Page 1

MODEL SR400

GATED PHOTON COUNTER

Phone: (408) 744-9040 • Fax: (408) 744-9049

email: info@thinkSRS.com • www.thinkSRS.com

1290-D Reamwood Avenue

Sunnyvale, California 94089

Copyright © 1987 – 2018 by SRS, Inc.

All Rights Reserved.

Revision 2.7 (11/2018)

Page 2

Page 3

Table of Contents

TABLE OF CONTENTS

CONDENSED INFORMATION

Safety and Preparation for Use 3

Specifications 5

Menu Display List 7

Abridged Command List 9

INSTRUMENT OVERVIEW

Signal Inputs / Discriminators 11

Counting 12

Gating 13

Count Modes 14

Outputs 14

Measurement Examples 17

OPERATION

Front Panel Summary 21

Power 21

Liquid Crystal Display 21

Menu Keys 21

Spin Knob 21

Start, Stop, and Reset 21

Instrument Status 22

Counter LED's 22

Inputs 22

Outputs 22

Rear Panel Summary 24

Power Entry Module 24

IEEE-488 Port 24

RS-232 Connector 24

Input 24

Output 24

Front Panel Menus 25

Mode Menu 25

Level Menu 27

Gate Menus 30

Setup Menu 31

Com Menu 31

INSTRUMENT SETUPS

Default Setup / Power On Clear 33

Quick Check 33

2 Photon Pile Up Correction 34

Gated Photon Counting 34

Synchronous or Chopped

Photon Counting 34

REMOTE PROGRAMMING

Communications 37

Command Syntax 37

Status LED's 38

RS-232 Echo 38

Try-out with ASCII Terminal 38

Detailed Command List 39

Mode 39

Levels 40

Gates 41

Front Panel 42

Interface 44

Store/Recall 45

Polled Data 45

Continuous Data 45

Examine Data 46

Status Byte 46

Secondary Status Byte 47

Errors / Data Window 47

Trouble Shooting Interface Problems 47

Common Hardware Problems 47

Common Software Problems 48

RS-232 INTERFACE

Data Communications Equipment 49

Echo 49

Wait Command 49

Termination Sequences 49

Example Programs 49

Microsoft BASIC 50

Microsoft FORTRAN 51

GPIB (IEEE-488) INTERFACE

GPIB Capabilities 53

Serial Polls and Service Requests 53

Example Programs 53

Microsoft BASIC 54

Microsoft C 56

TROUBLESHOOTING

LCD Contrast 59

Fan 59

Front Panel Test 59

Power On Reset 59

Quick Test 59

Counting 60

CALIBRATION AND REPAIR

Signal Input Offset 61

Signal Input Repair 61

1

Page 4

Table of Contents

USING PHOTOMULTIPLIER TUBES

PMT Selection for Photon Counting 63

Geometry 63

Spectral Response 63

Gain and Risetime 63

Dark Counts 64

PMT Base Design 64

Dynode Biasing 64

Snubbing 66

PMT Base Conclusions 67

Cathode Shielding 67

Preamplifiers 67

Gain Requirement 67

Plateauing a PMT 67

The 'Correct' Way 68

The 'Fast and Pretty Good' Way 68

TYPICAL EXPERIMENT

Energy Levels of Ruby 69

Apparatus 69

Operation 69

Instrument Configuration 70

Computer Data Acquisition 70

CIRCUIT DESCRIPTION

Microprocessor Control 73

Microprocessor System 73

RS-232 Interface 73

GPIB Interfac e 73

Input Ports 73

Slow Counters 73

Output Ports 73

Front Panel 73

D/A Converter 74

Fast Counters 74

Signal Inputs 74

Discriminators 74

A and B Counters 74

T Counter 75

Start / Stop and Dwell 75

Gate Generators 76

Digital Delay 76

Analog Delay 76

Delay Reset 77

Gates 77

Power Supply 77

PARTS LISTS

Main Assembly 79

Power Supply 93

Miscellaneous 95

SCHEMATIC DIAGRAMS

Signal Amplifiers SR400-1

Discriminators SR400-2

Fast Counters A and B Prescallers SR400-3

Fast Counters T Prescaller SR400-4

Slow Counters (A, B, T) SR400-5

Dwell Timer: Start/Stop SR400-6

Fast Gate Delay Ramps SR400-7

Slow Gate Delay Counters SR400-8

Fast Gate Ramps SR400-9

Width Oscillators SR400-10

Slow Gate Width Counters SR400-11

Microprocessor System SR400-12

Counters and Timers:

Digital Interface 1 SR400-13

Output Ports:

Digital Interface 2 SR400-14

Digital to Analog Converter SR400-15

Power Supply

2

Page 5

Safety and Preparation for Use

SAFETY AND PREPARATION FOR USE

**** CAUTION ****

This instrument may be damaged if operated with

the LINE VOLTAGE SELECTOR set for the

wrong ac line voltage or if the wrong fuse is

installed.

LINE VOLTAGE SELECTION

The SR400 operates from a 100V, 120V, 220V, or

240V nominal ac power source having a line

frequency of 50 or 60 Hz. Before connecting the

power cord to a power source, verify that the

LINE VOLTAGE SELECTOR card, located in the

rear panel fuse holder, is set so that the correct ac

input voltage value is visible.

Conversion to other ac input voltages requires a

change in the fuse holder voltage card position and

fuse value. Disconnect the power cord, open the

fuse holder cover door and rotate the fuse-pull

lever to remove the fuse. Remove the small

printed circuit board and select the operating

voltage by orienting the printed circuit board to

position the desired voltage to be visible when

pushed firmly into its slot. Rotate the fuse-pull

lever back into its normal position and insert the

correct fuse into the fuse holder.

LINE FUSE

Use 1 Amp slow blow fuse for 100V/120V as well

as 220V/240V.

LINE CORD

The SR400 has a detachable, three-wire power

cord for connection to the power source and to a

protective ground. The exposed metal parts of the

instrument are connected to the outlet ground to

protect against electrical shock. Always use an

outlet which has a properly connected protective

ground.

WARNING REGARDING USE WITH

PHOTOMULTIPLIERS

The signal inputs may be damaged if a

photomultiplier is used improperly with the photon

counter. When left completely unterminated, a

PMT will charge a cable to a few hundred Volts in

a very short time. If this cable is connected to a

signal input, the stored charge may damage the

front-end transistors. To avoid this problem,

provide a leakage path of about 100 KΩ to ground

inside the base of the PMT to prevent charge

accumulation.

CONNECTION TO OTHER INSTRUMENTS

All front panel BNC shields are connected to the

chassis ground and to the power outlet ground via

the power cord. Do not apply any voltage to either

the shields or to the outputs. The outputs are not

protected against connection to any potential other

than ground.

3

Page 6

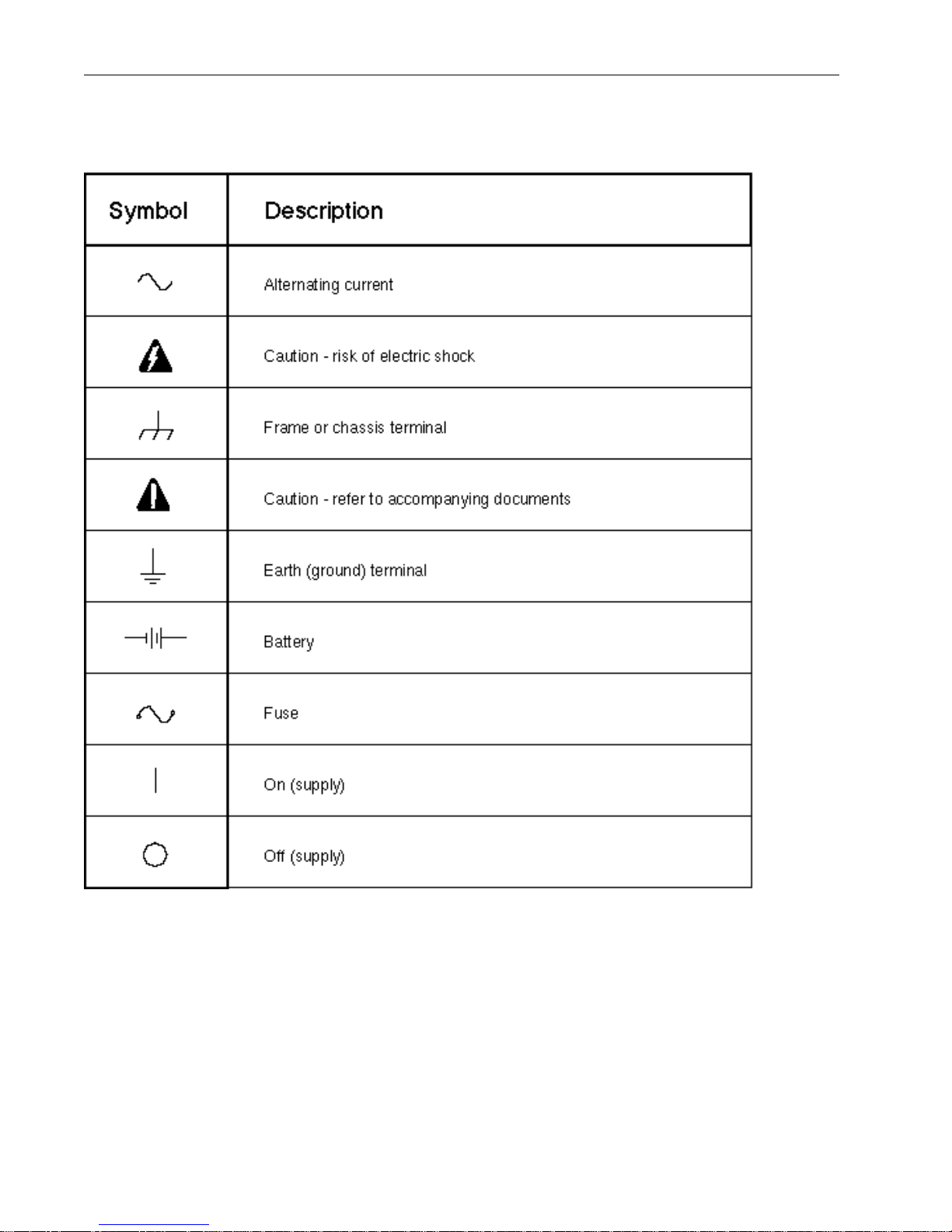

SRS Symbols

Symbols that may be found on SRS products

4

Page 7

SR400 Specifications

SR400 SPECIFICATIONS

OVERVIEW

There are three complete counters identified as A,

B, and T. All counters count up to 200 MHz.

Counter A can count INPUT 1 or the 10 MHz

internal clock. Counter A is gated by AGATE, and

has a count capacity of 10

9

.

Counter B can count INPUT 1 or INPUT 2.

Counter B is gated by BGATE, has a count

capacity of 10

9

and may be used as the preset

counter to determine the count interval.

Counter T can count the internal 10 MHz clock,

INPUT 2, or the gate trigger. This counter may be

preset to determine the count period for up to 25

hours or 9 x 10

11

counts, gates, or triggers. The

timer has an accuracy or 25 ppm from 0 to 50∞C.

SIGNAL INPUTS

Bandwidth: dc to 300 MHz

Input impedance: 50 Ohms

Linear range: ± 300 mV (at input)

Input protection: ± 5 Vdc, 50 V for 1 µs

Overload recovery: 5 ns for <10 µs duration

overload

DISCRIMINATORS

Counters A, B, and T have independent

discriminators when counting the signal inputs.

All discriminator levels may be set to a fixed level

or scanned. A rear panel INHIBIT input (TTL

active high) can inhibit the discriminators to stop

the count.

Referenced to the signal inputs:

Discriminator range: -300 mV to +300 mV.

Discriminator slope: Rising or Falling

Resolution: 0.2 mV

Input offset voltage: 1 mV

Minimum pulse input: 10 mV

Pulse pair resolution: 5 ns.

DISC outputs: NIM levels into 50 Ohms

TRIGGER INPUT

Impedance: 10 KOhms

Threshold: ±2.000 Vdc in 1 mV steps

Slope: Rising or Falling

Protection: 15 Vdc, 100 V for 1 µs

GATE GENERATORS

There are two independent gates, AGATE and

BGATE, which enable the A and B counters. Both

gates are triggered by the TRIGGER input. The

gates may be fixed in time or scanned. The GATE

outputs show the positions of the gates with

respect to the discriminator outpu ts.

Insertion delay: 25 ns

Maximum delay: 999.2 ms

Minimum gate width: 5 ns

Maximum gate width: 999.2 ms or CW

Resolution: 0.1%, 1 ns minimum

Accuracy: 2 ns +1%

Jitter: 200 ps rms +100 ppm

Maximum trigger rate:1 MHz

GATE view outputs: NIM levels into 50 Ohms

GATE view error: < 2 ns

COUNTING MODES

A and B for a period determined by T preSET and

T input.

A ± B for a period determined by T preSET and T

input.

A for a period determined by B preSET and B

input.

SCAN AND DWELL

The number of count PERIODS or data points in a

scan may be set from 1 to 2000. The duration of

one count period is determined by the preset

condition.

The time between consecutive count periods is the

DWELL TIME and can be set from 2 ms to 60 s.

The DWELL output will be TTL high during the

DWELL time. This output can be used to trigger

external devices.

At the end of a scan (of 1 to 2000 count periods)

counting may be programmed to STOP or START

the scan over again.

The START key begins the first count period of

the programmed scan.

5

Page 8

SR400 Specifications

The STOP key terminates the current count period

and pauses the scan. If scanning, gates and disc

levels are held at their last value. The STOP key

pressed while in a paused condition will reset the

scan and all scanned parameters will return to their

start values. The START key pressed while paused

resumes the scan by starting the next count period.

The DWELL TIME may also be set to

EXTERNAL. In this mode, count periods begin

with the START key or EXTERNAL START

INPUT (TTL rising edge). Count periods

terminate with the preset condition, the STOP key,

or the EXTERNAL STOP INPUT (TTL rising

edge). A STOP key while not counting resets the

scan. This allows completely variable dwell times

and/or counting periods.

All count data is internally buffered for one scan.

Data may be read over the computer interfaces

during or after a scan.

DISPLAY MODE

CONTINUOUS: Displays current counter value

HOLD: Displays final count value

D/A OUTPUT

The front panel D/A Output is proportional to A,

B, A-B, or A+B depending upon the counting

mode selected. The D/A output is updated at the

end of each count period.

There are two rear panel D/A outputs, PORT 1 and

PORT 2. These outputs may be set or scanned

from the front panel or via the computer interface.

Full scale: ± 10 Vdc

Resolution: 12 bits (5 mV)

Current rating: 10 mA

Output Impedance: < 1 Ohm

Accuracy: 0.1% + 5 mV

COMPUTER INTERFACE

IEEE-488 (GPIB) and RS-232 (up to 19.2 kbaud).

Full instrument control and data transmission.

GENERAL

Dimensions: 16" x 13" x 3.5"

Weight: 10 lbs

Power: 35 Watts from 100, 120,

220, or 240 Vac

Warranty: One year parts and labor

on materials and

workmanship

6

Page 9

Menu Display List

MENU DISPLAY LIST

MODE

COUNT=A,B FOR T PRESET

A=INPUT 1

B=INPUT 2 B SET=1E3

T=10MHZ T SET=1E0 s

N PERIODS=2000 [at 1234]

AT N=STOP DWELL=1E0s

D/A=A

D/A RANGE=LOG

DISPLAY=CONTINUOUS

LEVEL

TRIG SLOPE=RISE

TRIG LVL=+2.000 V

A DISC SLOPE=FALL

A DISC=SCAN ∆=-1.0 mV

A DISC LVL=-10.0 mV

B DISC SLOPE=FALL

B DISC=SCAN ∆=-1.0 mV

B DISC LVL=-10.0 mV

T DISC SLOPE=FALL

T DISC=SCAN ∆=-1.0 mV

T DISC LVL=-10.0 mV

PORT1=SCAN ∆=+0.100 V

PORT1 LVL=+0.500 V

PORT2=SCAN ∆=+0.100 V

PORT2 LVL=+0.500 V

A GATE

AGATE=SCAN ∆=1.000 µs

A DELAY=1.000 µs

A WIDTH=1.000 µs

SETUP

LCD CONTRAST=12

STORE=3 EXECUTE=>

RECALL=3 EXECUTE=>

B GATE

BGATE=SCAN ∆=1.000 µs

B DELAY=1.000 µs

B WIDTH=1.000 µs

COM

GPIB ADDR=23

RS-232 BAUD=9600

RS-232 BITS=8

RS-232 PARITY=NONE

RS-232 WAIT=6

RS-232 ECHO=OFF

DATA=

7

Page 10

Menu Display List

8

Page 11

Abridged Command List

ABRIDGED COMMAND LIST

The parameter i is 0,1,or 2 to select counter A,B, or T

MODE

CM j Set COUNT to mode j; A,B(0), A-B(1), A+B(2) for preset T,or A FOR B preset(3).

CI i,j Set counter i to input j; 10 MHz(0), INP 1(1), INP 2(2), TRIG(3).

CP i, n Set counter i preSET to 1 <= n <= 9E11.

NP m Set Number of PERIODS in a scan to 1 <= m <= 2000.

NN Read current count period number or scan position.

NE j Set end of scan mode to mode j; START(1) or STOP (0).

DT x Set DWELL time to 2E-3 <= x <= 6E1 s or EXTERNAL(0).

AS j Set D/A to source j; A(0), B(1), A-B(2), A+B(3).

AM j Set front panel D/A to RANGE j; LOG(0) or LINEAR (1-7).

SD j Set DISPLAY to mode j; CONTINUOUS(0) or HOLD(1).

LEVELS

TS j Set TRIG to SLOPE j; RISE(0) or FALL(1).

TL v Set TRIG LVL to -2.000 <= v <= 2.000 V.

DS i,j Set DISC i to SLOPE j; RISE(0) or FALL(1).

DM i,j Set DISC i to mode j; FIXED(0) or SCAN(1).

DY i,v Set DISC i scan step to -0.0200 <= v <= 0.0200 V.

DL i,v Set DISC i LVL to -0.3000 <= v <= 0.3000 V.

DZ i Read current DISC i LVL (during scan).

PM k, j Set PORT k (1 or 2) to mode j; FIXED(0) or SCAN(1).

PY k,v Set PORT k (1 or 2) scan step to -0.500 <= v <= 0.500 V.

PL k,v Set PORT k (1 or 2) LVL to -10.000 <= v <= 10.000 V.

PZ k Read current PORT k (1 or 2) LVL (during scan).

GATES

GM i,j Set GATE i to mode j; CW(0), FIXED(1), or SCAN(2).

GY i,t Set GATE i DELAY scan step to 0 <= t <= 99.92E-3 s.

GD i,t Set GATE i DELAY to 0 <= t <= 999.2E-3 s.

GZ i Read current GATE i DELAY position (during a scan).

GW i,t Set GATE i WIDTH to 0.005E-6 <= t <= 999.2E-3 s.

FRONT PANEL

CS Count start, same as START key.

CH Count pause, same as STOP key while counting.

CR Count reset, same as STOP key pressed twice.

CK j Simulate key press j.

RR Rotate knob right (CW or UP) 1 step.

RL Rotate knob left (CCW or DOWN) 1 step.

SC Read cursor position. Left(0), right(1), or inactive(2).

MI j Set front panel to mode j; local(0), remote(1), locked-out(2). RS-232 only.

MS string Display string on menu line.

MS Return menu line to normal display.

MD j,k Display line k of menu j.

MM Read menu number of display (j).

ML Read menu line of display (k).

9

Page 12

Abridged Command List

STORE/RECALL

ST m Store instrument settings to location m (1 to 9).

RC m Recall instrument settings from location m (1 to 9).

RC 0 Recall default settings.

INTERFACE

CL Clear instrument.

SV m Set GPIB SRQ mask to 0 <= m <= 255.

SS Read status byte.

SS j Read bit j(0-7) of status byte.

SI Read secondary status byte.

SI j Read bit j (0-2) of secondary status byte.

SW m Set RS-232 character wait interval to m*3.33 ms 0 <= m <= 25. RS-232 only.

SE j,k,l,m Set RS-232 terminator sequence to j,k,l,m (ASCII codes). RS-232 only.

SE Clear RS-232 terminator sequence to defaults. RS-232 only.

DATA

QA Read last count in counter A.

QB Read last count in counter B.

QA m Read from scan buffer point m(1-2000) for counter A.

QB m Read from scan buffer point m(1-2000) for counter B.

EA Send entire counter A buffer.

EB Send entire counter B buffer.

ET Send entire counter A and B buffer.

FA Start scan and send N PERIODS data points from counter A.

FB Start scan and send N PERIODS data points from counter B.

FT Start scan and send N PERIODS data points from both counters.

XA Read current contents of counter A.

XB Read current contents of counter B.

STATUS BYTE

Bit Description

0 Parameter changed

1 Data ready

2 Scan finished

3 Counter overflow

4 Rate error

5 Recall error

6 Service request

7 Command error

SECONDARY STATUS BYTE

Bit Description

0 Triggered

1 Inhibited

2 Counting

3-7 Unused

10

Page 13

Instrument Overview

INSTRUMENT OVERVIEW

SR400 OVERVIEW

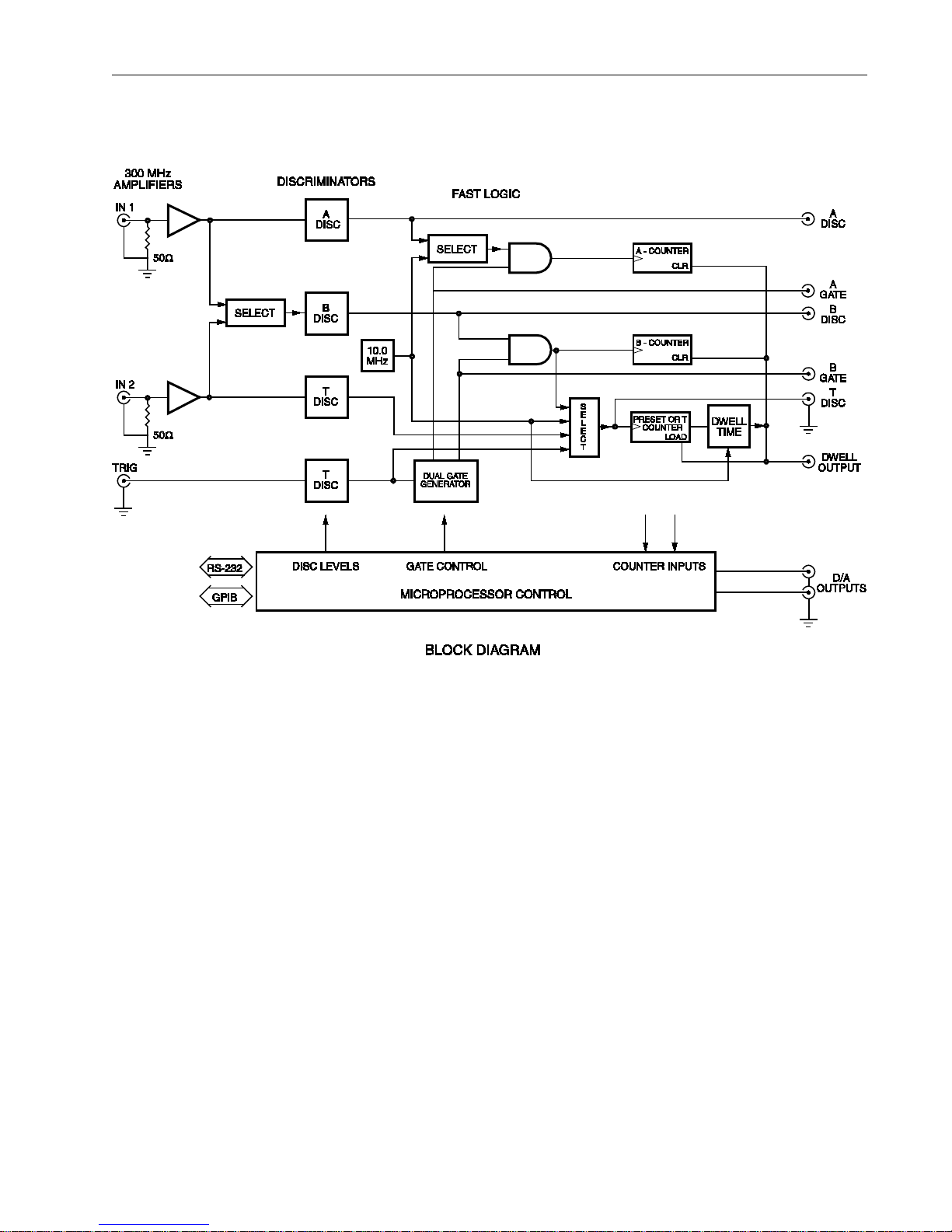

The SR400 architecture is diagrammed above.

There are three fast counters identified as counters

A, B, and T. All three counters operate at rates up

to 200 MHz. The input to each counter is selected

from a number of sources, including the two

analog signal inputs, the crystal timebase, and the

external trigger input. Counter T is presettable and

determines the measurement period. For pulsed

experiments, counters A and B may also be

synchronized to external events via the two

independent gate generators. The gate generator

provides gates from 5 ns to 1 s in duration with a

delay from external trigger ranging from 25 ns

to 1 s.

SIGNAL INPUTS AND DISCRIMINATORS

There are two independent analog signal inputs

labelled INPUT 1 and INPUT 2. They are

internally terminated into 50 Ω. The inputs can

accept signals of either polarity up to ±300 mV

and are protected to ±5V dc. Each input is

followed by a dc to 300 MHz amplifier. This

allows detection of pulses as s mall as 10 mV. If

greater sensitivity is required, the SR445A remote

amplifier is available. The SR445A can provide

gains from 5 to 625 at bandwidths up to 350 MHz.

There are three discriminators, one for each

counter. Each discriminator has selectable slope

and a threshold programmable from -300 mV to

+300 mV in 0.2 mV steps (referenced to the

inputs). Pulse-pair resolution is 5 ns and pulses of

either polarity may be detected. Each threshold

11

Page 14

Instrument Overview

may be programmed to scan in either direction

with selectable step size.

COUNTING

Each counter's input may be selected from a

number of sources. All multiplexing of counter

inputs is done internally to provide accurate timing

and ease of operation. Input cables should rarely

need to be swapped or disconnected to change

measurement modes.

The actual inputs to the counters can be viewed as

NIM level pulses from the DISC outputs on the

front panel. The DISC pulses are negative going

from 0 to -0.7 V. The falling edge is the active or

counted edge regardless of the discriminator slope

setting. The DISC outputs are very useful when

adjusting discriminator thresholds or gate timing.

When the START key is pressed, a START

command is received from the computer interface,

or the EXTERNAL START input is pulsed,

counter T is enabled to count. The COUNT

PERIOD begins with the first pulse from T

counter's input after START. The COUNT

PERIOD enables counters A and B to count their

respective inputs. If the A GATE and B GATE are

CW or continuous, all pulses that occur during the

COUNT PERIOD are counted. If the gates are

enabled, only the pulses that occur during those

gates which fall within the COUNT PERIOD are

counted.

Counter T is presettable from 1 to 9E11. When

counter T reaches the preset count, the COUNT

PERIOD is terminated and counting is halted on

all counters. When the input to counter T is the 10

MHz crystal timebase, the COUNT PERIOD is a

fixed time interval from 100 ns to 25 hours. When

the input is INPUT 2, the COUNT PERIOD is

externally determined and can be as short as 5 ns

and indefinitely long. This mode is used for source

compensation or reciprocal measurements. If the

input is TRIGGER, the COUNT PERIOD is a

fixed number of gates (each trigger provides one

gate). This results in a constant gate aperture time

during each COUNT PERIOD. N+1 Triggers are

required for N gates per period. If the input is B

PRESET, then counter T counts the B DISC

output gated by B GATE. This is for gated ratio or

reciprocal counting.

The SR400 may be programmed to cycle through

1 to 2000 COUNT PERIODS in a single scan. At

the end of the programmed scan, the counters may

be stopped or the scan may be restarted. If the end

of scan mode is STOP, then after the last COUNT

PERIOD in the scan, the counters are halted

indefinitely. A counter RESET is required to

rearm the counters and a START command starts

another scan. If the Number of PERIODS in the

scan is 1, then each START command results in

one COUNT PERIOD. If N PERIODS is greater

than 1, then consecutive COUNT PERIODS are

separated by the DWELL time. The DWELL time

may be set from 2 ms to 60 s. During the DWELL

time, counting is disabled and data may be

transferred or external parameters scanned. The

DWELL OUTPUT is a TTL output which is high

during the DWELL time. At the end of the

DWELL time, the next COUNT PERIOD begins

and the scan continues until N PERIODS have

been measured. If the end of scan mode is

START, one DWELL time separates the last

COUNT PERIOD of the completed scan and the

first COUNT PERIOD of the next scan.

Another DWELL mode is EXTERNAL. In this

mode, the EXTERNAL START input enables

counter T. The COUNT PERIOD begins with the

first pulse to counter T after START. Counting

then proceeds normally until the preset is reached.

At the end of the preset COUNT PERIOD, the

DWELL time is indefinite and the next COUNT

PERIOD starts with t he n ext EXTE RNAL ST ART

pulse. In this way, preset COUNT PERIODS may

be synchronized to external events. If externally

determined COUNT PERIODS are desired, then

the preset COUNT P ERIOD can be set to a value

much larger than actually required and the

EXTERNAL STOP input used to terminate the

COUNT PERIOD. The COUNT PERIOD then

starts with the first pulse to counter T after

EXTERNAL START and ends with EXTERNAL

STOP. The next EXTERNAL START be gins the

next COUNT PERIOD in the scan. When the scan

is finished and the scan end mode is STOP, a

RESET from the front panel or computer interface

is required to reset the scan. If the scan end mode

12

Page 15

Instrument Overview

is START, the next EXTERNAL START begins

the first COUNT PERIOD of the next scan.

SCANNING

In all scan modes, a number of parameters may be

scanned. These parameters are the three

discriminator thresholds (Pulse Height Analysis),

the two gate delays (Boxcar mode), and the two

D/A output ports (X-axis of recorder, scope, or

analog control of other apparatus).

After each COUNT PERIOD, each scanning

parameter is adjusted by one step. All changes are

made during the DWELL time so that all values

are stable during the COUNT PERIODS. The scan

limits are determined by the start position, the step

size, and the number of PERIODS in a scan. The

range of a scan is N PERIODS times the step size.

When the counters are reset, all scanned

parameters return to their start positions.

GATING

The gate generators may be disabled by setting the

gate modes to CW. In this mode, the gates are

continuously open and counting is enabled solely

by the COUNT PERIOD. This is appropriate for

CW sources or long counting intervals. If the

signal is pulsed or so weak that synchronous (lockin) measurement is required, then the gate

generators are required. The gates prevent pulses

that occur outside the time interval of interest from

being counted and improve signal to noise ratio.

When the gates are scanned, the time behavior of

the signal may be recovered.

The gates are triggered by the TRIGGER input.

The TRIGGER threshold is adjustable from -2V to

+2V and slope may be either RISE or FALL. The

discriminated trigger pulse may be viewed through

the T DISC output when the input to counter T is

set to TRIG. This can be helpful when setting the

trigger threshold.

The minimum insertion delay from trigger to gate

is 25 ns. The additional delay may be programmed

from 0 ns to 999.2 ms with a resolution of 1 part in

1000 or 1 ns, whichever is greater. The gate width

is adjustable from 5 ns to 999.2 ms with the same

resolution. The two gates are output as NIM pulses

from the GATE outputs. The gates are open when

the outputs are low. The gate outputs have a

timing accuracy with respect to the discriminator

outputs of 2 ns. This allows accurate timing of fast

gates relative to the signal.

The two gates have independent modes, delays,

and widths. This allows for a variety of

measurements. For example:

1) "Boxcar" mode. The gates are used to enable

the counters only when the signal is present. If the

gates are scanned, then the time profile of the

signal is recovered. Background subtraction can be

included by using one gate for the signal and an

equal width gate on the background, either before

or after the signal. The signal gate may be scanned

while the background gate held fixed. Gated

source compensation is also possible since

counters A and B may count different sources at

the same time or the same source at different

times. In the compensation mode, the COUNT

PERIOD is determined by the gated output of the

B discriminator and the COUNT MODE is A FOR

B PRESET.

2) "Lock-in" or "Chopped" mode. In this case, a

cw signal is chopped on and off. This can be

accomplished with a light chopper such as the

SR540. The light chopper reference output is used

to trigger the gates. The A GATE is positioned

during the "open" cycle and counts signal plus

noise. The B GATE is positioned during the

"closed" cycle and only counts the noise. The

counter outputs are subtracted to give only the

signal. The widths of both gates should be equal

and less than half of the chopper period. This

prevents frequency jitter in the chopper from

affecting the overlap of the gates with the open

and close cycles of the chopper.

When counter T is preset and its input is set to

TRIG, then each COUNT PERIOD consists of a

constant number of gates. N+I triggers are needed

for N gates per preiod. This is the usual mode of

gated operation. However, a number of other

modes are available. For example, if the input is

set to 10 MHz, each COUNT PERIOD consists of

the number of gates which occur during the

COUNT PERIOD time interval. If the input is a

signal input, then counting is both gated and

13

Page 16

Instrument Overview

source compensated. If the DWELL mode is

EXTERNAL, an EXTERNAL START p ulse s tart s

counting and an EXTERNAL STOP pulse stops

counting. The counters are enabled only during

those gates which occurred between the two

EXTERNAL pulses.

COUNT MODES

The length of a COUNT PERIOD is the time it

takes counter T to reach its preset count. If N

the preset count in counter T, and R

and Rt are the

a

is

t

mean pulse rates of the inputs to counters A and T,

then the COUNT PERIOD is

T = N

/ Rt

t

The number of counts in counter A will be

A = R

T = Ra Nt / Rt

a

Rate:

If R

= 10 MHz, then the COUNT PERIOD is a

t

constant amount of time and

A = R

( Nt / Rt ) ~ Ra

a

and counter A measures the mean rate of its input.

Gated:

If R

is the gate trigger rate and counter A is

t

gated, then the COUNT PER IOD is N

"effective" time the counter is enabled is N

where W

is the width of A gate and

a

but the

t/Rt

tWa

A = R

( Nt Wa ) ~ Ra

a

In this case, counter A measures the mean rate

during the A gate.

Source Compensated:

If Rt is INPUT 2, then the COUNT PERIOD is

determined by the pulse rate of INPUT 2 and the T

discriminator. Count A will be

A = N

Ra / Rt ~ Ra / Rt

t

and is proportional to the ratio of the rates of

counters A and T. If INPUT 2 monitors source

intensity, then the COUNT PERIOD will adjust

for fluctuations in the source. Counter A measures

the ratio of its mean input rate and the mean rate

of INPUT 2.

Reciprocal:

If R

is INPUT 2, then the COUNT PERIOD is

t

N

. If Ra is 10 MHz, then counter A measures

t/Rt

A = R

Nt / Rt = ( Ra Nt ) / Rt ~ 1 / Rt

a

and is proportional to the reciprocal of the count

rate of INPUT 2. Not e that ea ch COUNT PE RIOD

is determined by N

counts of INPUT 2, thus the

t

measurement time is determined by the signal

strength. Measurements of both strong and weak

signals are made to the same accuracy for constant

signal to noise ra tio .

Counter B:

Counter B may be used in all of the above modes

except Reciprocal. Since counter B is completely

independent of counter A, 2 sources of counts may

be measured simultaneously. These sources may

be the same signal or 2 different signals; the

sources may be discriminated at separate

thresholds; they may be non-gated or gated; if

gated, the 2 gates may be independently set.

Almost any measurement can be made.

In addition, counter B has a preset mode called A

FOR B PRESET. In this mode, the input to

counter B is sent to counter T. The COUNT

PERIOD is now determined by the B

discriminator and the B gate. If R

is INPUT 1,

a

then counter A is source compensated by the gated

input of counter B. This allows source

compensation of gated signals and sources. If R

a

is

10 MHz, then counter A measures the reciprocal

of the rate of counter B's gated input.

OUTPUTS

The front panel can display counts up to 10

9

- 1.

Counters A and B can be displayed as separate

counters or combined as A-B or A+B. When A

FOR B PRESET is the count mode, then only A

data is displayed.

14

Page 17

Instrument Overview

The front panel D/A output provides an analog

output proportional to A, B, A-B, or A+B

depending on the counting mode. The scale may

be logarithmic (1V/decade) or linear to any 3

digits.

If a chart recorder is used, the D/A output should

drive the Y axis. The X axis can be recorder

driven (strip chart mode) or the PORT1 or PORT2

outputs can be used to drive the X axis (scans).

This latter method allows accurate determination

of the X value of each point. If the DWELL output

is used as the pen lift, the points will be

unconnected.

If count rates are high and count periods short,

then scans may be displayed on an X-Y scope. The

D/A output is the Y drive and PORT1 or PORT2

is the X drive. The DWELL output should be used

as the blanking pulse.

15

Page 18

Instrument Overview

16

Page 19

Measurement Examples

MEASUREMENT EXAMP L ES

Example 1: Internally Triggered Gate Mode

This example, described under the heading “QUICK TEST” on page 59 of this manual, is easy to perform and

will quickly acquaint the user with the basic operation of the SR400.

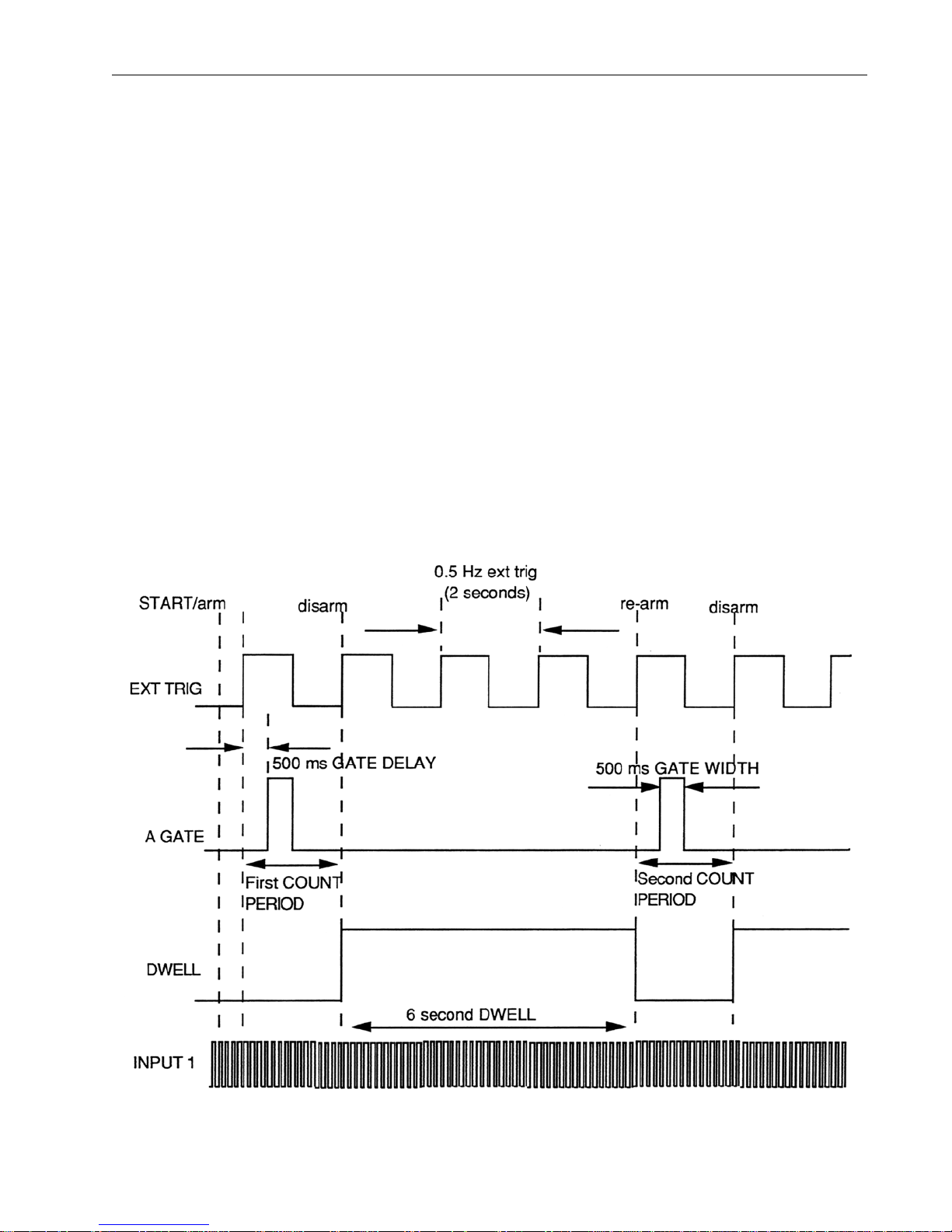

Example 2: Externally Triggered Gate Mode

In this example, the SR400 is programmed to make 10 counting measurements of a 10 kHz pulse train. For

each measurement, a gate will be delayed 500 ms from an external trigger pulse and will open of 500 ms

duration. Following the gate, there will be a 6 second dwell period* during which the counter will be

disarmed. After the dwell period, the counter will reset to 0 counts, re-arm and repeat the measurement. After

10 measurement cycles, the SR400 will stop counting and disarm. You will need a 10 kHz signal source and a

0.5 Hz square wave generator for this example.

*It is important to note that the dwell period begins at the first external trigger pulse arriving after the

gate is closed. Thus, even though there is only one gate opened for each measurement cycle, a minimum

of two external triggers are needed: one to trigger the gate and another to begin the dwell period.

The following timing diagram illustrates this example.

17

Page 20

Measurement Examples

1. Turn the SR400 off. Hold down the STOP (RESET) button while turning the SR400 on. Wait three seconds

and release the button.

2. Press the MODE key. Using the four arrow keys and the front panel knob, select the following parameters.

Unless otherwise indicated, leave all other settings at their default values:

T = TRIG TSET = 1E0

N PERIODS = 10 [AT 0]

AT N = STOP DWELL = 6E0 S

3. Press the A GATE key and select the following parameters:

A GATE = FIXED

A DELAY = 500 mS

A width = 500 mS

4. Press the LEVEL key and select the following parameters:

A DISC SLOPE = RISE

A DISC LVL = +150 mV

5. Using a function generator or a pulse generator, apply a 0.5 Hz, 5 V (TTL) signal to the TRIGGER INPUT

on the SR400.

6. Using a second signal source, apply a 10 kHz square wave (or pulse train) with an amplitude of

approximately 500 mV to the SIGNAL INPUT 1 on the SR400.

7. To view the COUNT PERIODS, press the MODE key and use the up/down arrow keys to display “N

PERIODS = 10 [at 0]”

Arm the counter by pressing the START button. (Alternatively, a TTL pulse applied to the START BNC on

the front panel will arm the counter.) Each measurement cycle should result in approximately 5,000 counts.

As an extension of the above example, the SR400 can be programmed to accumulate counts over numerous

gates. This is often done to improve the signal to noise ratio of low light level experiments. To accumulate

counts, set TSET (MODE menu) to the desired number of gates. For example, if you wish to accumulate over

five gates, set TSET – 5E0. In this case, six external triggers are required for each measurement cycle: five to

trigger the five gates and one to start the DWELL PERIOD. Any additional triggers received during the

DWELL PERIOD are ignored.

18

Page 21

Measurement Examples

Example 3: Externally Triggered Gate Mode

This example is a variation of Example 2, but requires no additional trigger pulses to begin the DWELL

PERIOD. In this example, the SR400 is programmed to make 10 counting measurements of a 10 kHz pulse

train. The counting gates, each 500 ms wide, are delayed 300 ms from external triggers arriving at a 1 Hz rate.

In this case, the SR400 requires only one trigger per COUNT PERIOD, however the trigger configuration is a

bit trickier than the previous example.

The following timing diagram illustrates this example.

To avoid the triggered dwell period, the T counter is logically ANDed with the A gate. This is accomplished

by letting the T counter count the SR400’s internal 10 MHz oscillator signal for a period extending our

beyond the A gate, but not exceeding the trigger repetition period (1 second in this case). Mathematically, this

is expressed:

A DELAY + A WIDTH < TSET < (1/Trigger Rate)

Furthermore, DWELL must be set to EXTERNAL in the MODE menu. This enables the SR400 to reset and

begin each COUNT PERIOD upon receiving a TTL pulse at the START BNC input.

19

Page 22

Measurement Examples

1. Turn the SR400 off. Hold down the STOP (RESET) button while turning the SR400 on. Wait three seconds

and release the button.

2. Press the MODE key. Using the four arrow keys and the front panel knob, select the following parameters.

Unless otherwise indicated, leave all other settings at their default values:

T = 10 MHz TSET = 9E -1 s

N PERIODS = 10 [AT 0]

AT N = STOP DWELL = EXTERNAL (Turn the knob counterclockwise until “DWELL = EXTERNAL” is

displayed.)

3. Press the A GATE key and select the following parameters:

A GATE = FIXED

A DELAY = 300 mS

A width = 500 mS

4. Press the LEVEL key and select the following parameters:

A DISC SLOPE = RISE

A DISC LVL = +150 mV

5. Using a function generator or a pulse generator, apply a 1 Hz, 5 V (TTL) signal to the EXTERNAL

START input on the SR400. Use a BNC ‘T; connector at the EXTERNAL START input and extend a cable

from the EXTERNAL START input to the TRIG input.

6. Using a second signal source, apply a 10 kHz square wave (or pulse train) with an amplitude of

approximately 500 mV to the SIGNAL INPUT 1 on the SR400.

7. To view the COUNT PERIODS, press the MODE key and use the up/down arrow keys to display “N

PERIODS = 10 [at 0]”

8. Arm the SR400 by pressing the STOP (RESET) button.

Each counting period should result in approximately 5,000 counts. After 10 counting measurements the

SR400 will disarm. To re-arm, press the STOP (RESET) button.

20

Page 23

Guide to Operation

GUIDE TO OPERATION

FRONT PANEL SUMMARY

POWER BUTTON

The SR400 is turned on by depressing the

POWER button. All instrument settings are stored

in nonvolatile memory and are retained when the

power is turned off. The model, firmware version,

and serial numbers of the unit will be displayed

briefly when the power is turned on. The recall

status is also dipslayed. If recall is OK, then the

instrument returned to the settings in effect when

the power was last turned off. If recall is ERR,

then the stored settings were lost and the default

settings are used. If recall is DEFAULT, then the

instrument is resetting to default conditions. This

is done if the STOP (RESET) key is held down

when the power is turned on. The default setup is

listed in the next chapter.

LIQUID CRYSTAL DISPLAY

The 2 line by 24 character LCD is the user

interface for data display and front panel

programming operations. The top line always

shows count data. The lower line is the menu line

and displays one line of setup information. The

LCD is backlit by an electroluminescent panel for

convenient operation in low light level conditions.

When in the SETUP menu, the contrast of the

LCD may be adjusted for optimum viewing.

MENU KEYS

All operating parameters of the SR400 are

grouped into six function menus. The six menu

keys select the group of functions to be

programmed. The four arrow keys select

individual parameters within each menu. The

selected parameter is displayed on the menu line

of the display.

The MODE menu selects the counting mode,

counter inputs, counter presets, scan mode and

length, dwell time, analog output, and display

mode. The LEVEL menu adjusts the

discriminator, trigger, and D/A levels. The A

GATE and B GATE menus program the gate

generators. The SETUP menu provides STORE

and RECALL of 9 different instrument setups and

adjustment of the LCD contrast. The COM menu

sets up the computer interface parameters and

displays received data. Detailed descriptions of the

menus are provided at the end of this section.

SPIN KNOB

All parameters are altered using the spin knob.

Whenever the menu line has an active or flashing

cursor, the displayed parameter can be adjusted

with the knob.

START, STOP, AND RESET

The two count keys, START and STOP, are used

to start, pause, and reset the counters.

A scan can be started only if the counters are in

the reset condition; all scanned parameters are at

their st art va lu es a nd the c ount er s ar e res et t o zero .

21

Page 24

Guide to Operation

In general, pressing the STOP key twice in

succession puts the counters into the reset

condition.

START begins the first COUNT PERIOD of the

programmed scan. If the DWELL time is

programmed, then the scan will continue

automatically. A STOP will pause the scan; the

current COUNT PERIOD is terminated and

ignored. A START while paused will resume the

scan. A STOP while paused resets the scan. If the

DWELL time is EXTERNAL, then a STOP during

the COUNT PERIOD terminates the COUNT

PERIOD and advances the scan. START begins

the next COUNT PERIOD i n the scan. A START

during a COUNT PERIOD or programmed

DWELL period is ignored.

A STOP while in a dwell period or pause resets

the scan; all scanned parameters return to their

start values and the counters are reset. In general,

2 consecutive presses of the STOP key will reset

the counters.

The SCAN led is on when a scan is in progress.

The SCAN led is off when the scan is paused or

the counters are reset.

INSTRUMENT STATUS

Six LED's indicate the instrument status. REM is

on when the front panel is locked out, ACT flashes

when there is activity on the computer interfaces,

and ERR flashes when there is a computer

interface error. COUNT is on during each COUNT

PERIOD, OVRN indicates that a counter has

exceeded 10

9

- 1 counts during a COUNT

PERIOD, and RATE flashes whenever a gate

delay or width exceeds the trigger period minus

1 µs. The RATE led also flashes if the trigger rate

exceeds 1 MHz, even if the gates are in the CW

mode.

COUNTER LED'S

The source LED's in the counter sections indicate

what each counter's input is. The counter inputs

are output through the DISC outputs. The SET

LED's indicate which counter, B or T, is the preset

counter. The B SET LED is on when the mode is

A FOR B PRESET, the T SET LED is on

otherwise.

INPUTS

The rising or falling edge of the TRIGGER input

triggers the gate generators. The input impedance

is 10 KΩ and the minimum pulse width is 10 ns.

The trigger level is adjustable from -2V to +2V

with either slope. The minimum pulse amplitude is

0.1 V.

The SIGNAL INPUTS, 1 and 2, are 50 Ω analog

inputs. Photomultiplier or preamplifier outputs are

connected to these inputs. These inputs are linear

between -300 mV to +300 mV and protected to

± 5 Vdc.

EXTERNAL START is a TTL input with the

rising edge active. The minimum pulse width is 20

ns. When the DWELL time is EXTERNAL, the

COUNT PERIOD begins with the rising edge of

START and ends with the preset condition or the

rising edge of STOP. When the DWELL time is

programmed, EXT START begins the scan.

EXTERNAL STOP is a TTL input with the rising

edge active. The minimum pulse width is 20 ns.

When the DWELL time is EXTERNAL, EXT

STOP ends each count period. Reset must be

accomplished via the STOP key or computer

interface. When the DWELL time is programmed,

EXT STOP resets the scan.

OUTPUTS

The DISC outputs are 50 Ω, NIM level, outputs

showing the actual inputs to the three counters.

These outputs are active low (-.7 V) and counting

occurs on the falling edge. The outputs are low

when the signal inputs exceed their threshold

levels with the correct slope.

Cables attached to the DISC outputs should be

kept far from the cables which carry the SIGNAL

inputs. The 0.7 V DISC pulses can be picked up

by the SIGNAL cables and discriminated. This

causes the discriminators to oscillate. This is not a

problem if the threshold is greater than 10 mV. If

smaller thresholds are required, careful

arrangement of the cables is necessary, or the

22

Page 25

Guide to Operation

DISC output should just be terminated at the front

panel.

The GATE outputs are 50 Ω, NIM level, outputs

showing the actual gates to counters A and B. The

GATE outputs are low (-.7 V) during the gate. The

timing accuracy between the GATE outputs and

DISC outputs is 2 ns.

The D/A analog output provides a -10V to +10V

output proportional to the count data with linear or

logarithmic scaling. Output impedance is < 1 Ω

and the maximum current output is 10 mA.

The DWELL output is a TTL level output which is

high whenever the counters are paused. The rising

edge may be used to trigger changes in external

parameters or data acquisition.

23

Page 26

Guide to Operation

REAR PANEL SUMMARY

POWER ENTRY MODULE

The power entry module is used to fuse the line,

select the line voltage, and block high frequency

noise from entering or exiting the instrument.

Refer to the first page of this manual for

instructions on selecting the correct line voltage

and fuse.

IEEE-488 STD PORT

The 24 pin IEEE-488 connector allows a computer

to control the SR400 via the IEEE-488 or GPIB

instrument bus. The address of the instrument is

set from the front panel using the COM menu.

RS-232 CONNECTOR

The RS-232 interface connector is configured as a

DCE. The baud rate, parity, character length, and

echo mode are programmed from the front panel

using the COM menu.

INPUT

INHIBIT is a TTL input which disables the A,B,

and Tdiscriminators when it is high. The minimum

pulse width is 10 ns.

OUTPUT

The PORT1 and PORT2 D/A analog outputs

provide -10 V to +10V, user programmable

outputs. The outputs may be scanned to drive the

X axis of a recorder or scope during scans. Output

impedance is < 1 Ω and the maximum current

output is 10 mA.

24

Page 27

Guide to Operation - Menus

FRONT PANEL MENUS

The lower line of the LCD display is the menu

line. Menu lines are grouped into six menus. To

select a new group or menu, press a new menu

key. The menu line that will be displayed is the

most recently active menu line of the new menu.

Each menu contains several lines. Each line may

consist of 1 or 2 displayed parameters. The

DOWN and UP keys change which menu line

within a menu will be displayed. The DOWN key

displays the next menu line and the UP key, the

previous line. Pressing either key many times in

succession will scroll through all of the menu lines

within a menu.

If the menu line contains two parameters, the

LEFT and RIGHT keys select between the two.

On some lines, the right hand parameter is active

only for certain values of other parameters. On

these lines, the right hand parameter may be

inactive.

The spin knob is used to modify the active

parameter. A flashing cursor precedes the value

which the knob will alter.

The following section details each menu line. The

lines are listed in the order in which the DOWN

key scrolls through each menu. For parameters

with limited choices, all selections are shown. For

numerical parameters, example values are shown.

MODE MENU

COUNT= A,B FOR T PRESET

A-B FOR T PRESET

A+B FOR T PRESET

A FOR B PRESET

This line selects the data display and the preset

counter. The upper line of the LCD is the count

display. There are four displays available; A and B

separately, A-B, A+B, or only A, depending upon

the COUNT selection. All count data is right

justified with leading zeroes off. The preset

counter is either T or B. The appropriate SET LED

will be on indicating which counter is preset. Note

that the choice of inputs to the counters determines

whether the count data measures rate, ratio, or

reciprocal.

Changing this line causes the counters to reset.

A= INPUT 1

10 MHz

The input to counter A can be either the internal

10 MHz timebase or the signal at INPUT 1

discriminated by the A discriminator. The selected

counter input can be viewed at the A DISC output.

The 10 MHz source is used for reciprocal

measurements or for quick testing of the counter

operation. The appropriate A counter source LED

is also lit.

Changing this line during a COUNT PERIOD may

result in a bad data point.

B= INPUT 2 BSET= ****

INPUT 1 1E0

9E11

The input to counter B can be either the signal at

INPUT 1 or INPUT 2 discriminated by the B

discriminator. The selected counter input can be

viewed at the B DISC output. The appropriate B

counter source LED is lit. Changing the counter

input during a COUNT PERIOD may result in a

bad data point.

If counter T is preset, the B SET parameter is

inactive (indicated by the **** on the display). If

counter B is preset (ratio or reciprocal

measurement), B SET is the B preset count from

1E0 to 9E11. Changing B SET during a scan

causes the counters to pause; any COUNT

PERIOD in progress is terminated and ignored. A

START begins the next COUNT PERIOD with

the new preset value.

T= 10 MHz TSET= 1E0 s

INPUT 2 1E7

TRIG 1E3

****

25

Page 28

Guide to Operation - Menus

The input to counter T can be the internal 10 MHz

timebase (rate measurement), the signal at INPUT

2 discriminated by T discriminator (ratio or

reciprocal measurement), or the TRIGGER input

discriminated by the trigger discriminator

(constant gate aperture). The selected counter

input can be viewed at the T DISC output. The

appropriate T counter source LED is lit.

If counter B is preset, this line is inactive

(indicated by the **** on the display). If counter T

is preset, both parameters on this line are active. T

SET is the preset value of counter T from 1E0 to

9E11. If the T input is 10 MHz, then T SET is

displayed as real time = T SET cycles of 10 MHz.

ChangingT SET during a scan causes the counters

to pause; any COUNT PERIOD in progress is

terminated and ignored. A START begins the next

COUNT PERIOD with the new preset value.

N PERIODS=2000 [at 1234]

This line programs the number of COUNT

PERIODS in one scan from 1 to 2000. N

PERIODS determines the length of the internal

data buffer and the range of any scanned

parameters. The quantity in brackets is the number

of completed COUNT PERIODS in the current

scan.

Changing N PERIODS during a scan changes the

length of the current scan. Reducing N PERIODS

past the current scan position will cause an end of

scan condition.

AT N= STOP DWELL= 1E0 s

START 2E-3 s

EXTERNAL

This line sets the end of scan mode and the

DWELL time. When a scan reaches N PERIODS,

the counters may be paused or restarted. AT

N=STOP causes an end of scan pause. All scanned

parameters are held at their final values. A counter

reset is required before another scan can begin. If

N PERIODS is 1, then each START results in one

COUNT PERIOD. If N PERIODS is gre ater than

1, then consecutive COUNT PERIODS are

separated by the DWELL time. During the

DWELL time, counting is disabled and scanned

parameters updated. The DWELL OUTPUT is

TTL high during the DWELL time.

If AT N=START, the counters will wait one

DWELL time at the end of each scan, during

which all scanned parameters return to their start

positions, and then another scan begins. This is

used for continuous data taking with the

measurement rate determined by the COUNT

PERIOD plus the DWELL TIME.

The DWELL time may be programmed from 2E-3

s to 6E1 s (1 minute) or set to EXTERNAL. The

internal DWELL time is based on the 10 MHz

timebase and may have 200 ns of indeterminacy.

Changing the DWELL time during a scan causes

the counters to pause; any COUNT PERIOD in

progress is terminated and ignored.

Setting the DWELL time below 2E-3 s results in

an EXTERNAL dwell. In this mode, the START

key, EXT START, or remote start command starts

the COUNT PERIOD. The COUNT PERIOD las t s

until the preset condition is reached. The following

DWELL time is indefinite; the next COUNT

PERIOD begins with another START. A STOP

key, EXT STOP, or remote stop command during

the COUNT PERIOD terminates the COUNT

PERIOD. Thus by programming the preset

COUNT PERIOD much longer than required, the

COUNT PERIOD may be determin ed by START

and STOP. Scanning proceeds as normal.

NOTE: If AT N=STOP, the counters will pause at

the end of a scan. A reset (STOP key, EXT STOP,

or remote reset command) is required to rearm the

counters before another scan can begin. In general,

to reset the counters at any time, the STOP ke y is

pressed twice in succession.

D/A= A

B

A+B

A-B

The D/A output is proportional to the count data

on the top line of the LCD. When the COUNT is

A-B, A+B, or A only, the D/A output can only

follow the data display. In these modes, the cursor

is inactive and the knob does nothing. If the

26

Page 29

Guide to Operation - Menus

COUNT is A,B FOR T PRESET, then the D/A

output can follow either A or B.

D/A RANGE= LOG

##765####

The D/A output scale can be either logarithmic or

linear. If the output is logarithmic, the scale is 1V

per decade with 1 count being 0V, 0 counts being 1V, and negative counts being -2V. If the scale is

linear, the output is proportional to 3 digits of the

count. These digits are shown while the ignored

digits are represented by #'s.

The D/A output is updated at the end of each

COUNT PERIOD. If the D/A output is driving a

chart recorder, the end of scan mode should be

STOP or the pen reset will mar the graph. If the

DWELL output is connected to the recorder pen

lift, data will be plotted as unconnected points,

otherwise, the discrete points will be connected.

DISPLAY= CONTINUOUS

HOLD

The count data on the upper line of the LCD can

be updated in two ways. CONTINUOUS mode

updates the display 20 times a second during the

COUNT PERIOD. Data is held during the

DWELL time at the final value reached during the

previous COUNT PERIOD. HOLD updates the

display only at the end of each COUNT PERIOD.

CONTINUOUS is useful when COUNT

PERIODS are long, HOLD is better when

COUNT PERIODS are short.

LEVEL MENU

TRIG SLOPE= RISE

FALL

The gate generator may be triggered on either the

rising or falling edge of the TRIGGER input.

TRIG LVL=+2.000 V

The gate TRIGGER threshold level may be

adjusted from -2.000 V to +2.000V. The

discriminated trigger pulses may be viewed

through the T DISC output when counter T is

preset and its input is TRIG. This can be helpful in

selecting a trigger level. The minimum pulse

amplitude required to trigger is 100 mV.

A DISC SLOPE= RISE

FALL

When A counter's input is INPUT 1, A

discriminator may be triggered by rising or falling

edges of the INPUT 1 signal. If the signal pulses

are negative going, then the slope should be

FALL. If the signal pulses are positive, then the

slope should be RISE. In either case, the A DISC

output is always active low; i.e., a discriminated

rising edge of the signal will be output as a

negative going NIM pulse at the A DISC output.

The falling edges of the A DISC output are

counted by counter A.

A DISC= FIXED

SCAN ∆= -1.0 mV

The threshold level of A discriminator may be

FIXED or SCANned. If the level is fixed, the right

hand parameter is not displayed. If the level is

scanned, then the right hand parameter is the step

size. At the end of each count period in a scan, the

level is incremented by one step size. The step size

can be varied from -20.0 mV to + 20.0 mV. The

range of a scan is N PERIODS times the step size.

The starting level is set in the next menu line.

The scan mode may be changed during a scan. If it

is changed to SCAN, the level begins scanning

from the start value on the next count period. If it

is changed to FIXED, the level returns to the start

level immediately.

The step size may also be changed during a scan.

The new step size will be in effect at the end of the

next count period. The scan is not reset or paused.

A DISC LVL = -10.0 mV

: -11.0 mV

The threshold level of A discriminator may be

adjusted from -300 mV to + 300 mV. This level is

27

Page 30

Guide to Operation - Menus

the fixed threshold when A DISC is FIXED and

the starting level when A DISC is SCANned.

When the A DISC mode is SCAN and a scan is in

progress, this line displays the current position of

the A DISC level. The cursor is inactive and

replaced by a ':'. The spin knob cannot adjust the

threshold while it is scanning. When the mode is

SCAN, the starting level may only be adjusted

when the counters are in reset.

B DISC SLOPE= RISE

FALL

B discriminator may be triggered by rising or

falling edges of the INPUT 1 or INPUT 2 signal.

If the signal pulses are negative going, then the

slope should be FALL. If the signal pulses are

positive, then the slope should be RISE. In either

case, the B DISC output is always active low; i.e.,

a discriminated rising edge of the signal will be

output as a negative going NIM pulse at the B

DISC output. The falling edges of the B DISC

output are counted by counter B.

B DISC= FIXED

SCAN ∆= -1.0 mV

The threshold level of B discriminator may be

FIXED or SCANned. If the level is FIXED, the

right hand parameter is not displayed. If the level

is scanned, then the right hand parameter is the

step size. At the end of each count period in a

scan, the level is incremented by one step size.

The step size can be varied from -20.0 mV to +

20.0 mV. The range of a scan is N PERIODS

times the step size. The starting level is set in the

next menu line.

The scan mode may be changed during a scan. If it

is changed to SCAN, the level begins scanning

from the start value on the next count period. If it

is changed to FIXED, the level returns to the start

level immediately.

The step size may also be changed during a scan.

The new step size will be in effect at the end of the

next count period. The scan is not reset or paused.

B DISC LVL = -10.0 mV

: -11.0 mV

The threshold level of B discriminator may be

adjusted from -300 mV to + 300 mV. This level is

the fixed threshold when B DISC is FIXED and

the starting level when B DISC is SCANned.

When the B DISC mode is SCAN and a scan is in

progress, this line displays the current position of

the B DISC level. The cursor is inactive and

replaced by a ':'. The spin knob cannot adjust the

threshold while it is scanning. When the mode is

SCAN, the starting level may only be adjusted

when the counters are in reset.

T DISC SLOPE= RISE

FALL

When T counter's input is INPUT 2, T

discriminator may be triggered by rising or falling

edges of the INPUT 2 signal. If the signal pulses

are negative going, then the slope should be

FALL. If the signal pulses are positive, then the

slope should be RISE. In either case, the T DISC

output is always active low; i.e., a discriminated

rising edge of the signal will be output as a

negative going NIM pulse at the T DISC output.

The falling edges of the T DISC output are

counted by counter T.

T DISC= FIXED

SCAN ∆= -1.0 mV

The threshold level of T discriminator may be

FIXED or SCANned. If the level is FIXED the

right ha nd parameter is not displayed. If the level

is scanned, then the right hand parameter is the

step size. At the end of each count period in a

scan, the level is incremented by one step size.

The step size can be varied from -20.0 mV to +

20.0 mV. The range of a scan is N PERIODS

times the step size. The starting level is set in the

next menu line.

The scan mode may be changed during a scan. If it

is changed to SCAN, the level begins scanning

from the start value on the next count period. If it

is changed to FIXED, the level returns to the start

level immediately.

28

Page 31

Guide to Operation - Menus

The step size may also be changed during a scan.

The new step size will be in effect at the end of the

next count period. The scan is not reset or paused.

T DISC LVL = -10.0 mV

: -11.0 mV

The threshold level of T discriminator may be

adjusted from -300 mV to + 300 mV. This level is

the fixed threshold when T DISC is FIXED and

the starting level when T DISC is SCANned.

When the T DISC mode is SCAN and a scan is in

progress, this line displays the current position of

the T DISC level. The cursor is inactive and

replaced by a ':'. The spin knob cannot adjust the

threshold while it is scanning. When the mode is

SCAN, the starting level may only be adjusted

when the counters are in reset.

PORT1= FIXED

SCAN ∆=+0.100 V

The level of the rear panel PORT1 output may be

FIXED or SCANned. If the level is scanned, then

the right hand parameter is the step size. At the

end of each count period in a scan, the level is

incremented by one step size. The step size can be

varied from -0.500 V to +0.500 V. The range of a

scan is N PERIODS times the step size. The

starting level is set in the next menu line.

The scan mode may be changed during a scan. If it

is changed to SCAN, the level begins scanning

from the start value on the next count period. If it

is changed to FIXED, the level returns to the start

level immediately.

The step size may also be changed during a scan.

The new step size will be in effect at the end of the

next count period. The scan is not reset or paused.

PORT1 = +0.500 V

: +0.600 V

The level of the rear panel PORT1 output may be

adjusted from -10 V to +10 V. This level is the

fixed output when PORT1 is FIXED and the

starting level when PORT1 is SCANned.

When the PORT1 mode is SCAN and a scan is in

progress, this line displays the current position of

the PORT1 level. The cursor is inactive and

replaced by a ':'. The spin knob cannot adjust the

level while it is scanning. When the mode is

SCAN, the starting level may only be adjusted

when the counters are in reset.

PORT2= FIXED

SCAN ∆=+0.100 V

The level of the rear panel PORT2 output may be

FIXED or SCANned. If the level is scanned, then

the right hand parameter is the step size. At the

end of each count period in a scan, the level is

incremented by one step size. The step size can be

varied from -0.500 V to +0.500 V. The range of a

scan is N PERIODS times the step size. The

starting level is set in the next menu line.

The scan mode may be changed during a scan. If it

is changed to SCAN, the level begins scanning

from the start value on the next count period. If it

is changed to FIXED, the level returns to the start

level immediately.

The step size may also be changed during a scan.

The new step size will be in effect at the end of the

next count period. The scan is not reset or paused.

PORT2 = +0.500 V

: +0.600 V

The level of the rear panel PORT2 output may be

adjusted from -10 V to +10 V. This level is the

fixed output when PORT2 is FIXED and the

starting level when PORT2 is SCANned.

When the PORT2 mode is SCAN and a scan is in

progress, this line displays the current position of

the PORT2 level. The cursor is inactive and

replaced by a ':'. The spin knob cannot adjust the

level while it is scanning. When the mode is

SCAN, the starting level may only be adjusted

when the counters are in reset.

29

Page 32

Guide to Operation - Menus

GATE MENUS

The A GATE and B GATE are identical in

operation. The discussion below describes the A

GATE menu. The B GATE menu is similar, the

only difference being that A GATE enables A

counter and B GATE enables B counter.

In order to provide 1 part in 1000 settability, gate

delay, width, and scan step times have variable

resolution depending upon the 4 most significant

digits of the time .

4 most significant digits resolution in 4th digit

1000 to 2048 1 (1001, 1002, 1003, ...)

2048 to 4096 2 (2048, 2050, 2052, ...)

4096 to 8192 4 (4096, 4100, 4104, ...)

8192 to 9992 8 (8192, 8200, 8208, ...)

Below 1.000 µs, the resolution is 1 ns.

For example, near 10.00 µs, the allowed times are

9.984 µs, 9.992 µs, 10.00 µs, 10.01 µs, etc. In each

case, the resolution is 1 part in 1000 or better.

Note that gates may be missed or truncated while

gate delays or widths are changed. Changing gate

parameters while counting may therefore cause

bad data to be collected. While scanning, all

changes to the gate delay are made during the

dwell time and do not affect the count data. The

GATE outputs may show missed gates during the

dwell time.

A GATE= CW

FIXED

SCAN ∆=1.000 µs

The A gate enables the A counter in three modes.

CW is continuous gating; counter A is enabled

during the entire count period. FIXED delay and

width enables the counter only during those gates

which occur during the count period. SCANning

increments the gate delay between count periods

during a scan.

The gate may be viewed through the A GATE

output. The counter is enabled when the output is

NIM low. If the mode is CW, the output is always

low, otherwise, it is low only during the gate.

If the gate delay is scanned, then the right hand

parameter is the step size. At the end of each count

period in a scan, the delay is incremented by one

step size. The step size can be varied from 0 to

99.92 ms. The range of a scan is N PERIODS

times the step size. The starting value of the delay

is set in the next menu line.

The scan mode may be changed during a scan. If it

is changed to SCAN, the delay begins scanning

from the start position on the next count period. If

it is changed to FIXED, the delay returns to the

start position immediately.

The step size may also be changed during a scan.

The new step size will be in effect at the end of the

next count period. The scan is not reset or paused.

A DELAY =****

=1.000 µs

: 2.000 µs

This line is inactive if the A GATE is CW. Even

when this is the case, the RATE LED will flash if

the trigger frequency exceeds 1 MHz.

If the A GATE mode is FIXED or SCAN, then the

delay of A GATE from trigger may be adjusted

from 0 to 999.2 ms. This is in addition to the fixed

25 ns insertion delay. This delay is the fixed delay

when A GATE is FIXED and the starting delay

when A GATE is SCANned.

The delay can be as long as the time between

triggers minus 1 µs. This is independent of the

gate width. Delays longer than the trigger period

minus 1 µs will result in missed gates and the

RATE led will flash.

When the A GATE mode is SCAN and a scan is in

progress, this line displays the current position of

the A GATE delay. The cursor is inactive and

replaced by a ':'. The spin knob cannot adjust the

delay while it is scanning. When the mode is

SCAN, the starting delay may only be adjusted

when the counters are in reset.

Because of the variable resolution of the delay, the

scan step may be less than the resolution of the

current delay. In this case, the delay is

incremented every n count periods where n is the

30

Page 33

Guide to Operation - Menus

number of scan steps needed to exceed the

resolution. In all cases, the delay only steps from

one allowed value to another and is as close to the

desired value as will be allowed by the resolution.

A WIDTH= ****

1.000 µs

This line is inactive if A GATE is CW. Even when

this is the case, the RATE LED will flash if the

trigger frequency exceeds 1 MHz.

If the A GATE mode is FIXED or SCAN, then the

width of A GATE may be adjusted from 0.005 µs

to 999.2 ms. The width can be as long as the time

between triggers minus 1 µs. This is independent

of the gate delay. Widths longer than the trigger

period minus 1 µs will result in missed gates and

the RATE led will flash. This allows gates from

one trigger to overlap the next trigger. When used

with a light chopper reference as the trigger, the

phase of the gates may be adjusted over nearly

360°.

B GATE= CW

FIXED

SCAN ∆=1.000 µs

See A GATE menu above.

B DELAY =1.000 µs

: 2.000 µs

See A DELAY menu above.

B width =1.000 µs

See A WIDTH menu above.

SETUP MENU

LCD CONTRAST=12

The LCD contrast may be adjusted for optimum

viewing. Larger values increase the contrast.

STORE=3 EXECUTE=>

9 instrument setups may be stored. Parameters in

the SETUP and COM menus are not stored by this

command. SETUP and COM parameters are

stored on power down as part of the current setup

only.

Use the spin knob to select a storage location, 1

through 9. The right arrow key will store the setup.

RECALL=3 EXECUTE=>

9 user stored instrument setups and 1 default setup

may be recalled. User locations 1 through 9 and

DEFault are the setups available. Parameters in the

SETUP and COM menus are not altered by this

command.

Use the spin knob to select a storage location, 1

through 9 or DEFault. The right arrow key will

recall the setup.

COM MENU

Communication parameters in this menu should

not be altered while the computer interface is

active. Changing any line except for DATA will

reset the computer interfaces and communication

buffers. Data in this menu is retained on power

down as part of the current setup.

GPIB ADDR=23

The instrument's GPIB address can set from 1 to

30.

RS-232 BAUD= 19200

9600

..

300

The instrument's RS-232 baud rate can be set to

any standard value from 300 to 19200 baud.

RS-232 BITS= 8

7

The RS-232 character length can be 7 or 8 bits. 8

bits is standard.

31

Page 34

Guide to Operation - Menus

RS-232 PARITY= NONE

EVEN

ODD

The RS-232 parity can be even, odd, or none.

RS-232 WAIT=6

The SR400 can be programmed to wait between

each character it sends over the RS-232 interface.

This is to accommodate computers with slow

computer interfaces. The wait interval is

programmed in units of 3.3 ms and can be set from

0 to 25. The default value is 6 and should be set to

a smaller value whenever possible.

RS-232 ECHO= OFF

ON

To control the SR400 from a terminal, the ECHO

feature is turned ON. This causes the unit to echo

back commands received over the RS-232 port. In

this mode, the SR400 will send line-feeds in

addition to carriage returns with each value

returned and will also send the prompts 'OK>' and

'??>' to indicate that the previous command was

either processed correctly or contained an error.

When controlling the SR400 from a computer, the

ECHO feature should be turned OFF.

DATA=

This line is the data window. The last 254

characters received over the computer interface

can be played back to help find errors. The spin

knob scrolls forward and backward through the

window. Unrecognized control characters are

displayed as 'cc'. Carriage return and line-feed are

shown as 'cr' and 'lf'.

The window always returns to the most recent data

whenever this line is first displayed or a new

character is received. Changing any COM

parameters clears the communication buffers and

clears this window.

32

Page 35

Instrument Setups

INSTRUMENT SETUPS

The SR400 Photon Counter is a very flexible

instrument capable of many modes of operation.

This section illustrates some of the measurements

that can be made.

DEFAULT SETUP / POWER ON CLEAR

If the STOP key is held down when the power is

turned on, the instrument settings will be set to the

defaults shown below instead of the settings in

effect when the power was turned off.

Menu Line Setting

COUNT= A,B FOR T PRESET

A= INPUT 1

B= INPUT 2

B SET= 1E3 (inactive)

T= 10 MHz

T SET= 1E0 s (1E7 counts)

N PERIODS= 1

AT N= STOP

DWELL= 1E0 s

D/A= A

D/A RANGE= LOG

DISPLAY= CONTINUOUS

TRIG SLOPE= RISE

TRIG LVL= +2.000 V

A DISC SLOPE= FALL

A DISC= FIXED (∆=+ 0.0 mV)

A DISC LVL= - 10.0 mV

B DISC SLOPE= FALL

B DISC= FIXED (∆=+ 0.0 mV)

B DISC LVL= - 10.0 mV

T DISC SLOPE= FALL

T DISC= FIXED (∆=+ 0.0 mV)

T DISC LVL= - 10.0 mV

PORT1= FIXED (∆=+ 0.000 V)

PORT1 LVL= + 0.000 V

PORT2= FIXED (∆=+ 0.000 V)

PORT2 LVL= + 0.000 V

A GATE= CW (∆=0.000 µs)

A DELAY= 0.000 µs

A WIDTH= 0.005 µs

B GATE= CW (∆=0.000 µs)

B DELAY= 0.000 µs

B WIDTH= 0.005 µs

LCD CONTRAST= 12

STORE= 1

RECALL= DEF

GPIB ADDR= 23

RS-232 BAUD= 9600

RS-232 BITS= 8

RS-232 PARITY= NONE

RS-232 WAIT= 6

RS-232 ECHO= OFF

In addition, the RS-232 te rmination sequence will

be set to a carriage return and the GPIB SRQ mask

reset to zero.

If the message RECALL ERROR is displayed on

power up without the STOP being held down, then

the instrument is ignoring the setup retained in

memory. This can be due to a low battery. In this

case, the instrument returns to the default setup.

The default setup may also be recalled using the

RECALL menu line or via the remote CL

command or a GPIB DCL or SDC command. In

these cases, the SETUP and COM menus are not

affected.

QUICK CHECK

Unplug all cables from the unit and recall the

default setup by holding the STOP key down

while turning the unit on. The message RECALL

DEFAULT should appear on the display for ~3 s.

Press the DOWN key once to go to the A=INPUT

1 menu line. Rotate the knob until A=10 MHz

appears on the menu line. To start a count period,

press the START key once. The data display

should show counting in counter A for 1 second