Ss Brewtech FTSs2, FTSs Product Manual

ENGINEERING BETTER BEER

FTSs2 Product Guide

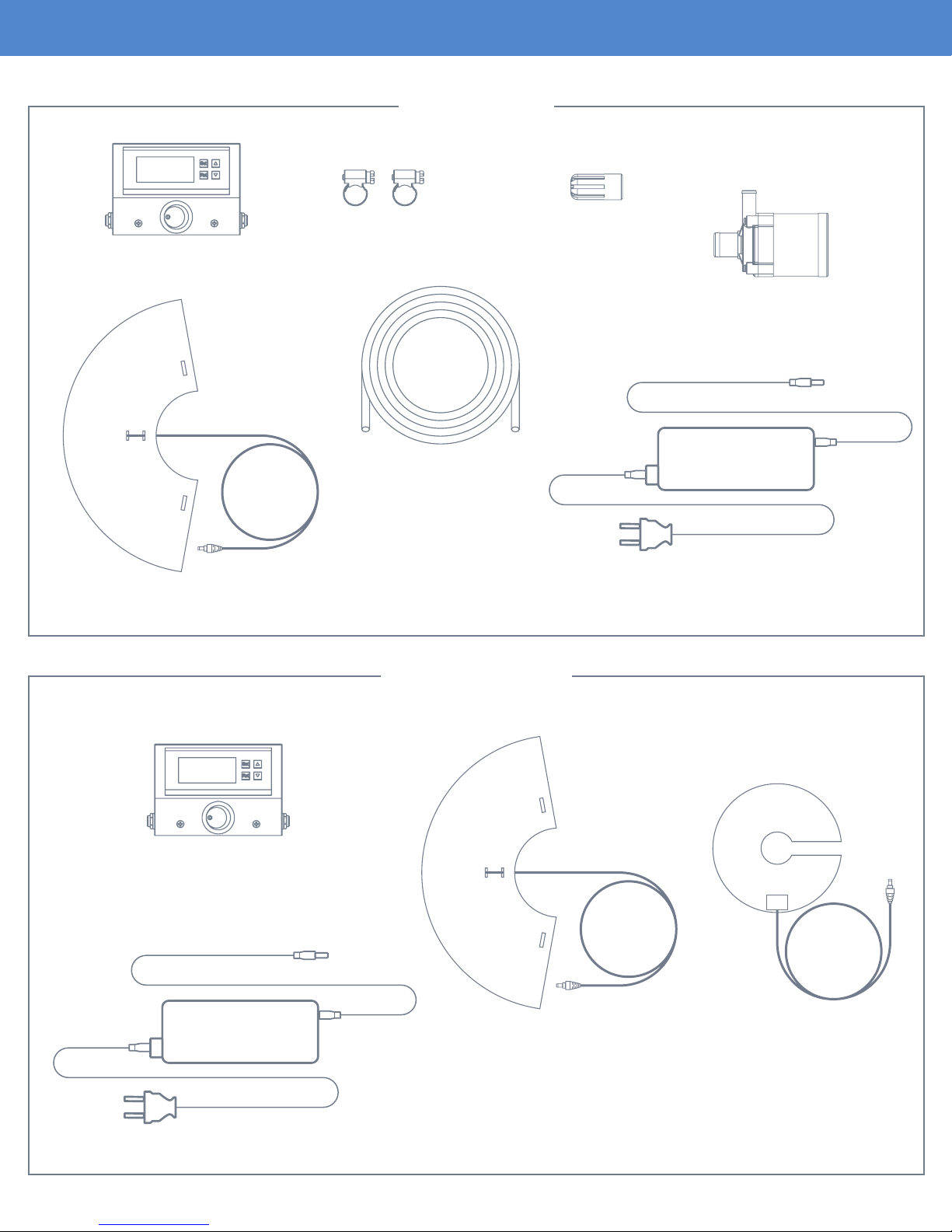

IN THE BOX

STANDARD KIT

FTSs2 Controller

Silicone Stopper

Hose Clamps

*(x2 Half bbl Chronical)

O-Rings

Pump Inlet Cover

Pro Grade Submersible Pump

Lock Nuts

Power Supply

Chronical

Neoprene Insulation Jacket

(Included with the Chronical Kit only)

Immersion Coil

*(x2 Half bbl Chronical)

Chronical

Cone Heating Pad

Vinyl

Tubing

Thermowell

Brew Bucket

Neoprene Insulation Jacket

(Included with the Brew Bucket Kit only)

Brew Bucket

Cone Heating Pad

FTSs Lid

Page 2

IN THE BOX (CONTINUED)

BME KIT

FTSs2 Controller

Cone Heating Pad

Hose Clamps

Vinyl

Pump Inlet Cover

Pro Grade Submersible Pump

Tubing

Power Supply

FTSs

2

Controller

UPGRADE KIT

Cone Heating Pad

(Included with the

Chronical Kit only)

Chronical

Brew Bucket

Cone Heating Pad

(Included with the

Brew Bucket Kit only)

Power Supply

Page 3

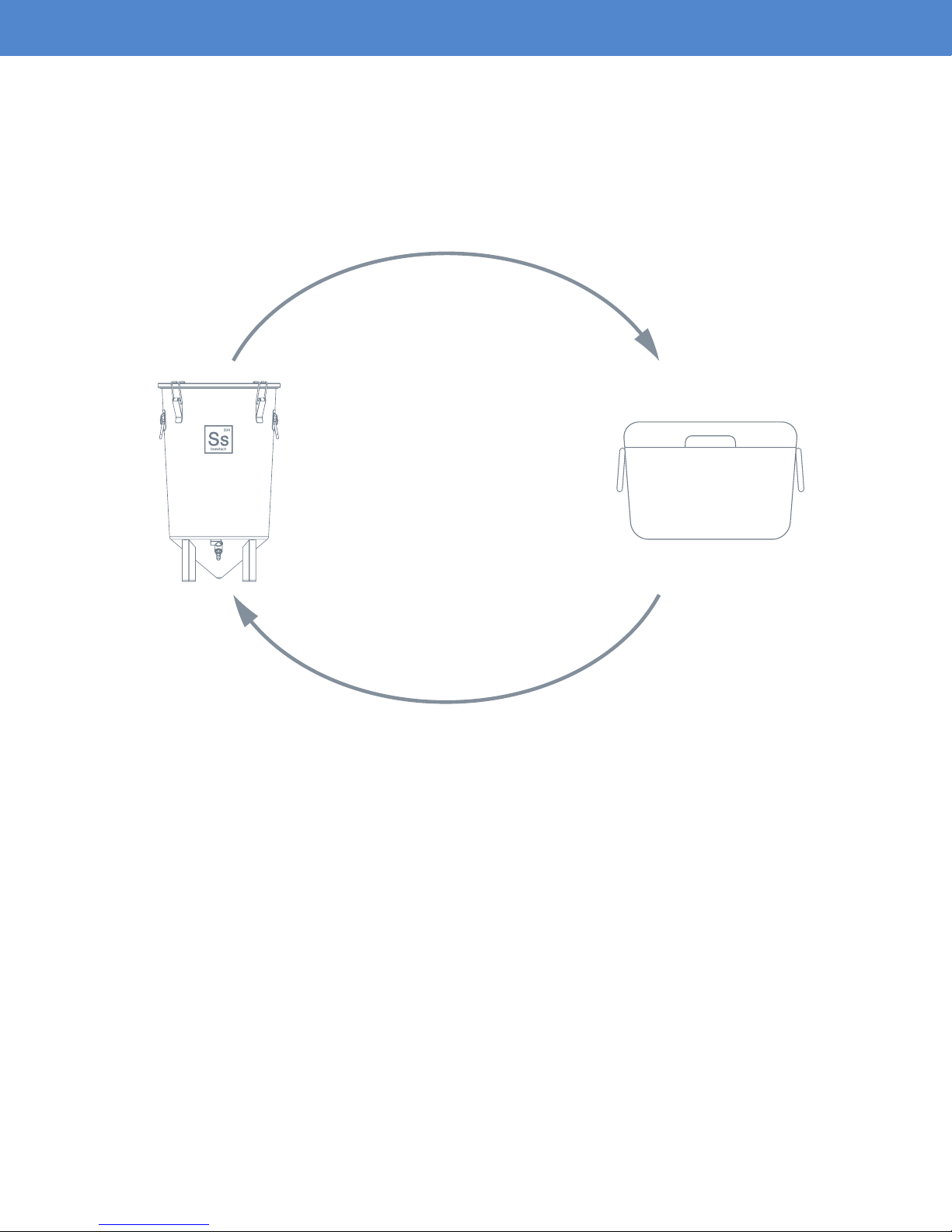

INTRODUCTION

SYSTEM OVERVIEW

The basic principle of the Fermentation Temperature Stabilization System (FTSs2) is to pump chilled

water or glycol through the immersion coil when the temperature of your wort is greater than the controller

set-point. The system is designed to use chilled ice water from a common cooler or glycol chiller. In this

conguration, the submersible pump will be placed in the bottom of the cooler.

Warm Water or Glycol

Low Pressure

Closed Loop System

Cold Water or Glycol

The FTSs

to the fermenter is then returned to the cooler to be used again.

If your setup requires more distance from the fermenter to the cooler, you can purchase common vinyl

tubing at most hardware stores. The pump is capable lifting the water up to 10 feet. Pumping beyond

10 feet will negatively affect efciency.

In a heating mode, the controller will activate the low wattage heater, which will in-turn begin to slowly

raise the temperature of the liquid volume starting at the fermenter’s cone. From there, convection will

foster the newly introduced heat to radiate up to the remaining liquid volume not in direct contact with

the cone. This key characteristic insures that hot-spots don’t form within the fermenter.

2

is intended to be a low pressure closed loop system. Water or glycol pumped from the cooler

Page 4

INTRODUCTION (CONTINUED)

NOTES ON EFFICIENCY

Efciency of your system depends on many variables. Ideally, you would have the fermenter in an area

where the temperatures are relatively moderate.

Since the system contains both heating and cooling, the controller will need to be properly setup to

avoid over cycling. Cycling is where the system runs the cooling or heating cycle long enough to overshoot the set point and past the threshold where it causes the opposite function to activate too quickly.

To avoid over cycling, we recommend you set the “delay” on your controller to at least 5 minutes. This

will allow sufcient time for the fermenter’s liquid temperature to stabilize and ultimately avoid over

cycling.

This will extend the life of the ice in your cooler. We recommend using ONLY block ice, frozen plastic

water jugs or similar. Cubed ice melts much faster than block ice thus requiring more frequent additions

of ice to ensure you maintain cold water. You should avoid using your FTSs

temperature to a pitching temperature. In addition to leaving all of the cold break* in your fermenter, it

will consume much of your cooling capacity and require you to replenish the ice early in the process.

2

to bring the wort from a high

*Cold break- A term that describes the precipitation or occulation of proteins, tannins, and hop matter

that occurs when wort is rapidly chilled.

PRE-ASSEMBLY INSTRUCTIONS

FIRST TIME CLEANING

Before you use your system, you will need to clean all manufacturing residues with either TSP (highly

recommended and can be found at any hardware store) or warm soapy water, followed by a good hot

water rinse. Please see the FAQ section on our website (www.ssbrewtech.com) regarding proper care

and cleaning of stainless steel.

SANITATION

Sanitize the immersion coil, thermowell, lid and gasket.

Page 5

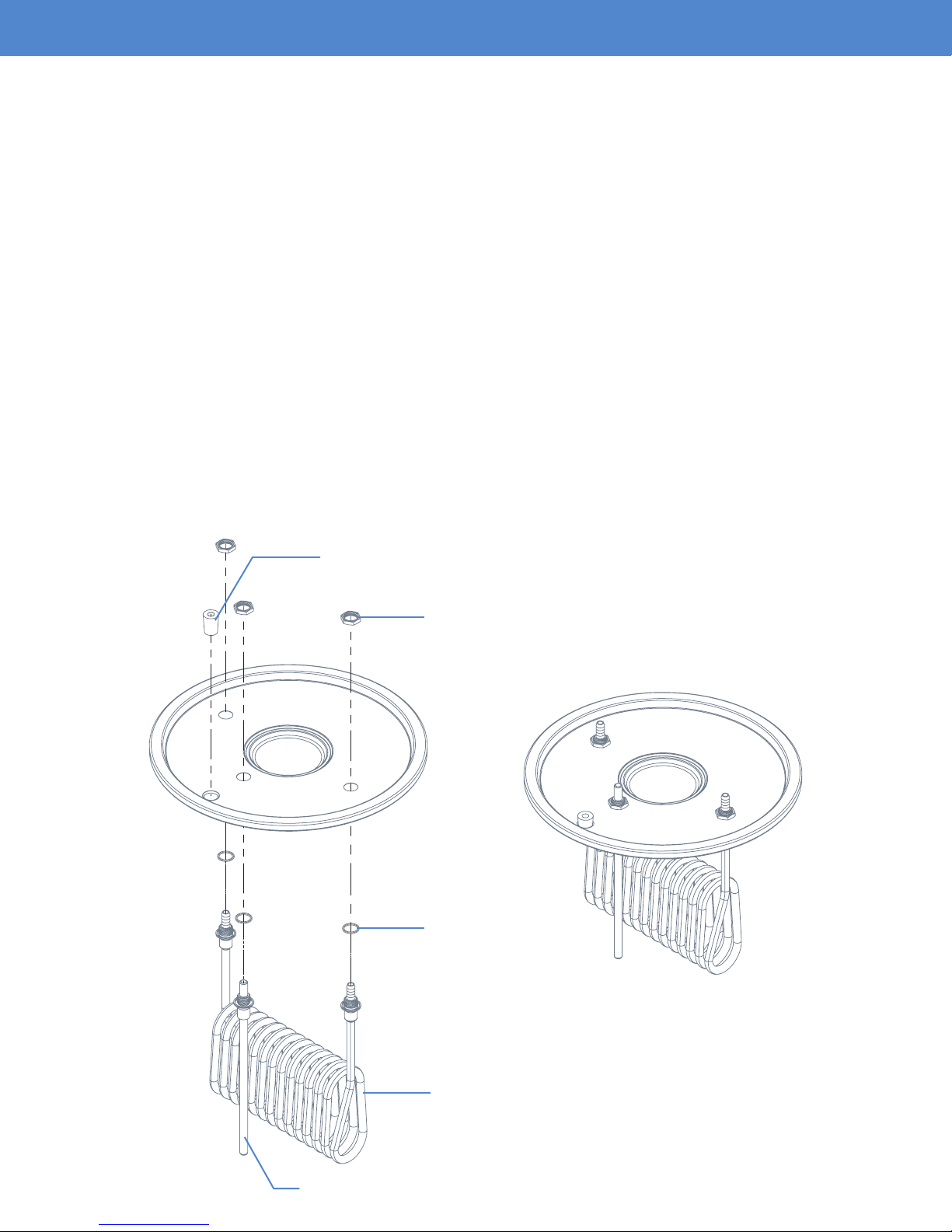

ASSEMBLY INSTRUCTIONS

BEFORE YOU BREW - SYSTEM ASSEMBLY

1. Think about where you want to locate your Brew Bucket or Chronical series fermenter, where you will

place the controller, and where you will place your chilled water source (whether that is an ice chest,

chilled corny keg in a cooler, glycol chiller, etc.).

2. Start by removing your fermenter’s ttings, lid, and neoprene jacket if it is already installed, and then

place the fermenter upside down on a surface that won’t mar the upper rim of the body. This will make

it easier to insure the heater is orientated correctly on the cone while you reinstall the neoprene jacket.

3. Place the low-wattage heater onto the cone so that it doesn’t interfere with the welded ttings, and

maximizes surface area contact with the fermenter body. Use a zip-tie to hold the heater’s shape until

the neoprene insulating jacket is reinstalled over the fermenter. The neoprene jacket will insure that the

heater is held tightly to the cone to maximize efciency.

3. Extend the wire from the low-wattage cone heater out of the bottom of the neoprene jacket.

4. Next, install the immersion coil and thermowell into the lid as shown (Note: there are extra o-rings

supplied; you only need to use the o-rings on the wort side of the lid).

Silicone Stopper

Lock Nut

O-Ring

Thermowell

Immersion Coil

Page 6

Loading...

Loading...