ENGINEERING BETTER BEER

FTSs Pro Modular Temperature Controller

- Europe -

INTRODUCTION

OVERVIEW

The FTSs Pro Modular Temperature Controller works in conjunction with a pressurized glycol system to

provide temperature control over the contents of your vessel. It functions by using a temperature sensor

to read the present value (PV) of your vessel, and triggering an output based on the set value (SV) in

order to match PV with SV. When cooling is called for, the solenoid valve will open to allow the ow of

glycol through your vessel’s cooling jackets or coils until the set value is achieved.

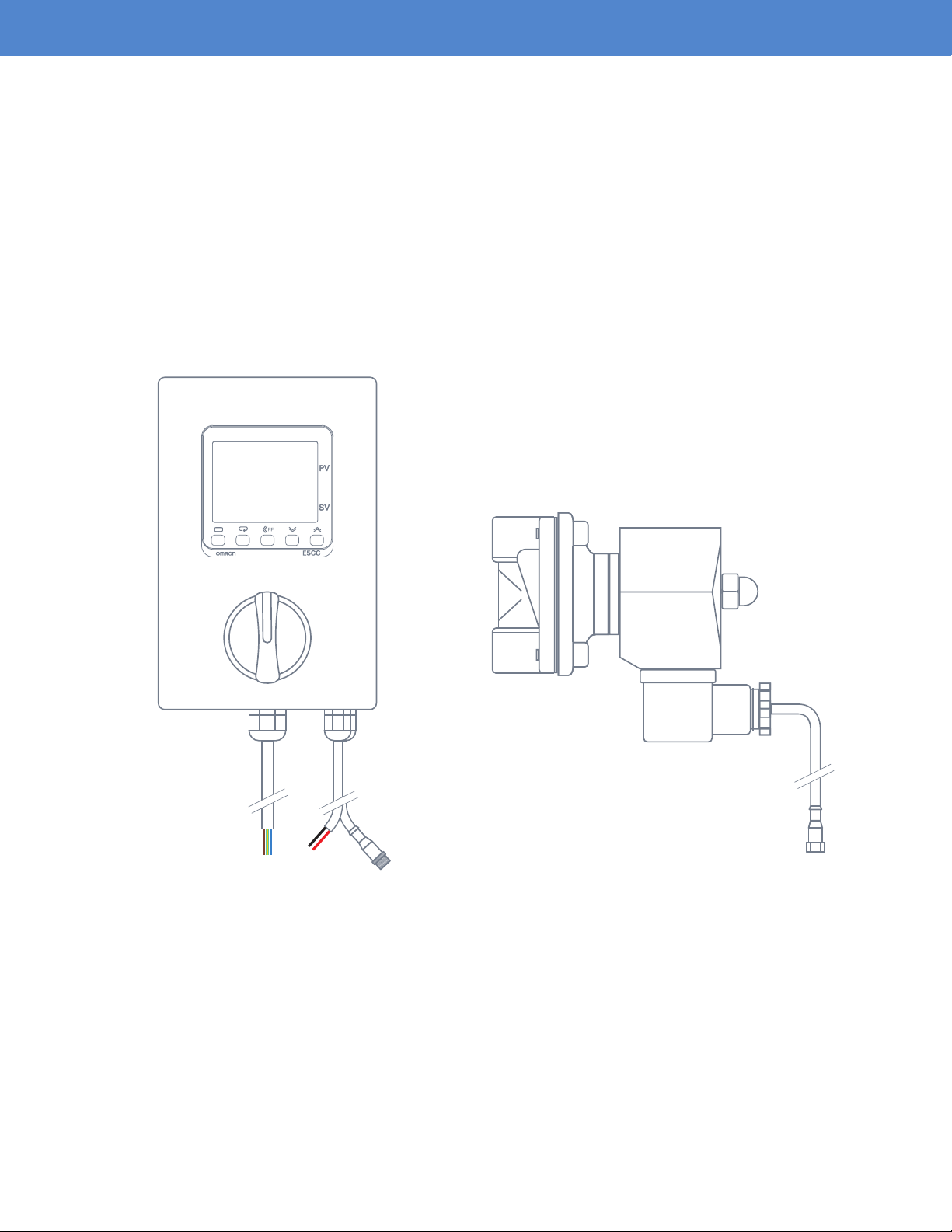

FTSs Pro Controller

Temperature

Solenoid Valve

OFF

Run Crash

Page 2

SETUP

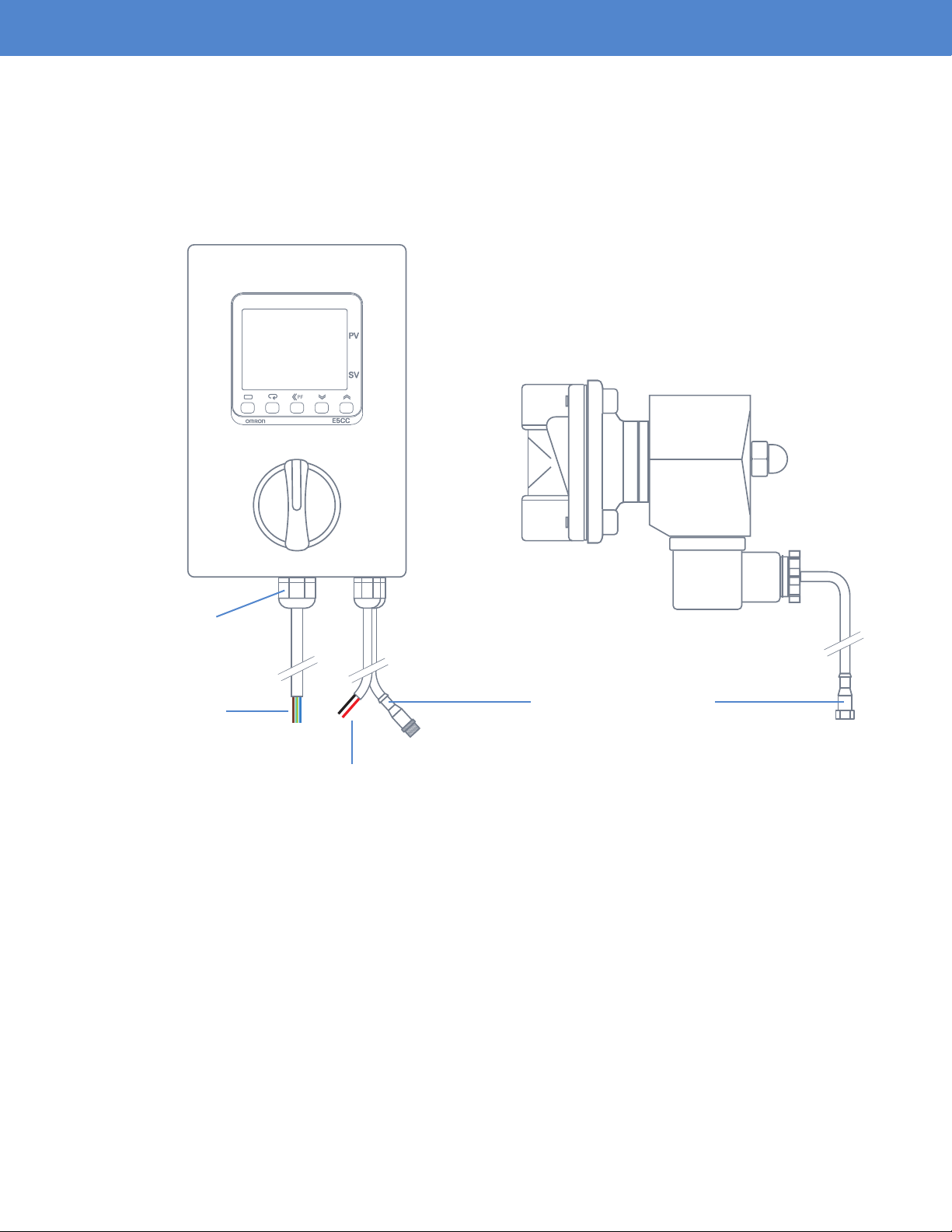

POWERING THE FTSs PRO

The FTSs Pro Modular Temperature Controller comes with a lead marked “110~240VAC-in”. The

three wires in this cable correspond to hot (brown wire), neutral (blue wire), and ground (green/yellow

wire). A plug is purposely omitted from the cable to accommodate various methods used for supplying

110~240VAC to the unit. If you are installing a plug, BE SURE that a GFCI breaker/receptacle is

installed.

Temperature

OFF

Run Crash

110~240VAC-In

Brown - Hot

Blue - Neutral

Green/Yellow - Ground

To Temperature Sensor

Solenoid Connection

SENSOR INSTALLATION

The FTSs Pro Modular Temperature Controller comes with a lead marked “Sensor”. The two wires in

this cable (red and black) will connect to your temperature sensor. If you are using an Ss Brewtech

vessel, your tank comes equipped with a PT100 platinum resistance thermometer. The red and black

wires will connect to terminals 1 and 2 on the thermometer’s plug. The orientation of the wires does not

matter, as long as they are connected to terminals 1 and 2.

SOLENOID INSTALLATION

The FTSs Pro Modular Temperature Controller comes with either a ½” (1-3.5 bbl Unitank) or ¾” (5 bbl

and larger Unitank) electric solenoid valve. Installation can be handled in a variety of ways based on

preference and setup. We recommend installation of a manual bypass piping/valve arrangement, as

well as piping/valve arrangement to clear the line of glycol in the event that service is needed.

Page 3

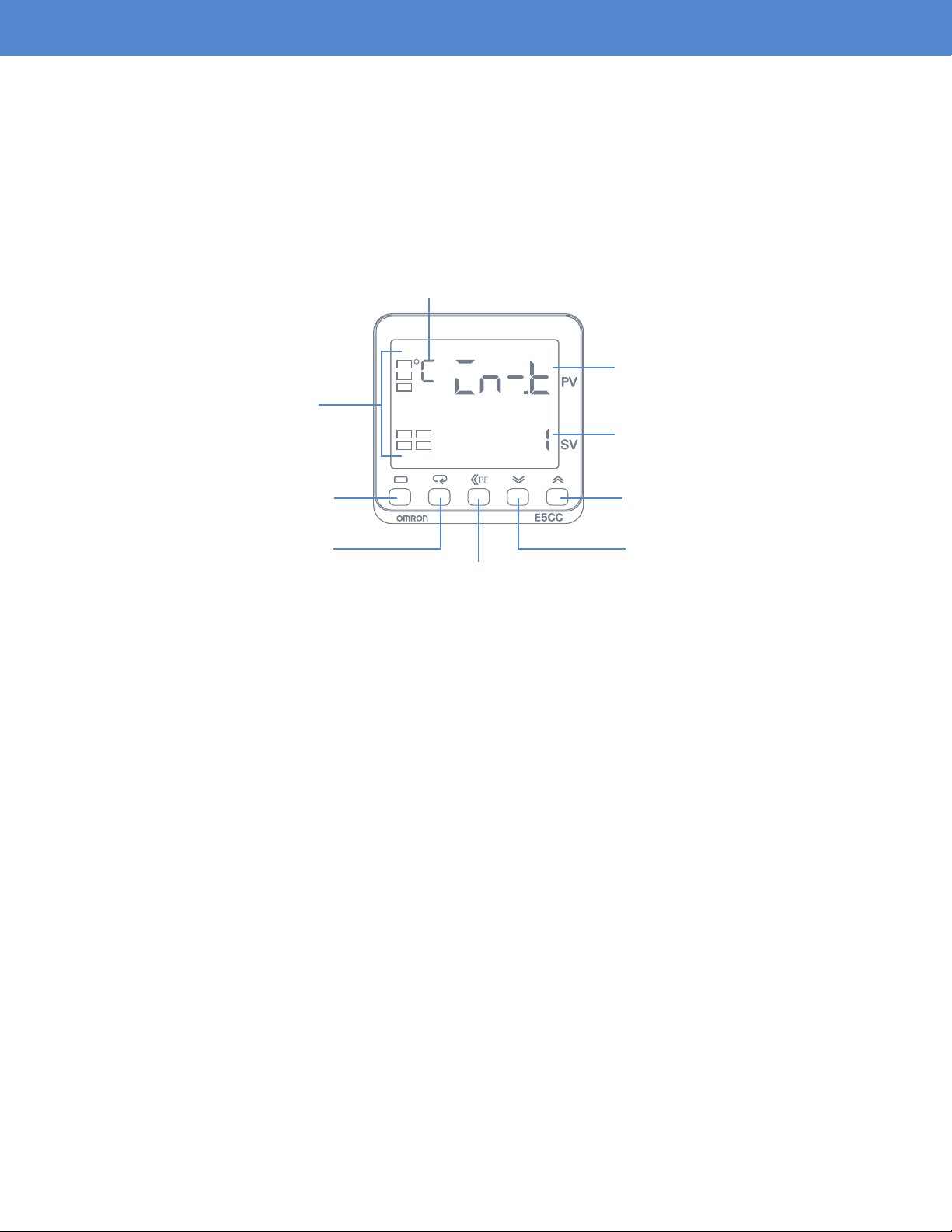

SENSOR: SETTINGS & CALIBRATION

SETTINGS

The input setting can be manipulated based on the type of sensor being used. The correct input setting

for a PT100 sensor is “Cn-t: 1”. This should be the default setting on your controller. If you are reading a

sensor error message (S.ERR), double check your connections to the sensor and ensure that “Cn-t” is

set to 1. If you are using a different type of sensor, see the included chart to determine the proper input

setting for your particular sensor.

Temperature Unit

No. 1 Display

Operation Indicators

No. 2 Display

Up KeyLevel Key

Down KeyMode Key

Shift Key

Ss Brewtech Pro Tanks ship with a PT100 type temperature senor included. To set the temp sensor

type, begin by pressing the “Level Key” (3 or more seconds).

Then press the “Mode Key” until you see “Cn-t”. Finally press the “Up” or “Down” Key to select “1” for a

PT100 probe. For other temp sensor options, please reference the table on the following page.

Press and hold the “Level Key” for more than 3 seconds to return to the primary display.

Page 4

SENSOR: SETTINGS & CALIBRATION (CONTINUED)

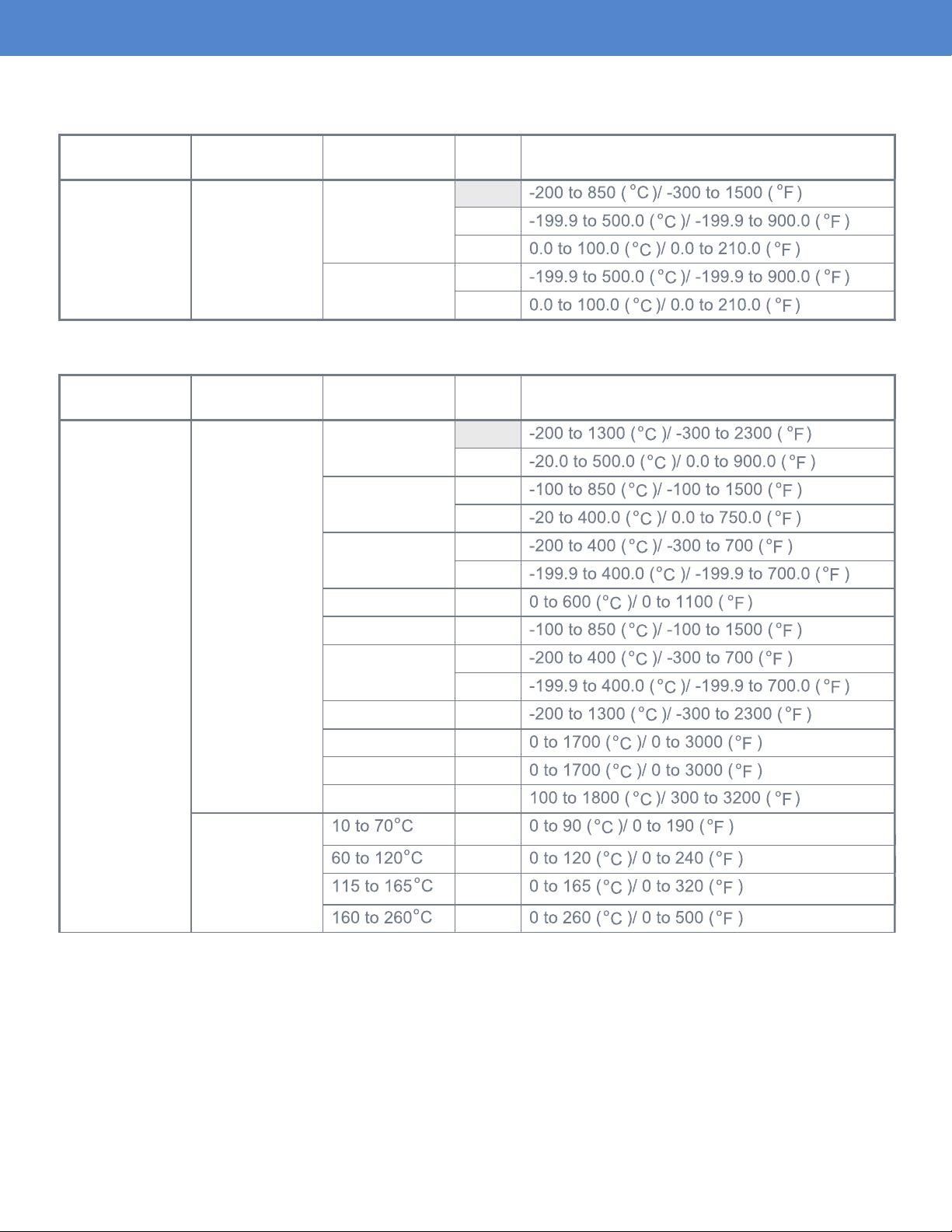

t

A

OTHER TEMP SENSOR OPTIONS

Platinum resistance thermometer input

type

Thermocouple

input type

Input type Name Set

Platinum

resistance

thermometer

Input type Name

Thermocouple

Infrared

emperature

sensor

ES1

Pt100

JPt100

K

J

T

E

L

U

N

R

S

10

B

11

Value

0

1

2

3

4

Set

Value

0

1

2

3

4

17

5

6

7

18

8

9

12

13

14

Input Temperature Setup Range

Input Temperature Setup Range

15

Page 5

SENSOR: SETTINGS & CALIBRATION (CONTINUED)

CALIBRATION

Before use, it is important to ensure that your sensor is properly calibrated. There are several ways of

calibrating a temperature sensor, but the simplest way is to use an ice-water mixture. When you insert

your sensor into an ice-water mixture, it should read 32°F (0°C). Perform the “ice method” of calibration

and document the offset, if any. You can then set a temperature offset on the controller to reect

this variation.

Press the “Level Key” for less than 1 second, and then use the “Mode Key” until you see “Cn5”. Next

use the “Up” or “Down” Key to change the temperature offset.

Press the “Level Key” for less than 1 second to exit to the main screen.

Temperature Unit

No. 1 Display

No. 2 Display

Up KeyLevel Key

Down KeyMode Key

Page 6

ADDITIONAL MENU SETTINGS

The FTSs Pro Modular Temperature controller uses an Omron Digital Controller as the “brains of the

operation”. It contains a whole host of menu options and settings that are not crucial to the basic

functioning of your FTSs Pro. Outlined below are a few of the more pertinent menu settings. For more

detailed information, please consult the Omron Programming Guides.

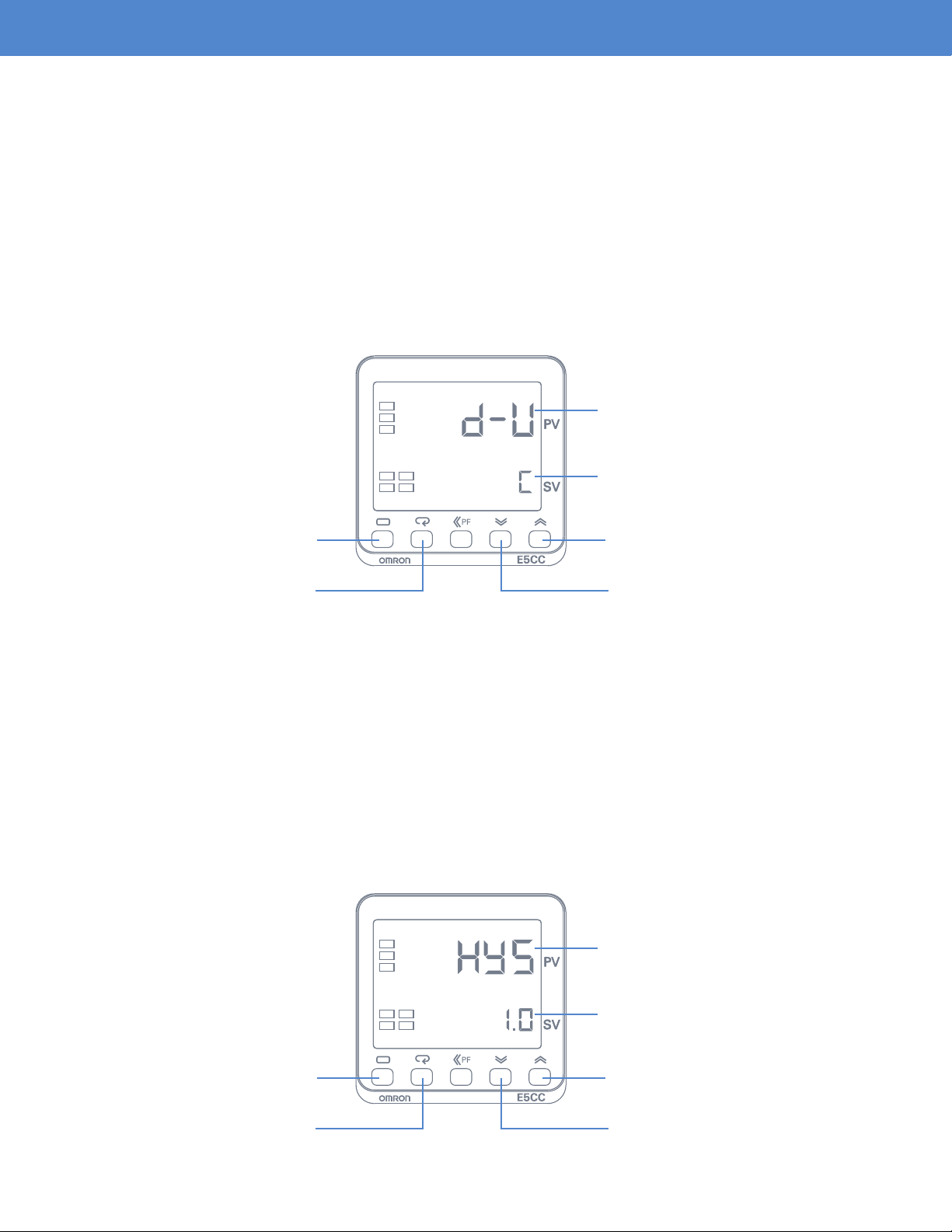

TEMPERATURE UNITS

The FTSs Pro Modular Temperature Controller allows the user to toggle between Fahrenheit and

Celsius. To do so, hold the “Level Key” for 3 or more seconds and then press the “Mode Key” until you

see “d-U”. Press the “Up” or “Down” Keys to toggle between Fahrenheit (F) and Celsius (C).

No. 1 Display

No. 2 Display

Level Key

Mode Key

Up Key

Down Key

HYSTERESIS

The FTSs Pro Modular Temperature Controller allows you to set a hysteresis value. This value

represents the number of degrees away from the set value that the Omron will trigger an output. Press

the “Level Key” for 3 or more seconds and then press the “Mode Key” until you see “HYS”. Press the

“Up” or “Down” Keys to adjust the value.

For example, if the hysteresis is set to “1” (default setting), then the solenoid valve will only open when

the PV is one degree or greater above the SV. We recommend leaving this value at “1” to prevent

over-cycling of the system.

No. 1 Display

Level Key

Mode Key

No. 2 Display

Up Key

Down Key

Page 7

ADDITIONAL MENU SETTINGS (CONTINUED)

DECIMAL POINTS

The controller can be set to adjust the decimal point displayed on the controller. This is handy if you

wish to have ner temperature control, or if you are using a smaller hysteresis value. Press and hold

the “Level Key” for less than 1 second and then press the “Mode Key” until you see “dP”. Use the “Up”

or “Down” Keys to move the decimal points. Press the “Level Key” for less than 1 second to exit.

No. 1 Display

No. 2 Display

Up KeyLevel Key

Down KeyMode Key

Page 8

OPERATIONS

RUN

When in “Run” mode, the user can select a set value using the up and down keys. This can be used to

maintain fermentation temperatures, or for cooling purposes. When the set value is below the present

value, “OUT” will display on the controller and the solenoid valve will open. When the set value is

achieved, “OUT” will disappear from the display and the solenoid valve will close.

Temperature

OUT1

OFF

Run Crash

CRASH

When in “Crash” mode, the user can quickly toggle to a programmable “crash” temperature (0°C, for

example). The controller will memorize this temperature, and by simply turning the switch you can

switch to this temperature without toggling the up and down keys.

Temperature

OUT1

OFF

Run Crash

Page 9

SsBrewtech.com

REV 04182019

Loading...

Loading...