Page 1

SSI TECHNOLOGIES, INC.

Copyright January 30, 2009

RoHS

SSI Technologies – Application Note PS-AN4

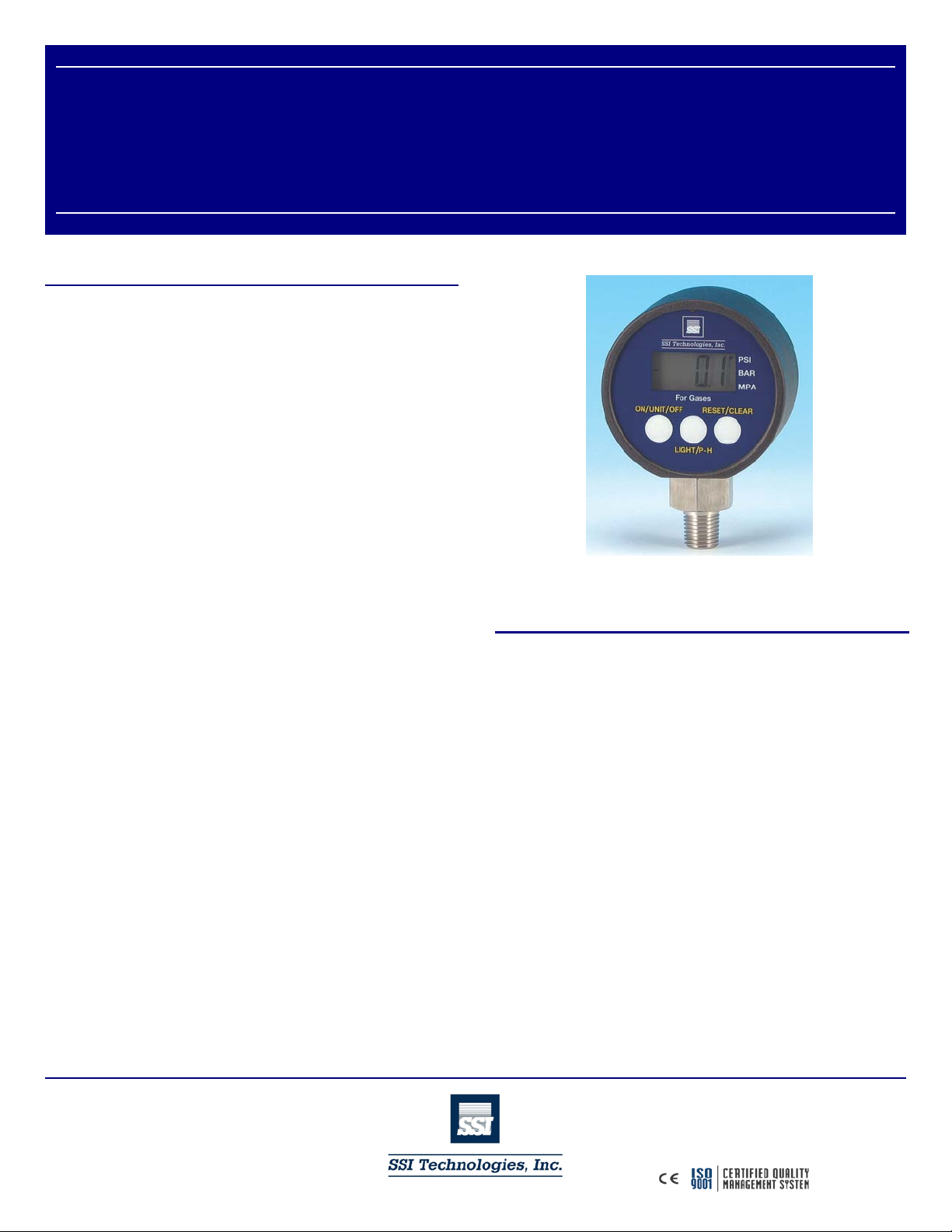

MediaGauge™ (Model MG-9V) Digital Pressure Gauge

Product Overview

Product Description

The MediaGauge™ Model MG-9V digital pressure gauge is

a stand alone 9V battery operated multi-functional digital

pressure gauge. The MG-9V digital pressure gauge

contains a media isolated piezoresistive pressure sensing

element, signal conditioning circuitry for temperature and

calibration compensation, a 304L stainless steel input

pressure port and a LCD back lit display. The MG-9V digital

pressure gauge has an accuracy of ± 0.25 % full scale. A

battery power saver mode is incorporated into the MG-9V to

automatically shut the LCD display off after 5 minutes

prolonging the battery’s life.

The MediaGauge™ MG-9V digital pressure gauge comes

standard with a variety of keypad operated functions –

multiple pressure unit display reading (PSI, BAR or MPA);

memory storage of maximum peak pressure reading; and

zero adjustment. A Ft of Head pressure measurement

display is available as an option for the MG-9V model.

The MediaGauge™ MG-9V digital pressure gauge is made

of all laser-welded 304L & 316L stainless steel for optimal

media isolation and usage in a wide variety of media. These

compact 3 inch, robust gauges measure pressures from

5 PSI to 5000 PSI and are well suited for a variety of

industrial and commercial applications such as refrigeration,

compressors, pumps, hydraulics, pneumatics and waste

water.

MediaGauge™ Model MG-9Vand Model MG-9V-F

Product Features

Superb Accuracy: ± 0.25% Full Scale

Pressure Ranges: 5, 15, 50, 75, 100, 200, 300, 500,

750, 1000, 1500, 2000, 3000, 5000 PSI

Keypad operated functions: Auto zero and peak hold

Operating Temperature: -10°C to 60°C

Storage Temperature: -20°C to 85°C

Typical Applications: General Purpose, Test, Process

Control, MRO, Water, Compressors, Refrigeration; Fuel

Cells; Pumps; Hydraulics; Spraying Syst em s;

The MediaGauge™ MG-9V digital pressure gauge has

better accuracy, longer life and standard multiple functions

which make it a better choice than mechanical pressure

gauges.

Controls Division

2643 West Court Street

Janesville, WI 53548-5011

Phone: (608)758-1500

Fax: (608)758-2491

www.ssitechnologies.com

Pneumatics; Flow; Robotics; Agriculture; Hydrogen

Storage

NIST traceable certificates available

NEMA 4X Rating

SSI Technologies Inc.

All Rights Reserved

Revision 4

1

Page 2

SSI TECHNOLOGIES, INC.

Copyright January 30, 2009

RoHS

SSI Technologies – Application Note PS-AN4

MediaGauge™ (Model MG-9V) Digital Pressure Gauge

Product Overview

Chemical Compatibilities: Any gas or liquid

compatible with 304L and 316L stainless steel. F or

example, Motor Oil, Diesel, Hydraulic fluid, Brake Fluid,

Water, Waste Water, Hydrogen, Nitrogen, and Air.

LCD Display Battery Saver Mode: MG-9V

automatically powers down after 5 minutes.

Multiple Pressure Units: PSI, BAR, MPA (kg/cm²)

(Optional Ft. of Head available)

Compact, Robust Package: 3 inches with black ABS

Thermoplastic case

Measurement Technology

In general, pressure measurement technology translates a

force from an induced pr essu re in to an el ec tric al quant ity. I n

digital pressure gauges, the electrical quantity is then

translated into pressure units and digitall y displayed.

316L stainless steel diaphragm and is then transferred

through the oil to the silicon sensor.

Strain gauges (resistive elements) in the silicon sensor are

used in a Wheatstone Bridge circuit. When the media’s

pressure is applied, the resistivity of the strain gauges

changes proportional to the pressure applied. One leg of

the bridge measures the input pressures port. The other

leg of the bridge is connected to the reference port (vacuum

pressure 0 PSI) the input pressure port is compared to.

Since piezoresistive pressure sensors are generally

sensitive to changes in temperature, the MediaGauge™

MG-9V digital pressure gauge uses signal conditioning to

compensate for temperature and calibration. The output

signal is then converted into one of 3 user selectable forms

(select units with the ON/UNIT/OFF button):

The SSI’s MediaGauge™ MG-9V digital pressure gauge

includes an 304L stainless steel input pressure port, a

piezoresistive pressure sensing element, signal conditioning

circuitry for temperature and calibration compensation, and

a LCD that displays the pressure measured in either PSI,

BAR or MPA (kg/cm²) units.

The piezoresistive sensing element consists of an oil-filled

micro-machined 316L stainless steel convoluted diaphragm

and a silicon crystal sensor. The silicon crystal sensor is

mounted on a 304L stainless steel housing and laser

welded to the diaphragm. Optimal media isolation is

achieved when the media’s pressure acts directly on the

Controls Division

2643 West Court Street

Janesville, WI 53548-5011

Phone: (608)758-1500

Fax: (608)758-2491

www.ssitechnologies.com

1) PSI

2) BAR

3) MPA (kg/cm²)

The MediaGauge™ MG-9V digital pressure gauge will

display the pressure reading after the ON/UNIT/OFF button

is depressed. The pressure measurement reading is

updated 3 times per second.

SSI Technologies Inc.

All Rights Reserved

Revision 4

2

Page 3

SSI TECHNOLOGIES, INC.

Copyright January 30, 2009

RoHS

SSI Technologies – Application Note PS-AN4

MediaGauge™ (Model MG-9V) Digital Pressure Gauge

Product Overview

MediaGauge™ MG-9V Panel Operation

The MediaGauge™ MG-9V panel has a LCD display and

three multi-functional buttons – ON/UNIT/OFF;

Backlight/P-H (Peak-Held) and RESET/CLEAR.

The

Backlight/P-H (Peak-Held) button is used to turn

the LCD backlight on/off and to display the maximum peak

pressure the unit has measured.

To turn the LCD backlight on: Press the Backlight/P-H

button once. To turn the LCD backlight off: Press the button

again.

To see the maximum peak pressure the unit has measured:

Press and hold down the Backlight/P-H button for 3

seconds. The maximum pressure reading will be blinking.

If the maximum pressure read was over the unit’s maximum

pressure range, o.L will be blinking on the display.

The

ON/UNIT/OFF button is used to display the

pressure reading; switch between pressure units (PSI; BAR;

and MPA) and to power down the unit.

To power on the unit: Press the ON/UNIT/OFF button. The

MediaGauge™ MG-9V has a battery saver mode and will

automatically shut off the display after 5 minutes.

To display the pressure reading in a different pressure unit:

Continue to depress the ON/UNIT/OFF button until the

arrow in the LCD points to the pressure units desired.

To manually power down the unit: Press the ON/UNIT/OFF

button and hold down for 3 seconds until OFF is displayed

and then release the button.

To return to the current pressure reading: Press the

Backlight/P-H button and hold down for 3 seconds.

The

RESET/CLEAR button is used to reset the gauge to

whatever pressure is currently applied to the port and to

clear the stored maximum peak pressur e reading.

To reference your MediaGauge™ digital pressure gauge to the

input port: Press and hold the RESET/CLEAR button for 3

seconds. The MediaGauge™ MG-9V will now be reference

to your input port. For example, if you have 20 psi on the

display and then you press and hold the RESET/CLEAR

button for 3 seconds the display will show 0.0 psi. A

measurement of 30 psi would then read as 10 psi on the

display.

To reset the MediaGauge™ digital pressure gauge: Make sure

the input port is either disconnected or connected to a 0 psi

input. Press and hold down the RESET/CLEAR button for 3

seconds.

Controls Division

2643 West Court Street

Janesville, WI 53548-5011

Phone: (608)758-1500

Fax: (608)758-2491

www.ssitechnologies.com

SSI Technologies Inc.

All Rights Reserved

Revision 4

3

Page 4

SSI TECHNOLOGIES, INC.

Copyright January 30, 2009

RoHS

SSI Technologies – Application Note PS-AN4

MediaGauge™ (Model MG-9V) Digital Pressure Gauge

Product Overview

To clear the maximum peak pressure reading: Press and hold

down the Backlight/P-H button for 3 seconds until the

maximum pressure reading appears on the LCD (it will be

blinking). Release the Backlight/P-H button. Press and

hold down RESET/CLEAR button for 3 second s.

Electrical Specifications

Supply Voltage 9V Battery

Response Time < 1 ms

Accuracy (75-3000 PSI) ± 0.25 FS

Thermal Error typ. (75-3000 PSI) ± 0.25 FS

Total Error (75-3000 PSI) ± 0.25 FS

Accuracy (15-50 PSI) ± 0.50 FS

Thermal Error Typ. (15-50 PSI) ± 0.50 FS

Electrical Specifications (Cont.)

Stability (Typical) < 0.25% Full Scale/Year

LCD Resolution (5 PSI) X.000

LCD Resolution (15 to 75 PSI) XX.00

LCD Resolution (100 to 750 PSI) XXX.0

Proof Pressure 3 X Full Scale

Burst Pressure

10 X Full Scale or 15,000

PSI whichever is less

Total Error (15-50 PSI) ± 0.50 FS

Accuracy (5 PSI) ± 1.00 FS

Thermal Error Typ. (5PSI) ± 1.00 FS

Total Error (5PSI) ± 1.00 FS

Controls Division

2643 West Court Street

Janesville, WI 53548-5011

Phone: (608)758-1500

Fax: (608)758-2491

www.ssitechnologies.com

Operating Temperature Range -10° to 60°C (14° to 140°F)

Storage Temperature Range -20° to 85°C (-4°to 185°F)

SSI Technologies Inc.

All Rights Reserved

Revision 4

4

Page 5

SSI TECHNOLOGIES, INC.

Copyright January 30, 2009

RoHS

, 20g

SSI Technologies – Application Note PS-AN4

MediaGauge™ (Model MG-9V) Digital Pressure Gauge

Product Overview

Tested Conditions

Humidity 250 Hours (40°C and 90% to 95% R.H.

Pressure/Temperature

Cycles

Thermal Shock

Vibration

> 1.8 million Cycles (0 to FS @ 8Hz and

-20° to 85°C)

250 Cycles (85 to -20°C. 0.5 hr soaks at

temperature

144 Hours (100 to 2000 Hz

sinusoidal in 3 axes)

Installation/Mounting

1) Mount the MediaGauge™ MG-9V digital pressure

gauge on a suitable (1/4” or 1/8” NPT) female

fitting. Use Teflon tape or pipe dope to seal the

threads.

2) Do no over tighten. Torque to 150 in lbs +/- 1 in lb.

Controls Division

2643 West Court Street

Janesville, WI 53548-5011

Phone: (608)758-1500

Fax: (608)758-2491

www.ssitechnologies.com

SSI Technologies Inc.

All Rights Reserved

Revision 4

5

Page 6

SSI TECHNOLOGIES, INC.

RoHS

SSI Technologies – Application Note PS-AN4

MediaGauge™ (Model MG-9V) Digital Pressure Gauge

Product Overview

MediaGauge™ with 22mm Hex and 1/4" - 18 NPT Process Connection

Controls Division

2643 West Court Street

Janesville, WI 53548-5011

Phone: (608)758-1500

Fax: (608)758-2491

www.ssitechnologies.com

6

Copyright January 30, 2009

SSI Technologies Inc.

All Rights Reserved

Revision 4

Page 7

SSI TECHNOLOGIES, INC.

RoHS

MG

-

500

- A -

9V

Product Family

Pressure Ranges

Port Configuration

Connector

SSI Technologies – Application Note PS-AN4

MediaGauge™ (Model MG-9V) Digital Pressure Gauge

Product Overview

Digital Pressure Gauge Ordering System

The following explains SSI’s MediaGauge™ Digital Pressure Gauge order number sequence.

Example

• MG

Ft of Head Options

MG 100 – A – 9V – F

200 – A – 9V – F

300 – A – 9V – F

Rubber Boot Options:

Order P/N 14405.1 for Model MG

• 5

• 15

• 50

• 75

• 100

• 200

• 300

• 500

• 750

• 1000

• 1500

• 2000

• 3000

• 5000

Hex Port

• A 22mm 1/4 - 18 NPT

• B 22mm 1/8 – 27 NPT

(Port B is valid only on MG

models and has a 6 week lead

time)

• 9V Battery, Operated

• 9V-F Battery, Operated with optional

Ft of Head units

(9V-F is valid only for MG

models)

Controls Division

2643 West Court Street

Janesville, WI 53548-5011

Phone: (608)758-1500

Fax: (608)758-2491

www.ssitechnologies.com

Copyright January 30, 2009

SSI Technologies Inc.

All Rights Reserved

Revision 4

7

Loading...

Loading...