Ss Brewtech eController 1V, eController 2V Product Manual

ENGINEERING BETTER BEER

eController Product Guide

OVERVIEW

eCONTROLLER 1V

The eController 1V is designed to be used with a brew-in-a-bag system (BIAB), but can also be useful

for someone who prefers modularity within their multi-vessel system. It can easily replace an existing

gas-red HLT or boil kettle in an existing 3 vessel brewing system. The 1V controller is designed to

operate one element, and is compatible with our line of 10 and 20 gallon eKettles. A 30A dedicated

GFCI protected circuit is required.

(1) Thermoprobe

eCONTROLLER 2V

The eController 2V is designed to be used as part of a 3 vessel, single infusion mash system. The

controller pairs perfectly with our line of insulated InfuSsion Mash Tuns, alongside a pair of temperature

controlled eKettles for the HLT (hot liquor tank) and boil kettle. The 2V controller can operate 2 elements

in total, albeit one at a time, and is compatible with our line of 10 and 20 gallon eKettles. Since only

one element can be operated at a time, the 2V controller retains the same 30A GFCI protected circuit

power requirement as the 1V.

(2) Thermoprobes

Page 2

INTRODUCTION

Designing every piece of our electric brewing equipment from scratch has enabled us to introduce

a new level of process control, exibility, and performance. Every detail has been carefully thought

through and rened.

Every component of our new eControllers was designed to enhance the eBrewing experience.

The custom extruded 6061 aircraft-grade aluminum housing is CNC machined, then coated in a

durable black anodized nish. This approach allowed us to keep the system compact, portable

and functional. The housing includes an integrated carry handle for easy setup and take down,

a T-slot for alternative mounting options along with a heatsink to keep the internal electrical

components cool.

The eController is driven by a PID controller, which doesn’t rely on high speed switching to module

heat. Voltage is modulated through an internal SSVR, which means element wattage will be directly

proportional to the set point on the eController. A rocker switch located just above the PID controller

allows the user to operate the controller in manual or automatic modes.

In manual mode, the proportional output can be ne-tuned on a scale of 0-100% of total element output,

which is ideal for dialing in a perfect rolling boil. Alternatively, in automatic mode, the PID algorithm

manages the proportional output relative to process temperature. To hold a steady HLT or mash temp

for instance. The eController quickly nds equilibrium with environmental heat loss characteristics, and

can maintain a high degree of accuracy during each brewing process.

The heater button allows the user to turn the element on or off without having to shut off the main

power or adjust the PID output setting. This is especially helpful if a boil-over occurs. This feature also

allows the eController to be used to monitor a process temperature, such as during runoff or in the latter

stages of the sparge process without the risk of dry ring the element. Lastly, the eController features

two accessory outputs, which would commonly be used for pumps, but could also be used for lighting

or even a phone charger.

Connectivity was an important consideration for our eControllers, we wanted the exibility and familiarity

of a plug that could be adapted to an existing customer supplied kettle or element, and the reliability

of a UL approved connector type. For 240VAC main power and element connectors, we chose on the

common NEMA L6-30 standard, which is a 3-wire twist-lock plug type, capable of carrying 30 amps

of current. For the accessory connections, we settled on using a NEMA 5-15 standard, which is just

a standard residential 120 VAC outlet. Finally, for the PT100 temperature probes we opted for the 3.5

mm mini jack connector standard, commonly used for headphones, which is both durable and easy

to use.

Page 3

ASSEMBLY

POWER SPECIFICATIONS

- 208-240VAC 60 Hz operation only

- 30A maximum total connected load

- Dedicated GFCI protected circuit required

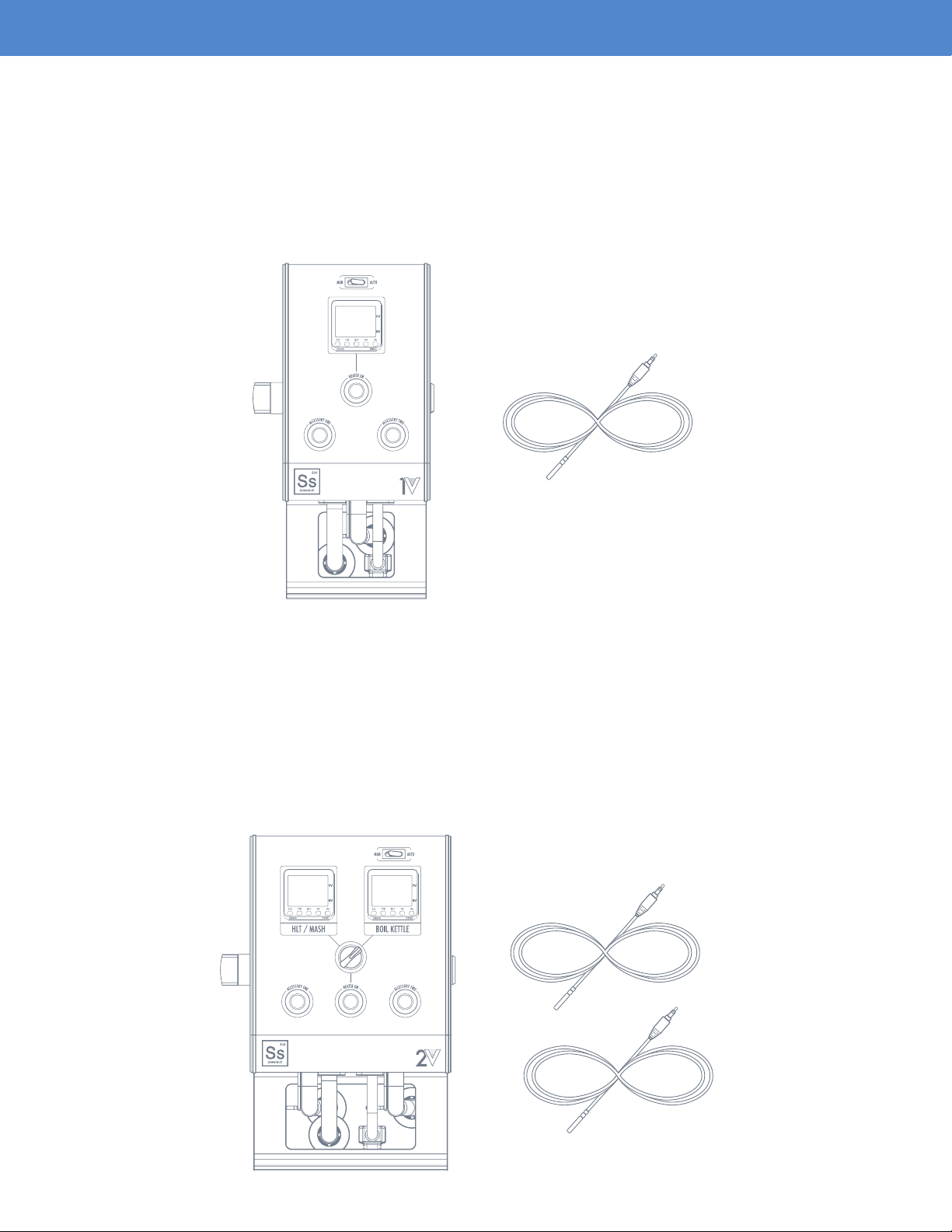

1V eCONTROLLER CONNECTIONS

(2) 110VAC NEMA 5-15P Side Mounted Controller

Receptacles (3 Amps max per outlet)

(1) 3.5MM Thermoprobe Connection Interface

(1) L6 - 30R Element Output

(1) 110VAC Accessory Power Input

2V eCONTROLLER CONNECTIONS

(1) L6 - 30P 208-240VAC

Main Power Input

(2) 110V NEMA 5-15P Side Mounted Controller

Receptacles (3 Amps max per outlet)

(2) L6 - 30R Element Output

(2) 3.5MM Thermoprobe

Connection Interface

(1) L6 - 30P 208-240VAC Main power input

(1) 110VAC Accessory Power Input

Page 4

ASSEMBLY (CONTINUED)

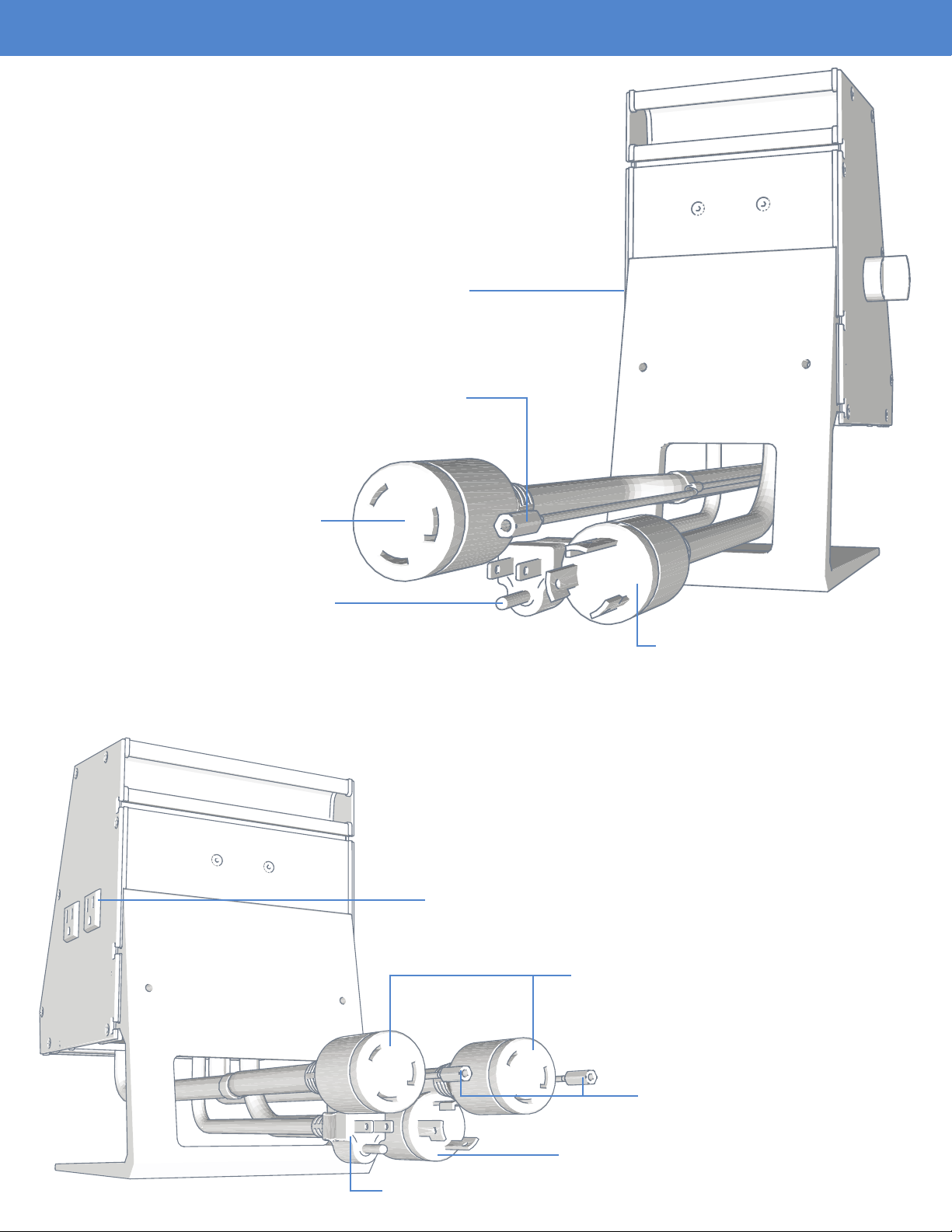

WARNING

Before plugging in the controller, ensure that both the heater activation button as well as the side

mounted on/off switch are not currently engaged. This will prevent accidental dry ring.

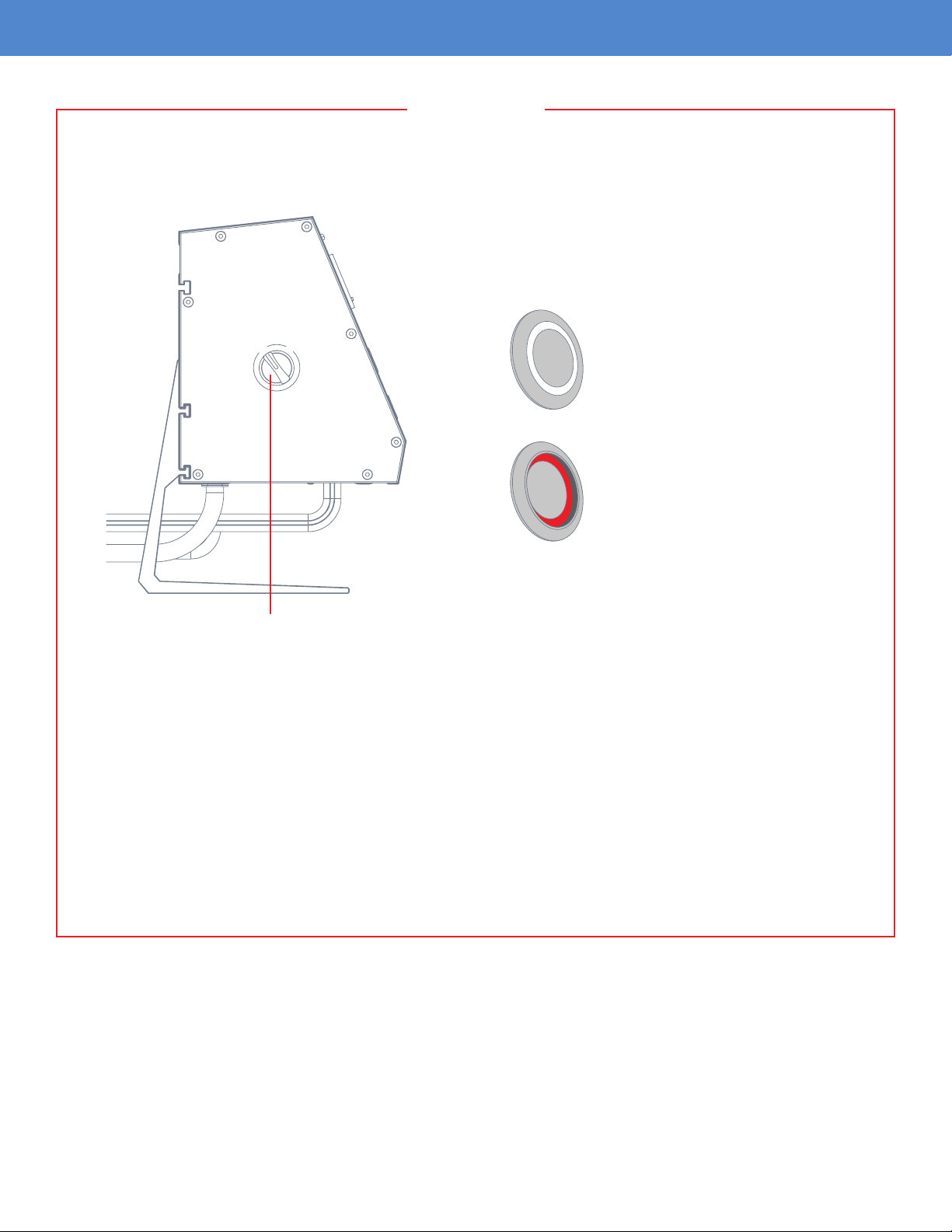

ACTIVATION BUTTON

O

O

F

N

F

N

F

F

O

O

Off Position

- Button is not recessed

- No indicator light

On Position

- Button is recessed

- Red indicator light

Side Mounted “ON/OFF” Switch in “OFF” Position

Always verify the element is fully submerged in water before activating the heater element. Dry

ring the element will cause irreversible damage to the element coil and void the element’s

warranty. Prolonged dry ring can cause damage to the vessel and other components, and can

result in personal injury or property damage.

Make sure that the unit is connected to a dedicated GFCI circuit.

Wear proper PPE (Personal Protective Equipment) when using the equipment. This would

include protective eyewear, gloves and apparel that would aid in prevention of scalding from

boiling water.

Page 5

Loading...

Loading...