Page 1

Voltage

Monitors

3 Phase Voltage Monitor

WVM Series

Motor Protector

Description

The WVM Series provides protection against premature equipment (motor) failure caused by voltage faults on

the 3 Phase Line. The WVM’s microcontroller design provides reliable protection even if regenerated voltages

are present. It combines dependable fault sensing with a 10 fault memory and a 6 LED status display. Part

instrument, part control, the WVM protects your equipment when you’re not there and displays what happened

when you return. The WVM is fully adjustable and includes time delays to prevent nuisance tripping and

improve system operation. Time delays include a 0.25 to 30 s adjustable trip delay, an adjustable 0.25 to 64

m (in 3 ranges) restart delay, plus a unique 3 to 15 s true random start delay. The random start delay prevents

voltage sags caused by simultaneous restarting of numerous motor loads after a power outage.

ANSI Device #27/47/59

Protects Against: Phase

Loss & Reversal; Over,

Under & Unbalanced

Voltages; Short Cycling

10 Fault Memory & Status

Displayed on 6 LED Readout

Switch Selectable Automatic

Restart, Delayed Automatic

Restart, & Manual Reset

Isolated 10 A SPDT Relay

Contacts

ASME A17.1 rule 210.6

NEMA MG1 14:30, 14:35

IEEE C62.41-1991 Level B

Approvals:

Listed

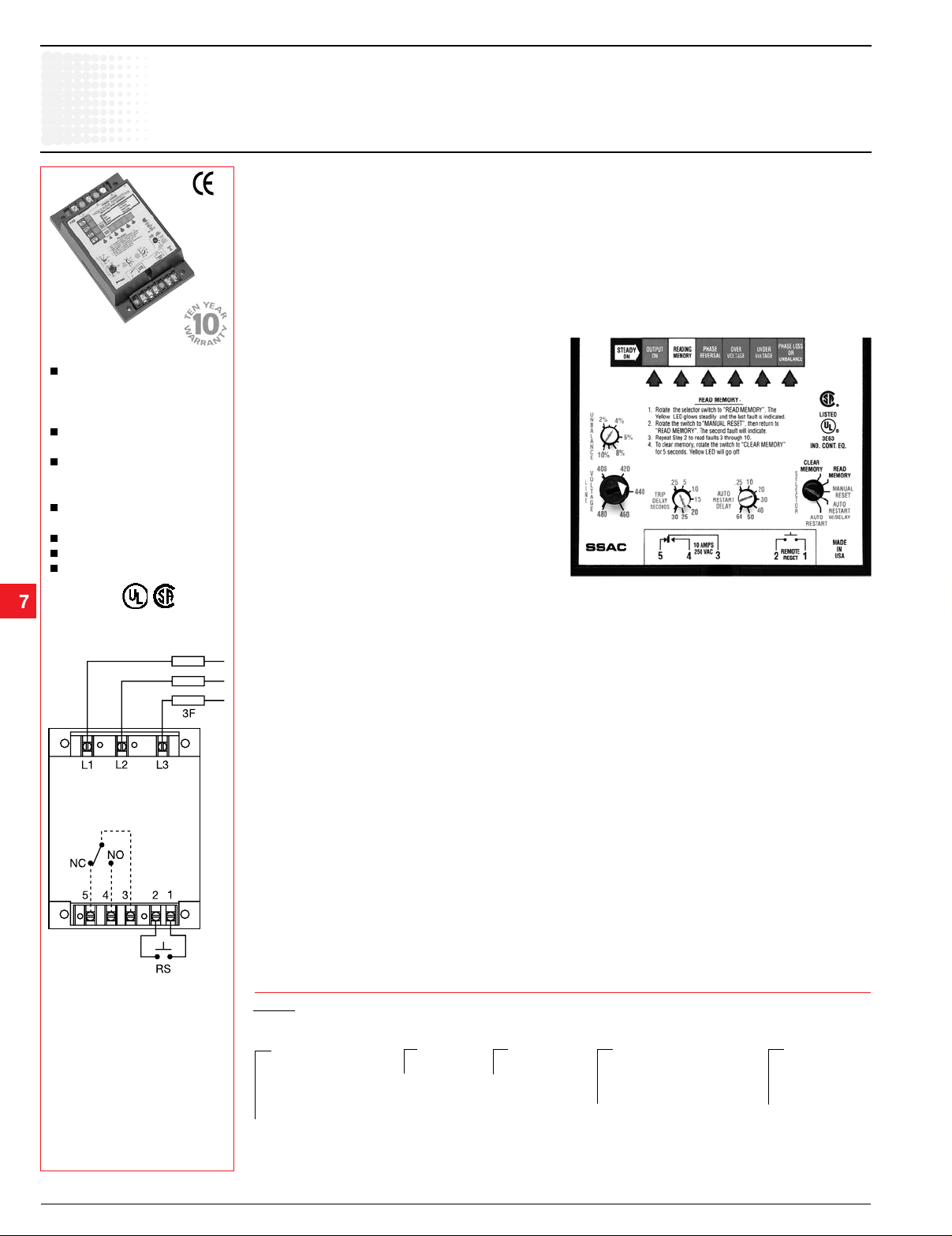

Connection

CAUTION:

2 amp max fast acting

fuses must be installed

externally in series with

each input. (3)

Relay contacts are isolated.

Dashed lines are internal

connections.

F = Fuses

NO = Normally Open

NC = Normally Closed

RS =

Optional Remote Reset Switch

Operation

The output relay is energized when all conditions

are acceptable and the WVM is reset. A restart

and/or random start delay may occur before the

output relay is energized.

Field Adjustment: Select the line voltage listed

on the motor’s name plate. This automatically sets

the over and under voltage trip points. Consult the

equipment’s manufacturer specifications for the

correct trip delay, unbalance percentage, and restart/

reset operation and restart delay. Make connection

to all three line phases as shown in the connection

diagram. Apply power. If the relay fails to energize,

view the LEDs for the cause, and correct the problem.

If the phase sequence is incorrect, swap any two

wires. No further adjustment should be required to

achieve maximum equipment protection.

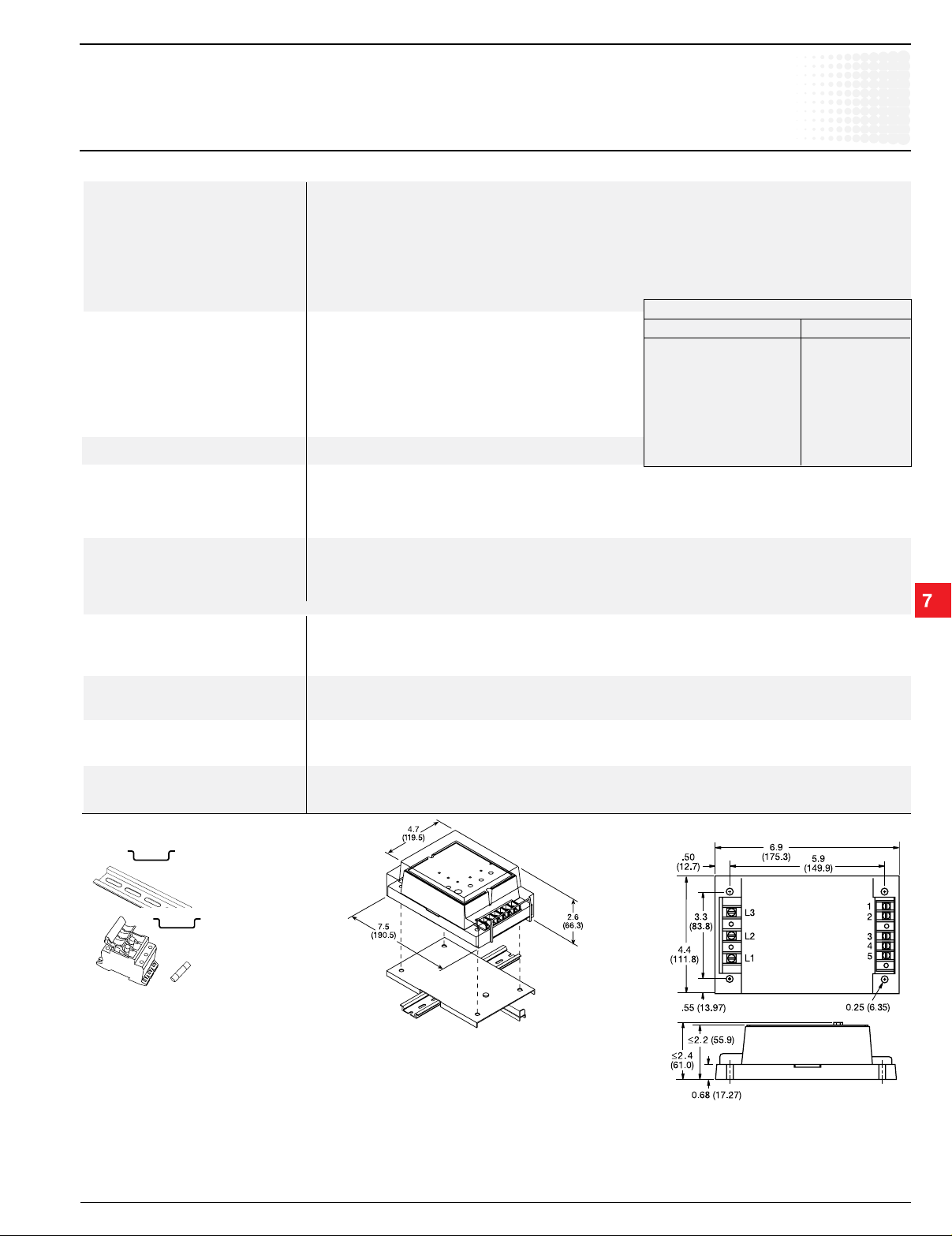

Read Memory: Fault(s) stored in the memory

are indicated when the yellow LED is flashing. To

read memory, rotate selector from Manual to Read

Memory. The last fault will be displayed. Repeat this

operation to read the second to the last fault. Repeat

until up to 10 faults are noted.

Memory Reset: To clear the memory of all

faults stored, rotate selector to Clear Memory

for 5 seconds. The yellow LED will turn off.

Memory Overload: The 11th fault causes the

first to be removed from memory. Only the 10

most recent faults are retained.

Random Start Delay: A new 3 to 15 s random start

delay is selected by the microcontroller when a fault

is corrected and when the operating voltage (L1, L2,

L3) is applied to the WVM. A random start delay does

not occur when the reset is manual.

Automatic Restart: Upon fault correction, the output

will re-energize after a random start delay.

Automatic Restart Upon Fault Trip: When a fault is

sensed for the full trip delay, the output de- energizes

and a restart delay is initiated. This delay locks out

the output for the delay period. Should the fault be

corrected by the end of the restart delay, the output

will re-energize after a random start delay. A restart

delay will also occur when operating voltage (L1, L2,

L3) is applied to the WVM.

Manual Reset: After a fault condition is corrected,

the WVM can be manually reset. There are two

methods; a customer supplied remote switch, or the

onboard selector switch.

WVM

Series

X

3 Phase Line Voltage

–6 - 200 ... 240 V AC

–8 - 355 ... 425 V AC

–9 - 400 ... 480 V AC

–0 - 500 ... 600 V AC

Example P/Ns:

WVM011AL,

WVM911AL-60 (No Random Restart Delay)

X

Unbalance Trip Delay

–1 - 2 ... 10%

X

–1 - 0.25 ... 30 s

Manual Reset (Onboard): Rotate selector switch

from the Manual Reset position to Auto Restart

w/ Delay then back again to Manual Reset within 3

seconds. The output will immediately energize.

Remote Reset: Reset (Restart) is accomplished

by a momentary contact closure across terminals 1

& 2. The output will immediately energize. Remote

switch requirements are ≥ 10 mA at 20 V DC and the

reset terminals are not isolated from line voltage. A

resistance of ≤ 20KΩ across terminals 1 & 2 will

cause immediate automatic restart.

Automatic Restart Upon Fault Correction:

(P/N includes an R)

When a fault is sensed for the full trip delay, the output

relay de-energizes. Upon correction of the fault, a

restart delay begins. At the end of this delay, the

output will re-energize after a random start delay. If

a fault occurs during restart timing, the restart time

delay will be reset to zero, and the output will not

energize until the restart delay is completed.

-60 Option: Add the suffix -60 to any automatic

restart part number to remove the Random Start

Delay feature. See example P/N‘s below.

X

Reset Method

–A - Switch Selectable:

Automatic Restart Upon Fault Trip

–R - Switch Selectable:

Automatic Restart Upon Fault

Correction

X

Restart Delay

–L - 0.25 ... 64 s

–N - 6 ... 300 s

–H - 0.25 ... 64 m

WVM02B01 12.13.06

7.4 Low Voltage Products & Systems

1TRC 001 009 C0202 ABB Inc. • 888-385-1221 • Technical assistance 800-377-7722 • www.ssac.com

Page 2

3 Phase Voltage Monitor

WVM Series

Motor Protector

Technical Data

Line Voltage

Type 3 phase Delta or Wye with no connection to neutral

Operating Voltage Adjustment Range

240 V AC 200 ... 240 V AC

380 V AC 355 ... 425 V AC

480 V AC 400 ... 480 V AC

600 V AC 500 ... 600 V AC

Frequency 50 ...60 Hz

Overvoltage, Undervoltage, &

Voltage Unbalance

Overvoltage Trip Point 109 ... 113% of adjusted voltage

Reset Voltage -2% of trip point

Undervoltage Trip Point 88 ... 92% of adjusted voltage

Reset Voltage +2% of trip point

Voltage Unbalance Adjustable from 2 ... 10%

Trip Delay Adjustable from 0.25 ... 30 s +/-15%

Phase Loss ≥ 15% unbalance

Response Time ≤ 200 ms

Random Start Delay Range 3 ... 15 s

Reset (Restart) Delay

Low Range 0.25 ... 64 s +/-15%

Normal Range 6 ... 300 s +/-15%

High Range 0.25 ... 64 m +/-15%

Fault Memory

Type Nonvolatile RAM

Capacity Stores last 10 faults

Status Indicators 6 LEDs provide existing status & memory readout

Note: 50% of operating line voltage must be applied to L1 & L2 for operation of status indicators

Output

Type Electromechanical relay

Form Isolated single pole double throw (SPDT)

Rating 10 A resistive @ 250 V AC; 6 A inductive (0.4 PF) at 250 V AC

Protection

Surge IEEE 62.41-1991 Level B

Isolation Voltage ≥ 2500 V RMS input to output

Mechanical

Mounting Surface with 2 or 4 #8 (M4 x 0.7) screws

Termination Screw terminals with captive wire clamps for up to #12 AWG ( 3.2 mm2) wire

Environmental

Operating/Storage Temperature -40°C ... +65°C / -40°C ... +85°C

Weight ≅ 25 oz ( 709 g)

Accessories

DIN rail P/Ns:

017322005 (Steel)

C103PM (Al)

Selected Unbalance % Reset %

2 1.8

3 2.7

4 3.6

5 4.5

6 5.4

7 6.3

8 7.2

9 8.1

10 9

Monitors

Reset on Balance

Mechanical View

Voltage

3-phase fuse

block/disconnect

P/N: P0700-241

2 AMP fuse

P/N: P0600-11

P/N: P1011-38

35mm DIN Rail Adaptor

The P1011-38 provides an easy

WVM02B01 09.15.04

method of mounting the WVM

Series on 35mm DIN rail. The

P1011-38 adaptor includes four

mounting screws. 7 x 4.5 x .33 in.

(177.8 x 114.3 x 8.4 mm)

Low Voltage Products & Systems 7.5

ABB Inc. • 888-385-1221 • Technical assistance 800-377-7722 • www.ssac.com 1TRC 001 009 C0202

P/N: P0500-153

Clear Tamperproof Cover

The P0500-153 protects against unauthorized adjustment

of the trip points. It prevents the resetting of manual units by

the equipment’s operator. It isolates line-level connection

po ints prevent in g contact during trou bleshoo ti ng

operations. Alignment dimples allow drilling (5 places) for

limited access to adjustment knobs and the reset switch.

Included are (2) spacers, (5) hole plugs. 7.5 x 4.7 x 2.6 in.

(190.5 x 119.4 x 66 mm)

Inches (Millimeters)

Inches (Millimeters)

Loading...

Loading...