SSP A9 Series, A9-2270, G9 Series, G9-2270, A9-1507 Operating Manual

...

M/104B/0411

Series A&G 9

Stainless Steel and Ductile Iron

Positive Displacement Rotary Lobe Pumps

Operating Manual

Alfa Laval Ltd

Birch Road, Eastbourne,

East Sussex BN23 6PQ

Tel No : (01323) 412555 Fax (01323) 412515

ISO9001: 2000 Quality Management System.

Alfa Laval Ltd

Birch Road, Eastbourne,

East Sussex BN23 6PQ

Tel No : (01323) 412555 Fax (01323) 412515

ISO9001 : 2000 Quality Management System.

Depending upon the pumping system and duty

condition the pump noise levels may vary. The

sound pressure level measurement stated is

given fortypical pumps/pump units at maximum

pressures/speeds, the results being taken on

water at ambient temperature:-

Recorded sound pressure level :- 85 dB(A):

(Ref 20uPa).

Note :- Readings taken in accordance with

ISO3746.

Electrical Supply :-

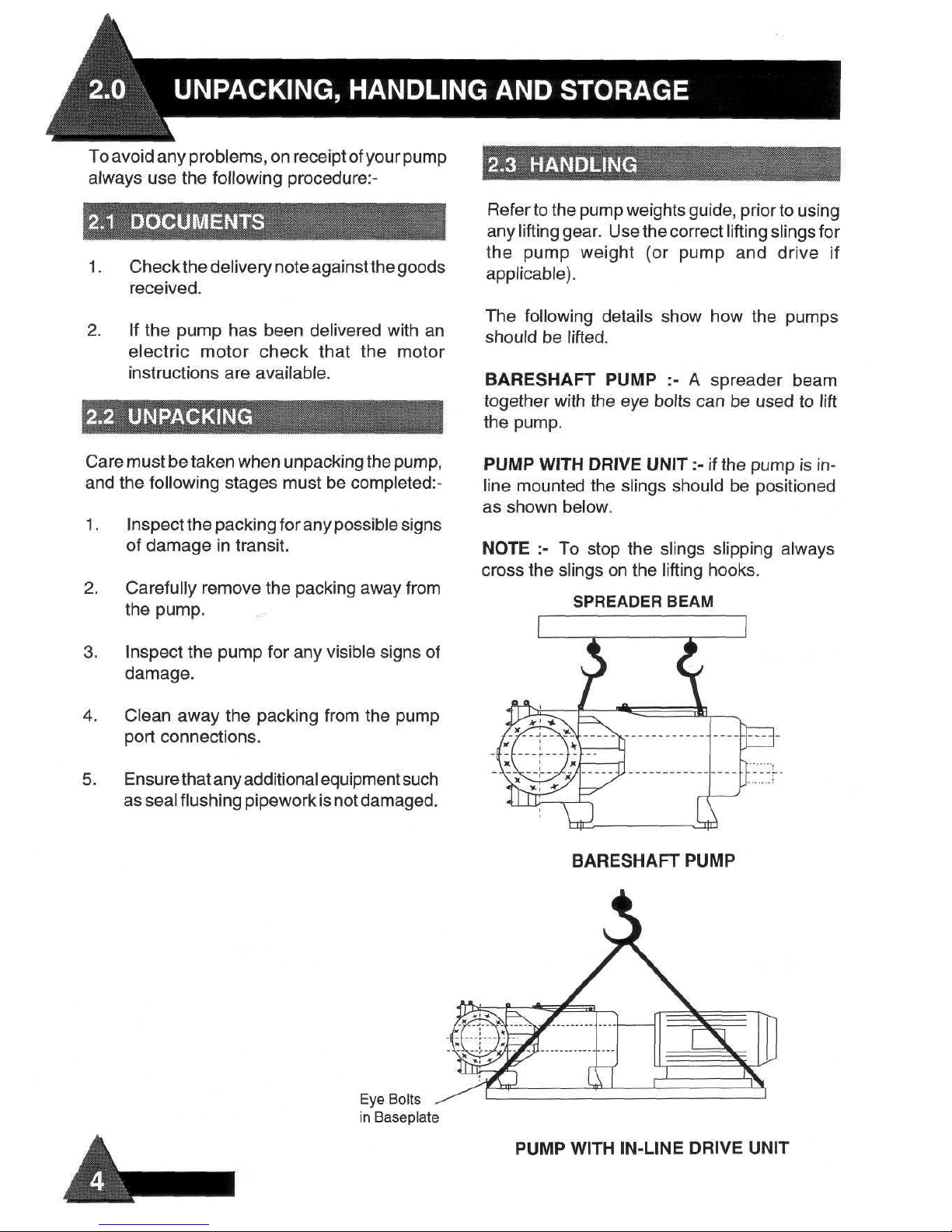

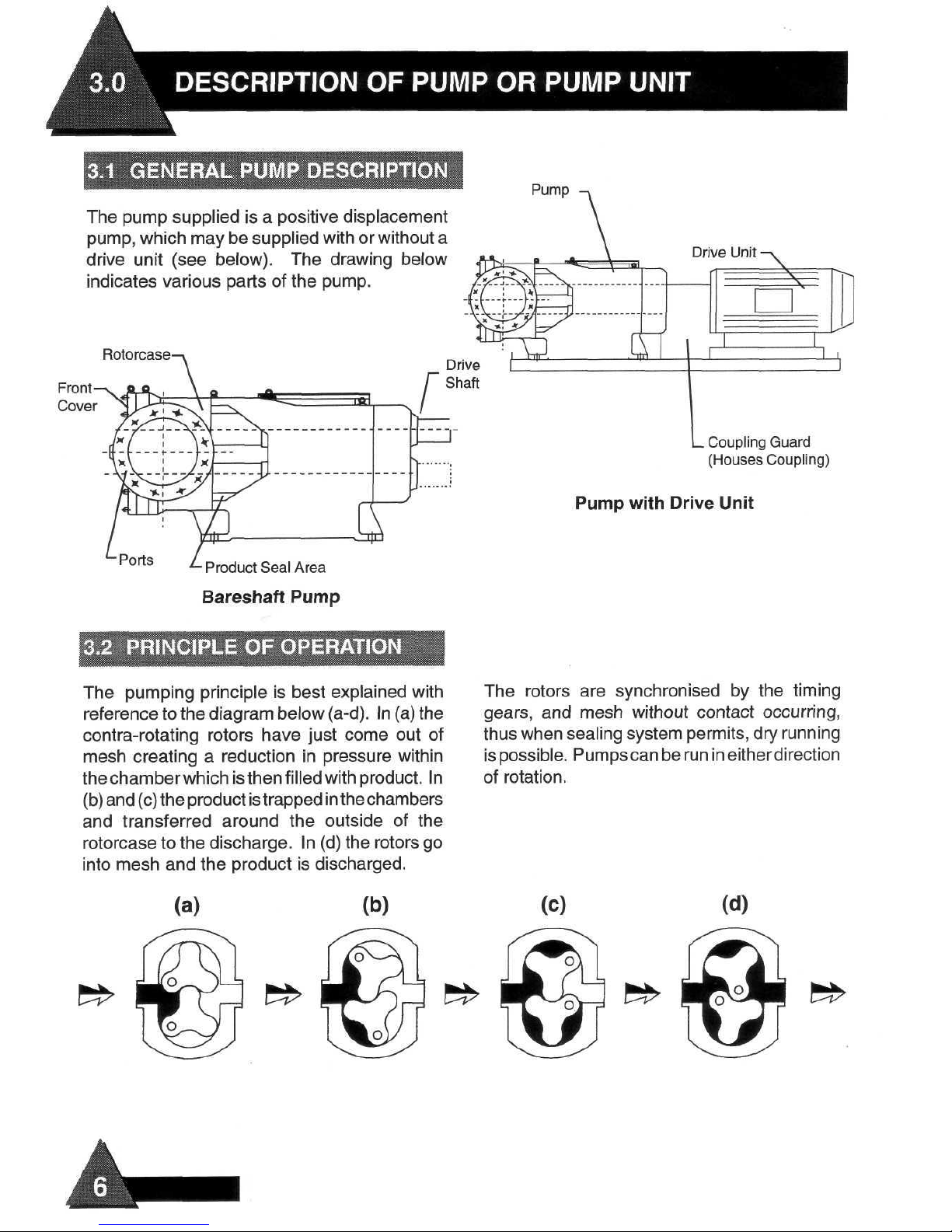

This pump may be supplied bareshaftorcoupled

to a drive unit for which a drive unit/electrical

supply will be required.

Note : The pump may be also driven by a

diesel/petrol drive unit.

Water Supply :-

Additional watersupplies may be required if the

pump is fitted with a product seal flushing

arrangement. Consult your supplier for flush

fluids compatible with products pumped.

The pump should only be used for the duty for

which it has been specified. The operating

pressure, speed and temperature limits have

been selected at the time of order and MUST

NOT be exceeded for the pump. These details

are stated on the original documentation and if

not available may be obtained from yoursupplier

quoting :- pump model and serial number.

This range of pumps has been designed to

offer a variety of duties including :-

Series G - general industrial, sewage and

effluent sludge transfer.

Series A - for hygienic and anti-corrosive

duties.

Pressures of up to 10 bar, speeds to 500 rpm

and temperatures to 200°C can be obtained on

this range of pumps depending on pump model/

size. These conditions cannot always be

obtained simultaneously. The model type/size

will be shown on the nameplate positioned on

the pump.

The pump/pump unit will have been selected

from the pump users specific application when

known and the pump serial number will relate

to this.

If the user has not specified the pumping

application or needs to change it, it is important

to confirm that the materials of construction

and product seals are compatible with the

pumping application and that adequate NPSH,

speed, pressure etc is available.

It is therefore strongly recommended that the

usercontact the supplierquoting:-pump model/

size, serial number and system details (eg

product, pressure, flow rate etc).

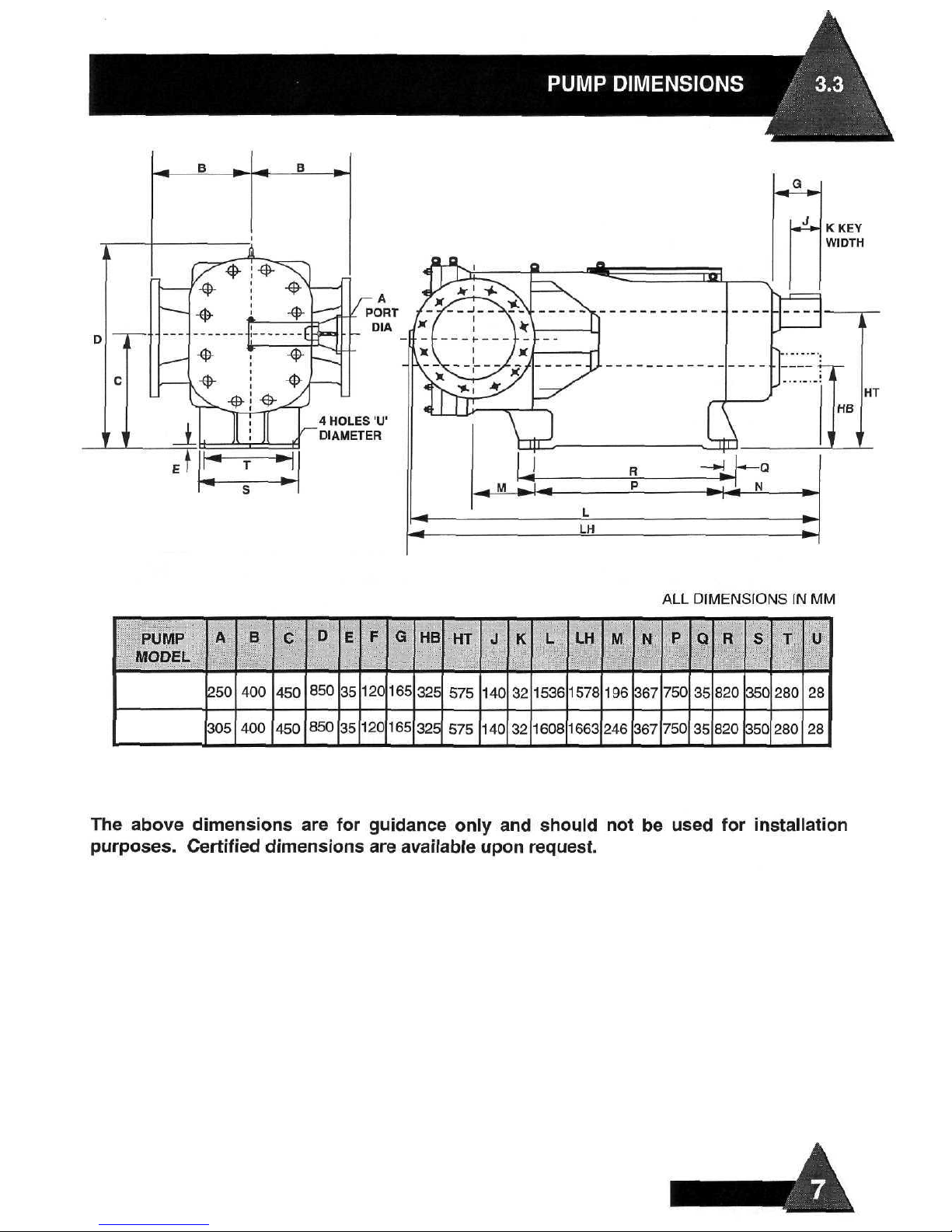

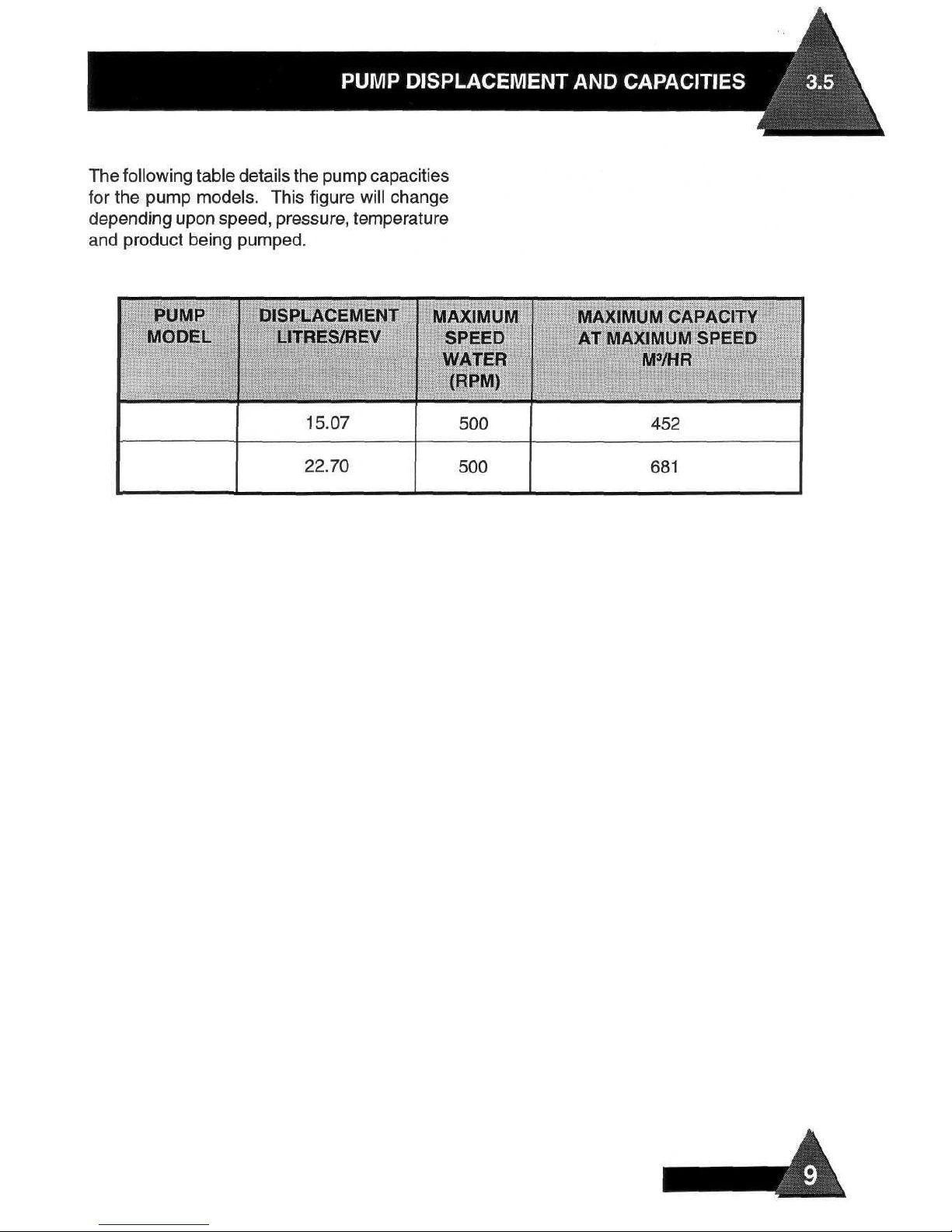

A9/G9-1507

A9/G9-2270

A9/G9-1507

A9/G9-2270

1362

1410

2000

2100

A9/G9-1507

A9/G9-2270

Loading...

Loading...