Page 1

Overcurrent & Undercurrent

(Window Current) Sensing

Adjustable Overcurrent &

Undercurrent Trip Points

Current Sensor is Included

10 A SPDT Isolated Output

Contacts

LED Indicators

Approvals:

Selector Switch

ON OFF

SW1

SW2

SW3

Not Used

Latched

Zero I

Output

Normally

Energized

Window Current Sensor

ECSW Series

Current Sensor

Description

The ECSW Series of single phase, AC window current sensors includes adjustable overcurrent and undercurrent

trip points. Detects locked rotor, a jam, loss of load, an open heater or lamp load, a broken belt, or loss of

suction. LED's aid in trip point adjustment and provide fault indication. The built-in toroidal sensor eliminates

the need for an external current transformer . The output can be electrically latched after a fault, or automatically

reset. Remote resetting of a latched output by removing input voltage. The unit includes switch selectable zero

current detection and normally de-energized or energized output operation. Time delays are included to

improve operation and eliminate nuisance tripping.

Operation

When the input voltage is applied, sensing delay on startup begins and the output transfers (if normally

energized is selected). Upon completion of the startup delay, sensing of the monitored current begins. As long

as current is above undercurrent trip point and below the overcurrent trip point (inside the window), the output

relay remains in its normal operating condition and both red LED's are OFF. The green LED glows when the

output is energized. If current varies outside the window, the associated red LED glows, and the trip delay

begins. If the current remains outside the window for the full trip delay, the relay transfers to fault condition

state. If the current returns to normal levels (inside the window) during the trip delay, the red LED goes OFF, the

trip delay is reset, and the output remains in the normal condition.

Reset: Remove input voltage or open latch switch. If zero current detection is selected, the unit will reset as

soon as zero current is detected.

Operation With Zero Current Detection Enabled: If the current decreases to zero within the trip delay period,

then zero current is viewed as an acceptable current level. The unit's output remains in its normal operating

state. This allows the monitored load to cycle ON and OFF without nuisance tripping the ECSW. Zero current

is defined as current flow of less than 250 milliamp-turns. Note: When zero current detect is selected, the

latching operation of switch SW2 is canceled; the output will not latch after a fault trip.

Notes on Operation:

1) There is no hysteresis on the trip points. The overcurrent and undercurrent trip points should be adjusted

to provide adequate protection against short cycling.

2) If the upper set point is set below the lower set point, both red LED's will glow indicating a setting error.

3) If zero current detection is selected (SW2 ON), and the system is wired to disconnect the monitored load,

the system may short cycle. After the unit trips, the load de-energizes, and zero current is detected. The

ECSW resets, and the load energizes again immediately and may be short cycled.

4) The sensing delay on start up only occurs when input voltage is applied. When zero current detection is

selected, the trip delay must be longer than the duration of the inrush current or the unit will trip on the

inrush current.

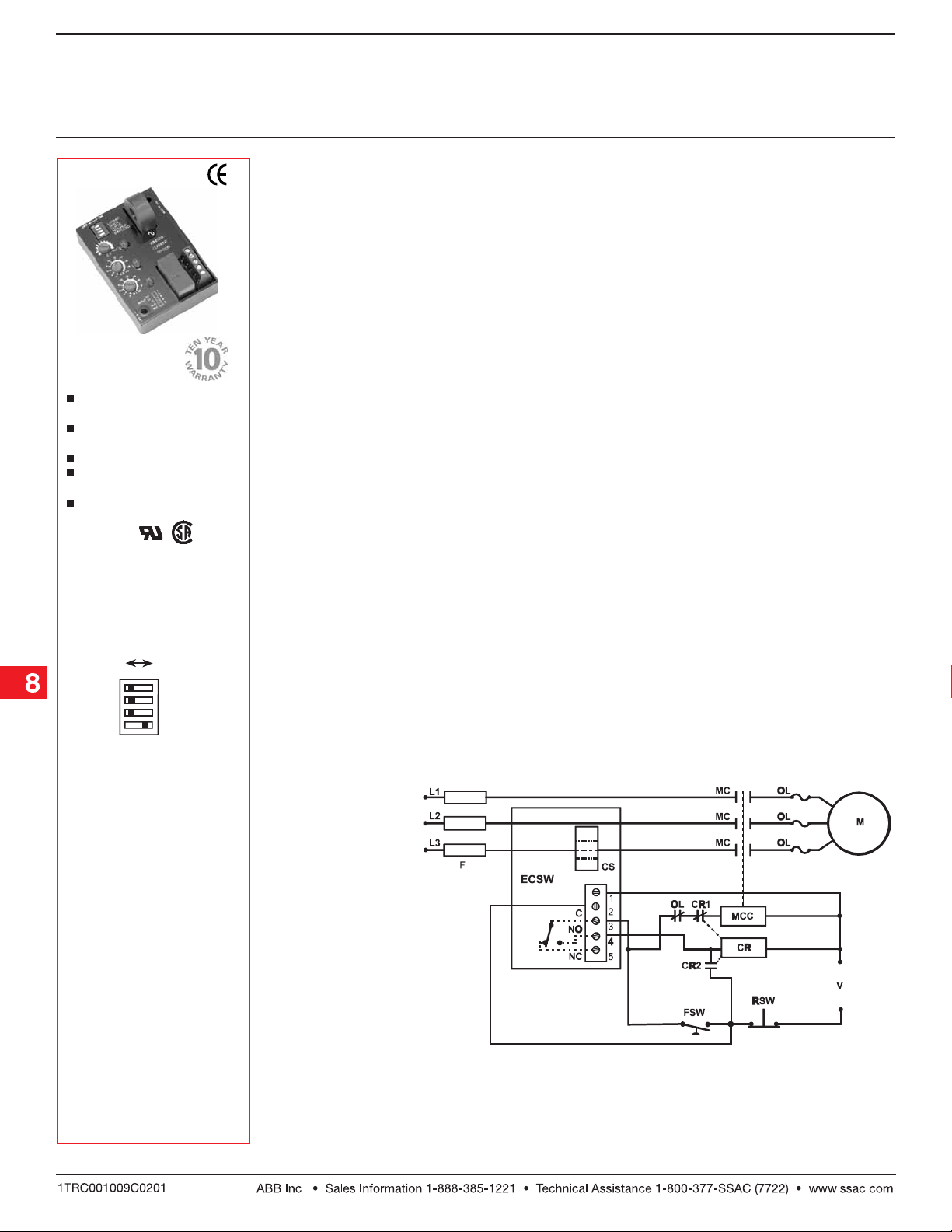

Typical Pump or Fan Protection Circuit Operation

Window Current Sensing: With the ECSW connected as shown in the diagram, a load may be monitored

and controlled for over and under current. The ECSW Series' on board CT (CS) may be placed on the line or

load side of the contactor. The ECSW selection switches are set for zero current sensing (see Selector Switch

SW2) and the output selection is normally de-energized (see Selector Switch SW3). The input voltage (V) is

applied to the ECSW continually. As the control switch (FSW) is closed, the input voltage (V) is applied to the

motor contactor coil (MCC), and the motor (M) energizes. As long as the current remains below the overcurrent

and above the undercurrent trip points, the ECSW's output contacts remain de-energized. If the load current

should rise above or fall below a trip point, for the full trip delay, the normally open (NO) contact will close,

energizing the control relay (CR) coil. The CR normally closed contact (CR1) opens and the MCC de-energizes

and CR latches on through its normally open contacts (CR2). Reset is accomplished by momentarily opening

the normally closed reset switch (RSW).

Connection

Mode Selection Switches

SW1 = Latched or Auto reset

selector

OFF - Automatic reset after a

fault

ON - Output relay latches

after a fault trips the

unit

SW2 = Zero current detection (below 250 mA)

OFF- Zero current detection

disabled

ON- Zero current detection

enabled

SW3 = Output during normal

operation

OFF- Output relay de-energized

ON - Output relay energized

Note: If the current falls to

zero within the trip delay, the

ECSW remains de-energized.

The sensing delay on startup

occurs when input voltage is

applied therefore trip delay

must be longer than the

duration of the motor's inrush

current. The external latching

relay CR2 is required in this

system to prevent rapid

cycling. A timer can be added

to provide an automatic reset.

MC = Motor Contactor M = Motor F = Fuses

OL = Overload RSW = Reset Switch

FSW = Fan or Float Switch CR = Control Relay

CS = Current Sensor MCC = Motor Contactor Coil

Note: The output is normally de-energized.

Low Voltage Products & Systems8.6

+

-

ECSW2B01 12.12. 05

Page 2

Window Current Sensor

ECSW Series

Current Sensor

Technical Data

Sensor

Type Toroid, through hole wiring for up to #4 AWG (21.1 mm2) THHN wire

Mo de Over and under current trip points (window current sensing)

Trip Point Range 0.5 ... 50 A in 3 adjustable ranges

Tolerance Guaranteed range

Maximum Allowable Current Steady - 50 A turns; Inrush - 300 A turns for 10 s

Trip Point vs. Temperature & Voltage +/- 5%

Response Time ≤ 75 ms

Frequency 45 ... 500 Hz

Type of Detection Peak detection

Zero Current Detection < 250 mA turns typical

Time Delay

Range 0.15 ... 50 s in 2 adjustable ranges or 0.08 ... 50 s fixed

Tolerance Adjustable: guaranteed range; Fixed: +/-10%

Sensing Delay On Start Up Fixed ≅ 0.1 ... 6 s in 1 s increments

Tolerance +40% -0%

Delay vs. Temperature & Voltage +/-1 5%

Input

Voltage 24, 120, or 230 V AC; 12 or 24 V DC

Tolerance 12 V DC & 24 V DC/AC -15% ... +20%

120 & 230 V AC -20% ... +10%

AC Line Frequency 50 ... 60 Hz

Output

Type Electromechanical relay

Mode: Switch selectable ON - Energized during normal operation, de-energized after a fault

OFF - De-energized during normal operation, energizes during a fault

Form Isolated, SPDT

Rating 10 A resistive at 240 V AC; 1/4 hp at 125 V AC;

Life Mechanical: 1 x 106; Electrical: 1 x 10

Latch Type Electrical

Reset Remove input voltage

Function Switch selectable latching function

Protection

Surge IEEE C62.41-1991 Level A

Circuitry Encapsulated

Isolation Voltage ≥ 2500 V RMS input to output

Insulation Resistance ≥ 100

Mechanical

Mounting Surface mount with two #6 (M3.5 x 0.6) screws

Termination 0.197 in. (5 mm) terminal blocks for up to

Environmental

Operating Temperature -40° C ... +60° C

Storage Temperature -40° C ... +85° C

Humidity 95% relative, non-condensing

Weight ≅ 6.4 oz (181 g)

1/2 hp at 250 V AC

MΩ

#12 (3.2 mm2) AWG wire

5

Connection

V = Voltage W = Monitored Wire

∆T = Adjustable Trip Delay

I> = Adjustable Overcurrent

I< = Adjustable Undercurrent

Mechanical View

Inches (Millimeters)

Ordering Table

X ECSW

Series Input

–1 - 12 V DC

–2 - 24 V AC

–3 - 24 V DC

–4 - 120 V AC

–6 - 230 V AC

ECSW2B01 12.12. 05

Example P/N: ECSW4LBCT Fixed - ECSW4HF10DT

Low Voltage Products & Systems 8.7

X

Trip Point Range

Adjustable Ranges

–L - 0.5 ... 5 A

–M - 2 ... 20 A

–H - 5 ... 50 A

Trip Delay

–A - Adjustable 0.15 ... 7 s

–B - Adjustable 0.5 ... 50 s

–F - Fixed*

Sensing Delay

on Start Up

–B - 0.1 s

–C - 1 s

–D - 2 s

–E - 3 s

–F - 4 s

–G - 5 s

–H - 6 s

*If Fixed Delay is selected, insert delay

[0.08 ... 50] in seconds. 0.1 ... 2 s in 0.1 s

increments; 2 ... 50 s in 1 s increments

XXX

Connection

–T - Terminal Blocks

Loading...

Loading...