Page 1

A TI REF

5050

220

220

.1 uF

332J100

20.000

TL074CN

TL074CN

TL074CN

CD4011BE

CD40106BE

TL072P

TL072P

TL072P

LM393P

LF

442CN

SSSR Labs MCU Chip

KOTELNIKOV 1.2

CD4042BE

KP590KH5

AD7545A

SM042, Assembly Manual

PCB Version 1.2

Page 2

SM042, Assembly Manual

PCB Version 1.2

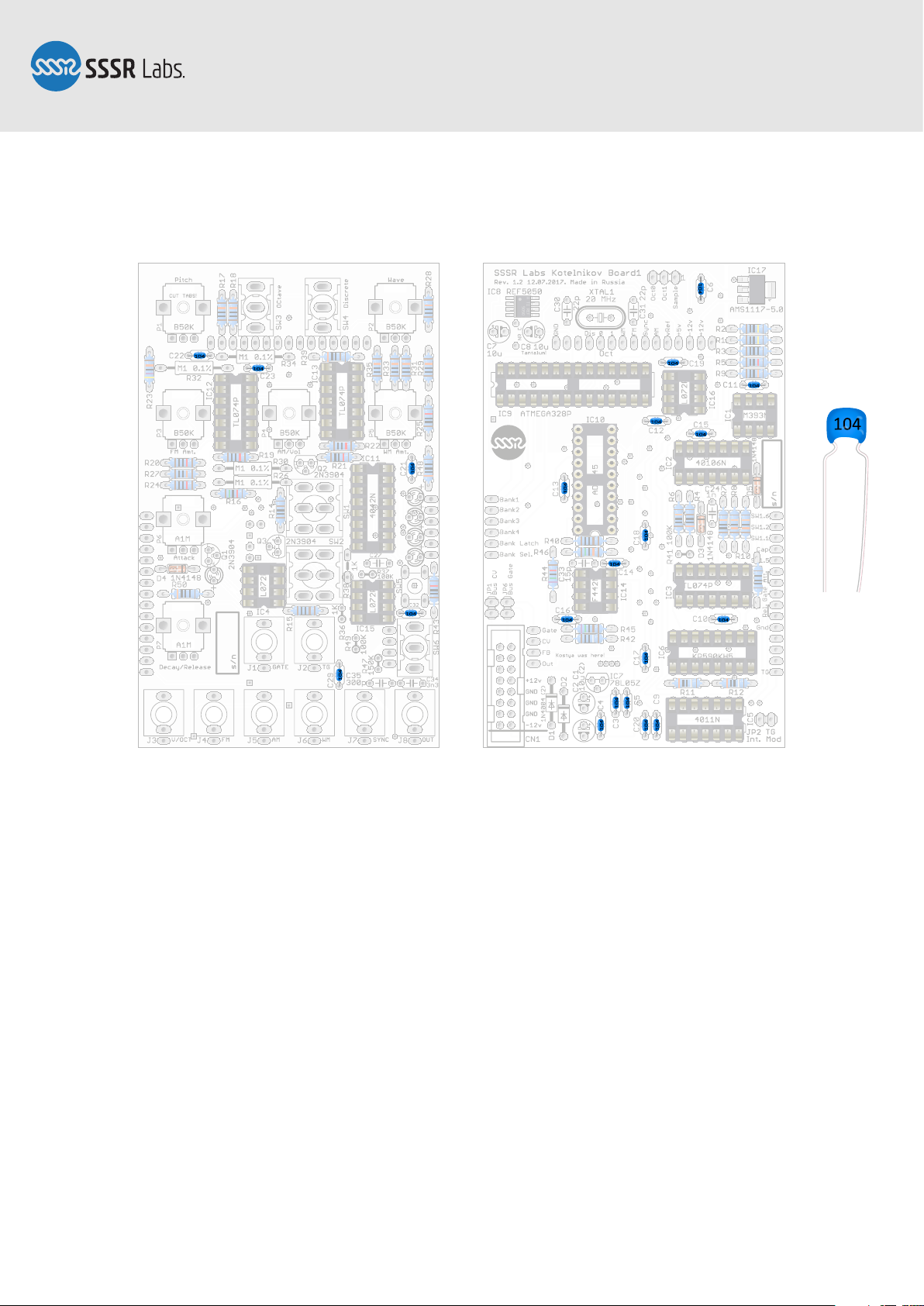

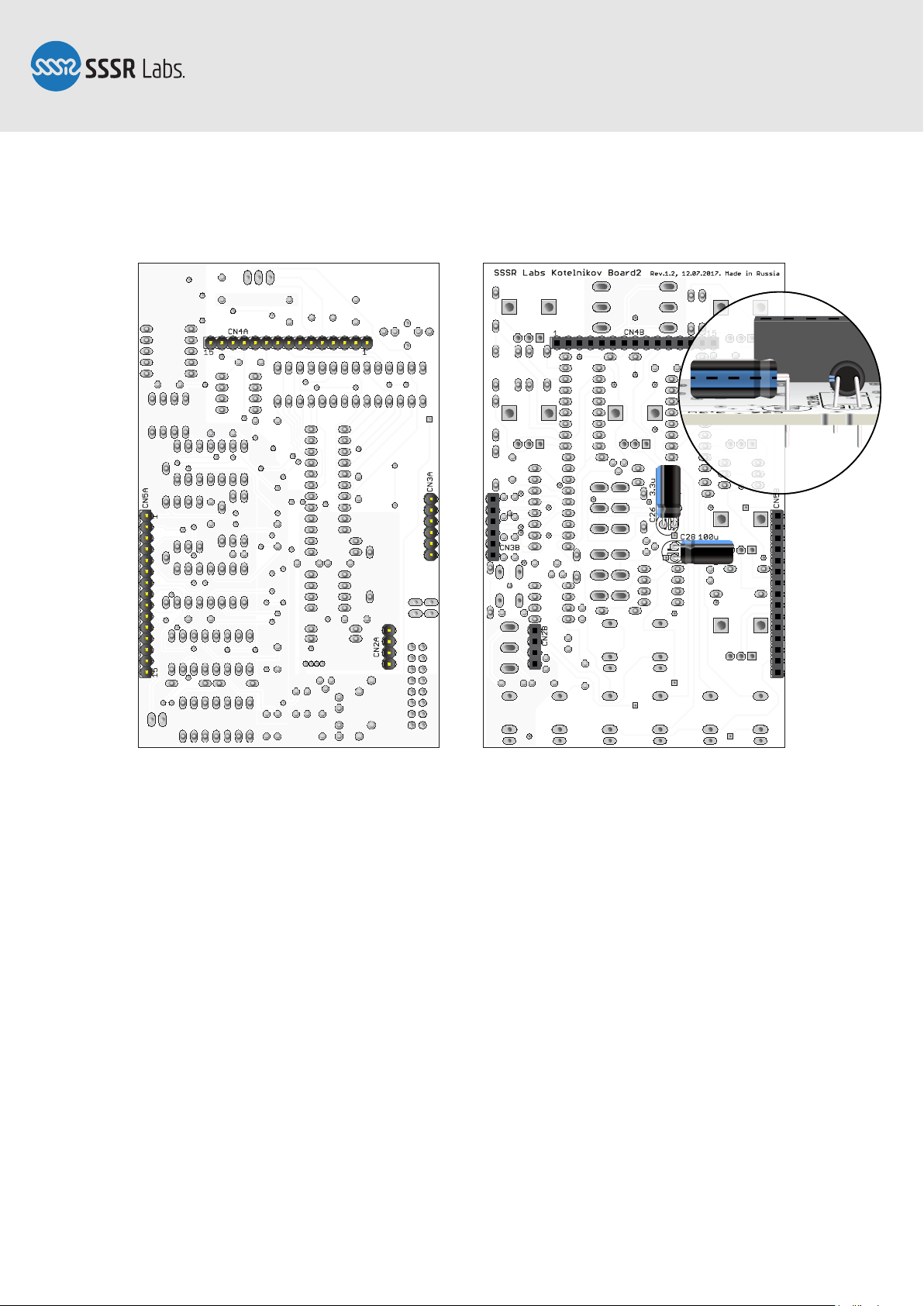

Step 1: PCB Top Side

The SM042 DIY Kit contains two boards:

Circuit board 1. (Rear) This board consists of the main powering, VCO and TG circuitry.

Circuit board 2. (Front) This board contains interface circuitry and the linear scaling

circuitry for CV and reference voltage.

Most of the components have to be placed on the top side of both boards, but pinheader connectors and couple of aluminium capacitors are have to be soldered to the

bottom side

The order of assembly briefly can be described like that: Install SMD components,

small diodes, horizontally placed resistors, IC sockets, small capacitors, the rest of

non-mechanical components, then LED, pin-headers and bottom-side capacitors, then

install all chips, power and jumper connectors, the tactile switch, then toggle

switches, potentiometers and jack sockets. The following manual will guide you

through the assembling process in details.

Page 2 of 18

Page 3

A TI REF

5050

A TI REF

5050

SM042, Assembly Manual

PCB Version 1.2

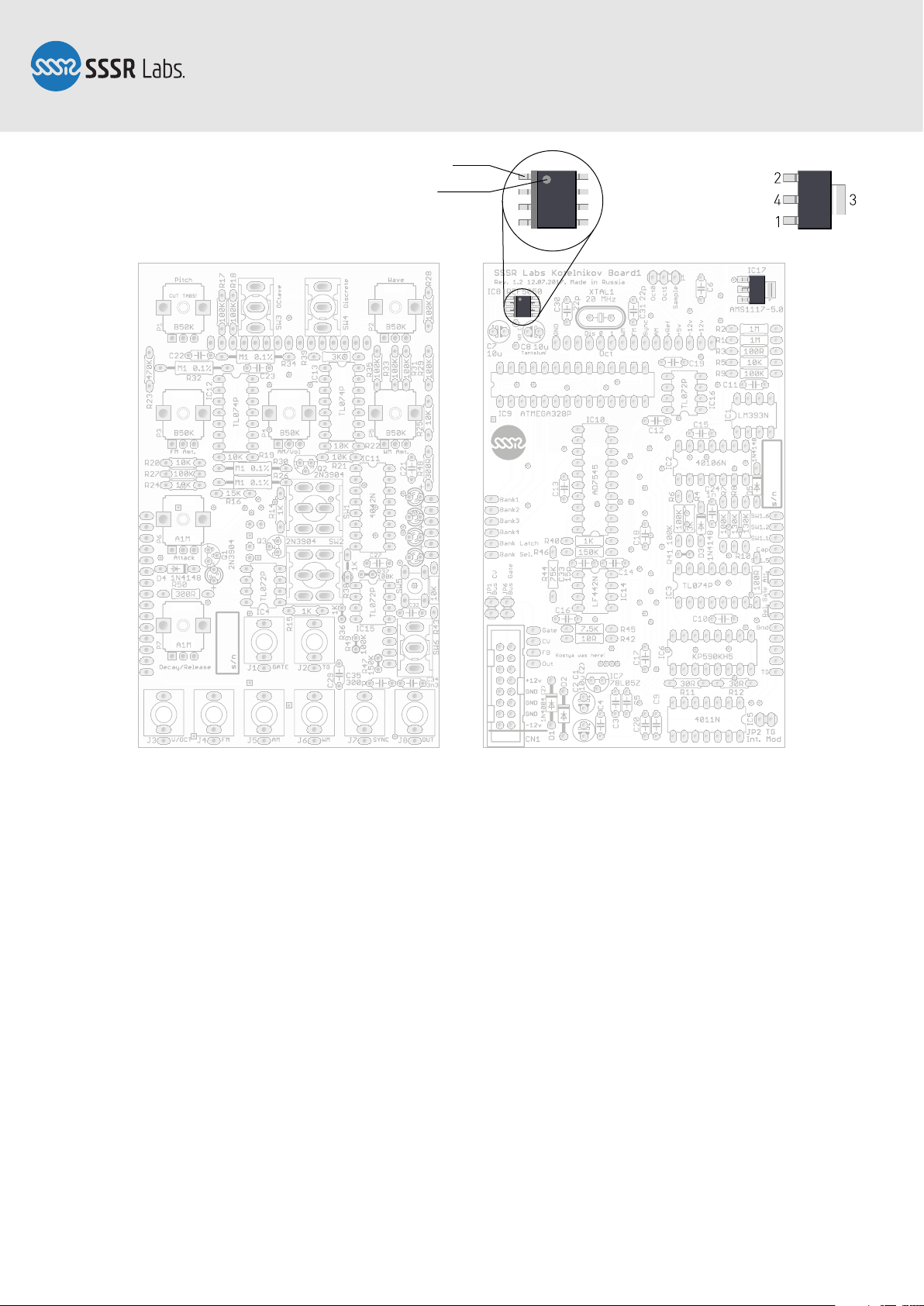

Pin 1

Key dot

Order of soldering

Step 2: SMD Components

The AMS1117-5.0 and REF5050 are the only two SMD components in our DIY kit. Place

the AMS1117 chip accurately aligned to its footprint, then solder pins according to the

order given in the picture above. The pin 4 (heatsink) will require long heating up. Don’t

worry about the overheating, this component is designed to be heated seriously! Install

the REF5050 chip oriented as shown on the picture above. Solder one of the pins in a

corner, align the chip well, solder the opposite corner, then the remaining pins.

Page 3 of 18

Page 4

A TI REF

5050

SM042, Assembly Manual

PCB Version 1.2

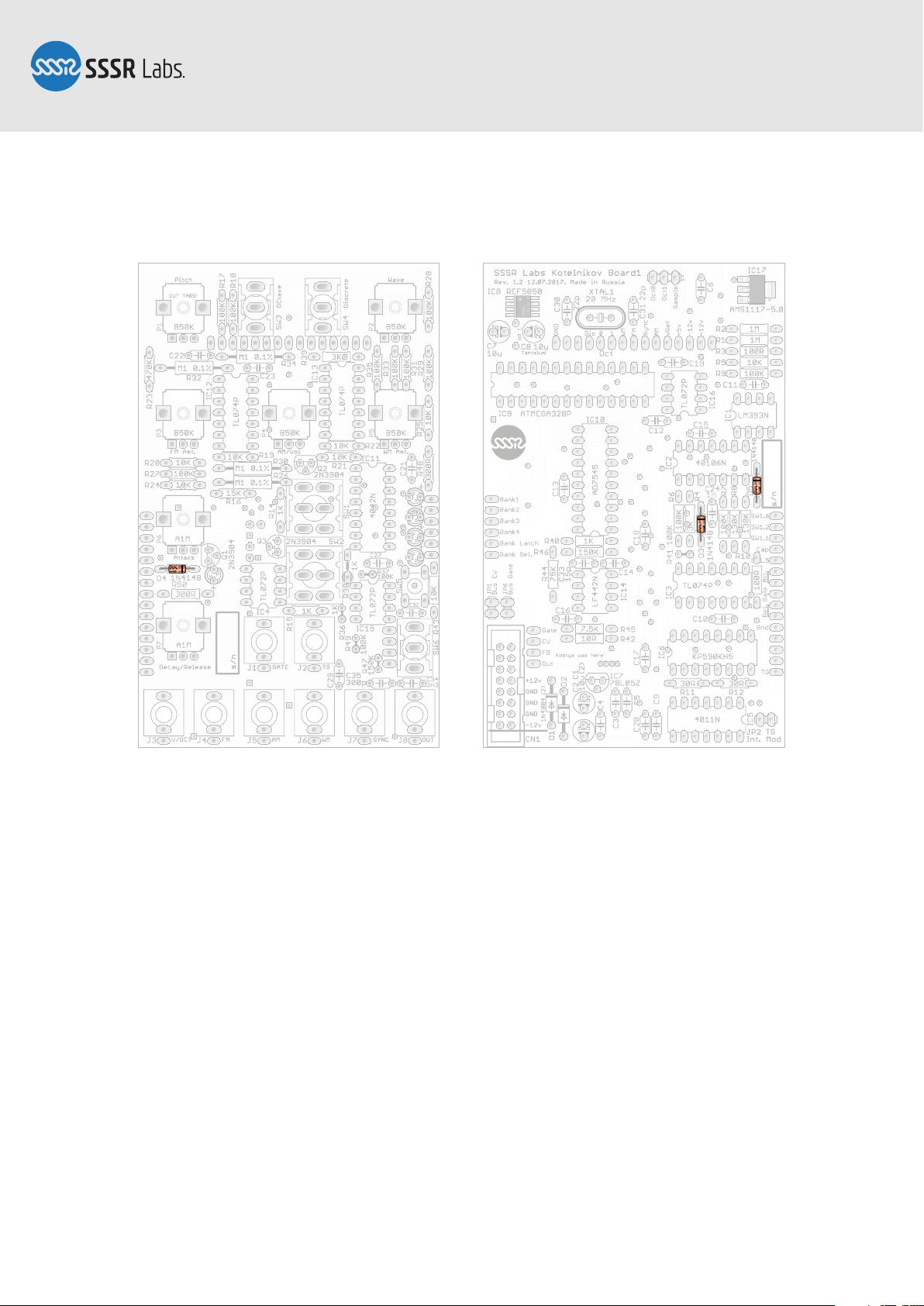

Step 3: Small Signal Diodes

Find the thinnest components: a silicon small-signal diodes. Notice the polarity. The

black stripes indicating the cathodes must correspond with stripes on the PCB. Solder

all diodes to the top side of the PCB, then proceed to step 4.

Page 4 of 18

Page 5

A TI REF

5050

Bend a bit

SM042, Assembly Manual

PCB Version 1.2

to the right

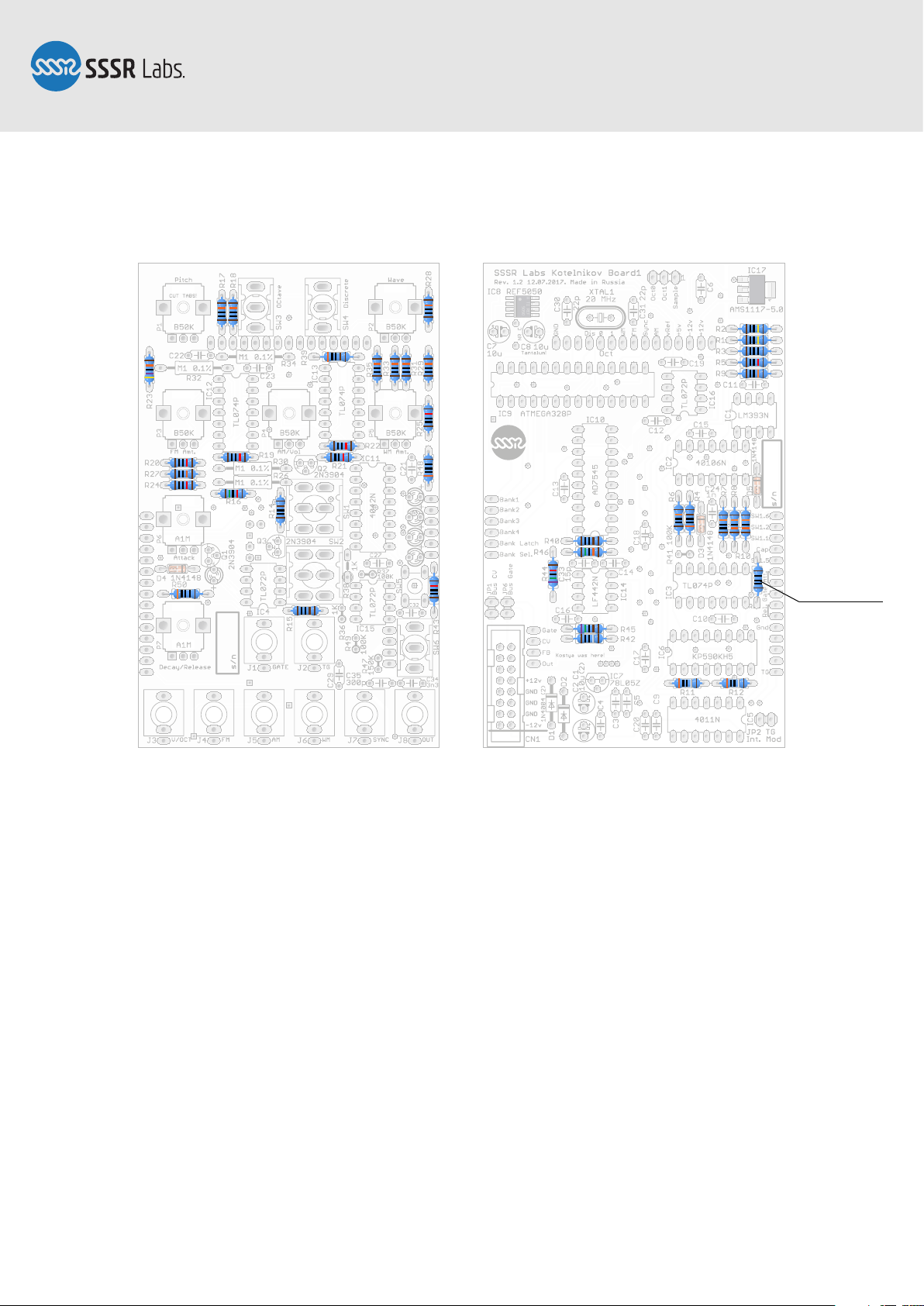

Step 4: Resistors

Install the resistors. You can use the above picture as the reference to verify values

before soldering.

Flip the PCB over, trim the pins and reflow and solder everything to the bottom side.

This technique is the best method to accurately and firmly solder axial components, so

it’s recommended to use it with all components allowing you access to the top side.

Page 5 of 18

Page 6

A TI REF

5050

Notch

SM042, Assembly Manual

PCB Version 1.2

Reverse direction!Pin 1

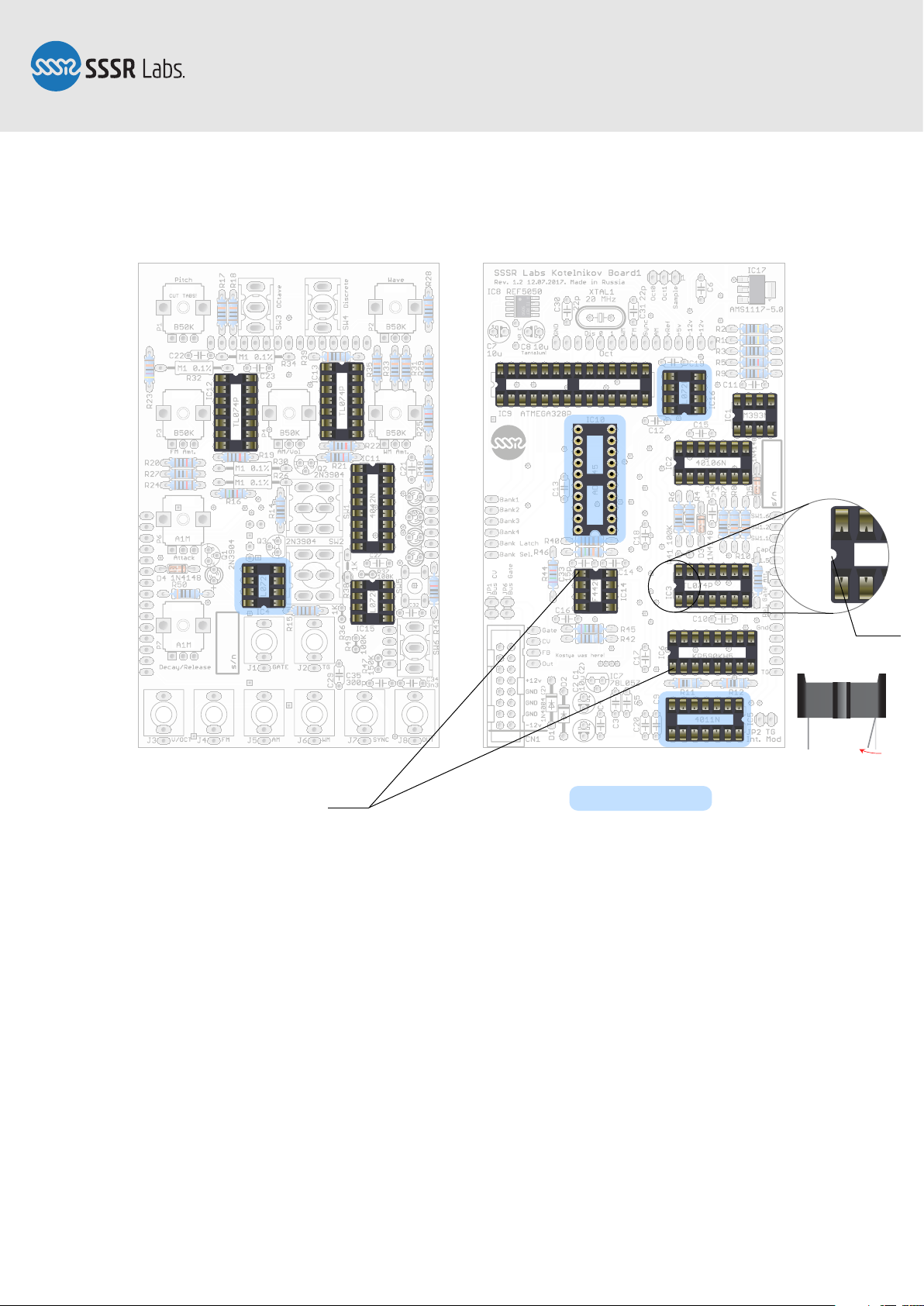

Step 5: IC Sockets

Insert all DIP IC sockets. Please pay double attention to the correct orientation. The

default orientation for chips in the module is the notch turned to the top, or to the left,

but there are chips with other directions, marked by blue areas in the picture.

These sockets are very slippy, so it’s practical to gently bend their pins towards each

other to help them fixate in the holes while you’re flipping the board over and soldering

them. It’s recommended to solder just two pins in the opposite corners of each socket

and then reflow them while pushing the socket closer to the surface of the PCB. Then

solder the remaining pins.

Page 6 of 18

Page 7

A TI REF

5050

SM042, Assembly Manual

PCB Version 1.2

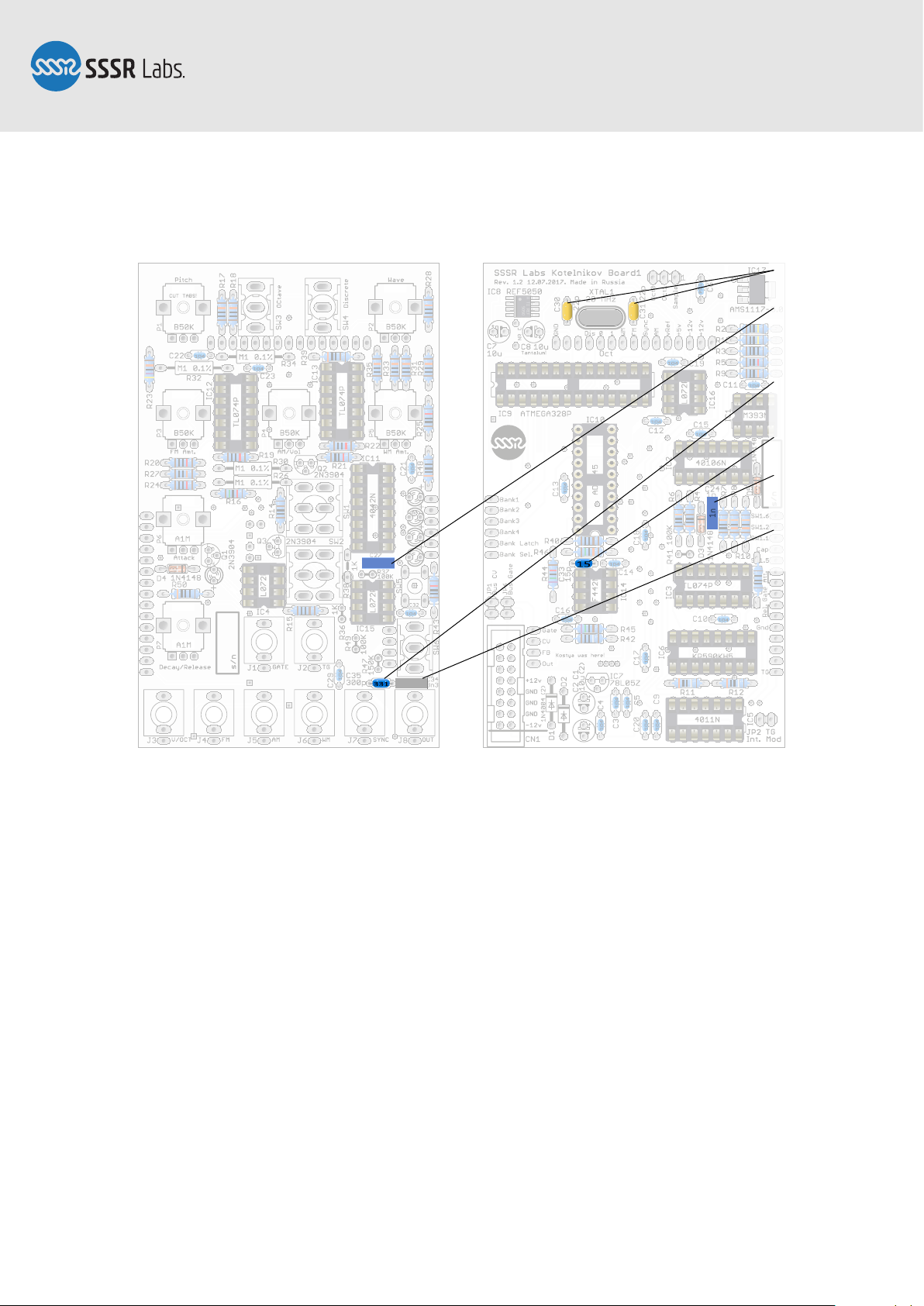

Step 6: Bypass Capacitors

Install and solder the 100 nF bypass capacitors, labelled as “104”. There are total of 21

of them. In some early kits, the MuRata ceramic capacitors was replaced with Epcos

polyester film capacitors.

Page 7 of 18

Page 8

A TI REF

5050

220

220

.1 uF

332J100

20.000

Identifying

SM042, Assembly Manual

PCB Version 1.2

capacitors:

22 or 220: 220 pF

.1μJ100

or μ10J100

or 104: 100 nF

331: 330 pF

(repl. for 300 pF)

15 or 150: 15 pF

1nJ100

or 102: 1 nF

332J100

or 332: 3.3 nF

Step 7: Other Small Capacitors And Quartz Crystal

Install other small capacitors. You can identify them by labels listed on the picture.

Also, it's good to know that there are two types of notation for a capacitor value.

Style 1: 3-digit. The first two digits should be read as they are, and then you need to

add as much zeroes as are indicated by the third digit, and interpret this as the value in

pF. 150 means 15 pF, 334 means 330000 pF (= 330 nF). Very simple.

Style 2: The value usually consists of 2 or 3 digits and a letter p, n or u (µ) indicating

the unit of the value. This letter actually stands in place of the decimal point, so 33n

means 33 nF, 3n3 means 3.3 nF, and n33 means 0.33 nF (= 330 pF). The following

“J100” on film capacitors indicates the tolerance class, and the voltage rating.

Page 8 of 18

Page 9

A TI REF

5050

220

220

.1 uF

332J100

20.000

≤8 mm

SM042, Assembly Manual

PCB Version 1.2

≥3 mm

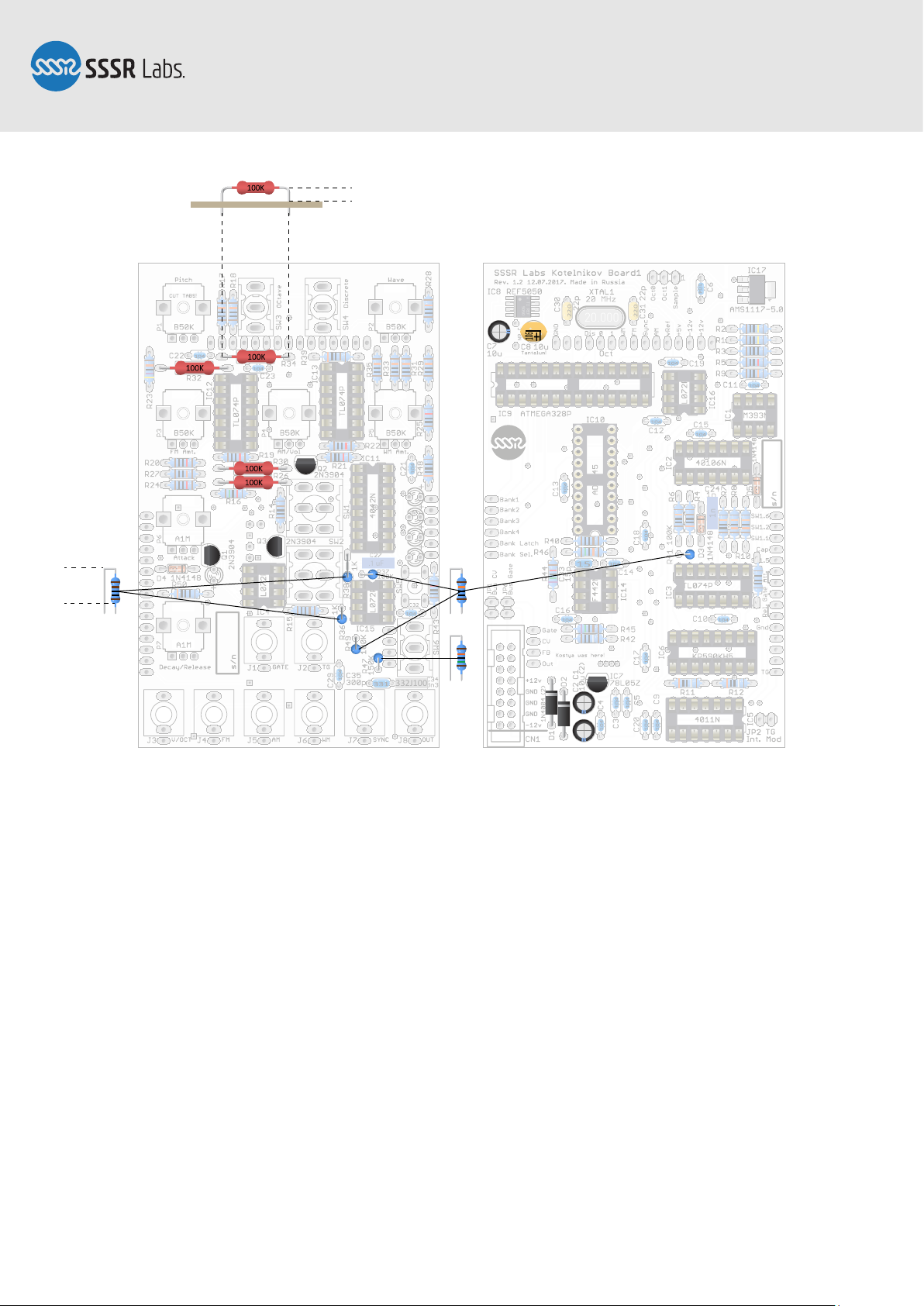

Step 8: Remaining Top-Side Components

Install precision 100K resistors into their places. They must be elevated above the

board as shown on the picture. This method of installation is required by the resistors'

design and it helps to keep values within tolerance. Then install rectifier diodes and

aluminium capacitors. All of those are all polarized components! As with the smallsignal diodes, cathodes of the rectifier diodes are marked with stripes on diodes and

footprints. All holes for the positive pins of electrolytic capacitors are marked with the

“+” sign. All positive pins on capacitors are longer than negative pins

Finally, install the vertically oriented resistors. The allowed height of the resistors

must be non greater than 8 mm to ensure that leads do not touch the surface of the

panel.

Page 9 of 18

Page 10

A TI REF

5050

220

220

.1 uF

332J100

20.000

SM042, Assembly Manual

PCB Version 1.2

Step 9: LED

Take two potentiometers or toggle switches, and two jack sockets. Install them into

places for P1, P2 (SW3, SW4), J1 and J2 but do not solder them. Then insert five LEDs

keeping the correct polarity. Anodes are indicated by the “+” sign on the board and the

longer pins. Remove the film from the front panel if there's any, and install the panel

onto the board through the switches and jack sockets. Holding the panel, turn the

module upside down and let all diodes slip into their holes. Then solder them one by

one keeping the correct clamping of the panel and LEDs' height.

Now, take off the panel and proceed to the next step.

Page 10 of 18

Page 11

3.3 μF 50v

SM042, Assembly Manual

PCB Version 1.2

Step 10: Bottom Side Components

You will find 4 complementary pairs of pin-headers tied together: 2 × 15-pin, 1 × 4-pin

and 1 × 6-pin. The female part must be installed on Board 2, and the male part — on

Board 1. Install connectors on the bottom side of Board 1, then construct a sandwich

out of both boards as shown on the picture. Solder all headers ensuring that all construction is clamped tight and secure.

Insert electrolytic capacitors into the bottom side of Board 2. Bend them as shown on

the picture, and solder. The holes for the positive pins are indicated with white stripes

and the negative are black. The positive pins are longer than the negative.

Page 11 of 18

Page 12

A TI REF

5050

220

220

.1 uF

332J100

20.000

TL074CN

TL074CN

TL074CN

CD4011BE

CD40106BE

TL072P

TL072P

TL072P

LM393P

LF

442CN

SSSR Labs MCU Chip

KOTELNIKOV 1.2

CD4042BE

KP590KH5

AD7545A

SM042, Assembly Manual

PCB Version 1.2

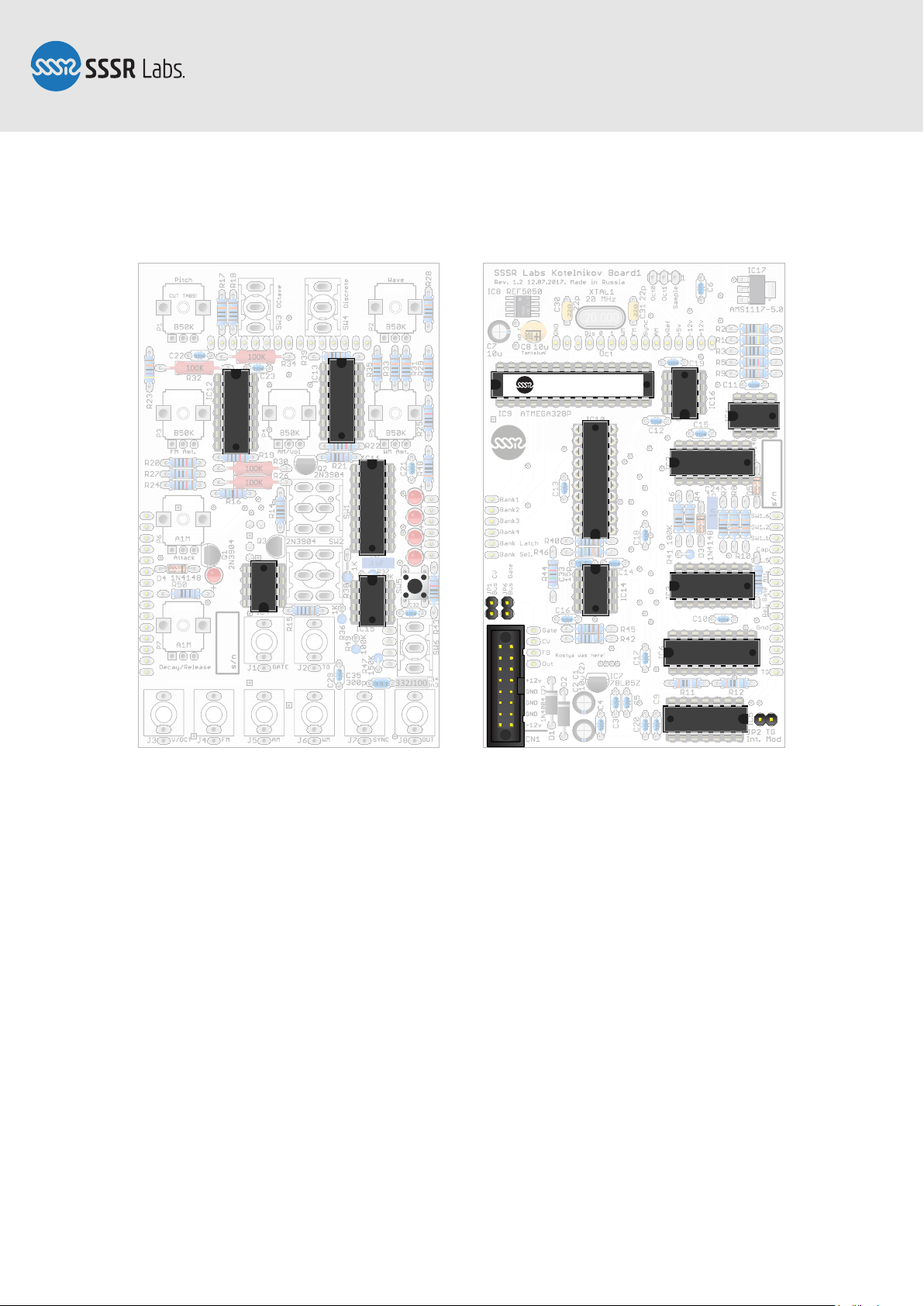

Step 11: Headers, Tactile Switch, IC

Install three 2-pin headers and wear the jumpers on. Then solder all headers.

Install the power pin-header. Notice the orientation! It’s recommended to solder two

pins in the opposite corners, then solder the remaining pins. The six pins from 3 to 8

are connected with the ground plane and require extra heating. It is also recommended to plug the power cable to prevent pins from bending if the plastic case has

started to melt due to extensive heating.

Insert all integrated circuits into their sockets. Refer to the picture for correct placement and orientation. Install and solder the tactile switch.

It’s highly recommended to clean the top sides of the boards now, before installing the

control hardware and the front panel.

Page 12 of 18

Page 13

A TI REF

5050

220

220

.1 uF

332J100

20.000

TL074CN

TL074CN

TL074CN

CD4011BE

CD40106BE

TL072P

TL072P

TL072P

LM393P

LF

442CN

SSSR Labs MCU Chip

KOTELNIKOV 1.2

CD4042BE

KP590KH5

AD7545A

SM042, Assembly Manual

PCB Version 1.2

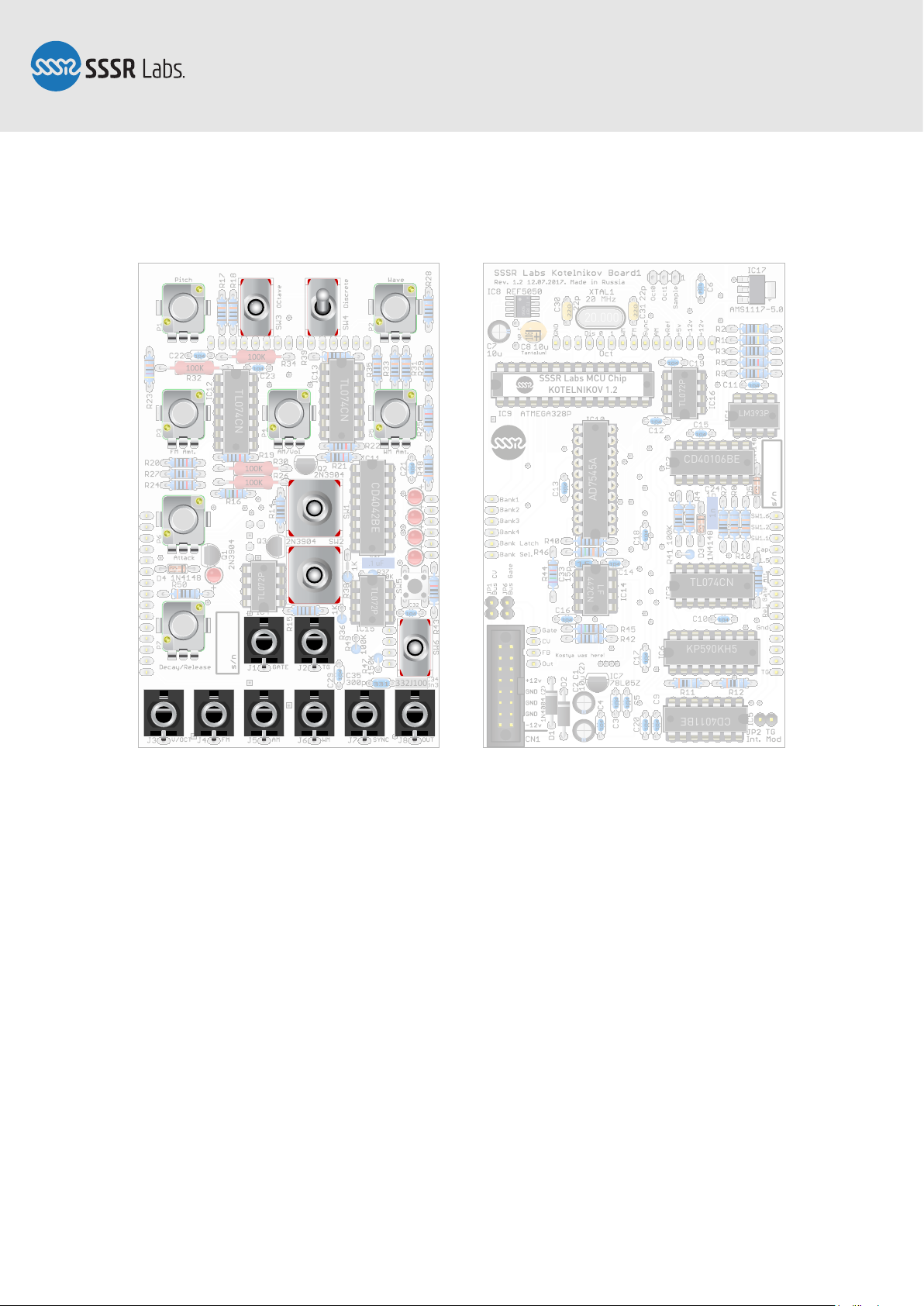

Step 12: Potentiometers, Switches, Jack Sockets

Install all potentiometers, toggle switches and jack sockets without washers and nuts.

Also, if there are fixing tabs on the potentiometers, you need to break them off with

pliers. The two 1M potentiometers must be installed in the TG area.

Page 13 of 18

Page 14

A TI REF

5050

220

220

.1 uF

332J100

20.000

TL074CN

TL074CN

TL074CN

CD4011BE

CD40106BE

TL072P

TL072P

TL072P

LM393P

LF

442CN

SSSR Labs MCU Chip

KOTELNIKOV 1.2

CD4042BE

KP590KH5

AD7545A

SM042, Assembly Manual

PCB Version 1.2

Step 13: Front Panel

Put on the panel back to its place. Since you do not longer need access to the top side

of the Board 2, you can put on and tighten all washers and nuts. Solder everything.

It is advisable to clean the Board 2 a second time, from the bottom side, but you must

do it carefully, avoiding moistening of the hardware. Any liquid inside the potentiometers, switches or jacks can cause serious performance degradation.

Page 14 of 18

Page 15

SM042, Assembly Manual

PCB Version 1.2

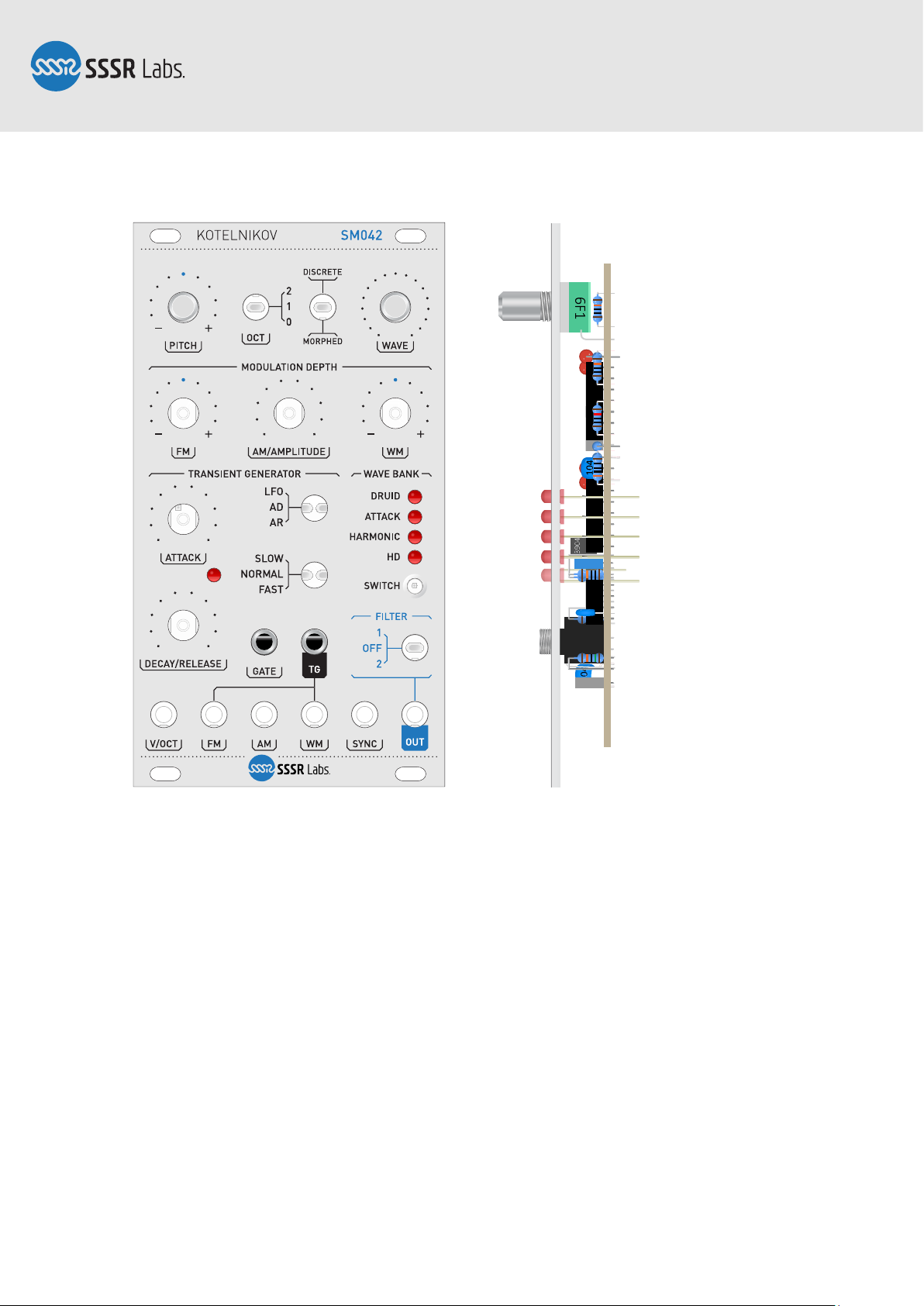

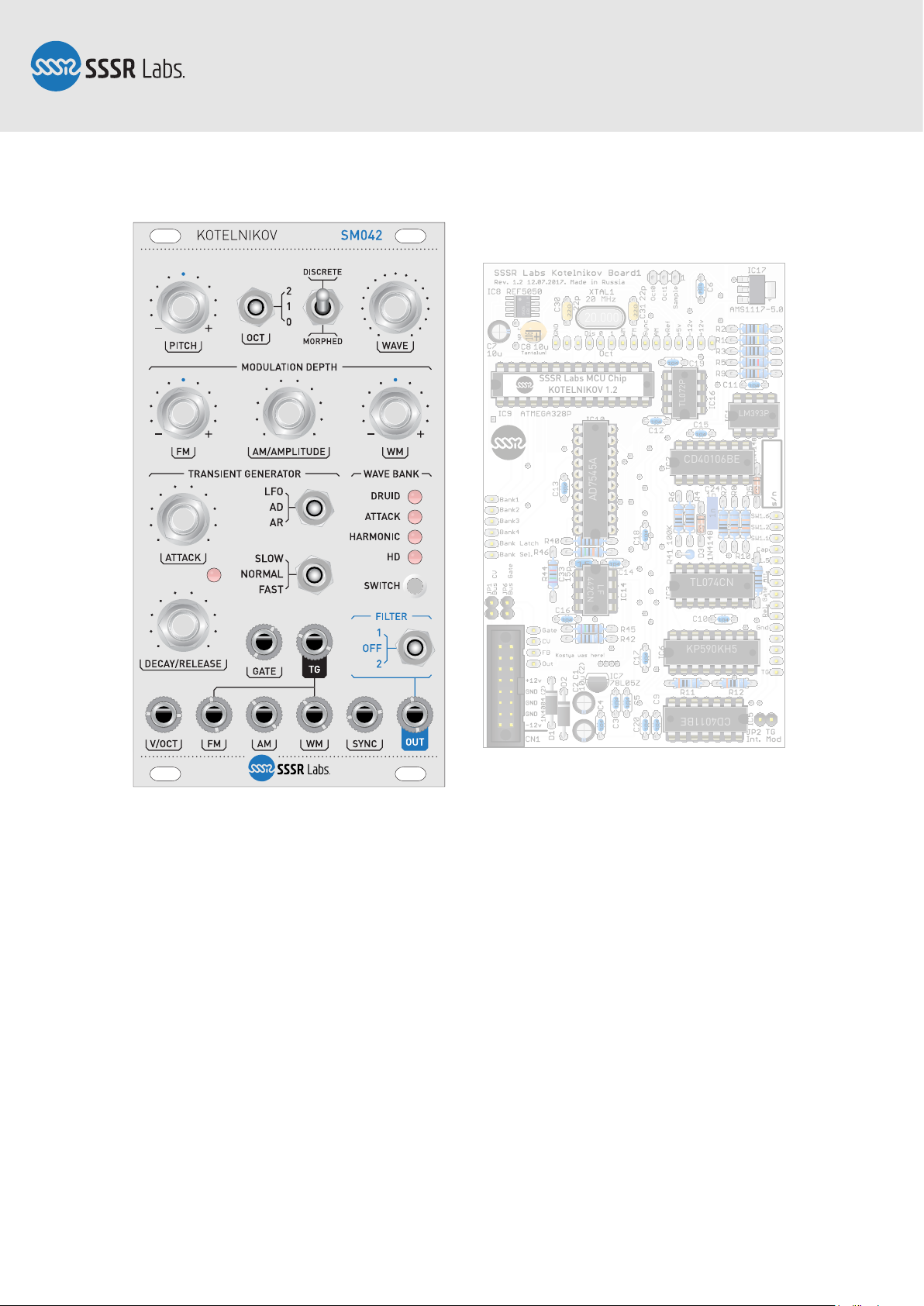

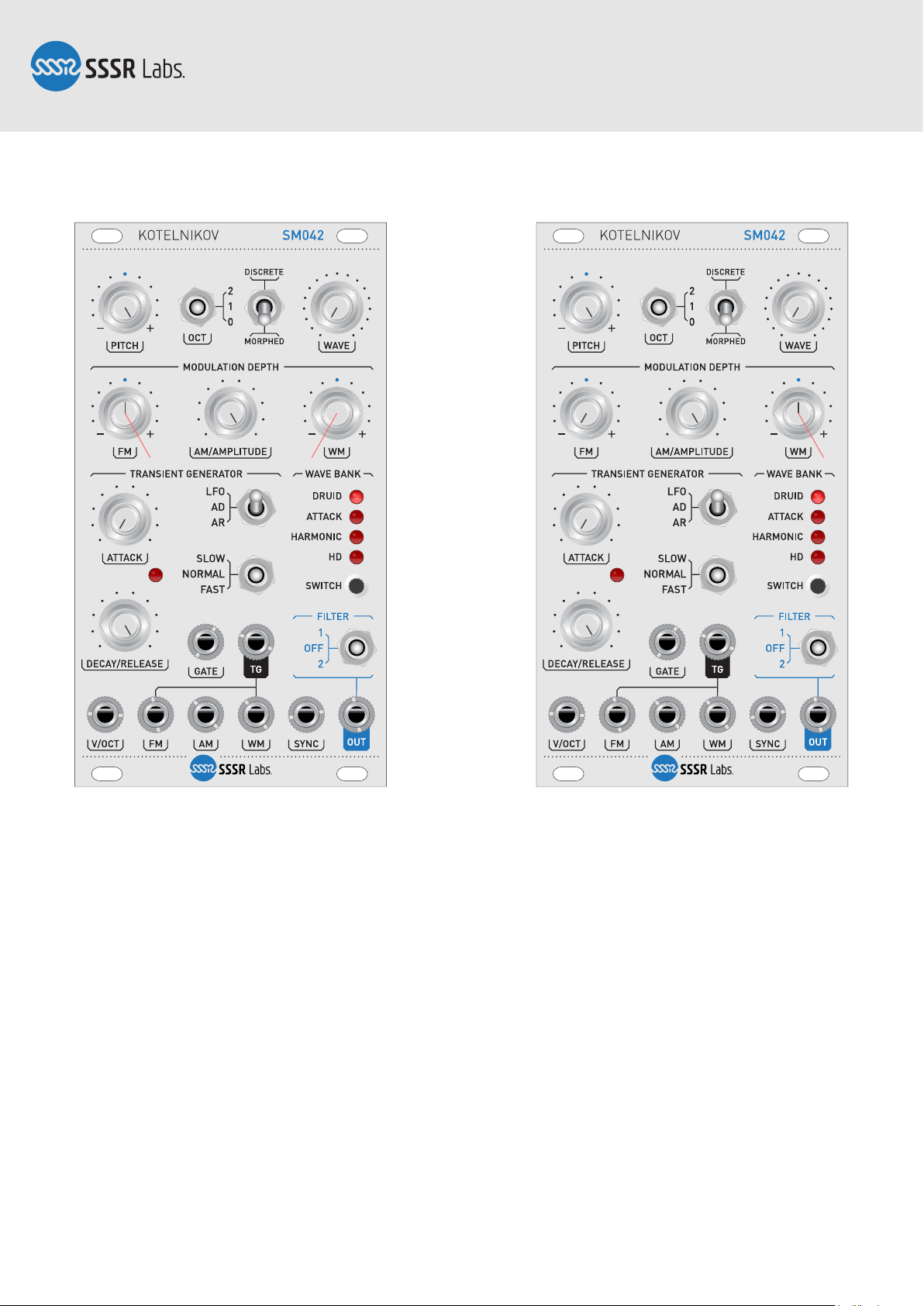

Step 14: First Power-On

The KOTELNIKOV module does not need any adjustment, but you can improve your

experience of using attenuverters if you're using round shafted potentiometers with

corresponding knobs.

Look over the module one more time and check everything you can.

Set the module to the settings pictured above. Connect the power, turn on your system

and make sure that DRUID indicator is on and TG LED is blinking. If it doesn't happen

for more than two seconds after powering-on, turn it off immediately and check for

build errors again.

If module is working as intended, you can proceed to knobs centering.

Page 15 of 18

Page 16

SM042, Assembly Manual

PCB Version 1.2

Step 15: Centering the Pitch Potentiometer

Prepare a thin permanent marker or a soft pencil. You are going to determine the

exact mid-points for all three polarized potentiometers.

For your convinience, you could also outline the pointer lines on the Wave, AM, Attack

and Decay shafts.

Set the module to the settings pictured above. Monitor the output frequency with an

oscilloscope, frequency meter, tuner or your ears and turn the Pitch shaft counterclockwise until the frequency stops changing. This will be the mid-point for the Pitch

knob. Now draw a straight line on the shaft's edge, pointing exactly to the top. Later,

this line will help you to put on the respective knob correctly.

Page 16 of 18

Page 17

SM042, Assembly Manual

PCB Version 1.2

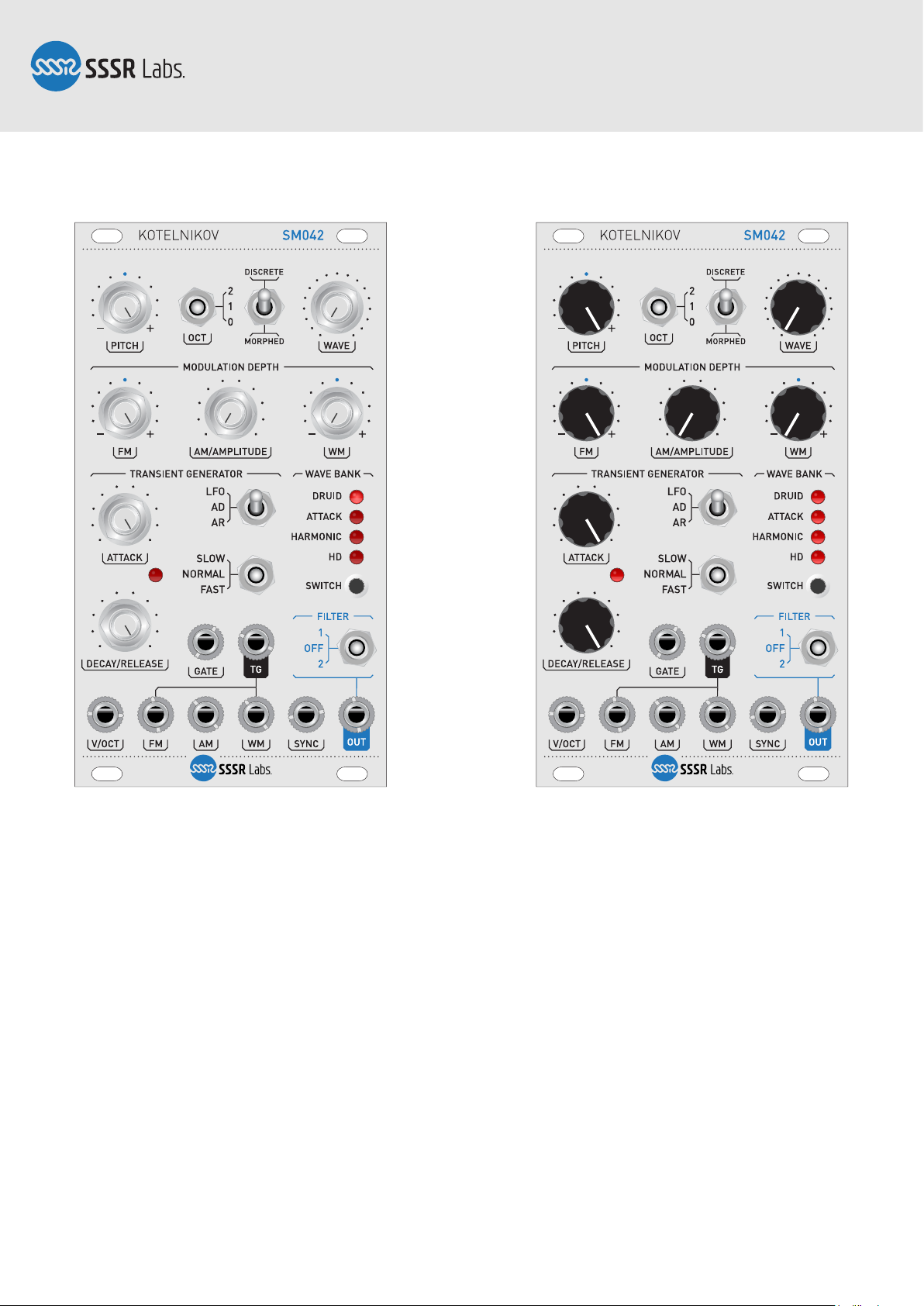

Step 16: Centering the FM and WM Potentiometers

Set the module to the settings shown on the left picture.

Module will sound like a kind of siren. Find the position of the FM shaft where frequency modulation is negligible or disappears completely. This is the mid-point for the

FM control. Outline the pointer line on this shaft.

Repeat this procedure with the WM shaft. The initial position is shown on the right

picture. The mid-point can be found using the similar procedure as for the FM shaft.

Page 17 of 18

Page 18

SM042, Assembly Manual

PCB Version 1.2

Step 17: Finishing the Build

Install the knobs. Some kits contain the D-Shaft sets of potentiometers and knobs.

Others contain the round shaft sets. If you have the round shaft set, you need to perform the following procedure. Turn all potentiometers to the position shown on the left

picture, then install each knob, one at a time, keeping it in the correct position. You

may also put the edge of a business card or other object of similar thickness under the

knob to make a little gap between the nut and the knob to prevent them from scraping

each other.

Once you have installed all knobs you are done building the module! Thank you for

purchasing an SSSR Labs product and we wish you to have a lot of fun with your new

module!

Page 18 of 18

Loading...

Loading...