Page 1

Operations Manual

SDS Data Logger

MODEL SDS 8020/8040

Universal Data Logger

Please read, understand, and follow these instructions before operating this equipment.

Super Systems, Inc. is not responsible for damages incurred due to a failure to comply with these

instructions. If at any time there are questions regarding the proper use of this data logger, please

contact us at (800) 666-4330 for assistance.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060 / 800-666-4330

Fax: 513-772-9466

www.supersystems.com

Super Systems Inc. Page 1 SDS Data Logger Manual #4565 Rev D

Page 2

Table of Contents

Product Overview _____________________________________________________________________________ 5

Product Description ________________________________________________________________________ 5

Product Specifications ______________________________________________________________________ 5

Software Installation _______________________________________________________________________ 6

Calibration _______________________________________________________________________________ 6

Getting Started ____________________________________________________________________________ 7

Analog Inputs _____________________________________________________________________________ 7

Thermocouple connections _________________________________________________________________ 7

Voltage connections ______________________________________________________________________ 7

4 – 20 mA. Current Loop connections ________________________________________________________ 7

Survey Templates __________________________________________________________________________ 8

Installation _________________________________________________________________________________ 10

Installing the SDS Software ________________________________________________________________ 10

Connecting The SDS Data Logger To A Network ______________________________________________ 11

SDS 8020/8040 Data Logger ___________________________________________________________________ 13

Menu List _______________________________________________________________________________ 13

Keypad Assignments ______________________________________________________________________ 16

1. Overview Display _____________________________________________________________________ 17

2. Display Survey Information _____________________________________________________________ 17

3. Display Input Settings __________________________________________________________________ 18

4. Display Input Offsets __________________________________________________________________ 19

5. Display Logged Data___________________________________________________________________ 19

6. Help ________________________________________________________________________________ 20

7. Select Input Channels __________________________________________________________________ 20

8. Modify Input Settings __________________________________________________________________ 21

9. Modify Input Offsets ___________________________________________________________________ 22

10. Select Survey Template ________________________________________________________________ 22

11. Battery Status _______________________________________________________________________ 23

12. About/Sign-On ______________________________________________________________________ 24

13. Revision Display _____________________________________________________________________ 24

14. Set Display Values ___________________________________________________________________ 25

15. Language/Lengua ____________________________________________________________________ 25

16. Quick Chart _________________________________________________________________________ 26

17. Overview Display Selected _____________________________________________________________ 26

18. Quick Chart Setup ____________________________________________________________________ 27

19. Modify Survey Information ____________________________________________________________ 27

20. Set the Date and Time _________________________________________________________________ 28

21. Port Setup __________________________________________________________________________ 29

22. Input Calibration _____________________________________________________________________ 29

TC Type mV Range Chart ______________________________________________________________ 30

23. Cold Junction Trim ___________________________________________________________________ 31

Firmware revision 1.09 or below _________________________________________________________ 32

Firmware Revision 1.10 and above _______________________________________________________ 33

Firmware Revision 1.11 and above _______________________________________________________ 34

Super Systems Inc. Page 2 SDS Data Logger Manual #4565 Rev D

Page 3

To Perform a Cold Junction Calibration____________________________________________________ 34

24. System Setup ________________________________________________________________________ 35

25. Set Pass Codes ______________________________________________________________________ 36

26. Set IP Address _______________________________________________________________________ 36

32. Survey Deviation Alarm Log ___________________________________________________________ 37

34. Clear Logged Data ___________________________________________________________________ 37

SDS Software _______________________________________________________________________________ 39

SDS Reporter ____________________________________________________________________________ 39

File Menu Options ________________________________________________________________________ 39

File Æ New / New Button_________________________________________________________________ 39

File Æ Open / Open Button _______________________________________________________________ 40

Manually Creating a Survey Record _________________________________________________________ 42

File Æ Save / File Æ Save As / Save Button __________________________________________________ 52

File Æ Export __________________________________________________________________________ 52

File Æ Print ____________________________________________________________________________ 52

Print Button ____________________________________________________________________________ 54

File Æ Print Preview _____________________________________________________________________ 54

File Æ Exit ____________________________________________________________________________ 54

SDS Menu Options ________________________________________________________________________ 54

SDS Æ Manage Survey Templates __________________________________________________________ 54

SDS Æ Download Surveys and Data ________________________________________________________ 55

SDS Æ Launch Direct FTP ________________________________________________________________ 58

FTP Login For Access to the A Drive ________________________________________________________ 60

SDS Æ View Real-time Data ______________________________________________________________ 61

SDS Æ Manage Survey Records ___________________________________________________________ 63

SDS Æ Perform Comms Test ______________________________________________________________ 65

Options Menu Options ____________________________________________________________________ 67

Options Æ Multiple SDS Mode ____________________________________________________________ 67

Options Æ Show Labels On Chart __________________________________________________________ 67

Help Menu Options _______________________________________________________________________ 67

Help Æ Check for Updates ________________________________________________________________ 67

Help Æ About __________________________________________________________________________ 68

SDS Data Tags ___________________________________________________________________________ 69

Creating a Personalized Template ___________________________________________________________ 74

SDS Template Manager ___________________________________________________________________ 77

SDS Reporter Versions 1.101.0.71 and below __________________________________________________ 77

Description/Function of Template Manager Screen buttons/menu options _________________________ 77

New Button / File Î New ______________________________________________________________ 77

Open Button / File Î Open _____________________________________________________________ 78

Save Buttons / File Î Save _____________________________________________________________ 79

File Î Save As _______________________________________________________________________ 79

Exit Button / File Î Exit _______________________________________________________________ 80

Add New Template Button ______________________________________________________________ 80

Save Changes to Template Button ________________________________________________________ 81

Delete Template Button ________________________________________________________________ 82

Description of Template Manager Screen Tabs ________________________________________________ 83

Template Information Tab ______________________________________________________________ 83

Survey Information Tab ________________________________________________________________ 84

Active TCs Tab ______________________________________________________________________ 85

Controller Information Tab _____________________________________________________________ 86

Super Systems Inc. Page 3 SDS Data Logger Manual #4565 Rev D

Page 4

SDS Reporter Versions 1.101.0.76 and above __________________________________________________ 87

Description/Function of Template Manager Screen buttons/menu options _________________________ 87

New Button / File Î New ______________________________________________________________ 87

Open Button / File Î Open _____________________________________________________________ 87

Save Buttons / File Î Save _____________________________________________________________ 88

File Î Save As _______________________________________________________________________ 88

Exit Button / File Î Exit _______________________________________________________________ 89

Add Template Button __________________________________________________________________ 89

Delete Button ________________________________________________________________________ 89

Copy Button _________________________________________________________________________ 89

Arrow Buttons _______________________________________________________________________ 89

Description of Template Manager Screen Tabs ________________________________________________ 90

Template Information Tab ______________________________________________________________ 90

Survey Information Tab ________________________________________________________________ 91

Active TCs Tab ______________________________________________________________________ 92

Controller Information Tab _____________________________________________________________ 93

Description of Template Manager Screen Fields _____________________________________________ 94

Notes ___________________________________________________________________________________ 95

Appendix A – Standard Calibration Range _______________________________________________________ 97

Revision History _____________________________________________________________________________ 98

Super Systems Inc. Page 4 SDS Data Logger Manual #4565 Rev D

Page 5

PPrroodduucctt OOvveerrvviieeww

Product Description

You’ll find all the necessary information related to how to use the product in this manual. The product is

broken up into 2 parts, the software and hardware components. This user guide is also written in this

manor.

SDS8020 / SDS8040 provides the hardware and software needed to meet industry standards for

thermocouple uniformity by logging and generating temperature and data log reports.

It is easy to use and addresses the many industrial applications where datalogging, trending, and

reporting is required. The product is available in either the 20 or 40-channel version with user-defined

inputs for each channel.

The easy to use Survey Template and Report Manager provides users with all the necessary tools to

generate uniformity reports. The Report Manager includes a report writer that allows the user to setup

reports to meet their specific requirements. The Template Manager allows survey specific data to be

created, updated and used during the reporting process. All reports can be printed, saved electronically

and emailed using the software utilities. The SDS software tools along with the data logger, combine to

create a powerful solution for data logging and reporting temperature uniformity surveys.

Product Specifications

• User defined “logging” intervals as frequently as 10 seconds

• Isolated inputs

• AC ( 90 – 240 V) and DC Power

• Rechargeable battery – Approximately 12 hours of “runtime”

• Dimensions: 16”D X 20”L X 8”H

• Password protected menu options

• Easy calibration

• Web-page enabled real-time view

• ETHERNET and RS232 serial communications

• 16-Bit A/D converter

• 128 Mbytes of on-board data

Super Systems Inc. Page 5 SDS Data Logger Manual #4565 Rev D

Page 6

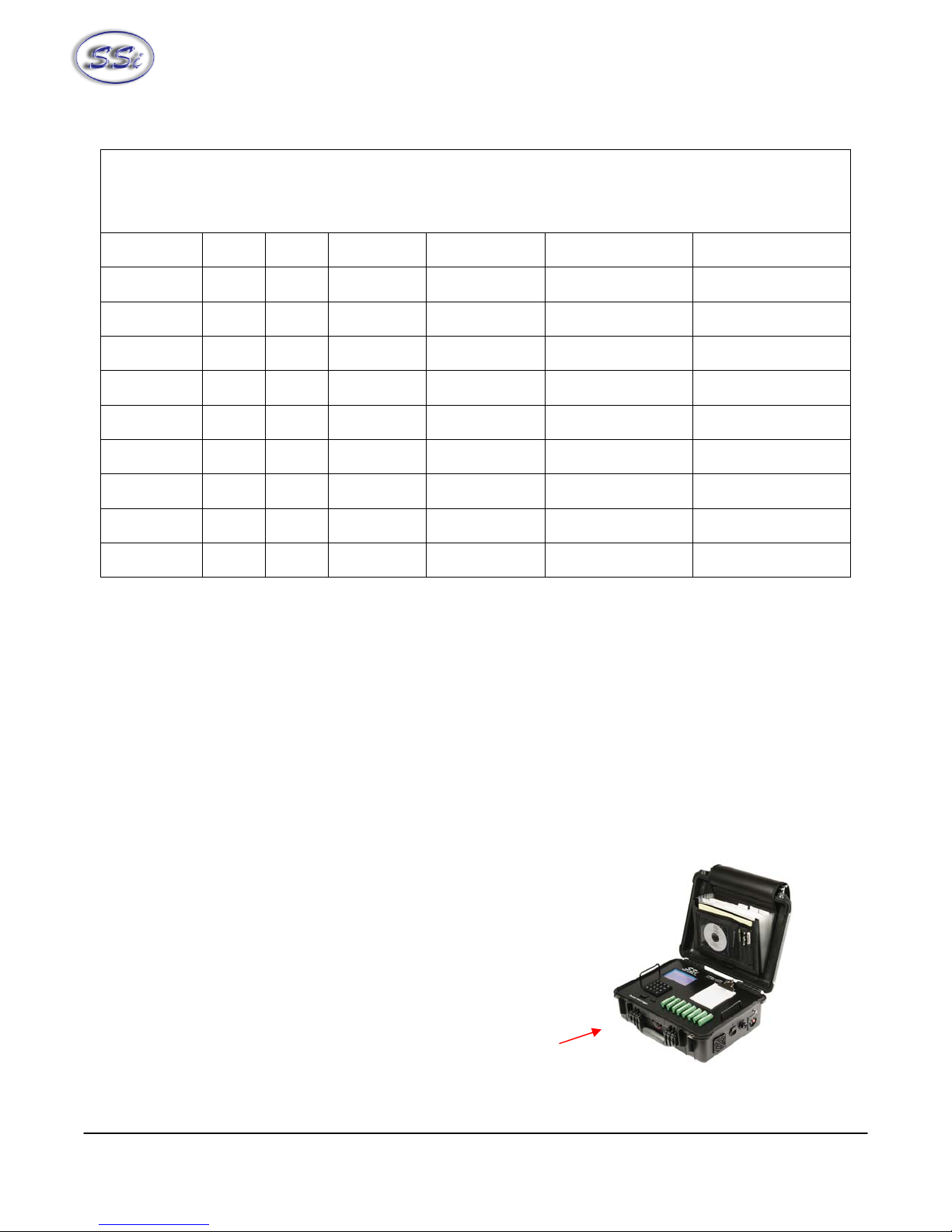

Degrees F. A/D Accuracy Accuracy Accuracy

TC Type Min Max Full scale Full Scale At 1600 Degrees F.

B 32 3308 0.0124% 0.0179% 0.29 0.65

C 32 4208 0.0062% 0.0067% 0.11 0.47

E -328 1832 0.0031% 0.0032% 0.05 0.41

J -346 2192 0.0031% 0.0036% 0.06 0.42

K -328 2502 0.0031% 0.0045% 0.07 0.43

N -328 2372 0.0031% 0.0052% 0.08 0.44

NNM 0 1409 0.0031% 0.0033% 0.05 0.41

R -58 3214 0.0062% 0.0118% 0.19 0.66

S -58 3214 0.0124% 0.0133% 0.21 0.57

T -328 752 0.0062% 0.0119% 0.19 0.55

At 1600 Degrees F with

thermister error

*** Note: Accuracy at 1600 Degrees F with thermister error requires SDS firmware level 1.10 or later ***

Software Installation

You will find the SDS Recorder software CD that ships with the unit includes all the reporting and

administrative utilities. Insert the CD into the CD ROM device on your computer and click the setup.exe

file. You will be given a step-by-step instruction for completing the installation process. See

SDS Software

section for more details.

Installing the

Calibration

The SDS data logger is calibrated prior to shipment. The

calibration process is available through menu option 22 on the

data logger. Instructions for calibration are included in this

manual. Super Systems calibrates the SDS data logger using

NIST traceable instruments that are listed on the calibration

certificate included with the device. The default calibration is

performed using a zero and span routine for the millivolt range of

0 – 80mV. Each range that is being used should be calibrated.

For a list of suggested mV ranges by thermocouple types, please

refer to the section on Input Calibration in the manual. Other

calibration ranges are available upon request.

An input device will be used to input a specific type K

thermocouple value and the data logger value will be recorded.

This will be performed at different temperatures and printed with the certificate.

Super Systems Inc. Page 6 SDS Data Logger Manual #4565 Rev D

Page 7

Getting Started

When logging data, the operator will use the on-board display to start and stop the data logging / survey

process. The first steps related to data logging are connecting the inputs to the terminal strips on the

data logger. Each terminal strip represents a single analog board with 5 inputs. You can remove these

terminal strips by pulling up on both ends of the terminal strip.

Depending on the model number, you have either 20 or 40 input channels for data logging. For each

channel there will be a positive and negative connection which must be attached to the appropriate input.

The operator defines an input type for each channel. This is performed through menu option 8 (

Input Settings

Once the inputs have been connected, the operator

selects which inputs will be included in the survey.

This is done in 2 ways. The template provides

operators with input selection but can be updated on

the data logger using the

When a template has been selected, the input

channels setup for the template, as defined in the

Template Manager, will be the selected channels for

the survey. As mentioned, this can be updated using menu option 7

select a template prior to running a survey. If you want to create new templates, please see

section

Analog Inputs

The Super Systems, Inc. 31541 Analog Board contains a group of five channels isolated from the main

DC power source. The board can be connected to thermocouples, voltage sources from 20mV full scale to

1.28 Volts full scale, or 4 – 20 mA current loops.

) on the data logger.

Select Input Channel

SDS Template Manager

option.

Select Input Channel

.

. Always

Modify

Thermocouple connections

Thermocouple wires can be connected directly to the terminal blocks. The thermocouple junctions should

not be grounded. If they do touch a ground reference, all thermocouples on a board must have a

common ground reference. If multiple thermocouples are connected to different ground reference points,

the accuracy of all thermocouples on the board cannot be guaranteed to be accurate.

Voltage connections

Voltages from 0 mV to 1.28 Volts can be directly connected to the terminal blocks. When measuring

ground-referenced voltages, all references must share a common ground reference. If the voltage

sources are connected to different ground reference points, the accuracy of all the voltage sources

connected to the board need to be checked for accuracy.

4 – 20 mA. Current Loop connections

Before connecting the current loop, insert the shorting jumper on the board for each channel used to

measure current loops. This jumper inserts the 62-ohm shunt resistor across the input of the A/D. If

multiple current loops are connected to one board, all must share the same power supply and ground

reference points or the accuracy of all the current loops need to be checked for accuracy.

Super Systems Inc. Page 7 SDS Data Logger Manual #4565 Rev D

Page 8

Survey Templates

The data logger will default to the last survey template used. To modify the template being used, the

operator can go to the

option. This data will be carried over for the reporting

process to make the reporting quick and easy. On the

Survey Template screen there are parameters that can

be modified for a specific survey such as setpoint.

After setting the required parameters, the start survey

process can be selected. This will timestamp the

selection and the data logger will log all channels that have been selected for logging.

The operator may receive deviation alarms depending on the

current input and setpoint as well as the alarm settings. The

alarm will notify the operator when an input is outside the

plus/minus tolerance for the setpoint. The alarm information

will display on the data logger and show the number of

channels above tolerance and below the tolerance. The

survey continues to run, it is simply providing the operator

with the information on the display.

Select Survey Template

menu

The operator can view the input channel data on a number of

different screens. The

channels on the device but by using the circular arrow key,

, the operator views the

“selected” input channels. By pressing the circular arrow key

again, the operator will get the

displaying trend data for a specific channel.

At anytime, the operator can view the data in real-time from

the computer using the SDS Recorder software. The real-time

data option when selected displays the data every 10 seconds. The system will update 10-second

intervals every minute. Follow instructions for connecting the datalogger to the PC.

The survey can be stopped from the

screen. On the Action option, entering a “0” and pressing the

Enter key will stop the survey.

After stopping the survey, other surveys can be taken by

repeating the above steps. At anytime, all survey data can be

downloaded to the PC using the Download Surveys And Data

option on SDS Recorder. Follow instructions for

connecting the datalogger to the PC.

Once the data has been downloaded, it is available

for reporting. By clicking on the file open menu

option, the operator will be given the Report dialog

to generate a survey report. Reports use logged

data and the user specified interval in the report.

The report template selected will form the final

report view with all the template data, survey data

and additional report parameters that are entered.

overview display

overview display

Quick Chart View

will display all

with only the

screen

Display Survey

Information

Super Systems Inc. Page 8 SDS Data Logger Manual #4565 Rev D

Page 9

The report templates are user defined and should be configured to meet your needs. All reports can be

saved and displayed at a later date.

Super Systems Inc. Page 9 SDS Data Logger Manual #4565 Rev D

Page 10

IInnssttaallllaattiioonn

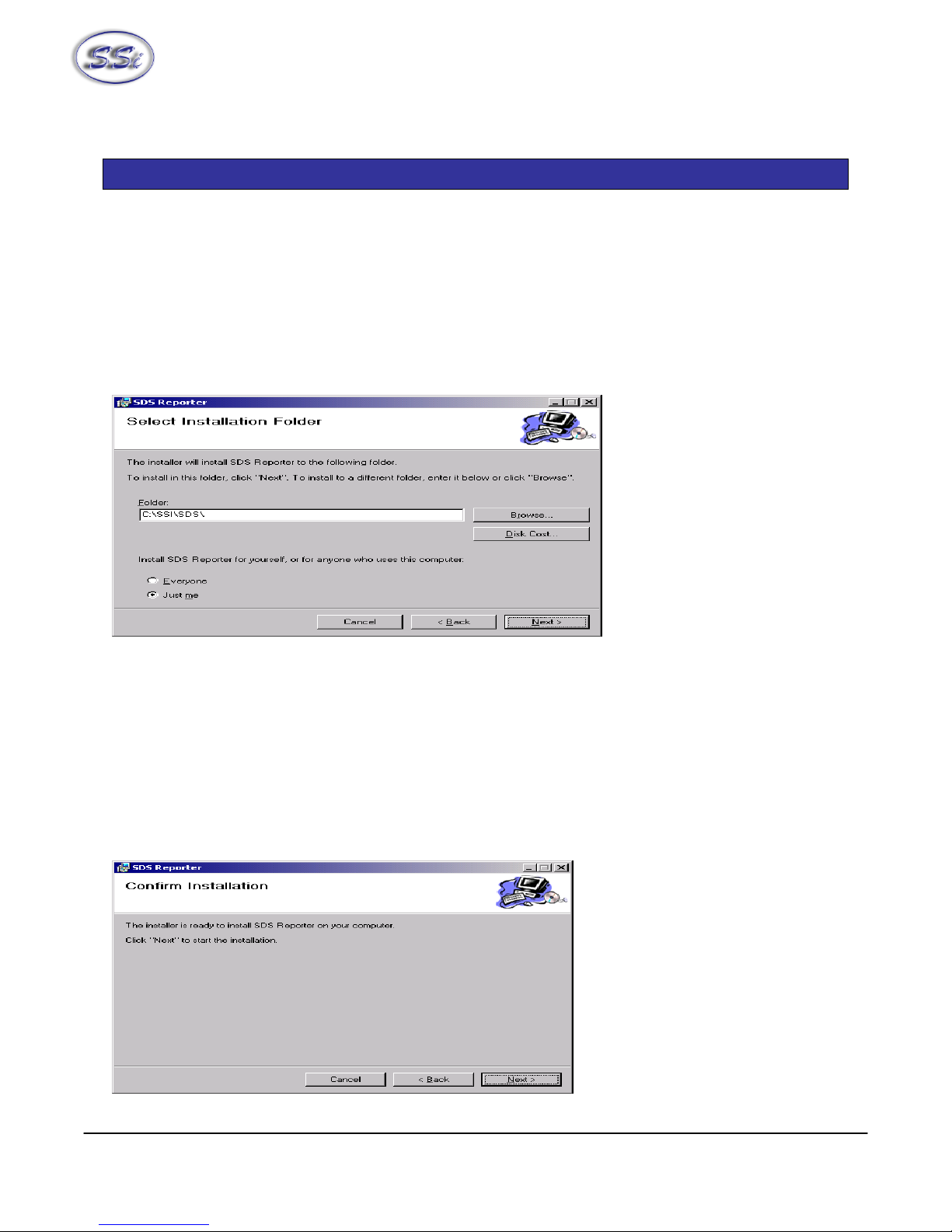

Installing the SDS Software

Note – The person installing the SDS Software must have administrative rights on the

computer(s) where the installation is taking place for the installation to be successful.

Double-click on the setup file, SDSSetup.msi to start the auto-installation. If there is no version of the

SDS Reporter running on the computer, the installation will prompt the user for the download location

(figure 1.1).

Figure 1.1 SDS Reporter setup screen

The default location is “C:\SSI\SDS”. Click on the “Browse” button to select an alternate location.

Clicking on the “Disk Cost…” button will display the available computer drives onto which the SDS

Reporter can be downloaded, as well as the total space, available space, and required space for each

drive. Selecting the “Everyone” option will install the SDS Reporter for all users on the computer, while

selecting the “Just me” option will only install the SDSReporter for the current user. Clicking on the

“Cancel” button will prompt the user to confirm exiting the setup without continuing. Clicking on the “<

Back” button will display the previous screen, which is the introduction screen for the installer. Clicking

the “Next >” button will continue with the installation process (figure 1.2).

Super Systems Inc. Page 10 SDS Data Logger Manual #4565 Rev D

Page 11

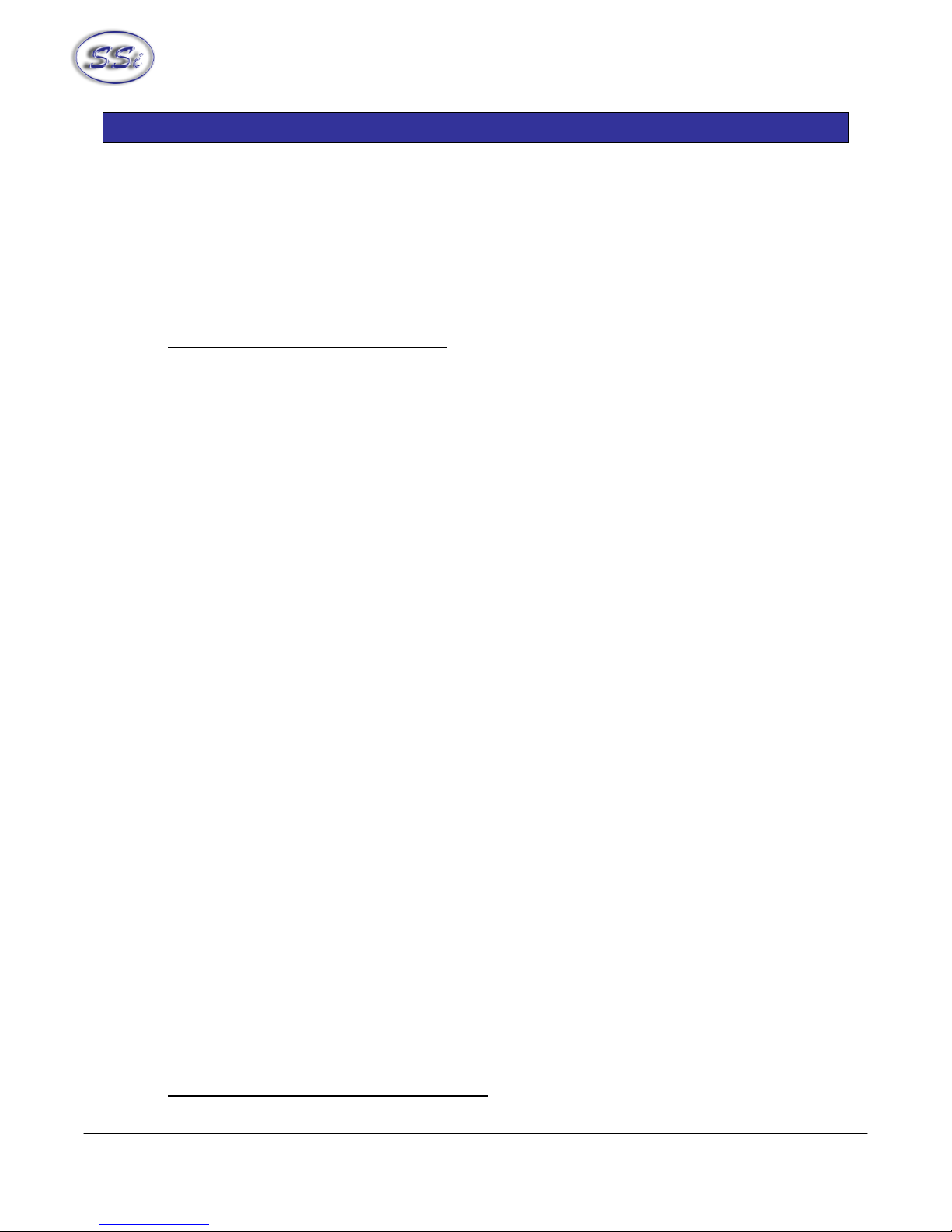

Figure 1.2 Installation ready screen

Clicking on the “Cancel” button will prompt the user to confirm exiting the setup without continuing.

Clicking on the “< Back” button will display the previous page, which is the installation setup page (figure

1.1). Clicking on the “Next >” button will install the software to the specified location. Once the

software has been installed, the installer can be closed. The SDS Reporter software will now be ready to

use.

If there is a version of the SDS Reporter already installed on the computer, the installer will either reinstall the software (Repair SDS Reporter option) or remove the software from the computer (Remove

SDS Reporter option) (figure 1.3). Clicking on the “Finish” button will proceed with the selected action.

Note: the installer does not remove any subfolders in the main SDS folder. These files will have to be

manually removed.

Figure 1.3 Repair/Remove SDS Reporter screen

Connecting The SDS Data Logger To A Network

Every SDS Data Logger shipped includes an Ethernet crossover

cable that will connect the data logger to a network. Once the

data logger is connected to a network, the SDS Reporter software

will be able to find it during any searches.

Connecting the data logger to your network or directly to

a PC is accomplished using the Ethernet port on your data logger.

Ethernet Port

If you are connecting the data logger to your network, you will need an Ethernet

cable (the cable provided is a crossover cable for direct connections to a PC). The

cable is plugged into the data logger Ethernet plug and then other end should be

plugged into a network hub. If the IP Address of the data logger needs to be

changed, this can be done on the data logger through the Set IP Address menu

option.

If you are not putting the data logger on the network, you should use the Ethernet crossover cable that

has been provided with the device. Ethernet crossover cables are most often used when connecting two

Super Systems Inc. Page 11 SDS Data Logger Manual #4565 Rev D

Page 12

Ethernet computers without a hub. An Ethernet crossover cable has it's send and receive wires crossed.

When using a hub or switch, this is automatically done for you.

With a crossover cable, you are forming a network between the computer that you are directly plugged

into and the data logger. There will be some network settings on the computer that you will have to

configure for the 2 devices to communicate. The data logger will have the network setting already setup

with the following IP address – 192.168.1.215. This can be modified through the Set IP Address screen

on the data logger.

Network settings can be found through the

Setting

, the operator will be

Control Panel

in Microsoft Windows. By selecting

given a list of the current

available connection types.

Using the crossover cable will

require the Local Area

Connection as seen in the below

diagram to be modified. The

Properties can be changed by

highlighting the connection and

using the right mouse button to

click and select the Properties tab

or by highlighting the connection and clicking on Change setting of this

connection.

Once the Local Area Connection Properties screen is displayed, the

Internet Protocol (TCP/IP) tab should be highlighted. Click the

Properties button to display Internet Protocol

(TCP/IP) Properties.

On the Internet Protocol (TCP/IP) Properties tab,

you will need to select the option for Use The

Following IP Address. Enter in the following data

on these fields.

Network

IP Address: 192.168.1.209

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.1.1

To change the network settings on your computer you may need addition information so please refer to

the computer manual.

Super Systems Inc. Page 12 SDS Data Logger Manual #4565 Rev D

Page 13

SSDDSS 88002200//88004400 DDaattaa LLooggggeerr

Menu List

The menu list shows the available pages displayed six at a time. To access the list, press the Esc key.

Depending upon where you are starting from, it may require pressing this button more than once. The

up (Ï) and down (Ð) arrows are used to scroll through the selections, which are repeated below. To go

to a specific page, either type in the page number and press Enter, or use the arrow keys to highlight

the selection and press Enter.

Operator Level – No Pass Code Required

1. Overview Display

2. Display Input Settings

3. Display Input Settings

4. Display Input Offsets

5. Display Logged Data

6. Help

7. Select Input Channels

8. Modify Input Settings

9. Modify Input Offsets

10. Select Survey Template

11. Battery Status

12. About/Sign-On

13. Revision Display

14. Set Display Values

15. Language/Lengua

16. Quick Chart

17. Overview Display Selected

18. Quick Chart Setup

19. Modify Survey Information

Supervisor Level – Level 1 Pass Code Required

Super Systems Inc. Page 13 SDS Data Logger Manual #4565 Rev D

Page 14

20. Set the Date and Time

21. Port Setup

22. Input Calibration

23. Cold Junction Trim

24. System Setup

Configuration Level – Level 2 Pass Code Required

25. Set Pass Codes

26. Set IP Address

Menu Pages 27, 28 and 29 are reserved for future use and do not exist at this time. To minimize the

possibility of unintended modifications to the instrument, certain menu pages will require the entry of a

pass code to access them. Pages 1 through 18 are Operator level screens that do not require any

security codes. Pages 20 through 24 are Supervisor screens requiring a Level 1 pass code (default = 1).

Pages 25 and 26 are Configuration screens requiring a Level 2 pass code (default = 2). At the bottom of

the menu screen is a status bar, which tells the current date and time. The status bar also displays the

internal temperature (IT) of the instrument. This internal temperature should never exceed 50.

Note About Menu Numbers

Each menu screen has a unique number that is displayed in the upper left-hand corner of the screen.

This number is shown for reference. If you know the menu number of the screen that you would like to

go to, the screen number can be typed and the enter key pushed to access that particular screen directly

from the Main Menu list or the Overview Display screen.

Super Systems Inc. Page 14 SDS Data Logger Manual #4565 Rev D

Page 15

Date and Time Quick Reference Chart

Code Day Code Hour Code Hour Code

Month

January 1 Sunday 0 12 am 0 12 pm 12

February 2 Monday 1 1 1 1 13

March 3 Tuesday 2 2 2 2 14

April 4 Wednesday 3 3 3 3 15

May 5 Thursday 4 4 4 4 16

June 6 Friday 5 5 5 5 17

July 7 Saturday 6 6 6 6 18

August 8 7 7 7 19

September 9 8 8 8 20

October 10 9 9 9 21

November 11 10 10 10 22

December 12 11 11 11 23

Super Systems Inc. Page 15 SDS Data Logger Manual #4565 Rev D

Page 16

Keypad Assignments

All of the functions of the SDS Data Logger are controlled from the keypad. The functions of each button

are as follows:

0 – 9 are used to enter numeric data that

can vary with each page

“.” Is used to enter a decimal point where

necessary for data entry

Enter is used when entering numeric data

from the keypad or initiating automatic

functions

Ï and Ð are used to navigate through the

menu options or scroll through data on a

specific page

ESC is the escape key. This clears any

entered text, and if continuously pressed,

toggles between the main page and the

menu list

The circular arrow key, , is used to scroll through data on various pages and to change the sign, +/-,

of values on some pages

Super Systems Inc. Page 16 SDS Data Logger Manual #4565 Rev D

Page 17

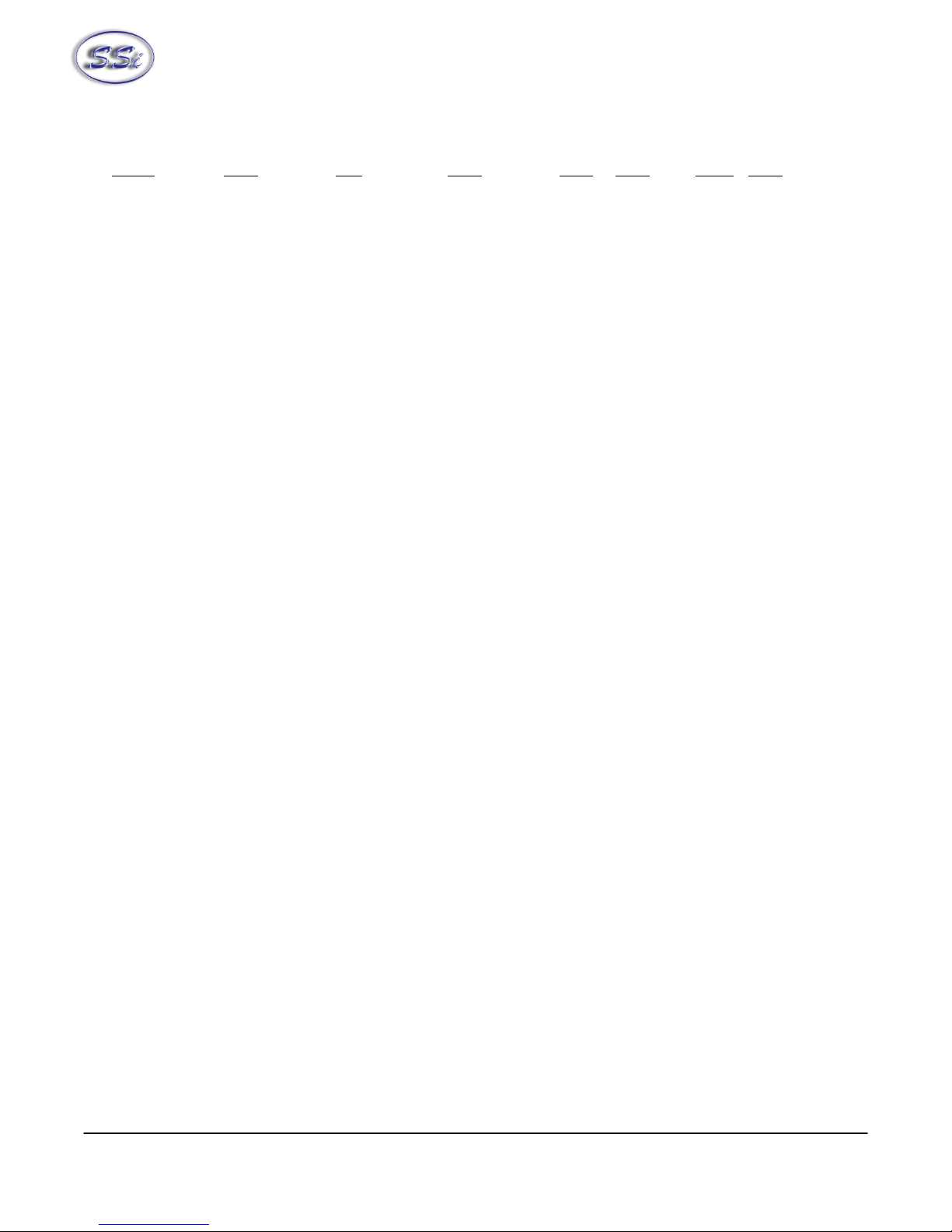

1. Overview Display

The Overview Display shows the current readings of the five thermocouples on all four or eight boards,

depending on the number of channels. Pressing the circular arrow key will display the

(menu option 16). Pressing the up or down arrow keys will display the

(menu option 9). Pressing any of the number keys (1-9) will display the corresponding menu option.

Modify Input Offsets

Quick Chart screen

screen

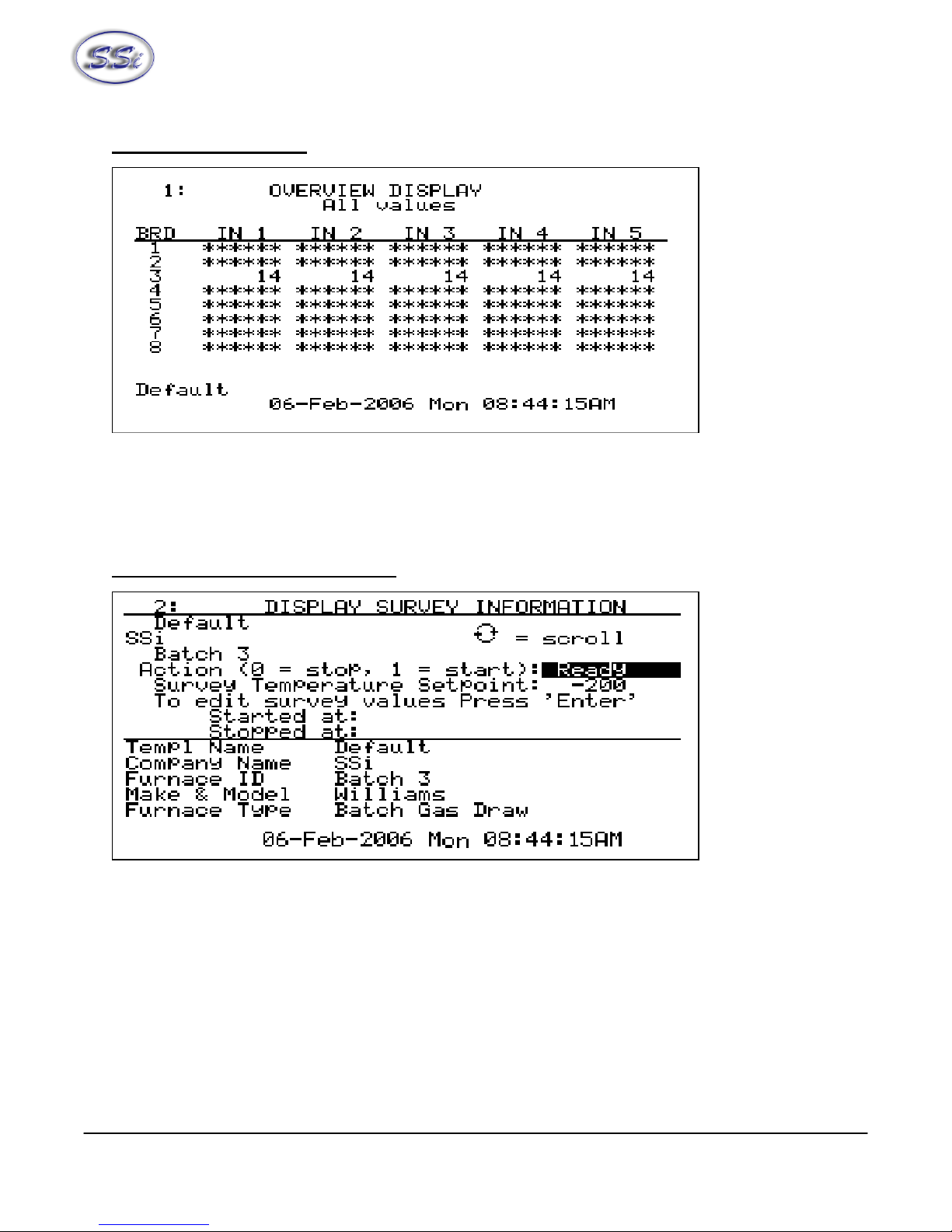

2. Display Survey Information

The Display Survey Information shows the survey information on the top half of the screen. Included is

the Template name, Company name, Furnace ID, Action (start or stop the survey), Survey Temperature

Setpoint, A field to edit the survey values, The Date/Time the survey was started and the Date/Time the

survey was stopped. Pressing the up or down arrow keys will scroll through the Action, Setpoint and Edit

survey fields. Pressing Enter on the line “To edit survey values Press ’Enter’” will display the

Survey Information

used in the survey. Currently, the only information that can be modified are the Setpoint, TC units, and

TC spool correction.

screen (menu option 19), which allows the user to modify some of the information

Modify

To start the survey, highlight the Action field, enter a 1 and then press Enter. Once a survey has been

started, “Testing” will appear in the highlighted area and the start Date/Time will be filled in the “Started

at” field.

Super Systems Inc. Page 17 SDS Data Logger Manual #4565 Rev D

Page 18

To stop a survey, highlight the Action field, enter a 0 and then press Enter. Once the survey has

finished, “Finished” will appear in the highlighted area and the stop Date/Time will be filled in the

“Stopped at” field.

To change the Setpoint, highlight the Setpoint field, enter in the new Setpoint and press Enter. Pressing

the circular arrow key while the setpoint field is highlighted will change the sign of the value entered.

The bottom half of the screen contains the full template data displayed five lines at a time: Template

Name, Company Name, Furnace ID, Furnace Make/Model, Furnace Type, Furnace Use, Furnace

Dimensions, Temperature Range, Date, Setpoint, Number of TCs, TC Type, TC Spool SN, TC Cal, TC Cal

Date, TC Spool Correction, SDS Calibrated By, SDS Cal Date, Duration, Operator, Interval, Specification,

TC Units, Simulated Load, Tolerance, Next Survey, Cont MFG, Cont Model, Cycle Time, Dead Band,

Output Limit, Prop Band, Rate, Reset, TC Gauge, and Notes. Pressing the circular arrow key will scroll

down through the template data, one line at a time. When the end of the template is reached, the scroll

will start over at the beginning of the template.

3. Display Input Settings

The Display Input Settings shows the input settings for all five thermocouples on all four/eight boards.

Pressing any of the number keys (1-9) will display the corresponding menu option. Pressing the down

arrow key will display the

Super Systems Inc. Page 18 SDS Data Logger Manual #4565 Rev D

Modify Input Settings

screen (menu option 8).

Page 19

4. Display Input Offsets

The Display Input Offsets screen displays the offsets for all five thermocouples on all four /eight boards,

depending on the SDS type. Pressing the down arrow key will display the

(menu option 9). Pressing any of the number keys (1-9) will display the corresponding menu option.

Modify Input Offsets

screen

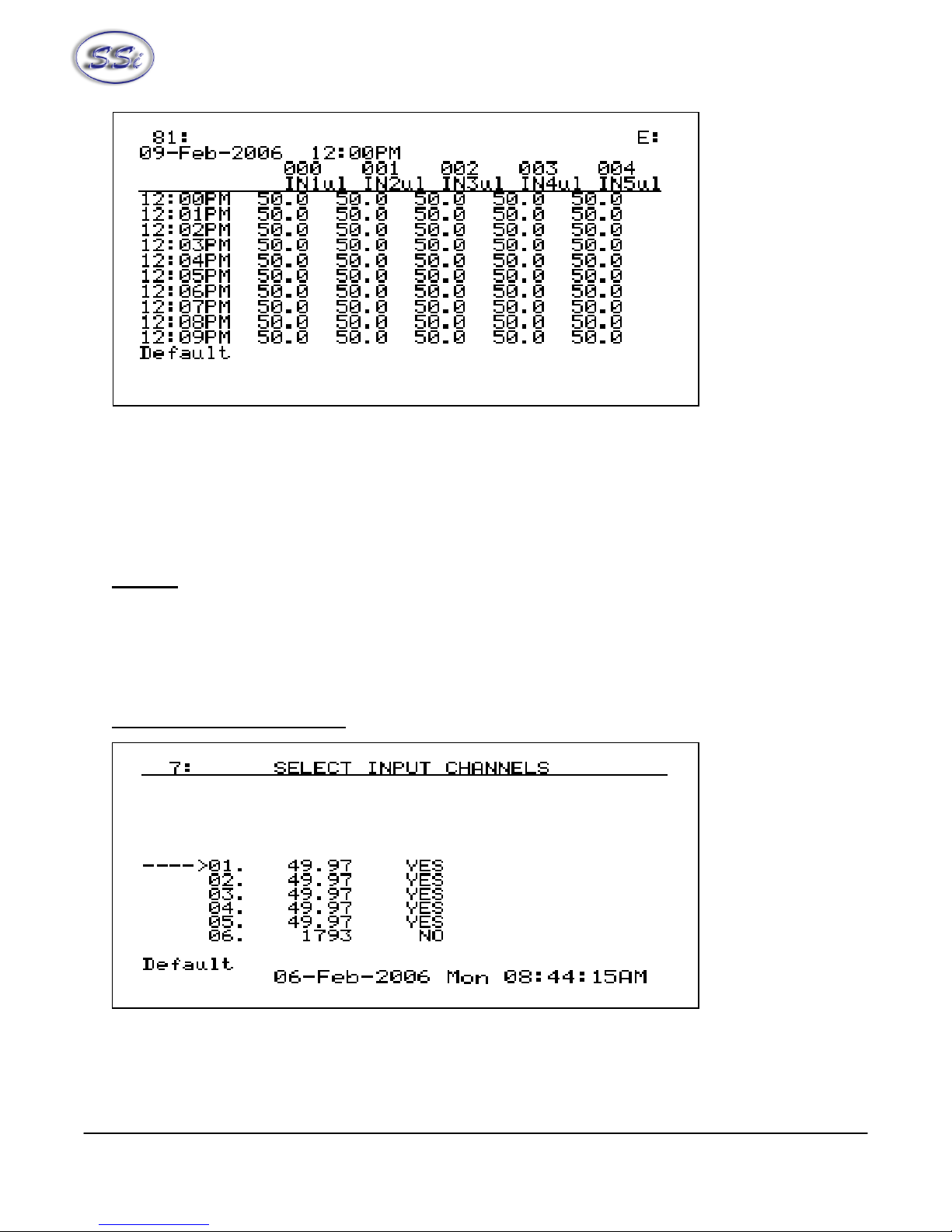

5. Display Logged Data

The Display Logged Data shows the logged data from a specific date, with the default setting being the

current hour of the current date. Pressing the down arrow key will allow the user to change the Year,

Month, Day, and Hour. To change the Year, highlight the area and enter any four-digit year between

1980 and 2179. To change the Month, enter a number corresponding to the appropriate month – i.e. 1

for January, 12 for December. To change the Day, enter a number between 1 and 31. To change the

Hour, enter a number between 0 and 23 corresponding to the appropriate hour – i.e. 0 for 12am and 23

for 11pm. Hours are based on the 24-hour clock. For a detailed reference for all of the codes, see the

Date and Time Quick Reference Chart

Display Press ’Enter’ here” will display the logged data.

section (Page 19). Pressing Enter on the line that says “To

Super Systems Inc. Page 19 SDS Data Logger Manual #4565 Rev D

Page 20

The first screen will display the first five inputs and the first ten minutes of data. Pressing the circular

arrow button will allow the user to scroll through the inputs, five inputs at a time. Pressing the down

arrow button will show the next ten minutes of logged data. Pressing the up arrow will show the

previous ten minutes of logged data. Pressing the ESC key will display the

Display Logged Data

Screen.

6. Help

The Help page can be used as a reference to briefly describe the functions of the various buttons on the

keypad. This manual is a better resource, however if it is not available this screen will be able to offer

information that will help in navigating through the screens on the SDS. To scroll through the screen

pages, press the down arrow key to scroll down and the up arrow key to scroll up.

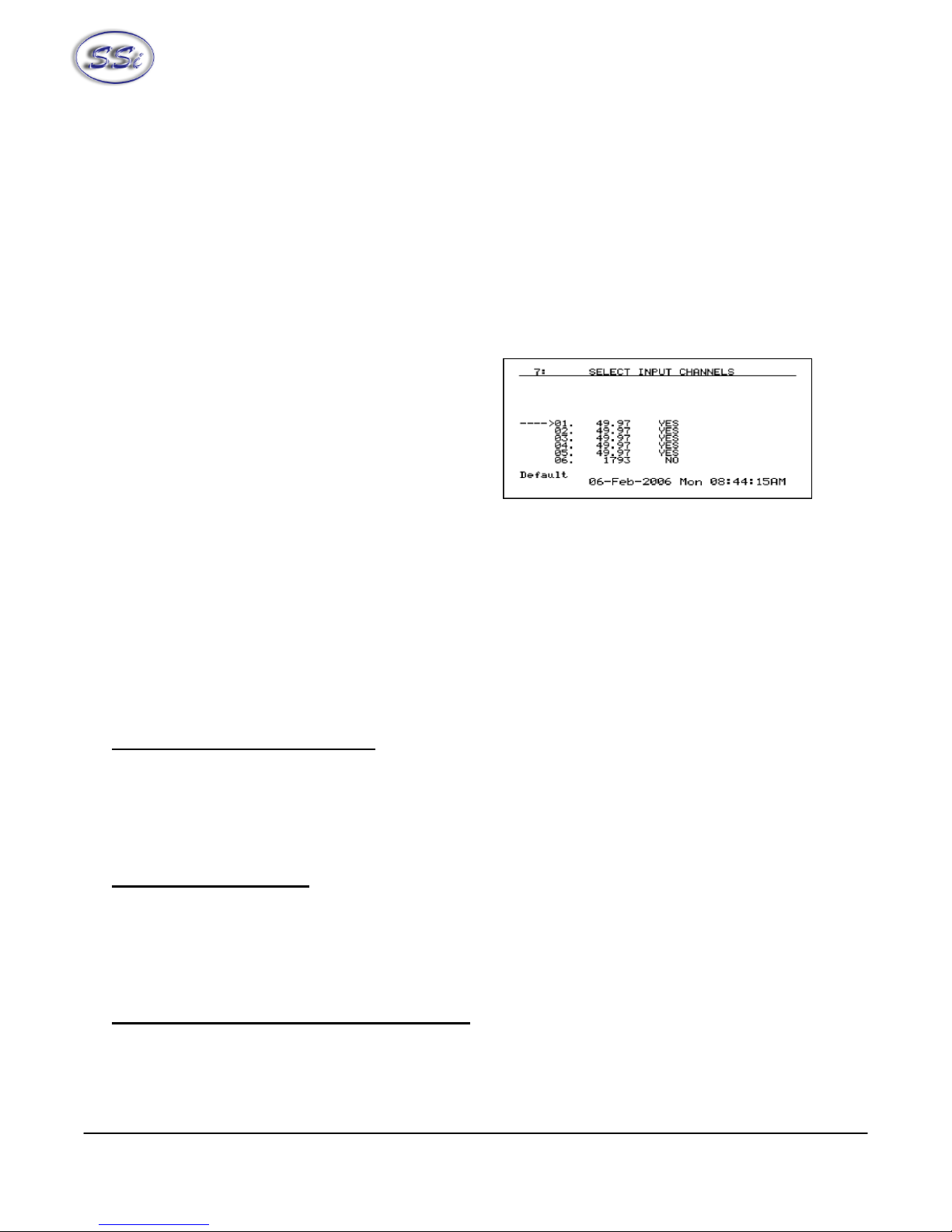

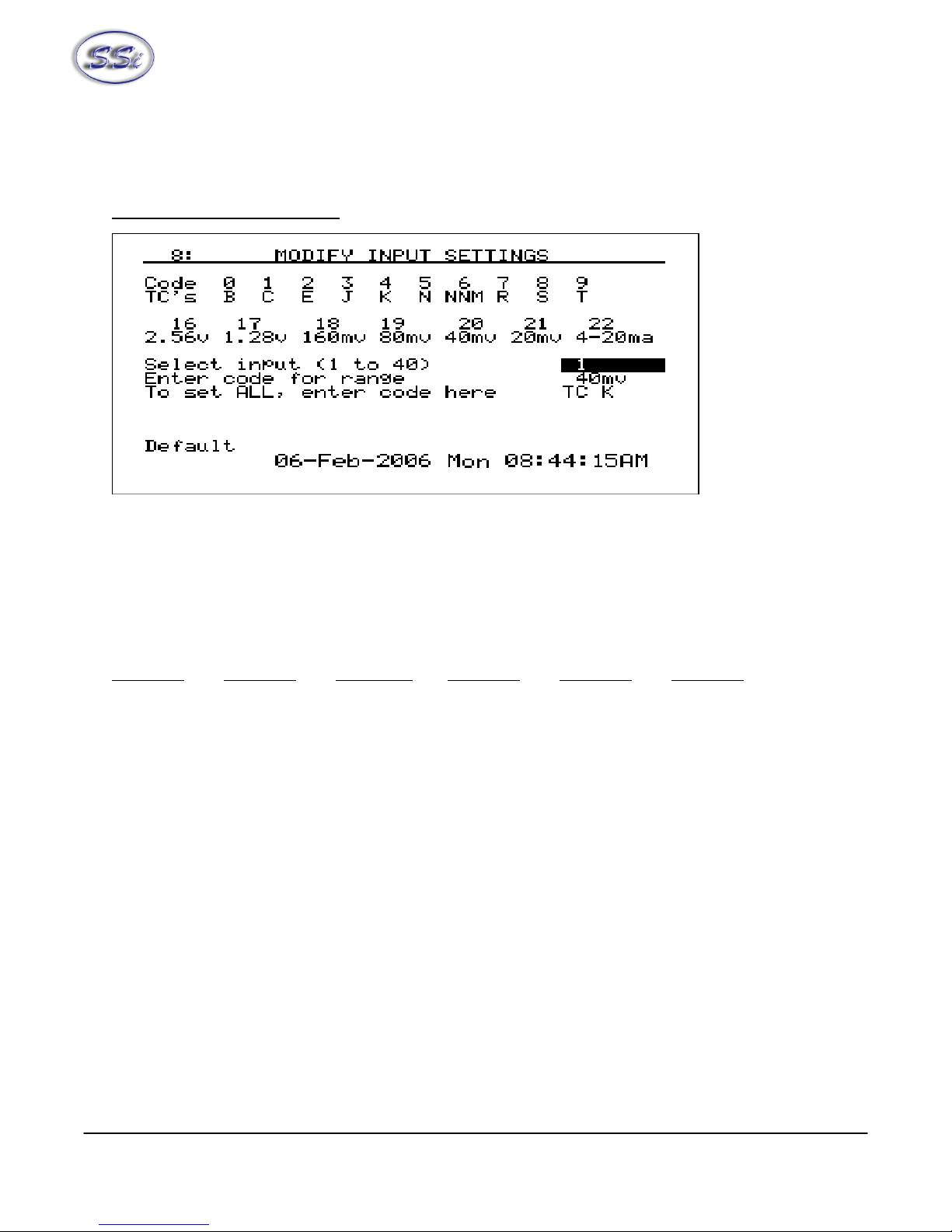

7. Select Input Channels

The Select Input Channels page allows the user to manually turn a thermocouple input “on” (“Yes”) or

“off” (“No”). The thermocouples are displayed from one to twenty / forty. Use the up or down arrow

keys to select a specific thermocouple. Enter a 1 and then press Enter to turn the thermocouple on, or

enter a 0 and press Enter to turn the thermocouple off. Pressing Enter without entering a 1 or a 0 will

Super Systems Inc. Page 20 SDS Data Logger Manual #4565 Rev D

Page 21

turn a thermocouple off as well. Pressing the circular arrow key will display the

Selected

screen.

screen (menu option 17). Pressing the ESC key will also display the

Overview Display

Overview Display Selected

8. Modify Input Settings

The Modify Input Settings allows the user to select a channel (input) and manually set the range/type, or

set the range/type for all of the channels. To select a channel, highlight the area and then enter a

number from 1 to 40 corresponding to the specific channel. Pressing the circular arrow key will scroll

through the input channels. To set the code for the range of one specific channel, scroll down to the

“Enter code for range” line and enter one of the codes from the list at the top of the screen. To enter a

code for all of the channels, scroll down to the “To set ALL, enter code here” line and enter the

appropriate code. The codes for the range are:

Num-Code

0 – B 3 – J 6 – NNM 9 – T 18 – 160mv 21 – 20mv

1 – C 4 – K 7 – R 16 – 2.56v 19 – 80mv 22 – 4-20ma

2 – E 5 – N 8 – S 17 – 1.28v 20 – 40mv

Pressing the up or down arrow keys will scroll up or down through the three input fields: “Select input (1

to 40)” line, “Enter code for range” line, and “To set ALL, enter code here” line.

Num-Code Num-Code Num-Code Num-Code Num-Code

Super Systems Inc. Page 21 SDS Data Logger Manual #4565 Rev D

Page 22

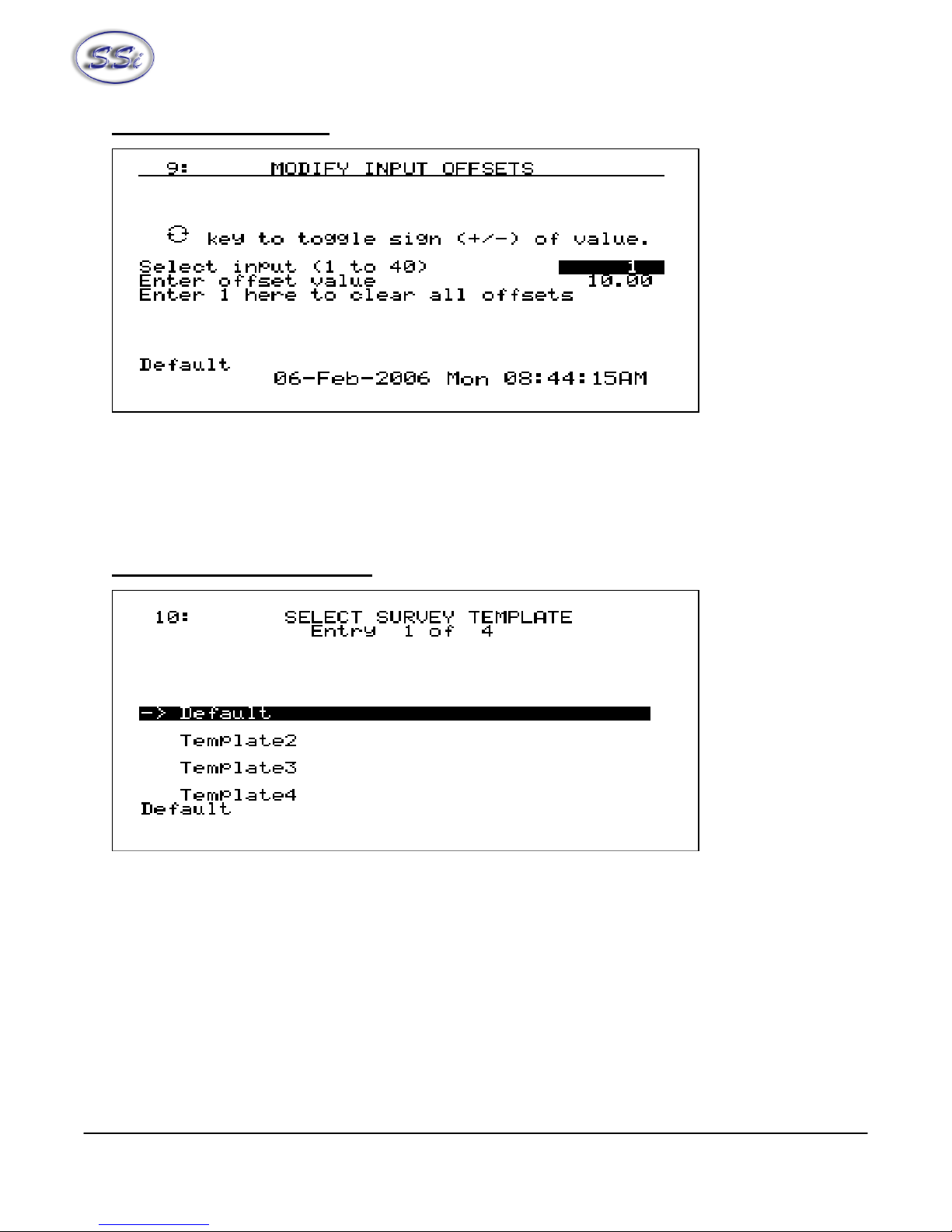

9. Modify Input Offsets

The Modify Input Offsets screen allows the user to modify the offsets of each channel, or to clear all of

the offsets. To select a channel, highlight the “Select Input” line and enter a number between 1 and 40.

To enter the offset value, highlight the “Enter offset value” line and enter a number between –1000 and

1000. The user can toggle the sign (+/-) of the number being entered by pressing the circular arrow

button. To clear out all of the offsets, highlight the “Enter 1 here to clear all offsets” line and enter a 1.

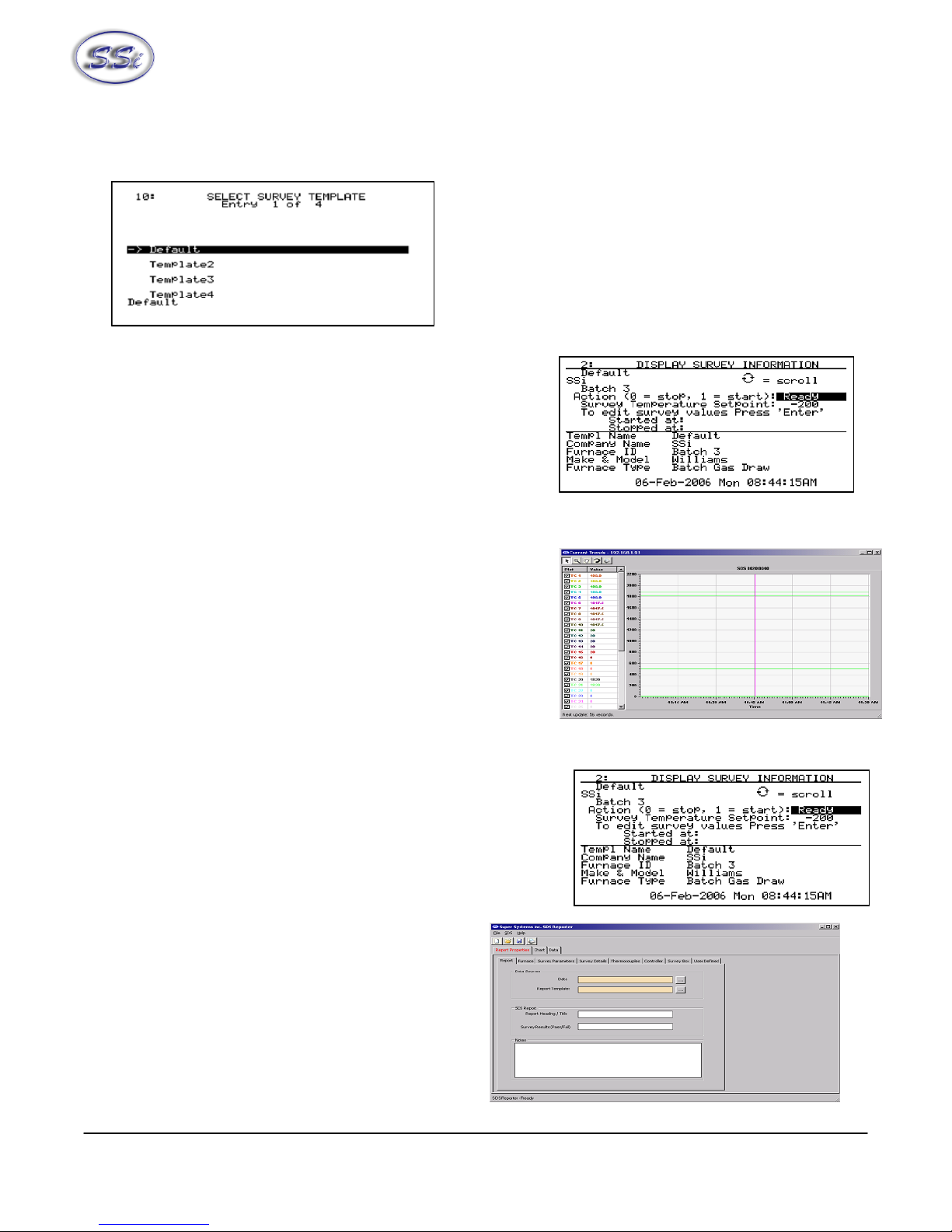

10. Select Survey Template

The Select Survey Template screen allows the user to manually select a template to run a survey from.

The SDS is capable of saving thirty-two templates per template file. Each template will be listed by

template name. To create a template, go to the Template Manager screen section,

Templates

arrow keys to highlight the template’s name and press Enter. The

will be displayed (menu option 2).

, using the SDS software and follow the procedures. To select a template, use the up or down

Display Survey Information

Manage Survey

screen

Super Systems Inc. Page 22 SDS Data Logger Manual #4565 Rev D

Page 23

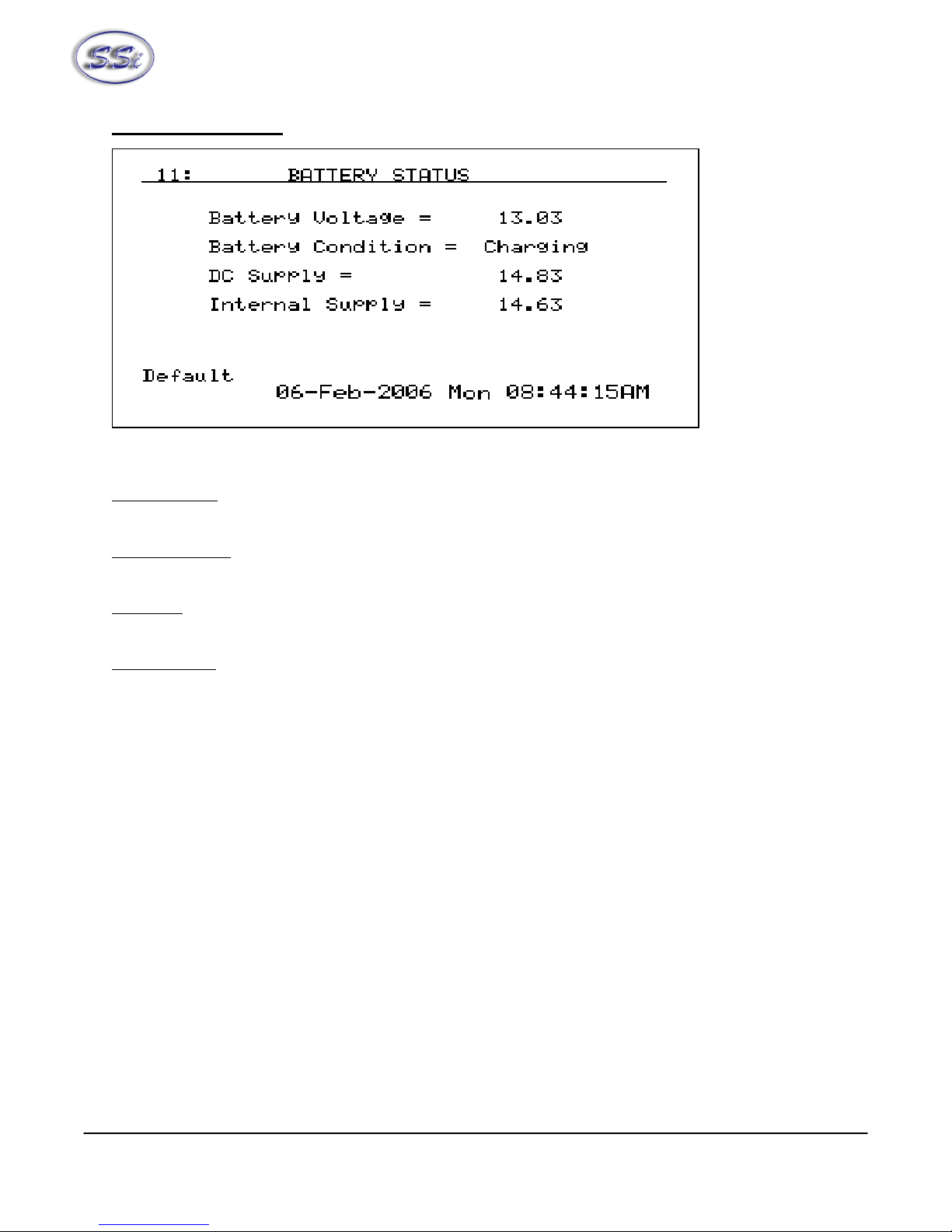

11. Battery Status

This page displays information about the instrument’s power supply.

Battery Voltage

plugged in, so a true measurement should be taken when it is not connected to AC power.

Battery Condition

voltage. When the instrument is plugged in, this will display

DC Supply

This will display 0 when the instrument is not plugged in.

Internal Supply

of the battery voltage and the DC supply.

If the instrument has been left unattended in the

may be possible to recharge the battery, but it will take a few days to accomplish this. Leave the

instrument plugged in and periodically check the battery voltage to see if it is increasing. If it is increasing

the battery is taking a charge. Remember: it could take three to four days if the battery is completely

dead.

The instrument should not be plugged in after every use. The battery will last longer if it is discharged

for four – five hours before it is charged If the battery gets low, a warning message will appear on the

screen, followed by an estimate of the amount of time until it runs out of power. The operator will

always have at least an hour of run time after the message is displayed. When it is plugged in to

recharge, the instrument can still be used. The instrument will recharge and operate at the same time.

The battery has approximately twelve hours of battery life when fully charged.

: This displays the DC voltage from the battery. It will read higher when the instrument is

: This will display the battery status as

: This will display the amount of power that is being generated by the internal power supply.

: this will display the amount of voltage that the instrument is seeing. This is the greater

Very Low, Low

Charging

ON

position, the battery may be completely dead. It

, or OK depending on the battery

.

Super Systems Inc. Page 23 SDS Data Logger Manual #4565 Rev D

Page 24

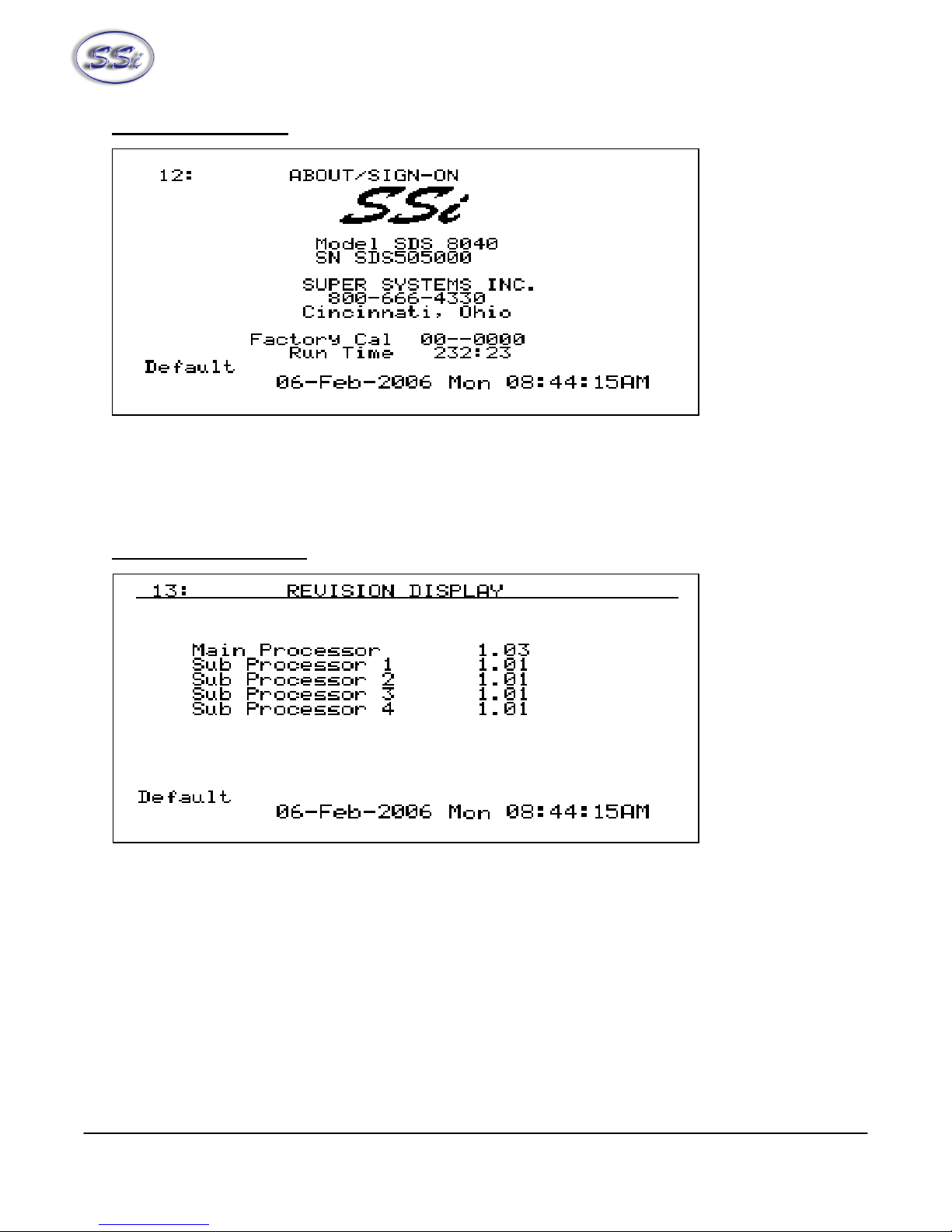

12. About/Sign-On

The above screen is the sign-on screen that shows the SSi logo, address, and phone. This page will also

display the instrument model and serial number, the date of the last factory calibration, and the number

of hours and minutes the instrument has been in use since the last factory calibration. Pressing the down

arrow key will display the

Revision Display

screen (menu option 13).

13. Revision Display

This screen displays the firmware revision levels for the instrument. Although the user cannot modify this

information, it may be helpful to report when contacting Super Systems for support. The “Main

Processor” value is the main firmware revision number for the SDS data logger.

Super Systems Inc. Page 24 SDS Data Logger Manual #4565 Rev D

Page 25

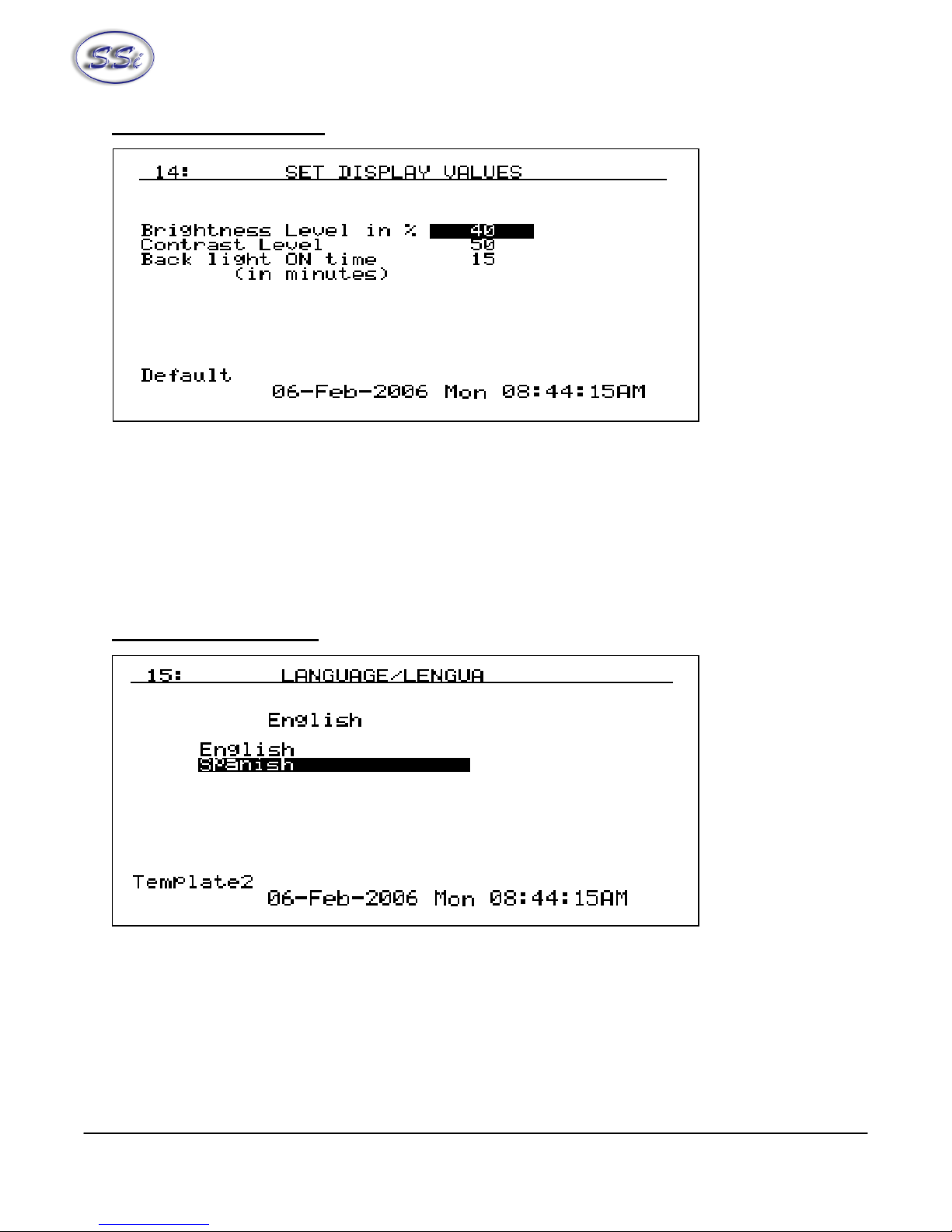

14. Set Display Values

This screen is used to adjust the display values. The backlight brightness and contrast are factory set to

40% and 50%, respectively, which is appropriate for most viewing conditions. Pressing the circular

arrow key will return these values to their default settings. The values for brightness and contrast can

range from 0 (dark) to 100 (bright). The backlight ON time is a power-saving feature that extends battery

life. The backlight ON feature will turn the backlight off if no buttons are pressed within a predetermined number of minutes. When the backlight goes off but the datalogger is not turned off, the

instrument is still functioning. The backlight can be restored by pressing any key. To disable this

function and keep the backlight always on, enter 0 and press Enter.

15. Language/Lengua

This screen allows the user to select a language to be used on the instrument. The SDS Data Logger

arrives with the necessary languages already downloaded. The selected language will always be listed

above the selections. To select a language, press the up or down arrow keys to highlight the desired

language and then press Enter.

Super Systems Inc. Page 25 SDS Data Logger Manual #4565 Rev D

Page 26

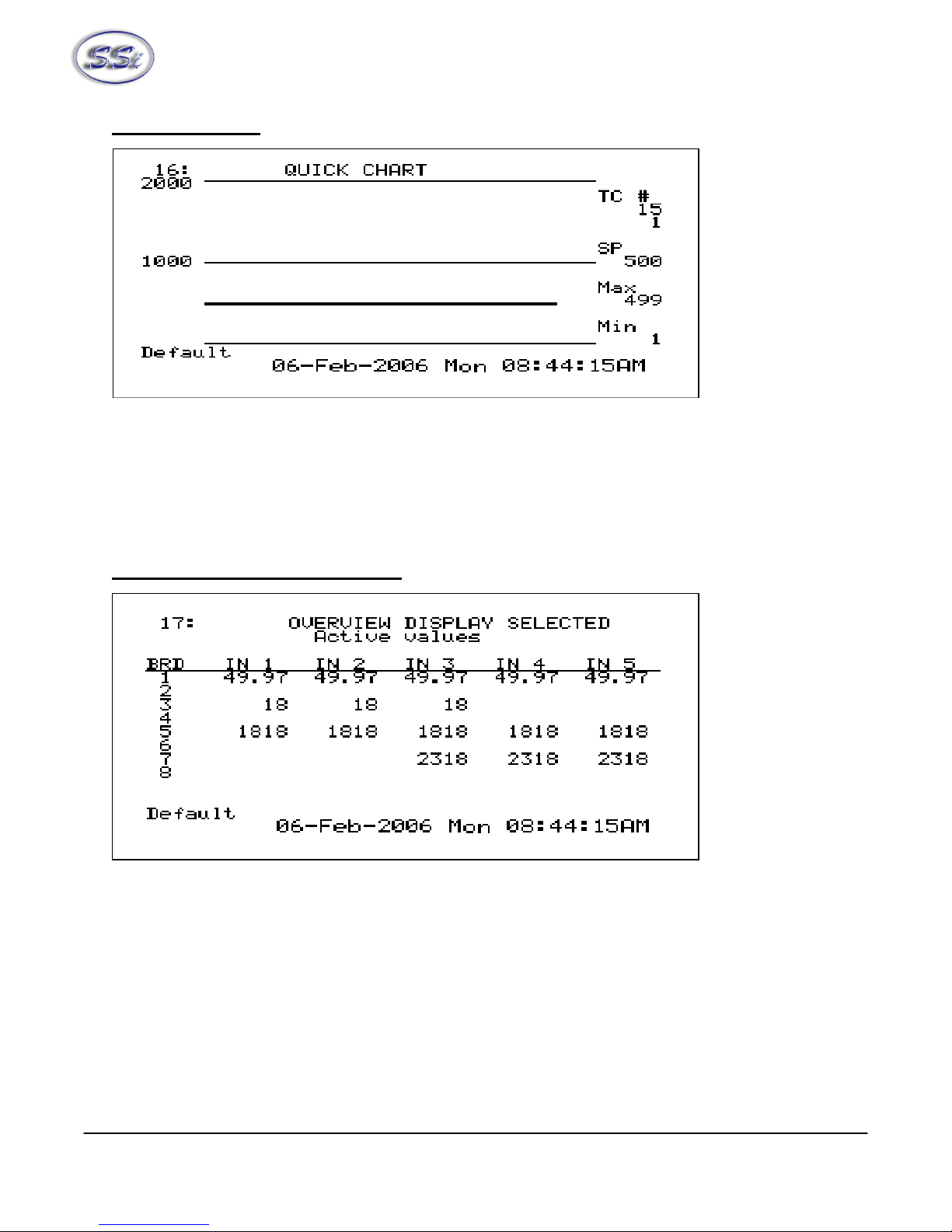

16. Quick Chart

This screen displays a trend chart for one active thermocouple over a period of ninety minutes. The

information on the right displays the active thermocouple number (TC), the temperature of that

thermocouple, the Setpoint (SP), the maximum value (Max) and the minimum value (Min). The

information on the left of the screen displays the full-scale value and the middle value as reference

points. Pressing the up or down arrow keys will display the

Pressing the circular arrow key will display the

Overview Display Selected

Quick Chart Setup

screen (menu option 18).

screen (menu option 17).

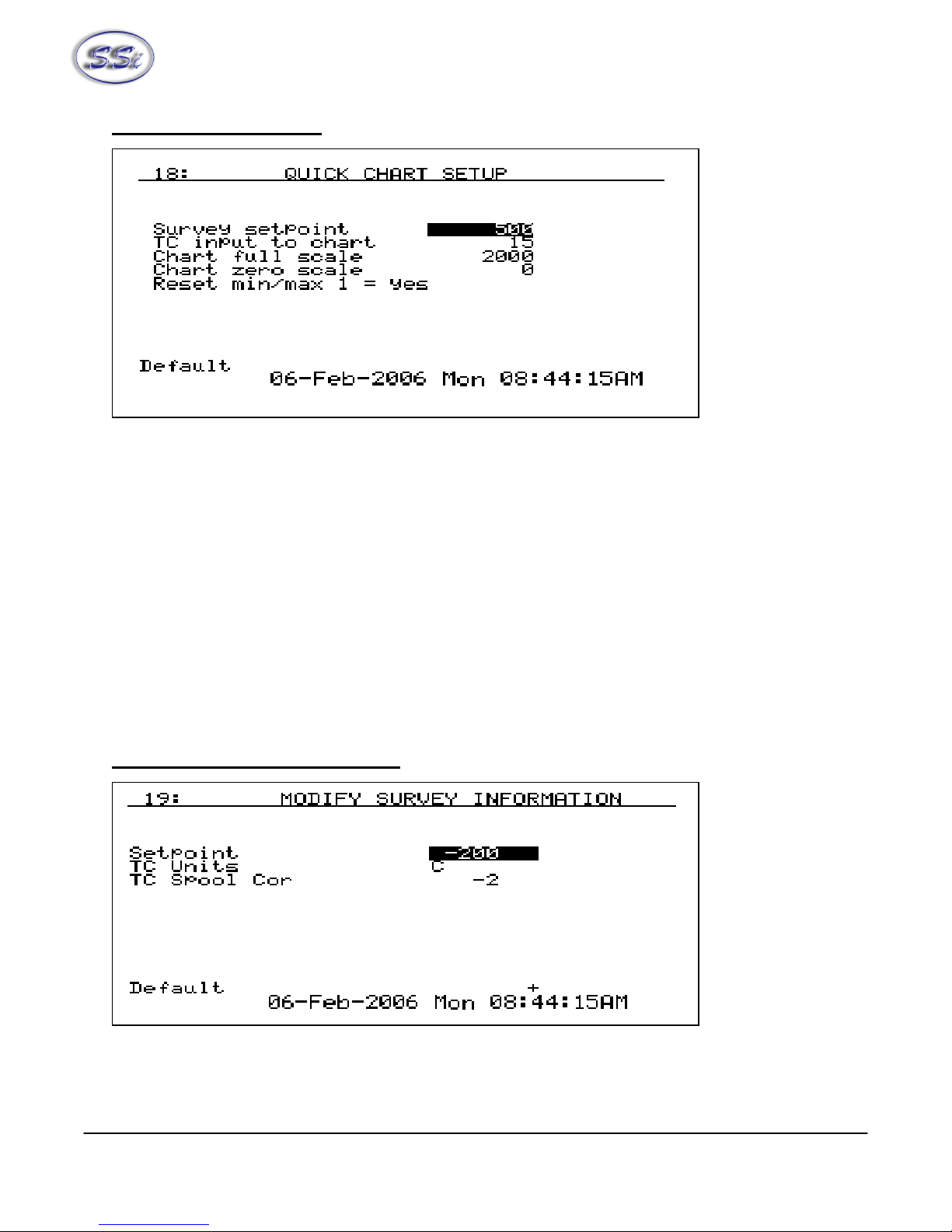

17. Overview Display Selected

This screen displays the active thermocouples on the instrument. Pressing the up or down arrow keys

will display the

will display the corresponding menu item. Pressing the circular arrow key will cycle through the

Deviation Alarm Log

Deviation Alarm Log

Select Input Channels

menu item (menu option 32) and the

menu item will show all deviation alarms that were logged.

screen (menu option 7). Pressing any of the number keys (1-9)

Survey

Overview Display

screen (menu option 1). The

Super Systems Inc. Page 26 SDS Data Logger Manual #4565 Rev D

Page 27

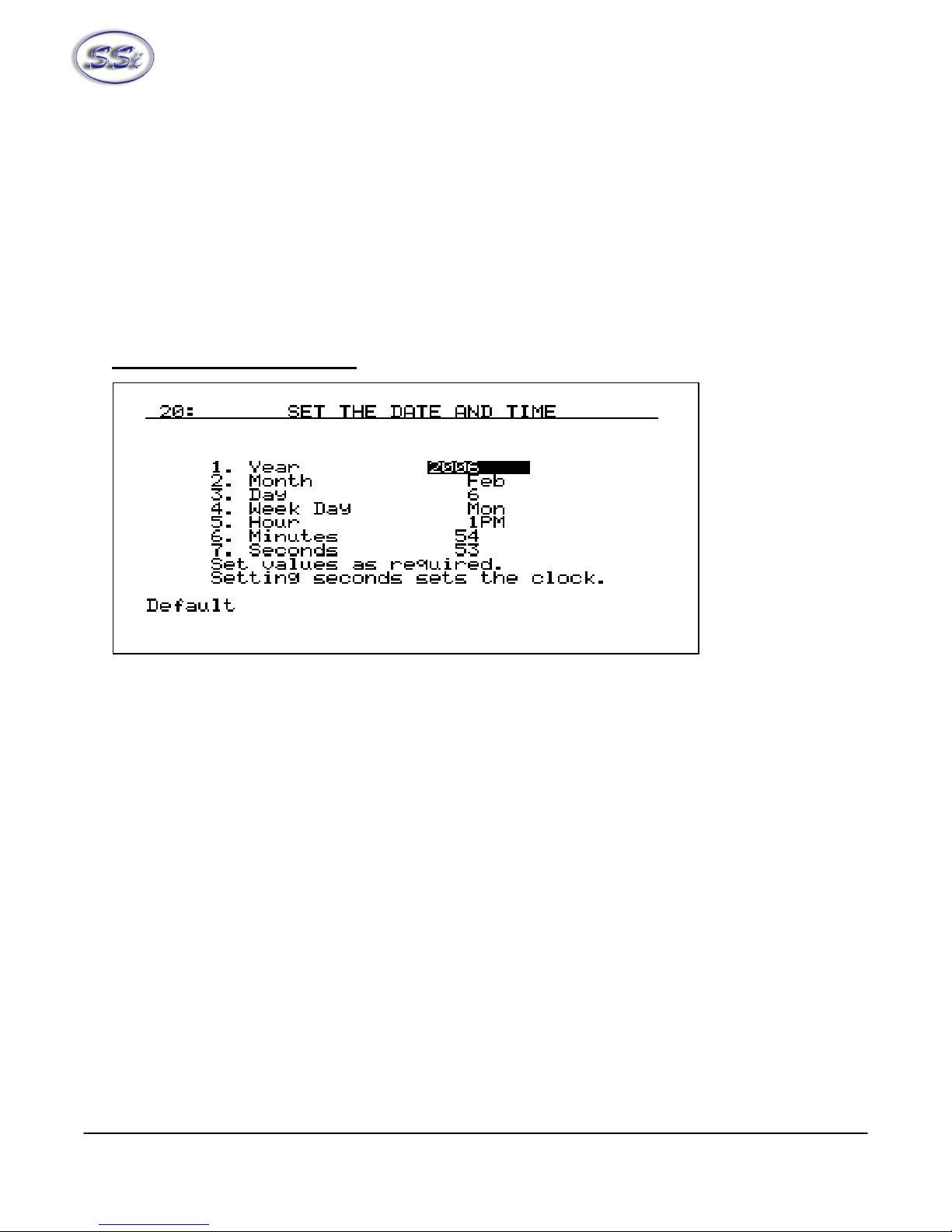

18. Quick Chart Setup

This screen displays the setup information for the Quick Chart. Valid values for the setup information

are:

Survey Setpoint: 0 through 9999

TC input to chart: 1 through 40

Chart full scale: 0 through 9999

Chart zero scale: 0 through 9999

Reset min/max 1 = yes: 0 or 1

To change a value, highlight the desired value to change, enter in the new value and then press Enter.

Pressing the circular arrow key or the ESC key will display the

Quick Chart

screen (menu option 16).

19. Modify Survey Information

This screen allows the user to modify some of the information used in the survey. Currently, only the

Setpoint, Temperature type (Fahrenheit or Celsius), and the TC Spool correction factor can be modified.

Super Systems Inc. Page 27 SDS Data Logger Manual #4565 Rev D

Page 28

To change any of these values, use the up or down arrow keys to highlight the field that is to be

changed, enter the new value, and press Enter. Valid values are:

Setpoint: -400 through 4000

TC Units: 0 for Fahrenheit and 1 for Celsius

TC Spool Correction: -100 through 100

For the Setpoint and the Spool Correction, the user can change the sign of the value by pressing the

circular arrow key. Pressing ESC will display the

Display Survey Information

screen (menu option 2).

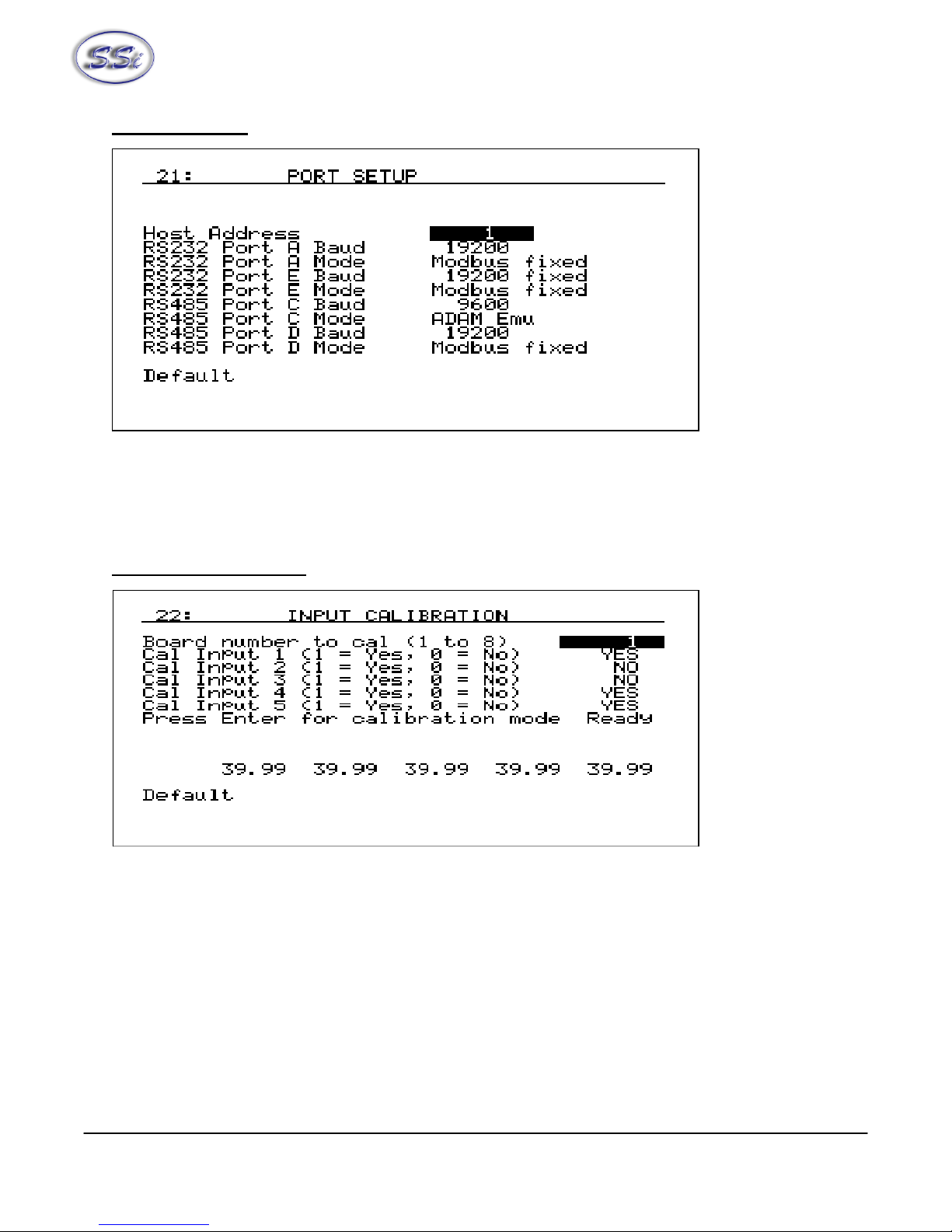

20. Set the Date and Time

This screen displays the date and time information for the instrument’s internal clock and calendar. Press

the up or down arrows to navigate to the part of the Date/Time that is going to be updated. Once the

desired part is highlighted, enter the new number and press Enter. Months are numbers 1 (January)

through 12 (December). Days are numbers 0 (Sunday) through 6 (Saturday). Hours are based on the

24-hour clock with numbers 0 (12 am) through 23 (11 pm). No changes will take place until the seconds

have been entered. For a detailed reference for all of the codes, see the

.

Chart

Date and Time Quick Reference

Super Systems Inc. Page 28 SDS Data Logger Manual #4565 Rev D

Page 29

21. Port Setup

This screen displays the parameters used for the communications ports. The factory default settings

should not need to be changed by the operator. To change the values that are not “Modbus fixed”, press

the circular arrow key to cycle through the available values. Pressing Enter will set the value as the

lowest value.

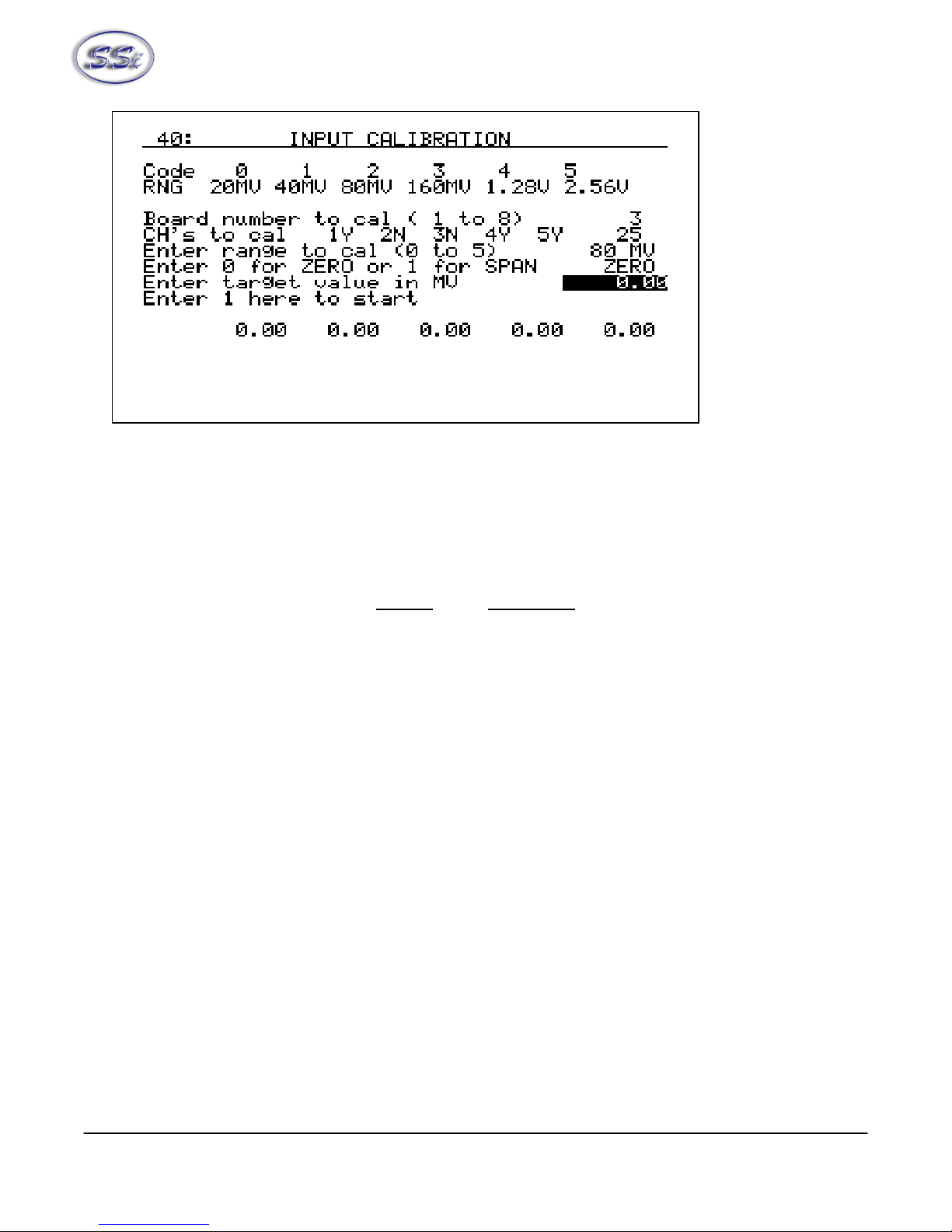

22. Input Calibration

This screen displays information to setup the calibration of the inputs. Calibration can be performed 1

channel at a time or from 1 – 5 inputs per board. The user can select board one through eight. The user

can also individually select each input (one through five) to calibrate, where 1 = yes (calibrate) and 0 =

no (do not calibrate). To continue the calibration setup, scroll down to the “Press Enter for calibration

mode” line and press Enter. This will display the setup for the calibration mode.

Super Systems Inc. Page 29 SDS Data Logger Manual #4565 Rev D

Page 30

The top of the screen displays the codes for the ranges. The codes are:

0 – 20MV 1 – 40MV 2 – 80MV 3 – 160MV 4 – 1.28V 5 – 2.56V

Below is a listing of the suggested ranges for the various TC types.

TC Type mV Range Chart

TC Type Range in mV

B 20

C 40

E 80

J 80

K 80

N 80

NNM 80

R 40

S 20

T 20

To select a board to calibrate, highlight the first line (“Board number to cal (1 to 8)”), enter the desired

board number that will be calibrated, then press Enter. The next line is the TCs (CH = Channels) to

calibrate. If there is a Y next to the TC, then it will be calibrated. If there is an N, then the TC will not

Super Systems Inc. Page 30 SDS Data Logger Manual #4565 Rev D

Page 31

be calibrated. To select the TCs to calibrate, enter a number between 0 and 31. To determine the

number, follow these steps:

TC1 has a “value” of 1, TC2 has a “value” of 2, TC3 has a “value” of 4, TC4 has a “value” of 8, and TC5

has a “value” of 16.

A TC that is on has a value of 1. A TC that is off has a value of 0.

Multiply the TC’s value by its “value” and add all 5 TC values up.

For example, we wish to calibrate TC1, TC4, and TC5. TC1 = 1 (1 * 1), TC2 = 0 (0 * 2), TC3 = 0 (0 *

4), TC4 = 8 (1 * 8), and TC5 = 16 (1 * 16). The number to enter would be 1 + 0 + 0 + 8 + 16 = 25.

The line will now look like this: CH’s to cal 1Y 2N 3N 4Y 5Y.

To select the range to calibrate, select one of the codes above (0 through 5) and press Enter. The mV

ranges displayed above are ideal because they cover the mV range for the selected thermocouple type.

On the next line, enter a 0 for ZERO or a 1 for SPAN. Enter the target value (in MV) as a value ranging

from 0 to 320. The SPAN value should be 90% of full scale. That means for 80mV, the span value

should be 72mV. Scroll down to the next line and enter 1 to start the calibration. DO NOT START THE

CALIBRATION until you have entered the proper value in the calibration device. Also be sure that the

polarity of the wires is hooked up properly.

When the calibration is finished, the “Enter 1 here to start” line will read “Ready 0”. Pressing ESC will

display the

The calibration process can be run multiple times and if initial calibration is off significantly, running

multiple times is recommended.

Input Calibration

first screen (menu option 22).

23. Cold Junction Trim

The instructions for performing the Cold Junction Trim on the inputs will depend on the firmware level of

the instrument that you have. You can determine the firmware version be checking menu option 13

Revision Display. The number to the right of the first line, “Main Processor”, will be the firmware level.

Please select the instructions below based on the firmware level of the instrument.

Super Systems Inc. Page 31 SDS Data Logger Manual #4565 Rev D

Page 32

Firmware revision 1.09 or below

This screen displays the setup information to trim the cold junction value of each board. Highlight the

first line (“Select board number”), enter the desired board number to trim, then press the Enter key. The

acceptable values for the board number are: 1 – 8. Any number entered over 8 will default to 8 and any

number entered less than 1 will default to 1. Press the down arrow key to highlight the next line (“Clear

trims, 1 = yes”). This line will allow an operator to clear out the previous cold junction trims for each

input. Enter a 1 for “yes” (clear input trims) or a 0 for “no” (do not clear input trims), and press the

Enter key.

the operator selected 1 (“yes”), the trims will be cleared once the Enter key has been pressed. Press the

down arrow key to highlight the “Modify brd CJ by (+/-)” line. This will allow an operator to modify a

board’s overall cold junction value. See the section

details on performing the cold junction calibration. Enter the desired cold junction trim value, and, if

necessary, press the circular arrow key to toggle the sign of the cold junction value.

circular arrow key will also toggle the “Clear trims” value between “yes” and “no”.

to begin the cold junction trim. When the trim has finished, the line will display 0.0, instead of the value

that was entered. This is because the offset is actually a recalibration of the board and after the

calibration process there will be no offset. If there are any trim values for the inputs, they must be

cleared before modifying the cold junction value for the board. If an operator attempts to change the

cold junction value without clearing the trim values, the “Modify brd CJ by (+/-)” line will display “Clr

Trims”. To set each individual input’s trim value, press the down arrow key to highlight the specific input.

The inputs are listed from top to bottom starting with input five and ending with input one. Enter the

desired trim value, and, if necessary, press the circular arrow key to toggle the sign of the trim value.

Press the Enter key to set the new trim value. The input trim values range from –18.00 to 18.00.

Note – Clearing the trims will only clear out the cold junction trims for the selected board.

To Perform a Cold Junction Calibration

below for

Note – Pressing the

Press the Enter key

If

Note –

The overall Cold Junction value is modified by adding or subtracting a value to the current value. The

individual input trim values are set to the entered value.

Super Systems Inc. Page 32 SDS Data Logger Manual #4565 Rev D

Page 33

Firmware Revision 1.10 and above

Depending on the revision level of the internal input board, the screen will resemble one of

the two following screens. One version uses one Cold Junction Trim value that is applied to

the entire board. The other version uses a unique Cold Junction Trim value for each of the

five inputs on that board. The instrument will automatically determine which screen should

be displayed based on the internal boards that are installed inside it.

Input Board Version 1.07 and below

This screen displays the setup information to trim the cold junction value of each board.

Note – Since

the Cold Junction screen’s functionality changes slightly based upon the input boards’ version, it is

important to know which version of boards is in the SDS Data Logger.

will be displayed in the top right corner. Highlight the first line (“Select board number”), enter the

desired board number to trim, then press the Enter key. The acceptable values for the board number

are: 1 – 8. Any number entered over 8 will default to 8 and any number entered less than 1 will default

to 1. The next section of the menu screen will look like the following:

Input 5 trim value

Input 4 trim value

Cold Junction Trim

Input 2 trim value

Input 1 trim value

The line for “Input 3 trim value” is shown as “Cold Junction Trim” because this line controls the actual

cold junction trim. Input boards with version 1.07 and below only contain one thermister per board; so

only one cold junction trim will be needed.

See the section

calibration. The “Cold Junction Trim” will adjust all of the inputs simultaneously. Any trim value entered

for inputs 5, 4, 2, or 1 will not be reset during the cold junction trim; therefore, those inputs would be

even more offset after the cold junction trim. For best results, perform the cold junction trim first, then

perform any necessary input trims. Press the down arrow key to highlight the “Cold Junction Trim” line.

This will allow an operator to modify a board’s overall cold junction value. Enter the desired cold junction

trim value, and, if necessary, press the circular arrow key to toggle the sign of the cold junction value.

Press the Enter key to begin the cold junction trim. While the system is working, the word “Busy” will

appear below the “Input 1 trim value” line. When the trim has finished, “Busy” will disappear. To set

each individual input’s trim value, press the down arrow key to highlight the specific input. The inputs

To Perform a Cold Junction Calibration

below for details on performing the cold junction

The input board version number

Super Systems Inc. Page 33 SDS Data Logger Manual #4565 Rev D

Page 34

are listed from top to bottom starting with input five and ending with input one (except for input three).

Enter the desired trim value, and, if necessary, press the circular arrow key to toggle the sign of the trim

value. Press the Enter key to set the new trim value.

Note – The overall Cold Junction value, as well as

any trim value, is modified by adding or subtracting a value to the current value.

Input Board Version 1.08 and higher

The functionality of the Cold Junction Trim menu screen is similar to the Cold Junction trim for the input

board versions 1.07 and below. The difference is that the new boards have five thermisters, instead of

only one, so each board must have five cold junction trims performed. The middle of the screen will look

like the following:

Input 5 trim value

Input 4 trim value

Input 3 trim value

Input 2 trim value

Input 1 trim value

See the section

calibration. Press the down arrow to highlight the input to be trimmed. Enter the desired cold junction

trim value, and, if necessary, press the circular arrow key to toggle the sign of the cold junction value.

Press the Enter key to begin the cold junction trim. While the system is working, the word “Busy” will

appear below the “Input 1 trim value” line. When the trim has finished, “Busy” will disappear.

To Perform a Cold Junction Calibration

below for details on performing the cold junction

Firmware Revision 1.11 and above

With Firmware revision 1.11, the title of the menu option 23 has become “CJ Calibration” instead of “Cold

Junction Trim”.

To Perform a Cold Junction Calibration

The user will need a thermocouple calibrator capable of outputting a thermocouple signal to calibrate the

cold junction value of the data logger. The user will need to connect the calibrator to one of the inputs

on the data logger for the channel that will be calibrated. It is recommended to let everything (calibrator

and datalogger) sit for approximately thirty minutes to allow the temperature to achieve equilibrium. Set

up the calibrator for the specific thermocouple type of the thermocouples in the datalogger, i.e. type K,

type J, etc. Then, source a specific temperature, like 1000 °F to the connected input. It is recommended

that the actual temperature used be similar to an appropriate process temperature. For example, if your

Super Systems Inc. Page 34 SDS Data Logger Manual #4565 Rev D

Page 35

equipment normally operates at 1700 °F, then perform the cold junction calibration using a 1700 °F

signal.

Firmware Version 1.09 and below

The user can source temperature to any one of the inputs, since the cold junction value is separate from

the input trim values, even though there is only one thermister per board. If the temperature being

sourced does not match the temperature displayed on the screen, the user will need to adjust the cold

junction value (“Modify brd CJ by (+/-) line) to match. After the cold junction value has been modified,

the user will be able to modify any of the input trims, if necessary.

Firmware Version 1.10 and above

Input Board Version 1.07 and below

The user will want to source the temperature to input three, since input boards with a version of 1.07 or

earlier only have one thermister, so the cold junction calibration will apply to the whole board. If the

temperature being sourced does not match the temperature displayed on the screen, then the user will

need to adjust the cold junction trim value to match. After the cold junction value has been modified,

the user will be able to adjust the trim values for inputs one, two, four, and five, if necessary.

Input Board Version 1.08 and above

The user will have to source the temperature to all five inputs, since input boards with a version of 1.08

or later have five thermisters per board, one for each input, so the cold junction calibration will have to

be made to each input separately. If the temperature being sourced does not match the temperature

displayed on the screen, then the user will need to adjust the input trim value to match.

24. System Setup

This screen displays any system setup information. Currently, the only information available is the

Survey Deviation Alarm Smart and the Temperature Resolution. To turn the Survey deviation Alarm

Smart on, enter a 1 and press Enter. To turn the Survey Deviation Alarm Smart off, enter a 0 and press

Enter. The Temperature resolution field accepts a 0, 1, or 2 as a value. The temperature resolution

affects the resolution of the temperatures displayed on the data logger.

Super Systems Inc. Page 35 SDS Data Logger Manual #4565 Rev D

Page 36

25. Set Pass Codes

This screen allows the user to set the pass codes to access the higher-level functions on the SDS. Menu

options 20 through 24 are considered Supervisor Level and they require a Level 1 pass code. Menu

options 25 and 26 are considered Configuration Level and they require a Level 2 pass code. The default

pass code for Level 1 is 1 and the default pass code for Level 2 is 2. There are 3 pass codes currently on

the SDS (there is no pass code for operator-level functions). To change the Level 1 Supervisor Pass

Code, use the up or down arrow keys to scroll to this line, enter the new pass code and press Enter.

The same is true to change the Level 2 Configuration Pass Code. Either of these pass codes may be

changed to a number between 0 and 512. Note: The Level 2 pass code will also work on all Level 1

menu options. The Level 3 menus are not visible, and Super Systems uses them when the instrument is

being set up prior to shipment.

26. Set IP Address

This screen displays the Ethernet communications address information. To change the IP Address, Net

Mask, or IP Gateway, use the up or down arrow keys to scroll to the appropriate section, enter the new

number and press Enter. To set the changes, scroll down to Set and press Enter.

changes are not set, then no changes will be saved

.

Note – if the

Super Systems Inc. Page 36 SDS Data Logger Manual #4565 Rev D

Page 37

32. Survey Deviation Alarm Log

The survey deviation alarm log will log all instances where the temperature of one of the survey channels

goes above or below the deviation band. The alarm log is on a one-minute update, so any alarm would

have to be present for more than a minute to be logged. The start and stop time of the alarm is listed at

the top of the screen on the line “AL 1 Start at”. The screen will display the each channel and which

channel was high or low. This log will be cleared out when the next survey is run.

34. Clear Logged Data

This screen will allow the user to clear out the logged data. This menu option is only accessible with the

SSi Special pass code that can be obtained from Super Systems Inc support. To begin clearing out the

datalog data, enter a 1 and press Enter. The middle-left of the screen will display “*** Busy ***” while

the SDS instrument is clearing out the data. When the instrument is finished clearing out the datalog

data, the message will change to “Clearing complete.” If there was an error, the SDS instrument will

display “File error -13”. For SDS firmware versions 1.09 or lower (SDS menu 13 –

is suggested that the datalog files be periodically deleted from the SDS data logger. All survey data that

is captured on the data logger is transferred to the PC using the SDS Reporter software and can be

reviewed at any time from that PC.

ten (110) days, or roughly three and a half (3 ½) months, will begin to experience issues with the data

logger. Datalog files can also be deleted by using the SDS → Download Surveys and Data menu option

on the SDS Reporter software to bring up the survey download screen. From the Download screen, the

Any data logger that retains datalog files for more than one hundred

Revision Display

), it

Super Systems Inc. Page 37 SDS Data Logger Manual #4565 Rev D

Page 38

Options → After Downloading → Delete datalog files from SDS menu option will delete the data log files

from the SDS after they have been downloaded to the local computer. Note: Once the datalog files have

been downloaded to the local computer, they will not be automatically deleted by the SDS Reporter

software. The only way to delete those datalog files will be to delete them manually.

Note – With

firmware version 1.10, when the file space begins to get low, every screen will begin to flash the

message “Flash Card Space Low!” at the bottom of the screen. If the file space eventually does get filled

up without any data log files begin deleted, the SDS Data Logger will begin to delete the oldest files.

When this happens, every screen will begin to flash the message “File Deletion is occurring!”

Super Systems Inc. Page 38 SDS Data Logger Manual #4565 Rev D

Page 39

SSDDSS SSooffttwwaarree

SDS Reporter

Figure 2.1 SDS Reporter initial screen

When the SDS Reporter software is started up, the user sees the above screen.(figure 2.1). The four

menu options to choose from are:

New

File Menu Options

, Open , Save , and Print .

File, SDS, Options

and

Help

. There are four buttons to choose from:

File Æ New / New Button

The New option allows the user to create a new report that will include the report properties, the trend

chart, and the TC data (figure 2.2). Note: the selected tab will be in Red when it is active only for the

three main tabs – Report Properties, Chart, and Data.

Super Systems Inc. Page 39 SDS Data Logger Manual #4565 Rev D

Page 40

Figure 2.2 Report Properties Tab

File Æ Open / Open Button

The Open menu option will allow the user to choose an existing report from a common Windows Open

dialog box. The software will open the dialog box in the “SDSReports” folder (typically C:\SSi\SDS\SDSReports) for existing reports (.SDSReport) to open.

The Report Properties tab contains several tabs, which in turn contain the information that makes up the

report. The first tab is the Report tab (figure 2.3), which contains the data to use for the report, the

report template to use, the report heading or title, the survey results, and any notes about the report.

Super Systems Inc. Page 40 SDS Data Logger Manual #4565 Rev D

Page 41

Figure 2.3 Report Properties Report tab

Clicking on the open box,

select the interval time (ten seconds, twenty seconds, thirty seconds, one minute, two minutes, or five

minutes) and also the specific survey to use (figure 2.4). This screen will only display survey data that

has already been downloaded (SDS → Download Surveys and Data).

Figure 2.4 Load Survey Data screen

The default interval is one minute. Select the survey to use and click on the “Use” button. Information

included with the data sources is: Template Name, [Company Name - Furnace Id], (Survey box Serial

number), and the date/time range of the survey data. Any manual entries will have [Manual Entry] at

the beginning. See the section

survey record manually. Clicking on the open box next to the “Report Template” field will open a dialog

box from which the user can select the specific report template to use for the report. The software will

open the dialog box in the “SDSReportTemplates” folder (typically C:\SSi\SDS\ReportTemplates) for

existing report templates to use. The “Report Heading / Title” field is for the heading or title of the

, next to the “Data” field will display a screen from which the user can

Manually Creating a Survey Record

for information on how to add a

Super Systems Inc. Page 41 SDS Data Logger Manual #4565 Rev D

Page 42

report and the “Survey Results (Pass/Fail)” field is for the results of the survey. The “Notes” field is for

any general notes for the report.

Manually Creating a Survey Record

Clicking on the “Advanced: Manually Create Survey Record” link from the Load Survey Data screen will

allow the user to create a survey record to use. Clicking on this link will display the “Manually Create

Survey Record” form (figure 2.5). Five pieces of data are required to manually create a record: the SDS

model, serial number, the start time and date of the survey, the end time and date of the survey, and the

TC Spool Offset.

Figure 2.5 Manually Create Survey Record form

The drop-down list next to “Survey Box Model” contains a list of the available models, the SDS8020 and

the SDS8040. Select they model type. Enter the SDS serial number on the next line, “Survey Box Serial

Number”. The SDS model and serial number can be found on the

on the SDS instrument. The process for selecting the start date/time and the end date/time is the same.

To select a date, click on the down arrow next to the time listed. This will bring up a calendar from

which the user can select a new date (figure 2.6). Select the new date by clicking on it.

Figure 2.6 Select new date

About / Sign-on

menu, menu option 12

The date of the survey start /end is listed to the right of the drop-down list. To select a time, click on the

hours, minutes, seconds or “AM/PM”. The selected field will be highlighted. Each field can be changed

by using the up or down arrows on the keyboard. If the survey start date is later than the survey end

date, a message will be displayed to the user and the record will not be added (figure 2.7).

Super Systems Inc. Page 42 SDS Data Logger Manual #4565 Rev D

Page 43

Figure 2.7 Survey start/end date error message

Enter the TC spool offset and click on the “Add Record” button to add the record. Clicking on the

“Cancel” button will cancel the add process and bring the user back to the “Load Survey Data” dialog

box. If the add was successful, a message box will be displayed (figure 2.8).

Figure 2.8 Record Add successful message

The added record will be displayed chronologically in the top of the list. Any record manually added will

begin with “[Manual Entry]” (figure 2.9). If the manually created survey is less than one second, it will

not be displayed in the list.

Figure 2.9 Manual entry on Load Survey Data form

Note – Most of the “Report Properties” tabs (Report, Furnace, Survey Box) will need to be filled out

manually as well.

The next tab is the Thermocouples tab (figure 2.10). This tab contains the information about the

thermocouple settings and it also lists the active thermocouples. The information in the thermocouple

settings includes: the temperature type (F or C), the number of thermocouples, the number of TCs used

in the report, the thermocouple type, the thermocouple gauge, the thermocouple spool number, whom

the thermocouple was calibrated by, the date the thermocouple was calibrated, and the thermocouple

spool correction factor. Clicking on the “Change” button will allow the user to change the spool

correction (figure 2.11).

Super Systems Inc. Page 43 SDS Data Logger Manual #4565 Rev D

Page 44

Figure 2.10 Report Properties Thermocouples Tab

Figure 2.11 Spool Correction screen

All values displayed to the users are corrected

. That means if there is a defined offset for the TC

Spool and a channel offset, the user would be shown the net result of those offsets into the value

displayed.

There are checkboxes for a possible forty thermocouples, but only the active thermocouples will have

checks in the checkboxes. Clicking on the “Define Control TC” link will allow the user to select the TC or

TCs that will be the control TC(s) (figure 2.12). The operator can select any of the thermocouples to be

the control TC(s) and provide an optional description for that TC.

Super Systems Inc. Page 44 SDS Data Logger Manual #4565 Rev D

Page 45

Figure 2.12 Define Control TC screen

Clicking on the Accept button will set the selected control TC(s). Once a control TC(s) has been selected,

the TC’s number will be in Red on the “Active Thermocouples” section of the Thermocouples tab.

The

thermocouple(s) that is identified as the control TC will not be used for the TC summary when identifying

hottest and coldest channels.

Clicking on the “View Offsets used in Survey” link will display a list of the offsets that were used on the

survey (figure 2.13).

the Offset defined for these TCs have already been incorporated into the value the operator would see.

IF there is a value for the TC Spool Correction Factor, that value will also be incorporated providing a

corrected view for the user.

All values that are displayed to the users are corrected values.

That means

Figure 2.13 TCOffsets screen

Super Systems Inc. Page 45 SDS Data Logger Manual #4565 Rev D

Page 46

Note: Checking or unchecking TCs on the Thermocouples Tab will affect the TCs plotted on the Chart

Tab.

The next tab is the Furnace tab (figure 2.14a and 2.14b), which contains the furnace ID, the make and

model of the furnace, the furnace type, the furnace use, the furnace’s operating range, the furnace

dimensions, the furnace class (newer versions only), and an optional image of the furnace.

Figure 2.14a Report Properties Furnace Tab (Version 1.101.0.76 & below)

Figure 2.14b Report Properties Furnace Tab (Version 1.101.0.80 & above)

Super Systems Inc. Page 46 SDS Data Logger Manual #4565 Rev D

Page 47

Clicking on the open box next the image frame will open a dialog box where the user can search for an

image of the furnace to use.

The next tab is the Survey Box tab, which contains information about the survey box itself, such as the

make and model, the serial number, whom the survey box was calibrated by, and the calibration date

(figure 2.15).

Figure 2.15 Report Properties Survey Box Tab

The next tab is the Survey Details Tab (figure 2.16). The Survey Details tab contains the company name,

the survey start date, the survey duration, the actual duration of the survey, the survey specifcation(s),

whom the survey was performed by, whom the survey was approved by, the date range for the survey,

and the due date of the next survey.

Figure 2.16 Report Properties Survey Details Tab

Super Systems Inc. Page 47 SDS Data Logger Manual #4565 Rev D

Page 48

The next tab is the Survey Parameters Tab (figure 2.17). The Survey Parameters tab contains: the

survey tolerance, the survey setpoint, the overtemp setpoint, the simulated load in pounds, and the

microns.

Figure 2.17 Report Properties Survey Parameters Tab

The next tab is the Controller Tab (figure 2.18a and 2.18b). This tab contains the Controller

manufacturer, the controller model, and the instrument type (newer versions only) in the “Temperature

Controller Settings” area and this tab also contains the PID Settings: cycle time, dead band, output limit,

PB (Gain), rate, and reset.

Figure 2.18a Report Properties Controller Tab (Version 1.101.0.76 & below)

Super Systems Inc. Page 48 SDS Data Logger Manual #4565 Rev D

Page 49

Figure 2.18b Report Properties Controller Tab (Version 1.101.0.80 & above)

The last tab in the Report Properties tab is the User Defined Tab (figure 2.19a and 2.19b). This tab

contains ten (version 1.101.0.76 & below) or twenty (version 1.101.0.80 & above) fields that can be

defined by the user and included in the report.

Figure 2.19a Report Properties User Defined Tab (Version 1.101.0.76 & below)

Super Systems Inc. Page 49 SDS Data Logger Manual #4565 Rev D

Page 50

Figure 2.19b Report Properties User Defined Tab (Version 1.101.0.80 & above)

To create a user defined field, click on the “Modify User Defined Fields”. This will display a screen that