Page 1

CANopen / PROFIBUS DP Gateway

GT200-DP-CO

User Manual

V 5.3 REV A

SST Automation

E-mail: SUPPORT@SSTCOMM.COM

WWW.SSTCOMM.COM

Page 2

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

2

Catalog

1 About This Document................................................................................................................................................ 4

1.1 General............................................................................................................................................................4

1.2 Important user information.............................................................................................................................4

1.3 Terms...............................................................................................................................................................4

2 Product Overview...................................................................................................................................................... 5

2.1 Product Function.............................................................................................................................................5

2.2 Product Feature............................................................................................................................................... 5

2.2.1 CANopen Acts as Master.................................................................................................................... 5

2.2.2 CANopen Acts as Slave.......................................................................................................................5

2.3 Technical Specifications................................................................................................................................. 6

2.4 Attention..........................................................................................................................................................7

2.5 Related Products............................................................................................................................................. 7

2.6 Revision History............................................................................................................................................. 8

3 Hardware Descriptions.............................................................................................................................................. 9

3.1 Indicators.......................................................................................................................................................10

3.2 DIP Switch.................................................................................................................................................... 10

3.3 Communication Interface............................................................................................................................. 11

3.3.1 PROFIBUS DP Connector.................................................................................................................11

3.3.2 CANopen Connector..........................................................................................................................11

3.4 Other Interface.............................................................................................................................................. 12

3.4.1 Power Interface..................................................................................................................................12

3.4.2 LED Display...................................................................................................................................... 13

3.4.3 PROFIBUS DP Address Setting Button............................................................................................13

4 Use Method..............................................................................................................................................................15

4.1 Quick Start Guide......................................................................................................................................... 15

4.2 Hardware Wiring...........................................................................................................................................15

4.3 Run................................................................................................................................................................16

4.3.1 Data Exchange Mode.........................................................................................................................16

4.3.2 PROFIBUS DP Data Module............................................................................................................ 18

4.3.3 How Step7 Read and Write Gateway Data....................................................................................... 23

4.3.4 How Step7 Select Data Module........................................................................................................ 25

5 Software Instructions............................................................................................................................................... 26

5.1 CANopen Acts as Master..............................................................................................................................26

5.1.1 Notes before Configuration............................................................................................................... 26

5.1.2 User Interface.....................................................................................................................................27

5.1.3 Device View Operation......................................................................................................................29

5.1.4 Configuration View Operation.......................................................................................................... 31

5.1.5 Hardware Configuration.................................................................................................................... 35

5.1.6 Load and Save Configuration............................................................................................................ 37

5.1.7 Auto Mapping.................................................................................................................................... 38

5.1.8 Export Excel File...............................................................................................................................38

5.1.9 Monitor.............................................................................................................................................. 38

5.2 CANopen Acts as Slave................................................................................................................................40

5.2.1 Notes before Configuration............................................................................................................... 40

5.2.2 User Interface.....................................................................................................................................41

5.2.3 Device View Operation......................................................................................................................43

5.2.4 Configuration View Operation.......................................................................................................... 44

5.2.5 Hardware Communication.................................................................................................................48

5.2.6 Load and Save Configuration............................................................................................................ 50

5.2.7 Auto Mapping.................................................................................................................................... 50

Page 3

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

3

5.2.8 Export Excel File...............................................................................................................................51

5.2.9 Monitor.............................................................................................................................................. 51

6 Installation................................................................................................................................................................54

6.1 Mechanical Dimension................................................................................................................................. 54

6.2 Installation.....................................................................................................................................................54

7 Failures and Suggestions......................................................................................................................................... 56

Appendix: Using STEP7 Set PROFIBUS DP............................................................................................................ 57

Page 4

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

4

1 About This Document

CAN: CAN bus is a kind of serial data communication protocol being developed by German BOSH from

CANopen: CANopen protocol is one of the standard being defined by CAN-in-Automation (CiA),

1.1 General

This document describes every parameters of the gateway GT200-DP-CO and provides using methods and

some announcements that help users use the gateway. Please read this document before using the gateway.

For further information, documentation etc., please visit the SSTCOMM website: http://www.sstcomm.com.

1.2 Important user information

The data and examples in this document cannot be copied without authorization. SSTCOMM may upgrade

the product without notifying users.

is the registered trade mark of SST Automation.

The product has many applications. The users must make sure that all operations and results are in

accordance with the safety of relevant field, and the safety includes laws, rules, codes and standards.

1.3 Terms

early 1980s for solving the data exchange method between modern car control and test instruments.

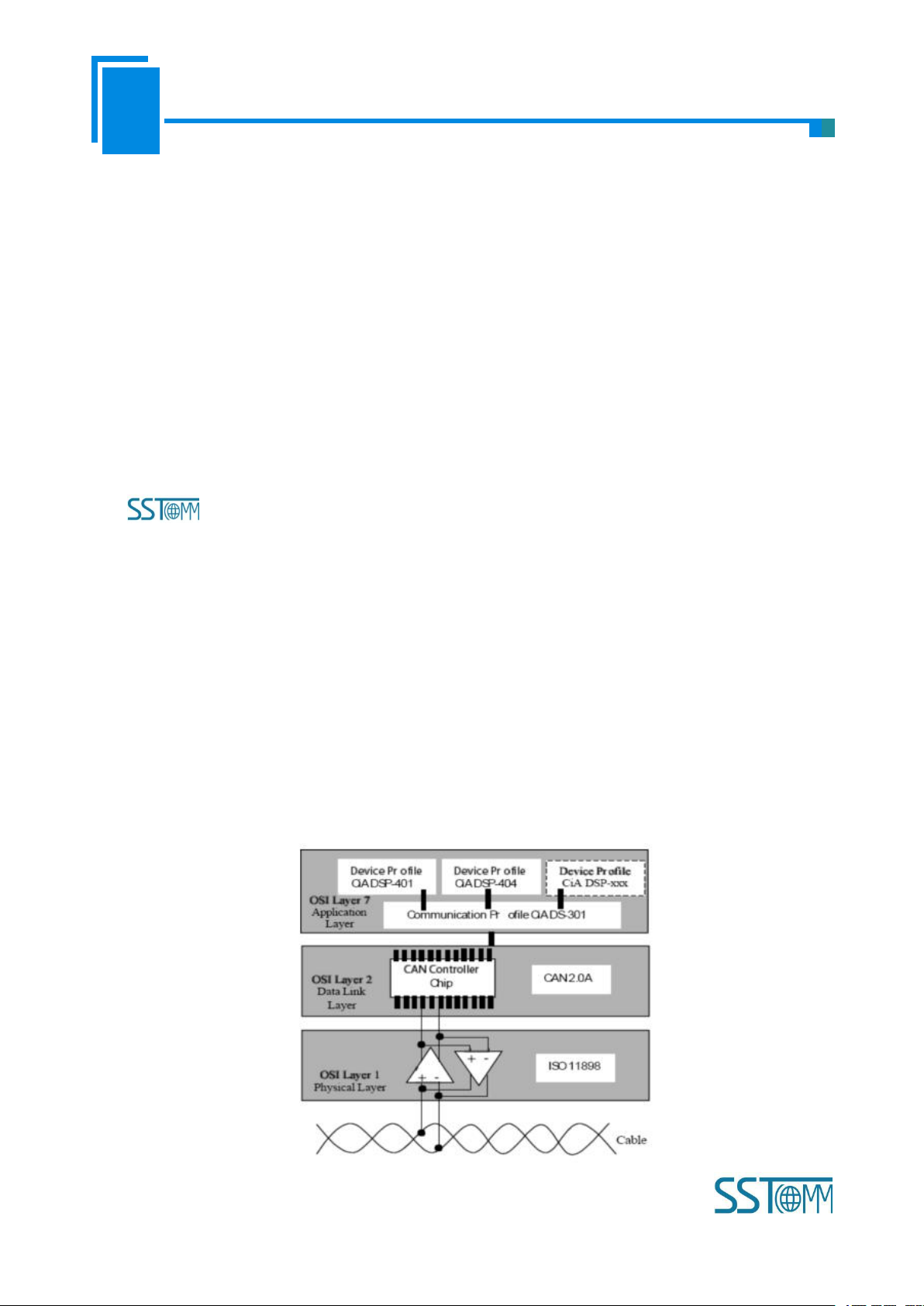

CANopen defined application layer (Application layer), communication description (CiA DS-301), device

description (CiA DSP-4XX), all cable and port (CiA DSP-303) and so on. In OSI model, the relationship

between CAN standard and CANopen protocol is shown as follow:

Page 5

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

5

2 Product Overview

Supports one CANopen master interface;

CANopen interface: 1KV photoelectric isolation;

Acts as a slave at the side of PROFIBUS DP network, PROFIBUS baud rate is self-adaptive, and up to

PROFIBUS input and output bytes can be selected, the maximum number is:

Supports one CANopen slave interface;

CANopen interface: 1KV photoelectric isolation;

Acts as a slave at the side of PROFIBUS DP network, PROFIBUS baud rate is self-adaptive, and up to

PROFIBUS input and output bytes can be selected, the maximum number is:

2.1 Product Function

CANopen side of GT200-DP-CO can be a master or a slave. When acting as a master, it supports connecting

multiple standard devices with CANopen slave interface to PROFIBUS DP bus; while acting as a slave, it

supports connecting CANopen master device to PROFIBUS DP bus.

2.2 Product Feature

2.2.1 CANopen Acts as Master

12M;

Max Input Bytes+ Max Output Bytes≤488 Bytes

①Max Input Bytes ≤244 Bytes

②Max Output Bytes ≤244 Bytes

2.2.2 CANopen Acts as Slave

12M;

Max Input Bytes+ Max Output Bytes≤488 Bytes

①Max Input Bytes ≤244 Bytes

②Max Output Bytes ≤244 Bytes

Page 6

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

6

2.3 Technical Specifications

CANopen baud rate: 50kbit/s, 100kbit/s, 125kbit/s, 250kbit/s, 500kbit/s, 1Mbps

PROFIBUS DP baud rate is self-adaptive and can be up to 12M

Supports at most 8 bytes of TPDO, 8 bytes of RPDO, fast Download SDO and fast Upload SDO;

Every CANopen node has default 4 TPDOs and 4 RPDOs. COB-ID of TPDO and RPDO has default value.

Every CANopen node also can have a self-defining COB-ID, but the COB-ID cannot be conflicting with

Supports maximum commands No. :(84)

Supports NMT management, TPDO time-out reset and SYNC function, besides, it also supports function

Supports connecting slaves with heartbeat and Guard life;

Same command can be mapped to different input or output buffer address of PROFIBUS DP;

Supports at most 8 bytes of TPDO, 8 bytes of RPDO

[1] Communication baud rate:

[2] CAN: ISO 11898-compatible CAN interface is CAN2.0A type with an 11-bit identification

[3] DS-301 V4.01 and CiA Draft Recommendation 303 compliant

CANopen master features:

Default value of Transmit PDO:

384 + node address (0x180+node address)

640 + node address (0x280+node address)

896 + node address (0x380+node address)

1152 + node address (0x480+node address)

Default value of Receive PDO:

512 + node address (0x200+node address)

768 + node address (0x300+ node address)

1024 + node address (0x400+ node address)

1280 + node address (0x500+node address).

CANopen protocol.

Max TPDO commands + Max RPDO commands + Max upload SDO commands + Max download SDO

commands≤84;

Max TPDO commands≤84;

Max RPDO commands≤84;

Max upload SDO commands≤84;

Max download SDO commands≤84;

of PROFIBUS DP controlling CANopen slave devices, etc.

CANopen slave features:

Page 7

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

7

fast Download SDO and fast Upload SDO;

Every CANopen node supports up to 42 TPDOs, 42 RPDOs. COB-ID of TPDO and RPDO has default

value or users can use self-defining COB-ID.

Support at most 42 TPDO and 42 RPDO;

Timeout clear function of RPDO and delay to start-up;

Supports SDO visiting input and output data exchange area;

Only support Heartbeat;

To prevent stress, prevent module panel damage;

To prevent bump, module may damage internal components;

Power supply voltage control in the prospectus, within the scope of the requirements to burn module;

To prevent water, water module will affect the normal work;

Please check the wiring, before any wrong or short circuit.

Default value of Transmit PDO:

384 + node address (0x180+node address)

640 + node address (0x280+node address)

896 + node address (0x380+node address)

1152 + node address (0x480+node address);

Default value of Receive PDO:

512 + node address (0x200+node address)

768 + node address (0x300+ node address)

1024 + node address (0x400+ node address)

1280 + node address (0x500+node address).

[4] Work circumstance temperature: -4℉~140℉(-20℃ to 60℃), REL Humidity: 5% to 95% (non-condensing);

[5] Power: 24VDC (11V~30V), maximum 90mA (24V);

[6] External dimensions size (W*H*D): 0.98 in*3.94 in*3.54 in (25mm*100mm*90mm);

[7] Installation: 35mm DIN RAIL;

2.4 Attention

2.5 Related Products

Related products include:

GT200-DP-CA, GT200-CO-EI and so on

More information about these products, please visit: http://www.sstcomm.com

Page 8

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

8

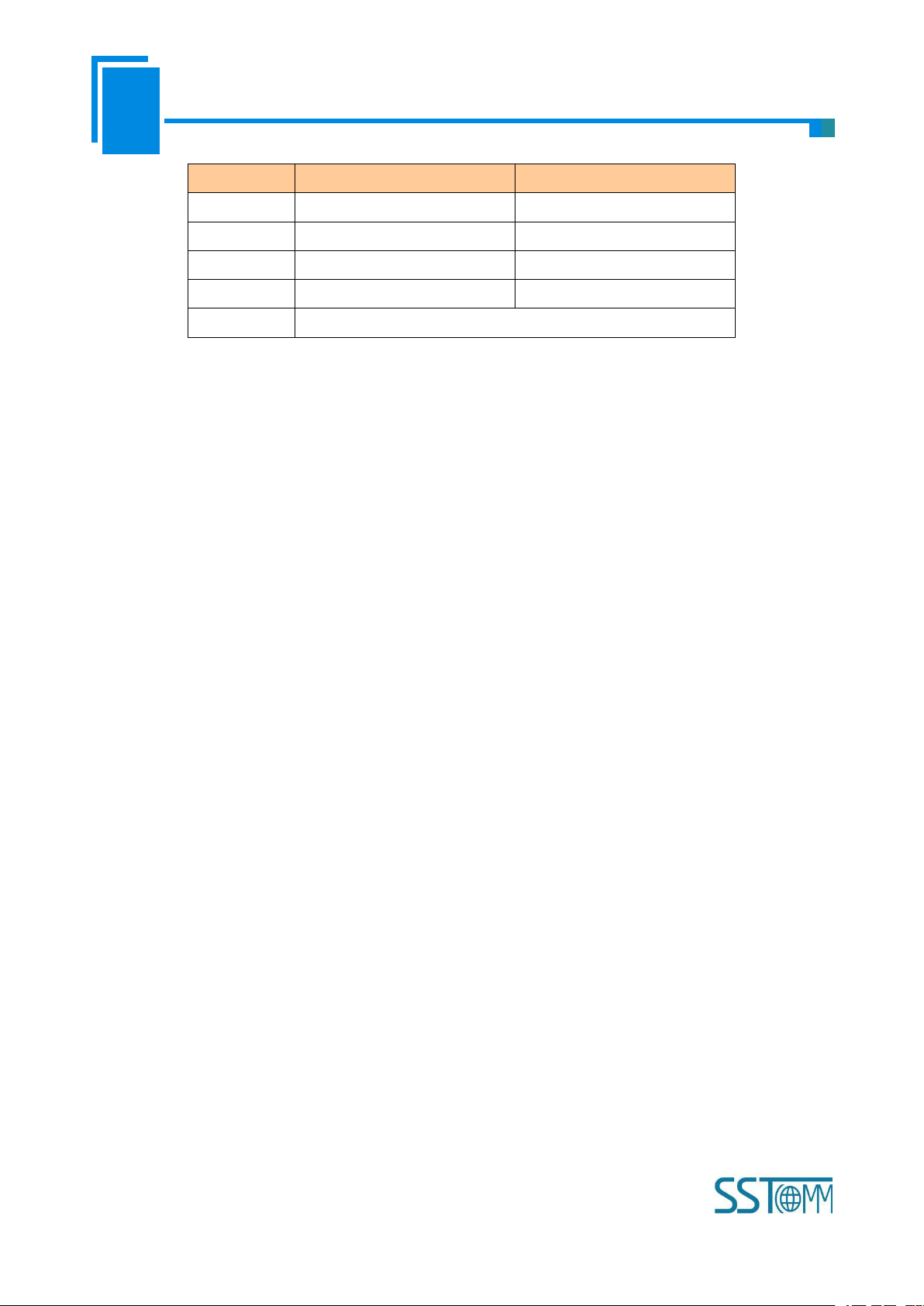

2.6 Revision History

Revision

Date

Chapter

Description

REV A

21/2/2017

All

First release V5.3, the

same with V5.2 REV A

REV A

3/3/2016

Chapter 5

First release V5.2 user

manual, add function of

SDO Send Concurrently,

Retries of SDO, SDO Poll

Delay Time

Page 9

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

9

3 Hardware Descriptions

CANopen Port

Power Port

PROFIBUS DP

Interface

PROFIBUS DP

Status Indicator

PROFIBUS DP

Address/Status

CANopen Status

Indicator

DIP Switch

DP Address

Setting Button

USB Config

Port

Page 10

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

10

3.1 Indicators

Indicators

Status

Description

PROFIBUS

Status

PBF

(red)

On

PROFIBUS DP connection has not been established

Off

PROFIBUS DP connection has been established

STA

(green)

Blinking

Exchanging data

Off

PROFIBUS DP status is abnormal

CANopen

Status

ERR

(bicolor)

Green on

The CAN network is normal

Red on

Bus Off

Red, Green and Off

alter alternately

The error counter of CAN controller reach or exceed alarm

value

RUN

(bicolor)

Green on

Node is in the run state

Green light on every

200ms, off every

1000ms

Node is in the stop state

Green light on every

200ms, off every

200ms

Node is in the pre-run state

Serial Port

TX

Red blinking

Serial port is sending data

Red off

Connection not established or goes wrong

RX

Green blinking

Receiving data

Green off

Connection not established or goes wrong

Off

On 1 2

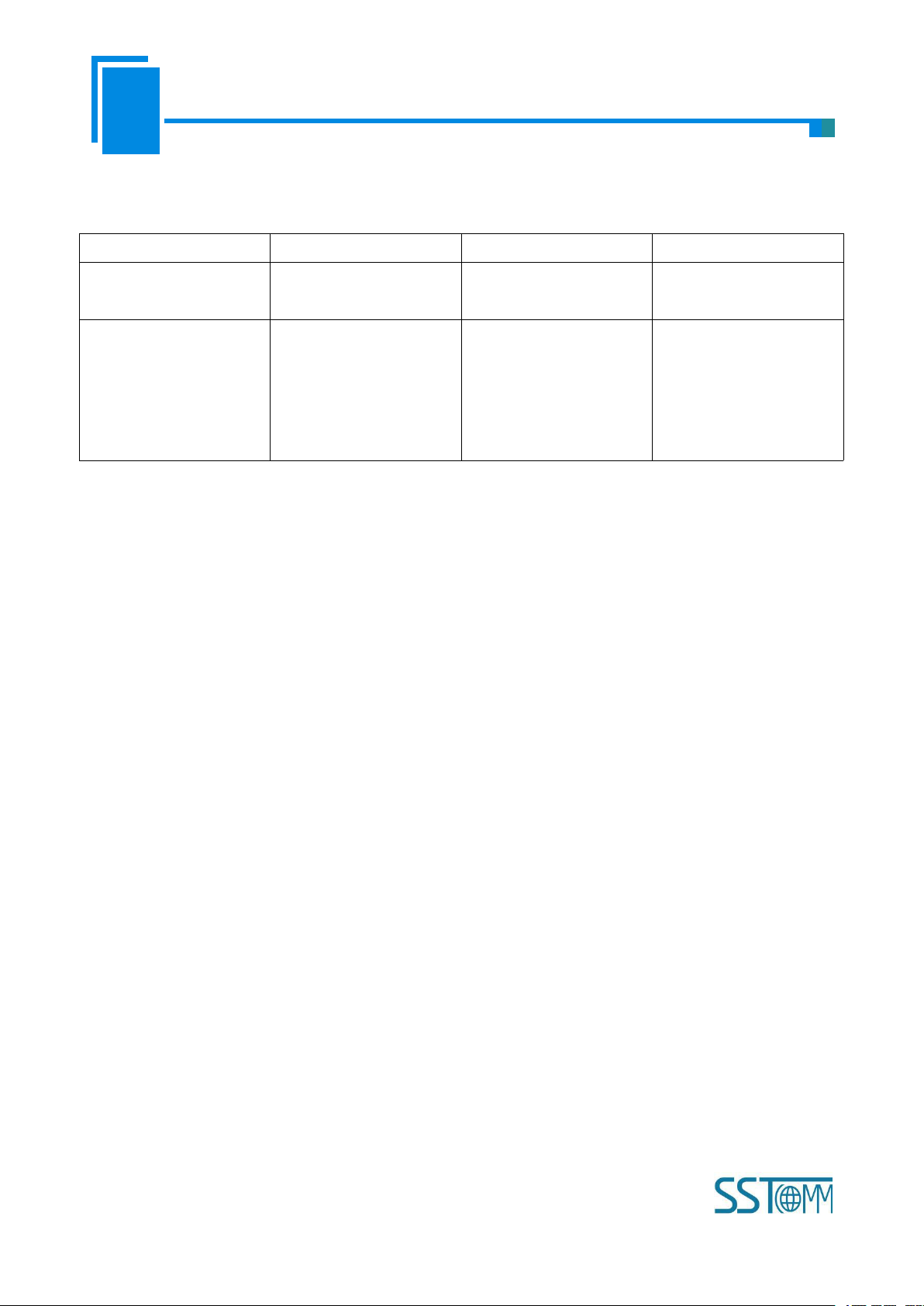

3.2 DIP Switch

Run mode to Configuration mode: Set bit2 to ON, the gateway enter into Configuration mode and no need to

restart the gateway (power off and power on).

Page 11

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

11

Function (1)

Mode (2)

Description

Off

Off

Run Mode, allow setting DP address

OffOnConfiguration Mode

On

Off

Run mode with debug function, not allow

setting DP address

On

On

Run Mode, prohibit setting DP address

(Locked)

Notes: Except for the Locked status, the switch of other three statuses, no need to restart the gateway.

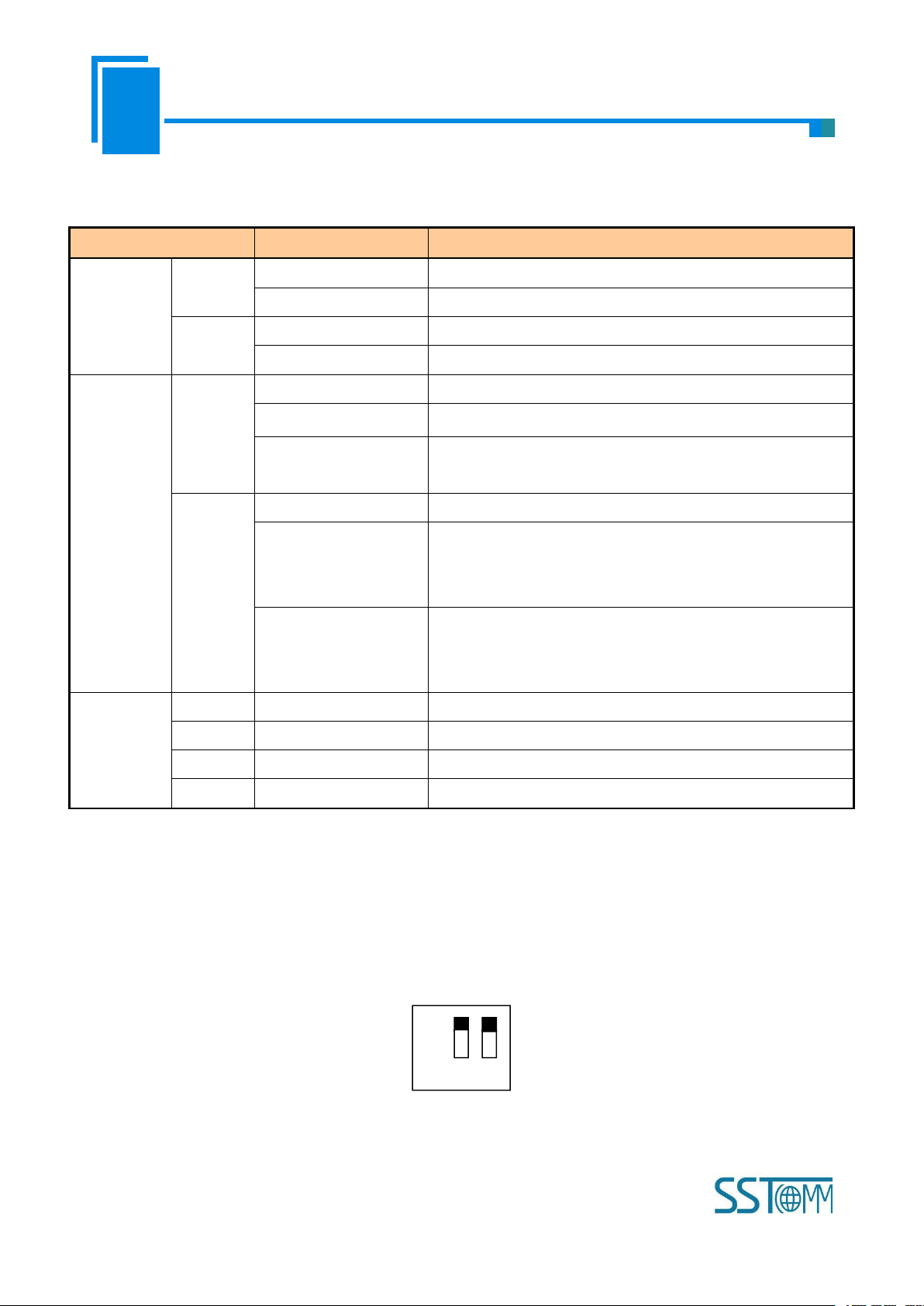

DB9 pin

Function

3

PROFI_B, Data positive

5

GND (optional)

8

PROFI_A, Data negative

5

1

PROFI_A (Pin 8)

GND (Pin 5)

PROFI_B (Pin 3)

3.3 Communication Interface

3.3.1 PROFIBUS DP Connector

PROFIBUS DP interface uses DB9 connector, and the pins are defined as follows:

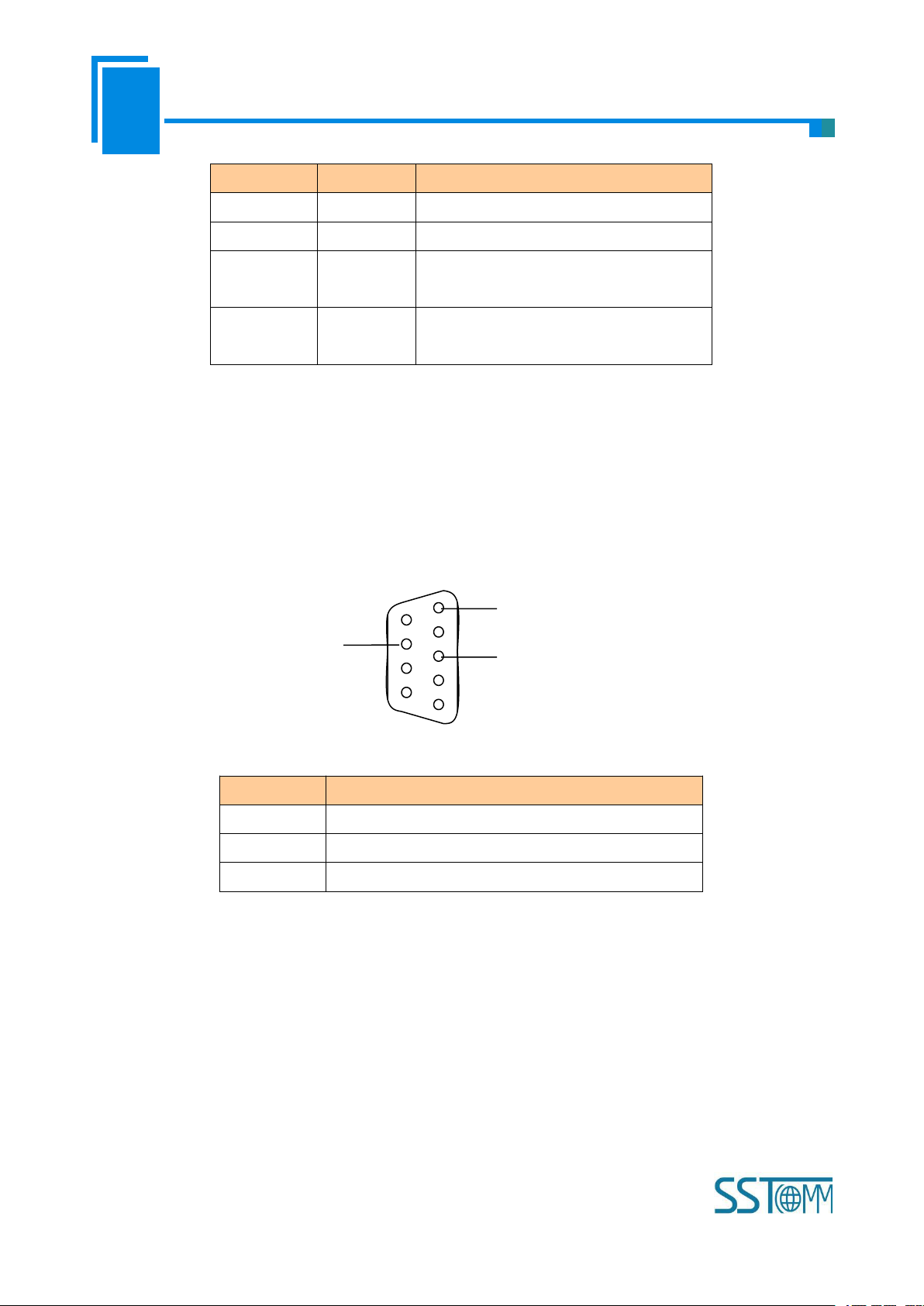

3.3.2 CANopen Connector

5-pin connector:

Page 12

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

12

V+

GND

CAN-L

Shield

CAN-H

5

1

Open five-pin connector at the side of CAN:

Pin

Connection

1

V+ (Optional)

2

CAN-H

3

Shield (Optional)

4

CAN-L

5

GND

Note 1: Connections of V+ and shield are optional, but connections of CAN-H, CAN-L and GND are necessary;

Note 2: GND, V+ of CANopen interface interlinks V+, GND of power interface internally. You can only power on

one of the two interfaces.

3.4 Other Interface

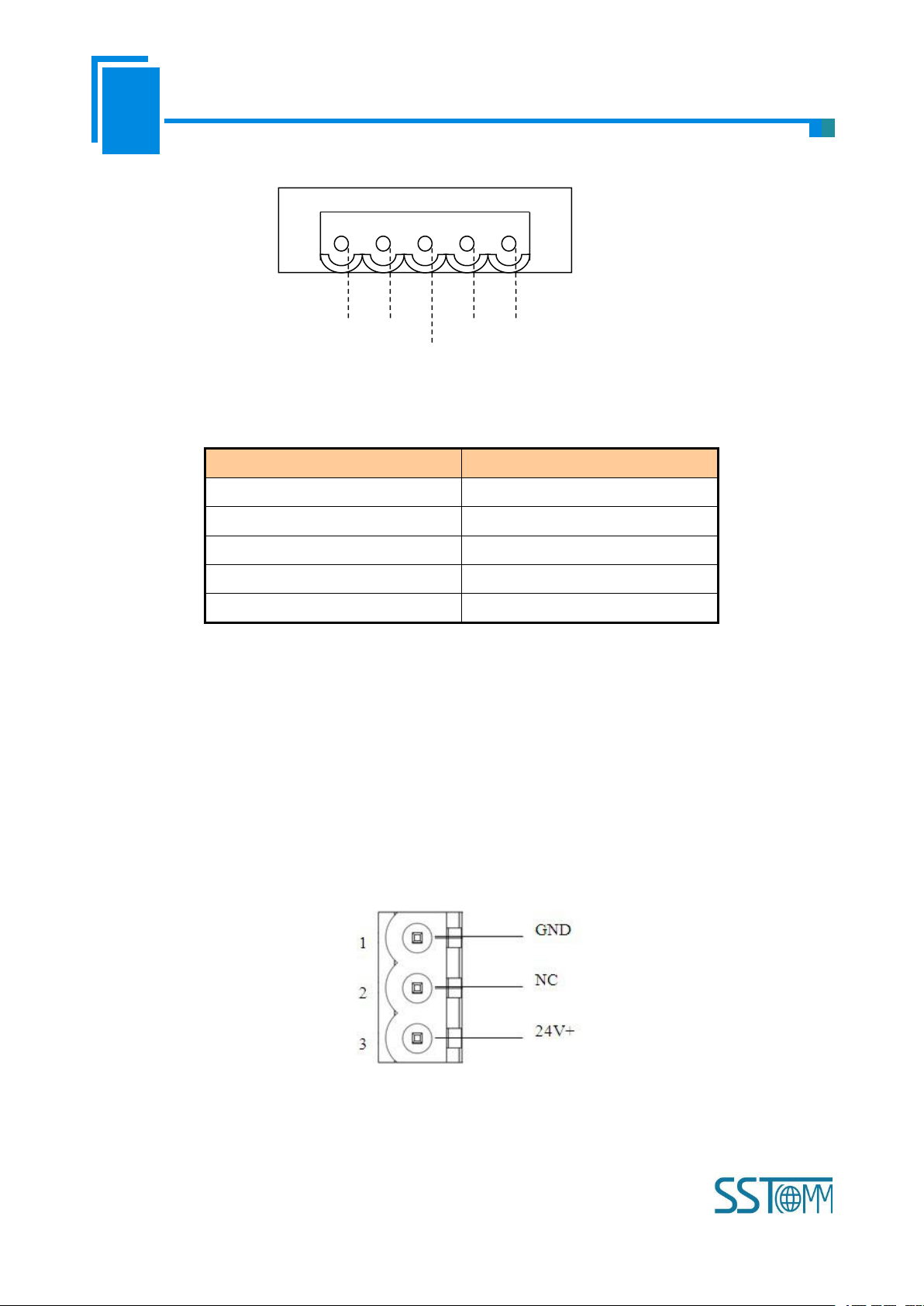

3.4.1 Power Interface

Note 1: 24V+, GND of power interface interlinks V+, GND of CANopen interface. You can only power on one of

the two interfaces.

Page 13

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

13

3.4.2 LED Display

In the configuration mode, LED display CF;

In the debug mode, LED displays “db”;

In the run mode, LED displays PROFIBUS DP slave address.

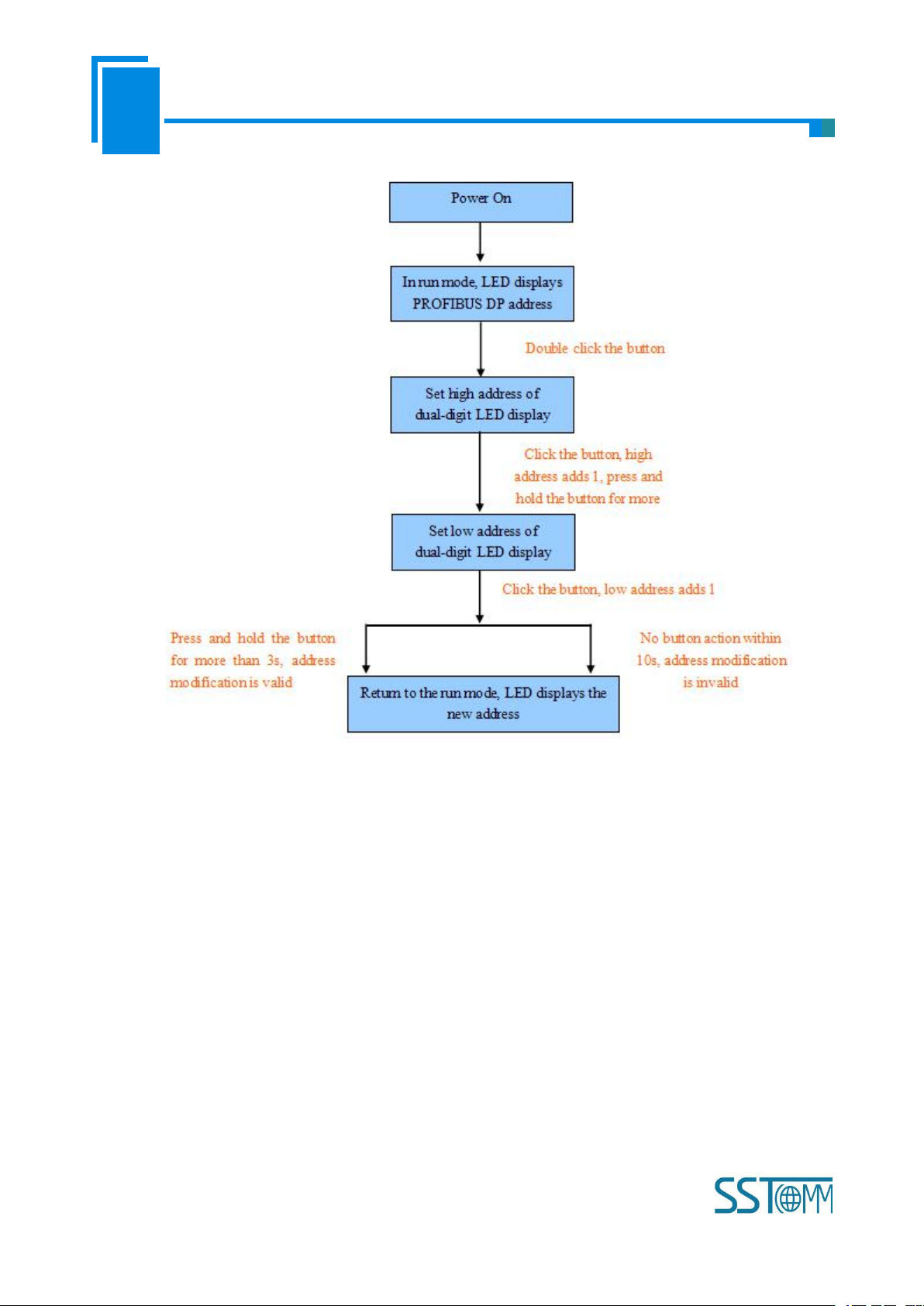

3.4.3 PROFIBUS DP Address Setting Button

The configuration button on the panel can set the PROFIBUS DP slave address.

In run mode of GT200-DP-CO, LED display is always on and displaying the current PROFIBUS DP address.

Quickly press (double-click) the button twice in succession, the high bit starts to flash, and the low bit is always

on, click the button to add 1 to start setting the high bit of PROFIBUS DP address. Long-press the button for 3

seconds, the high bit is always on, and the low bit starts to flash. Click the button to add 1 to start setting the low

bit of PROFIBUS DP address. At last, long-press the button again for 3 seconds, the address flashing three times

shows that the address is set successfully. If no button action within ten seconds, the gateway exits the status of

setting address and continues to display the original address. The configurable range of PROFIBUS DP address is

0 to 99 (Decimal).

PROFIBUS DP address setting method is as follow:

Page 14

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

14

Page 15

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

15

4 Use Method

4.1 Quick Start Guide

1. This gateway has two modes: configuration mode and run mode, you can select different mode through DIP

switch. Set “mode” bit of DIP switch to “on”, the gateway is in the configuration mode, and turn off the “mode”

bit, the gateway is in the run mode;

2. Use USB cable to connect to the USB port of PC and set “mode” bit of DIP switch to “on”, then power on the

device;

3. In the configuration mode, set CANopen baud rate, CANopen node ID, SDO commands (CANopen master

mode), PDO commands and data mapping between CANopen and PROFIBUS DP through gateway configuration

software SST-CP-CFG. (See chapter 4.3 for details).

4. Set "mode" bit of DIP switch to “off” state, configure PROFIBUS DP address through DP address setting

button, power on again and the module go into run mode.

5. Set the address of the PROFIBUS DP by pressing the button, note that this address must be the same as the

address of this slave in the DP master configuration; otherwise DP connection will be failed.

6. In run mode, users can debug data in input and output buffer through setting “function” bit of DIP switch to

“ON” status. Users can see the data in debug interface of SST-CP-CFG through USB interface; Users can use the

function at the beginning of network communication, when the network is OK, please close the debug function,

that is to set “function” bit of DIP switch to “off”.

4.2 Hardware Wiring

1. According to the PROFIBUS port instructions, properly connect with DB9. It is suggested to use standard

PROFIBUS DP connector.

2. According to the CAN port instructions, properly connect the pin 2 and 4 at least.

3. Check all connections whether they comply with the instructions.

4. Set “mode” bit of DIP switch to “Off”, power on the module, and the module go into run status.

Page 16

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

16

4.3 Run

4.3.1 Data Exchange Mode

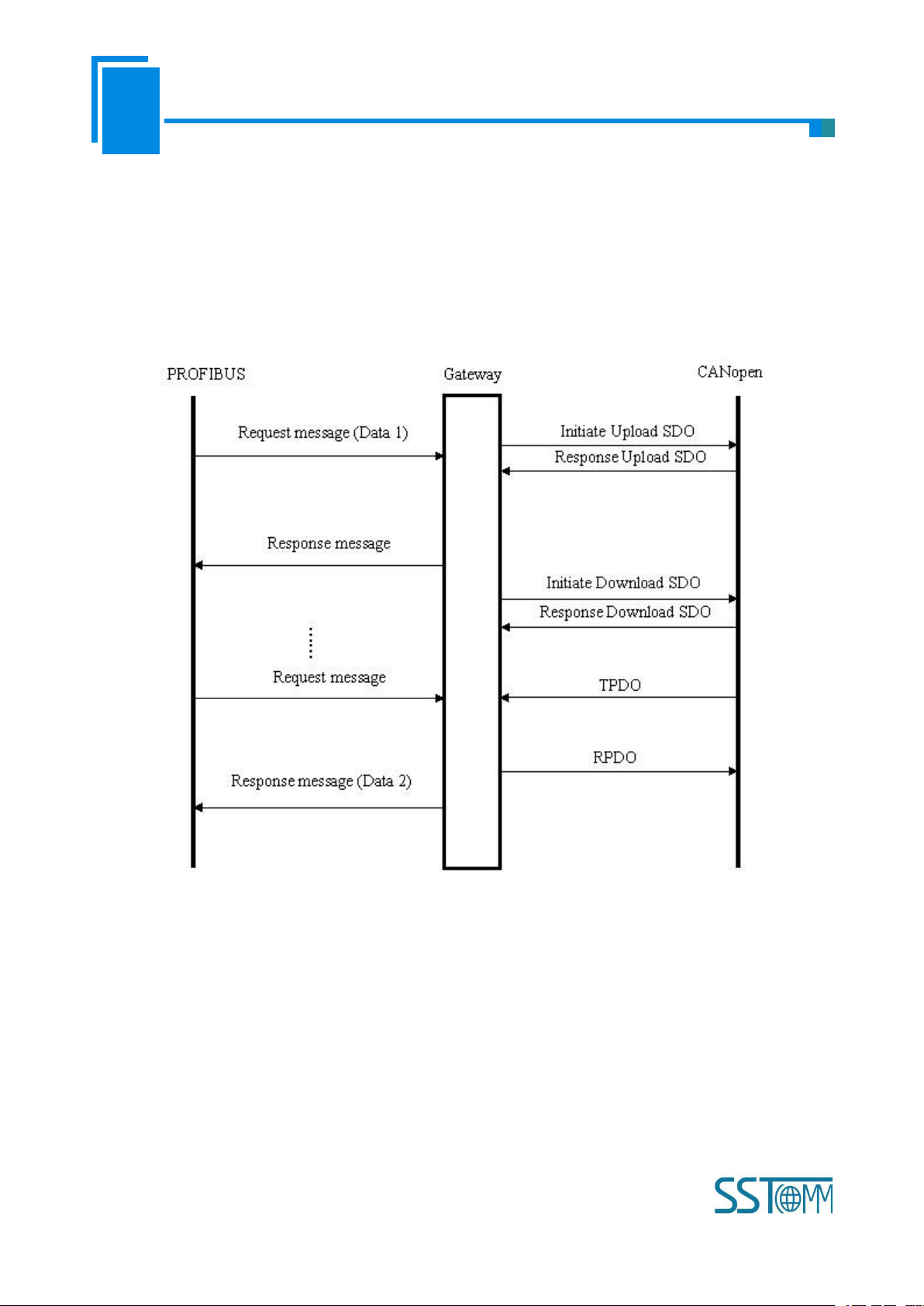

CANopen acts as master

Communication mode between CANopen and PROFIBUS DP is asynchronous mode, as shown below:

“Data 1” shows the data transfer process from PROFIBUS to CAN; “Data 2” shows the data transfer process

from CAN to PROFIBUS.

The gateway runs in CANopen network independently, and transmits read/write commands of CANopen

parameters periodically according object dictionary, also transmits and receives PDO commands. When receiving

I/O request from PROFIBUS DP, the gateway will instantly respond with the latest CANopen data to realize the

matching of network speed. This is asynchronous mode.

TPDO and RPDO applies producer/consumer mode, and often be used in the occasion with high requirement

about speed; Upload SDO and Download SDO applies client/server mode, the mode can guarantee safety of data,

and often be used in the occasion with low requirement about speed.

The data in output buffer of GT200-DP-CO (PROFIBUS DP) is the data being mapped to RPDO or

Page 17

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

17

Download SDO commands of CANopen slave. Outputting mode of GT200-DP-CO is change of value, that is,

until the DP output data is changed, GT200-DP-CO transmits corresponding commands (RPDO or Download

SDO) to CANopen network; For DP input data, GT200-DP-CO receives data through TPDO or Upload SDO

commands configured in the configuration software SST-CP-CFG and save the data to DP input buffer.

When the “Control&Status” bit is “Enable” in configuration software (SST-CP-CFG), there are two bytes in

the end of input and output buffer of GT200-DP-CO showing status of CANopen slaves and controlling status of

CANopen slave.

The last two bytes of input buffer (PROFIBUS DP) shows the status of CANopen slaves. The first byte of

this two bytes is address of CANopen slave and the second byte is status of CANopen slave (i.e. Pre-run status,

run status, stop status, for detailed information, please refer to CANopen protocol). One time it only shows status

of one CANopen slave, GT200-DP-CO applies FIFO mechanism to save all status of every CANopen slave and

output to PROFIBUS DP master in FIFO order.

The last two bytes of output buffer (PROFIBUS DP) is the status that DP master controls CANopen slaves.

The first byte of this two bytes is address of CANopen slave, the second byte is command controlling CANopen

slave (i.e. go into pre-run status, go into run status, go into stop status, reset node, reset application and reset

communication, for specific command format, please refer to NMT of CANopen protocol).

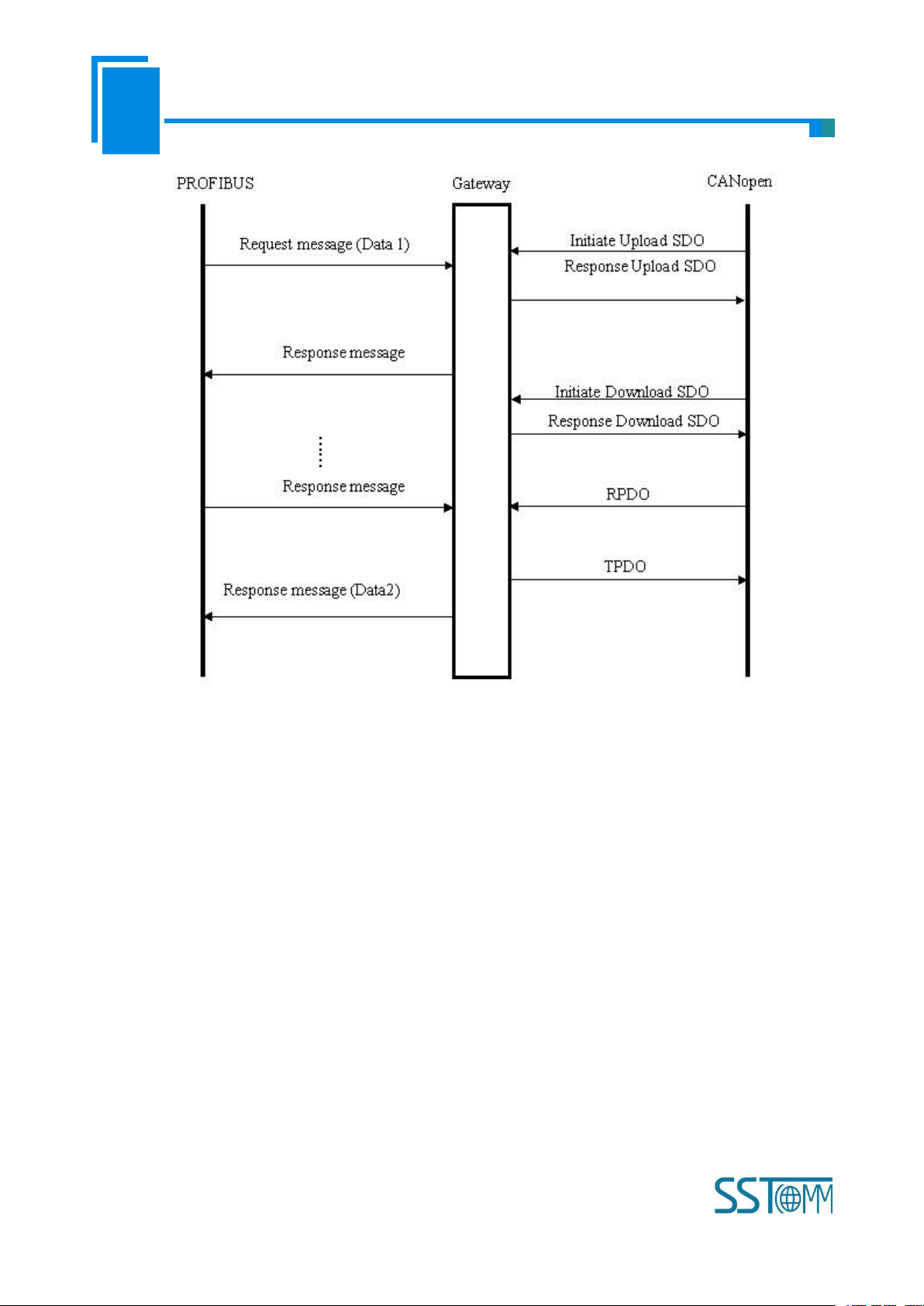

CANopen acts as slave

Communication mode between CANopen and PROFIBUS DP is asynchronous mode, as shown below:

Page 18

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

18

“Data 1” shows the data transfer process from PROFIBUS to CAN; “Data 2” shows the data transfer process

from CAN to PROFIBUS.

The gateway runs in CANopen network independently, and transmits read/write commands of CANopen

parameters periodically according object dictionary, also transmits and receives PDO commands. When receiving

I/O request from PROFIBUS DP, the gateway will instantly respond with the latest CANopen data to realize the

matching of network speed. This is asynchronous mode.

TPDO and RPDO applies producer/consumer mode, and often be used in the occasion with high requirement

about speed; Upload SDO and Download SDO applies client/server mode, the mode can guarantee safety of data,

and often be used in the occasion with low requirement about speed.

4.3.2 PROFIBUS DP Data Module

CANopen acts as master

The parameters the gateway provides are listed below:

Page 19

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

19

Number

Input

Output Instance

1

112 bytes

112 bytes

2

96 bytes

96 bytes

3

48 bytes

48 bytes

4

16 bytes

16 bytes

5

Setting through Hardware Configuration of PROFIBUS DP

Configure fixed input and output bytes in the software:

The data module of length consistent GT200-DP-CO supports is listed below:

The data module of byte consistent GT200-DP-CO supports is listed below:

The data module of word consistent GT200-DP-CO supports is listed below:

16 Byte In, 16 Byte Out: one 8 words Consistent

96 Byte In, 96 Byte Out: three 16 words Consistent

During Step7 programming, it needs to use package sending and receiving. Package sending and receiving

mainly adopts SFC15 (package sending) and SFC14 (package receiving). (Please refer to chapter 5 for details)

48 Byte In, 48 Byte Out

112 Byte In, 112 Byte Out

For the data module of byte and word consistent, users can use MOVE command to read/write data during

Step7 programming.

Page 20

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

20

CANopen acts as slave

Number

Input

Output Instance

1

112 bytes

112 bytes

2

96 bytes

96 bytes

3

48 bytes

48 bytes

4

16 bytes

16 bytes

5

Setting through Hardware Configuration of PROFIBUS DP

The data module of length consistent GT200-DP-CO supports is listed below:

The data module of byte consistent GT200-DP-CO supports is listed below:

The data module of word consistent GT200-DP-CO supports is listed below:

Input buffer 112/96/48/16

PROFIBU

GT200-DP-CO

CANopen bus

Output buffer 112/96/48/16

bytes

Input buffer

(max 244 bytes)

Output buffer

(max 244 bytes)

The parameters the gateway provides are listed below:

16 Byte In, 16 Byte Out: one 8 words Consistent

96 Byte In, 96 Byte Out: three 16 words Consistent

During Step7 programming, it needs to use package sending and receiving. Package sending and receiving

mainly adopts SFC15 (package sending) and SFC14 (package receiving). (Please refer to chapter 5 for details)

48 Byte In, 48 Byte Out

112 Byte In, 112 Byte Out

For the data module of byte and word consistent, users can use MOVE command to read/write data during

Page 21

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

21

Step7 programming.

Index

Sub-index

Description

0x200000Input No.0~No.3 byte of 224 bytes (4 bytes, writable)

0x200100Input No.4~No.7 byte of 224 bytes (4 bytes, writable)

0x200200Input No.8~No.11 byte of 224 bytes (4 bytes, writable)

0x2003

00

Input No.12~No.15 byte of 224 bytes (4 bytes, writable)

0x2004

00

Input No.16~No.19 byte of 224 bytes (4 bytes, writable)

0x2005

00

Input No.20~No.23 byte of 224 bytes (4 bytes, writable)

0x2006

00

Input No.24~No.27 byte of 224 bytes (4 bytes, writable)

…….

……

……

0x2036

00

Input No.216~No.219 byte of 244 bytes (4 bytes, writable)

0x2037

00

Input No.220~No.223 byte of 244 bytes (4 bytes, writable)

0x2038

00

Input No.224~No.227 byte of 244 bytes (4 bytes, writable)

0x2039

00

Input No.228~No.231 byte of 244 bytes (4 bytes, writable)

0x203a

00

Input No.232~No.235 byte of 244 bytes (4 bytes, writable)

0x203b

00

Input No.236~No.239 byte of 244 bytes (4 bytes, writable)

Input buffer

(max 244 bytes)

GT200-DP-CO

Output buffer

(max 244 bytes)

PROFIBUS

CANopen bus

Input, output buffer support fast SDO visit, the location where input/output buffer is located in is listed below:

Page 22

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

22

0x203c

00

Input No.240~No.243 byte of 244 bytes (4 bytes, writable)

0x3000

00

Output No.0~No.3 byte of 244 bytes (4 bytes, readable)

0x3001

00

Output No.4~No.7 byte of 244 bytes (4 bytes, readable)

0x3002

00

Output No.8~No.11 byte of 244 bytes (4 bytes, readable)

0x3003

00

Output No.12~No.15 byte of 244 bytes (4 bytes, readable)

0x3004

00

Output No.16~No.19 byte of 244 bytes (4 bytes, readable)

0x3005

00

Output No.20~No.23 byte of 244 bytes (4 bytes, readable)

0x3006

00

Output No.24~No.27 byte of 244 bytes (4 bytes, readable)

…….

……

……

0x3036

00

Output No.216~No.219 byte of 244 bytes (4 bytes, readable)

0x3037

00

Output No.220~No.223 byte of 244 bytes (4 bytes, readable)

0x3038

00

Output No.224~No.227 byte of 244 bytes (4 bytes, readable)

0x3039

00

Output No.228~No.231 byte of 244 bytes (4 bytes, readable)

0x303a

00

Output No.232~No.235 byte of 244 bytes (4 bytes, readable)

0x303b

00

Output No.236~No.239 byte of 244 bytes (4 bytes, readable)

0x303c

00

Output No.240~No.243 byte of 244 bytes (4 bytes, readable)

SDO read command (Upload SDO) request format

COBID=0x600+nodeID 8 bytes data 40 mm mm nn yy yy yy yy

Among them, 40 is fast read command, mm mm is index, nn is sub-index, yy yy yy yy is any value;

SDO read command response format

COBID=0x580+nodeID 8 bytes data 43 mm mm nn dd dd dd dd

Among them, 43 is the response of fast read command, mm mm is index, nn is sub-index, dd dd dd dd is the data

read from output buffer;

For example: nodeID is 1, read output buffer index through SDO read command: 0x3000, sub-index: data of 00

Request: COBID=0x601 8 bytes data 40 00 30 00 yy yy yy yy

Response: COBID=0x581 8bytes data 43 00 30 00 01 02 03 04

Among them: 01 02 03 04 is the data read from output buffer.

SDO write command (Download SDO) format

Page 23

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

23

COBID=0x600+nodeID 8 bytes data 23 mm mm nn dd dd dd dd

SDO read command request format that CANopen master sent

SDO read command request format that CANopen slave sent:

Among them, 23 is fast read command, mm mm is index, nn is sub index, dd dd dd dd is the data needs to be

written to input buffer;

SDO write command format

COBID=0x580+nodeID 8 bytes data 60 mm mm nn 00 00 00 00

Among them, 60 is fast write response, mm mm is index, nn is sub index, 00 00 00 00 is default value;

For example, nodeID is 1, write data (01 02 03 04) to input buffer index through SDO write command: 0x2000,

sub index: 00

Request: COBID=0x601 8 bytes data 23 00 20 00 01 02 03 04

Response: COBID=0x581 8bytes data 60 00 20 00 00 00 00 00

Among them: 01 02 03 04 is the data needs to be written to input buffer.

When CANopen side is salve, it supports visiting error register to estimate PROFIBUS communication state

through SDO:

COBID=0x600+nodeID 8bytes data 40 01 10 00 yy yy yy

Among them, 40 is fast read command, 0x1001 is index, 00 is sub index, yy yy yy yy is any value.

COBID=0x580+nodeID 8 bytes data 4f 01 10 00 00 yy yy yy yy (00 means PROFIBUS is not off)

4f 01 10 00 80 yy yy yy yy (80 means PROFIBUS is off)

Among them, 4f is fast read command response, 0x1001 is index, 00 is sub index, yy yy yy is any value.

4.3.3 How Step7 Read and Write Gateway Data

When you choose “Setting through Hardware Configuration of PROFIBUS DP” in the configuration

software SST-CP-CFG, you muse refer to this chapter. GT200-DP-CO provides new modules shown as below.

The maximum allowed number of modules is 64 in Step7. The maximum allowed number of input bytes is 244,

the max number of output bytes is 244 and the aggregate of maximum number of input bytes and output bytes is

488.

Page 24

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

24

Module

Integrity

4 Words Input, 4 Words Output

Word

8 Words Input, 8 Words Output

Word

24 Words Input, 24 Words Output

Word

56 Words Input, 56 Words Output

Word

1 Byte Input

Byte

1 Word Input

Word

2 Words Input

Word

4 Words Input

Word

8 Words Input

Word

16 Words Input

Word

32 Words Input

Word

64 Words Input

Word

2 Words Input Consistency

length

4 Words Input Consistency

length

8 Words Input Consistency

length

16 Words Input Consistency

length

1 Byte Output

Byte

1 Word Output

Word

2 Words Output

Word

4 Words Output

Word

8 Words Output

Word

16 Words Output

Word

32 Words Output

Word

64 Words Output

Word

2 Words Output Consistency

Total length

4 Words Output Consistency

Total length

8 Words Output Consistency

Total length

16 Words Output Consistency

Total length

As is shown above, the data modules which GT200-DP-CO supports include: Word integrity, Byte integrity

and length integrity.

For the data modules that support Word and Byte integrity, you can use command “MOVE” to access the

data during STEP7 programming.

For the data modules that support length integrity, user can take compression way to send and receive data.

Page 25

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

25

The compression way mainly uses “SFC 15” when sending and receiving uses “SFC 14”:

4.3.4 How Step7 Select Data Module

Generally, when the data modules include “Consistent”, this means this data module is length integrity. When

accessing data, you need to use SFC14 (read) and SFC15 (write) to read or write data. And those which didn’t

include “Consistent”, you can use “Move” command to access the data.

According to user’s demand of input/output bytes, there are so many alternatives for the selection of data

modules. For example: When user needs 20-words input ( The data number reading form Modbus slave through

PLC is 20 words), user can directly select data modules no less than 20 words input (32words Input 、64words

Input…) or input one input/output modules no less than 20 words (56 words Input,56words Output…).

Take “2 words Input Consistent” as an example, when you choose the module, you must use “SFC 14” to

access the data address. When some data of Modbus slave is two-word data, and needs high accuracy and real-

time, user generally select “2 words Input Consistent”, and not to select “2 words Input”. So, PLC can access the

whole data module during reading data, and it can also prevent data from burst changing (last word data and next

word data are not read in the same time) and causing incorrect data.

Page 26

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

26

5 Software Instructions

Users can use connect GT200-DP-CO to the PC with USB port and configure gateway’s relevant parameters

through SST-CP-CFG, including CANopen address, CAN baud rate and input/output data mapping bytes number

from CANopen network to PROFIBUS.

Configuring steps:

5.1 CANopen Acts as Master

5.1.1 Notes before Configuration

SST-CP-CFG is based on Windows platform. It is used to configure parameters and commands of GT200-

DP-CO.

Double-click the icon of the software, and you can see the "Protocols Type Selection" interface of the

software:

Select one protocol and you can see the main interface of the software:

Page 27

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

27

5.1.2 User Interface

Software interface include: Title bar, Menu bar, Toolbar, Status bar, Devices Plate, Configuration Plate and

Comment Plate.

Note: All the gray sections in the software cannot be changed.

Page 28

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

28

Toolbar:

Toolbar

Device plate: Users can select

operation objects including

Profibus network and

CANopen Network, and adding

nodes and commands

Menu Bar

Title Bar

Configuration plate:

Input configuration parameters,

gray parts cannot be changed

Comment plate: Explain

the function of the

configuration options

Toolbar is shown as below:

The function of Toolbar: New, Open, Save, Add Node, Delete Node, Add Command, Delete Command,

Upload, Download, Mapping Address Conflict Detection, Calculate Mapping Address, Export EXCEL and

Monitor.

New: Create a new configuration project

Open: Open a configuration project

Save: Save current configuration

Add Node: Add a node for CANopen master

Delete Node: Delete a node for CANopen master

Add Command: Add a CANopen command

Delete Command: Delete a CANopen command

Upload: Read the configuration information from the module and shown in the software

Download: Download the configuration file to the gateway

Mapping Address Conflict Detection: To check whether there are some conflicts with configured commands in

the gateway memory data buffer

Page 29

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

29

Calculate Mapping Address: Used to automatically calculate the mapped memory address without conflict by

each command

Export EXCEL: Export current configuration to the local hard disk, saved as .xls file

Monitor: Monitor the gateway memory buffer data

5.1.3 Device View Operation

5.1.3.1 Device View Interface

5.1.3.2 Operation Mode

Support three kinds of operation modes: edit menu, edit toolbar, and right-click edit menu.

Page 30

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

30

5.1.3.3 Operation Types

1) Add node: Left click on CANopen Network or existing nodes, and then perform the operation of adding a new

node. Then there is a new node named "New node" under CANopen Network.

2) Delete node: Left click on the node to be deleted, and then perform the operation of deleting node. The node

and all commands will be deleted.

3) Add commands: Left click on the node, and then perform the operation of adding command to add a command

for the node. It will pop up the command selecting dialog box for users to choose. Shown as below:

Commands: Upload SDO->Profibus In, Download SDO <-Profibus Out, Transmit PDO->Profibus In, Receive

PDO<-Profibus Out

Select commands: Double click a command (Take command selection under CANopen master mode as an

example)

4) Delete command: Left click a command and you can delete it.

5) Copy node: Left click on the existing node, choose the node and execute the operation of copying nodes

(include all commands under the node)

6) Paste node: Left click and choose any existing node, execute operation of pasting node. Then under the Modbus

TCP tree you can see a new node (include all commands under the node); Parameters of new node is default

Page 31

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

31

setting, it needs to be reset.

5.1.4 Configuration View Operation

5.1.4.1 PROFIBUS Network Configuration

Left click the Profibus network in device plate and you can see configuration interface of Profibus network:

Configurable items:

Number of Bytes: 112, 96, 48, 16 can be selected, and the default is 112.

5.1.4.2 CANopen Network Configuration

Configurable parameters are shown as below:

CANopen Baud Rate, CANopen Node ID, SDO Response Timeout, Enable NMT, Clear Data Time for

TPDO, Delay to Start up, SYNC Cycle and Control& Monitor Status.

CANopen configuration interface is shown as below:

Page 32

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

32

CANopen Baud Rate: 50K, 100K, 125K, 250K, 500K, 1M can be selected; the default value is 250K

CANopen Node ID: 1 to127, the default value is 1

SDO Response Timeout: This parameter is based on 10 milliseconds. The range of the parameter value is 1 to

2000. Default value is 200

Enable NMT: Whether to start all CANopen nodes on the network or not, the default is disable

Clear Data Time for TPDO: TPDO timeout value

Delay to start up: Delay value

SYNC: Synchronizing cycle

Control& Monitor Status: The first two bytes of output buffer is used as status byte of CANopen slave. The

0: Do not use the function;

Nonzero value: Use timeout function and the timeout value is nonzero integral multiple of 10 milliseconds,

the range is 0 to 2000, the default is 0

0: Do not use the function;

Nonzero value: Use the function, and delay value is nonzero integral multiple of 10 milliseconds, the range is

0 to 2000, the default is 100. When the value of "Enable NMT" is "Enable", the parameter is valid.

0: Do not use synchronizing cycle function

Nonzero value: Use the function, and the synchronizing cycle is nonzero integral multiple of 10 milliseconds,

the range is 1 to 2000, the default is 0

first byte of this two byte is address of CANopen salve, and the second byte is the command which controls

CANopen slave. Selecting "Enable", SST-CP-CFG will minus two bytes when calculating mapping address

automatically and this two byte are saved in the end of buffer.

Page 33

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

33

Errol Control: Function selection item. Non-zero means to use life guard protocol. Zero means to use

heartbeat protocol. The default is 0. The range is 0~2000.

The Cycle for RPDO Transmission: The Cycle for RPDO Transmission is based on 1ms. Zero means to use

Output Data Processing: When PROFIBUS DP is off, the RPDO data of DP output buffer will Clear and

The Cycle for SDO Transmission: The Cycle for SDO Transmission, is based on 1ms. Zero means Download

SDO Send Concurrently: Disable: The SDO request for a node must wait for the node’s response before

Retries of SDO: The CANopen master sends an SDO request command but does not receive a response from

SDO Poll Delay Time: The CANopen master sends the SDO request command and receives the response

the mode of change of value output; Non-zero means to send all RPDO according to the cycle. Sending cycle

equals setting value, the default value is 0. The range: 0~60000.

Hold; “Clear” means to set the data to zero; “Hold” means to keep the data unchanged before DP is off.

SDO uses mode of change of value output, Upload SDO uses the mode of non-stop reading slave data; Non-

zero means to send all SDO according to the cycle. Sending cycle equals setting value, the default value is 0.

The range: 0~60000.

initiating the next SDO request; Enable: Sending SDOs command requests of different nodes concurrently.

the slave, and the master repeatedly sends this SDO request command. Range: 0~5, default: 0

from the slave. The master needs to delay for a while before sending the next SDO request command. This

period of time is the SDO command polling delay time. Unit: ms, Range: 0~60000ms, default: 0ms.

5.1.4.3 Node Configuration

In the device interface, left click on a node and then the configuration interface is shown as below:

Page 34

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

34

5.1.4.4 Command Configuration

Slave address: CANopen slave address, the range is 1 to127

Index value: Object index value in object dictionary (decimal)

Sub-index value: Object sub-index value in object dictionary (decimal)

In the device interface, left click on a command and then the configuration interface is shown as below:

Page 35

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

35

Number of bytes: Number of bytes of mapping item

Mapping address: Memory address mapped in the gateway (Read only)

COB-ID: The CAN ID (decimal) of CANopen PDO:

Default value of Transmit PDO command: 384(0x180) + node ID or 640(0x280) + node ID or 896 (0x380) +

Mnemonic description: Users can input the description of project configuration items here; these are not

node ID or 1152(0x480) + node ID

Default value of Receive PDO: 512(0x200) + node ID or 768(0x300) + node ID or 1024 (0x400) + node ID

or 1280 (0x500) + node ID

downloaded to gateway actually

5.1.4.5 Comment Interface

Comment interface displays the explanation of relevant configuration item. When the configuration item is

"COB-ID", the comment interface is shown as below:

5.1.5 Hardware Configuration

Communication menu is shown as below:

5.1.5.1 COM Configuration

The software can scan usable serial port automatically, and show it in the port list. Finish all configurations,

click "OK" and save settings.

Remark: When you finish setting port, and other parameters are fixed value: 57600, 8, ODD, 8, 1.

Page 36

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

36

5.1.5.2 Upload

Select "Upload", it will read configurations form the gateway, and the interface is shown as below:

5.1.5.3 Download

Select "Download", it will download configurations to the gateway, and the interface is shown as below:

Page 37

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

37

Remark1: Please confirm the port in "COM Config" is the port that you are using before downloading the

configurations;

Remark2: Please confirm the configurations are correct before downloading configurations (you can use "Export

EXCEL" function and it can help you check the configurations).

5.1.6 Load and Save Configuration

5.1.6.1 Load Configuration Project

Select "Open", you can open the configuration project that you have saved.

5.1.6.2 Save Configuration Project

Select "Save" or "Save As", you can save the configuration project with chg as its extension.

Page 38

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

38

5.1.7 Auto Mapping

The mapping address of every command in the gateway must be calculated by fixed formula, users can use

"Calculate Mapping Address" to calculate mapping address automatically.

5.1.8 Export Excel File

Users can use the function to check the gateway configurations.

Select "Export EXCEL", you can save the configuration with .xls as its extension.

5.1.9 Monitor

When the first bit of DIP switch of GT200-DP-CO is set to "ON" status and the second bit is dialed to "OFF"

status, GT200-DP-CO is in the debug mode.

This function can monitor the data in the input buffer of gateway memory; the interface is shown as below:

Page 39

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

39

There are no data in the buffer and the interface is shown as below:

Users can click "Save content" button and save the data to disk of computer:

After using "Save content", the button will change to "Stop saving", click the button and you can cancel

saving the data to disk of computer:

When users click "Stop Displaying" button, it will stop showing the data in buffer:

Page 40

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

40

After using "Stop Displaying", the button will change to "Continue to display", click the button it will clear

the items before and show new contents again.

5.2 CANopen Acts as Slave

5.2.1 Notes before Configuration

Select one protocol and you can see the main interface of the software:

Page 41

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

41

5.2.2 User Interface

Software interface include: Title bar, Menu bar, Toolbar, Status bar, Devices Plate, Configuration Plate and

Comment Plate.

Page 42

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

42

Note: All the gray sections in the software cannot be changed.

Toolbar

Device plate: Users can select

operation objects including Profibus

network and CANopen Network,

and adding nodes and commands

Menu Bar

Title Bar

Configuration plate:

Input configuration parameters,

gray parts cannot be changed

Comment plate: Explain the

function of the configuration

options

Toolbar:

Toolbar is shown as bellow:

The function of Toolbar: New, Open, Save, Add Node, Delete Node, Add Command, Delete Command,

Upload, Download, Mapping Address Conflict Detection, Calculate Mapping Address, Export EXCEL and

Monitor.

New: Create a new configuration project

Open: Open a configuration project

Save: Save current configuration

Add Node: Add a node for CANopen slave node

Delete Node: Delete a node for CANopen slave node

Add Command: Add a CANopen command

Delete Command: Delete a CANopen command

Upload: Read the configuration information from the module and shown in the software

Download: Download the configuration file to the gateway

Mapping Address Conflict Detection: To check whether there are some conflicts with configured commands in

Page 43

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

43

the gateway memory data buffer

Calculate Mapping Address: Used to automatically calculate the mapped memory address without conflict by

each command

Export EXCEL: Export current configuration to the local hard disk, saved as .xls file

Monitor: Monitor the gateway memory buffer data

5.2.3 Device View Operation

5.2.3.1 Device View Interface

5.2.3.2 Operation Mode

Support three kinds of operation modes: edit menu, edit toolbar, and right-click edit menu.

Page 44

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

44

5.2.3.3 Operation Types

1) Add node: Left click on CANopen Network or existing nodes, and then perform the operation of adding a new

node. Then there is a new node named "New node" under CANopen Network.

2) Delete node: Left click on the node to be deleted, and then perform the operation of deleting node. The node

and all commands will be deleted.

3) Add commands: Left click on the node, and then perform the operation of adding command to add a command

for the node. It will pop up the command selecting dialog box for users to choose. Shown as below:

Commands: Transmit PDO<-Profibus Out, Receive PDO->Profibus In

Select commands: Double click a command

4) Delete commands: Left-click a command and you can delete it.

5.2.4 Configuration View Operation

5.2.4.1 PROFIBUS Configuration

Left click Profibus network in Device Section, and you can see configuration section of fieldbus:

Items: Protocol type, Profibus input and output bytes

Protocol type: Profibus

Profibus input and output bytes: 112, 96, 48, 16 can be selected, and the default is 112.

Page 45

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

45

5.2.4.2 CANopen Network Configuration

Configurable parameters are shown as below:

CANopen Baud Rate, CANopen Node ID, Clear Data Time for RPDO and Delay to Start up.

CANopen configuration interface is shown as below:

Page 46

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

46

CANopen Baud Rate: 50K, 100K, 125K, 250K, 500K and 1Mbps optional, default value is 250K.

CANopen Node ID: 1 to127, the default value is 1

Clear Data Time for RPDO: RPDO timeout value

0: Do not use the function;

Delay to start up: Delay value

Nonzero value: Use timeout function and the timeout value is nonzero integral multiple of 10 milliseconds,

the range is 0 to 200, the default is 0

0: Do not use the function;

Nonzero value: Use the function, and delay value is nonzero integral multiple of 10 milliseconds, the range is

0 to 2000, the default is 100. When the value of "Enable NMT" is "Enable", the parameter is valid.

5.2.4.3 Command Configuration

In the device interface, left click on a command and then the configuration interface is shown as below:

Page 47

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

47

Slave Address: CANopen slave address, the range is 1 to127

COB-ID: The CAN ID (decimal) of CANopen PDO:

Default value of Transmit PDO command: 384(0x180) + node ID or 640(0x280) + node ID or 896 (0x380) +

Mapping address: Memory address mapped in the gateway (Read only)

Mnemonic description: Users can input the description of project configuration items here; these are not

node ID or 1152(0x480) + node ID

Default value of Receive PDO: 512(0x200) + node ID or 768(0x300) + node ID or 1024 (0x400) + node ID

or 1280 (0x500) + node ID

downloaded to gateway actually

5.2.4.4 Comment Interface

Comment interface displays the explanation of relevant configuration item. When the configuration item is

"COB-ID", the comment interface is shown as below:

Page 48

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

48

5.2.5 Hardware Communication

Communication menu is shown as follow:

5.2.5.1 COM Configuration

The software can scan usable serial port automatically, and show it in the port list. Finish all configurations,

click "OK" and save settings.

Remark: When you finish setting port, and other parameters are fixed value: 57600, 8, 0DD, 8, 1

5.2.5.2 Upload

Select "Upload", it will read configurations form the gateway, and the interface is shown as below:

Page 49

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

49

5.2.5.3 Download

Select "Download", it will download configurations to the gateway, and the interface is shown as below:

Remark1: Please confirm the port in "COM Config" is the port that you are using before downloading the

configurations;

Remark2: Please confirm the configurations are correct before downloading configurations (you can use "Export

EXCEL" function and it can help you check the configurations).

Page 50

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

50

5.2.6 Load and Save Configuration

5.2.6.1 Load Configuration Project

Select "Open", you can open the configuration project that you have saved.

5.2.6.2 Save Configuration Project

Select "Save" or "Save As", you can save the configuration project with chg as its extension.

5.2.7 Auto Mapping

The mapping address of every command in the gateway must be calculated by fixed formula, users can use

"Calculate Mapping Address" to calculate mapping address automatically.

Page 51

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

51

5.2.8 Export Excel File

Users can use the function to check the gateway configurations.

Select "Export EXCEL", you can save the configuration with .xls as its extension.

5.2.9 Monitor

When the first bit of DIP switch of GT200-DP-CO is set to "ON" status and the second bit is set to "OFF"

status, GT200-DP-CO is in the debug mode.

This function can monitor the data in the input buffer of gateway memory; the interface is shown as below:

There are no data in the buffer and the interface is shown as below:

Page 52

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

52

Users can click "Save content" button and save the data to disk of computer:

After using "Save content", the button will change to "Stop saving", click the button and you can cancel

saving the data to disk of computer:

When users click "Stop Displaying" button, it will stop showing the data in buffer:

Page 53

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

53

After using "Stop Displaying", the button will change to "Continue to display", click the button it will clear

the items before and show new contents again.

Page 54

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

54

6 Installation

6.1 Mechanical Dimension

Dimension: 0.98 in (width)*3.94 in (height)*3.54 in (depth)

6.2 Installation

35mm DIN rail installation

Page 55

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

55

Page 56

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

56

7 Failures and Suggestions

Number

Description

Suggestions

1

PBF (PROFIBUS DP Failure) always read

PROFIBUS DP connection fail

2

PBF (PROFIBUS DP Failure) read out

PROFIBUS DP connection OK

3

CAN-STATUS read light on in run status

CAN BUS OFF or error counter beyond alert

value;

Check CAN baudrate of gateway, and the

baudrate must be the same with other nodes

of CAN network

4

CAN-STATUS read light blinking in run status

Need a terminal resistance1on CAN network

or there is no connection between gateway

with CAN network

5

CAN-STATUS green light on but CAN transmit and

receive data fail in run status

Need a terminal resistance1on CAN network

or the node connected with gateway fail

6

CAN-STATUS read light blinking in run status

occasionally

There is error frame form CAN network, will

not affect communication

7

CAN-STATUS read light always blinking in run

status and no data in PROFIBUS DP

Check the baudrate of all the nodes on the

CAN network; If they are all the same, please

change a low baudrate and try again

8

ERR and RUN lights blinking fast

Check PROFIBUS DP network

Note: Terminal resistance

When communication distance is long or communication baudrate is high, users need a terminal resistance

(120Ω/2W) in both terminals of communication lines.

1

Page 57

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

57

Appendix: Using STEP7 Set PROFIBUS DP

1. Open SIMATIC Manager ; Figure 1:

The following show how to use STEP7 to configure GT200-DP-CO:

First of all, copy *. gsd file to the following path: Step7\S7data\gsd\

Figure 1

2. Click File->New, create a new project; Figure 2:

3. Insert->Station->SIMATIC 300 Station; Figure3:

Figure 2

Page 58

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

58

Figure 3

4. Open S7 PLC hardware configuration: SIMATIC 300(1)->Hardware, double-click; Figure 4:

Figure 4

Page 59

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

59

5.Click Option->Update Catalog, update GSD in device catalog.

Figure 5

6. Here you can find your equipment in the right side of the window; Figure 6

Page 60

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

60

Figure 6

7. Set PLC rack, click the "Hardware Catalog \ SIMATIC 300 \ RACK-300 \ Rail"; Figure 7:

8. Set CPU module and select the corresponding device type and the occupied slots.

Figure 7

Page 61

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

61

9. Create PROFIBUS DP network and set up PROFIBUS DP: Click New and then Network settings, select DP;

10. Select PROFIBUS Master station address, Figure 9:

select a baud rate such as 187.5Kbps, then "OK". Double-click it; Figure 8:

Figure 8

Page 62

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

62

Figure 9

11. Drag GT200-DP-CO to PROFIBUS DP network bus, and drag data modules to slots, that is mapping the

Drag data module to

slots in lower left

table

Select PROFIBUS Address

input and output data module into master controller’s memory. Figure 10:

Figure 10

Page 63

User Manual

CANopen/PROFIBUS DP Gateway

GT 200 -DP -CO

WWW.SSTCOMM.COM

63

Operation is divided into two steps, the first step is dragging GT200-DP-CO to PROFIBUS DP network bus,

12. Compile and download into PLC.

the mouse will change shape, and that is to say, it can be placed. The second step is dragging data module into

master controller’s memory.

Note 1: Users configure input and output bytes of GT200-DP-CO through configuration software SST-CP-CFG.

If users select 48, and then drag “48 Byte In, 48 Byte Out” to the slots. The default is “112 Byte In, 112 Byte Out”.

Note 2: The PROFIBUS DP slave address must be in line with the settings of module DIP switch!

Loading...

Loading...