SSP Series S User Manual

Series S

Stainless Steel Positive Displacement Rotary Lobe Pumps

Operating Manual

M/101/0211

EC Declaration of Incorporation

The designating company

Alfa Laval

Company Name

Birch Road, Eastbourne, East Sussex BN23 6 PQ

Address

Phone: (01323) 412555 Fax: (01323) 412515

Phone and Fax No.

We hereby declare that the following machinery is intended for installation into a machine or to be assembled with other machines

into a machine. It must not be put into service until the machinery into which it is incorporated has been declared in conformity with

the provisions of the Machinery Directive 89/392/EEC, amendments 91/368/EEC, 93/44/EEC, 93/68/EEC.

Machine Description: Rotary Lobe Pump

Type/Size:

Serial Number:

This machinery has been designed and manufactured in accordance with the following transposed harmonised European Standards:

EN292: Parts 1 and 2: 1991 Safety of Machinery - Basic Concepts, general principles for design.

EN 294: 1992 Safety distances to prevent danger zones being reached by the upper limbs.

ISO9001: 2000 Quality Management System.

A technical construction file for this machinery is retained at the above address.

Signed Date

(Authorised Person)

Name Position

P. Sweet Quality Manager

3

EC Declaration of Conformity

The designating company

Alfa Laval

Company Name

Birch Road, Eastbourne, East Sussex BN23 6 PQ

Address

Phone: (01323) 412555 Fax: (01323) 412515

Phone and Fax No.

We hereby declare that the following machinery conforms to the machinery directive 89/392/EEC as amended by 91/368/EEC,

93/44/EEC and 93/68/EEC and to the following other relevant directives. The machinery has been designed and manufactured

in accordance with the transposed harmonised European standards; European and national standards as listed:

Machine Description: Rotary Lobe Pump - Motorised

Type/Size: Serial Number:

Other Applicable Directives: Electrical Equipment Low Voltage 73/23/EEC

Electromagnetic Compatibility 89/336/EEC

This machinery has been designed and manufactured in accordance with the following transposed harmonised European Standards:

EN292: Parts 1 and 2: 1991 Safety of Machinery - Basic concepts, general principles for design.

EN294: 1992 Safety distances to prevent danger zones being reached by the upper limbs.

EN60204: Part 1: 1993 Safety of Machinery - Electrical equipment of machines - specification for general

requirements.

BS5304: 1988 Code of Practice for Safety of Machinery.

ISO9001: 2000 Quality Management System.

A technical construction file for this machinery is retained at the above address.

Signed Date

(Authorised Person)

Name Position

P. Sweet Quality Manager

5

6

Table of contents

The information contained herein is correct at the time of issue but may be subject to change without prior notice.

1. General description ............................................................................. 8

1.1 General description ........................................................................ 8

2. Safety.................................................................................................... 9

2.1 Important information ...................................................................... 9

2.2 Warning signs ................................................................................. 9

2.3 Safety precautions ........................................................................ 10

3. Installation.......................................................................................... 11

3.1 Unpacking, Handling and Storage ................................................ 11

3.2 System design and installation ...................................................... 12

3.3 Flushed seal arrangements and pre-start up checks ................... 15

3.3 Flushing seal arrangement and pre-start up checks .................... 16

4. Maintenance....................................................................................... 17

4.1 Cleaning in place (CIP) ................................................................. 17

4.2 Maintenance schedule .................................................................. 18

4.3 Disassembly.................................................................................. 19

4.4 Assembly ...................................................................................... 22

4.5 Primary seals removal and fitting .................................................. 28

4.6 Pressure relief valve ...................................................................... 34

4.7 Troubleshooting ............................................................................ 36

5. Technical data .................................................................................... 37

5.1 Technical data............................................................................... 37

6. Parts list .............................................................................................. 38

6.1 S1-3 Pump .................................................................................... 38

6.2 S4 Pump ....................................................................................... 40

6.3 S5 Pump - Horizontally Ported...................................................... 42

6.4 S5 Pump - Vertically Ported .......................................................... 44

6.5 S6 Pump - Horizontally Ported...................................................... 46

6.6 S6 Pump - Vertically Ported .......................................................... 48

7

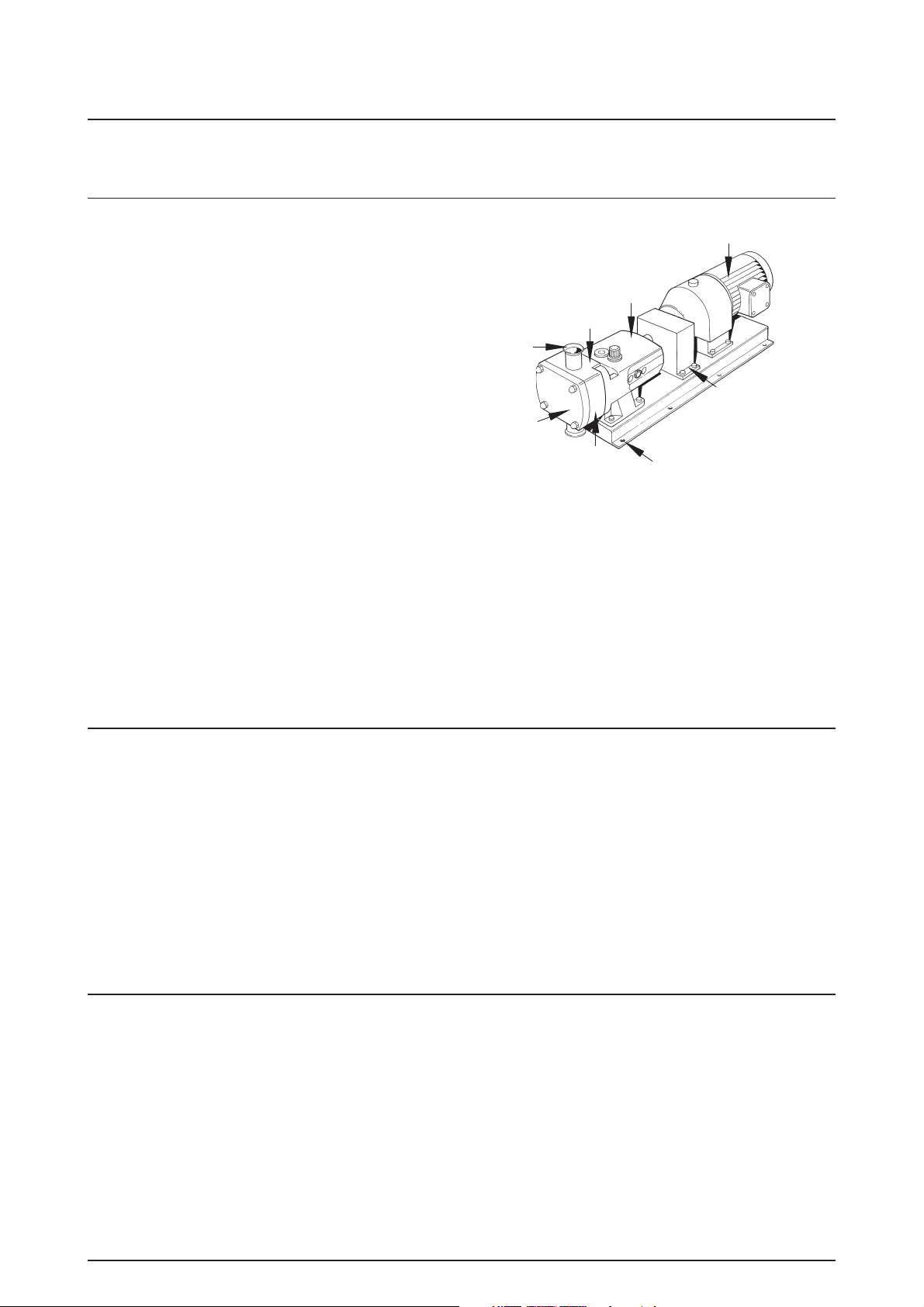

1.1 General description

The Series S pump supplied is a positive displacement rotary

lobe pump; it may be supplied with or without a drive unit (see

drawing). The drawing shown indicates various parts of the

pump unit.

1. General description

Drive unit

The Series S range has a universal gearbox design in models

S1 - 4. This enables the flexibility of mounting pumps with the

inlet and outlet ports in either a vertical or horizontal plane. The

port orientation, vertical or horizontal, may be changed by

Ports

Product

seal area

Gearbox

moving one of two available bolt-on feet on the gearbox. Port

orientation should be specified when ordering, but the

alternative foot design allows pumps that are already installed

being changed should the need arise.

Models S5 & 6 pumps can also have the inlet and outlet ports

in either horizontal or vertical plane. This is achieved by the use

Rotorcase

cover

Rotorcase

Baseplate fixing holes

Coupling guard

(encloses coupling)

of dedicated gearbox castings having either horizontal or

vertical shaft arrangements.

Pump duty conditions

The pump should only be used for the duty for which it has been specified. The operating pressure, speed and temperature limits

have been selected at the time of order and MUST NOT be exceeded. These details are stated on the original order

documentation and if not available may be obtained from your supplier quoting pump model and serial number.

Noise levels

Under certain operating conditions pumps and/or drives and/or the systems within which they are installed can produce sound

pressure levels in excess of 85dB[A]. When necessary, protection against noise should be taken.

8

2. Safety 2.1 Important information

2.2 Warning signs

Unsafe practices and other important information are emphasized in this manual.

Warnings are emphasized by means of special signs.

Always read the manual before using the pump!

WARNING!

Indicates that special procedures must be followed to avoid severe personal injury.

CAUTION!

Indicates that special procedures must be followed to avoid damage to the pump.

NOTE!

Indicates important information to simplify or clarify practices.

General warning:

Dangerous electrical voltage:

Caustic agents:

9

2.3 Safety precautions 2. Safety

All warnings in the manual are summarised on this page.

Pay special attention to the instructions below so that severe personal injury or damage to the pump are avoided.

Installation

AlwaysAlways

-

Always observe the technical data (see chapter 5).

AlwaysAlways

NeverNever

-

Never start in the wrong direction of rotation with liquid in the pump.

NeverNever

NeverNever

-

Never put your hands or fingers inside the port connections or anywhere close to rotating

NeverNever

shafts.

The pump

supplied with the drive unit).

Operation

-

-

-

-

-

OnlyOnly

Only handle toxic and acidic liquids in accordance with their manufacturers instructions and

OnlyOnly

recommendations.

Maintenance

-

- The pump must

- The pump and the pipelines must

-

AlwaysAlways

Always disconnect the power supply when the pump is being serviced.

AlwaysAlways

must must

must be electrically connected by authorised personnel (see the motor instructions

must must

AlwaysAlways

Always observe the technical data (see chapter 5).

AlwaysAlways

NeverNever

Never touch the pump or the pipelines when pumping hot liquids or when sterilising.

NeverNever

NeverNever

Never stand on the pump or pipelines.

NeverNever

NeverNever

Never run the pump with both the suction side and the pressure side blocked.

NeverNever

NeverNever

Never put your hands or fingers inside the port connections or anywhere close to rotating

NeverNever

shafts.

AlwaysAlways

Always observe the technical data (see chapter 5).

AlwaysAlways

nevernever

never be serviced when hot.

nevernever

nevernever

never be pressurised when the pump is being serviced.

nevernever

NeverNever

Never put your hands or fingers inside the port connections or anywhere close to rotating

NeverNever

shafts.

10

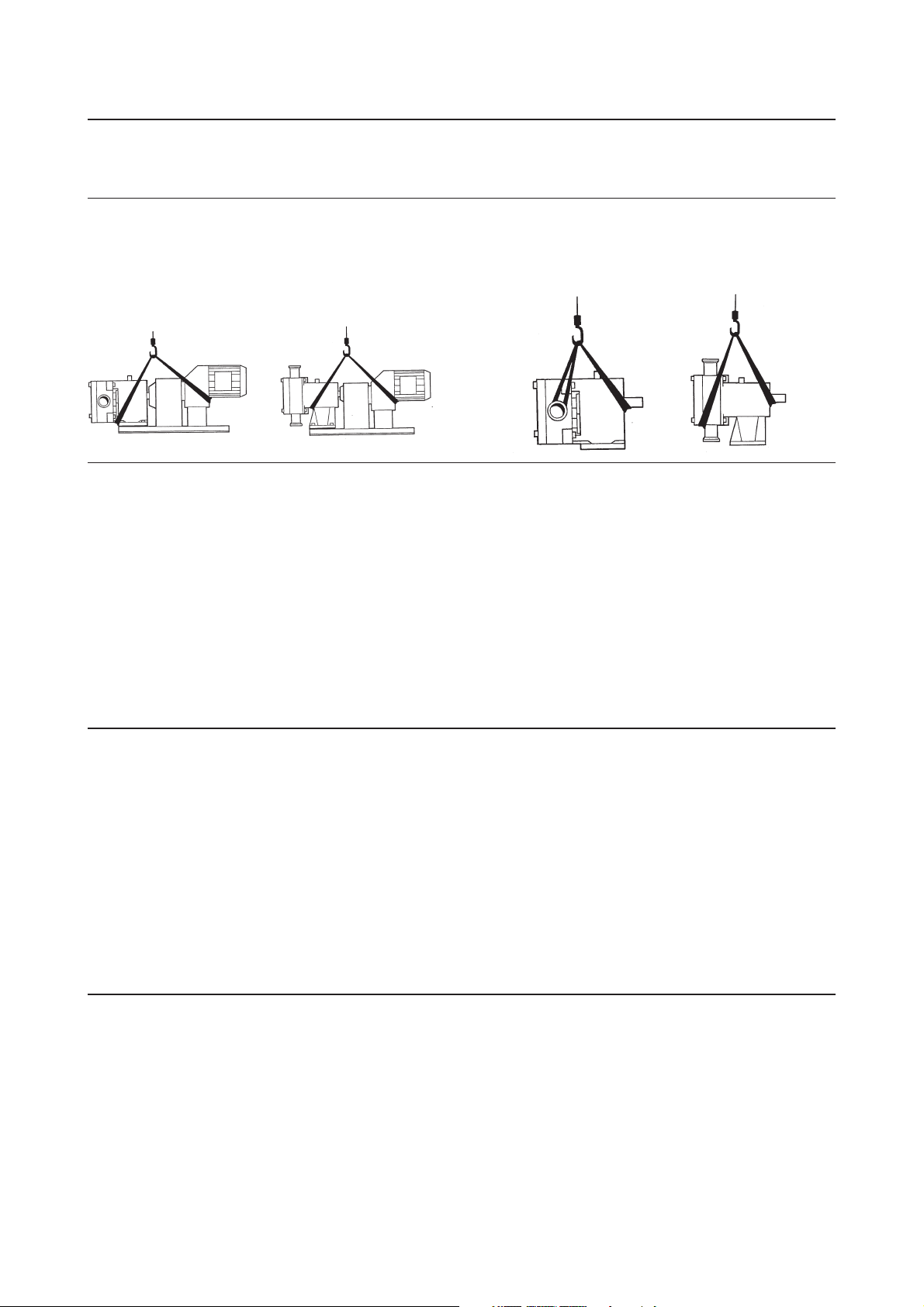

3. Installation 3.1 Unpacking, Handling and Storage

Step 1

Refer to the pump weights guide (chapter 5) before selecting and using any lifting gear. The drawings show how the pump should

be lifted.

Ensure that lifting equipment is correctly rated and used within these limits.

Pump with drive unit

Step 2

On receipt always:

- Check the delivery note against the goods received.

- If motorised, check that the drive instructions are available.

- Inspect the packing for signs of damage in transit.

- Carefully remove the packing away from the pump.

- Inspect the pump for any visible signs of damage.

- Clean away the packing from the pump port connections.

- Report any damage immediately to the carrier.

Step 3

After receipt and inspection, if the pump is not to be installed immediately, the pump should be repacked and placed in suitable

storage. The following points should be noted:

Bareshaft pump

- Plastic or gasket type port covers should be left in place.

- Pumps received wrapped with corrosion inhibiting treatment material should have wrapping replaced.

- A clean, dry storage location free from vibration should be selected. If a moist or dusty atmosphere is used for storage, further

protect the pump or unit with a suitable cover.

- Rotate the pump/pump unit by hand weekly, to prevent bearing damage.

- All associated ancillary equipment should be treated similarly.

11

3.2 System design and installation 3. Installation

Step 1

When designing the pumping system:

- Confirm the Net Positive Suction Head requirements of the

pump (NPSHr) are met by the system, as this is crucial for

ensuring the smooth operation of the pump and

preventing cavitation.

- Avoid suction lifts and manifold/common suction lines for

two pumps running in parallel, as this may cause vibration

or cavitation.

- Protect the pump against blockage from hard solid

objects e.g. nuts, bolts etc. Also protect the pump from

Plan view

accidental operation against a closed valve by using one of

the following methods: - relief valves, pressure switch, and

current limiting device.

Step 2

Before the pump is installed it is advisable to consider the following:

Always

- ensure that the mounting surface is flat to avoid distortion of the baseplate, as this will cause pump/motor shaft misalignment

and pump / motor unit damage.

Check

- pump shaft to motor shaft alignment is within manufacturers limits once the base plate has been secured.

Always allow at least 1 m for pump access / maintenance all around the pump.

- Fit suction and discharge pressure monitor points for diagnostic purposes.

- Fit valves if two pumps are to be used on manifold/common discharge lines.

- Make the necessary piping arrangements if flushing is required for the seal or if media is required for heating/cooling jackets.

- Do not subject the pump to rapid temperature changes. Pump seizure can result from thermal shock.

Discharge line

Suction line

Step 3

All pipework must be supported. The pump must not be allowed to support any of the pipework weight beyond the limits set in

the following table.

Remember:

Pipework supports must also support the weight of the product being pumped.

Always:

- Design short straight suction lines to reduce friction losses in the pipework thereby improving the NPSH available from the

system.

- Avoid bends, tees and any restrictions close to either suction or discharge side of pump. Use long radius bends wherever

possible.

- Provide isolating valves on each side of the pump to isolate the pump when necessary.

- Keep pipework horizontal where applicable to reduce air locks. Include eccentric reducers onsuction lines.

Plane ‘X’

Plane ‘Z’

12

Plane ‘Y’

3. Installation 3.2 System design and installation

Step 3 - continued

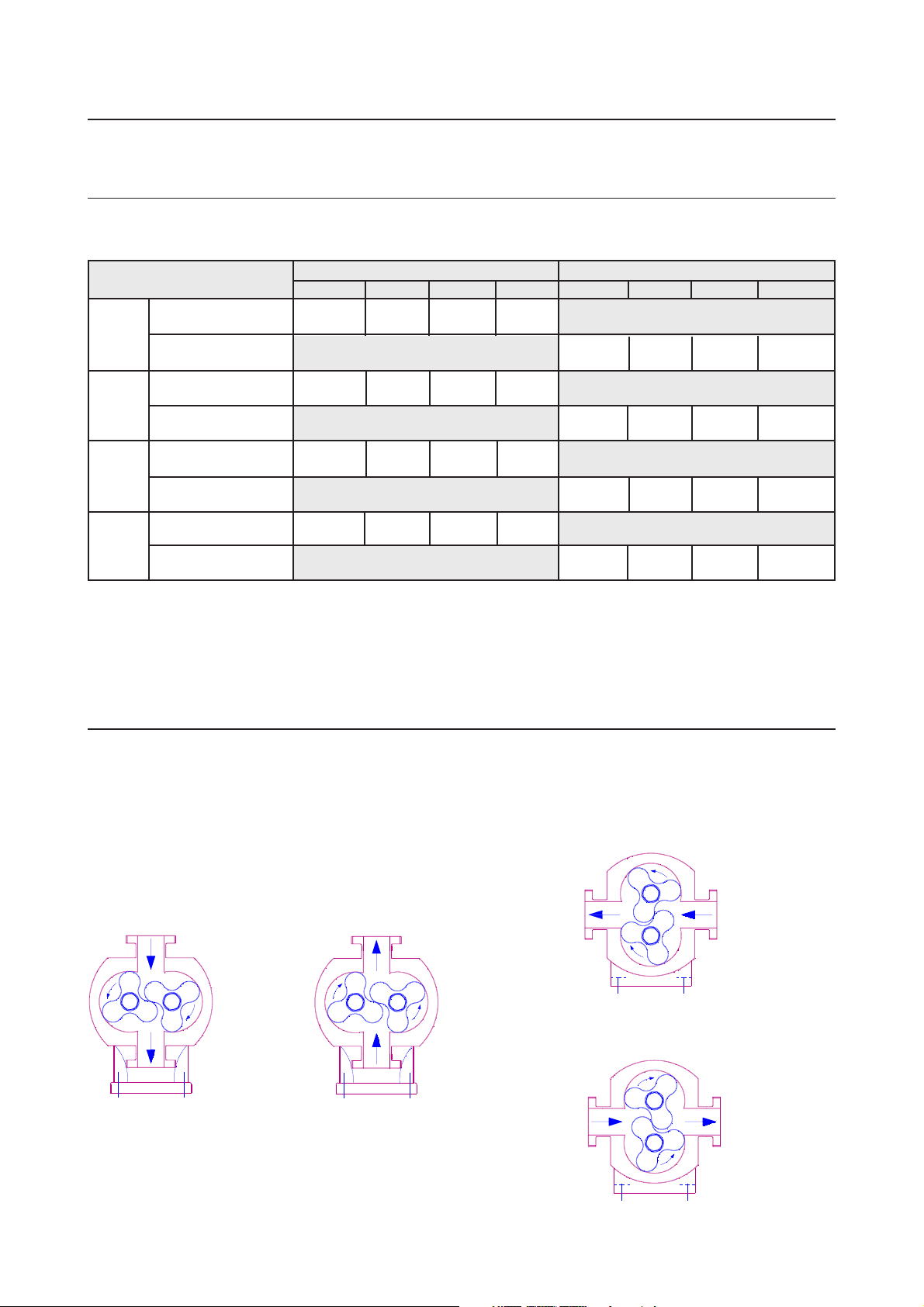

Table of Maximum Forces and Moments

Pump Forces Moments

Model FZ FY FX EF MZ MY MX EM

S1 Forces N 80 60 70 120

lbf 18 13 16 27

Moments Nm 75 90 115 165

lbft 55 66 85 122

S2 Forces N 125 100 110 195

lbf 28 22 25 44

Moments Nm 90 105 130 190

lbft 66 77 96 140

S3/4 Forces N 165 135 150 260

lbf 37 30 34 58

Moments Nm 100 115 140 205

lbft 74 85 103 151

S5/6 Forces N 300 250 250 460

lbf 67 56 56 103

Moments Nm 125 145 175 260

lbft 92 107 129 192

Step 4

The direction of flow is dictated by the direction of rotation of the drive shaft. Reversing the direction of rotation will reverse the

flow direction.

Suction Discharge

SuctionDischarge

Discharge

Suction

DischargeSuction

13

3.2 System design and installation 3. Installation

Step 5

The pump will not be supplied pre-filled with oil therefore this

table must be used to select recommended oil.

Oil changing: Oil level must be checked with the pump static.

First change: After 150 hours of operation, thereafter every

3000 hours of operation.

Oil filling: Fill with oil through the filler plug to the level indicated

in the sight glass.

NOTE!

On horizontally ported pumps the sight glass must be fitted to

the upper hole on the side of the gearcase.

Refer to technical data (chapter 5) for oil quantities required.

-20°C to +130°C +130

(-4°F to +266°F (+266°F to 392°F)

BP Energol GR - XP150 BP GRS15

Castrol Alpha SP150 Castrol Alpha SN150

Mobil Gear 629 Mobil Glycoyle 30

Shell Omala 150 Shell Tivela WA

Texaco Meropa 150 Texaco Synlube SAE90

Esso Spartan EP150 Esso IL1947

Pump Operating Temperature

o

C to 200°C

14

3. Installation 3.3 Flushed seal arrangements

and pre-start up checks

Step 1

A flushed seal arrangement is fitted in order to cool or clean the seal area.

It is important that:

- The flush is correctly connected (see below).

- A compatible flushing fluid is used and supplied at the correct pressure and flow rate.

- The flush is turned on at the same time/prior to starting the pump, and turned off at the same time/after stopping the

pump.

Step 2

Connecting the flush

The following equipment is strongly recommended when using a flushing system:

- Control valve and pressure gauge, to enable the correct flushing pressure to be obtained and monitored.

- Isolation valve and check valve, so that the flush can be turned off, and to stop any unwanted substances flowing in

the wrong direction.

- A method of visibly indicating flushing fluid flow.

Step 3

Flusing pipework

This suggested arrangement is for single mechanical seals. If

the pump is fitted with double mechanical seals or packed

glands the pressure gauges and control valves should be

fitted on the outlet side of the system.

Suggested visible indication of flow

Pipework & fittings not normally supplied by

pump manufacturer

Control valve

Check valve

Isolation valve

Flush inlet

Control

valve

Flush outlet to waste

Pressure gauge

Pressure gauge

Double mechanical

seal/packed gland

only

15

Loading...

Loading...