RTS 2nd Generation SERVO AMPLIFIER

1

PVD 3487 GB 03/2004

CONTENTS

SAFETY INSTRUCTIONS ……………………………………………………………………………3

1. GENERAL 5

2. TECHNICAL SPECIFICATIONS 6

2.1 RTS Servo amplifier performance chart 7

2.2 Block diagram 8

3. DIMENSIONS, LABELLING, 9

3.1 Dimensions 9

3.2 Labelling 23

4. - ELECTRICAL CONNECTIONS 24

4.1 General Wiring Requirements 24

4.1.1 Appliance handling 24

4.1.2 Electromagnetic compatibility 24

4.2 RTS Servo amplifier connection 25

4.3 Front Panel 30

4.4 Terminal blocks X1, X2 AND X3 35

4.5 Terminal block X2 connection 38

4.6 Terminal block X3 connection 38

4.7 Accessories 39

4.7.1 Plug-in Customisation card 39

4.7.2 Extra choke 39

4.7.3 Transformer 40

4.7.4 Mains filter 40

5. LED DISPLAYS 49

6. SERVO AMPLIFIER ADAPTATION 50

7. COMMISSIONING 51

RTS 2nd Generation SERVO AMPLIFIER

2

PVD 3487 GB 03/2004

7.1

Speed loop rapid adjustment 52

7.2 Complete speed loop adjustment 53

7.3 Diagnostic helpI 55

7.4 Calibration 56

7.4.1 Tachometric generator voltage calibration (R104) 58

7.4.2 Rated speed selection (R105) 59

7.4.3 Pulse current adjustment (R113) 60

7.4.4 Current limitation by external resistance or external voltage (terminal block X1) 60

7.4.4.1 By external resistance 60

7.4.4.2 By external voltage 60

7.4.5 Time constant adjustment I = f(t) (R109) 61

7.4.6 Adjustment of function I = f(t) (R103) 61

7.4.7 Adjustment of current limitation curve versus speed I F(n) (R131 - 132) 62

7.4.8 Calibration of function U - RI (R133 - R134) 63

7.4.9 Tripping limit calibration (R135) 64

7.4.10 Current loop gain adaptation to motor inductance (R136) 64

7.4.11 dc voltage calibration (RB) 65

Characteristics and dimensions subject to change without notice.

SSD Parvex SAS

8 Avenue du Lac / B.P 249 / F-21007 Dijon Cedex

Tél. : +33 (0)3 80 42 41 40 / Fax : +33 (0)3 80 42 41 23

www.SSDdrives.com

YOUR LOCAL CORRESPONDENT

RTS 2nd Generation SERVO AMPLIFIER

3

PVD 3487 GB 03/2004

SAFETY

Servodrives present two main types of hazard :

- Electrical hazard

Servoamplifiers may contain non-insulated live AC or DC

components. Users are advised to guard against access to live

parts before installing the equipment.

Even after the electrical panel is de-energized, voltages may be

present for more than a minute, until the power capacitors have

had time to discharge.

Specific features of the installation need to be studied to prevent

any accidental contact with live components :

- Connector lug protection ;

- Correctly fitted protection and earthing features ;

- Workplace insulation

(enclosure insulation humidity, etc.).

General recommendations :

• Check the bonding circuit;

• Lock the electrical cabinets;

• Use standardised equipment.

- Mechanical hazard

Servomotors can accelerate in milliseconds. Moving parts must be

screened off to prevent operators coming into contact with them.

The working procedure must allow the operator to keep well clear

of the danger area.

All assembly and commissioning work must be done by qualified

personnel who are familiar with the safety regulations (e.g. VDE

0105 or accreditation C18510).

RTS 2nd Generation SERVO AMPLIFIER

4

PVD 3487 GB 03/2004

Upon delivery

All servoamplifiers are thoroughly inspected during manufacture and tested at length for bugs

before shipment.

• Unpack the servoamplifier carefully and check it is in good condition.

• Also check that data on the manufacturer's plate comries with data on the order

acknowledgement.

If equipment has been damaged during transport, the addressee must file a complaint with the

carrier by recorded delivery mail within 24 hours

.

Caution

:

The packaging may contain essential documents or accessories, in particular :

• User Manual,

• Connectors.

Storage

Until installed, the servoamplifier must be stored in a dry place safe from sudden temperature

changes so condensation cannot form.

Special instructions for setting up the equipment

CAUTION

For this equipment to work correctly and safely it must be

transported, stored, installed and assembled in accordance with

this manual and must receive thorough care and attention..

Failure to comply with these safety instructions may lead to

serious injury or damage.

The cards contain components that are sensitive to electrostatic

discharges. Before touching a card you must get rid of the static

electricity on your body. The simplest way to do this is to touch a

conductive object that is connected to earth (e.g. bare metal

parts of equipment cabinets or earth pins of plugs).

RTS 2nd Generation SERVO AMPLIFIER

5

PVD 3487 GB 03/2004

1. GENERAL

The RTS servo amplifier is designed for four-quadrant control of DC servo motors up to

mechanical powers of 2500 W.

It incorporates power and chopping supplies, including the energy dissipation resistor for some

versions.

This integration makes for easier wiring and allows front panel access for a more user-friendly

appliance.

Two formats are available :

Wall mounted type with rear angle bracket

Europe single 3 u DIN rack type.

Several axes can thus be included in one 19" rack.

TECHNOLOGY

• CMS components (surface mounted).

• Genuine galvanic insulation to prevent sensitivity to interference.

• Hall effect current sensor.

• Chopping frequency 17 kHz.

• Speed bandwidth up to 150 Hz.

• Integrated short circuit protection.

• Speed range : With tachometer 1: 10 000

U-RI 1 : 10

• ± 10 V differential reference for speed or current.

• Differential tachometer input.

FUNCTIONS

• Switchable tachometer control in U-RI.

• Current or speed control.

• Current reduction with speed.

• Current reduction with temperature.

• External current reduction.

• Zero speed adjustment.

• Zero torque adjustment.

• Fault clearance (RESET).

• Analogue speed or torque information.

• Servo amplifier status relay.

• ± 15 V available.

RTS 2nd Generation SERVO AMPLIFIER

6

PVD 3487 GB 03/2004

- COMPLIANCE WITH STANDARDS

RTS bears the CE mark under European Directive 89/336/EEC as amended by Directive 93/68/EEC on

electromagnetic compatibility. This European Directive refers to the harmonised generic standards

EN50081-2 of December 1993 (Electrical Compatibility - Generic Standard for Emissions - Industrial

Environments) and EN50082-2 of June 1995 (Electromagnetic Compatibility - Generic Standard for

Immunity - Industrial Environments). These two harmonised generic standards are based on the following

standards :

• EN 55011 of July 1991 : Radiated and conducted emissions

• EN 50140 of August 1993 and ENV 50204 : Immunity to radiated electromagnetic fields

• EN 61000-4-8 of February 1994: Mains frequency magnetic fields

• EN 61000-4-2 of June 1995 : Electrostatic discharge

• ENV 50141 of August 1993 : Interference induced in cables

• EN 61000-4-4 of June 1995 : Rapid transient currents

Compliance with the reference standards above implies adherence to the instructions and wiring diagrams

in the technical documents supplied with the appliances.

Incorporation in Machinery

The design of the equipment means it can be used in machinery covered by Directive 89/392/EEC (Machine

Directive) provided that it is integrated (or incorporated and/or assembled) in accordance with the rules-ofthe-art by the machinery manufacturer and in keeping with the instructions in this booklet.

2. TECHNICAL SPECIFICATIONS

Power reduction with altitude Above 1000 m, 10% fall in useful power per 1000 m up to maximum 4000 m

Operating temperature

Normal use: 0 to + 40°C

Above 40°C, 35% fall in useful power per 10°C up to maximum 60°C

Storage temperature -30°C to +85°C

Chopping frequency 17 kHz current

Technology Photocoupler controlled MOS transistors.

Bandwidth in current Up to 1500 Hz

Bandwidth in speed Up to 150 Hz at 90° phase shift

Tachogenerator

maximum voltage

100 V at input

Speed range

1:10 000 with tachogenerator

1:10 with armature reaction (U - RI)

Static precision of speed for

load variation of 0 at In and

for servo amplifier rated

voltage

From Nmax to Nmax/100 +/- 0.5%

From Nmax/100 to Nmax/1000 +/-1.5%

From Nmax/1000 to Nmax/10 000 +/-10%

U-RI control, from Nmax to Nmax/10 +/-20%

Current control

Precision

Linearity

+/-2% of rated current at 25°C

+/-1% of rated current at 25°C

Electrical protection

- Galvanic insulation of power bridge

- Magnetic current sensor

- Power outputs protected against phase-to-phase and phase

to-ground short-circuits

Connections Plug-in terminal blocks on front panel

Protection IP20, IP20 for shrouded versions

RTS 2nd Generation SERVO AMPLIFIER

7

PVD 3487 GB 03/2004

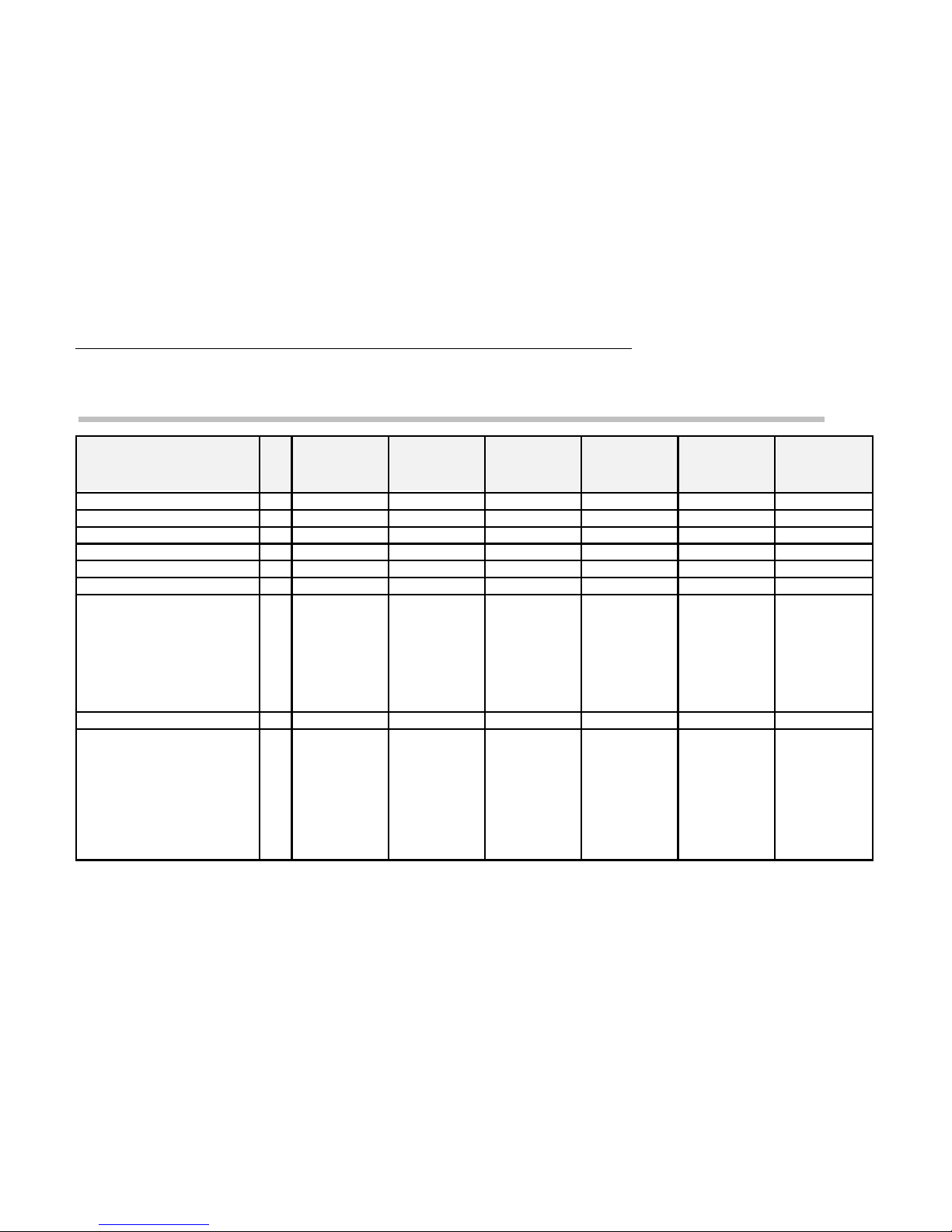

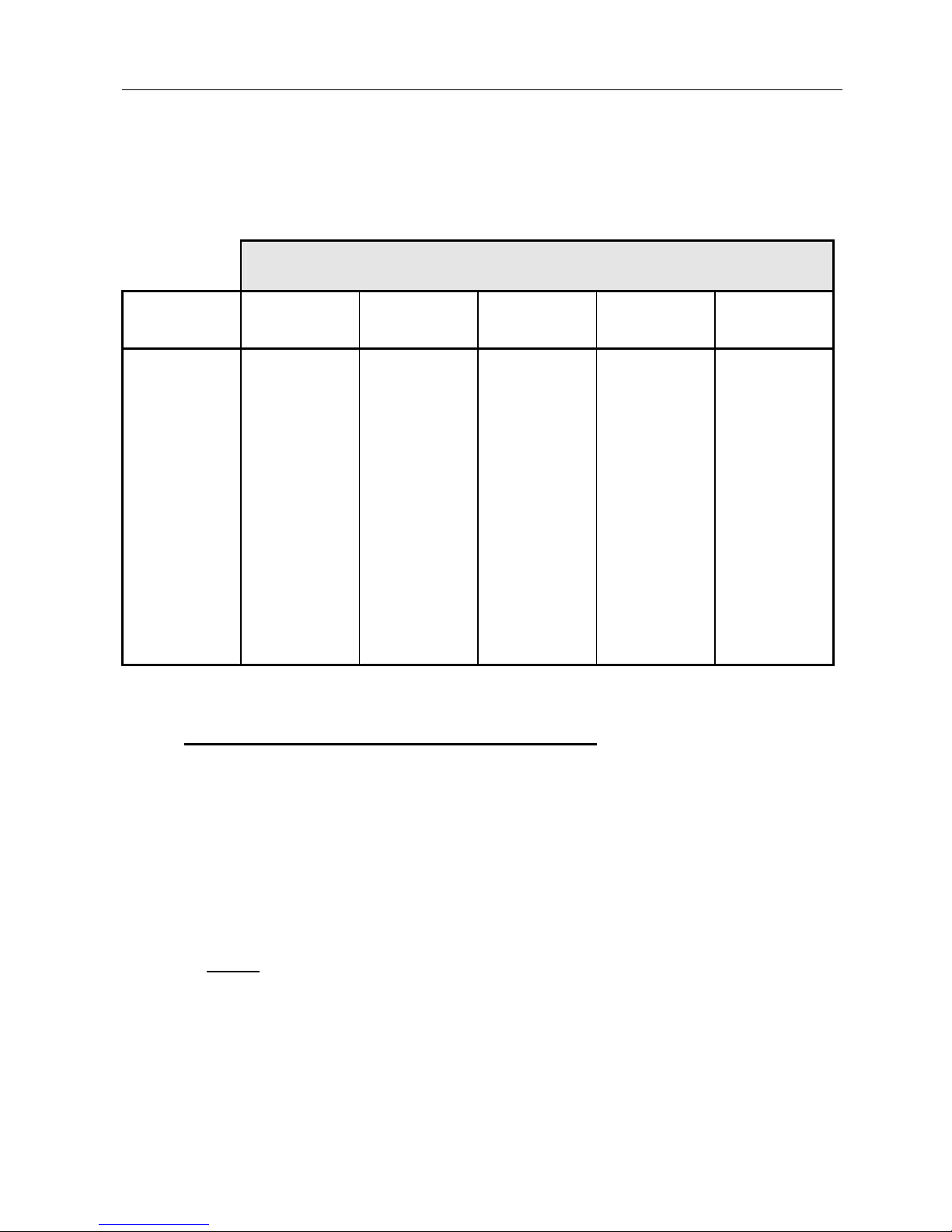

2.1 RTS Servo amplifier performance chart

RTS CHARACTERISTICS

at 40°C ambient temperature

3/10-40M

single-phase

10/20-60

single/three-

12/24---B

battery

12/24-130T

three-phase

20/40-130T

three-phase

16/32-190T

three-phase

Input voltage rangeV 18/36Vac 18/56Vac 16/60Vdc 58/116Vac 58/116Vac 82/164Vac

Rated input voltage V 32Vac+/-10% 48Vac+/-10% 100Vac+/-10% 100Vac+/-10% 135Vac+/-10%

Maximum output voltage V= 40 60 V battery -2V 130 130 190

Permanent output current A 3 10 12 12 20 16

Pulse current (2 sec) A 10 20 24 24 40 32

Minimum motor choke mH 1 0.4 0.4 0.8 0.4 0.8

BRAKING ENERGY

DISSIPATION CAPACITY

Mean power

Max pulse power

(4% of cycle)

Maximum, non-repetitive

W

W

sec

15W (option)

400 (option)

2

30

800

1

without

without

-

100

2500

1

180

4500

2

180

4500

2

Losses dissipated by RTS W 15 40 30 80 120 130

DIMENSIONS H x L x D (mm)

Rack version (single-phase)

Rack version (three-phase)

Wall-mounted (single-phase)

Wall-mounted (three-phase)

Rack/wall-mounted wei

g

ht

mm

mm

mm

mm

kg

130/51/216

--

150/61/212

--

0.8/1

--

130/51/216

180/61/212

150/61/212

0.8/1.2

--

130/51/216

(battery)

--

150/61/212

(battery)

0.8/1

--

130/61/216

--

150/92/212

0.85/1.8

--

--

--

150/115/221

1.9

--

--

--

150/115/221

1.9

RTS 2nd Generation SERVO AMPLIFIER

8

PVD 3487 GB 03/2004

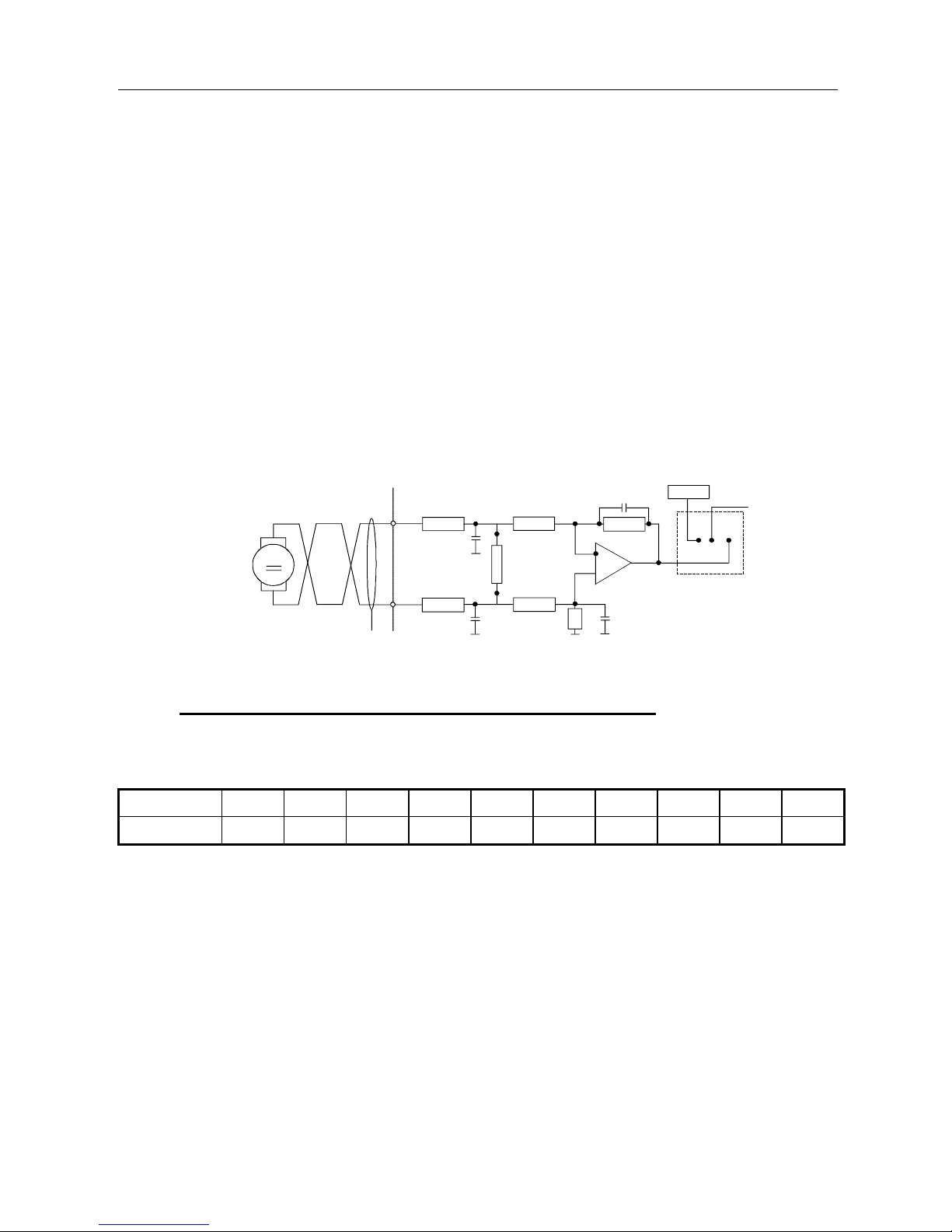

2.2 Block diagram

RTS 2nd Generation SERVO AMPLIFIER

9

PVD 3487 GB 03/2004

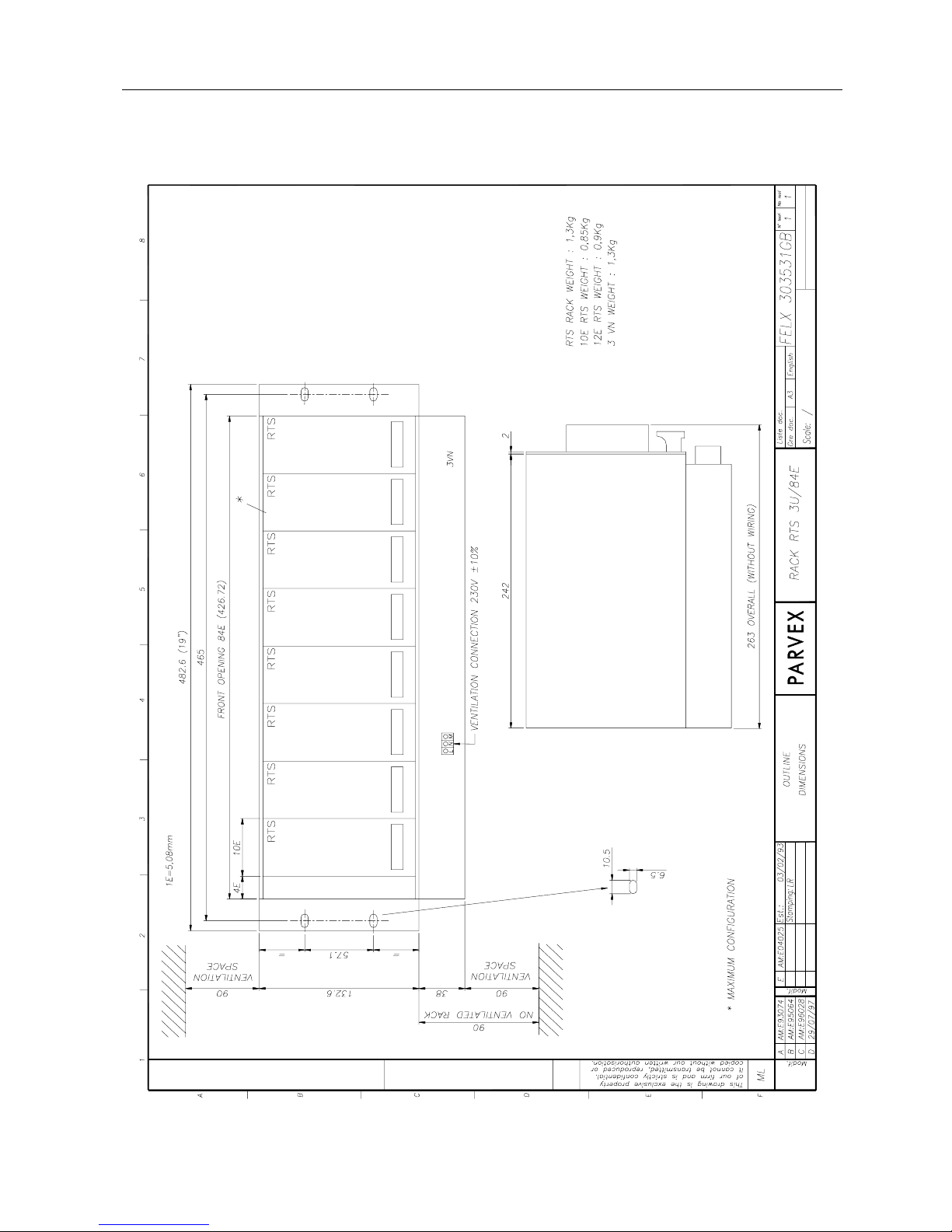

3. DIMENSIONS, LABELLING,

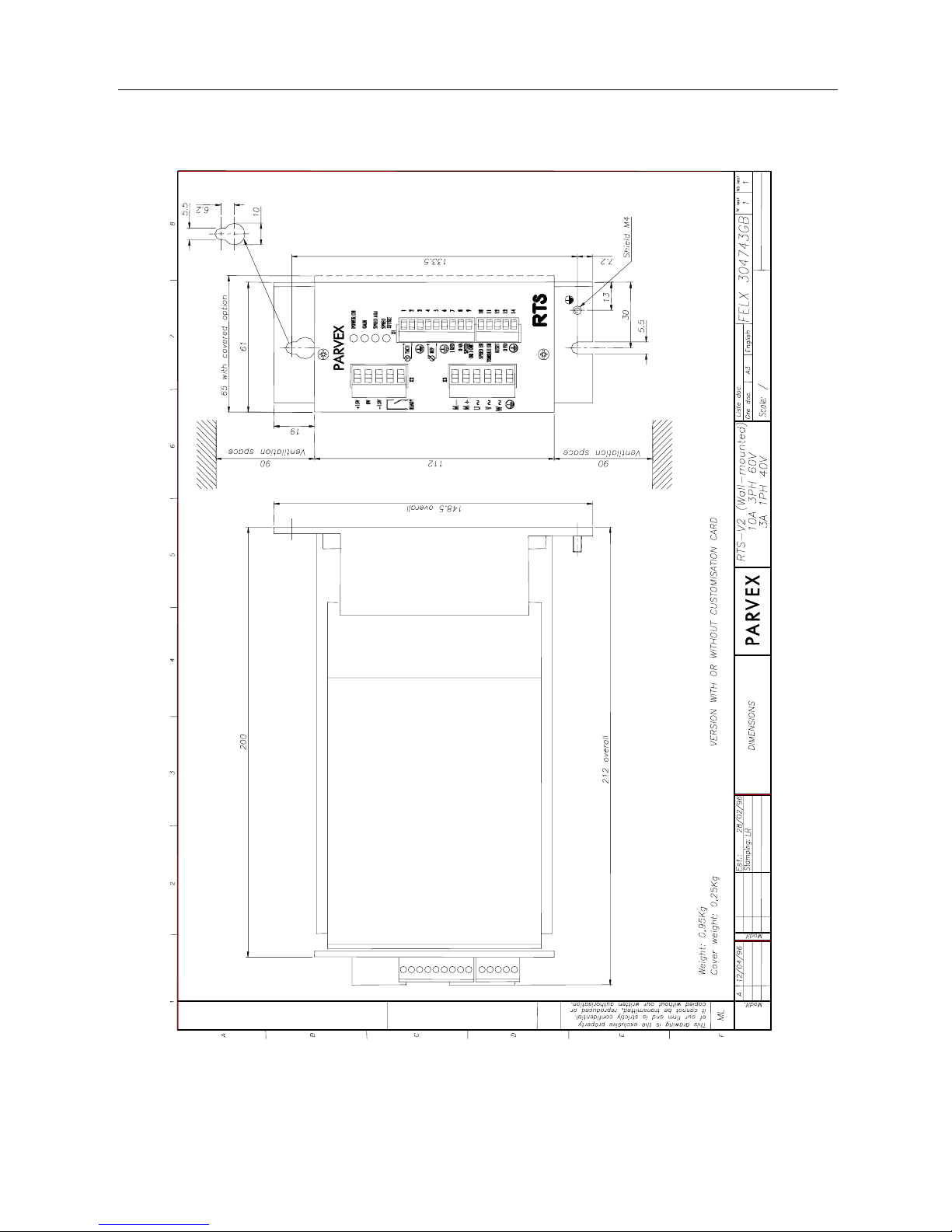

3.1 Dimensions

RTS servo amplifiers are available in two formats for vertical mounting :

- in single Europe 3U DIN rack, in two widths 10" and 19".

- wall- or panel-mounted, with rear angle bracket.

Racks are available with or without ventilation, while RTS wall-mounted versions have individual

ventilation where required (RTS 12/24-130T, RTS 20/40-130T and RTS 16/32-190T). Unventilated

racks are for RTS 3/10-40M only.

230 V single-phase fan connection : To terminal block located at the bottom of the rack front

panel.

- Power consumption : RACE234V22, 2 x 15W fans.

RACE238V32, 3 x 15W fans.

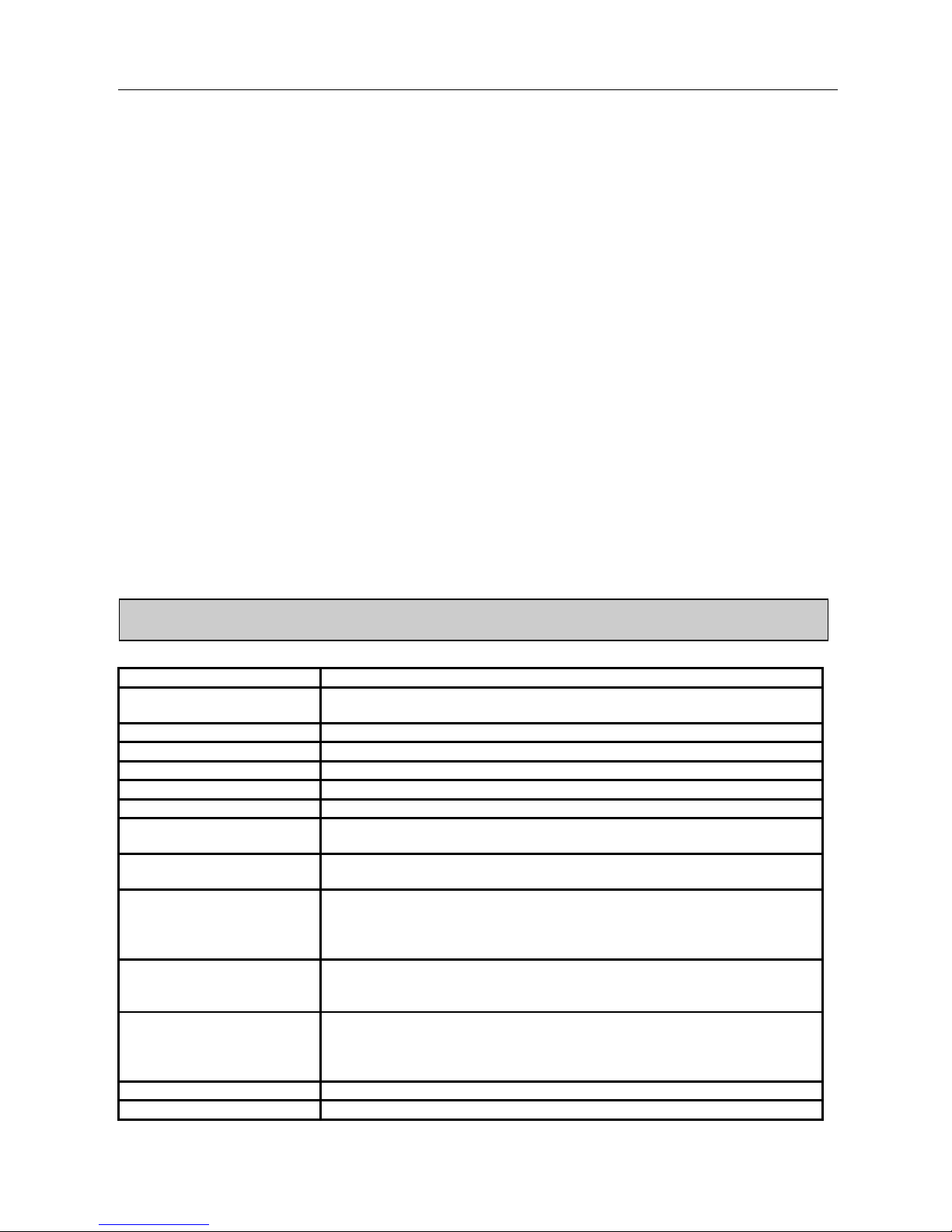

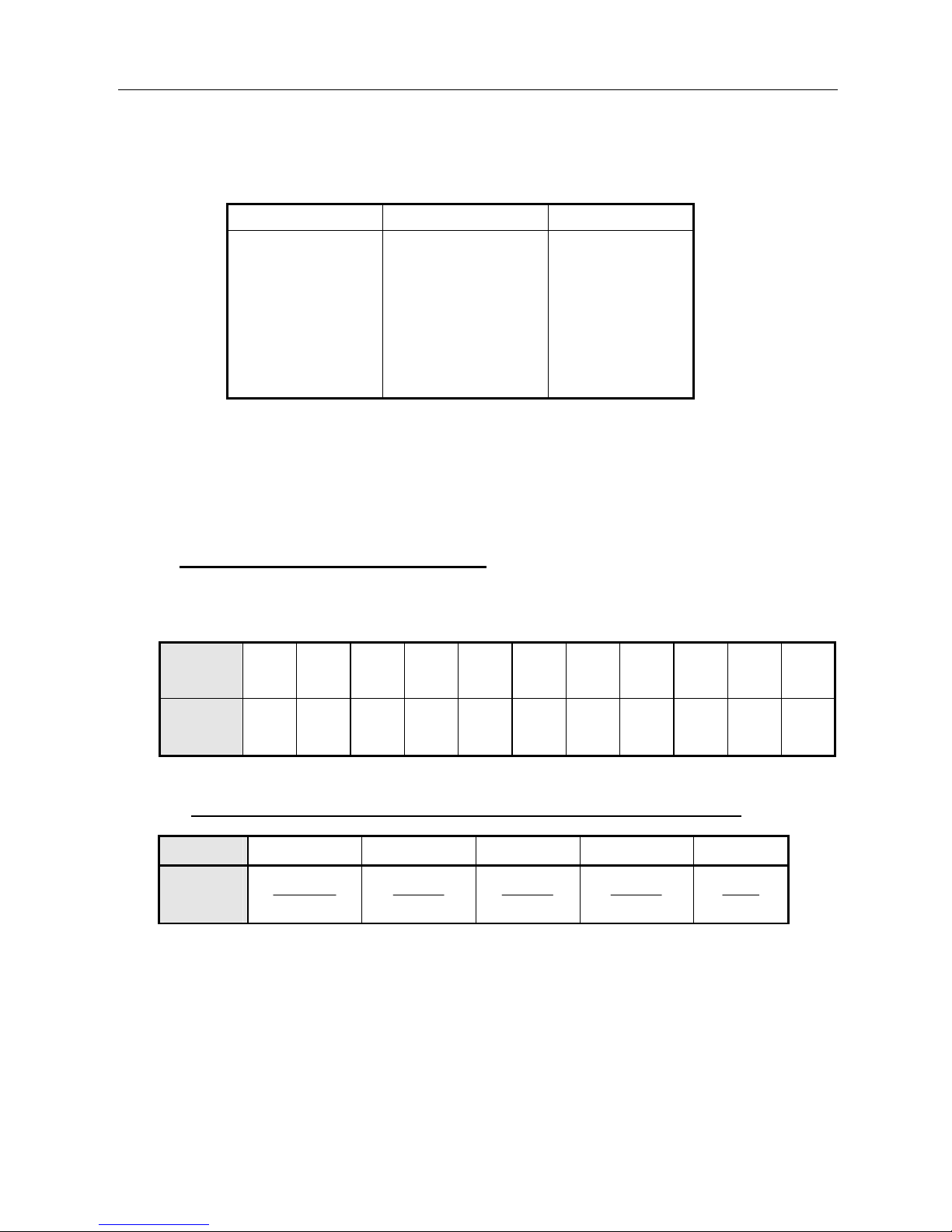

CODE WIDTH DIMENSIONS

RACE234 42E (10’’) FELX 303532 (p12)

RACE234V22 (

f

an-cooled

) 42E (10’’) FELX 303532(p12)

RACE238 84E (19’’) FELX 303531 (p11)

RACE238V32 (

f

an-cooled

) 84E (19’’) FELX 303531 (p11)

Dimensions :

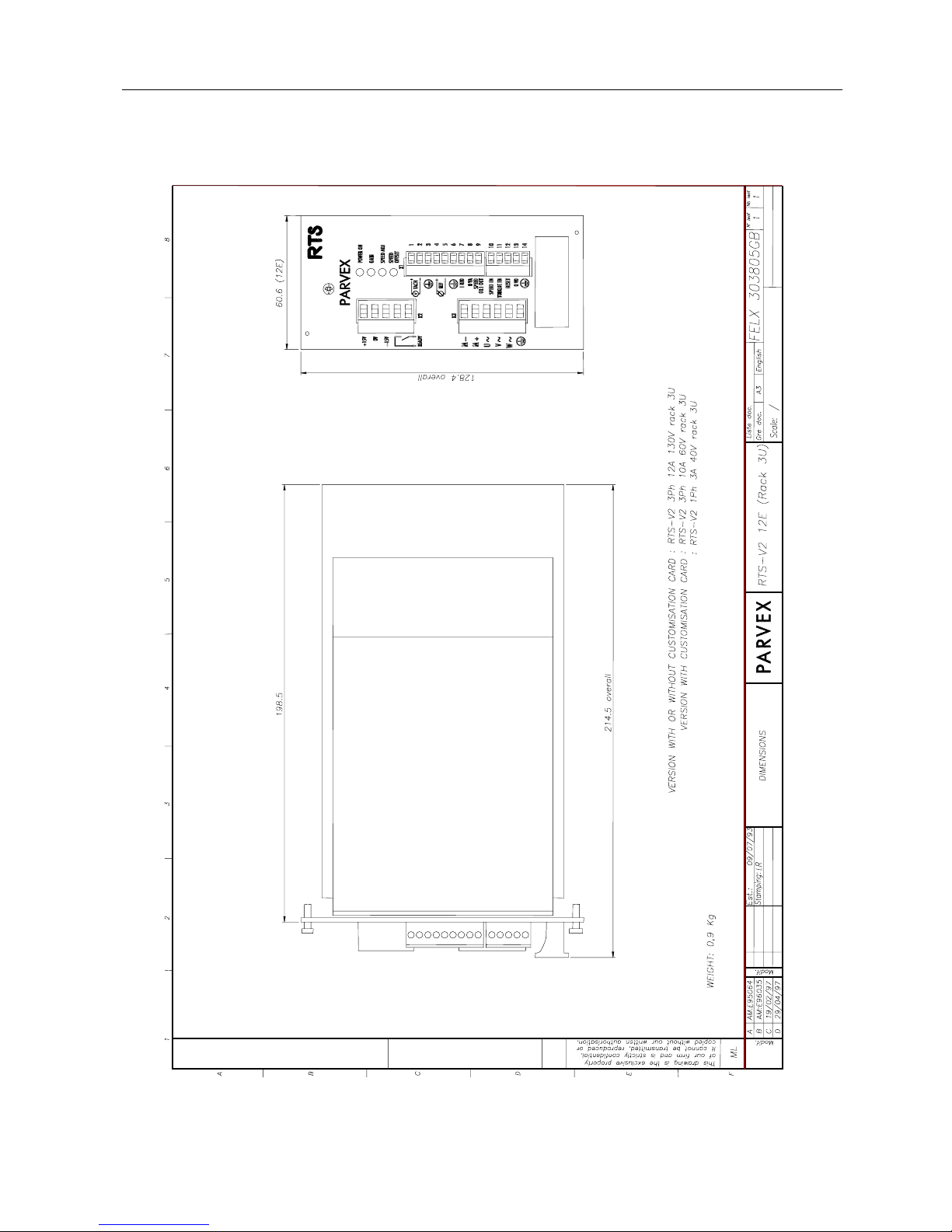

RTS

Parvex Ref.

Input supply

Compulsor

y

ventilation

Fan supply

voltage

Dimensional drawing ref.

Without

customisation

card

With

customisation

card

R

RTS 3/10-40M RTS 4104-301 Single-phase

No

A

*RTS 6104-301

C

K

RTS 10/20-60T RTS 43060102R Three-phase FELX 303440 FELX 303805

V

*RTS 63060102R

(p13) (p15)

e

Yes 230 V

r

s

Single-phase

i

o

RTS 12/24---B RTS 42BA0102 Battery FELX 303814

(p14)

n

RTS 12/24-

130T

RTS 43130102R

* RTS 63130102R

Three-phase

FELX 303805

(p15)

* With personalizing card RZ6602

RTS 2nd Generation SERVO AMPLIFIER

10

PVD 3487 GB 03/2004

RTS

PARVEX Ref.

Input supply

Ventilation

Supply

Dimensional

drawing

(with or without

customisation

card)

W

RTS 3/10-40M RTS 5104-301 Single-phase Not

A

* RTS 7104-301 fan-cooled

L

FELX 304743

L

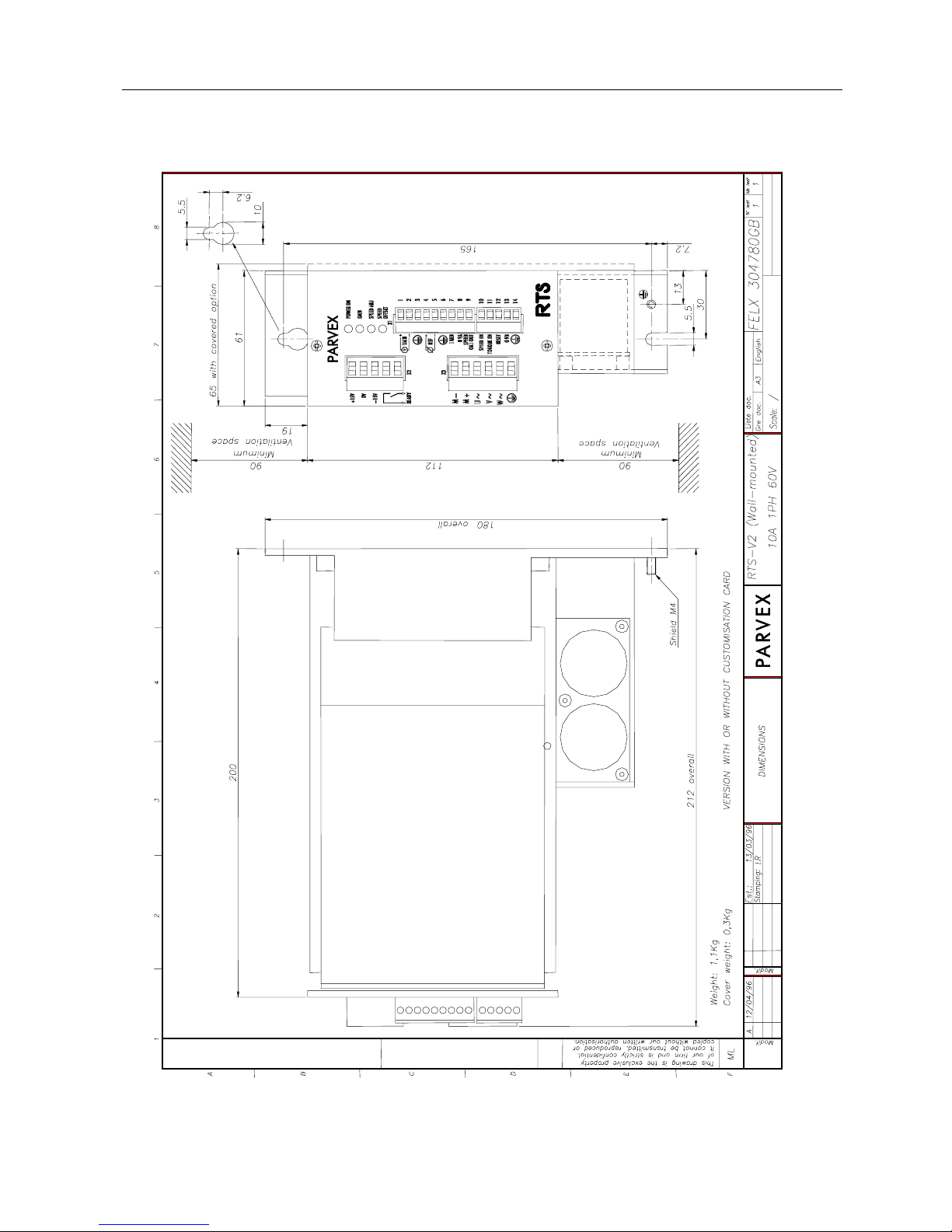

RTS 10/20-60T RTS53060102R Three-phase Not

(p16)

*RTS73060102R fan-cooled

M

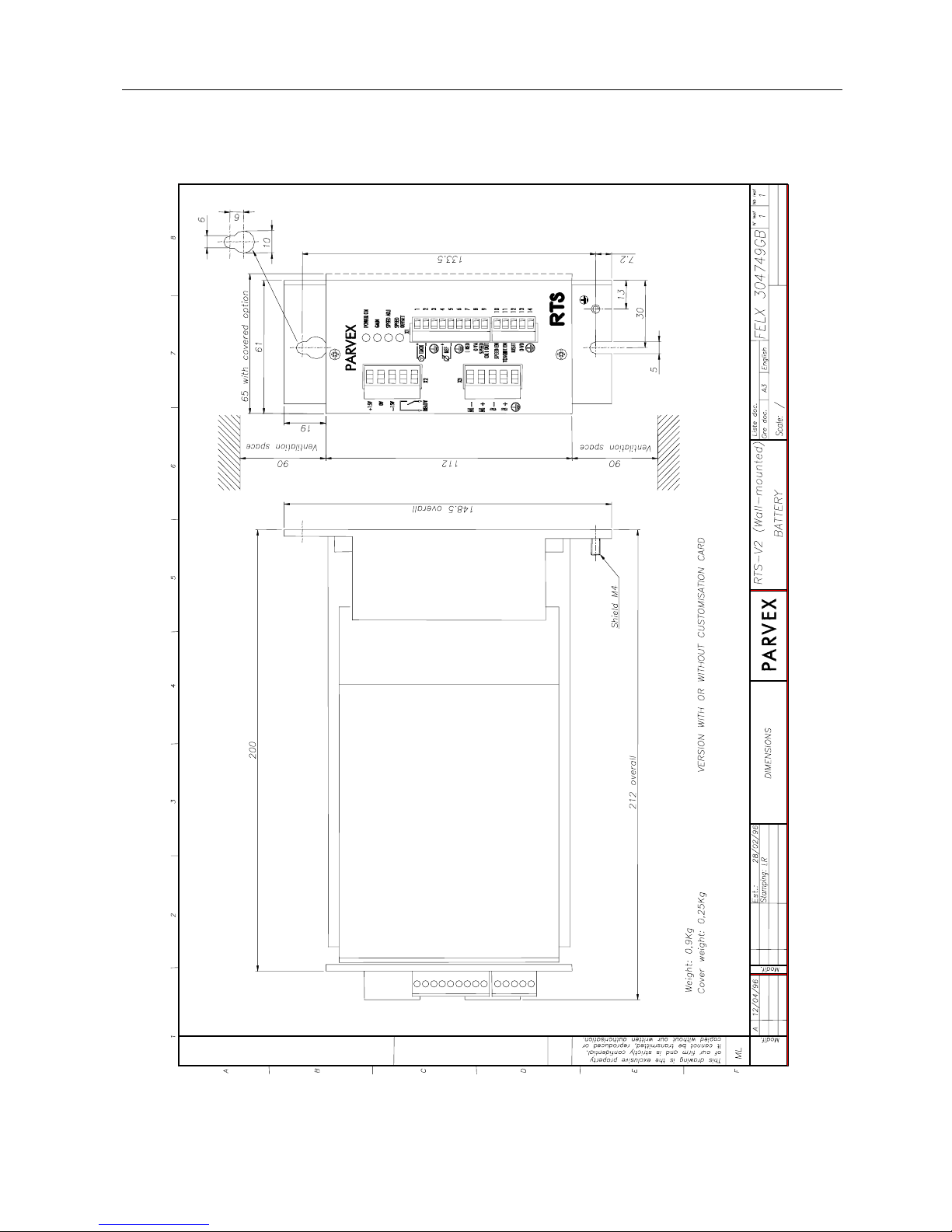

FELX 304749

O

RTS 12/24---B RTS 52BA0102 Battery Not

(p21)

U

* RTS 72BA0102 fan-cooled

N

FELX 304780

T

RTS 10/20-60M RTS 51060102R Single-phase Not

(p17)

E

* RTS 71060102R fan-cooled

D

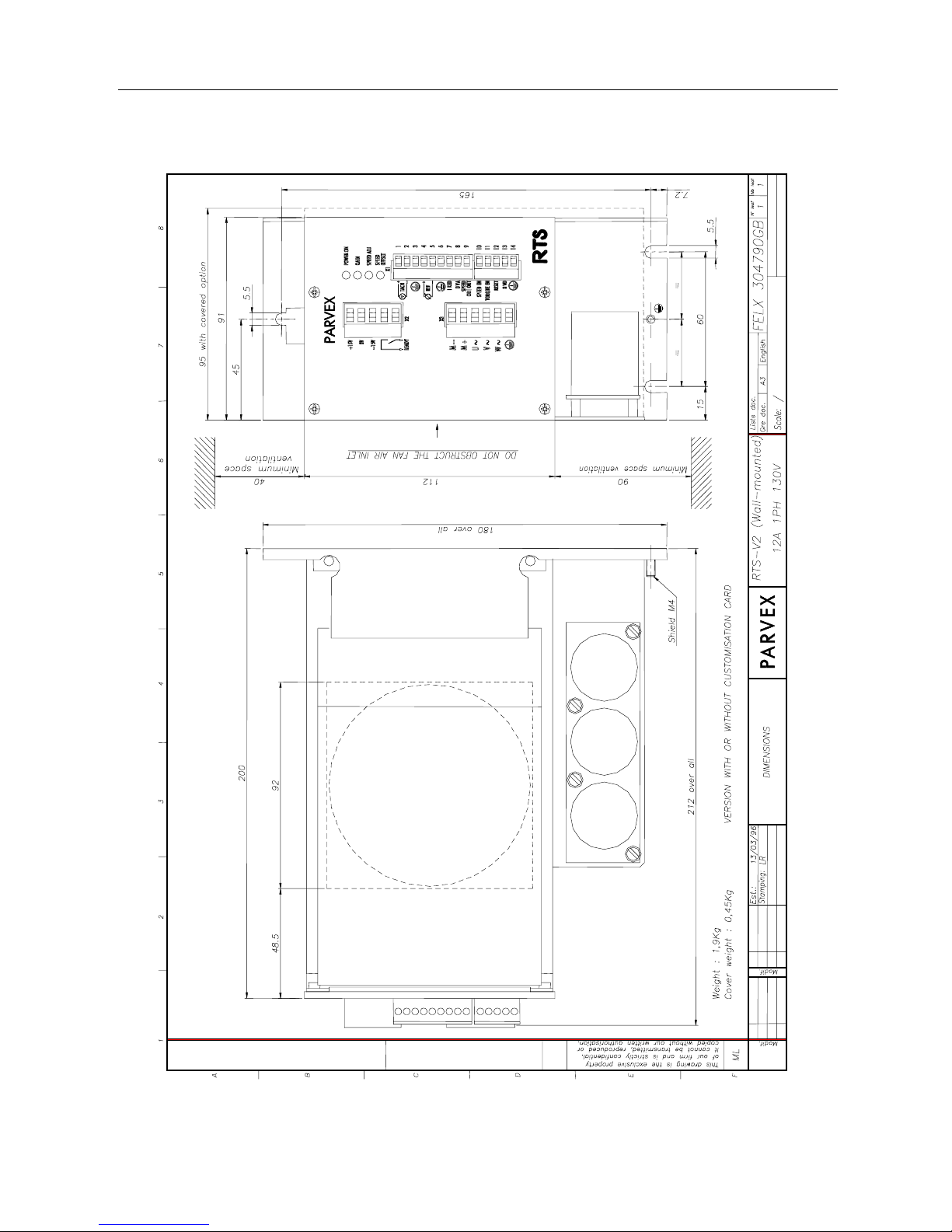

FELX 304790

RTS 12/24-130M RTS 51130102R

* RTS 71130102R

Single-phase fan-cooled

(p18)

FELX 304745

RTS 12/24-130T RTS 53130102R

* RTS 73130102R

Three-phase fan-cooled connection

Internal

(p19)

V

e

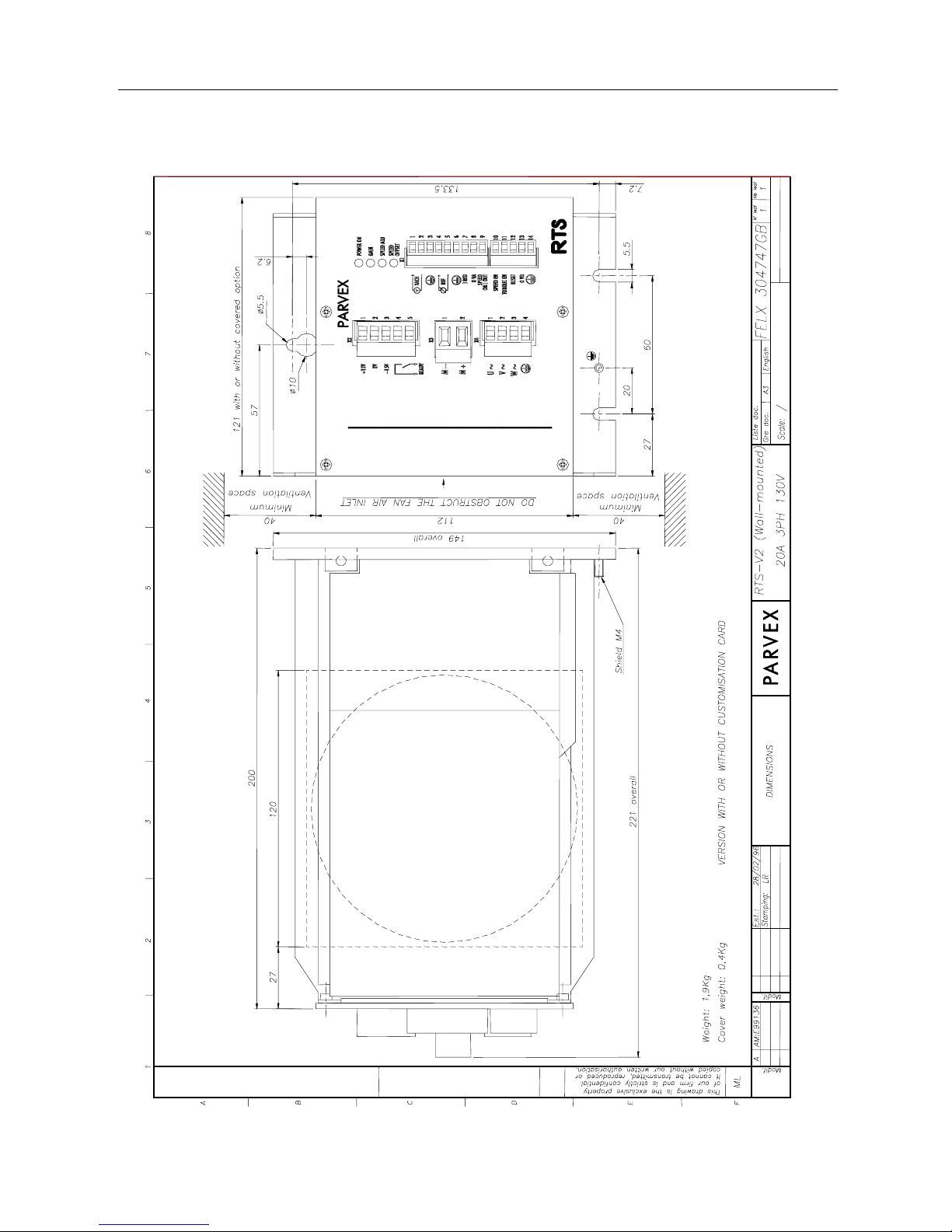

FELX 304747

r

s

RTS 20/40-130T RTS 53130204R

* RTS 753130204R

Three-phase fan-cooled connection

Internal

(p20)

i

o

FELX 304746

n

RTS 16/32-190T RTS 53190103R Three-phase fan-cooled connection

(p22)

* 753190103R Internal

* With customisation card RZ6602

RTS 2nd Generation SERVO AMPLIFIER

11

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

12

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

13

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

14

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

15

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

16

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

17

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

18

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

19

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

20

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

21

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

22

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

23

PVD 3487 GB 03/2004

3.2 Labelling

RTS SERVO AMPLIFIER IDENTIFICATION

Each RTS servo amplifier has an identification label affixed either on the metal plate at the rear for

wall-mounted versions or on the side of the heat sink for rack versions.

The information should be recorded and stored as with the information about the corresponding

servo motor. Remember to record the "A" and/or "B" label indications too.

SPECIMEN LABEL :

c RTS code d Number of phases

e Input voltage (ac) f Input current (ac)

g Output voltage (dc) h Output current (dc)

The output voltage and current values correspond to those of the RTS model (as in RTS servo

amplifier performance chart).

A self-adhesive label is placed on the RTS front panel. Label "A" records :

- N ---- :. servo amplifier serial number

- R----- :. type of motor associated with RTS.

- DT-V : emf of tachometric dynamo for 1000 rpm.

- 10V ----TR : reference value corresponding to maximum motor speed in rpm

(factory set).

Where the RTS is fitted with an RZ 6602 customisation card, some of these indications are

recorded on the self-adhesive label on the customisation card (label "B"). This label also

states the model of RTS.

LABEL "A" LABEL "B"

RTS --V --A

R----- DT-V

10V ----TR

N----

R----- DT-V

10V ----TR

RTS 2nd Generation SERVO AMPLIFIER

24

PVD 3487 GB 03/2004

4. - ELECTRICAL CONNECTIONS

4.1 General Wiring Requirements

4.1.1 Appliance handling

See the safety instructions given at the beginning of this manual. In particular, wait for all the front

panel LEDs to go off completely before doing any work on the servo-amplifier or servomotor.

4.1.2 Electromagnetic compatibility

EARTHING

Comply with all local safety regulations concerning earthing.

Utilize a metal surface as an earth reference plane (e.g. cabinet wall or assembly grid).

This conducting surface is termed the potential reference plate. All the equipment of an

electrical drive system is connected up to this potential reference plate by a low

impedance (or short distance) link. Ensure the connections provide good electrical

conduction by scraping off any surface paint and using fan washers. The drive will then

be earthed via a low impedance link between the potential reference plate and the earth

screw at the back of the RTS. If this link exceeds 30 cm, a flat braid should be used

instead of a conventional lead.

CONNECTIONS

Do not run low-level cables (resolver, inputs/outputs, NC or PC links) alongside what are

termed power cables (power supply or motor). Do not run the power supply cable and

the motor cables alongside one another otherwise mains filter attenuation will be lost.

These cables should be spaced at least 10 cm apart and should never cross, or only at

right-angles.

Except for the resolver signals, all low-level signals will be shielded with the shielding

connected at both ends. At the RTS end, the shielding is made continuous by the SubD connector mechanism.

The motor cables are limited to the minimum functional length. The yellow and green

motor cable lead must be connected to the box or front panel terminal block with the

shortest possible link.

This usually means shielded motor cable is not required. Chokes may also be inserted

into the motor phase leads.

RTS 2nd Generation SERVO AMPLIFIER

25

PVD 3487 GB 03/2004

MAINS FILTERING

The mains filter must be mounted as close as possible to the potential reference plate between

the mains and the power supply (p.46 and 47). Use shielded cable (or run the cable in metal

trunking).

Avoid running cables together, ahead of and after the filter.

Filters sometimes have high leakage currents. In this case, comply with the standard connection

diagrams when fitting them.

OTHER MEASURES

Self-inducting components must be protected against interference: brakes, contactor or relay

coils, fans, electro-magnets, etc.

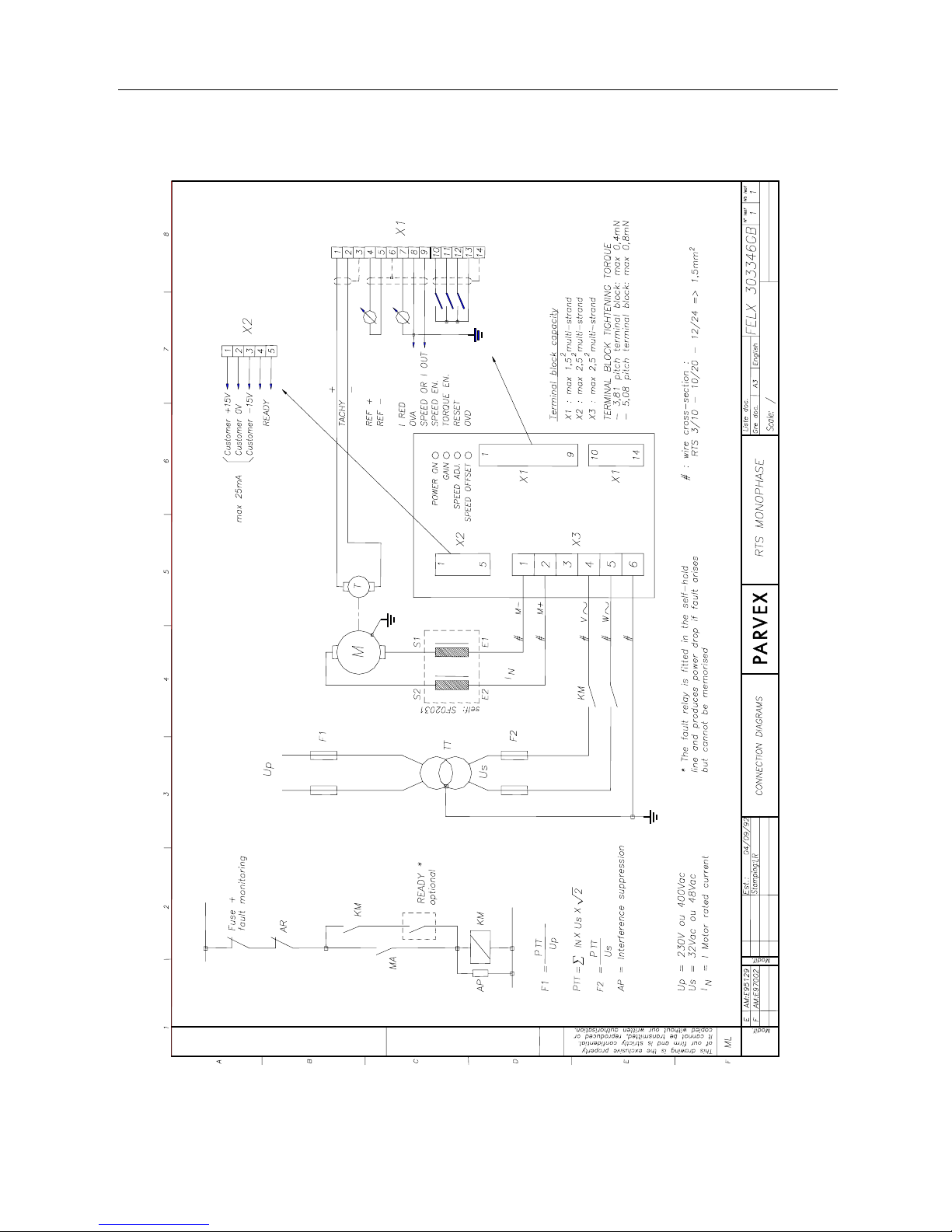

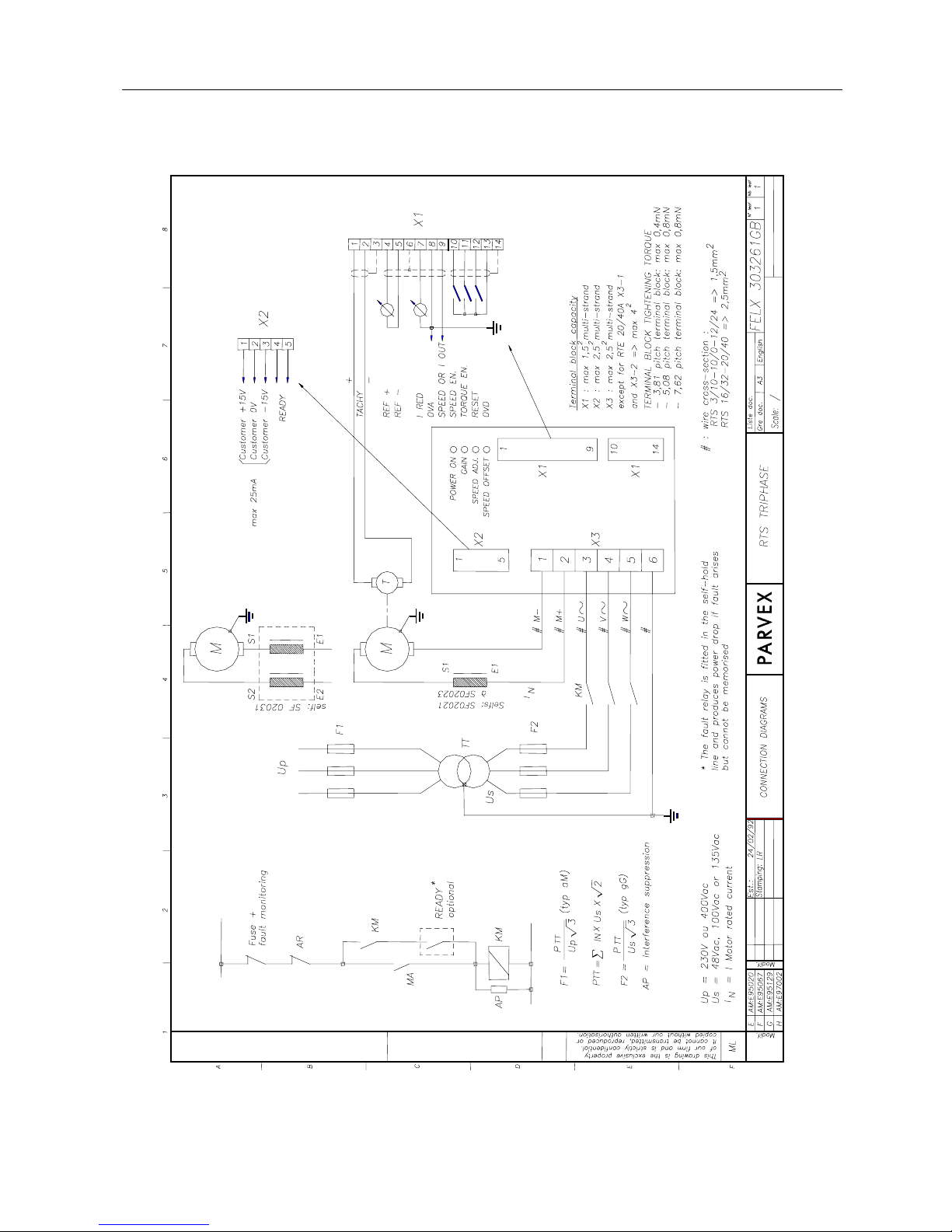

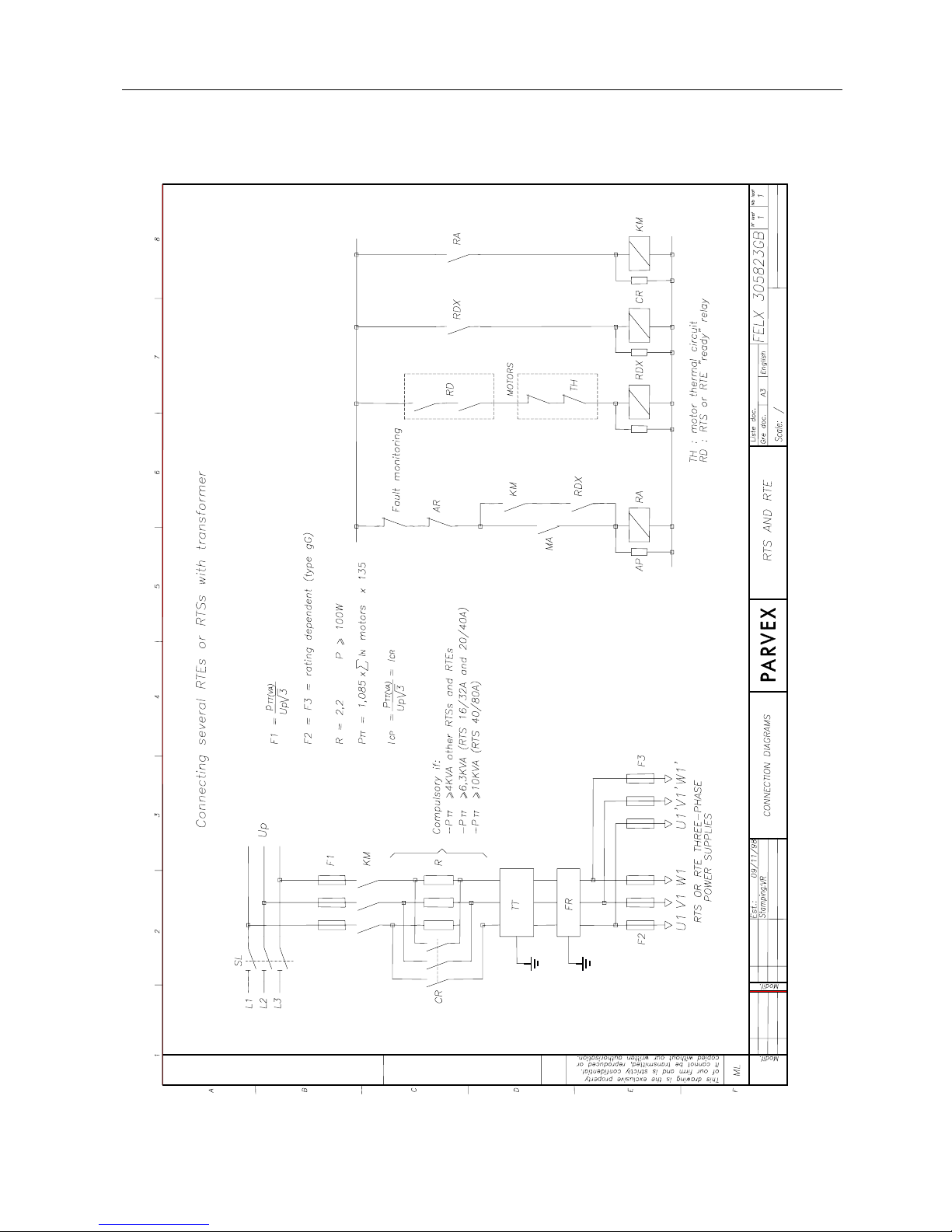

4.2 RTS Servo amplifier connection

As a supplement to the block diagram, see the appended diagrams :

- RTS single-phase FELX 303346 (p.26)

- RTS three-phase FELX 303261 (p.27)

- RTS battery FELX 303738 (p.28)

- Connecting serveral RTEs or RTSs with transformer FELX 305823 (p29)

The terminal block description and terminal functions are shown in the following pages :

The RTS servo amplifiers are factory set to match the characteristics of the servo motor to be

used or the application where known.

When the servo motor is fitted with a brake, adhere to the following activating sequence :

- Limit current (to a value less than the RTS setting),

- Engage brake,

- Cut RTS servo amplifier.

To restart, proceed as follows :

- limit current (as above),

- energise RTS,

- release brake,

- remove current limitation.

RTS 2nd Generation SERVO AMPLIFIER

26

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

27

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

28

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

29

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

30

PVD 3487 GB 03/2004

4.3 Front Panel

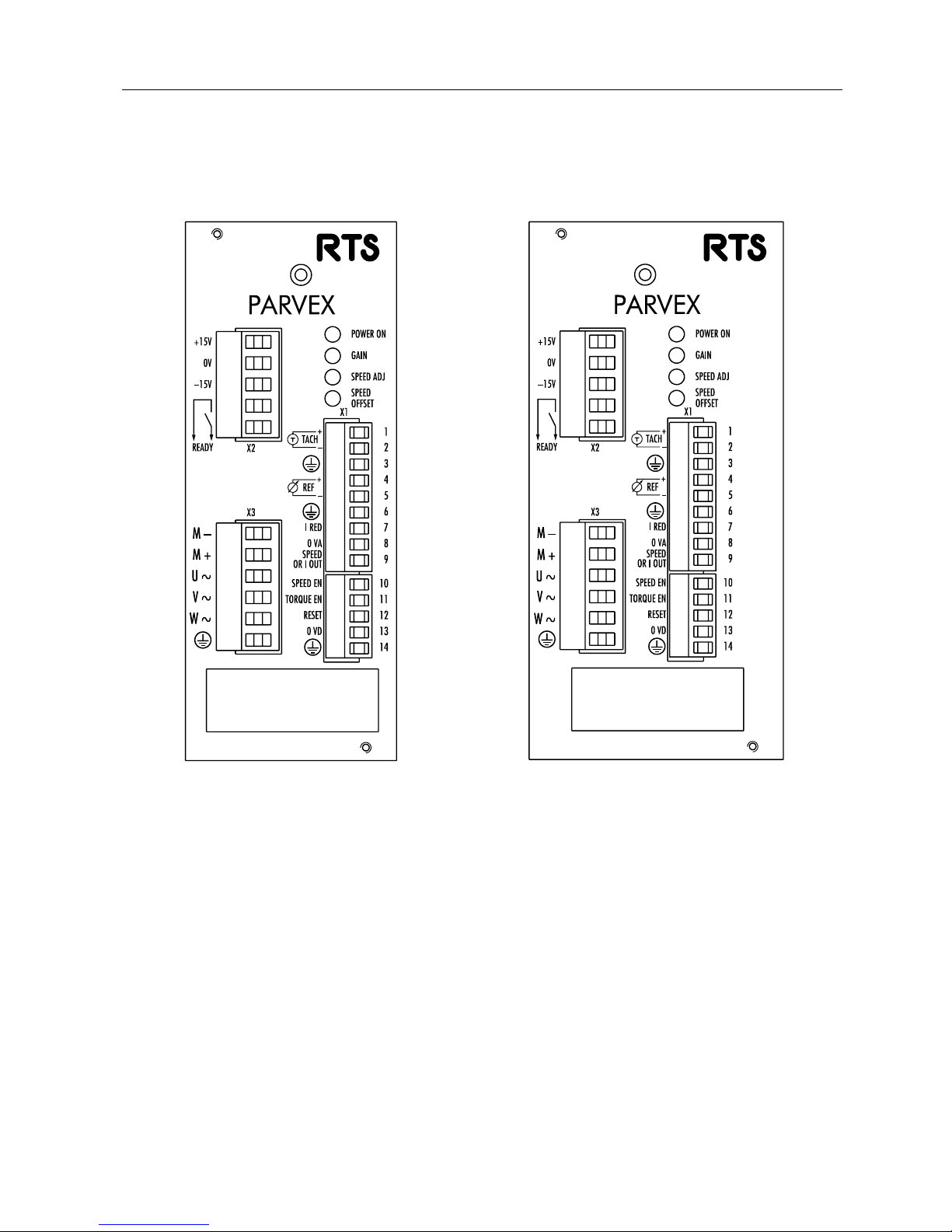

RTS V2 Battery (Rack) RTS V2 Battery (wall-mounted)

RTS 2nd Generation SERVO AMPLIFIER

31

PVD 3487 GB 03/2004

RTS V2 10 E (Rack) RTS V2 12 E (Rack)

RTS 2nd Generation SERVO AMPLIFIER

32

PVD 3487 GB 03/2004

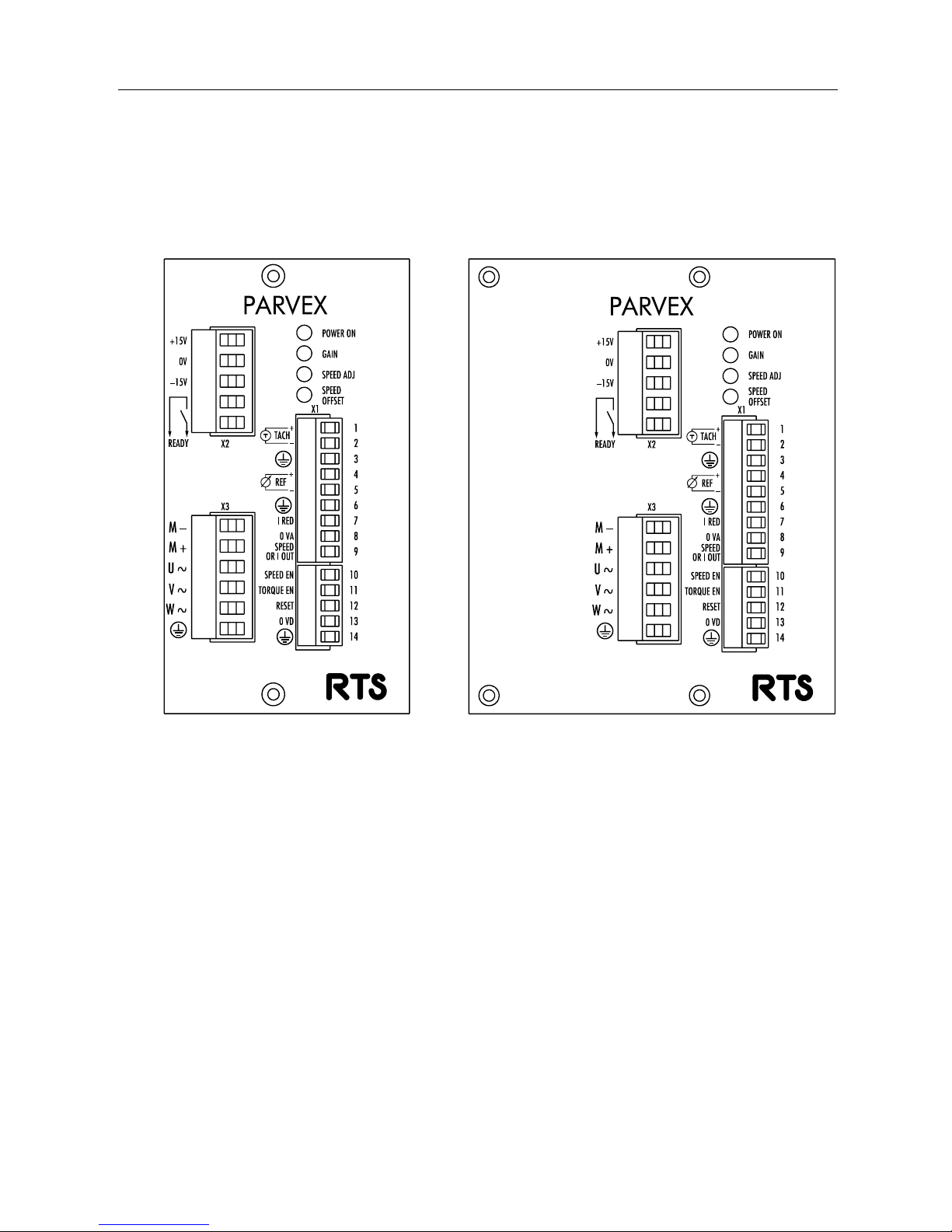

RTS V2 12 E (wall-mounted) RTS V2 12 A / 130V (wall-mounted)

1PH and 3PH

RTS 2nd Generation SERVO AMPLIFIER

33

PVD 3487 GB 03/2004

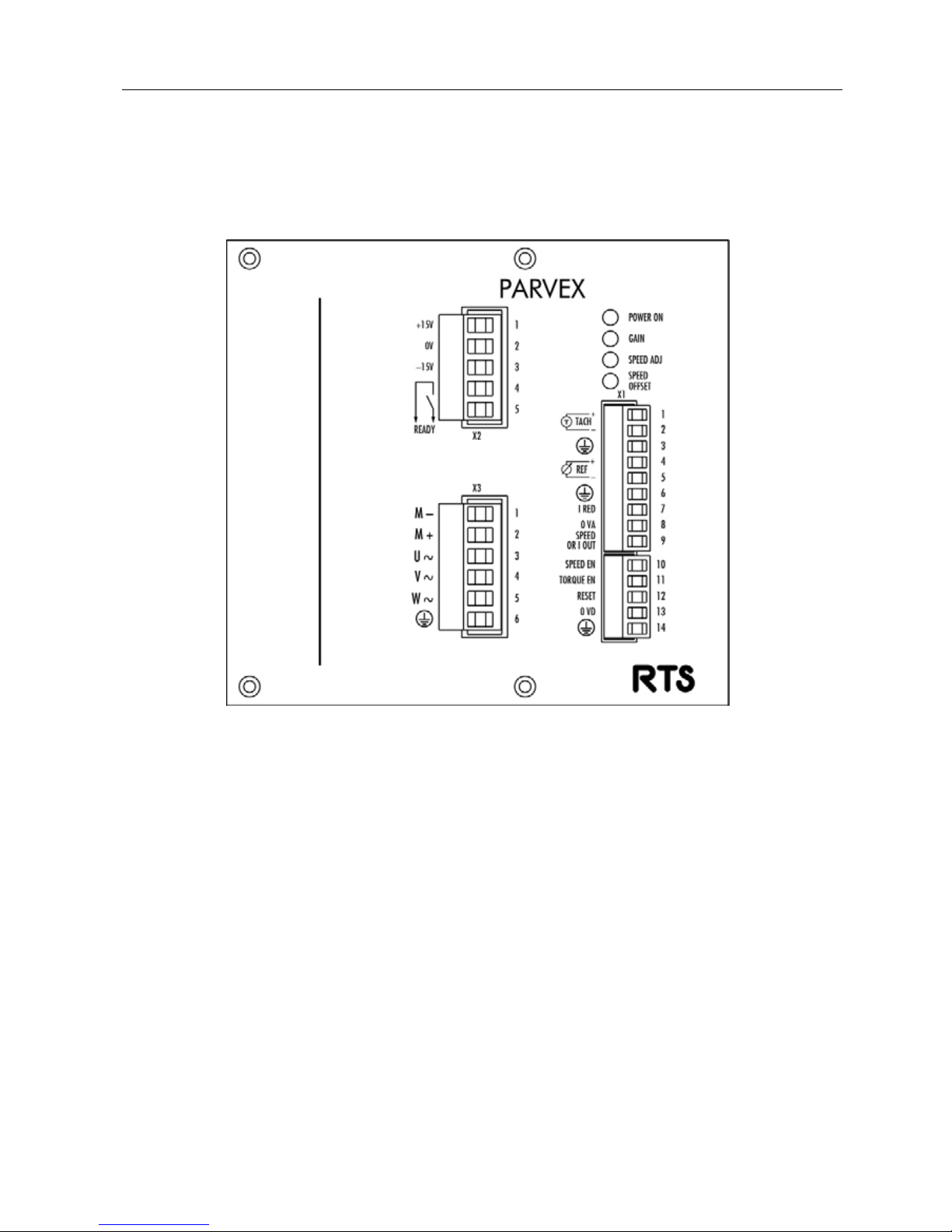

RTS V2 16 A / 190 V (wall-mounted)

RTS 2nd Generation SERVO AMPLIFIER

34

PVD 3487 GB 03/2004

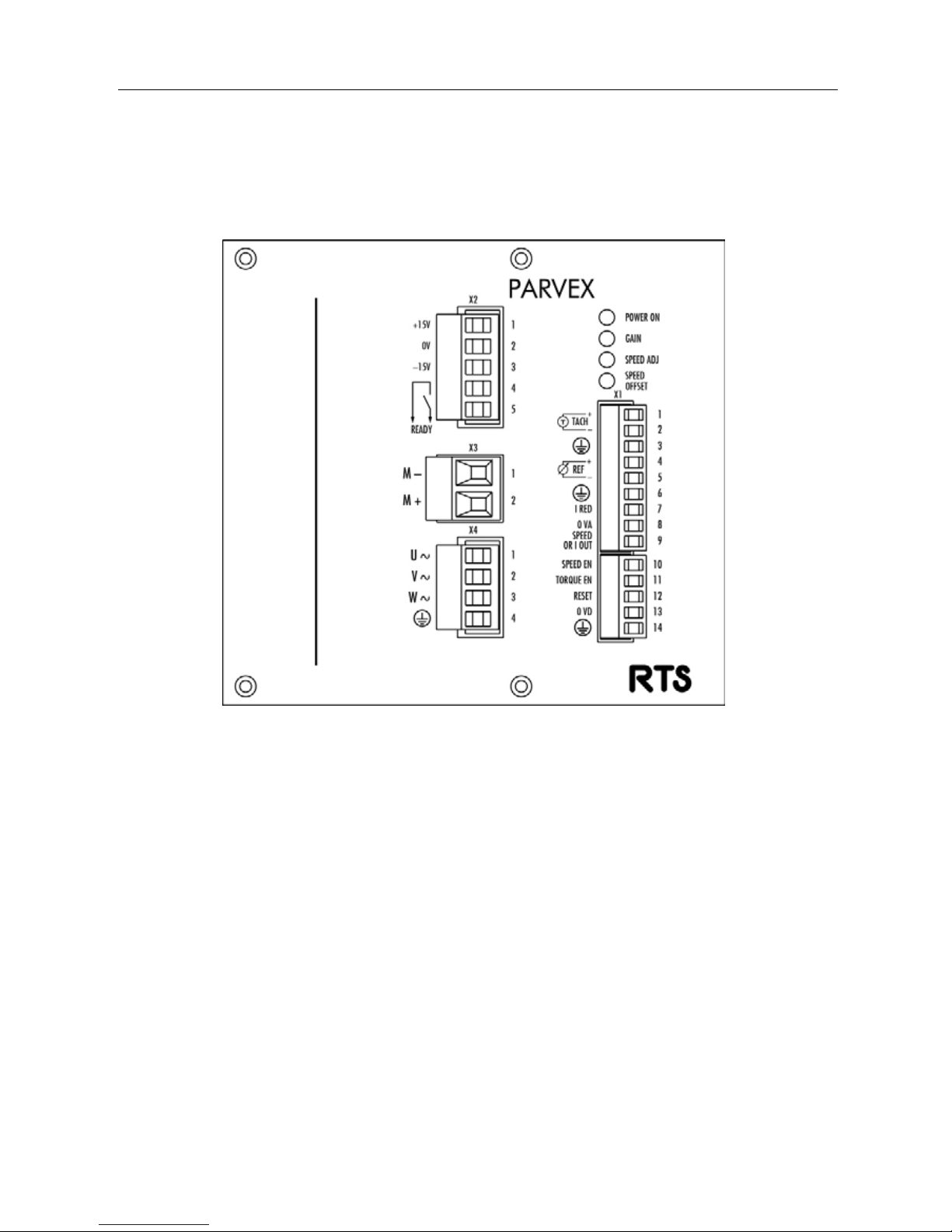

RTS V2 20 A / 130 V (wall-mounted)

RTS 2nd Generation SERVO AMPLIFIER

35

PVD 3487 GB 03/2004

4.4 Terminal blocks X1, X2 AND X3

Torque value : terminal block X1, 0.4 Nm terminal blocks X2 and X3, 0.8 Nm.

Terminal block X1 front panel connection Recommended cable cross-section : 0.5 mm² -

- 1.5 mm² multi-strand. Use shielded cables with the shielding connected as stated below.

DESCRIPTION

N° NAME

TERMINAL BLOCK X1

1

2

3

4

5

6

TACH+

TACH-

REF+

REF-

I

I

-

I

I

-

Tacho differential inputs. Use

shielded cable with shielding

connected to terminal 3. Input

voltage must not exceed 100 V.

Tachometric cable shielding. Do not

connect shielding at tacho end.

Speed or current differential

reference depending on position of

selector switch S1.

± 10 V corresponds to rated motor

speed at speed reference.

Use shielded cable with shielding

connected to terminal 6.

Shielding, to be connected at

numerical control end also.

TERMINAL

RTS 2nd Generation SERVO AMPLIFIER

36

PVD 3487 GB 03/2004

DESCRIPTION

N° NAME

TERMINAL BLOCK X1

7

8

9

10

I RED

% I max

R(KΩ)

0 VA

SPEED

OR

I OUT

SPEED

EN.

I

-

O

I

A

nalogue reduction of current.

Reduction may be controlled either

by voltage or by resistor between 7

and 8.

This input may be used for example

when the servo motor is against a

mechanical abutment.

Resistor value :

10 30 50 70 90 100

3.32 10 22,1 39.2 56.2 infinity

0 V reference to be connected

internally in the casing

Signal providing speed or current

image depending on selector switch

S2 position.

± 10 V corresponds to max speed or

current value. (Pulse current value

shown in RTS characteristics chart).

See also identification section.

Typical uses :

motion synchronisation, master-slave

mode, cutting tool wear monitoring...

To be connected via an external

contact to terminal 13 to enable

speed reference. Typical uses : limit

switch, emergency stop

TERMINAL

RTS 2nd Generation SERVO AMPLIFIER

37

PVD 3487 GB 03/2004

DESCRIPTION

N° NAME

TERMINAL BLOCK X1

11

12

13

14

TORQUE

EN.

RESET

I

I

-

-

To be connected via an external

contact to terminal 13 to enable

current; if terminal is not connected,

the motor free wheels.

When the motor is fitted with a

holding brake, synchronise control of

this input with brake control.

Reset. By connecting RESET to

terminal 13, faults are cleared and

the axis is ready again (if fault has

been corrected).

Switching the RTS off and then back

on has the same effect as RESET.

Logic 0 V, to be connected to

terminals 10, 11 and 12 via control

contacts.

Logic connection cable shielding

(terminals 10, 11 and 12).

TERMINAL

RTS 2nd Generation SERVO AMPLIFIER

38

PVD 3487 GB 03/2004

4.5 Terminal block X2 connection

Recommended cable cross-section : 0.5 - 1.5 mm²

DESCRIPTION

N° NAME

TERMINAL BLOCK X2

1

2

3

4

5

+15 V

0V

-15V

READY

READY

O

-

O

O

± 15 V (25 mA) available for external

applications.

Output via contact of sum of faults.

Contact opens if fault or mains failure

occurs.

Permissible current : 0.5 A

Permissible voltage : 220 V ac

4.6 Terminal block X3 connection

Recommended cable cross-section :

RTS 3/10 : 1.5 mm²; RTS 10/20, 12/24, 16/32, 20/40 : 2.5 mm²

DESCRIPTION

N° NAME

TERMINAL BLOCK X3

1

2

3

4

5

6

M-

M+

U ≈

V≈

W≈

O

I

I

I

-

Motor connection, cable crosssection to be used (see motor

dimensions section). Minimum motor

inductance must be 0.4 to 1 mH

depending on RTS rating.

Phase U of three-phase supply. For

single-phase supply, this input is not

connected.

Phase V.

Phase W

Ground to be wired to cabinet ground

rod by minimum 2.5 mm² lead.

TERMINAL

TERMINAL

RTS 2nd Generation SERVO AMPLIFIER

39

PVD 3487 GB 03/2004

4.7 Accessories

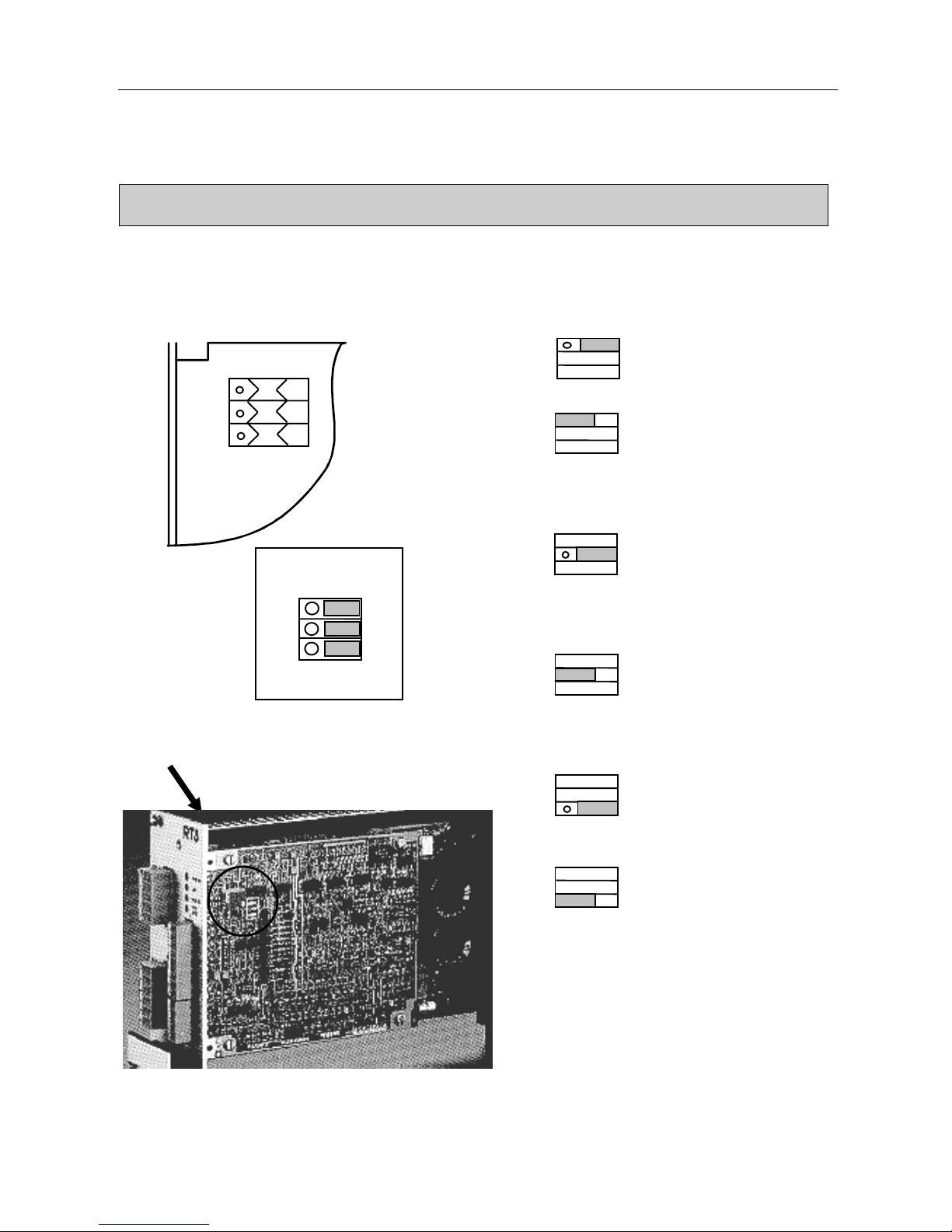

4.7.1 Plug-in Customisation card

The RTS includes a number of components for customising the axis. These components are

mounted as standard on the control card and may be mounted on a plug-in customisation card as

an option. This means a wider rack version of RTS 3/10-40M, RTS 10/20-60 three-phase and RTS

12/24 Battery (front panel width increased from 51 mm to 61 mm

).

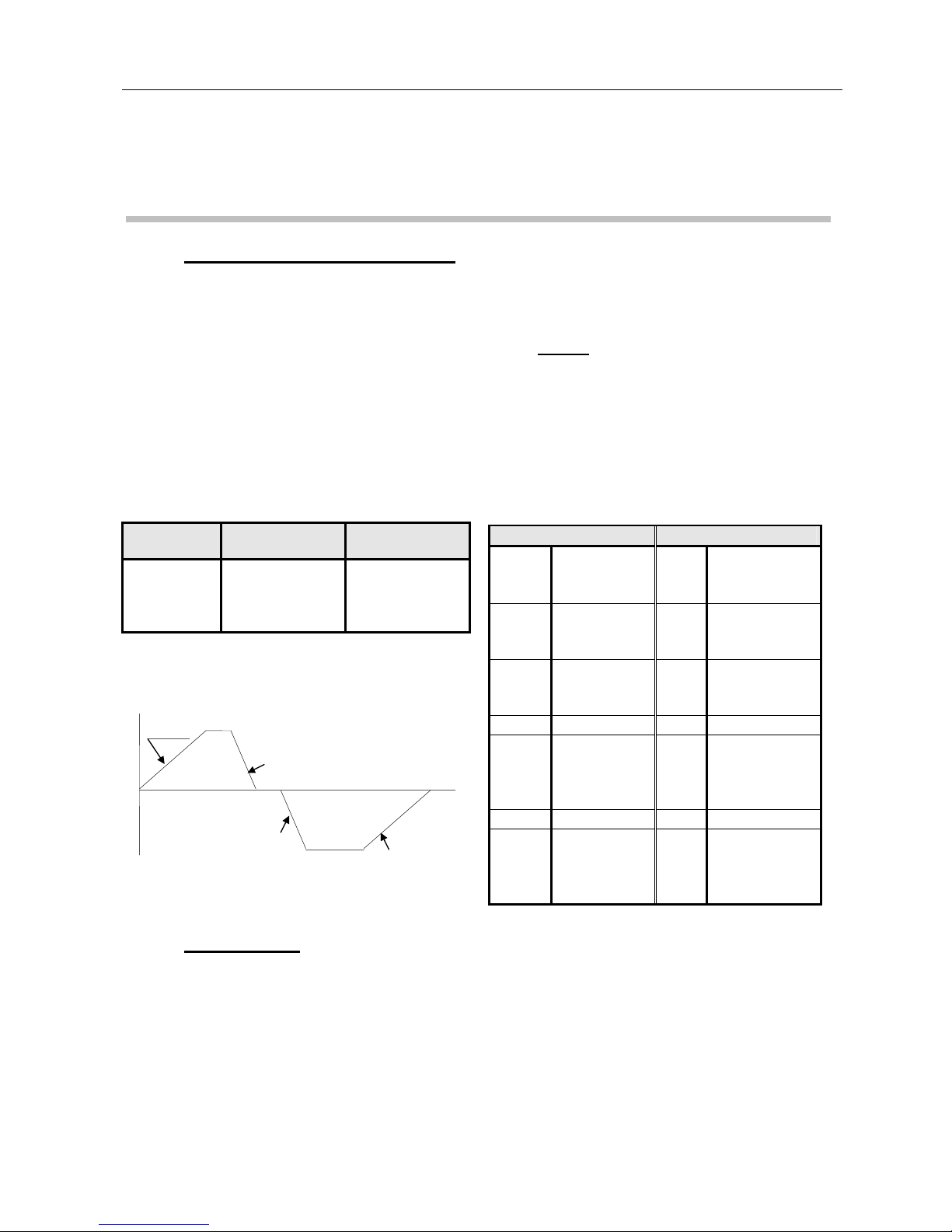

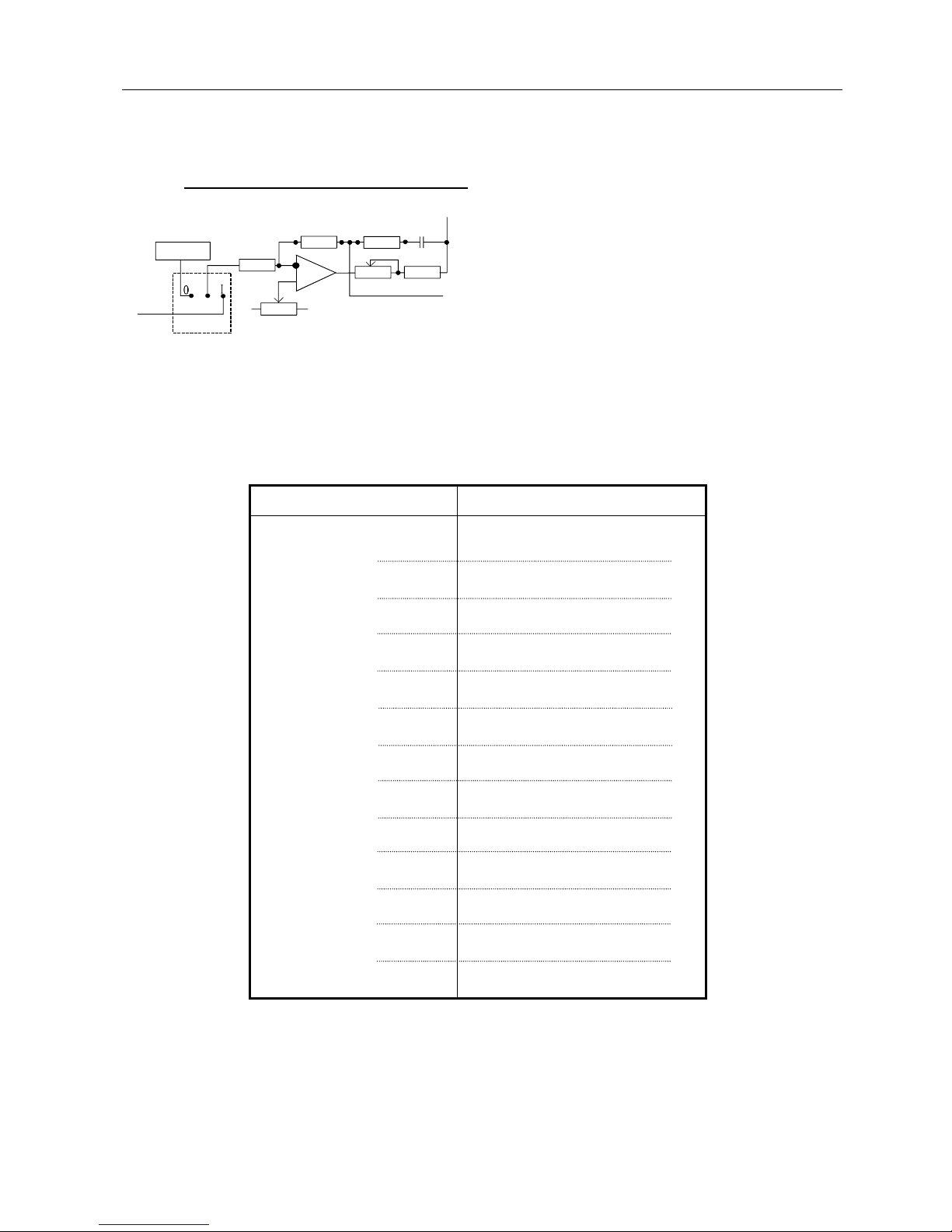

RAMP (Card RG 6601)

The ramp comes as a separate card that plugs into the RTS front panel. The card is also an

extension to terminals X1/1 to X1/9 of terminal block X1.

The ± 15 V available on RTS terminal X2 is used to power the card.

The card protrudes from the RTS by 62 mm. It is 36 mm high and 13 mm wide.

Adjustment : The ramp can be adjusted by potentiometers between 0.06 sec/Volt and 0.6 sec/Volt.

Reference Minimum time Maximum time

0 - 5V 0.3 sec 3 sec

0 - 10V 0.6 sec 6 sec

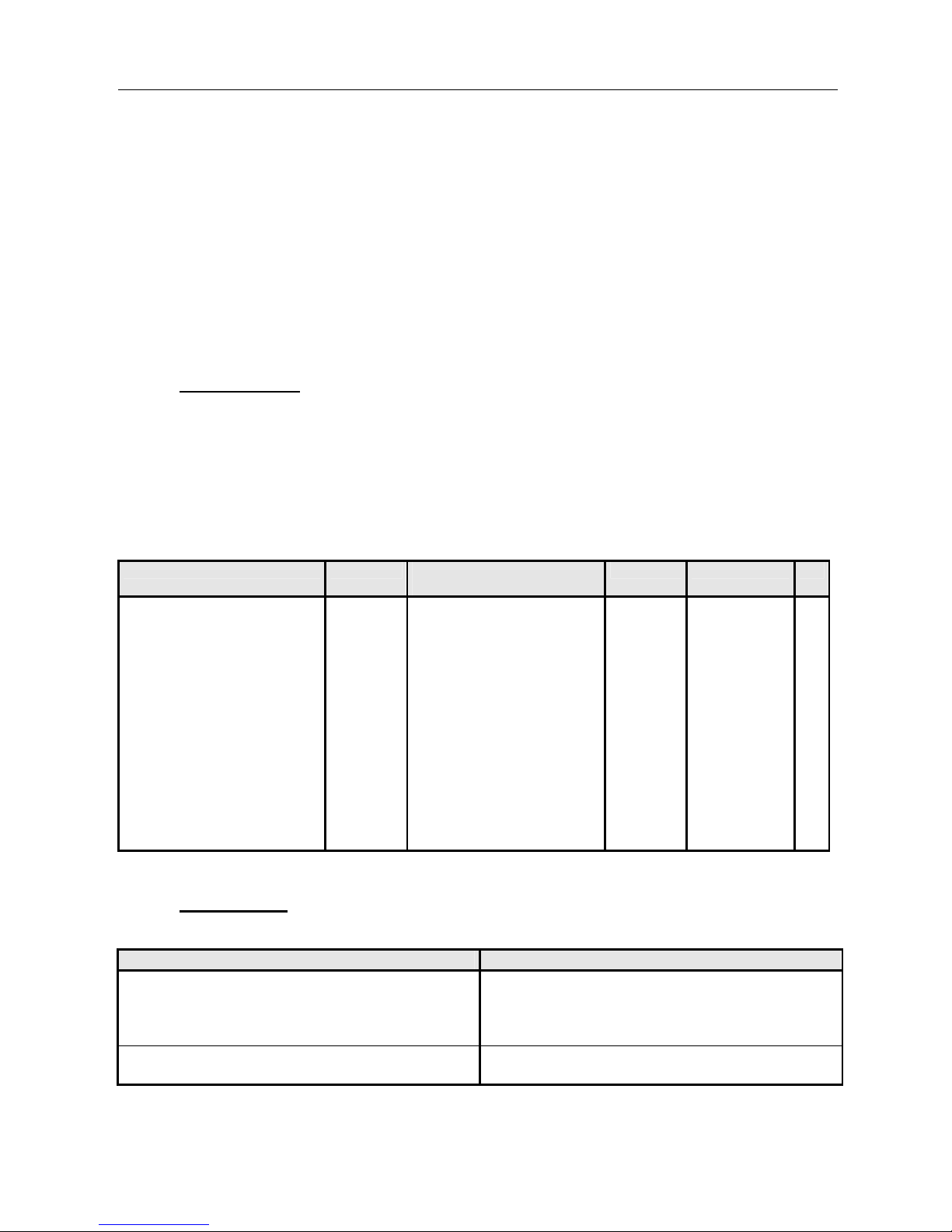

4.7.2 Extra choke

The extra choke is connected between the RTS and the servo motor, as near as possible to the

RTS. It must be used when the servo motor choke is less than the values in the table on page 7. It

should also be used when the RTS and servo motor are more than 50 m apart (or 25 m where

shielded cable is used).

X1 RG 6601 X2 RG 6601

X1/1

X1/2

Tacho inputs X2/1 +15 V (to be

connected to

X2/1)

X1/3 shielding X2/2 0V(to be

connected to

X2/2)

X1/4

X1/5

Speed

reference

inputs

X2/3 -15V(to be

connected to

X2/3)

X1/6 shielding

X1/7 Analogue

inputs

reduction of

current

X1/8 0 VA

X1/9 Analogue

Output

speed or

current value

Slopes A and B can be adjusted independently.

Slope A must equal Slope D

Slope B must equal slope C

Reference

Slope A

Slope C

Slope D

Slope B

RTS 2nd Generation SERVO AMPLIFIER

40

PVD 3487 GB 03/2004

Recommended combinations :

RTS 3/10-40M single-phase

RTS 10/20-60 single-phase SF020231 12A-2x0.25 mH

or three-phase drawing FELX 303434 (p.42).

RTS 12/24-130T three-phase

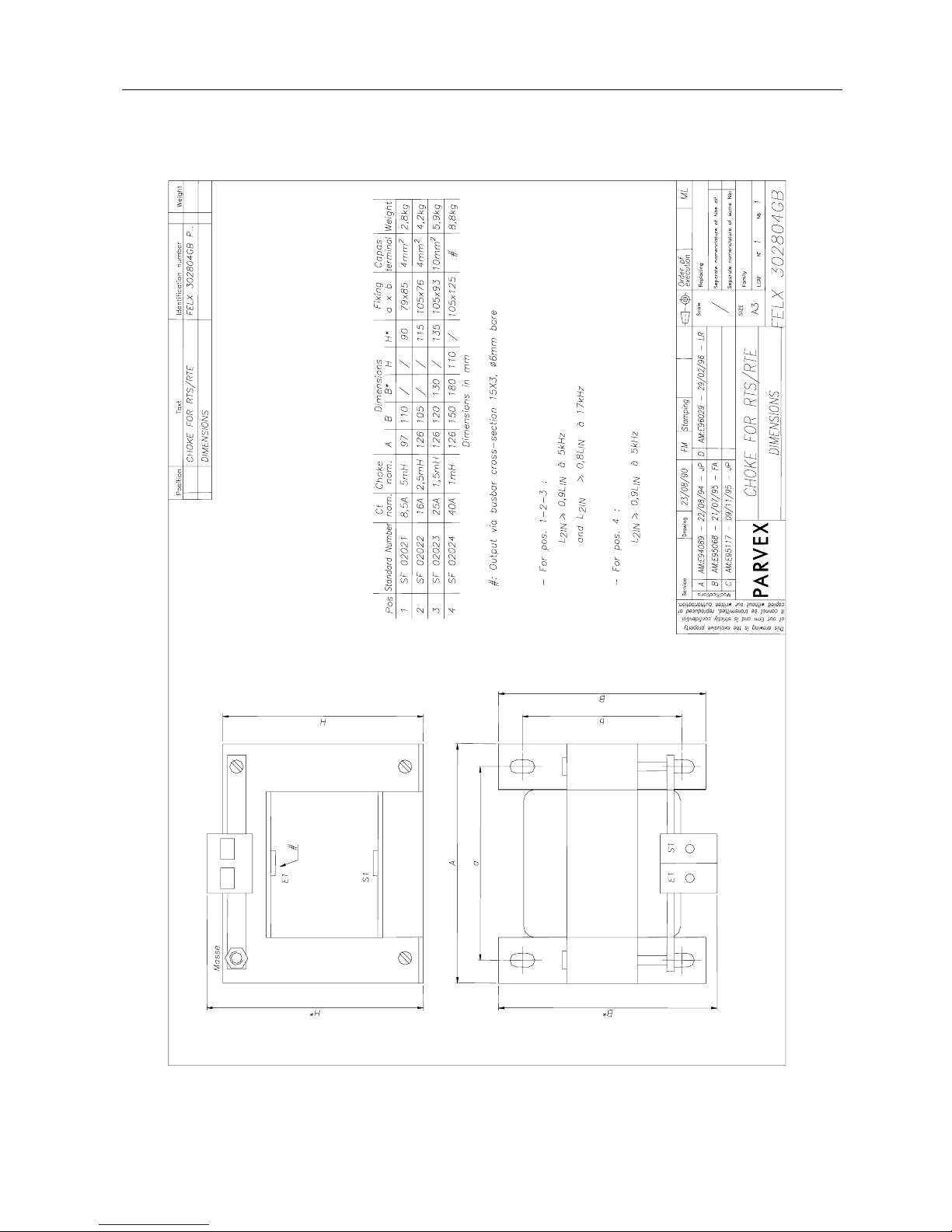

RTS 20/40-130T three-phase SF02023 25A-1.5 mH drawing FELX 302804 (p.41).

RTS 16/32-190T three-phase SF02022 16A-2.5 mH drawing FELX 302804 (p.41).

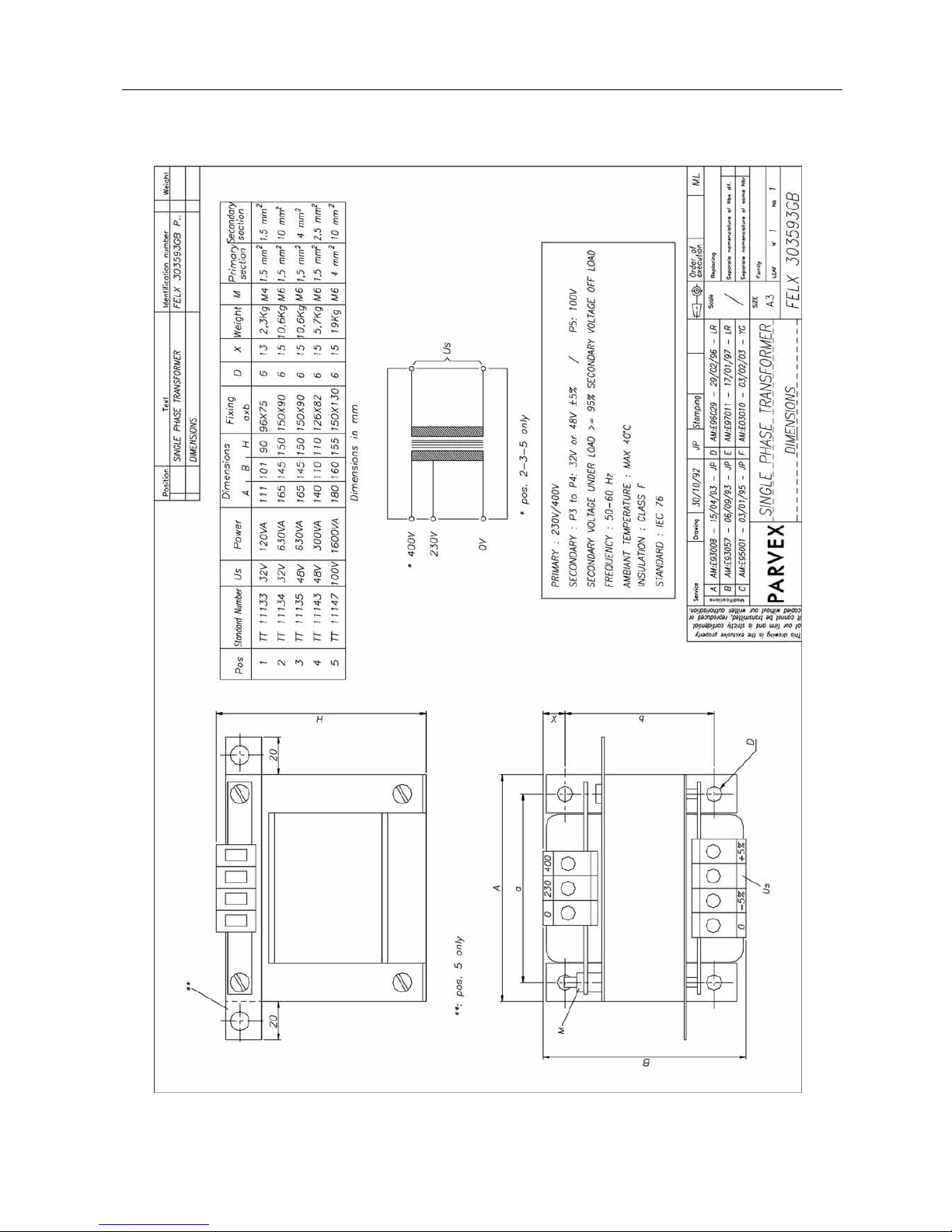

4.7.3 Transformer

General specifications

- Power supply 230/400 V - 50/60 Hz - single-phase or three-phase depending on model.

- Neutral brought out for three-phase models.

- Secondary with ± 5 % taps (except two models of drawing FELX 303740 (p.45))

- Voltage drop between load and off-load ≤ 5 %

Recommended combinations

SERVO AMPLIFIER MODEL NUMBER TRANSFORMER POWER

(VA)

CODE DRAWING P

RTS 3/10-40M single-phase

RTS 3/10-40M single-phase

RTS 10/20-60M single-phase

RTS 10/20-60T three-phase

RTS 10/20-60T three-phase

RTS 12/24-130T three-phase

RTS 12/24-130T three-phase

RTS 20/40-130T three-phase

RTS 16/32-190T three-phase

RTS 16/32-190T three-phase

RTS 16/32-190T three-phase

1

2 to 4

1

1

2 to 3

1

2

1

1

2

3

120

630

630

500

1600

1600

4000

2500

4000

6300

10000

TT 11133

TT 11134

TT 11135

TT 11136

TT 11137

TT 11139

TT 11141

TT 11140

TT 11118

TT 11119

TT 11120

FELX 303593

FELX 303593

FELX 303593

FELX 303594

FELX 303594

FELX 303740

FELX 303740

FELX 303740

FELX 302570

FELX 302570

FELX 302570

43

43

43

44

44

45

45

45

46

46

46

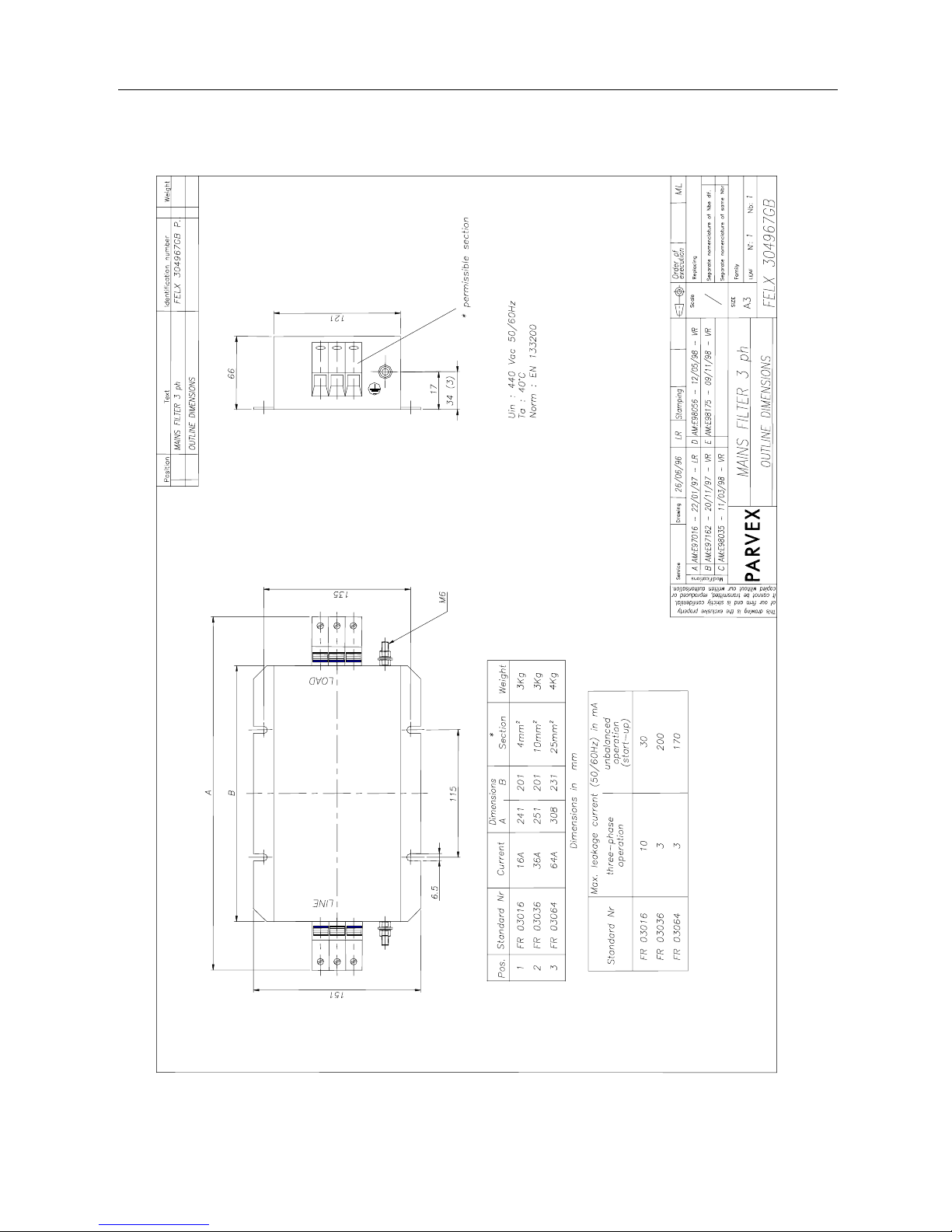

4.7.4 Mains filter

Choice of filters :

FILTER SERVOAMPLIFIER

FR13020

as per drawing PARVEXFELX305144

(p.47)

RTS 3/10-40

RTS 10/20-60

RTS 12/24-130

RTS 20/40-130

FR03016

as per drawing PARVEX FELX304967 (p.48)

RTS 16/32-190

RTS 2nd Generation SERVO AMPLIFIER

41

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

42

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

43

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

44

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

45

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

46

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

47

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

48

PVD 3487 GB 03/2004

RTS 2nd Generation SERVO AMPLIFIER

49

PVD 3487 GB 03/2004

5. LED DISPLAYS

LED displays are possible only if the supply voltage is present. The "Ready" relay, in this case,

must not be incorporated in the auto-hold of the power supply.

POWER ON

front panel

ON : energised - axis OK

OFF : no power on axis. Check wiring, fuses, internal

fuse : (FU 5x20) - 5 A (rating 3/10) - 10 A (gauge

10/20; 12/24 16/32; 20/40)

FLASHING : axis fault (see corresponding fault on side strip).

Miniature LED SIDE STRIP on side of RR 6605 card

RESET to clear faults (terminal 12)

FAULT DISPLAY

TAC

CT

MIU

MAU

dI/dT

IFT

CAUSE

- Tacho wire cut.

- Tacho wire inverted.

- Overspeed.

- Motor wire cut.

- Motor wire inverted.

Dissipater temperature too high.

LED remains on after cooling.

RESET to switch LED off.

Inadequate ac supply voltage (Min

U)

Power voltage too high (Max U).

Energy return from load too high.

Excessive ac input voltage.

Short-circuit of motor terminals

Excessive mean motor current

CORRECTION

* Check tacho wiring

* Check axis works correctly

without tacho

(selector S3 in position 0)

* Check motor wiring

* Check ventilation

* Ambient temperature too high :

fit ventilation system

* Check supply phases are

present

* Check input voltages

* Check transformer star-delta

coupling

* Check input voltages.

* Reduce axis working speed

to reduce braking energy.

* Increase servo amplifier gain.

* Check motor wiring.

* Inadequate motor choke

(Axem motor) : add series

choke.

* Reduce servo amplifier gain.

* Reduce working cycle.

NOTE : Recovery control is also displayed (REC)

RTS 2nd Generation SERVO AMPLIFIER

50

PVD 3487 GB 03/2004

6. SERVO AMPLIFIER ADAPTATION

Selector switch positions

* Selector S1

* Position Speed control.

Speed feedback is used.

Usual case.

* Position Current control.

Speed control is unused.

X1/4-X1/5 input becomes a

current reference.

* Selector S2

* Position X1/9 output indicates current

information. ± 10 V

corresponds to pulse current.

* Position X1/9 output indicates speed

information. ± 10 V

corresponds to rated speed of

application.

* Selector S3

* Position Tacho information is used in

speed control.

* Position Speed information is

calculated from servo motor

emf.

O I

O

I

O I

O I

O I

O I

Usual position :

S1

S2

S3

O I

RTS 2nd Generation SERVO AMPLIFIER

51

PVD 3487 GB 03/2004

7. COMMISSIONING

- Check the connection of the following items :

- transformer

- relay system, especially the emergency stop

- motor and any smoothing choke

- tachometer system

- ground circuit

- Speed and current inhibited (X1/10 and X1/11 not connected),

Connect the power to the servo amplifier. The "POWER ON" LED should light up (if

not check the transformer wiring and relay system). If the "POWER ON" LED flashes,

measure the transformer secondary voltage :

RTS 10/20 - 60 Us = 48 vac : 43 vac < Usec < 53 vac

RTS 3/10 - 40 M Us = 32 vac : 29 vac < Usec < 35 vac

RTS 12/24 - 130 T Us = 100 vac : 90 vac < Usec < 110 vac

RTS 13/32 - 190 T Us = 135 vac : 122 vac < Usec < 148 vac

RTS 20/40 - 130 T Us = 100 vac : 90 vac < Usec < 110 vac

Adjust the output voltage as required with the ± 5% transformer terminals.

- With zero speed reference (X1/4 = X1/5 = 0V)

Release the servo amplifier (X1/10 and X1/11 at 0V), the motor must be under torque.

If the motor races, cut the power and check the signals from the tachometer (cut-out or

inversion) before switching on again ("TAC" fault). If the motor "growls" or "vibrates"

with possibly an "IFT" fault, reduce servo amplifier gain by turning the front panel

potentiometer anti-clockwise. If the servo amplifier had switched to fault mode

("POWER ON" flashing) use RESET (X1/12 to 0V) to clear the fault.

- Gradually increase servo amplifier reference,

and monitor motor acceleration. Check the motor rotates in the opposite direction

when the reference is reversed. If a fault arises on inversion for a 10 V reference,

adjust servo amplifier gain (see paragraph : gain adjustment).

If the fault persists, wire the power transformer secondary to the -5% terminals ("MAU"

fault on LED strip).

RTS 2nd Generation SERVO AMPLIFIER

52

PVD 3487 GB 03/2004

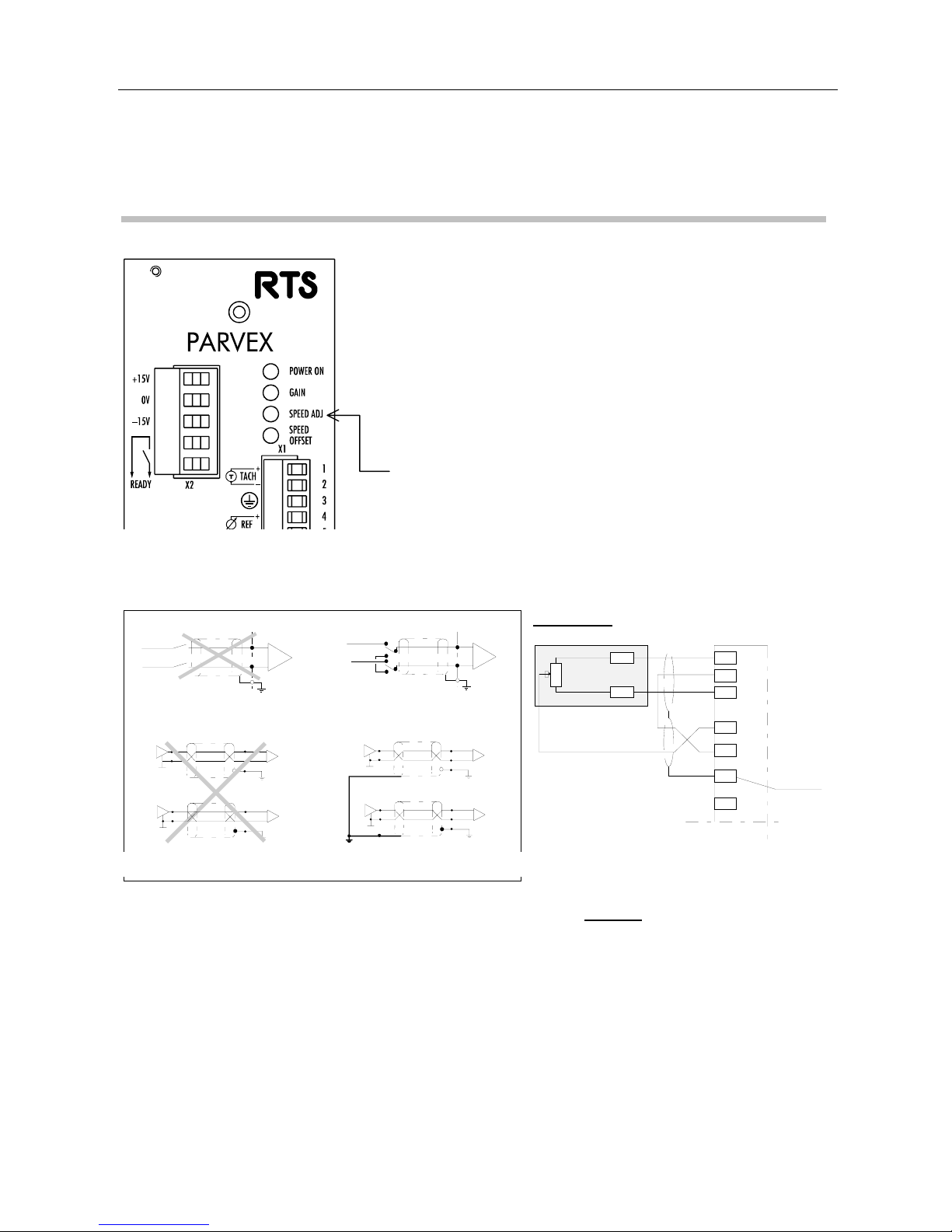

7.1 Speed loop rapid adjustment

* Offset adjustment

Once ambient temperature is stabilised, adjust zero speed to

the mid-position with the "SPEED OFFSET" potentiometer

on the front panel.

* Speed adjustment

The "SPEED ADJUST" potentiometer produces fine

calibration of speed for a given reference.

* Gain adjustment

By increasing gain, the servo motor becomes more rigid.

Turn the "GAIN" potentiometer clockwise until the motor is

unstable and vibrates.

Then turn the potentiometer back one or two turns. If there is

a large load on the potentiometer, the potentiometer

adjustment range may be inadequate and resistance R101

will have to be increased.

6

5

4

NON

5

4

OUI

6

RTS 1

5

4

6

NO

PLC/CN

RTS 2

5

4

6

RTS 1

5

4

6

YES

PLC/CN

RTS 2

5

4

6

Application : Potentiometer reference

..

+ 15 VDC

0V

- 15 VDC

1

2

3

5

4

6

8

Blindage

R1

R2

P

(1)

Bornier X2

Bornier X1

(1) Terminal 4 may be connected to terminal 8

Example

: ± 10 V

P = 10 kΩ linear

potentiometer

R1 and R2 = 2,2 kΩ, 1/2 W resistor

Shielding not connected at numerical control end

The connecting cable by shielded twisted pair for the tacho and reference is available as an option.

Inputs not connected

Terminal block X1

Terminal block X2

RTS 2nd Generation SERVO AMPLIFIER

53

PVD 3487 GB 03/2004

7.2 Complete speed loop adjustment

Systematically applicable when J charge ≥ 10 J motors

Caution As servo amplifiers are factory set based on

parametersprovided by the customer, this setting does

not usuallyrequire adjustment.

Before adjusting the speed loop, all the adjustable

parameters must be fixed (current limits, speed scale

setting, speed limits). Adjusting the speed scale setting

alters loop gain and means readjustments are required.

Equipment required

- Storage oscilloscope (digital if possible), easy to trip.

- Manual speed reference generator (battery box) or low

frequency generator with series capacitor to produce

zero mean speed (out and return about a position).

- Decade box for capacitor and resistor adjustment.

Reference battery box, with oscillator for automatic

control is available as an option.

Method

FIG 1

Adjust the gain potentiometer to the centre (so gain may

be varied up or down after adjustment).

Fit a large integration capacitor C101 - 10µF or strap.

Adjust proportional gain starting by R101 = 10 kΩ.

Increase R101 until 10% overshoot on speed reference

increment. Always use small speed reference increments

(e.g. ± 100 rpm or less) so the system remains linear. For

large increments, current limitation (= torque limitation)

masks the real situation and reduces overshoot.

The adjustment obtained with high speed increments

would be incorrect.

In many cases, it is not possible to increase gain to

produce overshoot especially for high inertia systems.

< 100 Hz

a

b

c

Temps

Vitesse prise entre

mesure N et 0V ana. dépassement : + 10 %

-

+

batterie

9 V

INVERSEUR

10K

Réf. E -

Réf. E +

15

14

Servoamplificateur

Gain

R108

R101

C103

C101

FIG 1 : a, b, c - graphs obtained with

increasing R101 values

Speed amp

INVERTER

10 K

1-5

Ref. E1-

Speed recorded

between N measurement

and 0 V analo

g

ue

overshoot : +10%

9 V

battery

Ref. E1+

1-

4

Time

RTS 2nd Generation SERVO AMPLIFIER

54

PVD 3487 GB 03/2004

FIG 2

In some cases, gain limitation is due to resonance: the

motor starts to whistle or vibrate at high frequencies (>

100 Hz). A -1 filter must be included at a frequency 3 to 4

times lower than the oscillation so the gain can be

increased by the same ratio. This can be done by

connecting a C103 capacitor in parallel with the R101

proportional gain resistor, and increasing the capacitor

until the whistling stops (usually several tens of nF) and

then continuing to increase gain while monitoring

overshoot and torque ripple. The C103 10 nF capacitor is

ready fitted as standard in parallel with the R101 gain

resistor.

FIG 3

When the gain is set, the C101 integration capacitor must

be reduced to produce 15 - 20% overshoot (still for small

speed increments).

100 à 300 Hz

a

b

c

Temps

a

b

c

Temps

Dépassement 20 %

Vitesse

FIG 3 : a, b, c - graphs obtained with

decreasing C101 values

FIG. 2 : a, b, c, - graphs obtained with

increasing C103 values

100 - 300 Hz

Time

Speed

20% overshoot

Time

RTS 2nd Generation SERVO AMPLIFIER

55

PVD 3487 GB 03/2004

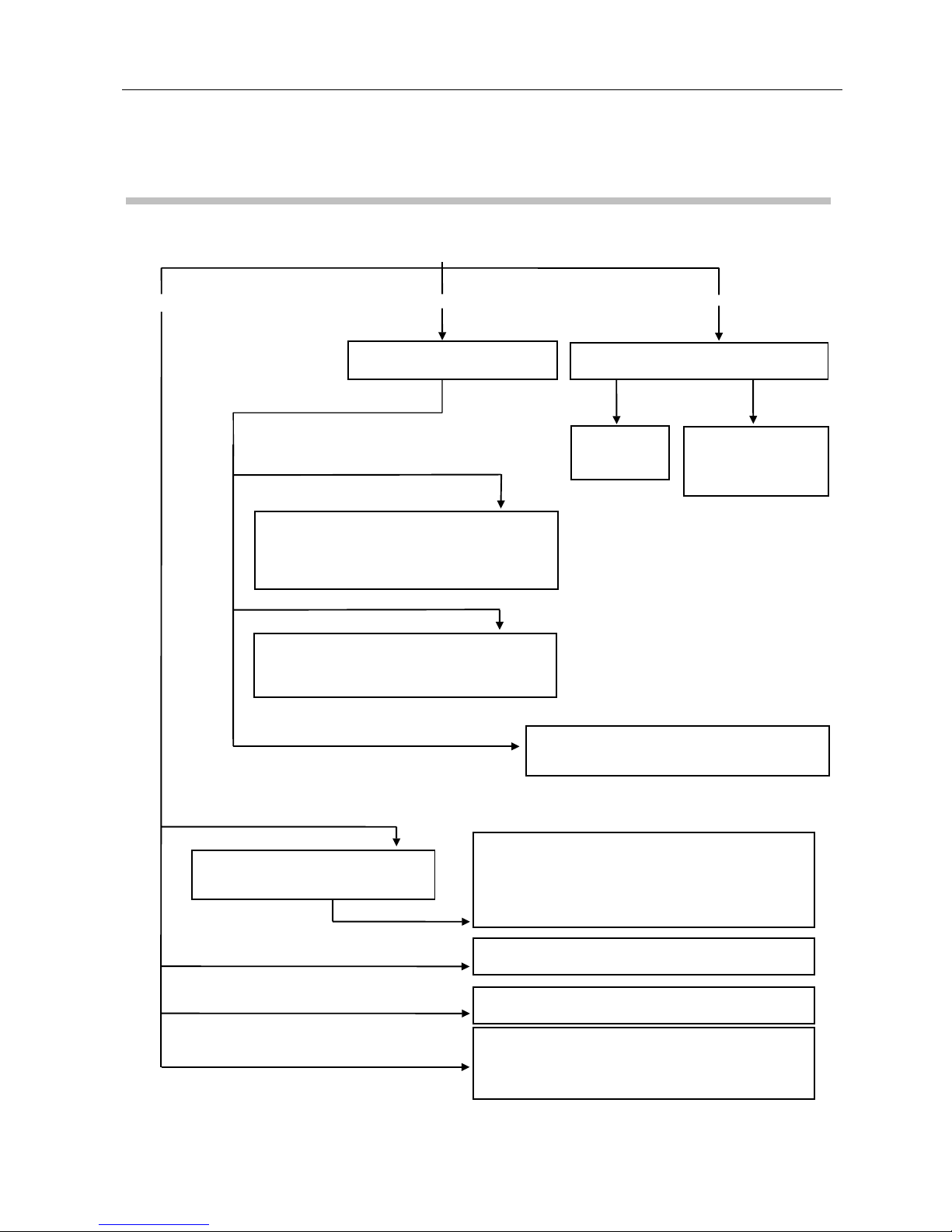

7.3 Diagnostic helpI

ENERGISING

Check :

• terminals X1/10 and X1/11 must be connected to 0V

• selector S1 must be in correct position

• reference voltage is present

"POWER ON" flashes

« POWER ON » on

"POWER ON" of

f

Check which LED on side of

card

Measure voltage at terminals U, V, W

Check fuse

F1 (gauge 5 x

20

)

Check fuses, main

switch and

transformer

connections

Voltage

No

Motor races and "TAC" LED lights up

Check tachometric dynamo wiring, invert

tacho wires if fault arises during first time use.

Motor under current control: selector S1 must

be changed.

Check motor wiring and fuses. If the dI/dT

LED is on, check the motor is not shortcircuited and there is no ground fault.

Motor fails to rotate

Check the ventilation system is working correctly.

A

mbient temperature of the electrical cabinet must

be less than 40°C.

"CT" (temperature) LED is on

The motor is unstable and vibrates

Reduce gain using the front panel

potentiometer : turn anti clockwise

Check the motor and servo amplifier are grounded

(mandatory).

Check the speed reference is stable (with oscilloscope)

and ±15 V voltages if necessary.

Check the customisation components correspond to the

motor.

No effect

Adjust zero speed with the "SPEED OFFSET"

p

otentiometer

Adjust speed with "SPEED OFFSET" potentiometer

Motor drifts

Incorrect speed

Motor fails to rotate

RTS 2nd Generation SERVO AMPLIFIER

56

PVD 3487 GB 03/2004

7.4 Calibration

The components below are stud mounted and used to calibrate the servo amplifier for the

corresponding motor. Calibration is done at the manufacturer's facility before delivery and these

components should not be modified.

CAUTION : Servo amplifiers are factory set and the information

in sections 7.4.1 - 7.4.11 are for reference only.

RTS 2nd Generation SERVO AMPLIFIER

57

PVD 3487 GB 03/2004

TACHOMETER SYSTEM EMF

RATED SPEED

RTS 2nd Generation SERVO AMPLIFIER

58

PVD 3487 GB 03/2004

Symbols used

Nn = rated speed of application for 10 V reference speed

Ilim = maximum pulse current of motor

Imax = maximum pulse current of servo amplifier

In = maximum rated current of motor

Ket = gradient of tachometric generator in V per thousands of rpm

Ke = back electromotive force of motor in volts per rpm

r = resistance of motor and its supply circuitry in ohms

L = inductance of motor in mHenrys

Ub = bus voltage in volts (1.35 x Vin AC)

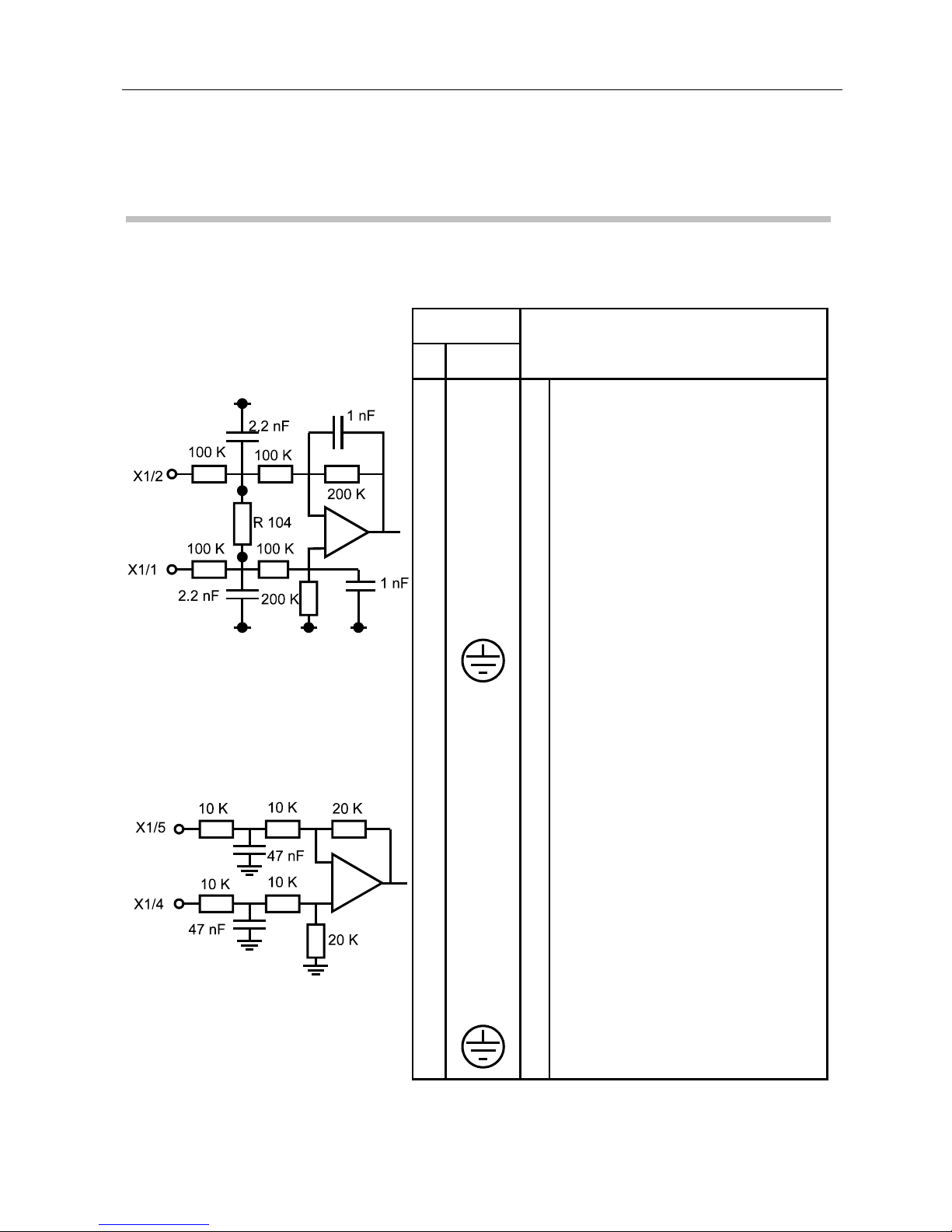

T

Tachy

+ X1/1

- X1/2

100 K

100 K

2.2 nF

R 104

100 K

100 K

2.2 nF 200 K 1nF

200 K

1nF

U - RI

O

I

S3

Sélection TACH

Y

ou U - RI

7.4.1 Tachometric generator voltage calibration (R104)

Resistor R104 is used to adapt the tachometric generator gradient to that of the servo amplifier

(2V/1000 rpm).

Ket 2 3 4 5 6 8 10 12 15 20

R 104 (kΩ) ∞

200 100 68 51 33 24 20 15 11

Do not exceed 100V on the tachometer input.

For a gradient of 1 V / 1000 rpm, short-circuit the solder tags Y1 and Y2 with R104 =

∞.

Standard tachometric generator values are :

3 V at 1 000 rpm e.g. TBN 103

6 V at 1 000 rpm e.g. TBN 206

20 V at 1 000 rpm e.g. TBN 420

These values are plated of tachometric generator. e.g.

Ke : 6 mVrpm or 6 V at 1000 rpm

TACHO selection

or U-RI

Tacho

RTS 2nd Generation SERVO AMPLIFIER

59

PVD 3487 GB 03/2004

7.4.2 Rated speed selection (R105)

Resistor R105 calibrates the useful speed of the

application. For a speed reference of ± 10 V, the

speed corresponding in rpm to the servo motor will

be determined by R105 according to the table

below.

Calibration accuracy supposes that R104

calibration value of the tacho is correctly set.

The "SPEED ADJUST" potentiometer on the front

panel allows easy fine adjustment of speed.

Turning it clockwise increases speed for a given

reference.

Speed Nn (rpm)

R 105 (kΩ)

700

770

869

950

1055

1200

1280

1400

1590

1650

1750

1800

1920

2100

2330

2600

2820

3100

3420

3700

4040

4400

4900

5200

274

221

182

150

121

110

100

82.5

68.1

56.2

47.5

39.2

The equipment may be adapted for speeds lower than those shown above but this hinders servo

amplifier performance with regard to drift and gain. The maximum value not to be exceeded for

R105 is 4.75 MΩ.

U - RI

S3

TACHO selection or U - RI

Offset

R105

R102

C102

10 K

Fine speed adjustment

39 K

RTS 2nd Generation SERVO AMPLIFIER

60

PVD 3487 GB 03/2004

7.4.3 Pulse current adjustment (R113)

R113 modifies the maximum current authorised by the servo amplifier.

The standard pulse current is twice the value of the permanent current. It may be set either

internally by using R113 or by using current reduction input X1/7 "Ired".

The table below shows the value of resistor R113 in kΩ versus the percentage of maximum

current.

% of maximum

current

10 20 30 40 50 60 70 80 90

R113 (kΩ)

0.392 0.825 1.5 2.21 3.32 4.75 7.5 12.1 33.2

7.4.4 Current limitation by external resistance or external voltage

(terminal block X1)

7.4.4.1 By external resistance

The table below shows the external resistor value

in kΩ versus the percentage of maximum current.

Voltage control between terminals 7 and 8 is also

possible. In this case, the current is linear with

10 V = I max.

% of maximum

current

10 20 30 40 50 60 70 80 90

Rext (kΩ)

3.32 6.81 10 15 22.1 27.4 39.2 47.5 56.2

7.4.4.2 By external voltage

Voltage control between terminals 7 and 8 is also possible. In this case, the current is linear with

10 V = I max.

47 k

+ 15 V

20 K

I Red

R ex.

870V A

RTS 2nd Generation SERVO AMPLIFIER

61

PVD 3487 GB 03/2004

7.4.5 Time constant adjustment I = f(t) (R109)

The system time constant is factory set so the

servo amplifier accepts maximum current for one

second, starting from I = 0. After one second the

servo amplifier switches automatically to safety

mode.

Standard resistor R109 is 562 kΩ for a maximum

current lasting 1 second. For a maximum current

lasting 2 seconds, resistor R109 must be 1210 kΩ.

7.4.6 Adjustment of function I = f(t) (R103)

Function I = f(t) is designed to protect the servo amplifier and servo motor if the mean current

required exceeds the rated current.

Resistor R103 is used to adjust the tripping limit authorised by the servo amplifier.

RTS 3/10 - 40

% of rated

current

50 60 70 80 90 100

R103 (kΩ)

1.82 2.74 3.92 4.75 6.81 8.25

RTS 10/20 - 60

12/24 - 130

12/24 - 24/48

16/32 - 190

20/40 - 130

% of rated

current

20 30 40 50 60 70 80 90

R103 (kΩ)

1,5 2,21 3,32 4,99 7,5 12,1 20 43,2

AUTION : For safety reasons the values of resistors R109 and R103 must not

be altered without authorisation from PARVEX - Warranty may be

affected.

4.7 M

R109

2 µF

10 K

+ 15 V

20 K

R 103

RTS 2nd Generation SERVO AMPLIFIER

62

PVD 3487 GB 03/2004

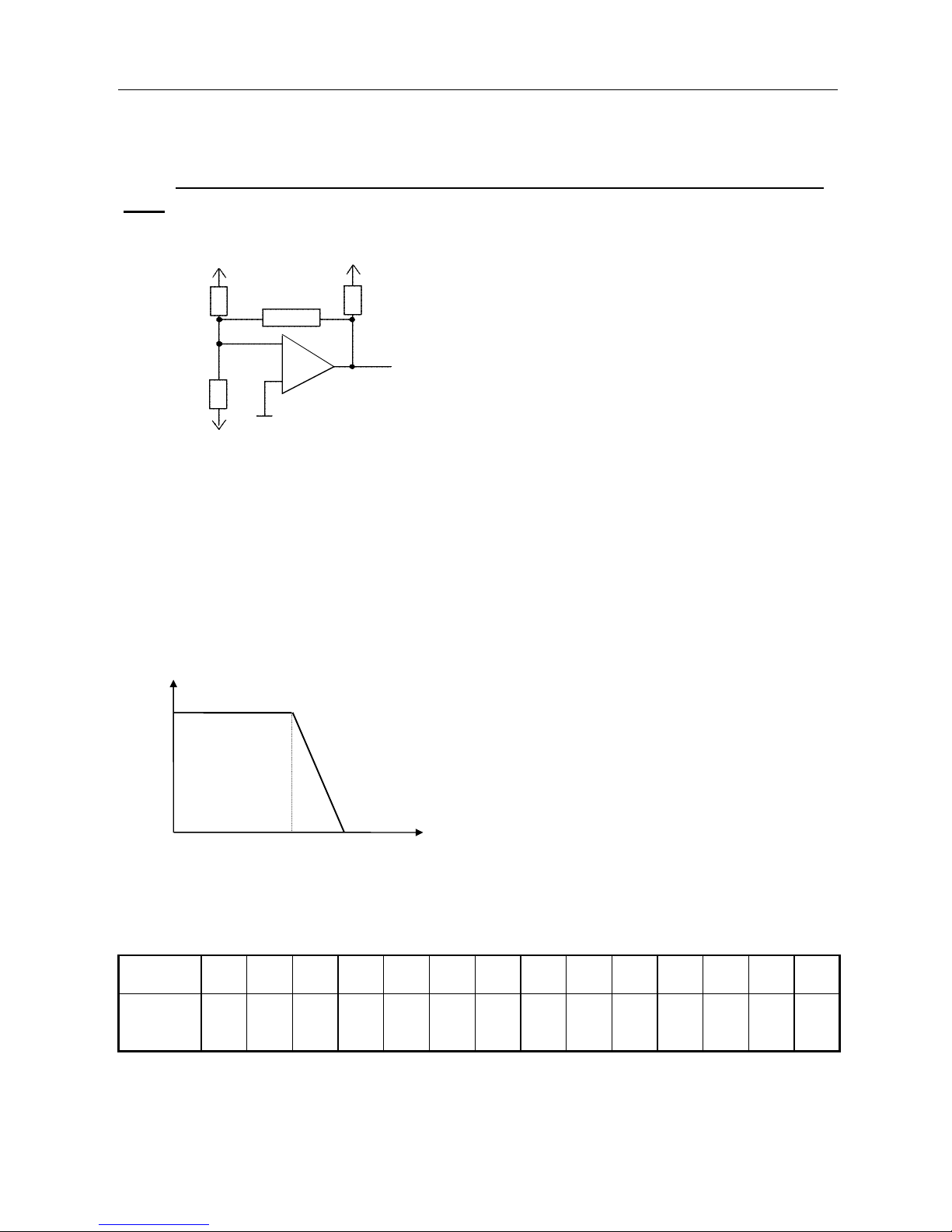

7.4.7 Adjustment of current limitation curve versus speed I F(n) (R131 -

132)

Resistor R131 is used to select the zero current point on the speed current diagram.

Resistor R132 determines the speed beyond which pulse current (selected by R113) begins

to decrease linearly with speed.

When function I = F(n) is not required :

R131 = 10 KΩ

R132 = 100 KΩ

Nr : speed in thousands of rpm above which

current decreases

Ns : speed in thousands of rpm at which current is

zero

R131 values

Ns

(rpm)

500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000

R 131

(kΩ)

16.2

82.5

56.2

39.2

33.3

27.4

22.1

20

18.2

16.2

15

13.7

12.1

12.1

+ 15 V

10 K

R 132

- 15 V

R 131

Réduction

de I

I

Ilim

Nr Ns N

Current

reduction

RTS 2nd Generation SERVO AMPLIFIER

63

PVD 3487 GB 03/2004

R132 values

% of maximum current

Ns - Nr

20

40

60

80

100

500

1000

1500

2000

2500

3000

3500

4000

27.4 k

Ω

12.1 k

Ω

8.25 k

Ω

6.81 k

Ω

5.62 k

Ω

4.75 k

Ω

3.32 k

Ω

3.32 k

Ω

47.5 k

Ω

22.1 k

Ω

16.2 k

Ω

12.1 k

Ω

10 k

Ω

6.82 k

Ω

6.82 k

Ω

5.62 k

Ω

100 k

Ω

33.2 k

Ω

22.1 k

Ω

18.2 k

Ω

15 k

Ω

10 k

Ω

10 k

Ω

8.25 k

Ω

82.5 k

Ω

47.5 k

Ω

33.2 k

Ω

22.1 k

Ω

18.2 k

Ω

15 k

Ω

13.7 k

Ω

12.1 k

Ω

121 k

Ω

56.2 k

Ω

39.2 k

Ω

27.4 k

Ω

22.1 k

Ω

18.2 k

Ω

16.2 k

Ω

15 k

Ω

7.4.8 Calibration of function U - RI (R133 - R134)

This adaptation is necessary even when operating with a tachogenerator to ensure tacho safety:

speed signals from "U - RI" and from the tacho are compared constantly and must be of the

same order of magnitude.

EMF per 1000 rpm : The electromotive force constant KE indicates the voltage measured on the

armature for an off-load speed of 1000 rpm, at 25°C. Under load, for agiven

voltage, motor speed will be:

I = current between terminals in Amps

R = armature resistance in Ohms

U = voltage across terminals in Volts

K

E = EMF constant in Volts per 1000 rpm

N = U - (RI)

x 1000

K

E

RTS 2nd Generation SERVO AMPLIFIER

64

PVD 3487 GB 03/2004

To calculate motor speed, coefficients R and KE must be calibrated by the resistor values

below :

R 133 [kΩ] R 134 [kΩ]

RTS 3/10 - 40

RTS 10/20 - 60

RTS 12/24 - 130

RTS 12/24 - 24 B 1)

RTS 12/24 - 48 B

RTS 16/32 - 190

RTS 20/40 - 130

180/ K

E

260/ KE

540/ K

E

96/ K

E

192/ K

E

760/ K

E

540/ K

E

40 R

60 R

32 R

154 R

77 R

32 R

64 R

e.g. RX 120 L servo motor with RTS 3/10-40

K

E = 11.5 V/1000 rpm R 133 = 15 kΩ

R = 2.5 Ω R 134 = 100 kΩ

1) with RR6606C : R133(kΩ)=192/ K

E ; R134(kΩ)=77R

7.4.9 Tripping limit calibration (R135)

Resistor R135 determines the tripping limit of maximum speed for tachometric servo control and

U - RI operation.

Nn

(rpm)

1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

R 135

(kΩ)

1.5

2.74

3.92

4.75

6.81

8.25

12.1

15

22.1

27.4

39.2

7.4.10 Current loop gain adaptation to motor inductance (R136)

RTS 3/10 10/20 12/24 16/32 20/40

R136

kΩ

Ub

L

3

10.5,2

Ub

L

3

10.5

Ub

L

3

10.6

Ub

L

3

10.8

Ub

L

4

10

Ub : drive bus direct voltage (Volts)

L : motor inductance and any additional inductance (mH)

When selecting R136 take the value immediately below in the following range and multiples

thereof::

10 - 12 - 15 - 18 - 22 - 27 - 33 - 39 - 47 - 56 - 68 - 75 - 82 - 100

RTS 2nd Generation SERVO AMPLIFIER

65

PVD 3487 GB 03/2004

7.4.11 dc voltage calibration (RB)

Resistor RB is used to adapt limit values: MAX U, MIN U, tripping of supply voltage recovery.

The standard values are as follows :

SERVO AMPLIFIER

MODEL

Input

voltage

VAC (1)

DC

voltage

Max

voltage

Min

voltage

Dissipation resistance

On limit Off limit

V V

RB

kΩ

RTS 3/10 - 40

RTS 10/20 - 60

RTS 12/24 - 130

20/40 - 130

RTS 12/24 - 48

RTS 12/24 - 24

RTS 16/32 - 190

32

48

100

48

24

135

43

65

135

48

24

190

57

86

179

64

34

240

27

40

83

30

16

112

53

79

164

-

-

221

50

75

156

-

-

210

200

∞

∞

∞

100

∞

(1) Remark : The RTS servo amplifier may be used with supply voltages different from

the standard values.

e.g. RTS 10/20-40 with 32 V supply

RTS 16/32-140 with 110 V supply

Please ask for details.

Loading...

Loading...