SSD COMPANY LIMITED 637f User Manual

637f

Servo drive

Product

Manual

07-02-10-01-E-V0505.doc

UL:07-02-01

UL:07-02-02-01

UL: 07-02-09-02

UL:07-02-10-02

UL:07-05-02-03

Additional Supporting Documentation

Product Manual Rack 6 U and EMV

Product Manual Power Supply Plug-in Module NE B

Feedback System HIPERFACE

®

Product - Manual Safe Standstill SBT

Product Manual SUCOnet K

UL:07-05-03-02

UL:07-05-04-02

UL:07-05-05-02

UL:07-05-07-02

UL:07-05-08-02

Product Manual Bus Interface CAN for 635 / 637 / 637+ / 637f

Product Manual Bus Interface DP for 635 / 637 / 637+ / 637f

Product Manual Bus Interface Interbus S for 635 / 637 / 637+ / 637f

Product Manual I/O Interface for 635 / 637 / 637+ / 637f

Product Manual Bus Interface Device Net for 635 / 637 / 637+ / 637f

________________________________________________________________________________________________________________________________________________________________________________________________________________________

2 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

UL:07-09-04-02

UL:10-06-03

UL: CD

UL:10-06-05

UL: 12-01

Additional Supporting Documentation

Product Manual Suppression Aids EH

Product Manual Serial Transfer Protocol

635 / 637 / 637+ / 637f EASY- Serial

EASYRIDER

Product Manual Software BIAS

Product Manual Accessories - Plugs

®

Windows - Software

®

UL:12-02

Product Manual Accessories - Cable

UL:12-03

Product Manual Ballast Resistors

©SSD Drives GmbH.

All rights reserved. No portion of this description may be produced or processed in any form without the

consent of the company.

Changes are subject to change without notice.

SSD Drives has registered in part trademark protection and legal protection of designs.

The handing over of the descriptions may not be construed as the transfer of any rights.

Made in Germany, 2005

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 3

Seite

Table of Contents

The Most Important Thing First ........................................................................7

Safety Precation .................................................................................................8

1 General Information................................................................................10

1.1 System Description.......................................................................................................................10

1.1.1 Digital Communication..................................................................................................................11

1.1.2 Operation configurations...............................................................................................................11

1.1.3 Compatibility with 637 Servo Drives (Not required for new projects)...........................................12

1.1.4 Compatibility with 637+ Servo Drives..........................................................................................12

1.2 Type Code ...............................................................................Fehler! Textmarke nicht definiert.

1.2.1 Combination possibilities for the various communications / I/O - modules..................................14

1.2.2 Layout module slots......................................................................................................................15

1.2.3 Layout of Power Board.................................................................................................................15

1.3 Range Data...................................................................................................................................16

1.3.1 Insulation Concept........................................................................................................................16

1.3.2 General Data.................................................................................................................................16

1.3.3 Compact Units 637f/K D6R...........................................................................................................17

1.3.4 Plug-In Modules 637f/D6R............................................................................................................18

1.3.5 Single- and Three-Phase Supply..................................................................................................19

1.3.6 Output Power................................................................................................................................20

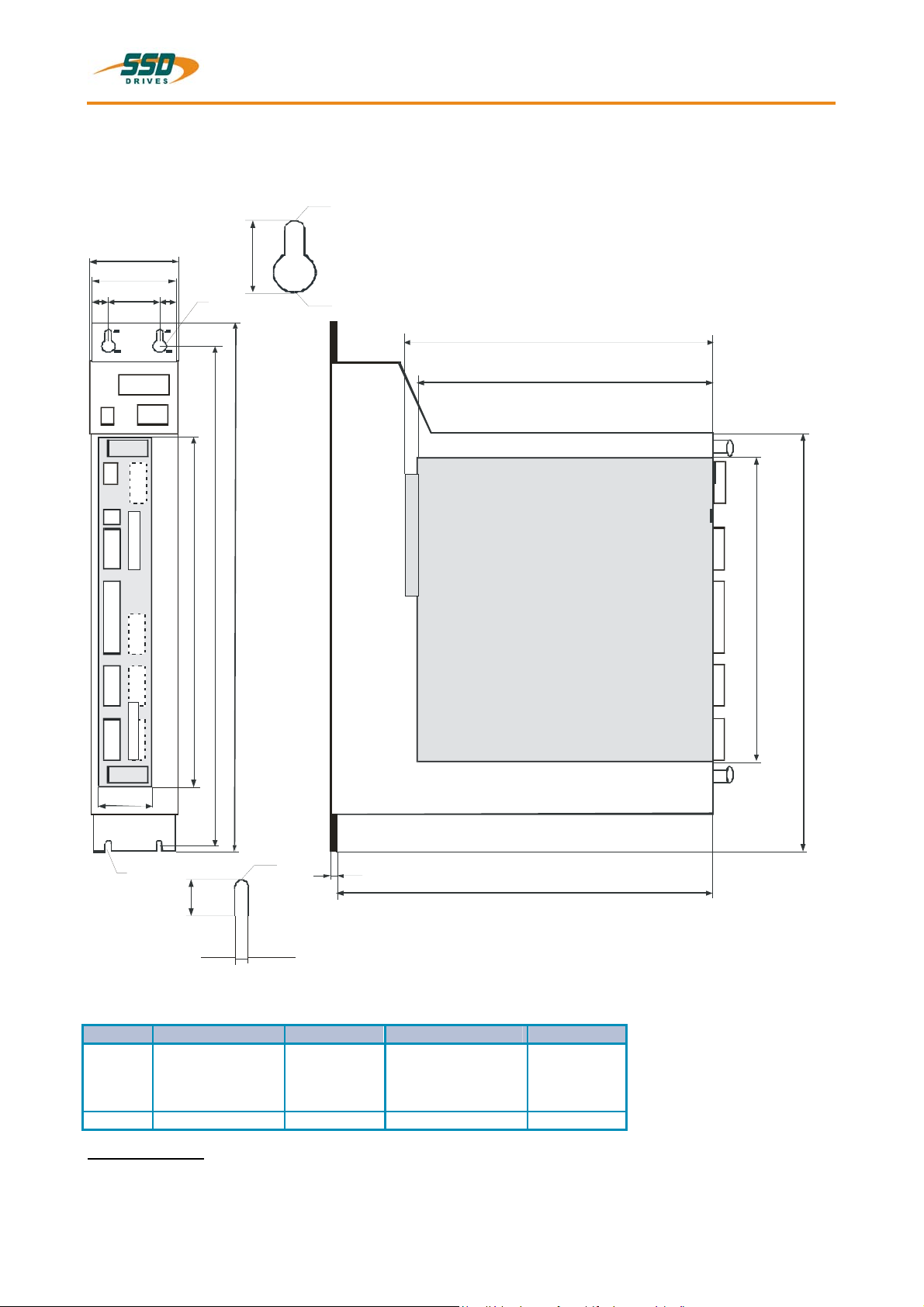

1.4 Dimensions...................................................................................................................................21

1.4.1 Dimensions for Compact Device and Plug-In Module..................................................................21

1.4.2 EMC-Clip (optional) .....................................................................................................................22

2 Connector Assignments and Functions ..............................................23

2.1 General View of Connections for Compact Device 637f/ K D6R 02 – 10 ....................................23

2.1.1 637f/K D6R 02...10 Width 14 HP..................................................................................................23

2.1.2 637f/K D6R 16...30 Width 20 HP..................................................................................................24

2.2 Connector Pin Assignments and Contact Functions....................................................................25

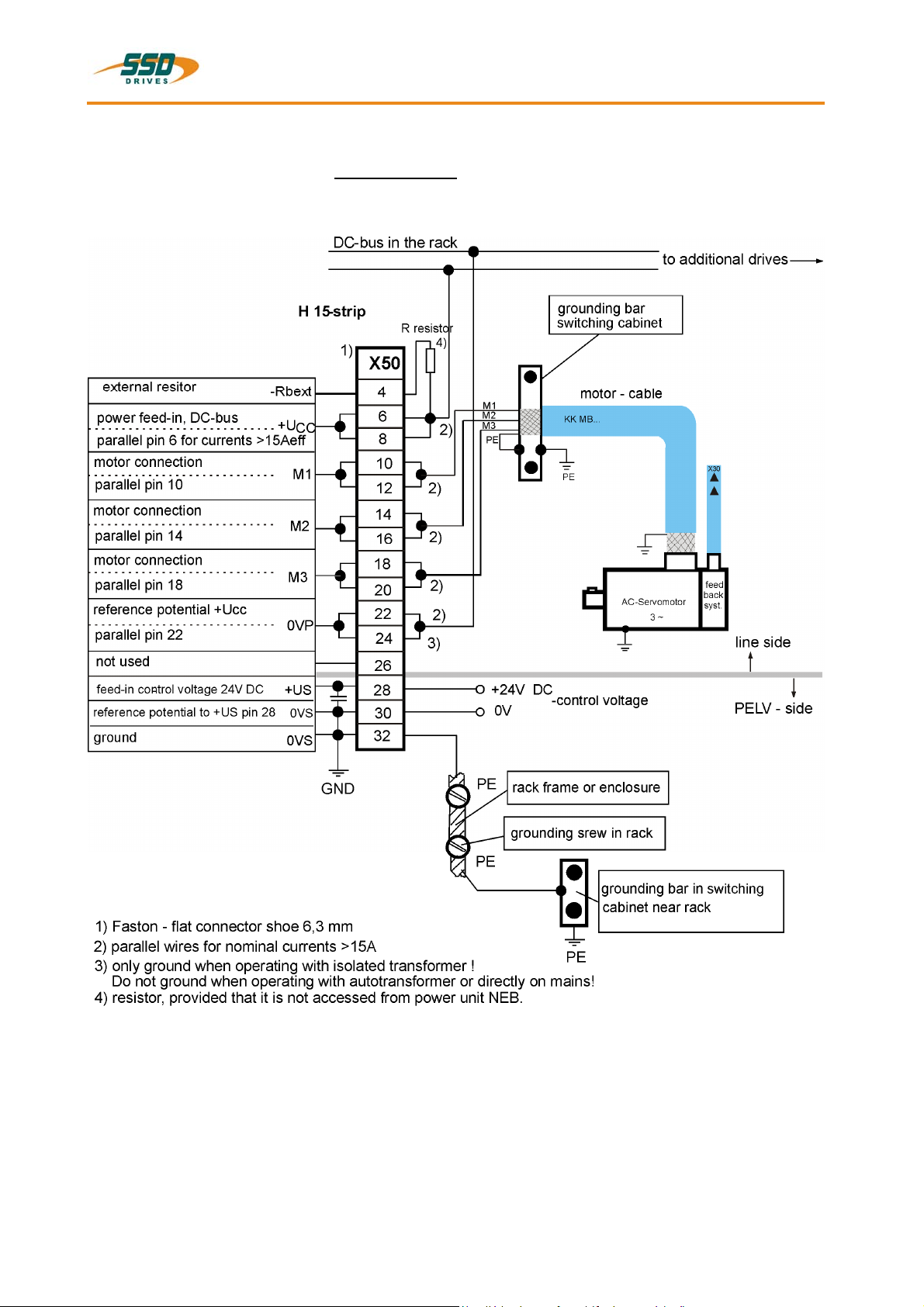

2.2.1 Power Connections for Plug-In Module 637f/D6R........................................................................25

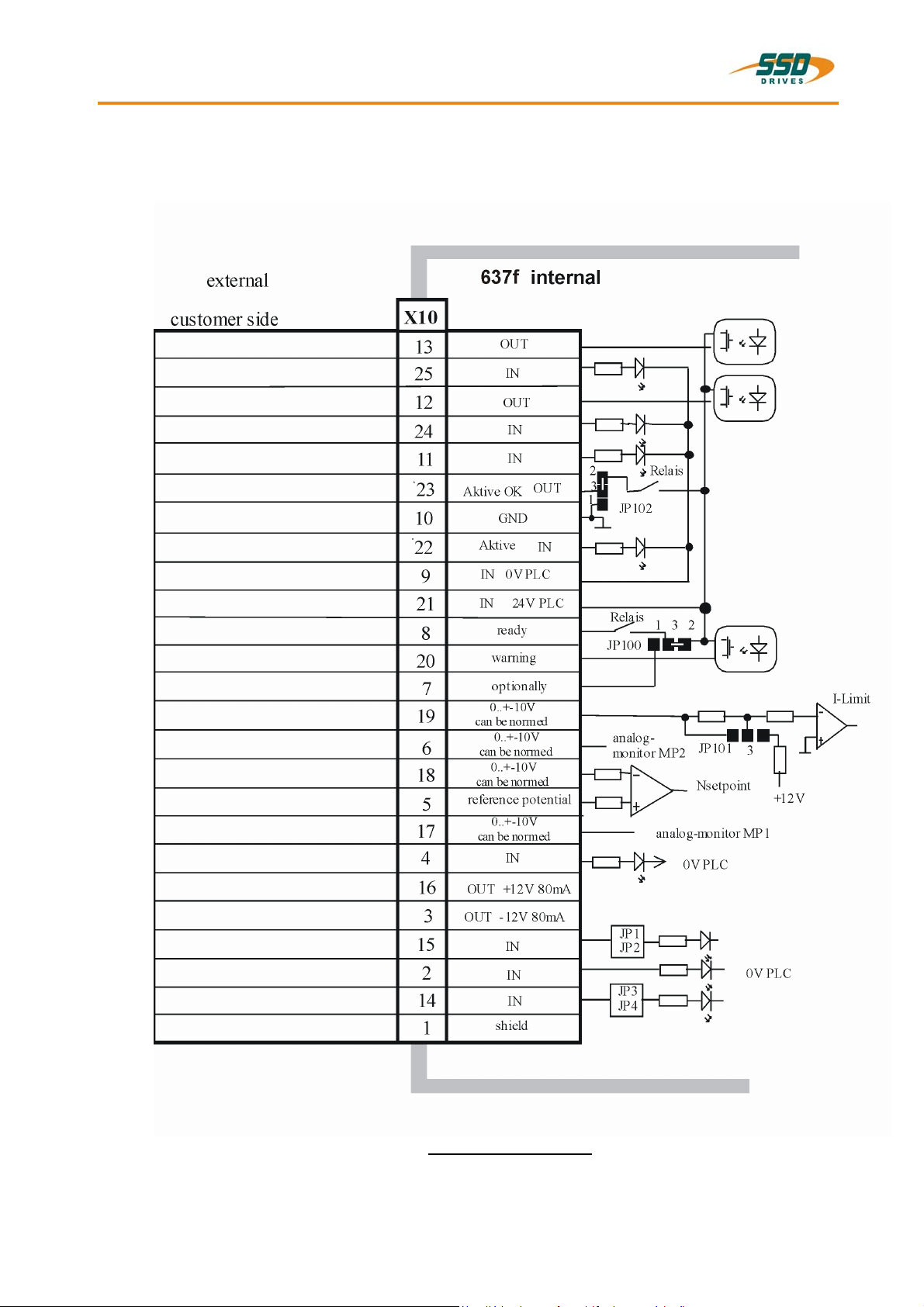

2.3 Signal Connections.......................................................................................................................26

2.3.1 Control Signal Plug X10 - SUB D25 Socket.................................................................................26

2.4 Feedback Sensor X30..................................................................................................................29

2.4.1 Function module X300..................................................................................................................29

2.4.2 Feedback Sensor Connection X30 (SUB D 09 Socket)...............................................................30

2.5 Multi-function X40.........................................................................................................................31

2.5.1 Incremental Output.......................................................................................................................32

2.5.2 Incremental-Input..........................................................................................................................32

2.5.3 Stepper Motor Input......................................................................................................................33

2.5.4 Stepper Motor Input......................................................................................................................33

2.5.5 SSI Encoder Interface...................................................................................................................34

2.6 Digital Interfaces...........................................................................................................................35

2.6.1 Service Interface - COM1 (RS232)...............................................................................................35

2.6.2 Fieldbus Interface - COM2............................................................................................................36

2.7 Option module RP SBT ................................................................................................................44

2.7.1 Safe Stop......................................................................................................................................44

2.7.2 Brake control and PTC evaluation................................................................................................45

________________________________________________________________________________________________________________________________________________________________________________________________________________________

4 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

Seite

Table of Contents

3 Operating modes....................................................................................46

3.1 Operating modes and pin functions..............................................................................................47

3.2 Configurable pin-functions (depending on the operating mode)..................................................48

3.3 Function diagrams from inputs and outputs .................................................................................49

4 Mechanical Installation ..........................................................................50

4.1 Mounting.......................................................................................................................................50

4.2 Control cabinet - mounting............................................................................................................50

4.3 Cooling..........................................................................................................................................50

5 Electrical Installation..............................................................................51

5.1 Safety............................................................................................................................................51

5.2 The danger of electric shocks.......................................................................................................51

5.3 Danger areas................................................................................................................................51

5.4 Grounding, safety grounding ........................................................................................................51

5.4.1 Ground connections......................................................................................................................51

5.5 Short-circuit capability and discharge currents.............................................................................51

5.6 Fuses, contactors, filters...............................................................................................................52

5.7 Correction of supply current .........................................................................................................53

5.8 Brake resistor................................................................................................................................54

5.8.1 Selection of the brake resistor......................................................................................................54

5.8.2 Configuration of the brake resistor ...............................................................................................55

6 Wiring instructions.................................................................................57

6.1 General Information......................................................................................................................57

6.2 Control cabling..............................................................................................................................57

6.3 Power cabling ...............................................................................................................................57

6.4 Installation of the rack...................................................................................................................57

6.5 Analog setpoint.............................................................................................................................57

6.6 Safety rules...................................................................................................................................57

6.7 Electromagnetic compatibility (EMC)............................................................................................57

6.7.1 Hints for mounting.........................................................................................................................58

6.7.2 Example for mounting...................................................................................................................59

6.7.3 Achieveable specifications and conditions...................................................................................59

7 Setting and programming......................................................................60

7.1 Jumper..........................................................................................................................................60

7.2 Digital communication see: Chapter 13........................................................................................60

8 Commissioning.......................................................................................61

8.1 Preparation ...................................................................................................................................61

8.2 Commissioning in steps................................................................................................................62

9 Diagnose und Fehlersuche....................................................................65

9.1 7-segment display.........................................................................................................................65

9.2 Reset of a regulator trouble..........................................................................................................69

9.3 Trouble shooting...........................................................................................................................70

10 Block circuit diagram.............................................................................71

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 5

Seite

Table of Contents

11 General Technical Data..........................................................................72

11.1 Power circuit .................................................................................................................................72

11.2 Control circuit................................................................................................................................72

11.3 Signal inputs and outputs, connection X10 ..................................................................................72

11.4 Signal inputs and outputs, connection X120B resp. 120C...........................................................73

11.5 Digital control................................................................................................................................73

11.6 Digitale communication.................................................................................................................74

11.7 Resolver evaluation/transmitter principle......................................................................................74

11.8 Controllersystem...........................................................................................................................74

11.9 Analog-Outps................................................................................................................................75

11.10 Thermal data.................................................................................................................................75

11.11 Mechanical data............................................................................................................................75

12 Disposal...................................................................................................76

13 Software...................................................................................................77

13.1 EASYRIDER® Windows - Software..............................................................................................77

13.2 SSD Drives programming language BIAS....................................................................................78

14 Certificates..............................................................................................81

15 Index ........................................................................................................86

16 Modification Record...............................................................................88

________________________________________________________________________________________________________________________________________________________________________________________________________________________

6 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

The Most Important Thing First

The Most Important Thing First

Thanks for your confidence choosing our product.

These operating instructions present themselves as an overview of the technical data and

features.

Please read the operating instructions before operating the product .

If you have any questions, please contact your nearest SSD Drives representative.

Improper application of the product in combination with dangerous voltage can lead to

injuries.

In addition, damage can also occur to motors or other products.

Therefore please observe our safety precautions strictly.

Safety precautions

We assume that, as an expert, you are familiar with the relevant safety regulations,

especially in accordance with VDE 0100, VDE 0113,VDE 0160, EN 50178, the accident

prevention regulations of the employers liability insurance company and the DIN

regulations and that you are able to use and apply them.

As well, relevant European Directives must be observed.

Depending on the kind of application, additional regulations e.g. UL, DIN are subject to be

observed.

If our products are operated in connection with components from other manufacturers,

their operating instructions are also subject to be observed strictly.

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 7

Safety Precation

Attention

Digital servo drives, corresponding to EN 50178/VDE 0160, are power

electronic components utilized for the regulation of the flow of energy in

electrical power installations. They are exclusively designed and configured to

supply SSD Drives, or SSD Drives approved, servo motors. Handling,

installation, operation, and maintenance are only permitted under the conditions

of and in keeping with the effective and/or legal regulations, regulation

publications and this technical document.

Safety Precautions

The operator must make sure that these regulations are strictly followed.

The Concept of Galvanic Separation and Insulation:

Galvanic separation and insulation corresponding to EN 50178/VDE 0160,

provides for additional insulation protection.

In addition, all digital signal inputs and outputs are provided with a galvanic

separation utilizing either a relay or an optical coupler. In this way, an increased

level of protection against potential interference and a limitation of potential

damage due to incorrect connections are provided.

The voltage level must not exceed the designated low safety voltage of 60V

DC or 25V AC, respectively, in accordance with EN 50178/VDE 0160.

The operator must make sure that these regulations are strictly followed.

High Voltage!

Danger of Electrocution!

Life Threatening Danger!

Danger !

Caution !

Due to safety considerations and the product guarantee, the

operator is prohibited from opening the servo drive case. Service,

maintenance and repair of SSD Drives products should only be

carried out by specified representatives of the company. Expert

configuration and professional installation, as described by this

document, are the best way to insure for the problem-free operation

of the SSD Drives servo drive!

________________________________________________________________________________________________________________________________________________________________________________________________________________________

8 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

Please

observe!

Safety Precautions

Pay Special Attention to the Following:

Permissible Protection Class: Protective Grounding - operation is only permitted

when the protective conductor is connected according to regulations.

The operation of servo drives is not allowed, under the sole use of a residual

current operated protective device as protection against indirect touching. The

servo drive may only be used in the rack or in its compact enclosure.

Furthermore the regulator is designed solely for control cabinet operation.

Work on or with the servo drive may only be carried out with insulated tools.

Installation work may only be done in a de-energized state. When working on

the drive, one should not only block the active – input, but also separate the

drive completely from the main power connection.

CAUTION - Risk of Electrical Shock:

Wait 3 minutes after switching the component off, to allow the capacitors to

discharge.

Screws sealed with varnish fulfill an important protection function and may not

be moved or removed.

It is prohibited to penetrate the inside of the unit with objects of any kind.

Protect the unit from falling parts, pieces of wire, metal parts, etc., during

installation or other work in the control cabinet. Metal parts can lead to

a short-circuit in the servo drive.

Before putting the unit into operation, remove additional covers so that the unit

does not overheat. With measurements at the servo drive it is absolutely

necessary to observe the potential separation

SSD Drives GmbH is not liable for damages which may occur when the

instructions and/or the applicable regulations are not explicitly observed!

Stop !

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 9

1 General Information

1 General Information

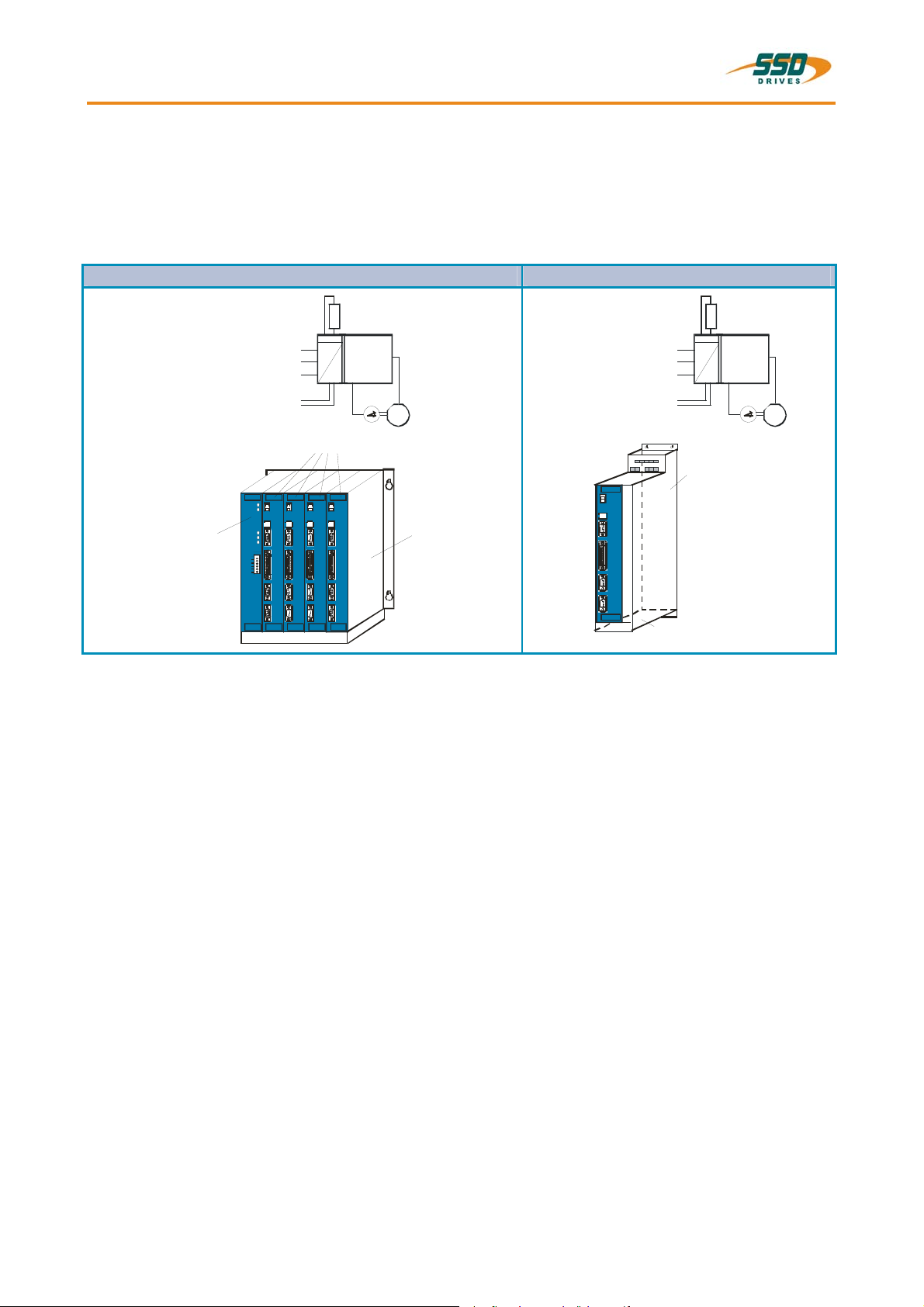

1.1 System Description

The 5th generation of the digital servo drive serves to regulate the current, speed and position of

AC servo motors, (standard: with resolver)

All control circuits and functions are realized digitally.

System variants

Rack - version: 637f/D6R.... Compact - version: 637f/K D6R....

Su pply volta ge:

1*oder 3* 230VAC/50..60Hz

3*40 0...460VA C/50..60Hz

Power supp ly

p lug -i n modul e

NE B

R

Us 24VDC

Fan

AC

DC

Servodrives

637f/ K D6 R

M

Rack, R6

R6 EMV

Su pply volta ge:

1*oder 3* 230VAC/50..60Hz

3*40 0...460VA C/50..60Hz

or

Us 24VDC

Servodrive

Fan

R

637f/ K D6 R

AC

DC

Power supply unit

Explanations for the rack and power supply modules are documented in separate descriptions.

If required, the returned braking energy can be drawn off into additional external ballast resistors.

The AC-supply voltage is fed directly or via transformer to the associated power supply module.

The devices are designed to be operated on networks which are grounded at the

centre point (TN networks) !

M

________________________________________________________________________________________________________________________________________________________________________________________________________________________

10 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

General Information 1

System Description

1.1.1 Digital Communication

Diagnostics / Setup

General: by 7 segment display

Comfortable: via PC with EASYRIDER

(serial interface RS232)

Communication

The serial-communication-protocol is open and fully documented.

(Explanation see separate documentation)

Every user has unrestricted access to all functions and parameters.

EASYRIDER

customer-ma de software

PLC Software

PLC, binary selectionl,+/- 10V

®

Windows – Software from version V8.xx

⌧

⌧

⌧

COM1

RS232

COM2

X10

RS232

RS422

RS485

CAN-BUS 1

CAN-BUS 2

SUCOnet K

Profibus DP

Interbus S

Devi ceNet

current-loop

position-loop

637f

speed-loop

PLC

instr uctions

1.1.2 Operation configurations

There are opportunities ranging from simple current and speed control to programmable position control

processes (PLC), supported by the 1500 BIAS command blocks.

"BIAS" User shell for intelligent drive controls

see:

chapter 3 Operating modes

chapter 13.2 BIAS commands

chapter 13.3 Extended BIAS commands

diagnostic s

setup

⌧

programming

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 11

1 General Information

System Description

1.1.3 Compatibility with 637 Servo Drives (Not required for new projects)

The 637f series servo drives are essentially pin- and functionally compatible with the servo drives 637.

However, when a servo drive 637 is replaced with a 637f drive, the existing application must be checked and

carefully tested to determine compliance under the corresponding safety precautions.

The following points should be checked in any case and eventually be adjusted before the function test:

1. Motor direction parameter and limit switch setting (see release note V6.12)

2. Position setpoints and comparison values have to be quadrupled, resp. sixteenfold

(low encoder resolution at 637)

3. Coupling factors in synchronous applications have to be quadrupled, resp. sixteenfold

(low encoder resolution at 637)

4. Execution of BIAS- and PLC programs is 2.25 times quicker than with the 637. This can cause timing

problems with improper programming (e.g. wait times with NOPs)

1.1.4 Compatibility with 637+ Servo Drives

(Not required for new projects)

Der Servoregler 637f ist voll funktionskompatibel zu 637+

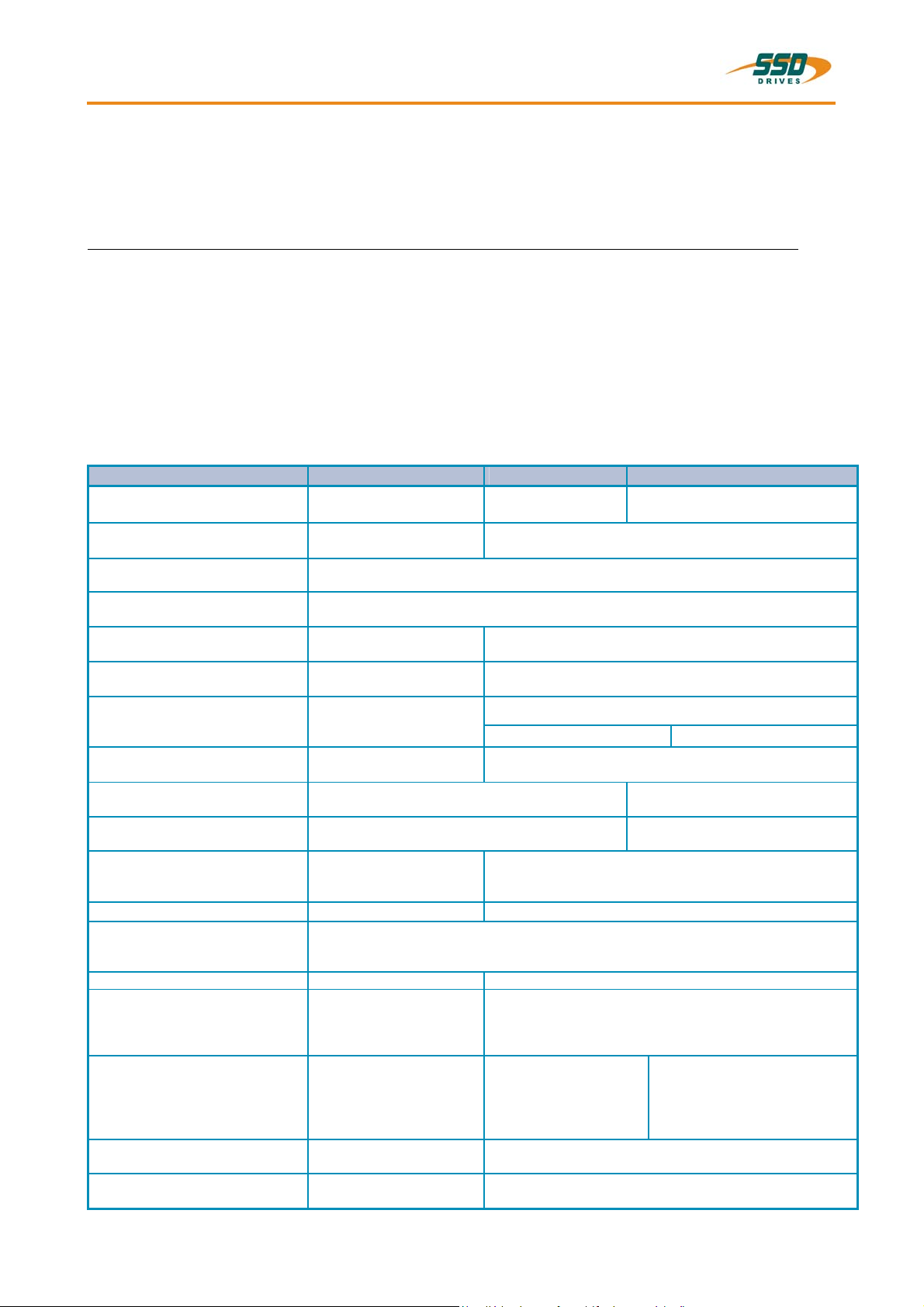

Funktion 637 637+ 637f

PC-Operating-Software

PC-Connection-Cable

see: chapter 2.6.2.3

Power Part, Power Data and

Power Connectors

Control Singals, Connector X10

see: chapter 2.3.2

Analog Set Point X10.5/18,

Resolution

Resolver Signals, Connector X30

see: chapter 2.4.2

Feedback – Interface - Module

X300

see: chapter 2.4.1

Multifunction, Connector X40

see: chapter 2.5

Interface, Connector COM2

see: chapter 2.6.2 – 2.6.2.9

Options Module

see: chapter 2.6.2 – 2.6.2.10

Operating Modes, BIAS –

Functions

see: chapter 3 and 13.2

PROG-Key present

Analog-Output - Test Signals

MP1/MP2:

> connector X 10

> Front Test Sockets yes no

Technical Data

Analog Out

MP1 / X10.17

MP2 / X10.6

Control Loops

see: chapter 11.5

Control Loop Parameters

Jumper

see: chapter 7.1

EASYRIDER

or Windows Version

PC - SUBD-9 to

LEMO connector (COM1)

12/14 Bit Resolution

command set compatible

12/14 bits ≈ 1revolution

7 bits , Rout = 10 kOhm

7 bits , Rout = 10 kOhm

®

DOS Version

12 bits

pin–compatible

-

compatible

position value

Generally compatible,

EASYRIDER®

Windows Version

equal pinning and function

equal

equal

X 10.6 / X 10.17

performance boost

compared

cycle time twice as fast

EASYRIDER®

Windows Version V8.xx

PC - SUBD-9 to

4-pin module connector (COM1)

equal

14 bits

extended functionality

16 Bit Resolution

HIPERFACE

- SIN / COS

extended functionality

extended functionality

CAN BUS 2, RP_2Cx

extended functionality

RP_SBT

future extensions possible

position value 16 bit ≈ 1 revolution

not available

8 bits , Rout = 1.8 kOhm

10 bits , Rout = 1.8 kOhm

to 637:

possible optimization required

JP2.2, JP2.3, JP2.7, JP2.8

performance boost

compared to 637f:

cycle time for speed twice as

fast,

position eight times as fast

as

________________________________________________________________________________________________________________________________________________________________________________________________________________________

12 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

General Information 1

1.2 Modle code

standard optional special

marking

type: 637f/

a

X D6R XX .S5 -X -X -XXX -XXX -XXx -XXX

marking description

a

b

c

d .S5 = Digital servo drive 5th generation

e

f

g1

g2

h

i

at assignment [C] Interface you can used 1 x CAN *

XXXX/ = 637f ≅ SSD Drives-fast-design

K = 1-axis-compact digital-servo drive system

0 = design plug-in device

D6R = Digital 6U drive

Rated current:

02 = 2 amps

04 = 4 amps

06 = 6 amps

10 = 10 amps

16 = 16 amps

22 = 22 amps

30 = 30 amps

Intermediate circuit rated voltage:

-3 = 325V (230V AC) 16..30A only as rack system possible

-7 = 650V (460V AC)

-E = With EMC-Clip unit

-0 = Without EMC-Clip unit

additional option modules on the drive for communication via COM2

-000 = None option

-232 = RS 232 interface ≅ slot A (B)

-422 = RS 422 interface ≅ slot A (B)

-485 = RS 485 interface ≅ slot A (B)

-CAN = CAN – Bus ≅ slot A (B)

-2CA = 2 x CAN (without I/O’s) ≅ slot B (A) / [C*]

-2C8 = 2 x CAN + 4 outputs and 4 inputs ≅ slot B (A) / [C*]

-DEV = CAN - Bus / DeviceNet ≅ slot B (A)

-SUC = SUCOnet K ≅ slot B (A)

-PDP = Profibus DP ≅ slot B (A)

-IBS = Interbus S (Attention: changed front plate) ≅ slot B (A)

-EA5 = I/O interface (5 inputs, 2 outputs) ≅ slot B (A)

additional option modules on the drive via X200

-000 = No Options

-EAE = I/O interface (14 inputs, 10 outputs) ≅ slot C

-SBT = Safety – Board Module ≅ slot C

X300 – Function module

-RD2 = Standard X30

-HF2 = HIPERFACE module 2nd version ≅ slot D

-SC2 = Sinus / Cosinus - module 2nd version ≅ slot D

Entry only at use

-Sxx = Special - resistance - setting

-X7x = Broad-band contact X10.7 - X10.8

-BSx = Protection moisture condensation

-B7x = Protection moisture condensation + Broad-band contact X10.7 - X10.8

-923 = Jumper 209 / 2 - 3 open , by SBT - Option Thermo - Contact X30 (PTC / NTC)

Typical Example

A typical example of an order of a 1-axis compact device in SSD Drives design:

Type:

a b c d e f g1 g2 h i

637f/ KD6R 02 .S5 -3 -0 -2CA -EAE -RD2 -

b c d e f g1 g2 h i

(Attention: changed front plate)

Resolver module 2nd version ≅ slot D

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 13

1 General Information

x

x

Modle Code

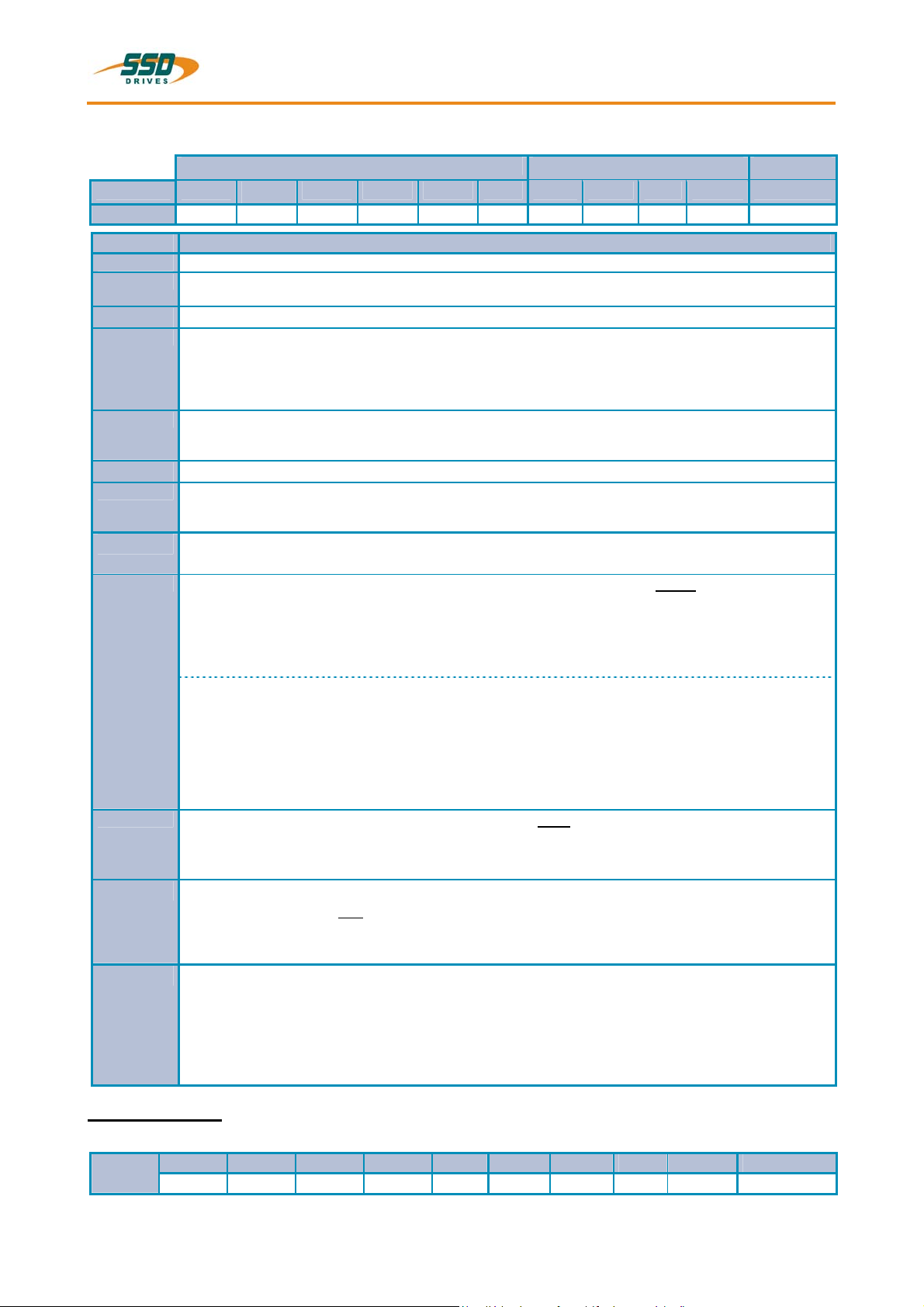

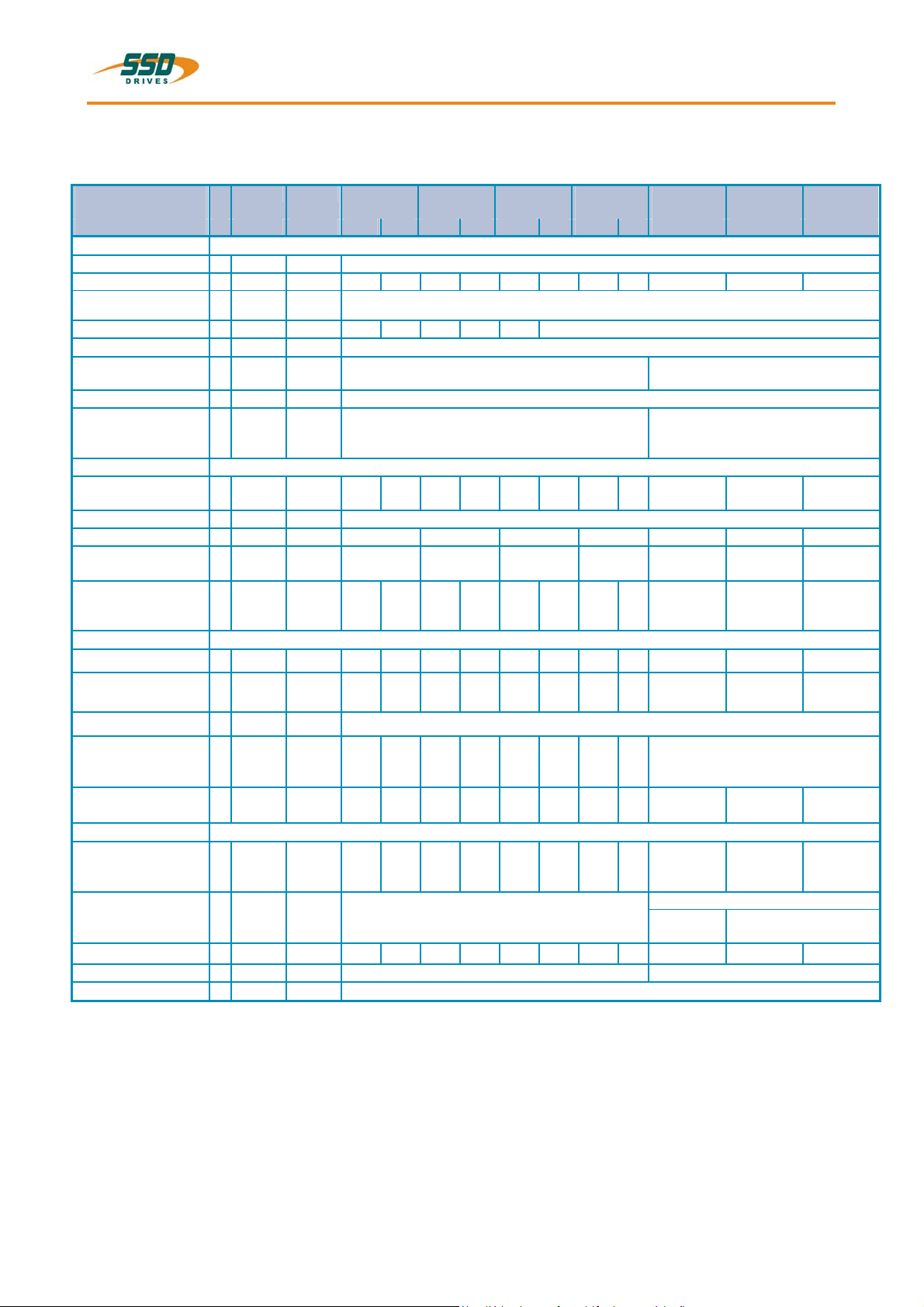

1.2.1 Combination possibilities for the various communications / I/O - modules

Slots A B C

Option modules 232 422 485 CAN 2CA 2C8 DEV SUC PDP IBS EA5 EAE SBT *2CA *2C8

Type Codel

637f/xD6Rxx.S5-x-x-232-000-xxx

637f/xD6Rxx.S5-x-x-232-EAE-xxx

637f/xD6Rxx.S5-x-x-232-SBT-xxx

637f/xD6Rxx.S5-x-x-232-2CA-xxx

637f/xD6Rxx.S5-x-x-232-2C8-xxx

637f/xD6Rxx.S5-x-x-422-000-xxx

637f/xD6Rxx.S5-x-x-422-EAE-xxx

637f/xD6Rxx.S5-x-x-422-SBT-xxx

637f/xD6Rxx.S5-x-x-422-2CA-xxx

637f/xD6Rxx.S5-x-x-422-2C8-xxx

637f/xD6Rxx.S5-x-x-485-000-xxx

637f/xD6Rxx.S5-x-x-485-EAE-xxx

637f/xD6Rxx.S5-x-x-485-SBT-xxx

637f/xD6Rxx.S5-x-x-485-2CA-xxx

637f/xD6Rxx.S5-x-x-485-2C8-xxx

637f/xD6Rxx.S5-x-x-CAN-000-xxx

637f/xD6Rxx.S5-x-x-CAN-EAE-

xxx

637f/xD6Rxx.S5-x-x-CAN-SBT-xx

637f/xD6Rxx.S5-x-x-2CA-000-xxx

637f/xD6Rxx.S5-x-x-2CA-EAE-xxx

637f/xD6Rxx.S5-x-x-2CA-SBT-xxx

637f/xD6Rxx.S5-x-x-2C8-000-xxx

637f/xD6Rxx.S5-x-x-2C8-EAE-xxx

637f/xD6Rxx.S5-x-x-2C8-SBT-xxx

637f/xD6Rxx.S5-x-x-DEV-000-xxx

637f/xD6Rxx.S5-x-x-DEV-EAE-xxx

637f/xD6Rxx.S5-x-x-DEV-SBT-xxx

637f/xD6Rxx.S5-x-x-SUC-000-xxx

637f/xD6Rxx.S5-x-x-SUC-EAE-xx

637f/xD6Rxx.S5-x-x-SUC-SBT-xxx

637f/xD6Rxx.S5-x-x-PDP-000-xxx

637f/xD6Rxx.S5-x-x-PDP-EAE-xxx

637f/xD6Rxx.S5-x-x-PDP-SBT-xxx

637f/xD6Rxx.S5-x-x-PDP-2CA-xxx

637f/xD6Rxx.S5-x-x-PDP-2C8-xxx

637f/xD6Rxx.S5-x-x-IBS-000-xxx

637f/xD6Rxx.S5-x-x-IBS-EAE-xxx

637f/xD6Rxx.S5-x-x-IBS-SBT-xxx

637f/xD6Rxx.S5-x-x-EA5-000-xxx

637f/xD6Rxx.S5-x-x-EA5-EAE-xxx

637f/xD6Rxx.S5-x-x-EA5-SBT-xxx

637f/xD6Rxx.S5-x-x-000-EAE-xxx

637f/xD6Rxx.S5-x-x-000-SBT-xxx

-000 = none option possible com bination at assignment [C] Interface you can used 1 x CAN *

-

-

-

-

-

- -

- -

- -

- -

- -

- - -

- - -

- - -

- - - -

- - - -

- - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

Example:

637f/xD6Rxx.S5-x-x-232-EAE-RD2

… -232 = on slot A

… -EAE = on slot C

… -RD2 = on slot D (Motor - Feedbacksystem)

- - - - - - - - - - - - - -

- - - -

- - - -

- - - -

- - - -

- - -

- - -

- - -

- - -

- - -

- -

- -

- -

- -

- -

-

- - - - -

-

- - - - - -

-

- - - - - - -

-

- - - - - - - -

-

- - - - - - - - -

-

- - - - -

-

- - - - - -

-

- - - - - - -

-

- - - - - - - -

-

- - - - - - - - -

-

- - - - -

-

- - - - - -

-

- - - - - - -

-

- - - - - - - -

-

-

-

-

- - - - - - - - -

-

- - - - -

-

- - - - - -

-

- - - - - - - - -

-

- - - - -

-

- - - - - -

- - - - - - - - -

- - - - -

- - - - - -

-

- - - - - - - -

-

- - - -

-

- - - - -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- -

- -

- -

- -

- -

- - -

- - -

- - -

- - - -

- - - -

- - - -

- - - - -

- - - - - -

- - - - - - -

- - -

- - - -

- - - - - -

- -

- - -

- - - -

- - - - -

- - -

- -

- - -

- -

- - -

- -

- - -

- -

- -

- -

- - -

- -

- - -

- -

- - -

- -

- - -

- -

- - - -

-

- -

- - -

- -

- - - -

- - -

-

- -

- - -

- -

-

-

-

-

________________________________________________________________________________________________________________________________________________________________________________________________________________________

14 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

General Information 1

Modle Code

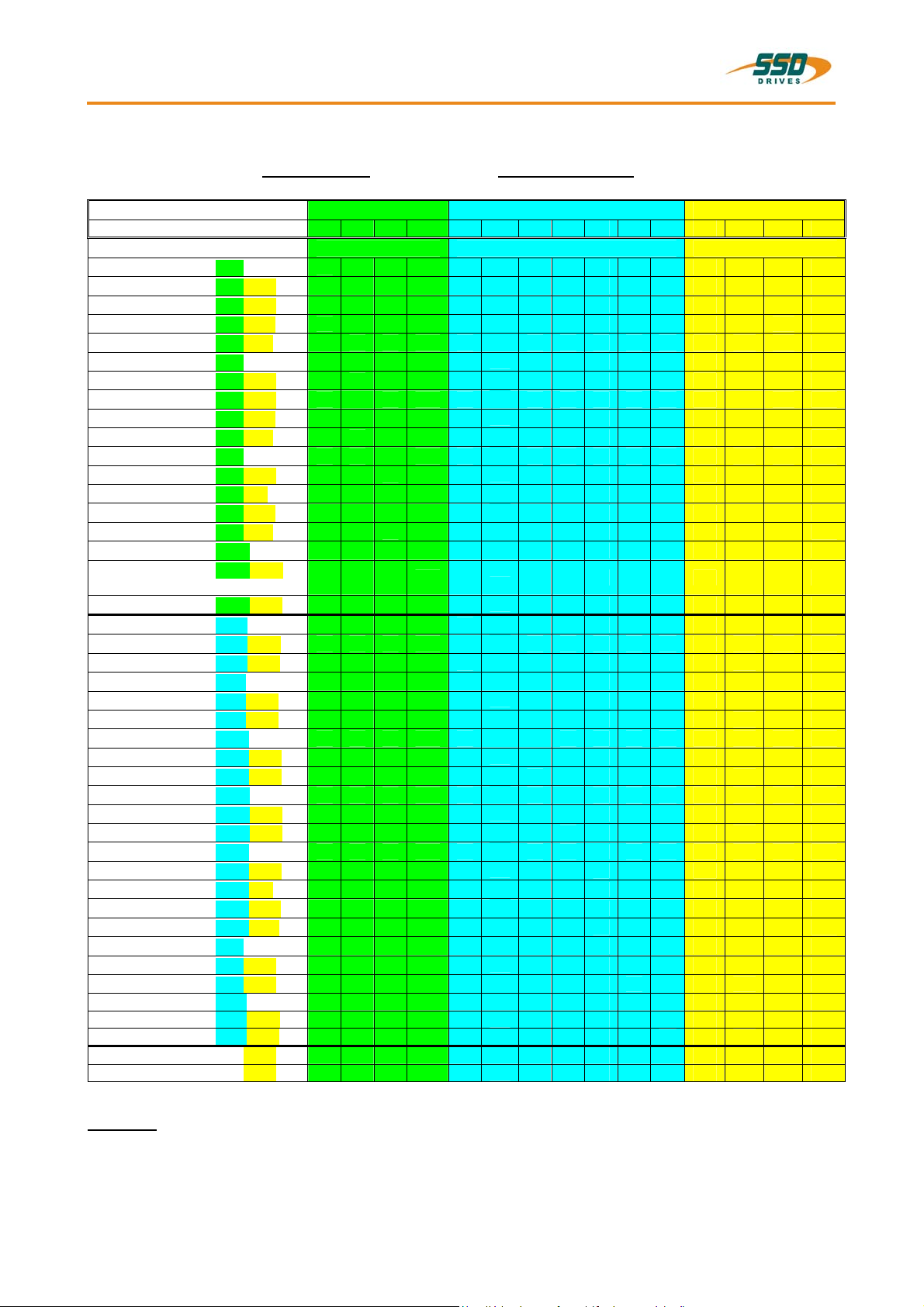

1.2.2 Layout module slots

Module slots:

A -232

-422

-485

-CAN

B -2CA

-2C8

-DEV

-SUC

-PDP

-IBS

-EA5

C -EAE

-SBT

*-2CA

*-2C8

Motor - Feedbacksysteme:

-RD2: Standard resolver

D -HF2: Option HIPERFACE

* kann nur 1 mal CAN verwendet werden

Note: The option modules of the slots A / B / C can only be reached after removing the cooling plate.

1.2.3 Layout of Power Board

View solder side (solder jumper)

JP2.8

JP2.3

JP2.7

JP2.2

JP101. 1/ 2/ 3

JP102 1/ 3/ 2

JP100 2/ 3/ 1

JP1 1/ 3/ 2

JP2 2/ 3/ 1

JP3 1/ 3/ 2

JP4 2/ 3/ 1

JP209. 1/ 2/ 3

Solder jumper function

see: Chapter 7.1

®

-SC2: Option rotor position transmitter

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 15

1 General Information

1.3 Range Data

1.3.1 Insulation Concept

COM1

COM2

Remote IN

X10

analog

X10

digital

X30

X40

1)

dep. Optionsmodule

1)

GND

doubl e insulation VDE 0160

Insul ation of cont rol voltage supply

Tak e Car e ! The insulat ion of control ( Com1..X40) depends on the insulation of control voltage suppl y

Required for safe separation (P E LV): d ouble insulation

Additional in su lation via opto-coup ler o r r elay (wit hout Safet y-Func tions)

see addit i onal hint s, c hapter 2.4. 2

power - terminal s

L1, L2, L3

DC-bus

M1, M2, M3

brak - ci r quit

Us DC 24 V

PE

custome r pa rt

power supply

DC 24 V

AC

1.3.2 General Data

Enclosure Rating for Mounting in a Cubicle

Operating Temperature Range EN 50178 / VDE 0160, class 3K3

Storage Temperature Range -25°...+55° C

Air Pressure 86 kPa - 106 kPa

Humidity 5% - 85%, 40°C

Operating Temp 0...40°C

Reduced Operation

De-rating of the Output Current

Altitude h

Reduced Operation

De-rating of the Output Current

Safety Over Voltage - Category of Power Circuit EN 50178 / VDE 0160, UL, cUL III,

Pollution Degree - for Mounting in a Cubicle VDE / UL: 2

Vibration Test in Accordance with

DIN IEC 68-2-6, Test FC

Condition for Testing

Frequency Range

Amplitude

Acceleration

Test Time per Axis

Frequency Sweep Speed

IP20

1)

>40°...< 50°C

2% /°C

1)

h ≤ 1000m

h > 1000...≤ 4000m

1% / 100m

10...57Hz 57...150Hz

0,075 mm

1g

10 sweep cycle

1 octave/min

1)

Use only fan-cooled devices. For reduced operating

conditions, no UL approval is available.

L1

N

________________________________________________________________________________________________________________________________________________________________________________________________________________________

16 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

General Information 1

Range Data

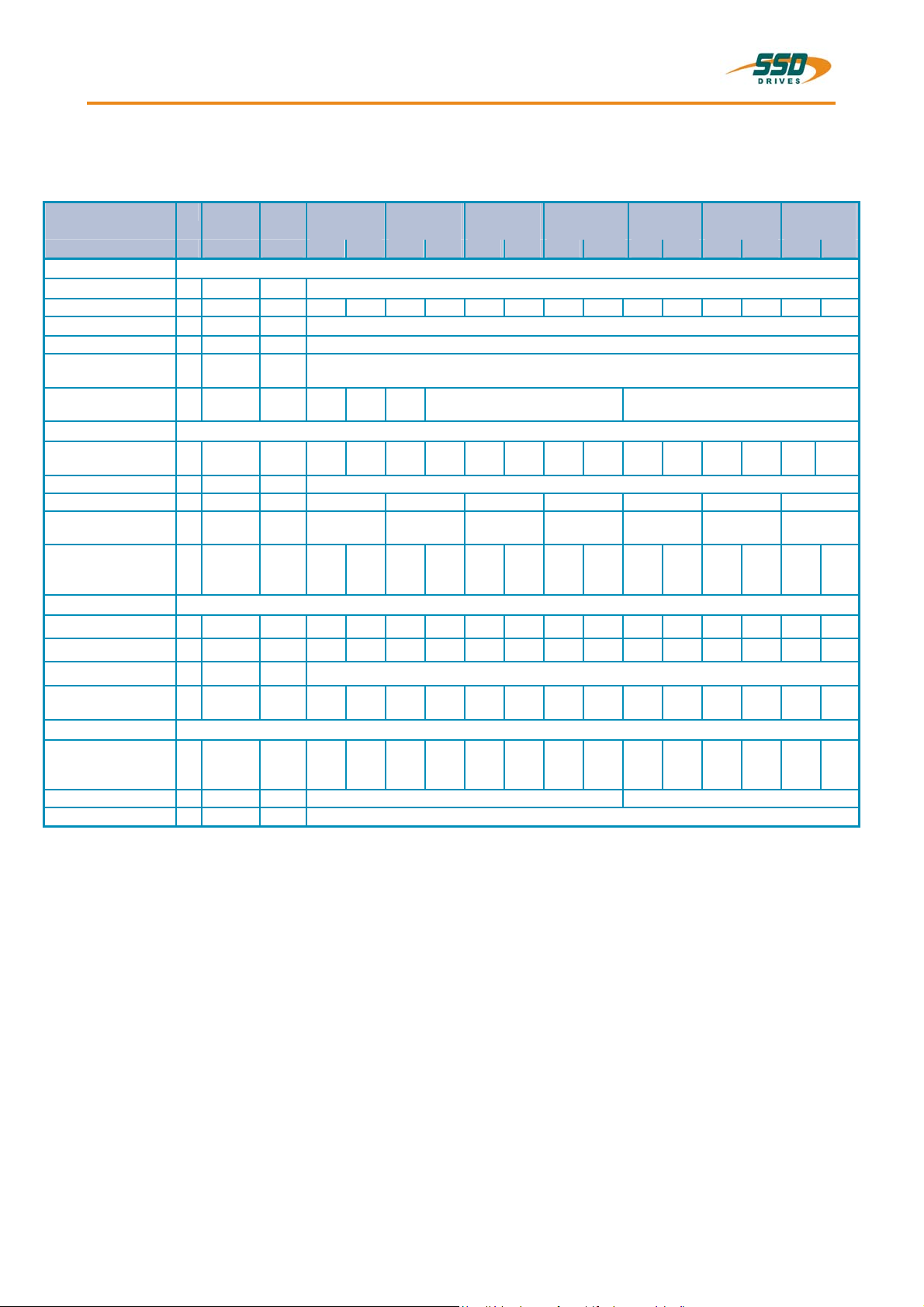

1.3.3 Compact Units 637f/K D6R

Compact Units

-3 -7 -3 -7 -3 -7 -3 -7 -7 -7 -7

Input

Supply Voltage

50..60 Hz

Phases

Supply Peparation

Power-On Current

Limit

Control Voltage

Control Current

incl. Fan

Output

Sine-Wave Voltage

at Un

De-rating of Unr

Rated Current RMS

Max. Current RMS

Time for Imax

Min. Motor

Inductance

(terminal / terminal)

Brake Circuit

Setpoint DC

Max. Power

min. [V] 14

Un [V] 230 460 230 460 230 460 230 460 460 460 460

max.

1;3 3 1;3 3 1;3 3

Fuses, contacts, filters see chapter 5.6

model

1)

Us [V] 21,5....24....29, attention: insulation-concept chapter 1.3.1

Is

DC

Unr [Veff] 220 447 220 447 220 447 220 447 447 447 447 3)

Inr [A] 2 4 6 10 16 22 30

Imaxr

4)

min.

Lph/ph [mH] 6,0 12,0 3,0 6,0 2,0 4,0 1,2 2,4 2,0 1,1 0,8

Ub [V] 375 730 375 730 375 730 375 730 730 730 730

637f / K D6R 02

.S5

toleranc

e

K D6R 04

.S5

K D6R 06

.S5

K D6R 10

.S5

+ 10%

NTC 4 Ohm NTC 2 Ohm

[A] Continuous: max. 1,2A Power-On-Peak:

nom. 3A; max.. 6A / 0,8 mS, 2,5A / 25 mS

depending upon load and single or 3-phase supply. (see chapter 1.3.5)

[A]

Sec

4

5

8

5

12

5

20

5

K D6R 16

.S5

K D6R 22

.S5

K D6R 30

Continuous: max 1,5A PowerOn-Peak: nom. 3A;

max. 6A / 0,8 mS, 3A / 25 mS

32

5

44

5

.S5

60

5

Pbmax [kW] 4,5 8,7 4,5 8,7 6,7 13,0 11,2 21,7 29,0 34,8 34,8

3)

Continuous Power

Internal Resistor

Min. External

Resistor

General

Power Loss

Fan, Electronic

24V DC

Pbnenn [W]

2)

Rbint

Pd

Pmax

Rbextmi

n

[Ω]

[W]

[kW]

[Ω]

PE loss

[W]

[V]

≤ 560

100

30

1,4

30

1,7

30

1,4

30

1,7

30

1,4

30

1,7

30

1,4

30

1,7

------

300

100

300

100

300

100

300

47 82 47 82 27 47 15 27 20 15 15

29

29

29

29

29

29

29

29

2 Piece L 024 / (12TE * 25)

1 Piece L 024 / (12TE * 15)

36

2 Piece L 024 / (16TE x 25) Fan Models

1 2 Piece L 024 /

36

(16TE x 20)

Power Stage per A

[W/A] 9 12 9 12 9 12 9 12 12 12 12

Weight [kg] 5,0 8,8

Additional Data

see: chapter 11

1) Suggested: transformer-based supply

2) Use only SSD Drives-released types

3) Max. continuous performance reduced to 80%, see chapter 1.3.6

4) References chapter 1.3.6

36

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 17

1 General Information

t

Range Data

1.3.4 Plug-In Modules 637f/D6R

Plug-In Modules

-3 -7 -3 -7 -3 -7 -3 -7 -3 -7 -3 -7 -3 -7

Input

DC-BUS Rated min. [V] 20

Ug [V] 325 650 325 650 325 650 325 650 325 650 325 650 325 650

max.

Control Voltage Us [V] 24V DC +20% -10%, attention: insulation-concept chapter 1.3.1

Control Current

Fan

Output

Sine-Wave Voltage

at Un

De-rating of Unr depending on load and single or 3-phase supply (see chapter 1.3.5)

Rated Current RMS Inr [A] 2 4 6 10 16 22 30 3)

Max. Current RMS

Time for Imax

Min. Motor

Inductance

(terminal / terminal)

Brake-Circuit

Setpoint DC

Max. Power

Continuous Rating

Min. External

Resistor

General

Power Loss

Electronic

Output Stage per A

Weight [kg] 1,5 4,0

Additional Data

1)

Is

DC

2)

Typ

Unr [Veff] 220 447 220 447 220 447 220 447 220 447 220 447 220 447

Imaxr [A]

Lph/ph [mH] 6,0 12,0 3,0 6,0 2,0 4,0 1,2 2,4 1,0 2,0 0,55 1,1 0,4 0,8

Ub [V] 375 730 375 730 375 730 375 730 375 730 375 730 375 730

Pbmax [kW] 4,5 8,7 4,5 8,7 6,7 13,0 11,2 21,7 15,0 29,0 18,0 34,8 18,0 34,8

Pbnenn [W]

2)

Rbextmin

PE loss

1) Suggested: transformer-based supply

2) Use only SSD Drives-released types

3) Max. continuous performance reduced to 80%, see chapter 1.3.6

4) References chapter 1.3.6

637f/ D6R 02

.S5

olerance + 10%

[A]

min. 4 5 Sec

[Ω]

[W]

[W/A]

Continuous: max 0,8A Power-On-Peak: nom. 2A; max 5A / 0,8 mS, 2A / 25mS

L220

---

33 63 33 63 22 43 12 24 10 20 8,2 15 8,2 15

20

9

D6R 04

.S5

--- L220K L220G

K

8

5 Sec

20

20

9

12

20

12

D6R 06

.S5

12

5 Sec

20

20

12

9

D6R 10

.S5

20

5 Sec

≤ 560

20

9

see chapter 11

20

12

D6R 16

.S5

32

5 Sec

20

20

12

9

D6R 22

.S5

44

5 Sec

20

20

12

9

D6R 30

.S5

60

5 Sec

20

20

12

9

3)

________________________________________________________________________________________________________________________________________________________________________________________________________________________

18 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

General Information 1

Range Data

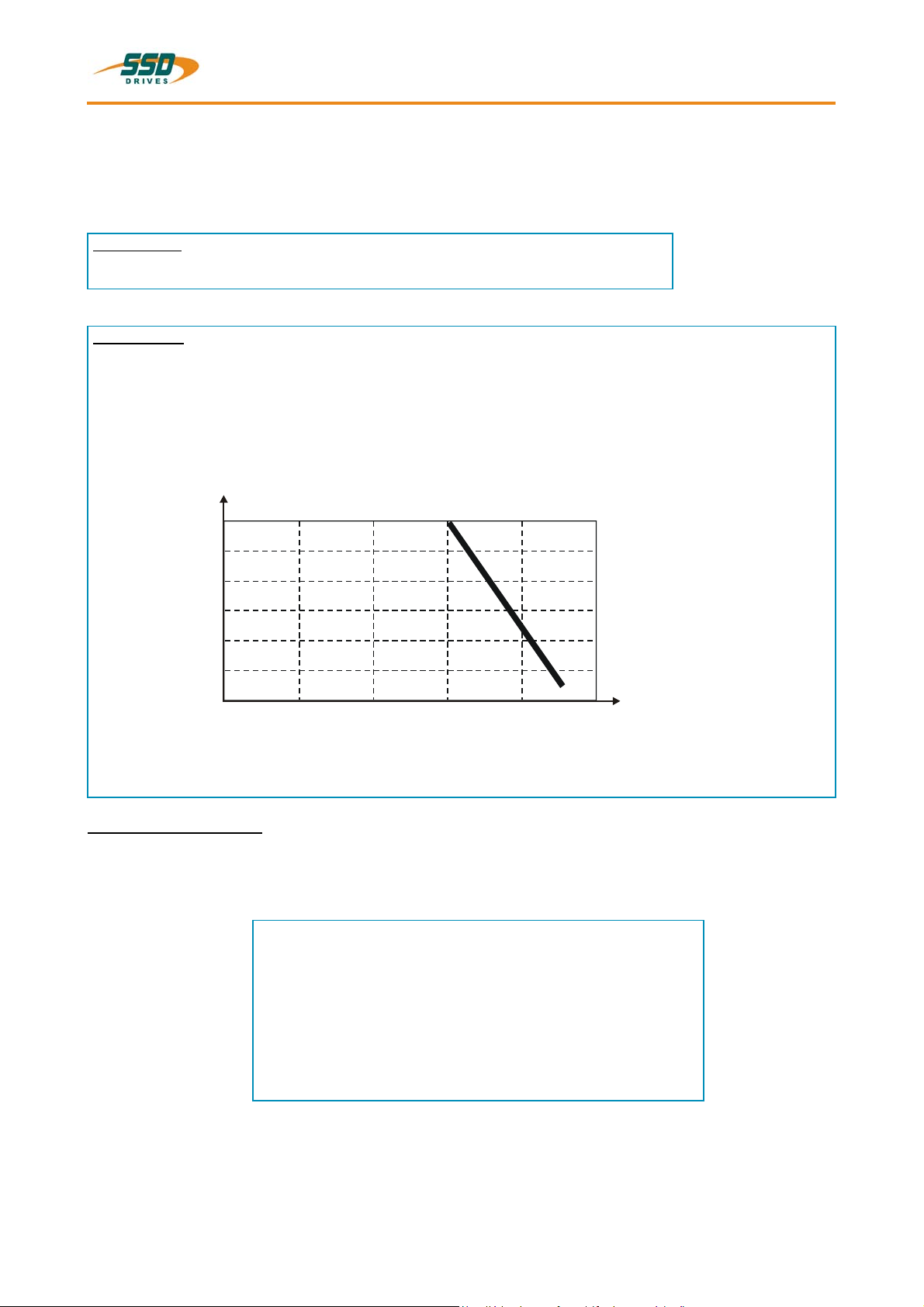

1.3.5 Single- and Three-Phase Supply

Due to the line-ripple of the DC-Bus, the rate of usable output voltage is reduced as follows.

This reduction affects the maximum attainable speed of the applied motor.

Three-phase

The unloaded output voltage will be reduced to approx. 90%, maximally 85

%

Single-phase

only servo drive 637f / ..02 up to 06

see the following diagram:

supply:

supply: 50 – 60 Hz

Derating of servo drive output voltag e in case of single-phase operationen

Output curr en t [A ]

RMS

12

10

8

6

4

Hint for parameterization:

To avoid unexpected tripping of the under voltage threshold, the parameter setting should be left on

default values (EASYRIDER

Required motor-terminal-voltage for specified speed.

2

0

0

20 40 60 80 100

Output voltage in % of unloaded condition

®

Windows – Software).

Approximation: (up to 3000RPM)

Ukl = 1,2 * (EMF * n / 1000) + I * (Rph + RL) [V]

Ukl Required motor voltage [V

EMF Back-EMF of motor [V

Rph Resistance of motor (between terminals) [

RL Line resistance of motor cable [

I Motor-current [A

RMS

[%]

]

RMS

] / 1000 RPM

RMS

Ω]

Ω]

]

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 19

1 General Information

Range Data

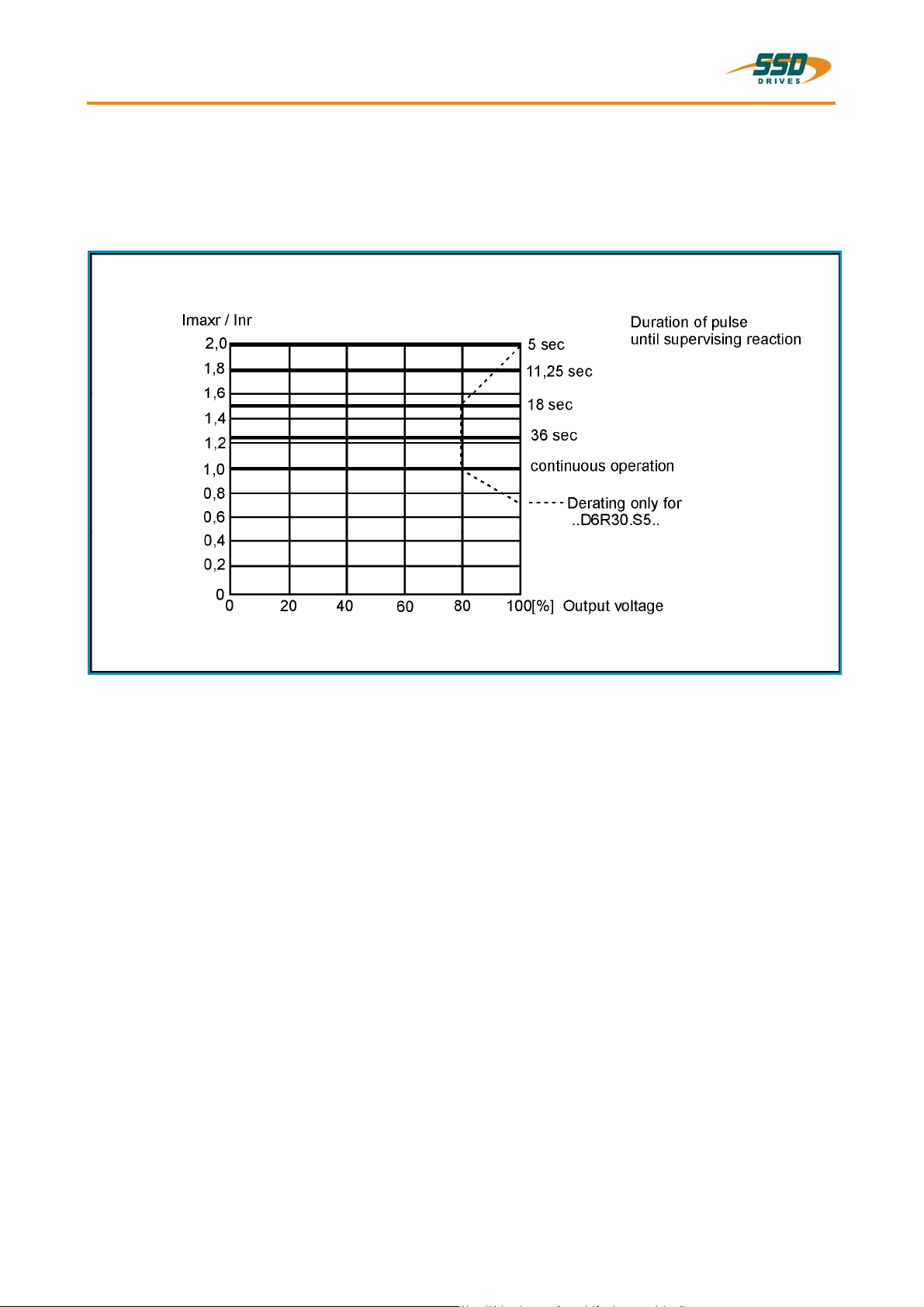

1.3.6 Output Power

In case of continuous operation in the full-load range, the limits as shown in the following diagram

need to be respected.

Typical servo applications are not affected by this restriction. (S3 operation: Start/Stop).

________________________________________________________________________________________________________________________________________________________________________________________________________________________

20 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

2

General Information 1

1.4 Dimensions

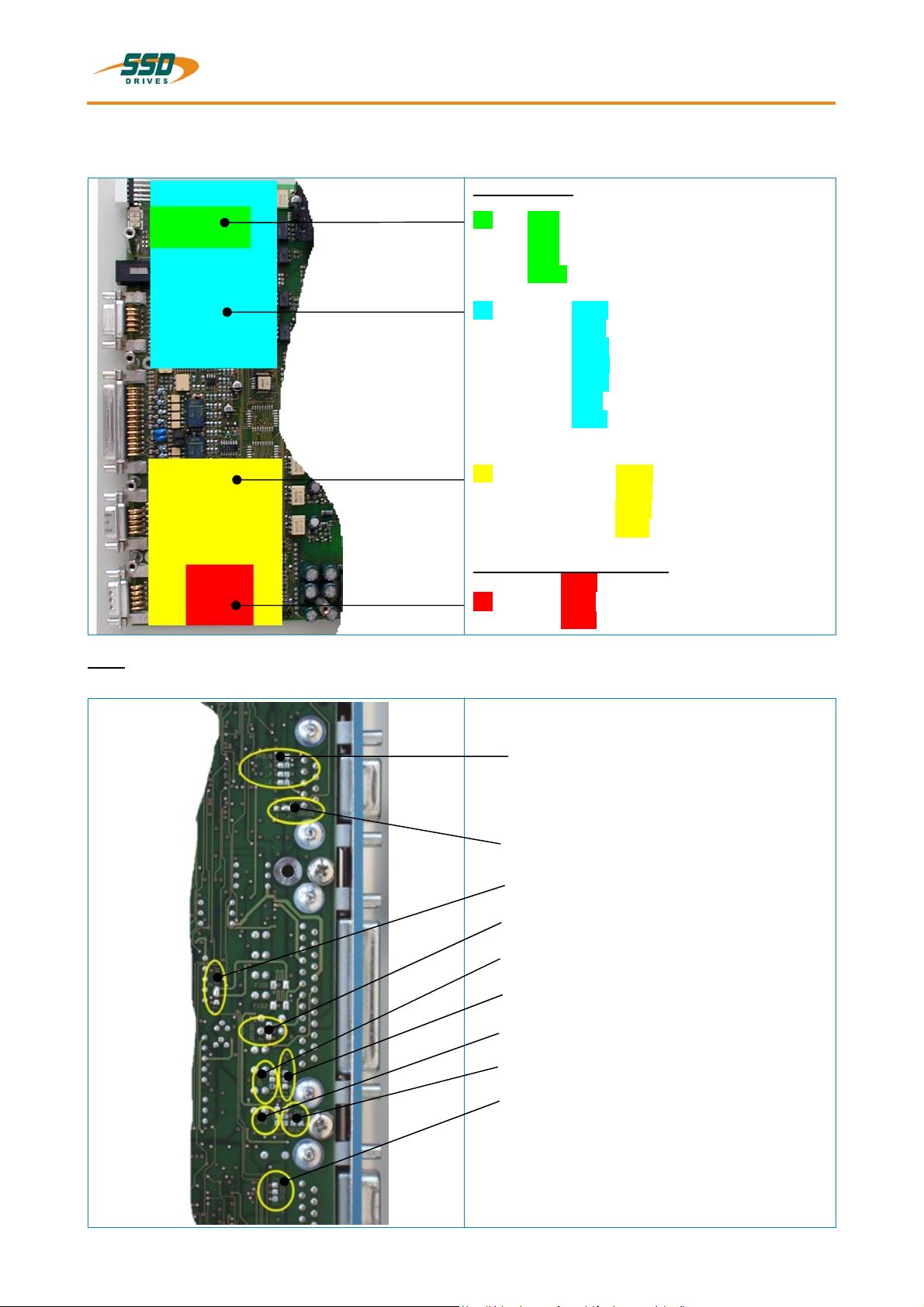

1.4.1 Dimensions for Compact Device and Plug-In Module

front side

D

A

18

B

D

C

d

400

262

386

Ø 5,

detail

Ø 10

243

220

plug -in modu l e

space for fan

a

d

Ø 5,2

1,6

280

detail

9

5,2

637f/K D6R 02...10 width 637f/K D6R 16...30 width

A 65,0 mm 14 HP 104,6 mm 20 HP

B 60,0 mm 100,0 mm

C 30,0 mm 71,0 mm

D 14,5 mm 14,5 mm

a 40,2 mm 8 HP 80,4 mm 16 HP

1 HP ≈ 5,08mm

Important Note:

You will need additional space on the front side, of approx. 70 mm, for the signal mating plugs!

233

304

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 21

1 General Information

Dimensions

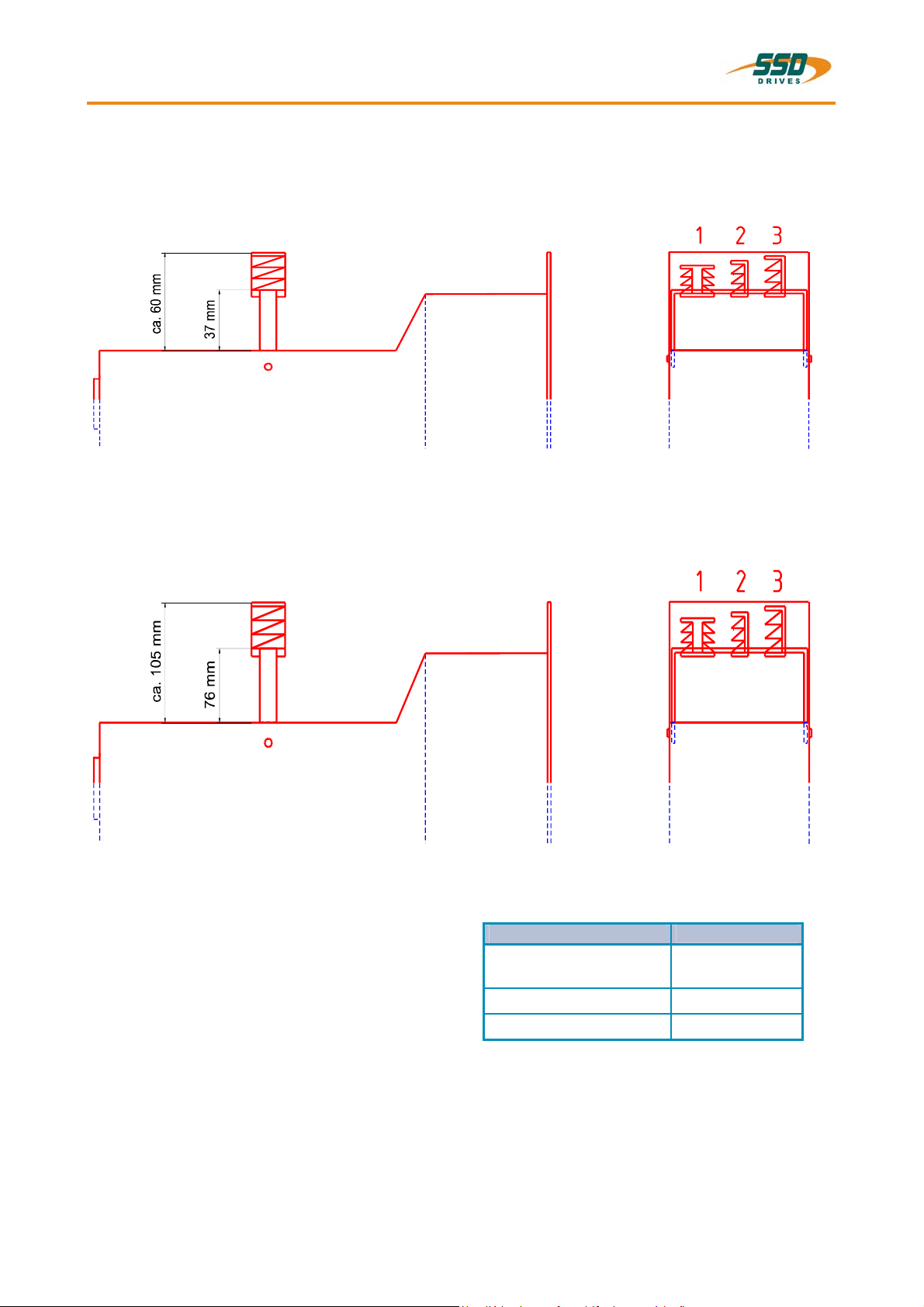

1.4.2 EMC-Clip (optional)

1.4.2.1 For 8 HP Drive

side view front view

1.4.2.2 For 16 HP Drive

side view front view

EMC - Clip for

Feedback cable

1

(e.g. Resolver)

Mains cable

Motor cable

2

3

Meaning:

1,2,3 = cage clamp terminals

________________________________________________________________________________________________________________________________________________________________________________________________________________________

22 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

2 Connector Assignments and Functions

Connector Assignments and Functions 2

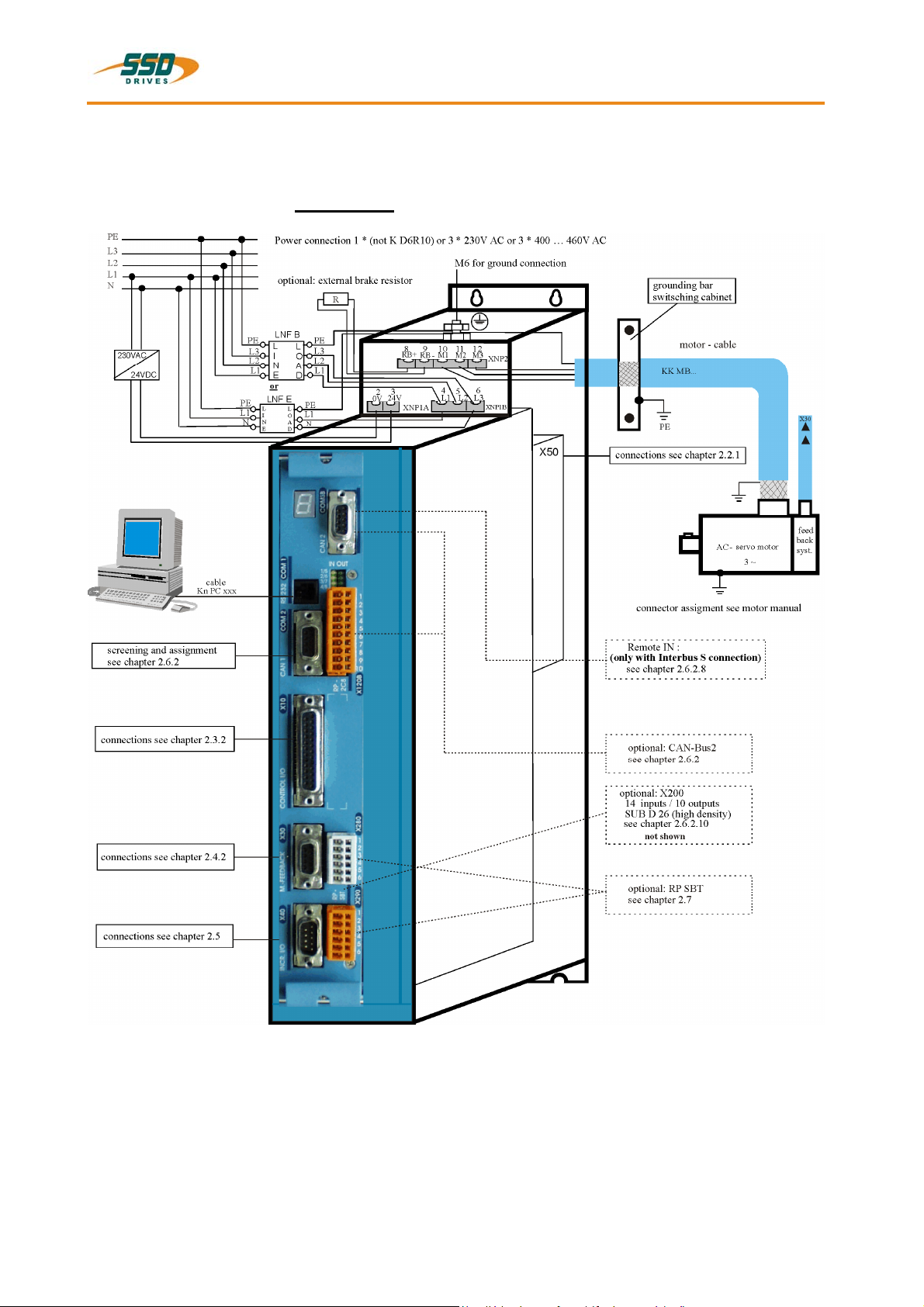

2.1 General View of Connections for Compact Device 637f/ K D6R 02 – 10

2.1.1 637f/K D6R 02...10 Width 14 HP

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 23

2 Connector Assignments and Functions

General View of Connections for Compact Device 637f/ K D6R 02 – 10

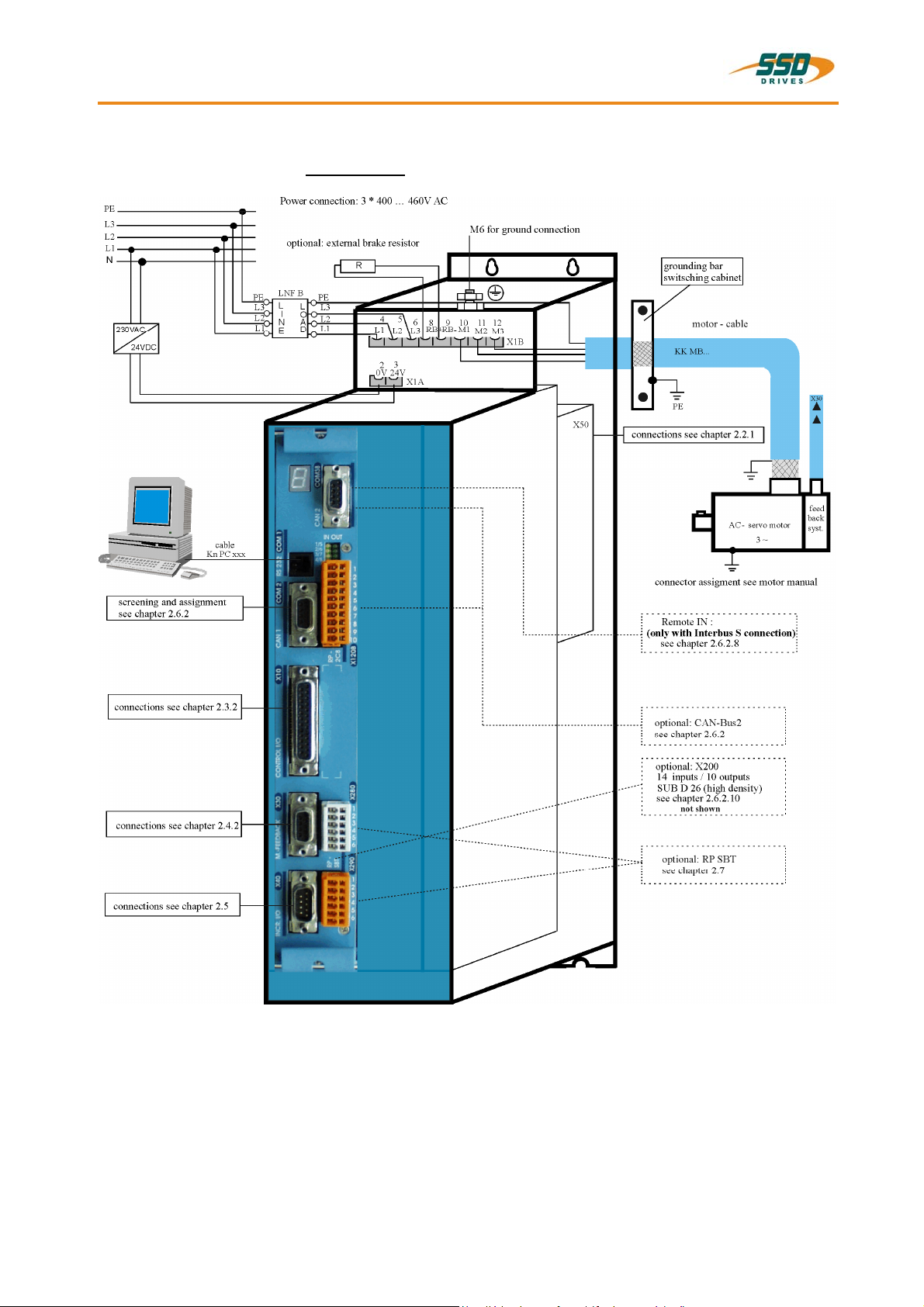

2.1.2 637f/K D6R 16...30 Width 20 HP

________________________________________________________________________________________________________________________________________________________________________________________________________________________

24 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

Connector Assignments and Functions 2

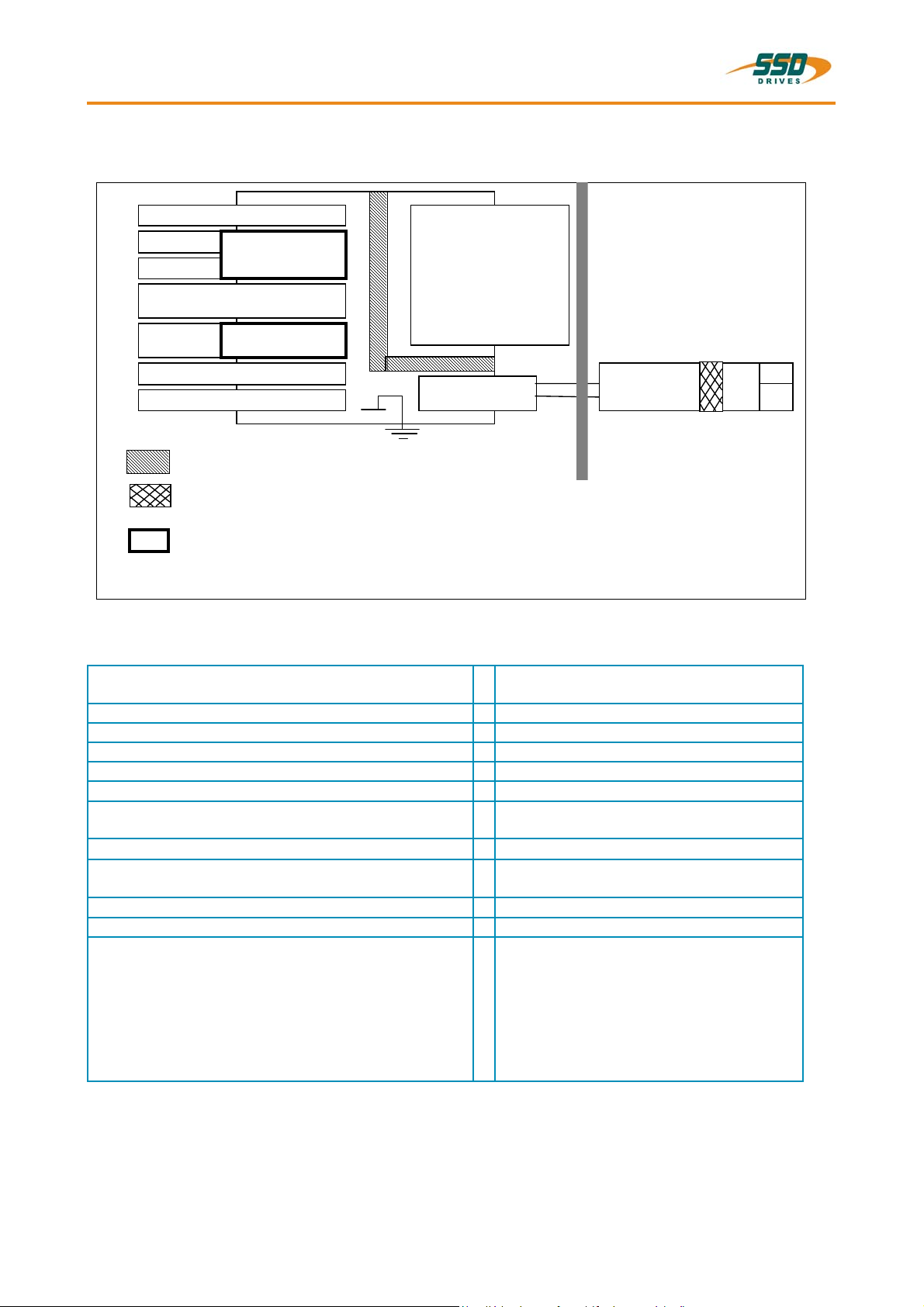

2.2 Connector Pin Assignments and Contact Functions

2.2.1 Power Connections for Plug-In Module 637f/D6R

(at the rear of the rack)

(H15 multiple pin strip according to DIN 41612)

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 25

2 Connector Assignments and Functions

2.3 Signal Connections

2.3.1 Control Signal Plug X10 - SUB D25 Socket

Complete Representation X10

Reference to pin 22 & pin 23: With controllers with option module SBT, kindly note the extended

functions of these signals (see documentation 07-02-10-02-E-Vxxxx).

________________________________________________________________________________________________________________________________________________________________________________________________________________________

26 Product Manual Type: 637f 07-02-10-01-E-V0505.doc

Connector Assignments and Functions 2

Signal Connections

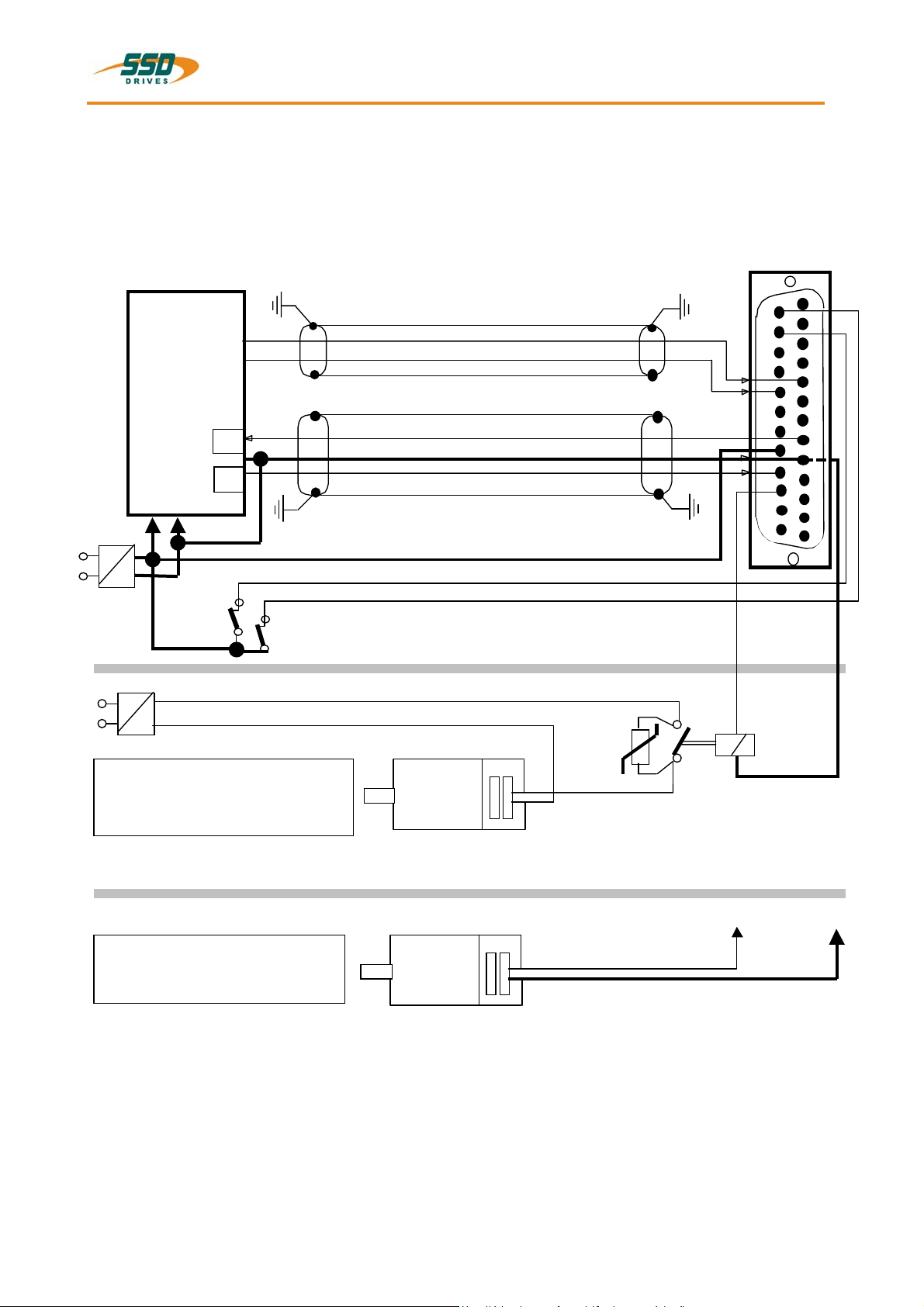

Control Signal Plug X10 - SUB D25 Socket

Connection Example

(without option SBT)

drive side

control signal plug X10

model: SUB D 25

PLC

1)

1)

24V

0V

-

+

2)

L1

~

=

N

PELV-

isolation

2)

L1

~

N

Supply may be used for mutliple brakes

=

+24V (br)

0V (br)

sprea d out

sprea d out

mecanical

limit switches

+/- 10V

output ready

0V refer ence point, I/ O-s u pply

input active

+24V, I/O-supply

option: brake

V1

K1

22

14

15

16

17

18

19

20

21

23

24

25

1

2

3

4

5

6

7

8

9

10

11

12

13

Brake-Connection Type A :

when Is olation-Type of Break - Inst allation is

Basic (not PELV). The PELC - Isolation of

Control - Cirquit s i s uneffect ed.

Eurotherm

AC-Servomotor

3 ~

option: brake

Brake-Connection Type B :

when isol ation-type of break - in sta llation is

PELV.

AC-Servomotor

3 ~

1) Security- and supervising logic, to be programmed by user !

2) IMPORTANT:

The power-supply for the motor-brake has to be adapted to the type of brake.

Voltage-Drops caused by long cables also may effect malfunctions of the brake.

V1: Varistor e.g.. Siemens Q69X3431, 38 V DC

K1: Couple-relais min. 2A,/60VDC PELV Isolation

X10.23 X10.9

________________________________________________________________________________________________________________________________________________________________________________________________________________________

07-02-10-01-E-V0505.doc Product Manaul Type: 637f 27

Loading...

Loading...