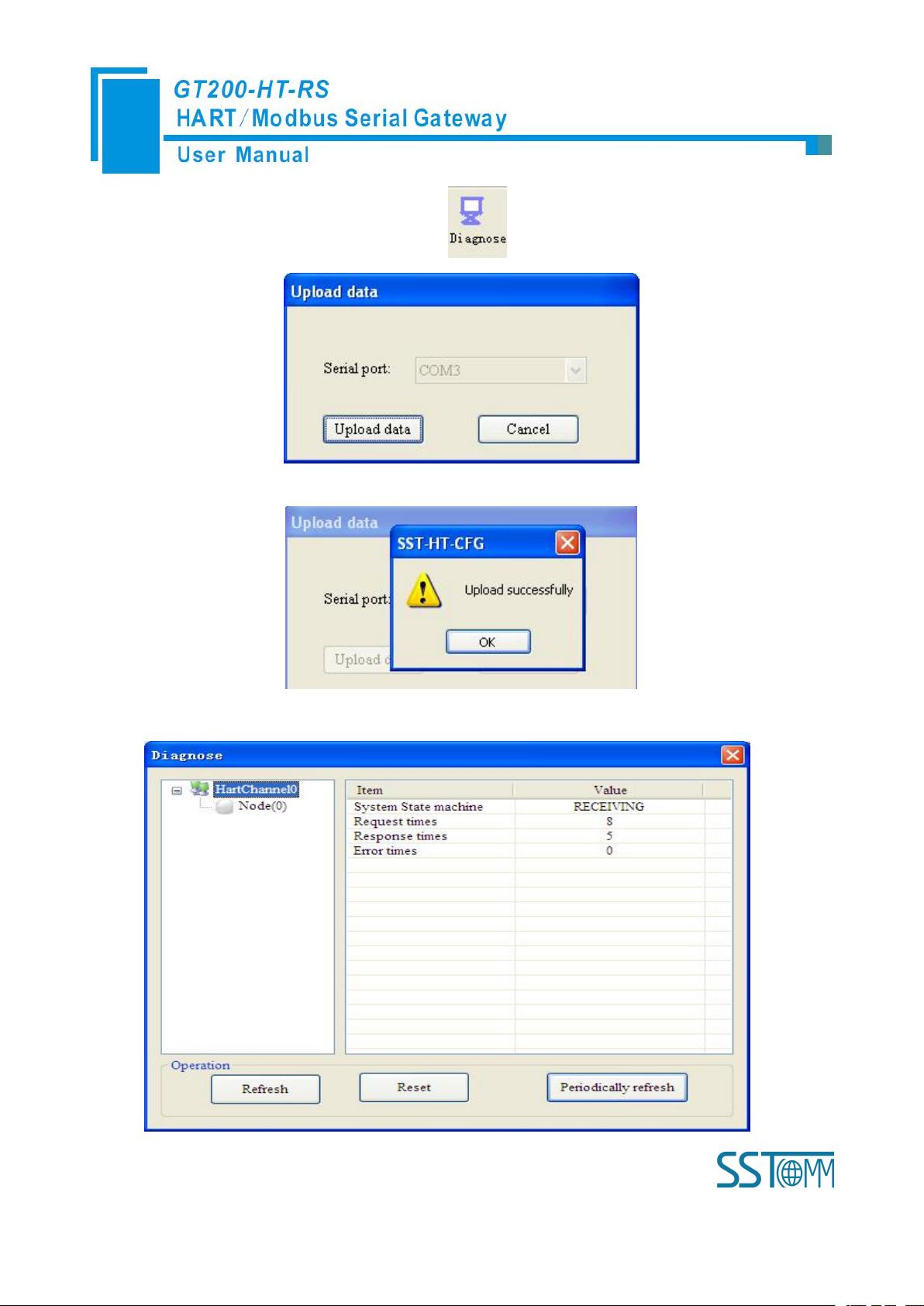

3. Click “Tool—Diagnose” or click on the icon , Interface is as follows:

4. Click “Upload data” will see a picture as below:

5. Click “OK” button to get in the interface of diagnose:

Page 36

WWW.SSTCOMM.COM 36

Click on “HartChannel0” in this interface, it will show the status of HART fieldbus part in the right place,

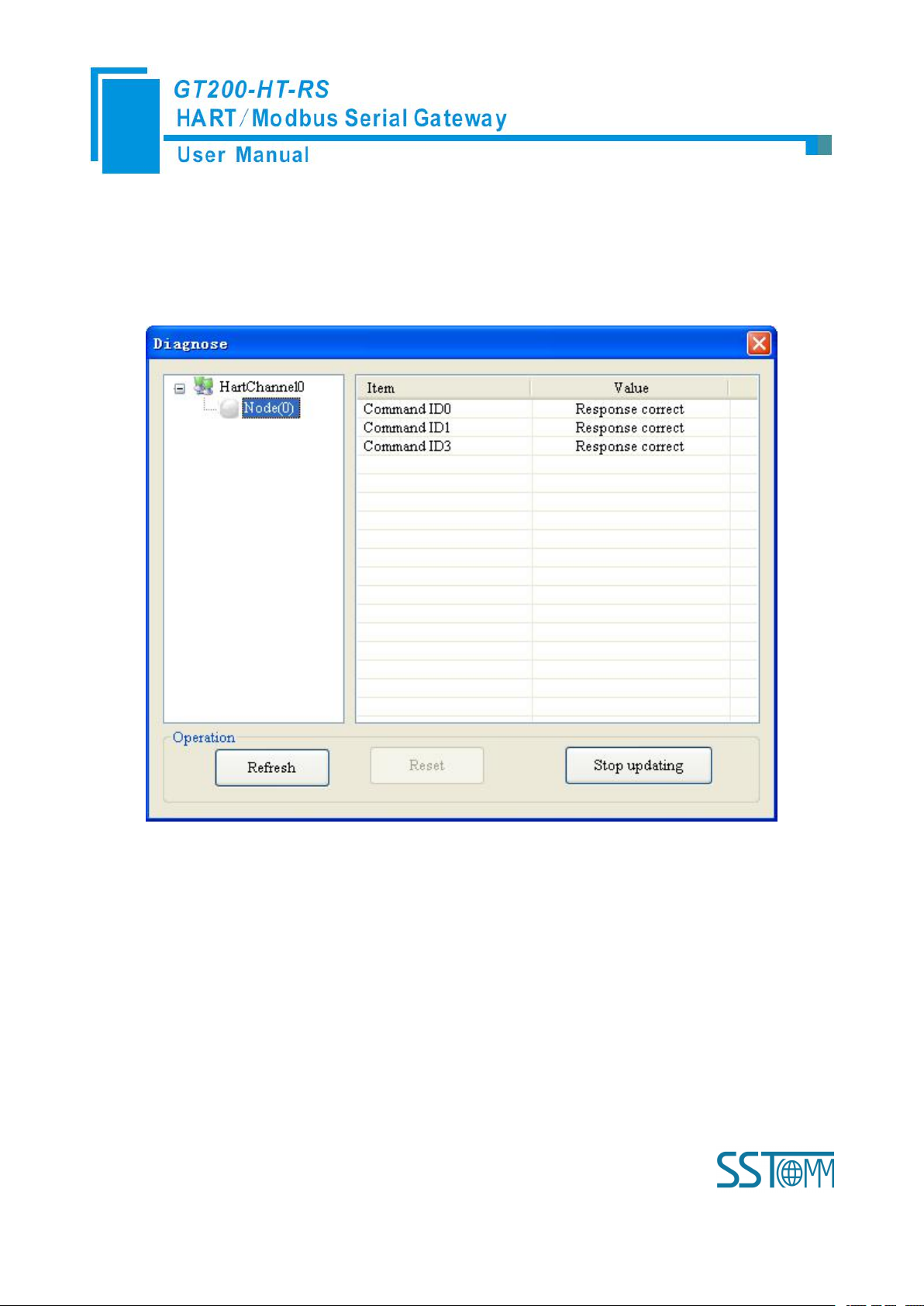

6. Click Node(x), it is shown as below:

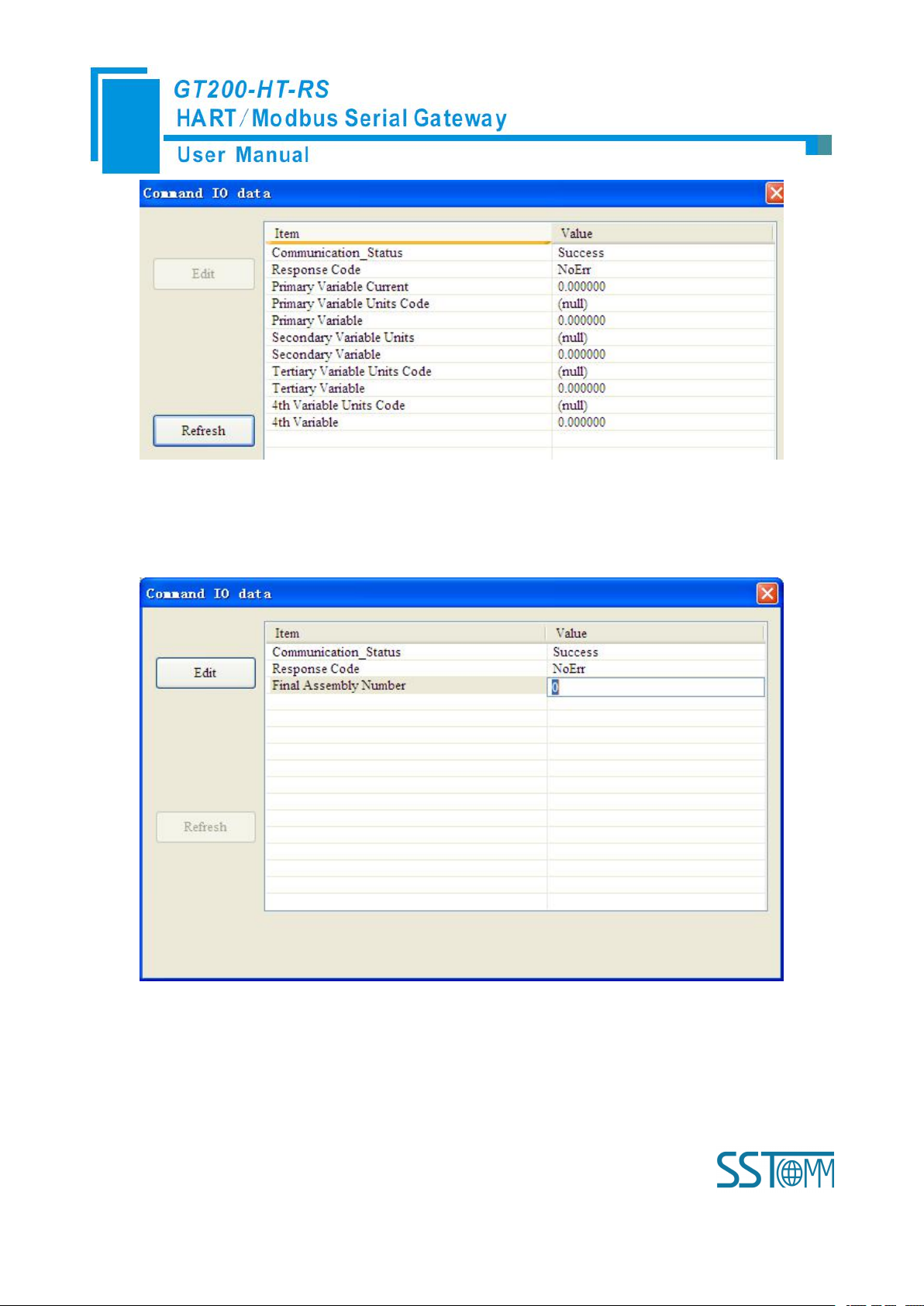

7. Double click command 0, 1, 2, 3, 6, 11, 12, 13, 14, 15, 16, 17, 18, 19 will show their command

press “Refresh” button will update the data once, click on “Periodically refresh”, the software will update the data

every 500ms.

It shows the response status of configured commands.

Click “Refresh” will fresh these command status, “Periodically refresh” will fresh command status once.

information, command 6, 17, 18 and 19 can start data input.

Page 37

WWW.SSTCOMM.COM 37

Click the“Refresh” button will update the data, click the “Edit” button doesn’t work in the Read-only

command.

Double click “CMD19” will show the window as below:

Click the value or attribute you want to change, like “Final Assembly Number”, change relevant values, and

click “Modify” can execute this operation of write command.

Page 38

WWW.SSTCOMM.COM 38

4.2.10 Serial Debug

1. Set the DIP switch’s debug bit to ON state and the configuration bit to OFF state, restart the gateway.

2. Use a serial port line to connect the GT200-HT-RS’s RS-232 port and computer RS-232 serial port or

3. Click “Tool—Serial Debugging Assistant” or click on the icon , Interface is as follows:

Through this function could send any request message to Hart instruments and record the response

information. Steps are as follows:

Now GT200-HT-RS is in the debug mode.

use USB way to connect it, open the software “SST-HT-CFG”, Click “Config—Serial Connection”,

Select the correct serial port

In this interface, click “Auto-send” or “Send” will combine data head, data, and check code into one frame

and send out it. The data that the gateway received from HART fieldbus will be shown in the blank place below.

Page 39

WWW.SSTCOMM.COM 39

The “Checksum” button only checks part of the data. Here is an example.

In this example, command ID0 is composed of data head, data and check code. It uses short address; when

you click “Send”, you will get the response data.

Note: Under this function, gateway will stop to execute the configured command; Turn off this function,

gateway will return to execute the configured command.

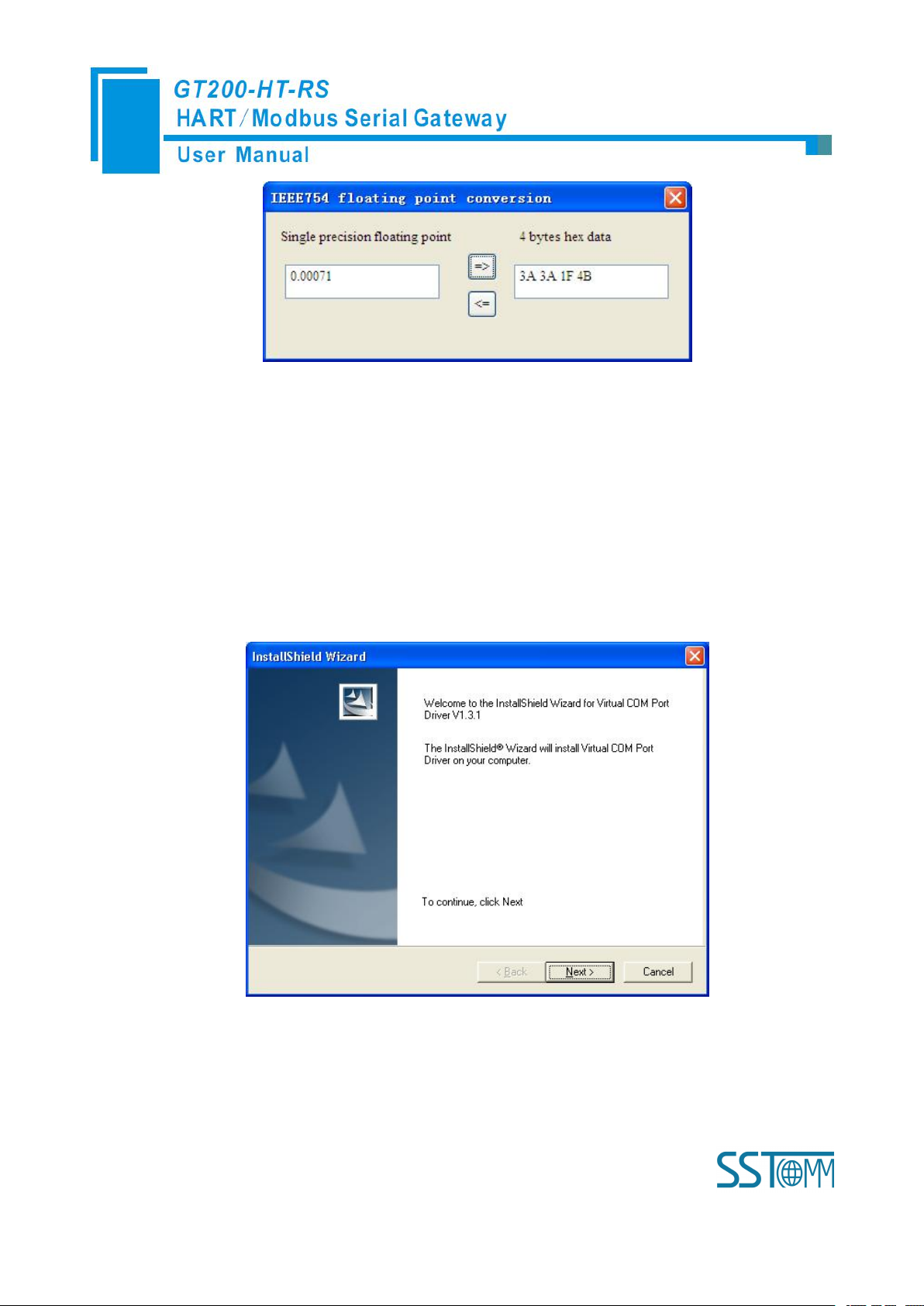

4.2.11 Useful Tools

In the “Tools” menu, there are two useful tools: They are used to finish data conversion.

PACKED ASCII conversion:

IEEE 754 conversion:

Page 40

WWW.SSTCOMM.COM 40

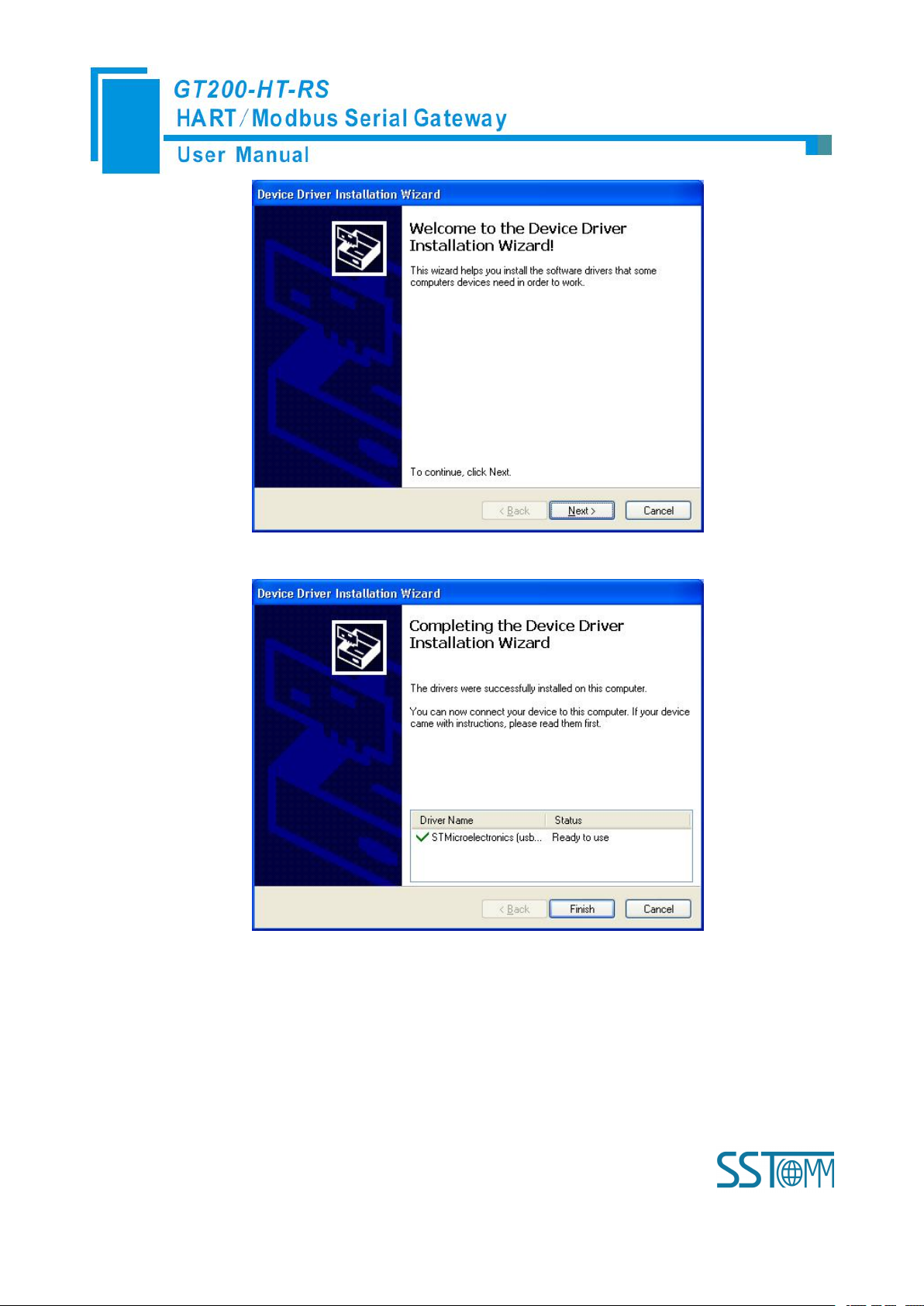

4.2.12 Use USB Port

For now, USB port is only used for debugging and configuration. Its function is the same as RS-232 under

configuration and debug. After installing USB driver, this USB driver will generate a virtual COM port on PC,

GT200-HT-RS can communicate with PC through this virtual COM port. Please ensure that this USB driver is

installed before using this function.

Installing driver, as show below:

Click “Next”,

Page 41

WWW.SSTCOMM.COM 41

Click “Next”,

Click “Finish”, to finish the installation of USB driver.

How to find this virtual COM port? Use USB cable line to connect GT200-HT-RS and PC, set bit 2 of DIP

switch to ON, and power on the product. Open the “Computer Management” of PC, you will find there is one new

COM port under “Port (COM&LPT), as shown “STMicroelectronics Virtual COM Port (COM3), that is the

virtual COM Port:

Page 42

WWW.SSTCOMM.COM 42

Noted: Different computer, the serial number will be different.

Open SST-HT-CFG software, click “Config” and choose Serial port, here choose COM3, as shown below:

After choosing serial port, click “Upload” on the toolbar,

Page 43

WWW.SSTCOMM.COM 43

After clicking Upload data, it will show uploading succeeded:

Page 44

WWW.SSTCOMM.COM 44

Page 45

WWW.SSTCOMM.COM 45

5 Working Principle

Gateway

memory

address

Corresponding

Modbus register

address

Description

Read-only part

0-1599

0-799

The HART data input area

1600-1619

800-809

Device 0_cmd0 data

1620-1639

810-819

Device 1_cmd0 data

……

……

……Device 15_cmd0 data

1920

960H

Gateway status

1921

960L

Send times of Gateway’s HART port

1922

961H

Receive times of Gateway’s HART port

1923

961L

HART communication error times

1924-1943

962-971

Reserved

1944

972H

Device 0_cmd0’s response status

1945

972L

Device 1_cmd0’s response status

……

……

……Device15 _cmd0’s response status

1960-2119

980-1059

The response status of the user command

2120-2391

1060-1195

Reserved

2392

1196H

Universal receive label

2393

1196L

Universal receive Error Counter

2394-2395

1197

Universal receive data length

2396-2695

1198-1347

Universal receive data

2696-2999

Reserved

Readable

and

writable

part

3000-3999

0000-0499

The HART data output area

4000

0500H

Reset to send, receive, error counter

Inside the gateway it opens up a length of 5000 bytes of memory as the data exchange of input and output

buffers. Memory of 0 to 2999 acts as the storage area of the HART input data and device status. Memory of 3000

to 4999 acts as storage area of the HART output data and control variables. The specific assignment shown in the

table below:

Page 46

WWW.SSTCOMM.COM 46

4001

0500L

Polling enabled

4002

0501H

Trigger label

4003

0501L

Trigger command number

4004-4269

0502-0634

Reserved

4270

0635H

Universal send label

4271

0635L

Universal mode enabled

4272-4273

0636

Universal send data length

4274-4573

0637-0786

Universal to send data

The HART data input area: Store the data that HART slave device sends to gateway.

The HART data output area: Store the data that the gateway sends to the HART slave device.

Device 0_cmd0~ Device 15_cmd0: When operating a slave command for the first time, the gateway internal

will automatically execute the No. 0 command to obtain the device information (to obtain the long address).

Gateway status: The gateway status indicates what the gateway state is in the HART network, defined as:

Send times of HART port on gateway: The HART send counter

Receive times of HART port on gateway: The HART receive counter

HART communication error times: The HART Receive error counter

The response status of Device 0_cmd0~ Device 15_cmd0: Show that the response status of the internal

The response status of user command: Show that the response status of the user command

The response data of this internal command is stored in this area.

0---- No HART communication

1----sending

2---- Waiting for a response

3---- Handling a response

command

Command state is defined:

0---- Not executed

1---- Correct response

2---- Parity error

3---- No answer

Page 47

WWW.SSTCOMM.COM 47

4---- Error defined in agreement

Universal Receive label: The receive label under the universal mode, this value which changes one time

Universal receive data length: Indicating the received data length under the universal mode

Universal Receive Error Counter: Indicate the universal receive error number

Universal receive data: Store the received data at HART side under the universal mode

Reset send, receive, error counter: The gateway’s control signal, when the value of memory changes,

Polling is enabled: This bit is readable and writable, writing 1 enables the polling output, writing 0 disables

Trigger label: Change the value will result in a trigger operation

Trigger command number: Command number executed by trigger operation

Universal mode enabled: The value of 1 indicates a universal transfer function is enabled, otherwise disables

Universal send label: The send label under the universal mode, this value changes in time will lead to send a

The universal send data length: The length of send data under the universal mode

Universal to send data: Data needs to send under the universal mode

5---- Not connected

indicates that HART end receives a HART frame

gateway causes all the counter to 0

polling output; Reading 1 indicates that the polling state is enabled, 0 indicates that the polling is in the

disabled state

universal transport function

HART frame

Page 48

WWW.SSTCOMM.COM 48

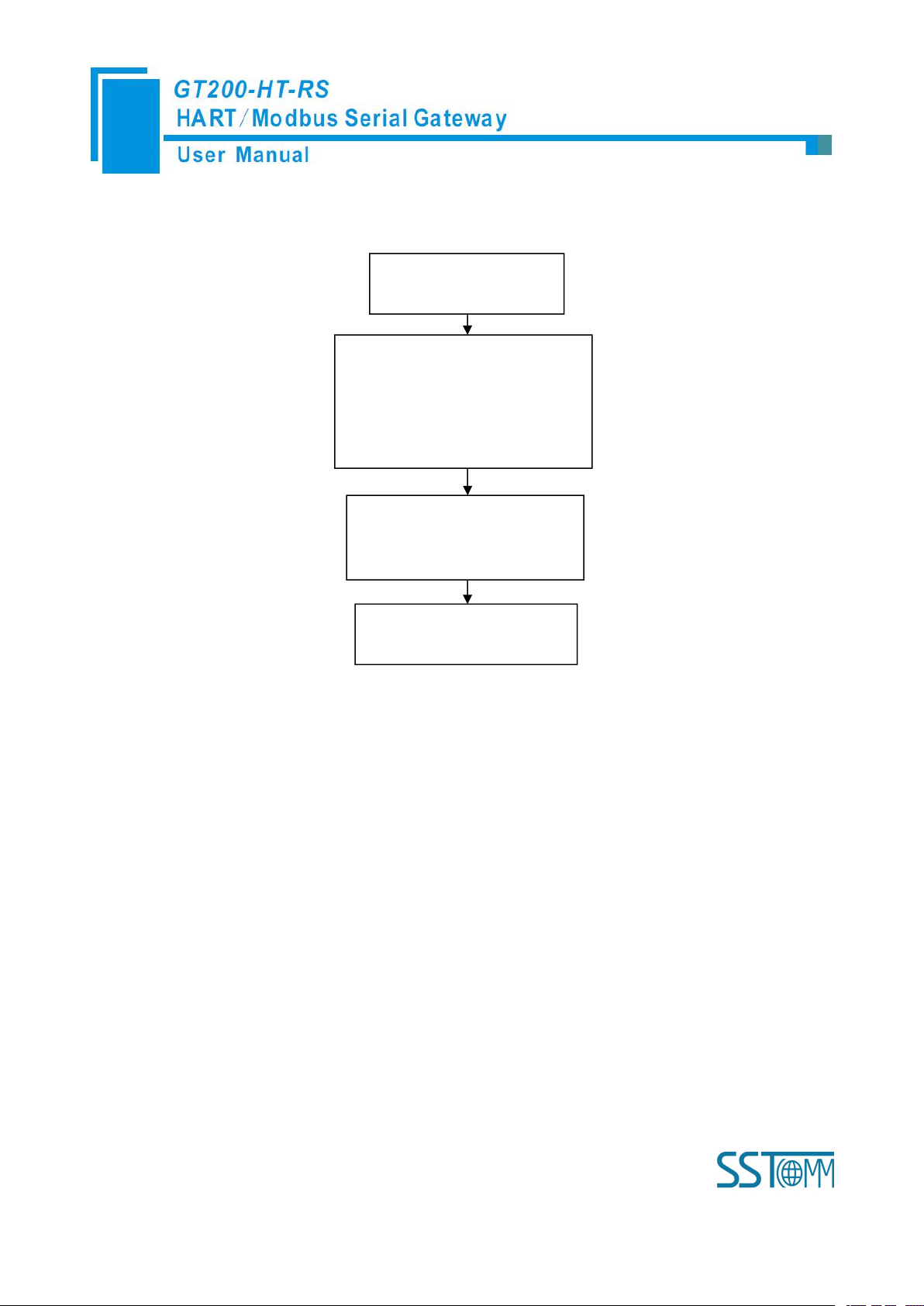

5.1 Flowchart of Executing One HART Command

Initialization

output

Satisfy the

polling output

Satisfy Change

of state output

Meet the

trigger output

Execute

command

Input Data

Output Data

Field

instruments

Data

State

Data

Slave's

response

Y

The next

command

Current command

N

N

N

N

Sent to the slave

command frame

Quit

5.2 Universal Send and Receive Data

There are two universal ways for user to select: One is that fieldbus is defined as universal mode. The

gateway will receive the serial data in the way of 3.5 character timeout broken frame and send out the data

unmodified from the HART interface. Gateway sends data out from serial which is received from HART interface

without modification. The character timeout is determined by baud rate, such as 19200, Character timeout is

Page 49

WWW.SSTCOMM.COM 49

considered to be (1/19200) * 10 * 3.5 ≈ 2ms. The other is to start transmit-receive of HART common frame of

06H command "common

mode enable" bit is 1

10H command will write the data

to a continuous region which

address begins from “Universal

mode send data”

The length of the data written to

"The universal send data length"

address with 06H command

06H command to change "the

Universal send data label”

HART indirectly through Modbus command, here is an example:

The gateway will store the received HART frame in a continuous region within "the Universal receive data"

as a starting address and write the length of the received data in the "Universal received data length". Then change

the value of the Universal receive label". If no data is received within the response waiting time, the gateway will

order "universal receive error counter" to plus 1. Before sending the general frame, user should read the universal

receive label and the error counter. After transmitting the general frame, it needs to read these two values

continuously until one of them changes.

5.3 Trigger Command

Users can use Modbus command to trigger any HART command which is configured by gateway. The

specific approach is: using command ID6 of Modbus to write the user command number which needs to be

triggered (when SST-HT-CFG configures commands, the software will automatically calculate and display) to the

"trigger command number". Then rewriting "the trigger label" can trigger the value to change and trigger the

Page 50

WWW.SSTCOMM.COM 50

gateway to finish a trigger operation. Parts of response data in the device will be stored to "the receive data

memory" which specified by this command number.

5.4 Data Exchange with Modbus

When fieldbus is configured as "Modbus slave", user can exchange data, inquire about the status of gateway

and manage according to the corresponding address of gateway in the internal input and output buffer; Also you

can do some trigger operation and transmission of common frame.

Page 51

WWW.SSTCOMM.COM 51

6 Installation

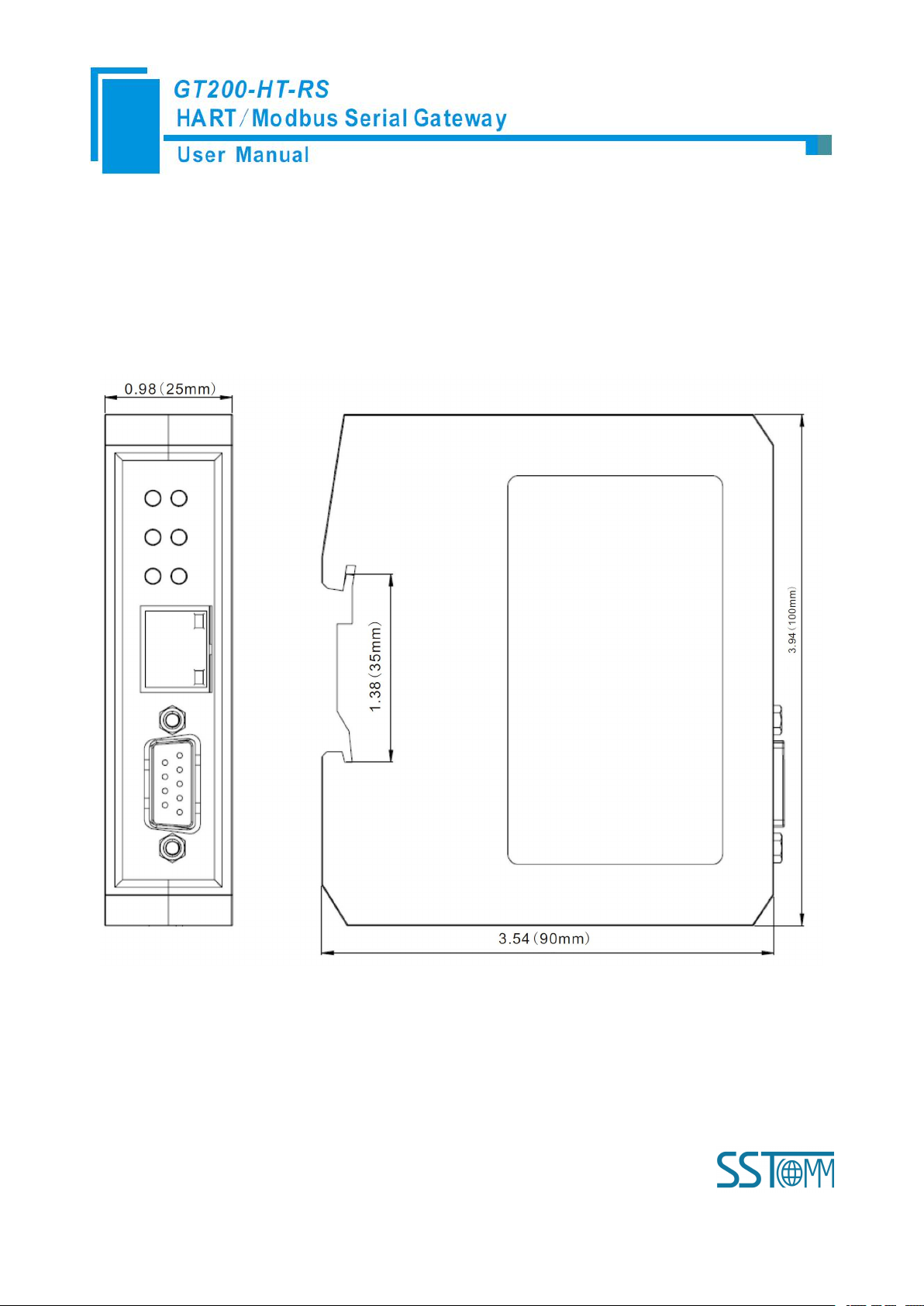

6.1 Machine Dimension

Size: 0.98 in (width)*3.94 in (height)*3.54 in (depth)

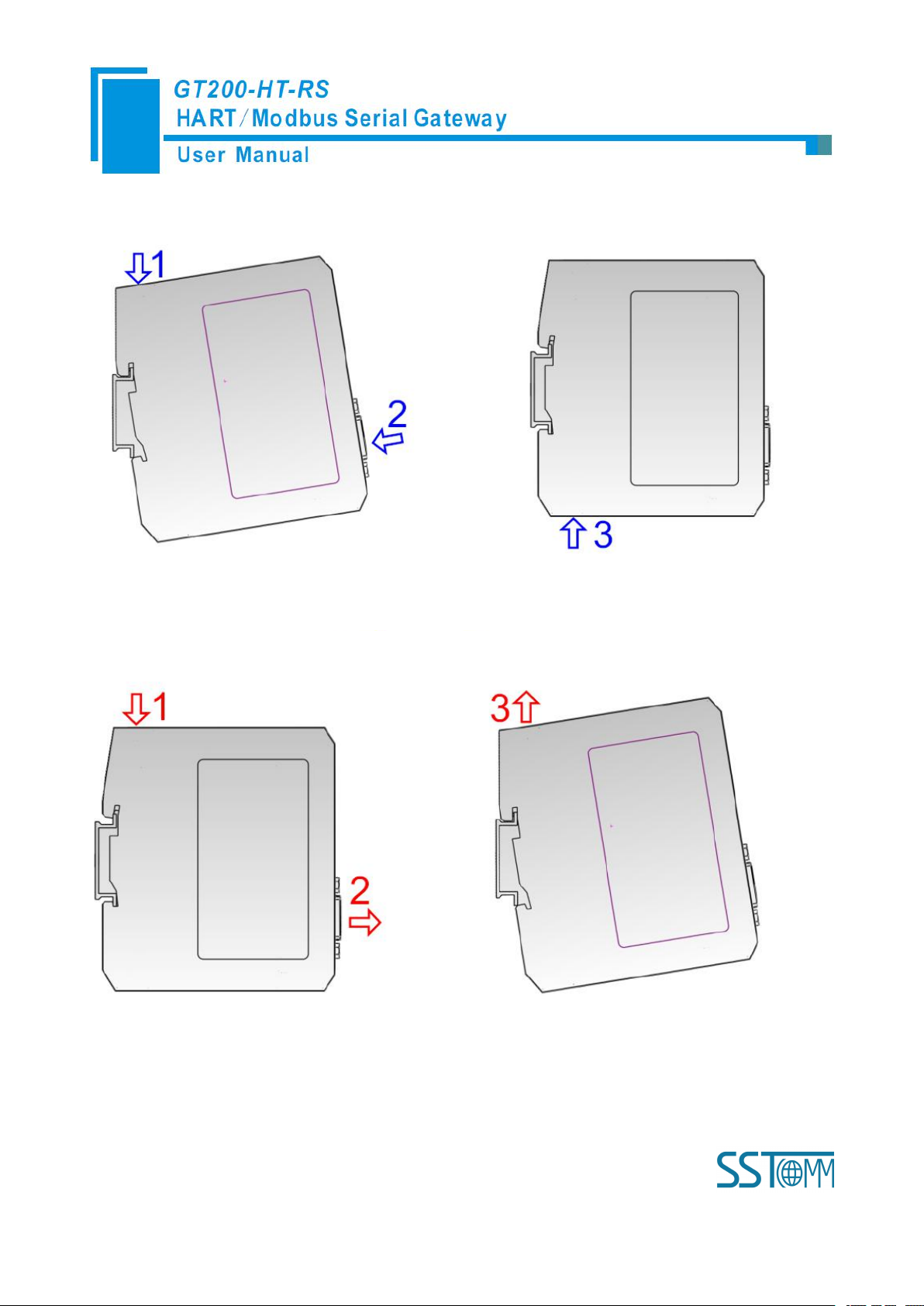

6.2 Installation Method

Using 1.38 in (35mm) DIN RAIL

Page 52

WWW.SSTCOMM.COM 52

Installing the gateway

Uninstalling the gateway

Loading...

Loading...