Page 1

Universal Serial/PROFIBUS DP Gateway

GT200-DP-RS

User Manual

V6.1

SST Automation

E-mail: SUPPORT@SSTCOMM.COM

WWW.SSTCOMM.COM

Page 2

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

2

Catalog

1 About the Gateway

.....................................................................................................................................................................

4

1.1 Product Function

.............................................................................................................................................................

4

1.2 Product Features

.............................................................................................................................................................

4

1.3 Technical Specifications

.................................................................................................................................................

4

1.4 Related Products

.............................................................................................................................................................

6

2 Quick Start Guide

......................................................................................................................................................................

7

2.1 Power Wiring

..................................................................................................................................................................

7

2.2 Wiring with PC

...............................................................................................................................................................

7

2.3 Configuration Method

....................................................................................................................................................

7

2.4 Wiring with Serial Device

..............................................................................................................................................

9

2.5 Wiring PROFIBUS DP Interface

..................................................................................................................................

10

2.6 Debug

............................................................................................................................................................................

11

3 Hardware Descriptions

............................................................................................................................................................

12

3.1 Product Appearance

......................................................................................................................................................

12

3.2 Indicators

......................................................................................................................................................................

13

3.3 LED Display and Button

..............................................................................................................................................

13

3.3.1 LED Display

......................................................................................................................................................

13

3.3.2 PROFIBUS DP Address Setting Button

............................................................................................................

14

3.4 Interface

........................................................................................................................................................................

15

3.4.1 Power Interface

..................................................................................................................................................

15

3.4.2 PROFIBUS DP Interface

...................................................................................................................................

15

3.4.3 RS-485/RS-422 Interface

..................................................................................................................................

16

3.4.4 RS-232 Interface

................................................................................................................................................

17

4 Working Principle

....................................................................................................................................................................

18

4.1 Modbus Master

.............................................................................................................................................................

18

4.2 Modbus Slave

...............................................................................................................................................................

18

5 Universal Mode

........................................................................................................................................................................

20

5.1 Data Exchange

..............................................................................................................................................................

20

5.2 Universal Protocol

........................................................................................................................................................

21

6 Software Instructions

...............................................................................................................................................................

23

6.1 Notes before Configuring

.............................................................................................................................................

23

6.2 User Interface

................................................................................................................................................................

23

6.3 The Operation of Equipment View

...............................................................................................................................

26

6.3.1 Equipment View Interface

.................................................................................................................................

26

6.3.2 Operation Mode of Equipment View

................................................................................................................

26

6.3.3 Operation Types of Equipment View

................................................................................................................

27

6.4 The Operation of Configuration View

..........................................................................................................................

28

6.4.1 Interface of Fieldbus Configuration View

.........................................................................................................

28

6.4.2 Interface of Subnet Configuration View

...........................................................................................................

29

Page 3

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

3

6.4.3 Interface of Node Configuration View

..............................................................................................................

34

6.4.4 Interface of Command Configuration View

......................................................................................................

35

6.4.5 Notes View

.........................................................................................................................................................

37

6.5 Conflict Detection

.........................................................................................................................................................

38

6.5.1 Operation of Command List

..............................................................................................................................

39

6.5.2 Operation of Memory Mapping Area

................................................................................................................

40

6.6 Hardware Communication

............................................................................................................................................

41

6.6.1 Serial Configuration

..........................................................................................................................................

41

6.6.2 Upload Configuration

........................................................................................................................................

42

6.6.3 Download Configuration

...................................................................................................................................

42

6.7 Load and Save Configuration

.......................................................................................................................................

43

6.7.1 Load Configuration Project

...............................................................................................................................

43

6.7.2 Save Configuration Project

...............................................................................................................................

43

6.8 Export EXCEL

..............................................................................................................................................................

44

6.9 Debug

............................................................................................................................................................................

45

6.9.1 Debug Interface of 4.X or 3.X

...........................................................................................................................

46

6.9.2 Debug Interface of 5.x and above

.....................................................................................................................

49

7 PROFIBUS DP Hardware Configuration Instructions

............................................................................................................

54

7.1 Register GSD file

..........................................................................................................................................................

54

7.2 DPRS2A.GSD-Configuration software configuration mode use

..............................................................................

56

7.3 DPRS2M.GSD-DP Hardware Configuration of Modbus master

..............................................................................

57

7.4 DPRS2S.GSD-DP Hardware Configuration of Modbus slave

..................................................................................

62

7.5 DPRS2T.GSD-DP Hardware Configuration of User Config

....................................................................................

65

8 Installation

...............................................................................................................................................................................

69

8.1 Machine Dimension

......................................................................................................................................................

69

8.2 Installation Method

.......................................................................................................................................................

69

Appendix A: Using STEP 7 to Set PROFIBUS DP

...................................................................................................................

71

Appendix B: How STEP7 Access Data of Gateway and Select Data Module

..........................................................................

78

How STEP7 Access Data of Gateway

................................................................................................................................

78

How STEP7 Select Data Module

.......................................................................................................................................

79

Page 4

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

4

1 About the Gateway

1.1 Product Function

The gateway GT200-DP-RS enables data to establish communication between the serial port and PROFIBUS DP

(PROFIBUS DP master such as Siemens PLC). At the same time it can remotely obtain real-time I / O data, status and other

information of the connected PLC and serial device via docking cloud platforms such as bokaiyun to achieve remote

monitoring. The gateway can connect multiple devices with Modbus/RS-485/RS-232/RS-422 interface with PROFIBUS DP,

meaning that Modbus/RS-485/RS-232/RS-422 network devices can be converted to PROFIBUS DP network devices.

1.2 Product Features

Wide Application: Any devices with RS-485/RS-232/RS-422 can be connected to PROFIBUS DP network through

GT200-DP-RS. For example Variable-frequency Drive with Modbus protocol interface, Motor starting protector,

transmitters.

Easy to use: Users don’t need to know more knowledge about PROFIBUS and Modbus, and they can configure the

gateway according to the user manual in a short time without complex programming.

Transparent communication: Users can refer to mapping relations between PROFIBUS DP data area and Modbus data

area to realize the transparent data communication between PROFIBUS DP and Modbus.

1.3 Technical Specifications

1. Act as a PROFIBUS DP slave at the side of PROFIBUS DP, while Modbus master, Modbus slave and Universal

mode can be selected at serial side and serial interface can be selected RS-232, RS-485 or RS-422. The mapping of

PROFIBUS DP and Modbus communication data area can achieve transparent communication of PROFIBUS and Modbus;

2. Serial: RS-485, RS-232, RS-422, half-duplex. Baud rate: 300, 600, 1200, 2400, 4800, 9600, 19.2 K, 38.4K, 57.6K

and 115.2Kbps can be selected. Parity check mode: None, Odd Even, Mark and space can be selected;

Page 5

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

5

3. As a Modbus master, it supports 01H, 02H, 03H, 04H, 05H, 06H, 0FH and 10H function codes.

Use configuration software to configure:

It can be configured up to 100 Modbus commands. 03H and 04H support "Word / Byte mapping". Through the

high-byte or low-byte mapping of the registers can effectively utilize PROFIBUS DP input-byte; Support monitoring

status of Modbus slave; Support clearing data or keep the last data when input-data is abnormal; Support

re-transmitting data when response is timeout;

Hardware configuration of PROFIBUS DP master (Abbr. DP master hardware configuration):

Support configuring at most 48 Modbus commands; Support monitoring status of Modbus slave; Support

clearing data or keep the last data when input-data is abnormal; Support re-transmitting data when response is

timeout;

4. Modbus slave supports 01H, 02H, 03H, 04H, 05H, 06H 0FH and 10H function codes;

5. Support the control mode of character timeout and character number in universal mode, and have the function of

sending automatically;

6. DP/V0 PROFIBUS DP communication capability, in accordance with EN50170;

7. As a PROFIBUS DP slave, baud rate is self-adaptive, and the maximum baud rate is 12Mbps;

8. PROFIBUS DP input-byte and output-byte number can be freely set and the maximum input and output bytes are:

Max Input bytes ≤244 Bytes

Max Output bytes ≤244 Bytes

Max Input Bytes + Output Bytes ≤488Bytes

9. Support clearing data or keep the last data when input-data is abnormal;

10. Update firmware function;

11. Power: 24VDC (11V~30V), 80mA;

12. Working circumstance temperature: -4℉~140℉ (-20℃~60℃), Humidity: 5%~ 95% (non-condensing);

13. External dimensions (W*H*D): 0.98 in*3.94 in *3.54 in (25mm*100mm*90mm);

14. Installation: 35mm DIN RAIL;

15. Protection Level: IP20;

16. Test standard: In accordance with EMC test standard.

Page 6

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

6

1.4 Related Products

Other related products in SSTCOMM: GT100-DP-RS and so on.

If you want to get more information about these products, please visit SSTCOMM website: http://www.sstcomm.com.

Page 7

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

7

2 Quick Start Guide

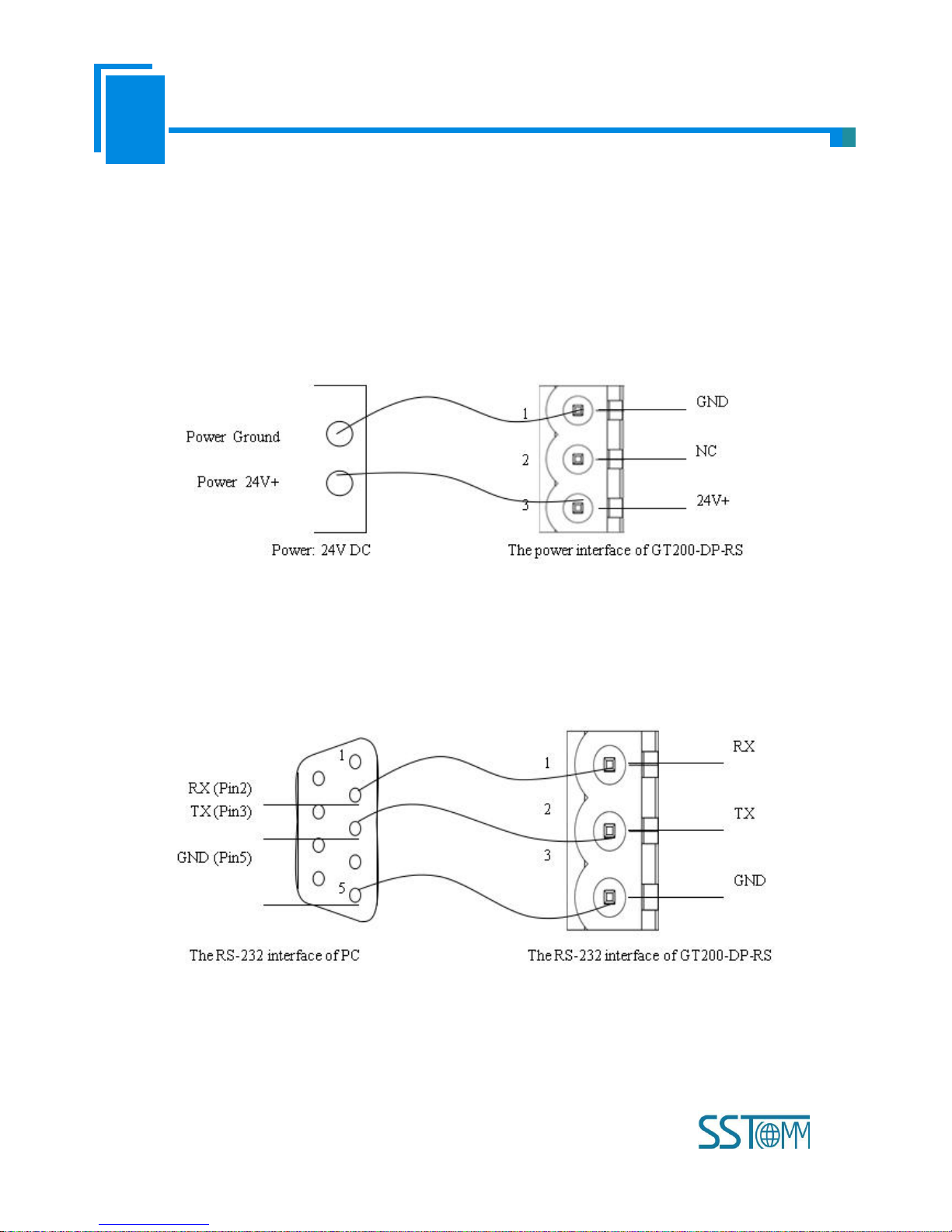

2.1 Power Wiring

The power is 24V DC, wiring method is shown as follow:

2.2 Wiring with PC

Establish the connection the RS-232 interface of gateway with PC, the wiring method is shown as follow:

2.3 Configuration Method

GT200-DP-RS V6.1 version product supports two methods to configure: One is through configuration software, the

Page 8

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

8

other is through DP hardware configuration (this method is new added function of V6.X). It also supports USB and RS232

interface to configure. The LED Display of GT200-DP-RS will show in DP slave address and “-U” or “-P” alternately.

When showing “-U” on LED Display, the gateway is in the “Software configuration” state; When showing “-P”, it means

the gateway is in “DP Hardware Configuration” state.

1) When using “Setting through configuration software”, users can choose to use USB interface or RS-232 interface to

configure. If users use USB interface to configure it, they can download and upload the configuration under run and

configuration mode. USB interface can auto-detect and switch to the configuration mode. If users use RS-232 interface to

configure the gateway, GT200-DP-RS should be entered into configuration mode and finish upload and download tasks.

How to enter into configuration mode? Power on GT200-DP-RS, long press button for 5s, LED display shows CF blinking.

Click the button again to enter into configuration mode, LED display shows CF on.

Configuration software is named SST-MPG-CFG. Double click the application and install the configuration software

SST-MPG-CFG. Users can finish the installation lightly according to the wizard. Power on GT200-DP-RS, long press

button for 5s, LED display shows CF blinking. Click the button again to enter into configuration mode, LED display shows

CF on. Open the software SST-MPG-CFG and users can configure GT200-DP-RS.

2) Use “DP Hardware Configuration” way, first of all, users should confirm that LED display is showing “-P”, if it shows

“-P”, that means the gateway has been entered into “DP Hardware Configuration” status. Users can configure the gateway

in DP hardware configuration, no need to upload/download configuration in the software; If the LED display shows “-U”,

users should download the configuration that is “DP Hardware Configuration” in SST-MPG-CFG to let the gateway enter

into this mode, then users can use DP Hardware way to configure the gateway.

Page 9

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

9

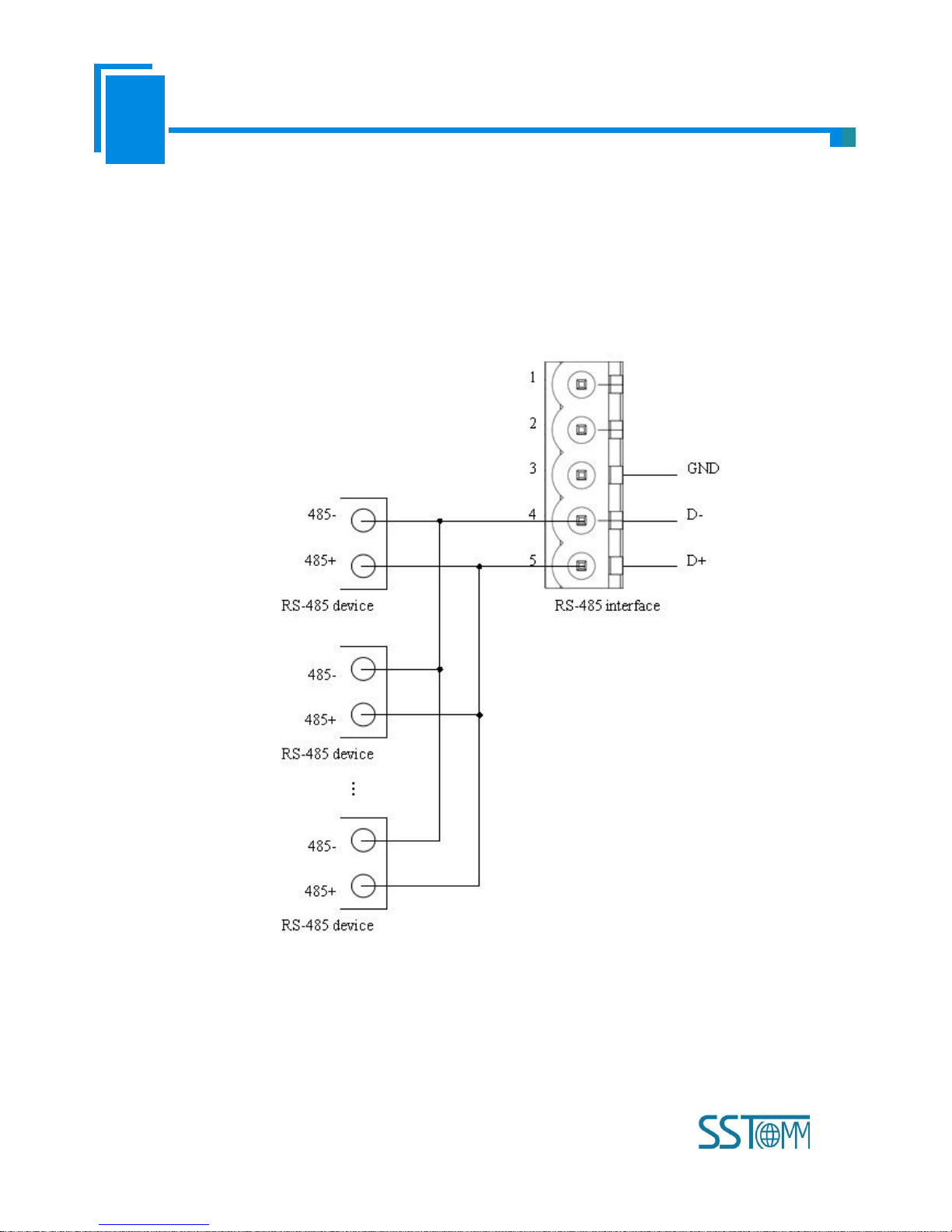

2.4 Wiring with Serial Device

After finishing configuration, wire communication interface, the wiring method of RS-232 is the same with "wiring

with PC", the wiring method of RS-485 is shown as follow:

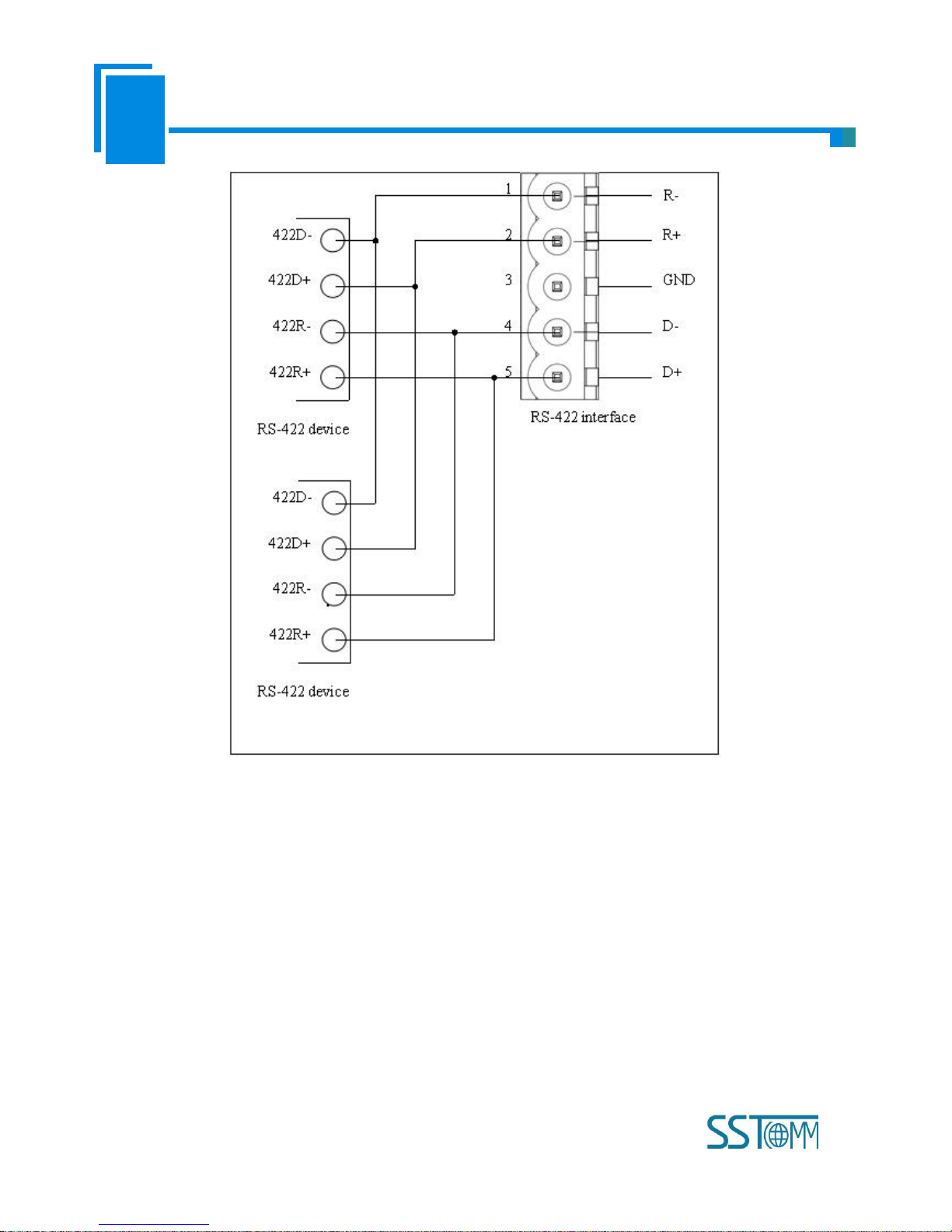

The wiring method of RS-422 is shown as follow:

Page 10

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

10

When RS-485 is in the communication of point to multi-point, to prevent the reflection and obstruction of signal, users

need to use two terminal resistances in furthest ports of line, and the parameters are 120Ω 1/2W.

Note: There is no terminal resistor inside RS-485 interface of GT200-DP-RS.

2.5 Wiring PROFIBUS DP Interface

Suggest wiring PROFIBUS DP with standard PROFIBUS DP connector. The description of PROFIBUS DP interface

has been shown in chapter 4.4.2.

Set the address of PROFIBUS DP through button on the panel.

Under normal run mode, LED display shows the address of PROFIBUS DP.

Register GSD file to PROFIBUS DP master configuration software (STEP7), and configure parameters.

Page 11

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

11

PBF light being off and STA light being blinking show the connection with PROFIBUS DP master is successful!

2.6 Debug

GT200-DP-RS supports three operating modes: Modbus Master, Modbus Slave and User Config. GT200-DP-RS

supports debugging function in three modes. Quickly press the button for 3 times, GT200-DP-RS enter into debug mode,

the LED display shows “db” always on.

Notes: Under “Software Configuration” mode, the gateway can enter into Debug without DP master; Under “DP

Hardware Configuration” mode, the Debug function is enabled when connecting DP master, it is disabled without DP

master communication.

Page 12

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

12

3 Hardware Descriptions

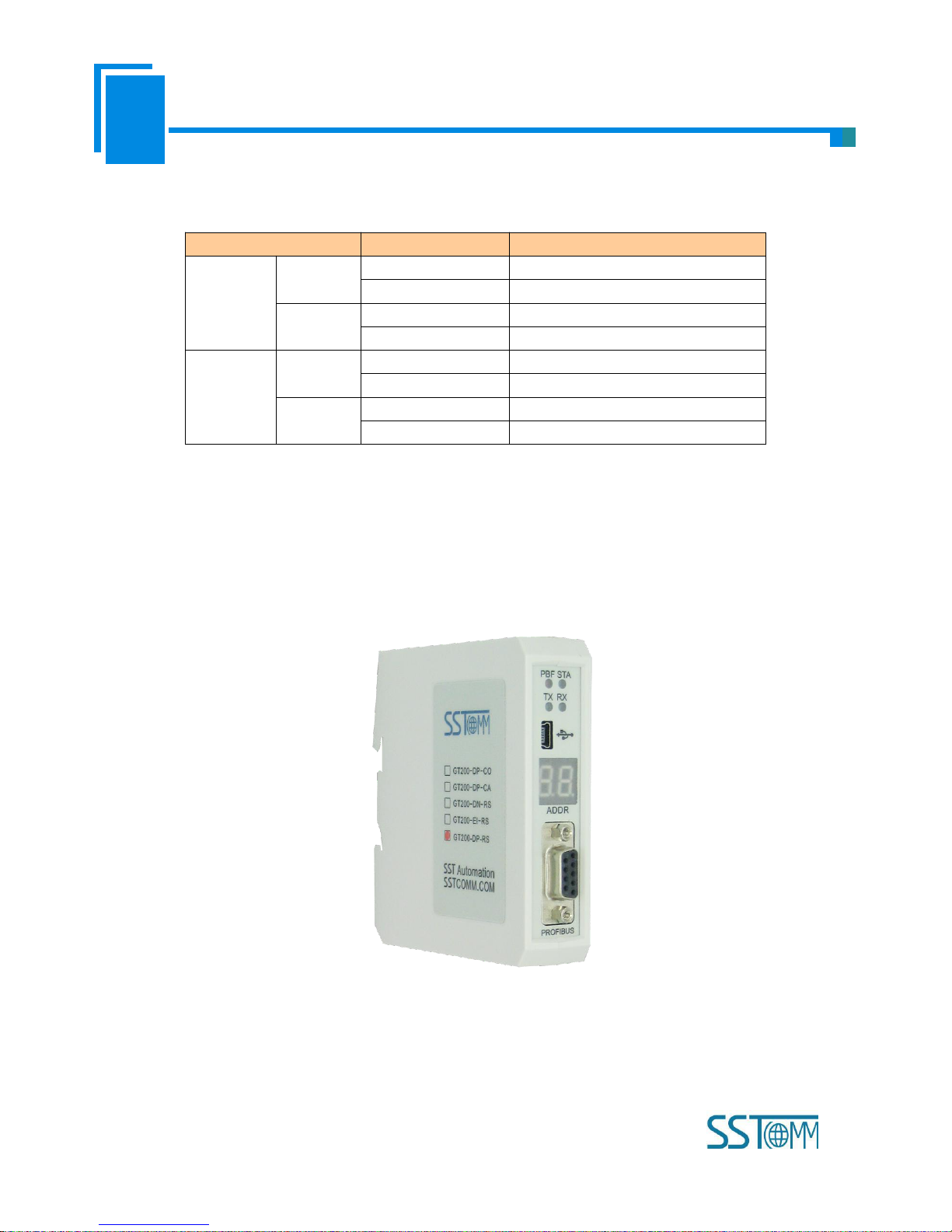

3.1 Product Appearance

Note: This picture is for reference only. Product appearance should accord to the real object.

Power Interface

RS-485/RS-422

Interface

RS-232 Interface

PROFIBUS DP

Interface

Indicators

LED Display

Button

USB Interface

Page 13

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

13

3.2 Indicators

Indicators

State

Description

PB

PBF

Always Red

PROFIBUS DP communication fails.

Close

Communication is ok.

STA

Green Blinking

PROFIBUS DP is communicating.

Close

PROFIBUS DP is not communicating.

RS-232/485

/422

TX

Green Blinking

RS-485/422 port is sending data.

Close

RS-485/422 port isn't sending data.

RX

Green Blinking

RS-485/422 port is receiving data.

Close

RS-485/422 port isn't receiving data.

3.3 LED Display and Button

3.3.1 LED Display

LED display is in the front of the product.

There are three display conditions:

Page 14

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

14

LED display

Description

CF

The gateway is in the configuration mode.

db

The gateway is in the debug mode.

Number+“-P” or

“-U” alternate

blinking

The gateway is in the run mode. The number shows the PROFIBUS DP slave

address. “-U” shows the gateway is in the “Software Configuration” mode; “-P”

shows the gateway is in the “DP Hardware Configuration” mode.

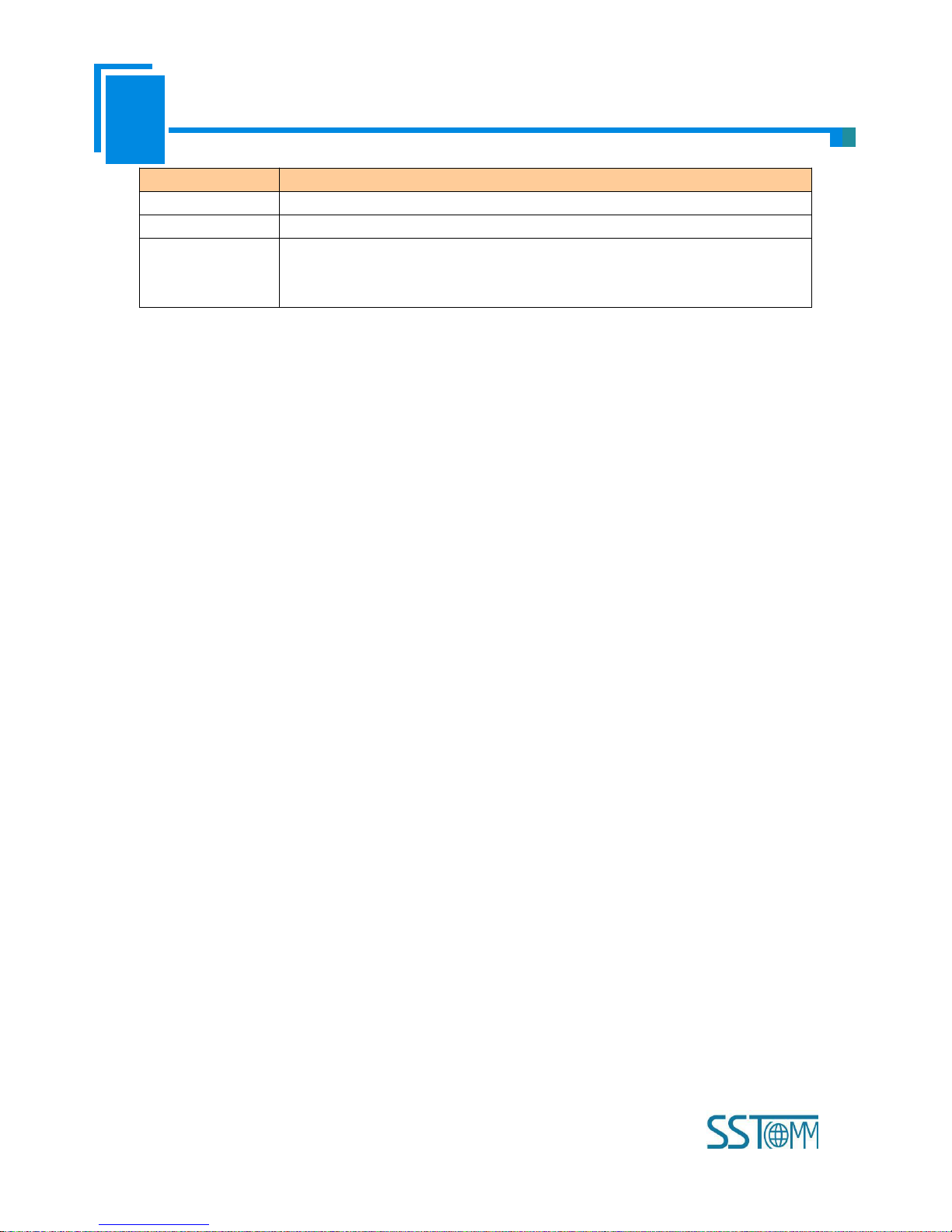

3.3.2 PROFIBUS DP Address Setting Button

Configuration button on the front panel can be used to set the address of the PROFIBUS DP slave. Now, we have three

operation ways to provide users.

1) Under normal working condition of the GT200-DP-RS, digital tube always displays the address of the current

PROFIBUS DP address. Quickly press (double-click) the button twice in succession, the high bit starts flash, and the low bit

always on, click the button to add 1 to start setting the PROFIBUS DP address high bit. Long-press the button for 2.5

seconds, the high bit is always on, and the low bit starts flash. Click the button to add 1to start setting the PROFIBUS DP

address low bit. Then long-press the button for 2.5 seconds to save DP address.

2) Long press button for 5 seconds, LED display shows CF blinking, click button to enter into configuration state, the

LED display shows CF on, users can upload and download the configuration under this mode. When it is done, long press

2.5 seconds to enter into the run mode, the LED display shows DP address.

3) Quick click the button for three times in 3s to enter into debug mode, the LED display shows db is always on. Users

can do the serial debugging and other actions. When it is done, click the button three times in 3s to enter into the run mode,

the LED display shows DP address.

Notes: After entering into PROFIBUS DP address setting, the gateway will exit the address setting state automatically

and keep showing the original address without any action button within 10 seconds. The settable range of PROFIBUS DP

address is 0~99 (DEC).

The operation instruction of button is shown as below:

Page 15

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

15

3.4 Interface

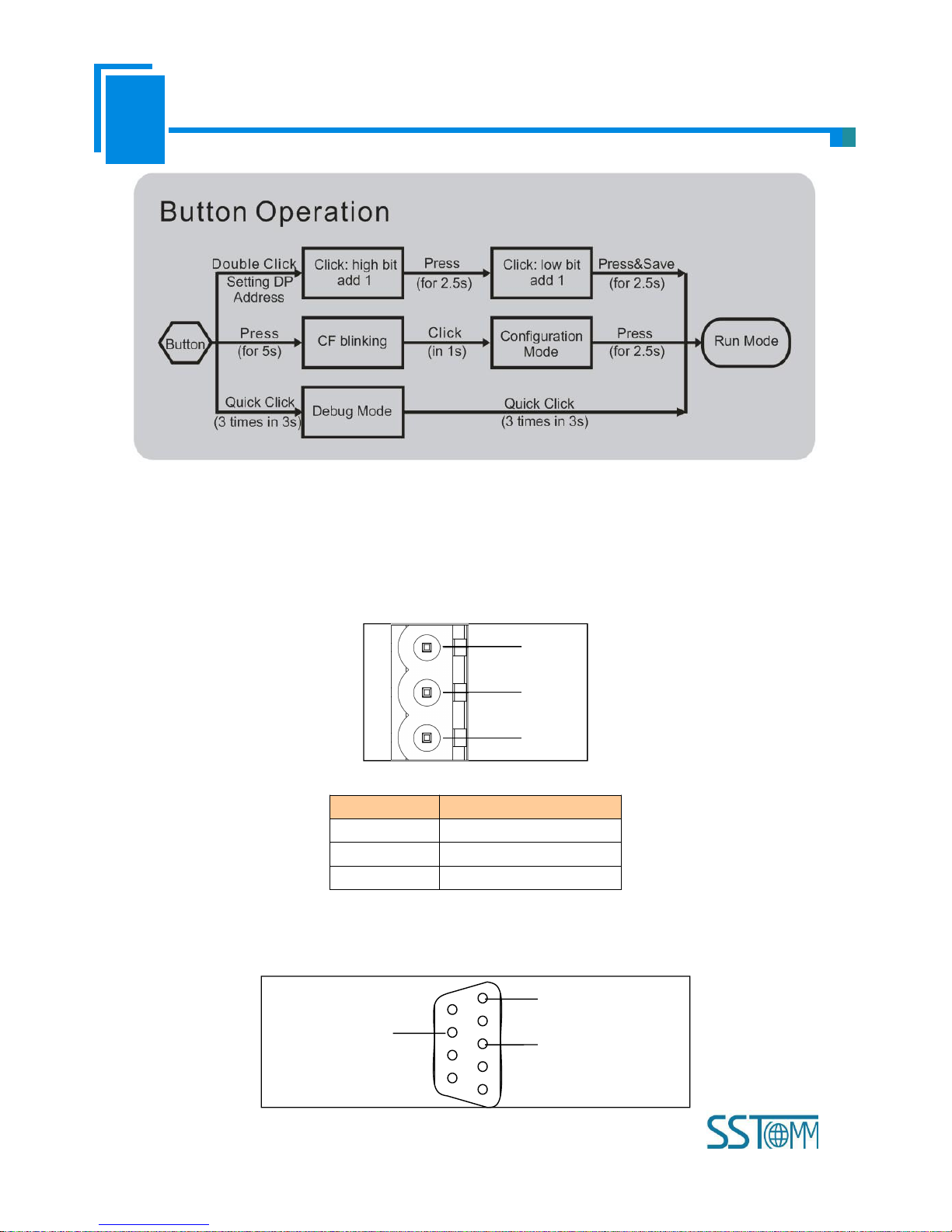

3.4.1 Power Interface

GNDNC24V+

1

2

3

Pin

Function

1

GND

2

NC(No Connect)

3

24V+, DC plus 24V

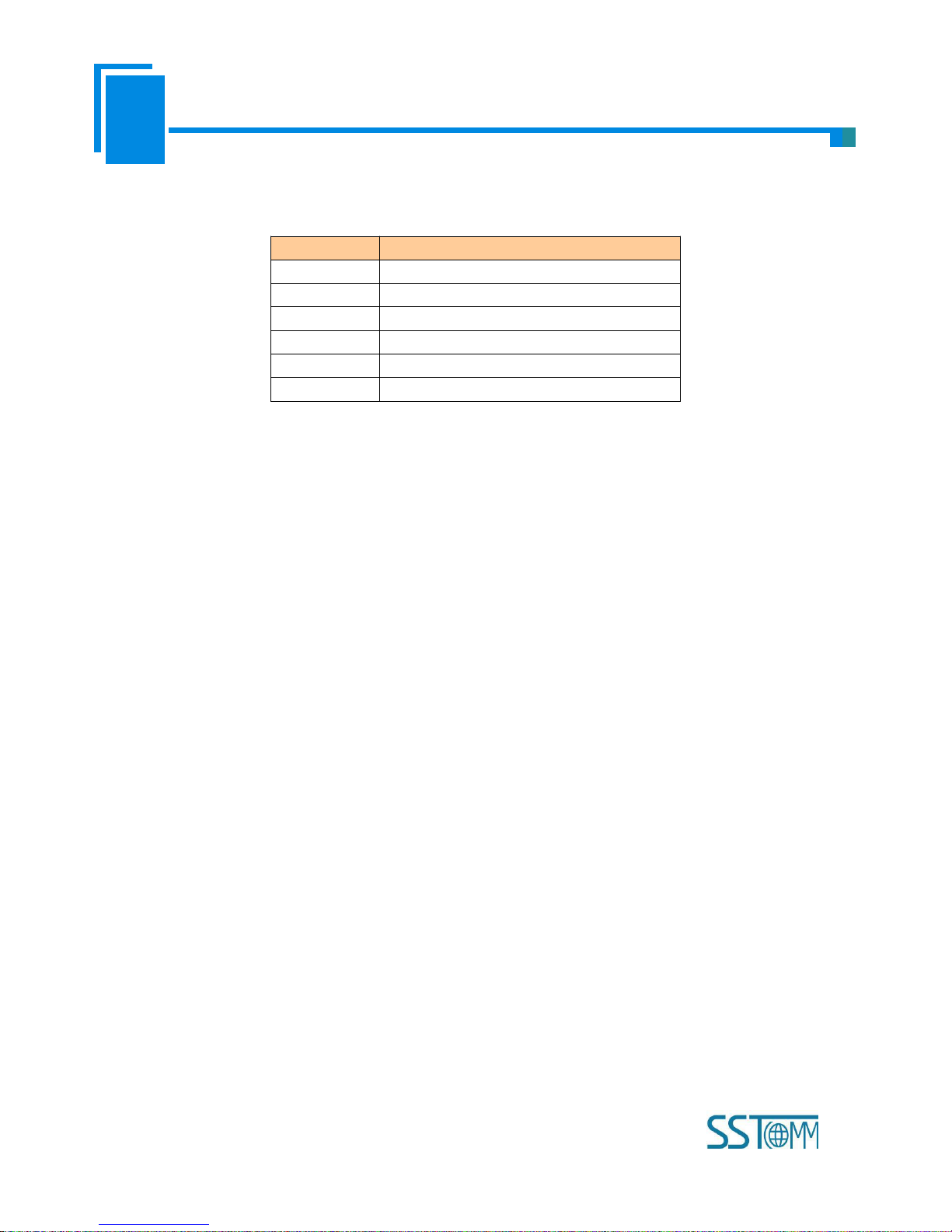

3.4.2 PROFIBUS DP Interface

5

1

PROFI_A (Pin 8)

GND (Pin 5)

PROFI_B (Pin 3)

Page 16

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

16

PROFIBUS DP interface uses DB9 male-connector, and the pins are defined as follow:

Pin

Function

3

PROFI_B, Data positive

4

RTS

5

GND

6

+5VOutput

8

PROFI_A, Data negative

Bolt

SHIELD, Bus cable shield ground

PROFI_B (pin 3), PROFI_A (pin 8) and the shield GND (bolt) must be connected; RTS (pin 4) can be used to

determine the direction of transmission by equipment; +5 V (Pin 6) and GND (Pin 5) are used for the bus terminal, and can

also be used supply to fiber optic transceivers. The maximum output current of pin 5 and pin6 is 80mA.

3.4.3 RS-485/RS-422 Interface

The RS-485 interface of GT200-DP-RS is standard, and the RS-485 characteristics of the product are shown as

follows:

1. The basic characteristics of RS-485 transmission technology

① Network topology: Linear bus, there are active bus termination resistors at both sides.

② Transfer rate: 300 bps~115.2Kbps.

③ Media: Shielded twisted-pair cable and also can cancel the shielding, depending on environmental conditions

(EMC).

④Site number: 32 stations per subsection (without repeater), and can up to 127 stations (with RS-485 repeater).

⑤Plug connection: 3-pin pluggable terminal.

2. The main points on RS-485 transmission equipment installation

①All the equipment be connected with RS-485 bus;

②Subsection can be connected up to 32 sites;

③The farthest end of each bus has a termination resistor—120Ω 1/2W to ensure reliable operation of the network.

Serial interface uses 5-pin pluggable terminal and users can wire it according to the wiring instructions on the panel.

Page 17

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

17

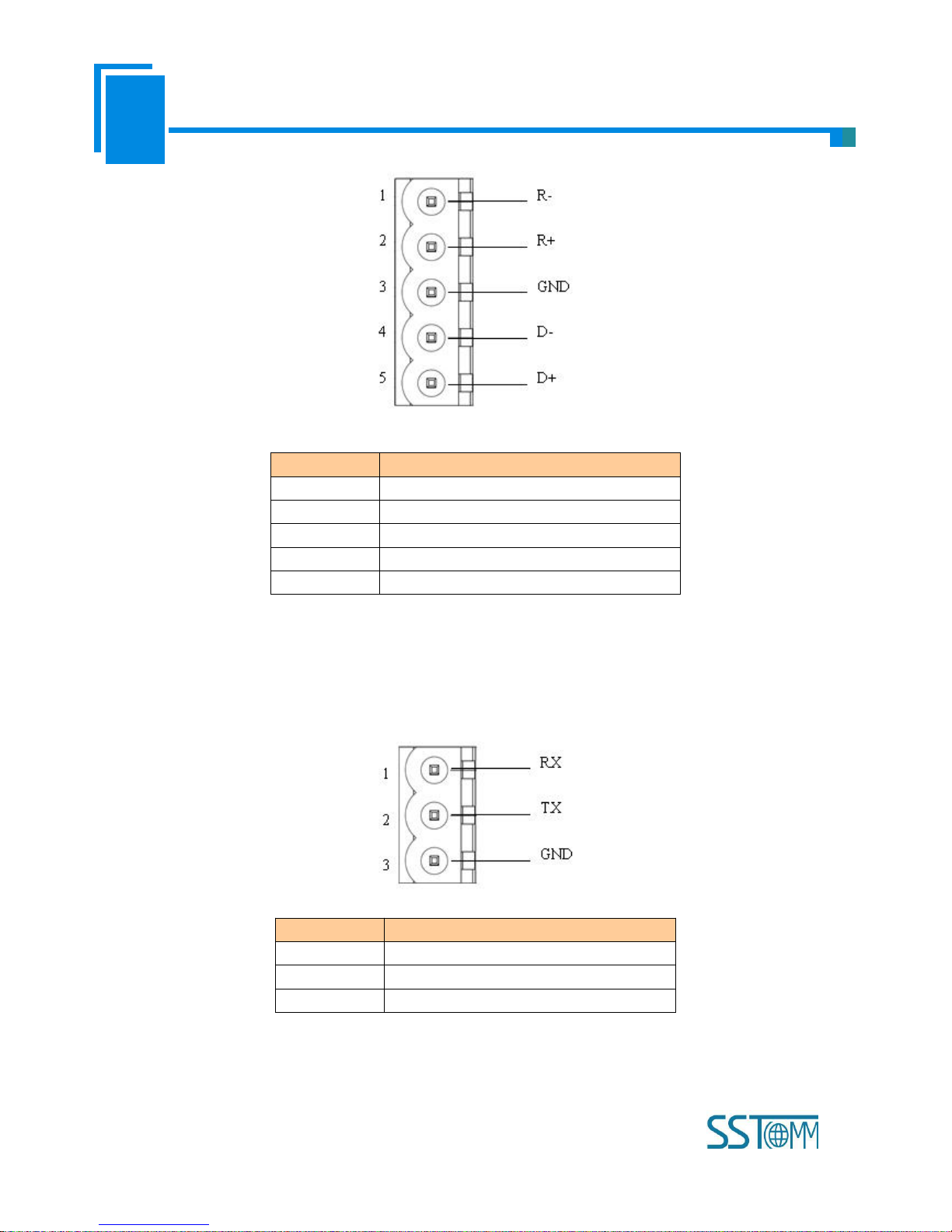

Pin

Function

1

R-, RS-422 Receive Negative

2

R+, RS-422 Receive Positive

3

GND

4

D-, RS-485/RS-422 Transmit Negative

5

D+, RS-485/RS-422Transmit Positive

3.4.4 RS-232 Interface

RS-232 interface uses a 3-pin pluggable open terminal, and its pin description is shown as follows:

Pin

Function

1

RX, Connect user device RS-232's RX

2

TX, Connect user device RS-232's TX

3

GND, Connect user device RS-232's GND

Page 18

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

18

4 Working Principle

4.1 Modbus Master

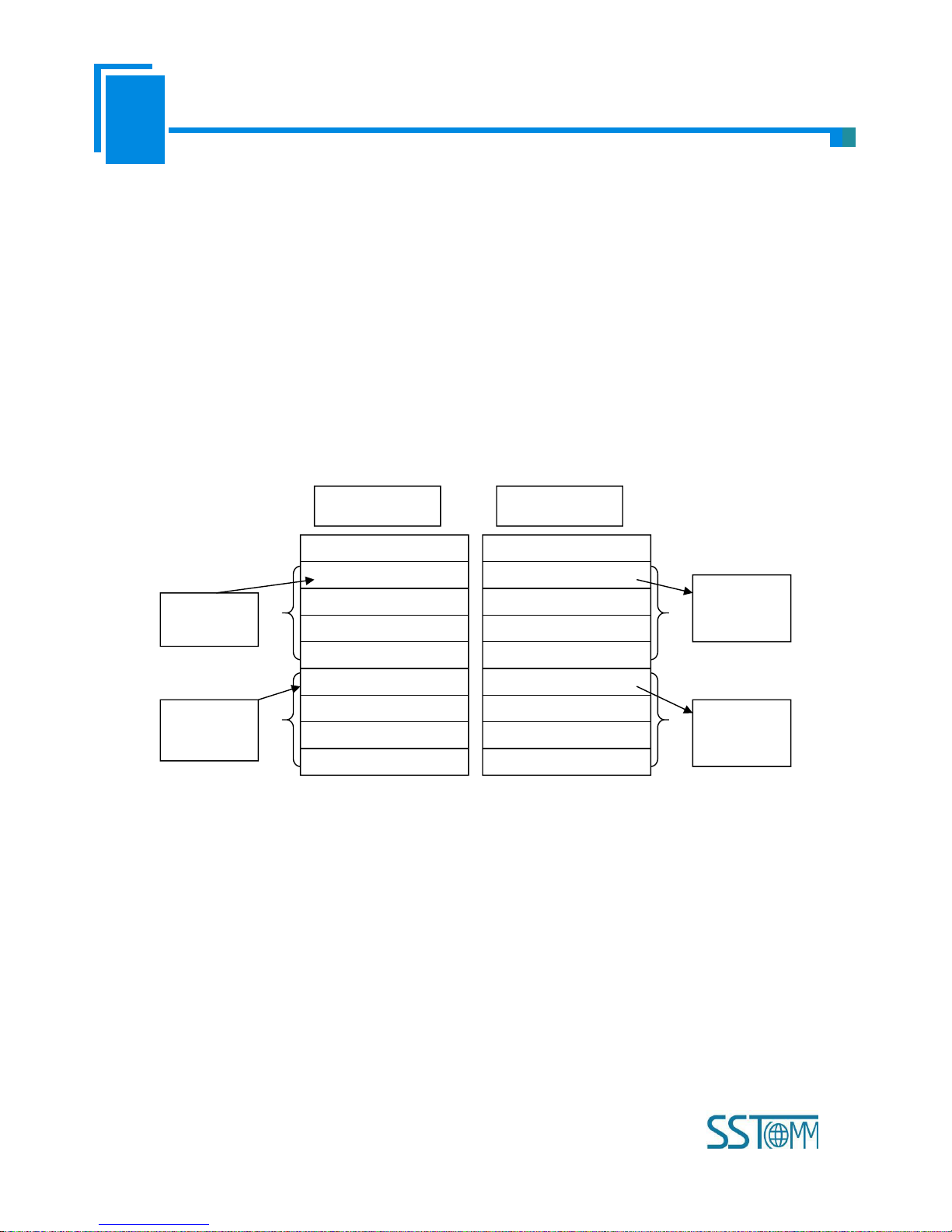

The data conversion between Modbus and PROFIBUS of GT200-DP-RS is established by mapping. GT200-DP-RS

has two data buffers, one is PROFIBUS network input buffer; the other is PROFIBUS network output buffer. Command ID

1, 2, 3 and 4 of Modbus puts the data read from Modbus slave station into network input buffer for reading by PROFIBUS

network; Command ID 5, 6, 15 and 16 of Modbus write the data from network output buffer into Modbus slave station.

Modbus

Device 1

Modbus

Device 2

Modbus

Device 3

Modbus

Device 4

Input buffer

Output buffer

Support 01H, 02H, 03H, 04H, 05H, 06H, 0FH, 10H function codes, when using “DP Hardware Configuration”, users

can configure 48 Modbus commands Module. When using “Software Configuration”, users can configure at most 100

Modbus commands in the software SST-MPG-CFG.

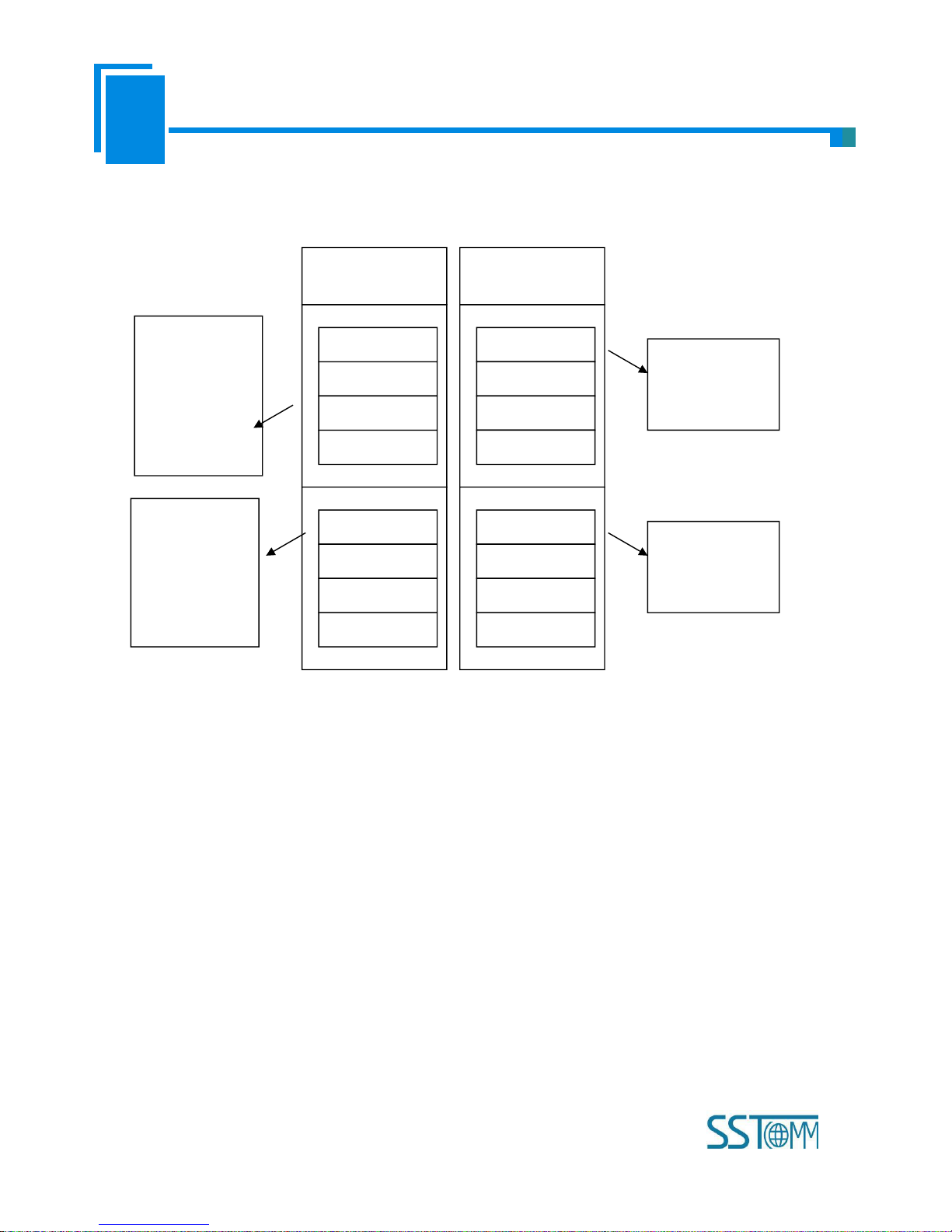

4.2 Modbus Slave

The data conversion between Modbus of GT200-DP-RS Modbus Slave and PROFIBUS is established by mapping

relation. GT200-DP-RS has two data buffers, one is PROFIBUS network input buffer, and the other is PROFIBUS network

output buffer. Network input and output buffers are relative to PROFIBUS. Modbus write-register commands write data

Page 19

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

19

into network input buffer for PROFIBUS network reading. Modbus read-register commands data from network output

buffer, and transmit to Modbus master device through response messages.

PROFIBUS

Input buffer

4xxxx

00000 (40001)

00001 (40002)

00002 (40003)

… …

0xxxx

00000 (00001)

00001 (00002)

00002 (00003)

… …

PROFIBUS

Output buffer

3xxxx

00000 (30001)

00001 (30002)

00002 (30003)

… …

1xxxx

00000 (10001)

00001 (10002)

00002 (10003)

… …

Modbus write

commands: 06H

and 10H

Modbus read

commands: 03H

Modbus write

commands: 05H

and 0FH

Modbus read

commands: 01H

Modbus read

commands: 04H

Modbus read

commands: 02H

Support Modbus register address area 3 (3xxxx), area 4 (4xxxx), area 0 (0xxxx) and area 1 (1xxxx); and area 3

supports 04H function code; area 4 supports 03H, 06H, and 10H function codes; area 0 supports 01H, 05H, and 0FH

function codes; 1 area supports 02H function code.

PROFIBUS DP input buffer being relative to Modbus side is Modbus master output, mapping to Modbus holding

registers 4xxxx (10H and 06H commands are used to write data, 03H command is used to read back data) and loops 0xxxx

(0FH and 05H commands are used to write data, 01H command is used to read back data).

PROFIBUS DP output buffet being relative to Modbus side is Modbus master input, mapping to Modbus input

registers 3xxxx (04H command is used to read data) and input bits 1xxxx (02H command is used to read data).

Page 20

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

20

5 Universal Mode

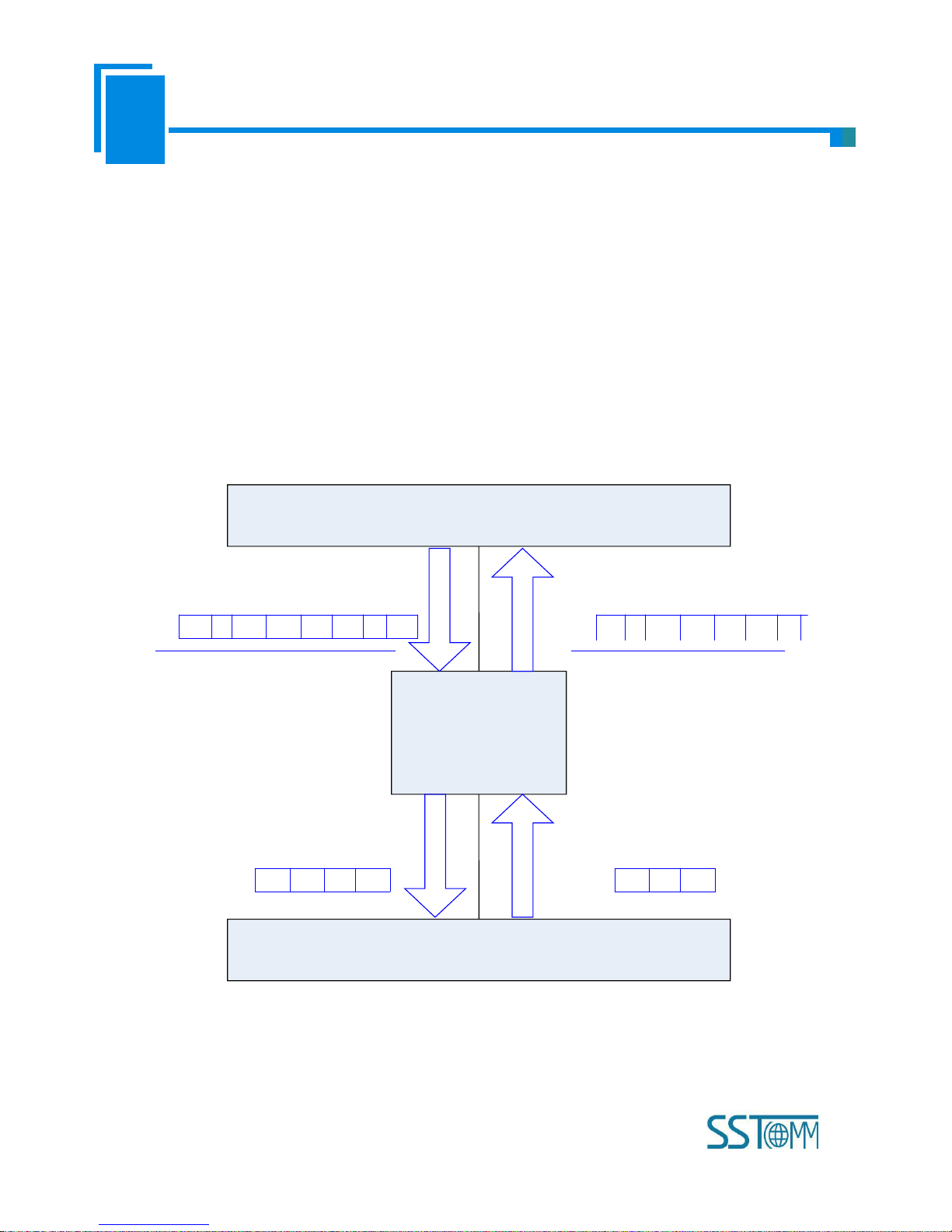

5.1 Data Exchange

This product provides data communication between PROFIBUS DP and RS-485/RS-232. The communication between

PROFIBUS DP and RS-485/RS-232 is bidirectional. The output data of PROFIBUS DP can be sent to RS-485/RS-232

fieldbus through the interface of RS-485/RS-232 and the data received from RS-485/RS-232 is put into input data of

PROFIBUS DP. Data exchange is shown as follows:

Above, "EO" is transaction number of PROFIBUS output data; "i" is serial data number included in output data being

transmitted; "D1" to "Di" are data being transmitted by serial; "Ei" is transaction number of PROFIBUS input data; "j" is

serial data number included in input data receiving form serial; "D1" to "Dj" are data receiving form serial.

EoiD1D2…Di0

…

EijD1D2…Dj0

…

D1D2…DiD1…Dj

PROFIBUS

DP

RS

-485

/RS-232

GT200-DP-RS

PROFIBUS output data

PROFIBUS input data

Serial output data

Serial input data

Page 21

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

21

5.2 Universal Protocol

PROFIBUS DP output data format:

[Transaction number][Length of serial output data n][Serial output data 1]… [Serial output data n] [0x00] … [0x00]

|— n —| |— m —|

Note:

The number of PROFIBUS DP output byte should be greater than or equal to n + 1;

M 0x00 are filling data (also for arbitrary number); n + m +1 should be equal to the number of PROFIBUS DP

output-byte.

Transaction number: When transmit output data; the transaction number must add 1 to show a new frame data.

Example:

If users select the number of PROFIBUS DP input byte and output-byte is 8-byte input and 8-byte output, length of

serial output-data is 3, data are 01 02 03. Current transaction number is 0.

The format of output-data is:

[01][03][01][02][03][00][00][00][00]

PROFIBUS DP input data format:

[Transaction number][Length of serial input data n] [Serial input data 1] … [Serial input data n] [0x00] … [0x00]

|— n —| |— m —|

Note:

The number of PROFIBUS DP input byte should be greater than or equal to n + 1;

M 0x00 are filling data (also for arbitrary number); n + m +1 should be equal to the number of PROFIBUS DP

input-byte.

Transaction number: The transaction number adds 1 showing a new frame input data.

Example:

Page 22

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

22

If users select the number of PROFIBUS DP input-byte and output byte is 8-byte input and 8-byte output, length of

serial input-data is 3, data are 04 05 06. Current transaction number is 0.

The format of input data is:

[01][03][04][05][06][00][00][00][00]

Page 23

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

23

6 Software Instructions

6.1 Notes before Configuring

SST-MPG-CFG is a product based on Windows platform, and it can set related parameters and commands of Modbus

and PROFIBUS DP of GT200-DP-RS.

Double-click the icon to enter configuration interface:

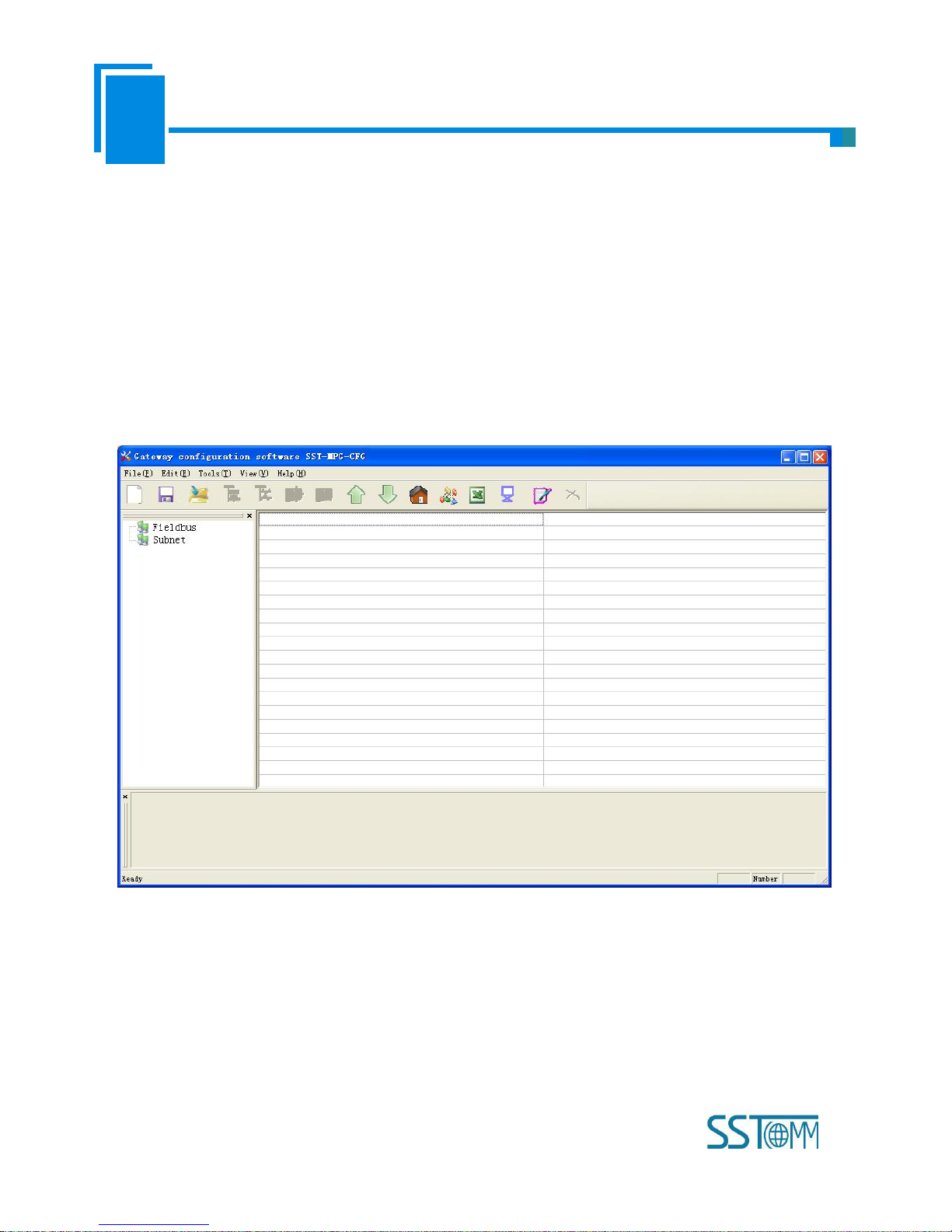

6.2 User Interface

SST-MPG-CFG interface include: title bar, menu bar, toolbar, status bar, equipment section, configuration section and

notes section.

Note: All the gray part in the software cannot be modified.

Page 24

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

24

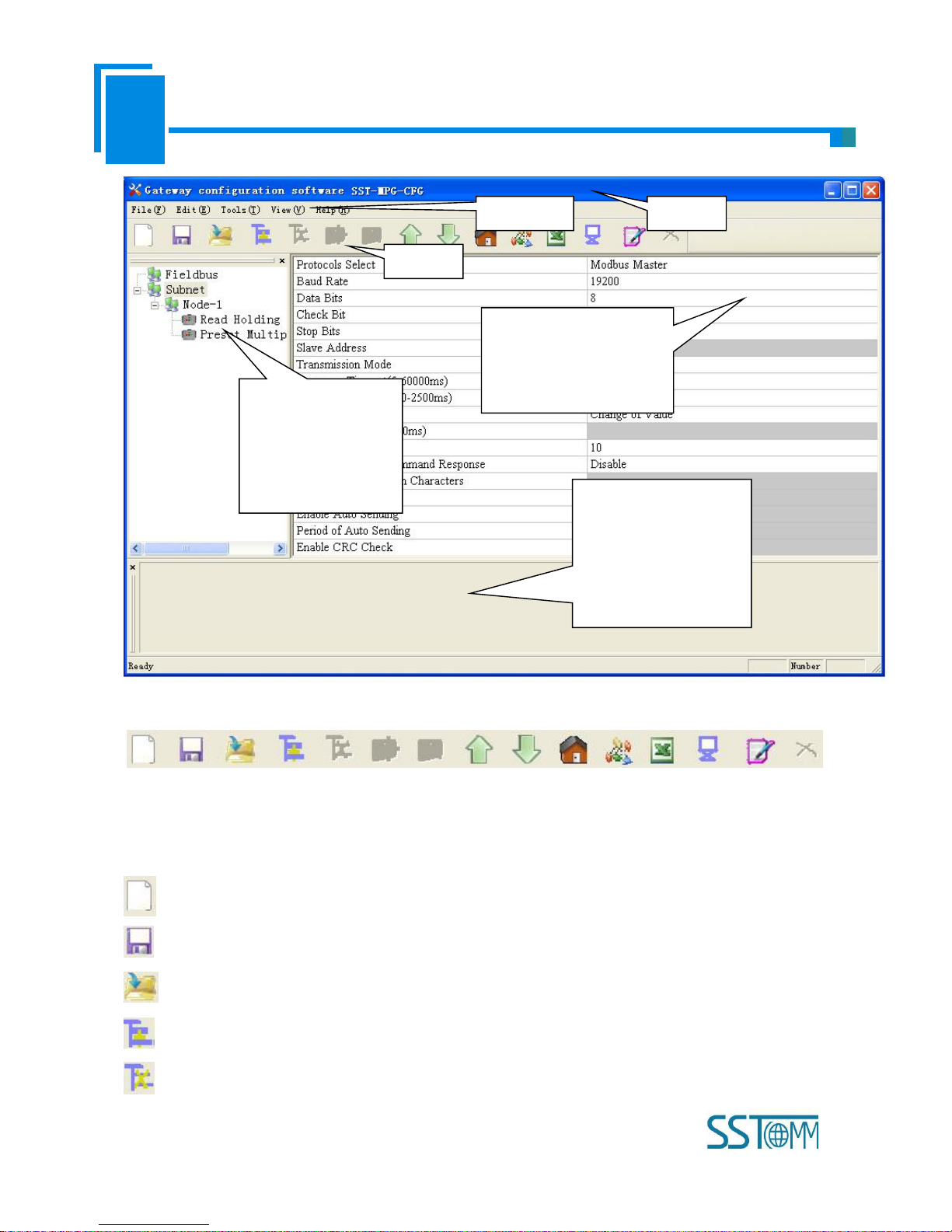

Toolbar is shown as below:

Functions separately from left to right are: new, save, open, add nodes, delete nodes, add commands, delete commands,

upload configuration, download configuration, calculate mapping address, conflict detection, Export EXCEL, debug, edit

base address and cancel edit address.

New: Create a new configuration project

Save: Save the current configuration

Open: Open a configuration project

Add Nodes: Add a Modbus slave node

Delete Nodes: Delete a Modbus slave node

Equipment section: can

choose the operating

targets, including fieldbus

or sub-network and add

the nodes and

Menu bar

Toolbar

Title bar

Configuration section: input

configuration parameters, gray

part cannot be modified, while

white part can be modified.

Notes section: The specific

explanation to the nouns

appearing in the

configuration and devices to

help users to understand and

operate.

Page 25

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

25

Add Commands: Add a Modbus command

Delete Commands: Delete a Modbus command

Upload Configuration: Read the configuration from the module and show it in the software

Download Configuration: Download the configuration from the software to the module

Calculate Mapping Address: Calculating mapping address automatically

Conflict Detection: Detect whether there is conflict in memory data buffer of the gateway

Export EXCEL: Export the current configuration to local hard disk and save it as .xls file

Debug: For debugging Modbus communications, and defining the network fault

Edit Base Address: Advanced function

Cancel Base Address: Advanced function

Page 26

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

26

6.3 The Operation of Equipment View

6.3.1 Equipment View Interface

6.3.2 Operation Mode of Equipment View

The equipment view supports three types of operation: Edit Menu, Edit Toolbar and Right click edit Menu.

Page 27

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

27

6.3.3 Operation Types of Equipment View

1) Add nodes: Right click on subnet or existing nodes, and then perform the operation of adding a new node. Then

there is a new node named "new node" under subnet.

2) Delete nodes: Right click on the node to be deleted, and then perform the operation of deleting the node. The node

and its all commands will be deleted.

3) Add commands: Right click on the node, and then perform the operation of adding command to add a command for

the node. The dialog box will be shown as follow:

Currently, it supports the commands: 01, 02, 03, 04, 05, 06, 15 and 16.

Select the command: Double click the command

4) Delete commands: Right-click on the command and then perform the operation of deleting the command.

5) Rename nodes: Left click on the node to be renamed, and then the edit status will be shown and you can rename it.

6) Copy node: Left click on the existing node, choose the node and execute the operation of copying nodes (include all

commands under the node)

7) Paste node: Left click and choose any existing node, execute operation of pasting node. Then under the subnet tree

you can see a new node (include all commands under the node); Parameters of new node is default setting, it needs to be

Page 28

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

28

reset.

6.4 The Operation of Configuration View

6.4.1 Interface of Fieldbus Configuration View

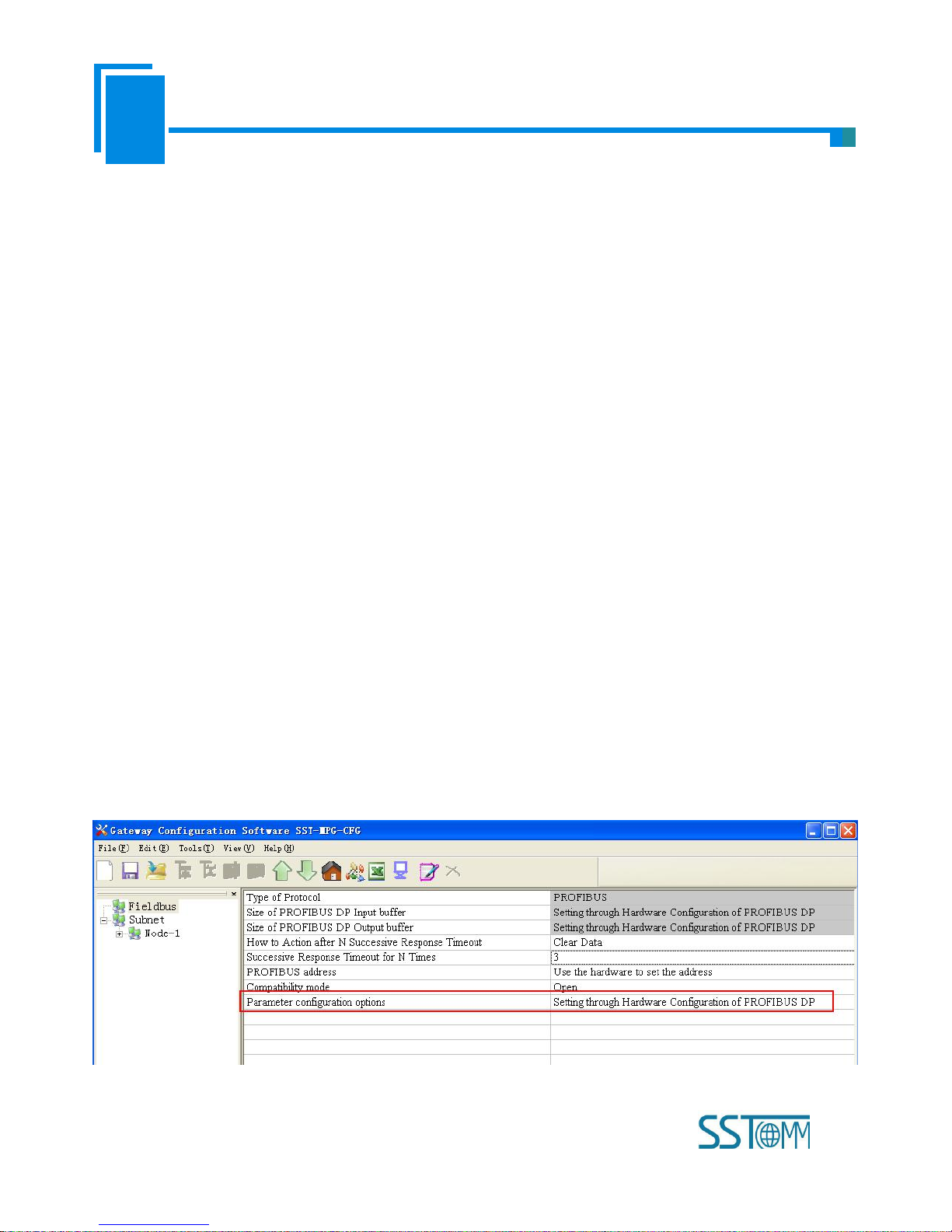

In the interface of device view, click fieldbus, and then the configuration view is shown as follows:

Configurable items include: "Type of Protocol", "Size of PROFIBUS DP Input buffer", "Size of PROFIBUS DP Input

buffer", "How to action after N successive response timeout", "Successive response timeout for N times", "PROFIBUS

address", "Compatliblity mode" and "Parameter configuration options".

Size of PROFIBUS DP Input buffer: Set in PROFIBUS DP master configuration software, cannot be modified;

Size of PROFIBUS DP Input buffer: Set in PROFIBUS DP master configuration software, cannot be modified;

How to action after N successive response timeout: Clear data or Hold data can be selected;

Successive response timeout for N times: 2 to 254 can be selected;

PROFIBUS address: Use the hardware to set the address or PROFIBUS address can be selected;

Compatliblity mode: Open or Close can be selected;

Parameter configuration options:Setting through configuration software or Setting through Hardware Configuration of

PROFIBUS DP can be selected.

Page 29

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

29

6.4.2 Interface of Subnet Configuration View

1) Choose Modbus Master in protocol type

Configurable parameters are shown as follows:

Baud Rate, Data Bits, Check Bit, Stop bit, Transmission mode, Response timeout, Delay between Polls, Output Mode,

Scan Rate, Status of Modbus Command Response, Communication interface, Time Interval between Character(Sending)

and Time Interval between Character(Receiving).

Interface of configuration view is shown as below:

Page 30

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

30

Baud Rate: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600 and 115200bps optional

Data bits: 8

Check Bit: none, odd, even, mark and space optional

Stop bits: 1, 2

Transmission mode: RTU, ASCII optional

Response timeout: When the Modbus master send commands, the time waiting for response from the slave, the range

is 5~60000ms.

Delay between polls: After one Modbus command has been sent and has received correct response, the delay time

before next command being sent, the range is: 0 ~ 2500ms.

Output Mode:

Modbus writing command (output command) has 3 kinds of outputting modes: Cycle, Forbidden and Change of Value

output.

Cycle: The same with Modbus read command, and output according to the scanning ratio.

Forbidden: Prohibit outputting Modbus write command.

Change of Value: When the output data has changed, it outputs the write command and stop outputting after receiving

Page 31

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

31

correct response.

Scan rate: Ratio of slow scan and fast scan. If the fast scan command sends 10 times, slow scan command sends 1

time.

Status of Modbus Command Response: disable, 1byte, 2bytes, 3bytes, 4bytes, 5bytes, 6bytes, 7bytes, 8bytes, 9bytes,

10bytes, 11bytes, 12bytes and 13bytes can be selected. They locate in the first several bytes of PROFIBUS input data and

show the status of Modbus commands. The bit 0 of the first byte shows the status of the first Modbus command and six

bytes can show all status of 48 commands. The value of status is 0, when the communication is OK and the value is 1.

Communication interface: There are RS-232 and RS-485 to be selected. (Note: If using the RS-422, here select

RS-485)

Time interval between Characters (Sending): Serial port of GT200-DP-RS will send every byte according to the

time interval. The range of value is 0 to 600, and the unit is 0.1ms. If the value is 100, then the time interval is 100* 0.1 ms

=10ms. (Note: The time interval does not contain/cover the frame interval of Modbus protocol)

Time interval between Characters (Receiving): Serial port of GT200-DP-RS will use this time interval as the judge

receiving end basis. The range of value is 0 to 600, and the unit is 0.1ms. If the value is 100, then the time interval is 100*

0.1 ms =10ms. (Note: The time interval does not contain/cover the frame interval of Modbus protocol)

Note: The reference time of gateway receiving data and broking frame: Time interval between characters

(Receiving) + 3.5 character time of Modbus protocol. Make sure that the response wait time is greater than time

interval between characters + 3.5 character time.

2) Choose Modbus Slave in protocol type

Configurable parameters are shown as follows:

Baud Rate, Data Bits, Check Bit, Stops Bits, Slave Address, Transmission Mode, Communication Interface, Time

interval between Character (Sending) and Time Interval between Character (Receiving).

Interface of configuration view is shown as follow:

Page 32

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

32

Baud Rate: 300, 600, 1200, 2400,4800, 9600, 19200, 38400, 57600 and 115200bps optional.

Data Bits: 8

Check Bit: none, odd, even, mark and space optional

Stop Bits: 1, 2

Slave Address: range is 0~247.

Transmission Mode: RTU, ASCII

Communication Interface: There are RS-232 and RS-485 to be selected. (Note: If using the RS-422, here select

RS-485)

Time interval between Characters (Sending): Serial port of GT200-DP-RS will send every byte according to the

time interval. The range of value is 0 to 600, and the unit is 0.1ms. If the value is 100, then the time interval is 100* 0.1 ms

=10ms. (Note: The time interval does not contain/cover the frame interval of Modbus protocol)

Time interval between Characters (Receiving): Serial port of GT200-DP-RS will use this time interval as the judge

receiving end basis. The range of value is 0 to 600, and the unit is 0.1ms. If the value is 100, then the time interval is 100*

0.1 ms =10ms. (Note: The time interval does not contain/cover the frame interval of Modbus protocol)

Page 33

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

33

3) Choose User Config in protocol type:

Configurable parameters are shown as follows:

Baud Rate, Data Bits, Check Bit, Stop Bits, Frame Type, Time interval between Characters, Frame Length, Enable

Auto Sending, Period of Auto Sending, Enable CRC Check, Communication Interface, Time interval between Character

(Sending) and Time interval between Character (Receiving).

Interface of configuration view is shown as follow:

Baud Rate: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600 and 115200bps optional

Data Bits: 8

Check Bit: none, odd, even, mark and space optional

Stop Bits: 1, 2

Frame Type: Time Interval between Characters, Frame length optional

Time interval between characters: It is maximum time interval between characters and used to decide whether a

frame is terminated or not. User input, the default is 10, and the range is 10 ~ 60000ms.

Frame Length: User input, the default is 111 and the range is 1 ~ 223, only valid when the frame type is frame length.

Page 34

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

34

Enable Auto Sending: There are Enable and Disable to be selected.

Period of Auto Sending: User input, the default is 1000 and the range is 10 ~ 60000ms, only valid when the Enable

Auto Sending is Enabled

Enable CRC Check: Enable, Disable optional

Communication Interface: RS-232, RS-485 optional. (Note: If using the RS-422, here select RS-485)

Time interval between Characters (Sending): Serial port of GT200-DP-RS will send every byte according to the

time interval. The range of value is 0 to 600, and the unit is 0.1ms. If the value is 100, then the time interval is 100* 0.1 ms

=10ms. (Note: The time interval does not contain/cover the frame interval of Modbus protocol)

Time interval between Characters (Receiving): Serial port of GT200-DP-RS will use this time interval as the judge

receiving end basis. The range of value is 0 to 600, and the unit is 0.1ms. If the value is 100, then the time interval is 100*

0.1 ms =10ms. (Note: The time interval does not contain/cover the frame interval of Modbus protocol)

6.4.3 Interface of Node Configuration View

When the protocol type of subnet is "Modbus Master", in the interface of device view, left click a node, and then

configuration interface is shown as follow:

Page 35

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

35

In the moment, you can modify the Modbus slave node address in the configuration view interface.

6.4.4 Interface of Command Configuration View

In the interface of device view, left click a command and then configuration interface is shown as follow:

Page 36

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

36

Configurable parameters are shown as follows:

Starting Address, Number of Data, Mapping Address (HEX), Mapping Bit (0~7) and Type of Scan

Starting Address: The starting address of register or switching value or loop and so on in Modbus slave and the range

is 0~65535.

Notes: This address in SST-MPG-CFG is protocol address, when users input PLC address, it will pop up the below

dialog box after entering. After clicking OK, the PLC address users input will be converted into protocol address.

Following table shows the PLC address and corresponding protocol address examples:

Command

PLC address examples

Corresponding protocol address

Coil state

00001~00010

00000~00009

Input state

10001~10010

00000~00009

Holding register

40001~40010

00000~00009

Input register

30001~30010

00000~00009

Page 37

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

37

Number of Data: number of register/switching value/coil in Modbus slave

Mapping address (HEX): The starting address of data in memory buffer of the module.

The address range of data mapping in the module memory:

Read command: 0x0000~ 0x00F3

Write command: 0x4000 ~ 0x40F3

When write command is used exchanging locally, it also can use: 0x0000 ~ 0x00F3

Mapping bit (0 - 7): For the bit operation commands, the position range of start-bit byte is 0 ~ 7

Data filter: There are three kinds of types: full word, high byte, low byte. Every register has two bytes. Full word

mapping is taking two bytes of register into gateway memory buffer; High byte mapping is taking the high byte of register

into gateway memory buffer; Low byte mapping is taking the low byte of register into gateway memory buffer.

Type of scan: There are two kinds of scanning mode: fast scan and slow scan. It is fit for requests of user about fast

scan or slow scan of different commands. Slow scan is equal to fast scan being multiplied by scan ratio. (Configure it in the

interface of subnet configuration interface)

Byte Swap: There are three kinds of types: no swap, double-byte swap and four-byte swap. Modbus function code

03H, 04H, 06H and 10H support different byte swap types.

6.4.5 Notes View

Notes view displays the explanation of configuration. The notes that show how to action after N successive response

timeout is shown as follow:

Page 38

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

38

6.5 Conflict Detection

For the detection of whether there exists conflict of "the starting address of memory mapping", if conflict it can adjust

in time. The interface is shown as follow:

Page 39

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

39

6.5.1 Operation of Command List

All the configuration commands can be shown at the command list. Each select box before command is used for

checking the memory-mapping location of that command. Click on the command can select the check box, and in the

memory-mapping area it can show the corresponding share of spatial location. Click the command again will remove the

selected box and it doesn’t show the mapping location. The function can be used to conflict detection of memory mapping

area.

Page 40

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

40

6.5.2 Operation of Memory Mapping Area

Memory mapping area is divided two parts: input area and output area.

Input-mapping address: 0x0000 ~ 0x3FFF;

Output-mapping address: 0x4000 ~ 0x7FFF.

Each box represents a byte address.

Green: Read command show in the input-mapping area; no conflict;

Yellow: Write command show when the mapping addresses in the input area; no conflict;

Blue: When the address mapping area is located in the output area; no conflict.

Red: Output area or input area, different commands occupy the same byte address, the byte is shown as red.

For bit operation commands, the meanings of above shows are also applicable.

Click the input-output regional grid, whether the grid is occupied or not is shown as follows:

Page 41

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

41

6.6 Hardware Communication

Hardware communications' menu items are shown as follow:

6.6.1 Serial Configuration

The software automatically scan the available serial port of system, and the available serial can be shown in serial list.

After modifying all items, pressing "OK" to save your settings.

Notes: Apart from the serial port number, the other parameters are fixed values: 19200, 8, N, 1.

Page 42

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

42

6.6.2 Upload Configuration

Choose upload configuration, upload the gateway configuration information from the device to the software, the

display interface is shown as follows:

Note: Before uploading the configuration, please check whether the "serial port configuration" is the available port.

6.6.3 Download Configuration

Choose download configuration, download the configurated gateway information to the gateway, the display interface

Page 43

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

43

is shown as follows:

Note 1: Before downloading the configuration, please check whether the "serial port configuration" is the available

port.

Note 2: Before downloading the configuration, make sure that all configurations has been completed.

6.7 Load and Save Configuration

6.7.1 Load Configuration Project

Choosing "Open" can save a project.

6.7.2 Save Configuration Project

Choosing "Save" can open a saved project before.

Page 44

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

44

6.8 Export EXCEL

Excel document helps users to examine the configuration related.

Choose the icon , save the configuration as excel document and choose the right path.

Double click to open excel document, three modes as "Modbus master", "Modbus slave", "Universal mode" are

different from each other slightly.

Modbus master: The document has three parts: "Command List", "Fieldbus", and "Subnet".

Command list: Modbus command list 缺少图片

Fieldbus: Bus type and relevant parameters

Subnet: Modbus subnet parameters

As follows:

Modbus slave: The document has two parts: "Subnet" and "Fieldbus".

Subnet: Modbus subnet parameters

Fieldbus: Bus type and relevant parameters

As follows:

Universal mode: The document has two parts: "Subnet" and "Fieldbus".

Page 45

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

45

Subnet: Modbus subnet parameters

Fieldbus: Bus type and relevant parameters

As follows:

6.9 Debug

This function is for debugging Modbus network communications, the interface is shown as follows:

Click Debug button will show up the firmware select dialog box, choose the matched version:

Page 46

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

46

6.9.1 Debug Interface of 4.X or 3.X

Firmware Version of 4.X or 3.X only supports debug function in the protocol of "Modbus Master"

Status: shows communication state with slave: response ok, response timeout, response abnormal and response error

Slave Address: slave address in the configuration file (HEX)

Starting Address: "Modbus register starting address" (HEX) in the configuration file

Data/Exception Code: display the slave data or exception code (HEX)

Memory mapping address: Starting address of data writing in the gateway

Data: Data writing into the gateway

When Modbus has no response or response timeout:

Page 47

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

47

When Modbus responses are right:

Page 48

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

48

After filling the "Memory mapping address" and "Data" correctly, users can click on "Send" button to transmit the

packet.

Page 49

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

49

User clicks on the "Save Content" button can save the received data to a computer's hard disk.

6.9.2 Debug Interface of 5.x and above

Modbus master:

Page 50

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

50

Status: shows communication state with slave: respond correctly, response timeout, respond abnormally and response

error

Slave Address: slave address in the configuration file (only master, HEX)

Function Code (Command): Modbus command in the configuration file (only master, HEX)

Starting Address:"Modbus register starting address" (HEX) in the configuration file (only master, HEX)

Data/Exception Code: display the slave data or exception code (HEX)

Notes: When the gateway is configured as Modbus master, it will show slave address, function code and starting

address.

Read Data: show the latest read data (HEX)

Memory mapping address: Starting address of data writing in the gateway

Data: Data writing into the gateway

When users want to fill in correct "memory mapping address" and "data", you can click "send" button to send the

Page 51

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

51

package out.

Save Content/Stop Saving: the software supports saving data to local disk. When saving is over, users need to click

"Stop Saving" to save it.

Stop Displaying/Continue to Display: the software supports dynamic or static data debugging.

Clear Data: click this button, it will clear the data in the debug interface.

Stop debug and exit: click the button or the exit button to close the debug interface.

Exit: Force quit.

When Modbus has response timeout:

When Modbus slave responses are right:

Page 52

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

52

The debug interface of user config and Modbus slave:

Page 53

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

53

The debug function of user config and slave is send input buffer data and output buffer data of PROFIBUS to the

debug interface alternately, users can send debug data to simulate the input data of PROFIBUS.

Page 54

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

54

7 PROFIBUS DP Hardware Configuration Instructions

GT200-DP-RS V6.X version has four GSD files, "Software Configuration" has a corresponding GSD file, and “DP

Hardware Configuration” has three corresponding GSD files. As follows:

DPRS2V60A.GSD-Configuration software configuration mode use

DPRS2V60M.GSD-DP Hardware Configuration of Modbus master

DPRS2V60S.GSD-DP Hardware Configuration of Modbus slave

DPRS2V60T.GSD-DP Hardware Configuration under universal mode

It needs to import the GSD file in the PROFIBUS DP master configuration software, and then set the relevant

parameters. Take the following Step7 configuration software as an example:

7.1 Register GSD file

Open an existing project in STEP 7, under the Hardware configuration interface, click Options->Install GSD file,

Figure 1:

The popup interface is shown as Figure 2, select GSD file needs to be installed, click “Install GSD File”, and click

“Close” after registering completely, close the register window.

Page 55

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

55

In the menu, select Options -> Update Catalog, update the registered devices in the device catalog

You can find the registered device in the right window /PROFIBUS DP/Additional Field Devices/General/Converter/,

shown as Figure 4:

Page 56

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

56

7.2 DPRS2A.GSD-Configuration software configuration mode use

After registering DPRS2A.GSD completely, you can find GT200-DP-RS V6.0 device in the catalog .In the

SST-MPG-CFG configuration mode, GT200-DP-RS achieves the functions of the three types of protocols, which are

Modbus master, Modbus slave, Universal mode. and perform data exchange between serial port and DP master.

In the Step7 configuration, GT200-DP-RS offers Module numbers up to 64, Max Input 244 bytes, Max Output 244 bytes,

Max Input or Output 488Bytes.

Module

Integrity

4 Words Input,4 Words Output

word

8 Words Input,8 Words Output

word

24 Words Input,24 Words Output

word

56 Words Input,56 Words Output

word

1 Byte Input

byte

1 Word Input

word

2 Words Input

word

4 Words Input

word

8 Words Input

word

16 Words Input

word

Page 57

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

57

32 Words Input

word

64 Words Input

word

2 Words Input Consistent

length

4 Words Input Consistent

length

8 Words Input Consistent

length

16 Words Input Consistent

length

1 Byte Output

byte

1 Word Output

word

2 Words Output

word

4 Words Output

word

8 Words Output

word

16 Words Output

word

32 Words Output

word

64 Words Output

word

2 Words Output Consistent

length

4 Words Output Consistent

length

8 Words Output Consistent

length

16 Words Output Consistent

length

GT200-DP-RS supports data including word complete, byte complete, and length complete

The user selects the data block as long as it is not less than the number of bytes transmitted. who can select one or more

data block.

7.3 DPRS2M.GSD-DP Hardware Configuration of Modbus master

After registering DPRS2M.GSD completely, you can find GT200-DP-RS Modbus Master V6.0 device in the catalog.

That is to say GT200-DP-RS act as a Modbus master at the side of Modbus.

Page 58

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

58

PROFIBUS DP slave property parameter:

In configuration interface, double click “GT200-DP-RS Modbus Master V6.0” in PROFIBUS DP network, the popup

property interface is shown as follow:

Configurable parameters include:

Baud rate (bps): Configure serial baud rate, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200bps can

be selected;

Data bits, Parity bit, Stop bits: 8 None 1, 8 Odd 1, 8 Even 1, 8 Mark 1, 8 Space 1 and 8 None 2 can be selected;

Protocol Type: If what you drag to the PROFIBUS DP bus is “GT200-DP-RSModbus Master”, the parameter is

“Modbus Master”, if what you drag to the PROFIBUS DP bus is “GT200-DP-RS Modbus Slave”, the parameter is

“Modbus Slave”.

Response Timeout: It is available when “Protocol Type” is Modbus Master, 100, 200, 300, 400, 500, 600, 700, 800,

900, 1000, 1500, 2000, 3000, 4000, 5000ms can be selected.

Delay Between Polls: It is available when “Protocol Type” is Modbus Master, No Delay, 50, 100, 150, 200, 300, 400,

500, 600, 700, 800, 900, 1000, 1500, 2000ms can be selected.

Transmission Mode: Set Modbus transmission mode, RTU or ASCII can be selected.

Write Mode: Set output mode, Change of value or Cycle can be selected.

Page 59

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

59

Response Timeout Action: Enter Data, Clear / Hold Data, default state is Hold Data;

Response Timeout for N times: the number of over times, the input range: 2-254, the default value is 3;

Communication Interface: communication interface, RS485 and RS232 can be chosen, the default is RS485.

Module Parameter

GT200-DP-RS Modbus Master supports modules include: Control Module, Status Module, Exception Module,

Read Module, Write Module.

■ The module set as Modbus command is Read Module, Write Module, as follows:

Read Module : (Modbus Read Command) Read 1-8 Bits(0xxxx)~Read 249-256 Bits(0xxxx), Read 1-8

Bits(1xxxx)~Read 249-256 Bits(1xxxx), Read 1 Words(4xxxx)~Read 64 Words (4xxxx), Read 2

Words(4xxxx)Consistent~Read 16 Words(4xxxx)Consistent, Read 1 Words(3xxxx)~Read 64 Words(3xxxx), Read 2

Words(3xxxx)Consistent~Read 16 Words(3xxxx)Consistent

Write Module : (Modbus Write Command)Write Single Bits(0xxxx)~Write 249-256 Bits(0xxxx), Write Single

Words(4xxxx)~Write 64 Words(4xxxx), Write 2 Words(4xxxx)Consistent~Write 16 Words(4xxxx)Consistent~Write 64

Words(4xxxx), Write 2 Words(4xxxx)Consistent~Write 16 Words(4xxxx)Consistent

(No. 3 area is the function code 04H; No. 4 area is the function code 03H, 06H, 10H; No. 0 area is the function

code 01H, 05H, 0FH; No. 1 area is the function code 02H.)

In configuration interface, double-click Module that is already dragged to the left bottom of the GT200-DP-RSrelevant

table, the popup interface is shown as follow:

Page 60

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

60

Configurable parameters include:

Slave address: Set Modbus slave address which is needed to connect with GT200-DP-RS, 1 to 247 can be selected;

Function: No need to set, every function code has its own module;

Starting Address: Set register starting address, 0~65535 can be selected;

No. of Points: Number of data, only those modules that are relevant with 01H, 02H, 0FH function codes need to set

the number of data;

Other Module like Control Module, Stats Module and Exception Module are shown below:

Control Module:Control (8 Commands) ~ Control (48 Commands)

As a Modbus master, users can control the transmission of Modbus command from the PROFIBUS terminal, the

provided 6 control Module can be selected, every GT200-DP-RS only can be configured one control Module.

Notes: if no need of the control Modbus command, the control Module is no need to configure, Modbus

command can send automatically.

Control (8 Commands) ~ Control (48 Commands): Select one kind control from 6, every bit of the control block

control 1 Modbus command. When the enable is needed, set 1 to the corresponding bit; otherwise, set 0.

Page 61

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

61

a) Control (8 Commands): Control the transmitting of the 8 commands which is after the slots occupied by the

Control Module, it occupies 1 byte of the output area.

b) Control (16 Commands): Control the transmitting of the 16 commands which is after the slots occupied by the

Control Module, it occupies 2 bytes of the output area.

c) Control (24 Commands): Control the transmitting of the 24 commands which is after the slots occupied by the

Control Module, it occupies 3 bytes of the output area.

d) Control (32 Commands): Control the transmitting of the 32 commands which is after the slots occupied by the

Control Module, it occupies 4 bytes of the output area.

e) Control (40 Commands): Control the transmitting of the 40 commands which is after the slots occupied by the

Control Module, it occupies 5 bytes of the output area.

f) Control (48commands): Control the transmitting of the 48 commands which is after the slots occupied by the

Control Module, it occupies 6 bytes of the output area.

Notes: When users add the control block, the control block should be added in front of the slots which occupied by

Read Module and Write Module.

For example:

If users need to configure 7 commands (7 read/write data block) during actual using process, then you can select

control block “Control (8 Commands)”, which means the control commands numbers of the selected “Control Module”

should be equals or more than the numbers of the configured commands.

Assume the data block of PROFIBUS DP master slots is shown as below:

After powering on the gateway, if the communication of PROFIBUS DP is normal (STA green light blinking), users

need to evaluate the output address QB0 to enable the required sending command. If only the 2nd (Read 1-8bits (1xxxx) )

Page 62

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

62

and the fourth (Read 8 Words (3xxxx) ) command need to be configured by enable, set 1 to the 2nd bit and 4th bit of the

first byte in output area. That means evaluate the output address QB0 as 9 (00001001).

Status Module: Status (8 Commands) ~ Status (48 Commands), Exception Codes

As a Modbus master, PROFIBUS side can monitor the status of Modbus commands, and provide two kinds of method

to monitor Modbus commands status:

Status (8 Commands) ~ Status (48 Commands): Select one kind status from 6, and every bit means the status of every

Modbus command respectively. The value is 1 when response is correct, and when times of abnormal response, timeout or

error count up to 3 the value is 0. The count clears when response is right.

a) Status (8 Commands): Monitoring 8 commands

b) Status (16 Commands): Monitoring 16 commands

c) Status (24 Commands): Monitoring 24 commands

d) Status (32 Commands): Monitoring 32 commands

e) Status (40 Commands): Monitoring 40 commands

f) Status (48 Commands): Monitoring 48 commands

Exception codes: 1 word Module, can monitor the executive condition of Modbus commands

High byte indicates Modbus command index 0~47, low byte indicates abnormal code or error code. When response is

correct, error code is 0, when response is abnormal or overtime or error, the highest bit of high byte is set to 1. Abnormal

code come from devices, the error code is 0xFF when response overtime or error.

7.4 DPRS2S.GSD-DP Hardware Configuration of Modbus slave

After registering DPRS2S.GSD completely, you can find GT200-DP-RS Modbus Master V6.0 device in the catalog.

That is to say GT200-DP-RS act as a Modbus slave at the side of Modbus.

Page 63

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

63

PROFIBUS DP slave property parameter:

In configuration interface, double click “GT200-DP-RS Modbus Slave V6.0” in PROFIBUS DP network, the popup

property interface is shown as follow:

Configurable parameters include:

Baud rate (bps): Configure serial baud rate, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200bps can

be selected;

Data bits, Parity bit, Stop bits: 8 None 1, 8 Odd 1, 8 Even 1, 8 Mark 1, 8 Space 1 and 8 None 2 can be selected;

Page 64

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

64

Protocol Type: If what you drag to the PROFIBUS DP bus is “GT200-DP-RSModbus Master”, the parameter is

“Modbus Master”, if what you drag to the PROFIBUS DP bus is “GT200-DP-RS Modbus Slave”, the parameter is

“Modbus Slave”.

Slave Address: When Protocol Type is Modbus Slave, configure the slave address of GT200-DP-RS, 1~247 can be

selected.

Transmission Mode: Set Modbus transmission mode, RTU or ASCII can be selected.

Communication Interfaces: RS458 and RS232 can be selected, the defautl is RS485..

Module Parameter

GT200-DP-RS Modbus slave supports modules include: Status Module, Input Module, Output Module.

■ The module set as Modbus command is Input module and Output Module, as follows:

Input Module : (Modbus Read Command) 8 Bits Input(0xxxx)~128 Bits Input(0xxxx), 1 Word Input (4xxxx)~64

Words Input (4xxxx), 2 Words Input(4xxxx)Consistent~16 Words Input(4xxxx)Consistent

Output Module : (Modbus 写 命 令)8 Bits Input(1xxxx)~128 Bits Input(1xxxx), 1 Word Input(3xxxx)~64 Words

Input(3xxxx), 2 Words Input(3xxxx)Consistent~16 Words Input(3xxxx)Consistent

(No. 3 area is the function code 04H; No. 4 area is the function code 03H, 06H, 10H; No. 0 area is the function

code 01H, 05H, 0FH; No. 1 area is the function code 02H.)

In configuration interface, double-click Module that is already dragged to the left bottom of the GT200-DP-RSrelevant

table, the popup interface is shown as follow:

Page 65

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

65

Function: When draging one Module, the function is fixed. It means this function includes 03H (3), 06H (6) and

10H(16).:

Other Module: Stats Module is shown below:

Status Module: As modbus slave, PROFIBUS can monitor Modbus network status, PROFIBUS side can provide

Modbus network status Module, which occupies one byte. When slave receives one correct request, the status byte add 1.

7.5 DPRS2T.GSD-DP Hardware Configuration of Universal Mode

After registering DPRS2T.GSD completely, you can find GT200-DP-RS Modbus Serial V6.0 device in the catalog.

That is to say GT200-DP-RS executes the function of universal mode, which can connect self-defined protocol serial

devices..

Page 66

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

66

PROFIBUS DP slave property parameter:

In configuration interface, double click “GT200-DP-RS Modbus Slave V6.0” in PROFIBUS DP network, the popup

property interface is shown as follow:

Configurable parameters include:

Baud rate (bps): Configure serial baud rate, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200bps can

Page 67

User Manual

Universal Serial/PROFIBUS DP Gateway

GT 200 -D P-R S

WWW.SSTCOMM.COM

67

be selected;

Data bits,Parity bit,Stop bits:Configuration data bits, test mode and stop bits, 8 None 1, 8 Odd 1, 8 Even 1, 8 Mark

1, 8 Space 1, 8 None 2 Optional;

Protocol Type:Serial, which means "universal mode", cannot be changed;

Receiving Frame Type : There are two control modes for serial receive data. "Time Interval Between Characters"

(character timed out) and "Frame Length" (character number)are available. Character timeout: by judging the time interval

between characters and characters to determine the end of a frame of serial data; number of characters: by determining the

number of characters to determine the end of a frame of serial data.

Interval Between Characters (ms): Character Timeout: The maximum time interval between characters and

characters in general mode.

Frame Length: Number of characters: In general mode, the serial port receives the number of data frame characters.

Valid only if the control mode is a number of characters.

Enable Auto Sending(ms): Auto send, with "On" and "Off" optional, the default is "off". "Open": send the serial data,

according to the automatic send cycle to send serial data. "Off", according to the general mode output rule output data.

Period of Auto Sending (ms): Automatic transmission period, the serial port automatically send data cycle. Valid only

when "Enable Auto Sending (ms): Auto Send" is on.

Enable CRC Check: CRC check, with "On" and "Off" optional, the default is "off". "Open": when serial send data, it

will automatically add two bytes of CRC checksum; when serial data receive dataf, it will automatically determine if the

CRC check code is normal, and in the PROFIBUS input data automatically remove the two bytes of CRC Check code.

Communication Interface: communication interface, RS485 and RS232 optional, the default is RS485.

Communication Interface: communication interface, RS485 and RS232 optional, the default is RS485.