Technical data sheet RD200-350-0-TB-EN-V1.3.doc

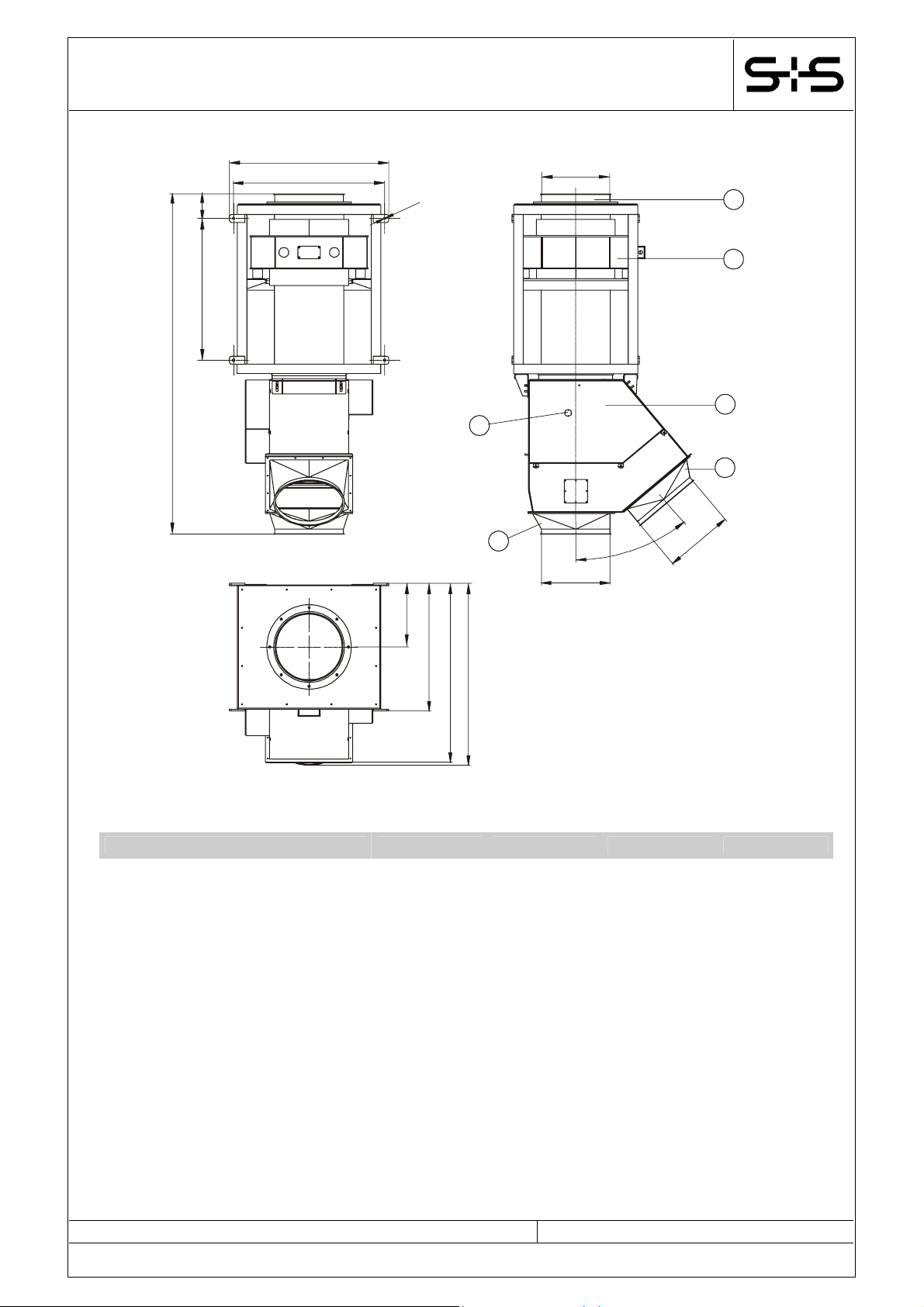

RAPID DUAL 200-350 metal separator

J

Dimensions

C

B

F

D

E

3

1

Ø

6

Page 1 of 2

ØA

1

2

3

4

5

°

0

4

A

Ø

ØA

G

1 Inlet

H

I

J

2 Detection coil

3 Separation unit

4 Reject outlet

5 Material outlet

6 Compressed-air connection

J

Technical data

All dimensions in mm

Model number RAPID DUAL 200 RAPID DUAL 250 RAPID DUAL 300 RAPID DUAL 350

Article number RD200-0 RD250-0 RD300-0 RD350-0

Nominal width ∅A Jacob system connector

199 mm 249 mm 299 mm 349 mm

Effective ID of inlet pipe ∅ 187.6 mm 234.6 mm 299 mm 349 mm

B 523 mm 523 mm 730 mm 730 mm

C 123 mm 123 mm 125 mm 125 mm

D 680 mm 680 mm 820 mm 820 mm

E 640 mm 640 mm 780 mm 780 mm

F 1450 mm 1450 mm 1750 mm 1750 mm

G 287 mm 287 mm 328 mm 328 mm

H 574 mm 574 mm 656 mm 656 mm

I 781 mm 781 mm 920 mm 920 mm

J 818 mm 837 mm 910 mm 933 mm

Maximum sensitivity

Maximum throughput

Weight (kg)

1)

The stated detection sensitivity (ferrous ball Ø in mm) applies for nonconductive products at the standard operation frequency and refers to the centre of the detection aperture

(most disadvantageous position). Products that show intrinsic conductivity due to moisture content, electrolytes or other conductive contents may reduce the sensitivity as well as

variations of product temperature, environmental effects (mechanical shocks and vibrations, electromagnetic pollution) or the set product angle. The detectable size of metal

particles depends on their nature, shape and position while passing the metal detector.

2)

The stated throughput rate is based on well pourable granules. The shape of the particles and thus the flow characteristic of the bulk material determine the throughput rate

which can vary. Upstream installed magnet separators may also reduce the throughput rate due to reduction of the cross section.

125 175 250 300

1)

∅ Ferrous ball

2)

1.8 mm 2.5 mm 3.0 mm 3.5 mm

44.000 l/h 69.000 l/h 100.000 l/h 136.000 l/h

Subject to change without notice ! 10-12-02

Technical data sheet RD200-350-0-TB-EN-V1.3.doc

Page 2 of 2

RAPID DUAL 200-350 metal separator

J

Conditions of use

Use: To analyse free-falling bulk materials such as granulates, meat, minced meat and others

Bulk material classification:

• Grain shape:

• Max. grain size:

• Pourability:

• Attributes:

• Material flow:

• Bulk material temperature:

• Ambient temperature:

Max. conveying pipe

pressure:

J

Scope of delivery / Design / Connections

Scope of delivery: Complete system with integrated detection coil, separation unit (double flap) and remote control

Mechanical design:

Electrical design: Control unit; detached, cable length 3m

J

Options / Accessories

Visual alarm

Failure indication

Failure and metal indication

Audible alarm

Failure indication

Failure and metal indication

Combination alarm (visual alarm and audible

alarm)

Failure indication

Failure and metal indication

J

Special versions / Supplementary systems

Model with improved wearout protection

Pipe transition pieces with flanges

Explosion-proof version ATEX

Granulates, Pellets, Flakes

Ball ø < 8mm, cylinder ø < 8mm length 20mm, flake 100x100x10mm

Good, medium, bad

Dry, damp, not abrasive, product effects (conductivity) can potentially be compensated

Free fall, fall height max. 700mm above equipment top edge

(No back draft of material)

Maximum +80° C

-10° C to +60° C

25 mbar

unit PRIMUS; feeder and outlets for good and reject material with “Jacob” connector.

Detection unit and control enclosure: sheet steel, varnished, aluminium grey (RAL 9007)

Separation unit: stainless steel 1.4301 (AISI 304), bead blasted

Scanning pipe: PE-EL

Parts in contact with product: stainless steel 1.4301 (AISI 304), PE-EL, Teflon, POM

Compressed air-connection: 5-8 bar, 6/8 mm hose connection

Compressed air consumption: RAPID DUAL-P 200-250: 1.7 litre / switch operation,

RAPID DUAL-P 300-350: 2.7 litre / switch operation

Operating voltage: 100-240 VAC (±10%), 50/60 Hz

Current consumption: approx 160 mA / 115 V, approx. 80 mA / 230 V

Mains cable: 1.8 m with plug

Ingress protection: IP 54

Eject duration: adjustable from 0.05 to 29 sec

Self-monitoring system: detection coil and outputs

Scanning sensitivity: selectable with 8 adjustments

Operation: see technical data sheet for Control Unit PRIUMS

Compressed-air monitor

Filter control valve

Monitor system for diverter

Counter (number of detections)

Push button for manual rejection

Special varnishes

Cable set for remote control unit:

6 m, 10 m, 15 m

UL/CSA certificate

US-power cable

Test samples

Control Unit SENSITY for higher sensitivity

Magnet systems for pre-removal of ferrous metals

Hopper magnet

Inline magnet

Inline chute magnet

…………………………………………

Subject to change without notice ! 10-12-02

Loading...

Loading...