Page 1

Version 4.2 (May 14, 2019)

User Manual

PTC10

Programmable Temperature Controller

Page 2

PTC10 Programmable Temperature Controller

Certification

Stanford Research Systems certifies that this product met its published specifications at the time of shipment.

Warranty

This Stanford Research Systems product is warranted against defects in materials and workmanship for a period of

one (1) year from the date of shipment.

Service

For warranty service or repair, this product must be returned to a Stanford Research Systems authorized service

facility. Contact Stanford Research Systems or an authorized representative before returning this product for repair.

Information in this document is subject to change without notice.

Copyright © Stanford Research Systems, Inc., 2018. All rights reserved.

Stanford Research Systems, Inc.

1290-C Reamwood Avenue

Sunnyvale, California 94089

Phone: (408) 744-9040

Fax: (408) 744-9049

www.thinkSRS.com

Printed in the USA

Page 3

Contents i

PTC10 Programmable Temperature Controller

Contents

Safety and preparation for use....................................................................................... v

Specifications .................................................................................................................. vii

Introduction 1

I/O cards ............................................................................................................................ 2

PTC320 thermistor/diode/RTD card .................................................................................... 2

PTC321 RTD reader ................................................................................................................ 5

PTC323 2-channel thermistor/diode/RTD card ................................................................... 6

PTC330 thermocouple reader .............................................................................................. 11

PTC420 AC output card........................................................................................................ 13

PTC430 50 W DC output card ............................................................................................. 14

PTC431 100W DC output card ............................................................................................ 15

PTC440 TEC driver ............................................................................................................... 17

PTC510 analog I/O card ....................................................................................................... 20

PTC520 digital I/O card ........................................................................................................ 20

Operation 23

Quick start tutorial ........................................................................................................ 24

Turn the instrument on .......................................................................................................... 24

The Select screen ................................................................................................................... 24

Configure the sensor inputs ................................................................................................... 24

If the sensor reading does not appear ................................................................................... 25

Plot data .................................................................................................................................. 25

Test the outputs ..................................................................................................................... 26

Set the data logging rate ......................................................................................................... 27

Save data to and retrieve data from a USB memory device ................................................ 27

Interface with a computer ...................................................................................................... 28

Control a temperature........................................................................................................... 29

Acquiring and logging data ........................................................................................... 36

Input filters .............................................................................................................................. 36

Custom calibration tables ...................................................................................................... 36

Virtual channels ...................................................................................................................... 38

Logging data to internal memory ........................................................................................... 39

Logging data to USB ............................................................................................................... 39

ADC sampling and logged data ............................................................................................. 39

Format of PTC10 log files ...................................................................................................... 40

Using the system fan ..................................................................................................... 41

Using PID feedback ........................................................................................................ 42

...................................................................... 42

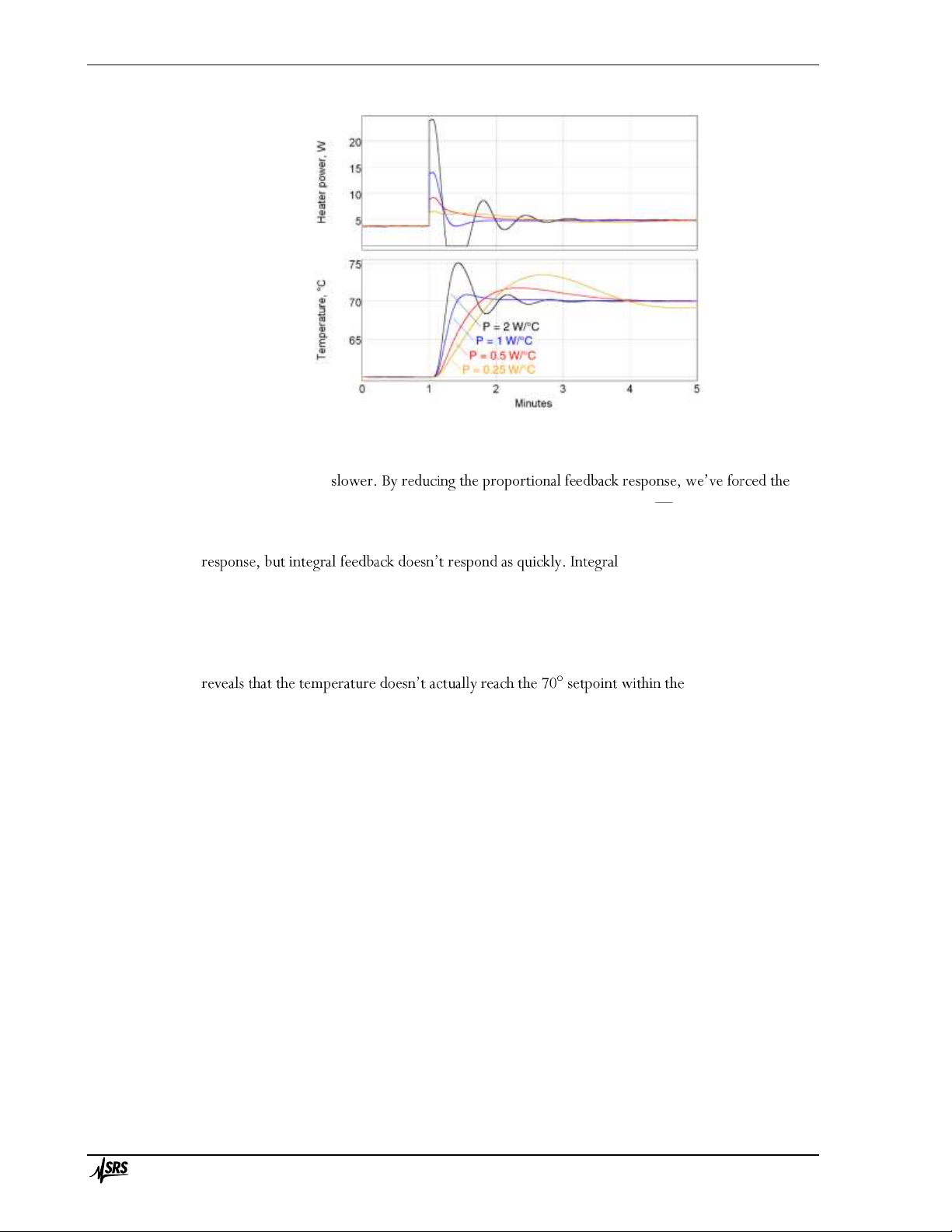

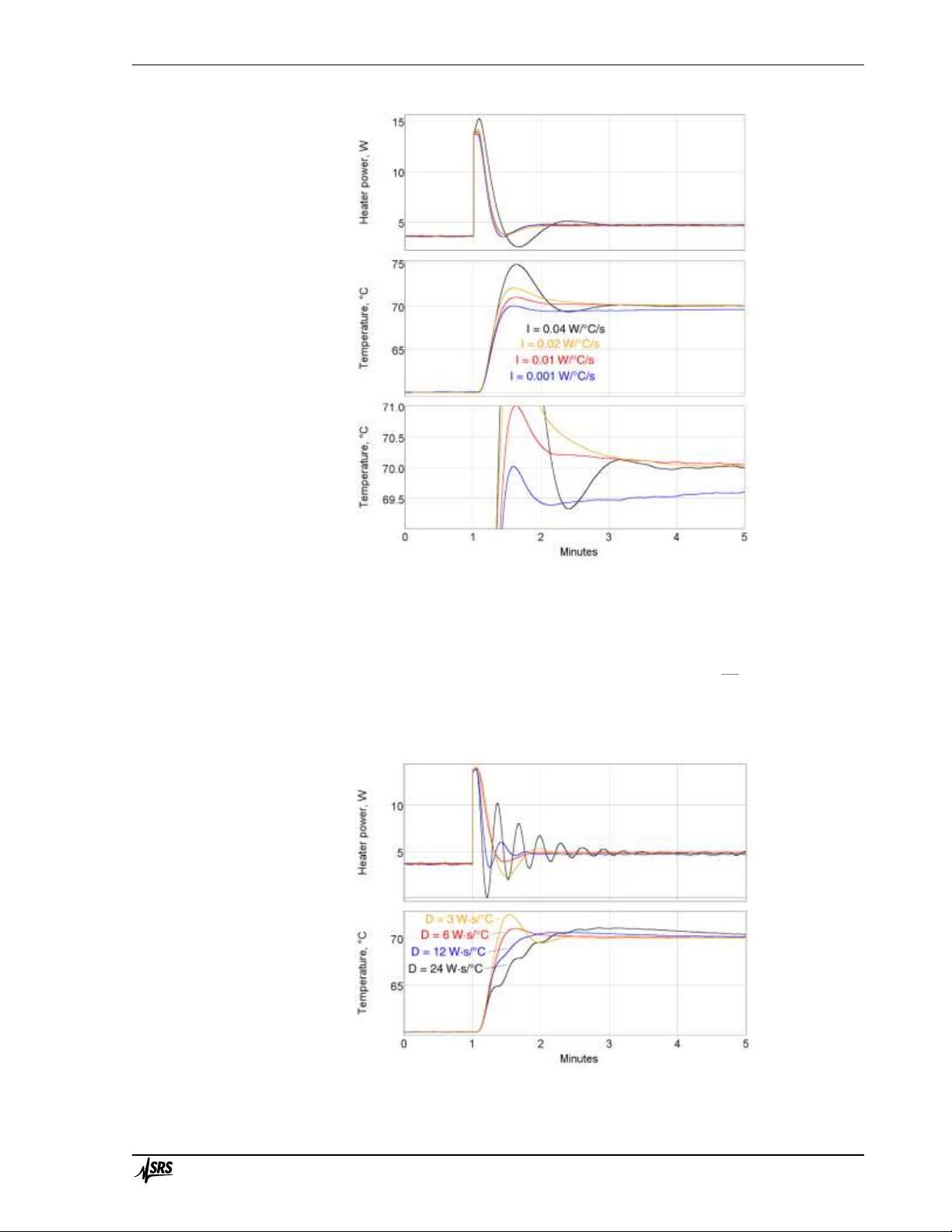

Basic PID feedback concepts ................................................................................................. 42

Manual tuning .......................................................................................................................... 43

Automatic tuning algorithms .................................................................................................. 46

Using the automatic tuner...................................................................................................... 49

Front-panel controls ................................................................................................ ...... 52

Page 4

Contents ii

PTC10 Programmable Temperature Controller

USB logging indicator ............................................................................................................. 52

.............................................................................................................................. 52

.............................................................................................................. 52

....................................................................................................................... 53

.................................................................................................................. 54

........................................................................................................................... 54

................................................................................................................... 59

................................................................................................................... 64

..................................................................................................................... 78

Firm ware updates .......................................................................................................... 85

Replacing the clock battery .......................................................................................... 86

Remote programm ing 87

Connecting to the PTC10 ...................................................................................................... 87

Communication, assembly, and run-time errors .................................................................. 90

Concurrent macros ................................................................................................................ 90

Macro names .......................................................................................................................... 91

Command syntax ................................................................................................................... 91

Rem ote instructions ...................................................................................................... 95

General instructions ............................................................................................................... 95

IEEE 488.2 Instructions ........................................................................................................... 99

Program submenu ................................................................................................................ 103

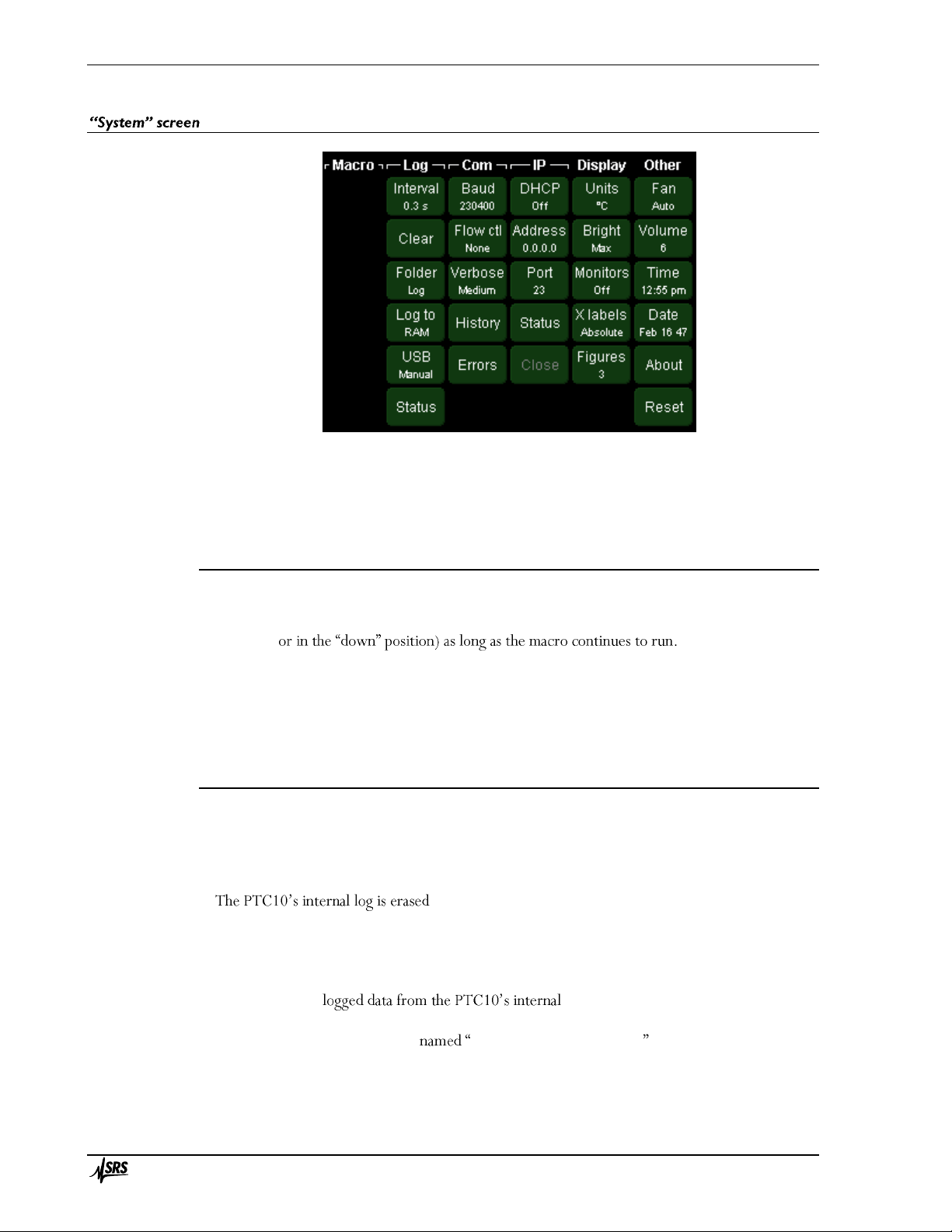

System submenu ................................................................................................................... 106

<channel> submenu ............................................................................................................ 110

Error codes ........................................................................................................................... 121

Startup macro ....................................................................................................................... 122

Sam ple m acros ............................................................................................................. 123

Temperature profiles ........................................................................................................... 123

Control a feedback setpoint with an analog input .............................................................. 124

PID input scheduling ............................................................................................................. 124

Show channels with tripped alarms on the Numeric screen ............................................. 125

Make a virtual channel show the PID setpoint ................................................................ .... 125

Linearizing outputs when interfacing with external power supplies .................................. 125

Control instrument functions with the digital IO lines ....................................................... 126

Drive a solid state relay with the digital IO lines ................................................................. 127

PC applications 129

PTCFileConverter ....................................................................................................... 130

FileGrapher ................................................................................................................... 132

File menu ................................ ............................................................................................... 132

Edit menu .............................................................................................................................. 132

Process menu ....................................................................................................................... 134

Special menu ......................................................................................................................... 136

Command line and macro instructions ............................................................................... 137

Circuit description 141

Core system cards ....................................................................................................... 142

PTC212 CPU board ............................................................................................................. 142

PTC221 backplane ............................................................................................................... 142

Page 5

Contents iii

PTC10 Programmable Temperature Controller

PTC231 front panel .............................................................................................................. 144

PTC240 GPIB card ............................................................................................................... 145

I/O cards ........................................................................................................................ 146

PTC320 1-channel thermistor/diode/RTD reader ........................................................... 146

PTC321 4-channel RTD reader ........................................................................................... 147

PTC330 thermocouple reader ............................................................................................ 148

PTC420 AC output card...................................................................................................... 149

PTC430 50W DC output card ............................................................................................ 149

PTC431 100W DC output card .......................................................................................... 150

PTC440 TEC driver ............................................................................................................. 151

PTC510 analog I/O card ..................................................................................................... 152

PTC520 digital I/O card ...................................................................................................... 153

Parts List 155

PTC212 CPU board ............................................................................................................. 155

PTC221 backplane ............................................................................................................... 165

PTC231 front panel .............................................................................................................. 167

PTC240 GPIB option ........................................................................................................... 169

PTC320 1-channel thermistor, diode, and RTD reader .................................................... 170

PTC321 4-channel RTD reader ........................................................................................... 173

PTC330 thermocouple reader ............................................................................................ 176

PTC420 AC output card...................................................................................................... 180

PTC430 50W DC output card ............................................................................................ 182

PTC440 TEC driver ............................................................................................................. 184

PTC510 analog I/O card ..................................................................................................... 187

PTC520 digital I/O card ...................................................................................................... 189

Schematics 193

Page 6

Page 7

Safety and Preparation for Use v

PTC10 Programmable Temperature Controller

Line voltage

The PTC10 operates from an 88 to 264 VAC power source having a line frequency between 47

and 63 Hz.

Power entry module

A power entry module, labeled AC POWER on the back panel of the PTC10, provides

connection to the power source and to a protective ground.

Power cord

The PTC10 package includes a detachable, three-wire power cord for connection to the power

source and protective ground.

The exposed metal parts of the box are connected to the power ground to protect against

electrical shock. Always use an outlet which has a properly connected protective ground. Consult

with an electrician if necessary.

Grounding

A chassis grounding lug is available on the back panel of the PTC10. Connect a heavy duty

ground wire, #12AWG or larger, from the chassis ground lug directly to a facility earth ground to

provide additional protection against electrical shock.

Line fuse

Use a 10 A/250 V 3AB Slo-Blo fuse.

Operate only with covers in place

To avoid personal injury, do not remove the product covers or panels. Do not operate the

product without all covers and panels in place.

Serviceable parts

The PTC10 does not include any user serviceable parts inside. Refer service to a qualified

technician.

Page 8

Page 9

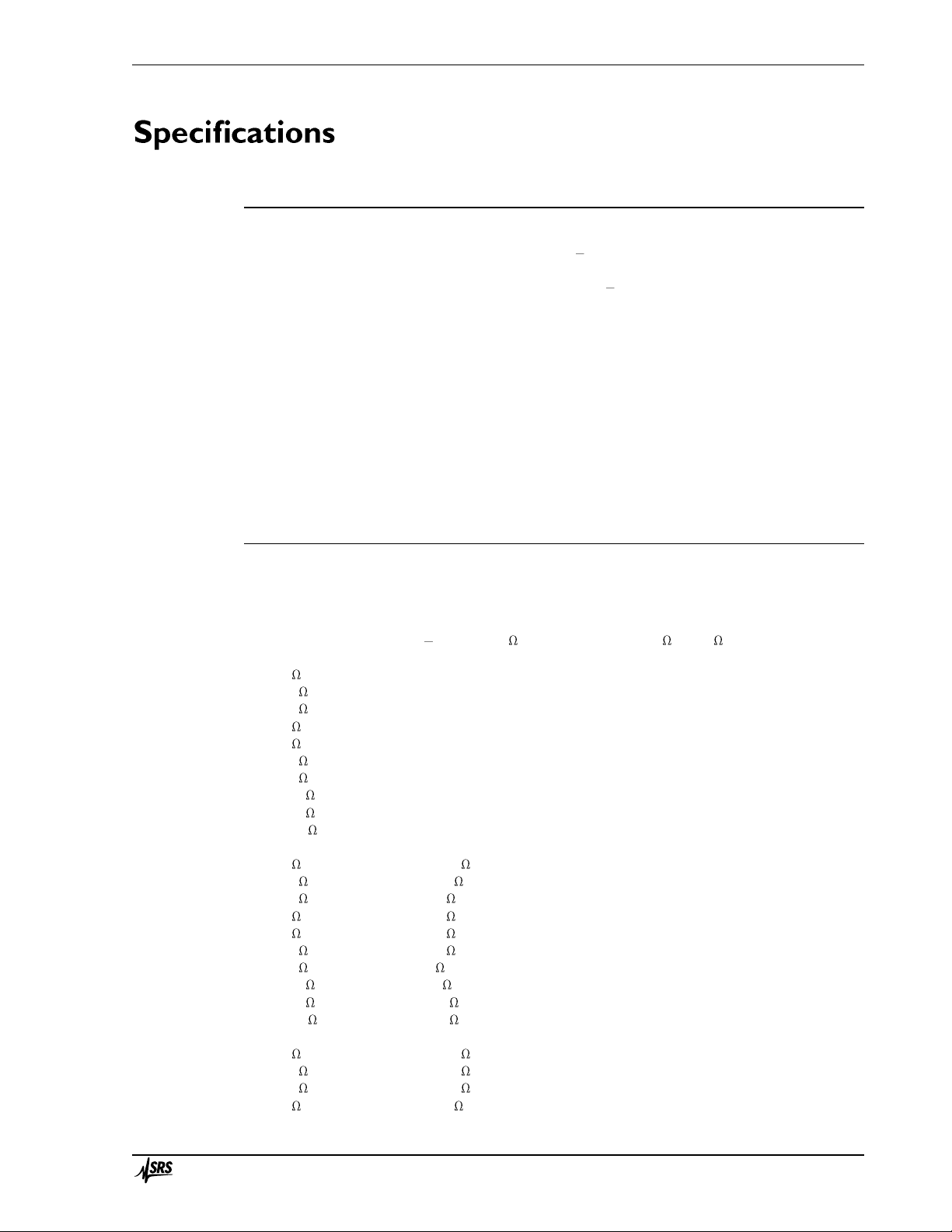

Specifications vii

PTC10 Programmable Temperature Controller

PTC10 temperature controller

Maximum PID rate 50 or 60 Hz, depending on AC line frequency

Data logging rate 10 samples/second/channel 1 sample/hour/channel (can be set

independently for each channel or globally for all channels)

Display resolution 0.001 °C, °F, K, V, A, W, etc. if 1000 < displayed value < 1000;

6 significant figures otherwise

PID feedback auto-tuning Single step response or relay tuning with conservative, moderate, and

aggressive response targets

Display 320 × 240 pixel touchscreen; numeric and graphical data displays.

Alarms Upper and lower temperaturelimits or rate-of-change limits can be set on each

channel. If exceeded, an audio alarm and a relay closure occur.

Computer interface USB, Ethernet, and RS-232; optional GPIB (IEEE488.2)

Power 10 A, 88 to 132 VAC or 176 to 264 VAC, 47 to 63 Hz or DC

Dimensions 17"× 5" × 18" (WHL)

Weight 25 lbs.

Warranty One year parts and labor on defects in material and workmanship.

PTC320 thermistor, diode, and RTD reader

Inputs One input for 2-wire or 4-wire thermistor, diode, or RTD

Connector 6-pin 240° push-pull DIN socket

Thermistors

Range 0 30, 100, 300 ; 1, 3, 10, 30, 100, 300 k ; 2.5 M

Excitation current

30 range 200 µA

100 range 100 µA

300 range 50 µA

1 k range 30 µA

3 k range 20 µA

10 k range 10 µA

30 k range 5 µA

100 k range 3 µA

300 k range 2 µA

2.5 M range 1 µA

Initial accuracy

30 range ±0.025

100 range ±0.06

300 range ±0.1

1 k range ±0.2

3 k range ±0.6

10 k range ±1.3

30 k range ±4

100 k range ±10

300 k range ±250

2.5 M range ±30 k

Drift due to temperature

30 range ±0.002 /°C

100 range ±0.006 /°C

300 range ±0.006 /°C

1 k range ±0.01 /°C

Page 10

Specifications viii

PTC10 Programmable Temperature Controller

3 k range ±0.03 /°C

10 k range ±0.1 /°C

30 k range ±0.15 /°C

100 k range ±0.5 /°C

300 k range ±3 /°C

2.5 M range ±2000 /°C

RMS noise

30 range 0.003

100 range 0.006

300 range 0.012

1 k range 0.02 (= 2 mK for 300 thermistor at 25°C)

3 k range 0.03 (= 0.8 mK for 1 k thermistor at 25°C)

10 k range 0.06 (= 0.6 mK for 2252 thermistor at 25°C)

30 k range 0.1 (= 0.3 mK for 10 k thermistor at 25°C)

100 k range 0.3 (= 0.2 mK for 30 k thermistor at 25°C)

300 k range 3 (= 0.7 mK for 100 k thermistor at 25°C)

2.5 M range 25 (= 1.8 mK for 300 k thermistor at 25°C)

Diodes

Excitation current output 10 µA

Initial accuracy ± 100 ppm

Drift ±5 ppm/°C

Voltage input 0 2.5 V

Initial accuracy 10 µV + 0.01% of reading

Drift ±5 ppm/°C

RMS noise 1.5 µV

RTDs

Range 0 30, 100, 300 ; 1, 3, 10, 30, 100, 250 k , 2.5 M

Excitation

30 range 3 mA

100 range 2 mA

300 range 1 mA

1 k range 500 µA

3 k range 200 µA

10 k range 100 µA

30 k range 50 µA

100 k range 10 µA

300 k range 5 µA

2.5 M range 1 µA

Initial accuracy

30 range ±0.004

100 range ±0.008

300 range ±0.02 (=±50 mK for Pt100 RTD at 25°C)

1 k range ±0.04

3 k range ±0.1

10 k range ±0.2

30 k range ±1

100 k range ±2.5

300 k range ±16

2.5 M range ±30 k

Drift due to temperature

30 range ±0.0006 /°C

100 range ±0.001 /°C

300 range ±0.0015 /°C (=±5 mK/°C for Pt100 RTD at 25°C)

1 k range ±0.005 /°C

3 k range ±0.01 /°C

10 k range ±0.03 /°C

Page 11

Specifications ix

PTC10 Programmable Temperature Controller

30 k range ±0.06 /°C

100 k range ±0.2 /°C

300 k range ±3 /°C

2.5 M range ±2000 /°C

RMS noise

30 range 0.00012

100 range 0.0003

300 range 0.0006 ( = 1.4 mK for Pt100 RTD at 25°C)

1 k range 0.0013

3 k range 0.003

10 k range 0.006

30 k range 0.012

100 k range 0.07

300 k range 0.25

2.5 M range 25

PTC321 Pt RTD reader

Inputs Four 4-wire inputs for 100 Pt RTDs

Connector 5-pin, 3.5mm header

Range 0 400

IEC751 Pt100 RTDs 215 °C to 850 °C

Excitation current 1 mA

Initial accuracy ±30 mK

Drift due to temperature 1.4 mK/°C

Drift due to time ±15 mK/year (at 25°C ambient temperature)

Noise 2 mK RMS (at 25°C sensor temperature and 10 samples/s)

Signal detection Card detects open and short circuit conditions

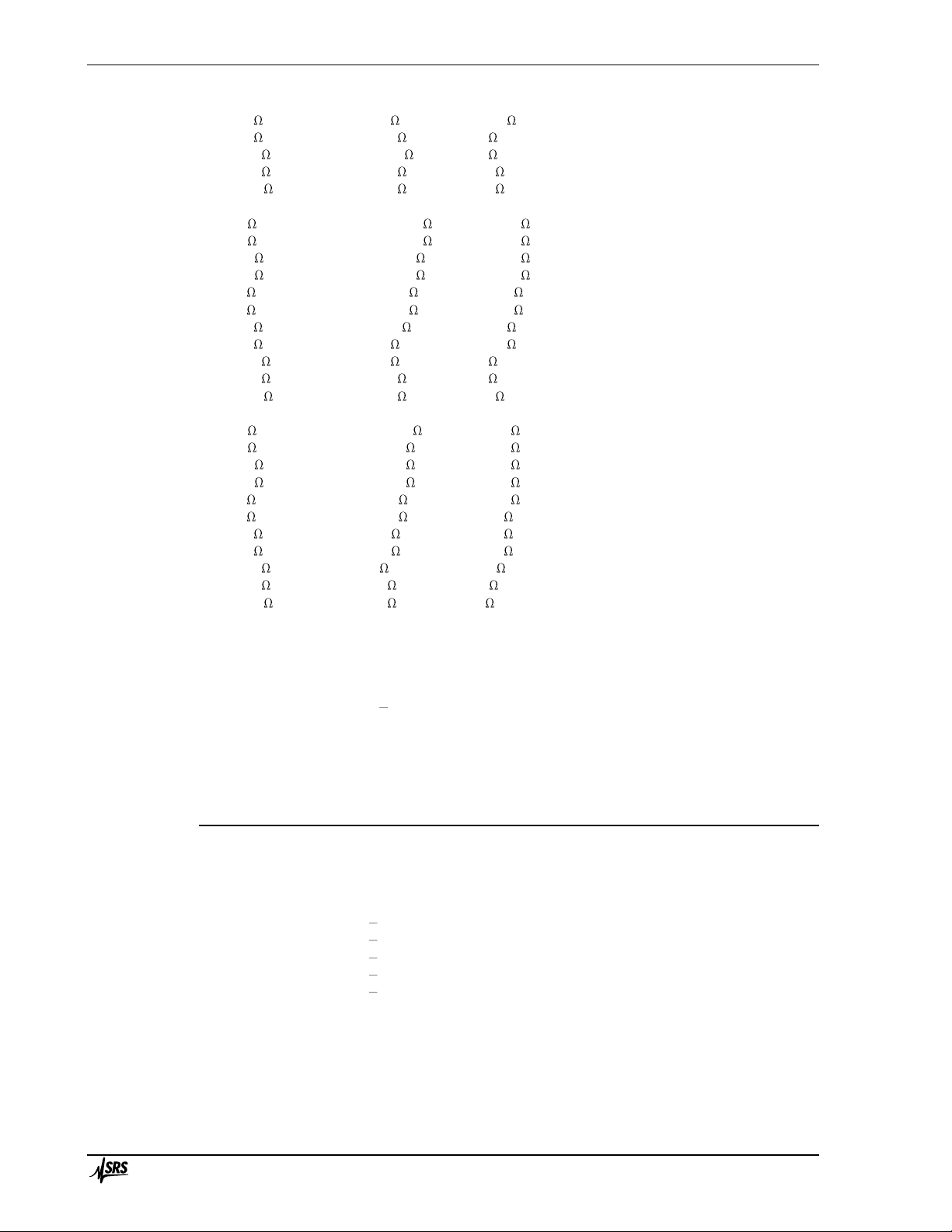

PTC323 thermistor, diode, and RTD reader

Inputs Two inputs for 4-wire thermistor, diode, or RTD

Connectors One 9-pin D-sub socket

RTDs and thermistors

Range 0 10, 30, 100, 300 ; 1, 3, 10, 30, 100, 300 k ; 2.5 M , or auto

Excitation current Low power High power

10 range 1 mA 3 mA

30 range 300 µA 3 mA

100 range 100 µA 2 mA

300 range 30 µA 1 mA

1 k range 10 µA 500 µA

3 k range 3 µA 200 µA

10 k range 1 µA 50 µA

30 k range 300 nA 50 µA

100 k range 100 nA 5 µA

300 k range 30 nA 5 µA

2.5 M range 1 µA 1 µA

Initial accuracy (AC current, at midrange)

10 range ±0.007 ±0.005

30 range ±0.03 ±0.005

100 range ±0.07 ±0.008

300 range ±0.25 ±0.015 (=±40 mK for Pt100 RTD at 25°C)

1 k range ±0.6 ±0.05

3 k range ±2 ±0.1

Page 12

Specifications x

PTC10 Programmable Temperature Controller

10 k range ±6 ±0.25

30 k range ±25 ±1

100 k range ±150 ±4

300 k range ±1 k ±13

2.5 M range ±3 k ±3 k

Typical drift due to temperature (at midrange)

10 range ±0.0002 /°C ±0.0001 /°C

30 range ±0.0004 /°C ±0.0001 /°C

100 range ±0.002 /°C ±0.0002 /°C

300 range ±0.004 /°C ±0.0004 /°C

1 k range ±0.01 /°C ±0.001 /°C

3 k range ±0.06 /°C ±0.003 /°C

10 k range ±0.2 /°C ±0.01 /°C

30 k range ±1 /°C ±0.02 /°C

100 k range ±3 /°C ±1 /°C

300 k range ±20 /°C ±2 /°C

2.5 M range ±30 /°C ±50 /°C

RMS noise (DC current, at midrange)

10 range 0.0003 0.0001

30 range 0.001 0.0001

100 range 0.002 0.0002

300 range 0.006 0.0003 ( = 0.8 mK for Pt100 RTD at 25°C)

1 k range 0.02 0.0007

3 k range 0.06 0.002

10 k range 0.2 0.007

30 k range 1.0 0.008

100 k range 6 0.12

300 k range 40 0.2

2.5 M range 10 10

Diodes

Excitation current output 10 µA

Initial accuracy ± 100 ppm

Drift ±5 ppm/°C

Voltage input 0 2.5 V

Initial accuracy 10 µV + 0.01% of reading

Drift ±5 ppm/°C

RMS noise 3 µV

PTC330 thermocouple reader

Inputs Four optoisolated thermocouple inputs

Connector Mini thermocouple jacks

Thermocouple types E, J, K, N, or T

Range ±500 mV

Type E 270 °C to 980 °C (range of calibration table with cold junction at 25°C)

Type J 210 °C to 1177 °C

Type K 270 °C to 1342 °C

Type N 270 °C to 1281 °C

Type T 270 °C to 383 °C

Input capacitance <1 pF

Accuracy ±500 mK (over 12 months)

Noise 20 mK RMS (at 10 samples/s)

Drift due to temperature 20 mK/°C (type K thermocouple at 164.0 K)

CMRR 100 dB

Common mode isolation 250 VAC

Page 13

Specifications xi

PTC10 Programmable Temperature Controller

PTC420 AC output card

Output One line voltage output switched by solid-state relay

Connector NEMA 5-15 (3-prong North American wall socket); a heater cable with a

mating plug on one side and stripped ends on the other is included

Output voltage 120/240 VAC

Max. output current 5 A

On/off cycle time Adjustable between 1 and 240 s

Max. line voltage 250 VAC

Surge current 100 A max. (non-repetitive)

Output resolution 0.1% at 10 s cycle time

Heater resistance (min.) 24 (110 VAC), 46 (230 VAC)

PTC430 50 W DC output card

Output One linear, unipolar DC current source

Connector Two banana jacks, 0.75 inch center-to-center spacing

Range 50 V 1A, 20 V 2 A, 50 V 0.5A, 20 V 0.5 A,50 V 0.1A, or 20 V 0.1 A

Output resolution 24 bits with dithering enabled or 16 bits with dithering disabled

Accuracy ±1 mA (1 A range)

±0.1 mA (0.5 A range)

±0.01 mA (0.1 A range)

Noise (rms), 50 load, 6 µA (50 V 1 A and 20 V 2 A ranges)

DC 10 Hz 1.5 µA (0.5 A range)

0.2 µA (0.1 A range)

PTC431 100W DC output card

Output One unipolar DC current source

Connector #6 screw terminals. Accepts 12 22 AWG wire or #6 spade terminals up to

-lb.

Range 50 V 2A, 50V 0.6A, 50V 0.2A, 20V 2A, 20V 0.6A, 20V 0.2A

Output resolution 16 bits

Accuracy ±1 mA (2 A range)

±0.5 mA (0.6 A range)

±0.2 mA (0.2 A range)

Noise (rms), 25 load, 5 µA (2 A range)

DC 10 Hz 1.5 µA (0.6 A range)

0.5 µA (0.2 A range)

PTC440 TEC driver

Output One linear, bipolar DC current source

Input One 2- or 4-wire thermistor/RTD/IC temperature sensor input

Connector One 15-pin DB15-F

TEC driver

Output current -5 A +5A

Maximum power 50W

Compliance voltage 12 V (at 0 A current)

Output resolution 0.15 mA

Accuracy ±5 mA

Current noise 0.02 mA (at 0.5A current, 22 ohm resistive load, 0.01-10 Hz bandwidth)

Page 14

Specifications xii

PTC10 Programmable Temperature Controller

Temperature sensor input

Compatible sensors

Thermistors 2 or 4-wire NTC thermistors

RTDs 4-wire platinum RTDs, 100 1000 at 0°C

IC sensors LM335, AD590, or equivalent

Excitation current 10 µA, 100 µA, or 1 mA

Input range

Resistance 1 250 k

Voltage 0 2.5V

Current 0 1 mA

RMS electronic noise (sensor at 25°C)

10 µA excitation

1 k thermistor 0.7 = 15 mK

2252 thermistor 0.6 = 5 mK

10 k thermistor 1 = 4 mK

100 µA excitation

1 k thermistor 0.1 = 1.5 mK

2252 k thermistor 0.1 = 0.7 mK

10 k thermistor 0.2 = 0.5 mK

1 mA excitation

100 Pt RTD 0.003 = 8 mK

LM135/235/335 4 mK RMS

AD590/592 6 mK RMS

Initial accuracy

10 µA excitation

1 k thermistor 1.2 = 30 mK

2252 thermistor 10 = 100 mK

10 k thermistor 66 = 150 mK

100 µA excitation

1 k thermistor 0.06 = 1.6 mK

2252 k thermistor 0.1 = 10 mK

10 k thermistor 0.5 = 1.1 mK

1 mA excitation

100 Pt RTD 0.004 = 5 mK

LM135/235/335 70 mK

AD590/592 400 mK (sensor at 25°C)

Thermal drift

10 µA excitation

100 µA excitation

1 mA excitation

LM135/235/335

AD592/592

Analog I/O

Inputs/outputs 4 voltage I/O channels, independantly configurable as inputs or outputs

Connector 4 BNC jacks

Range ±10 V

Resolution 24-bit input, 16-bit output

ADC noise 30 µV RMS = 100 µV p-p (10 samples/s)

Digital I/O

Digital I/O

Inputs/outputs 8 optoisolated TTL lines, configurable as either 8 inputs or 8 outputs

Page 15

Specifications xiii

PTC10 Programmable Temperature Controller

Connector One DB-25F

Relays

Outputs 4 independent SPDT relays

Connector One 12-pin 3.5mm header

Maximum current 5 A

Maximum voltage 250 VAC

Page 16

Page 17

Introduction 1

PTC10 Programmable Temperature Controller

Introduction

The PTC10 is a high-performance, general-purpose laboratory temperature controller that can

monitor and control temperatures with millikelvin resolution. Its features include:

Modular design

The PTC10 can accept up to four I/O cards, each of which can read up to four temperature

sensors and/or drive one heater. The instrument can be customized by selecting the I/O cards best

suited to your application. The PTC10 also comes standard with four ±10V I/O channels that can

be used with external amplifiers to read signals and drive heaters.

Reads up to 16 tem perature sensors

Temperature input cards are available for reading thermocouples, RTDs, thermistors, and

diodes. For optimal signal-to-noise ratio, each temperature input channel has its own 24-bit ADC.

Drives up to 6 heaters

Three kinds of heater driver cards are available for driving resistive heaters and thermoelectric

devices. Depending on the model of driver card used, two or three heaters can be directly driven at

full power. In addition, the unpowered voltage I/O channels included as standard equipment can

be used to drive heaters with the help of an external amplifier.

Graphical touchscreen display

The PTC10 can display temperature measurements and heater output on graphs or numeric

displays. Any combination of channels can be displayed, and four different channel combinations

can be saved and recalled. Touchscreen operation makes the instrument versatile and easy to use.

Logs data to USB memory devices

Up to 10 data points/second/channel can be logged to standard USB memory sticks and hard

drives. The data can be transferred to a computer by simply plugging the USB device into a PC and

copying the log files. Windows applications are included to graph PTC10 log files and to convert

them to various ASCII text formats.

Up to 6 feedback loops

The PTC10 can control up to six different temperatures (one for each heater output) by

continually adjusting the amount of power supplied to heaters. Each feedback loop can run as fast as

50 or 60 Hz, depending on the frequency of your AC power.

Runs user programs

A macro programming language makes it possible to customize the functionality of the

instrument. Conditional statements, variables, and subroutine calls are supported. Up to 10 user

programs can run concurrently.

Computer com m unications

The PTC10 can receive text commands and send responses over USB, RS-232, Ethernet, and an

optional GPIB interface. All aspects of PTC10 operation can be controlled over these interfaces.

Eight digital I/O lines are also provided; these can interact with user programs to control most

aspects

Page 18

Introduction 2

PTC10 Programmable Temperature Controller

on removable circuit boards. The chassis has

four wide and two narrow slots for these I/O cards. The wide slots (which are labeled 1 4 on the

back panel) can be occupied by optional temperature input and/or heater driver cards. The narrow

slots (slots 5 and 6) are occupied by general-purpose analog and digital I/O cards included as

standard equipment.

Replacing I/O cards

Cards can be added, removed, or rearranged by the user. No firmware setup is needed; the

system automatically recognizes the new cards. For most purposes, the six slots are identical and

cards do not need to be arranged in any particular order. However, the lower-numbered slots are

preferred for output cards because these slots get the most cooling from the fan. In addition, alarms

can only activate relays on a digital I/O card if the card is installed in slot 6.

Some channel-specific settings (PID feedback parameters, alarm settings, sensor type, custom

calibration data, and filter settings) may be lost when I/O cards are replaced or rearranged.

However, factory calibration is stored on the card and is not lost.

To add or replace an I/O card:

1. Unplug the PTC10 from the wall; otherwise, even if the instrument is switched off, live line

voltage could be present. Removing and installing I/O cards while the power is turned on

may permanently damage the instrument.

large Philips head screws on the

sides of the cover and lifting the cover straight up.

3. Remove the two flathead Phillips screws immediately t

back panel.

4. Remove the I/O card by pulling up alternately on the front and back of the card.

5. Install the new I/O card. Put the back of the card in place first, then press firmly down on

the front of the card. Ensure that the top of the card is level with the tops of all the other

cards.

6. Re-install the two back-panel screws and re-attach the top cover. The card can be damaged

if the screws are not installed.

7. Turn the PTC10 on. The new card should automatically appear on the Select screen, and

remote commands for the new card should automatically become available.

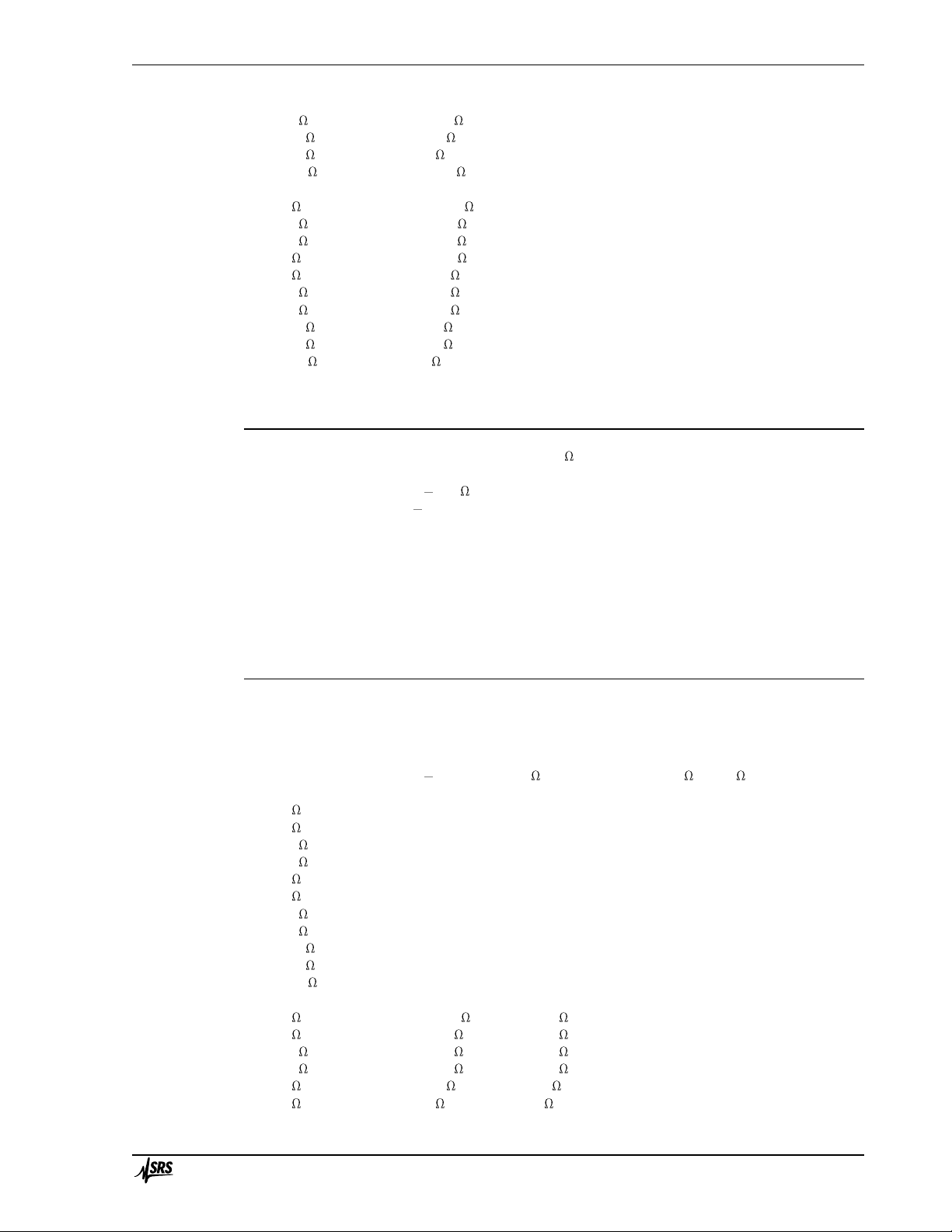

PTC320 thermistor/diode/RTD card

The PTC320 is a single-channel, multi-range input card that can read a variety of temperature

sensors. It can read resistances between 1 and 2.5 M , and can also read diode temperature

sensors.

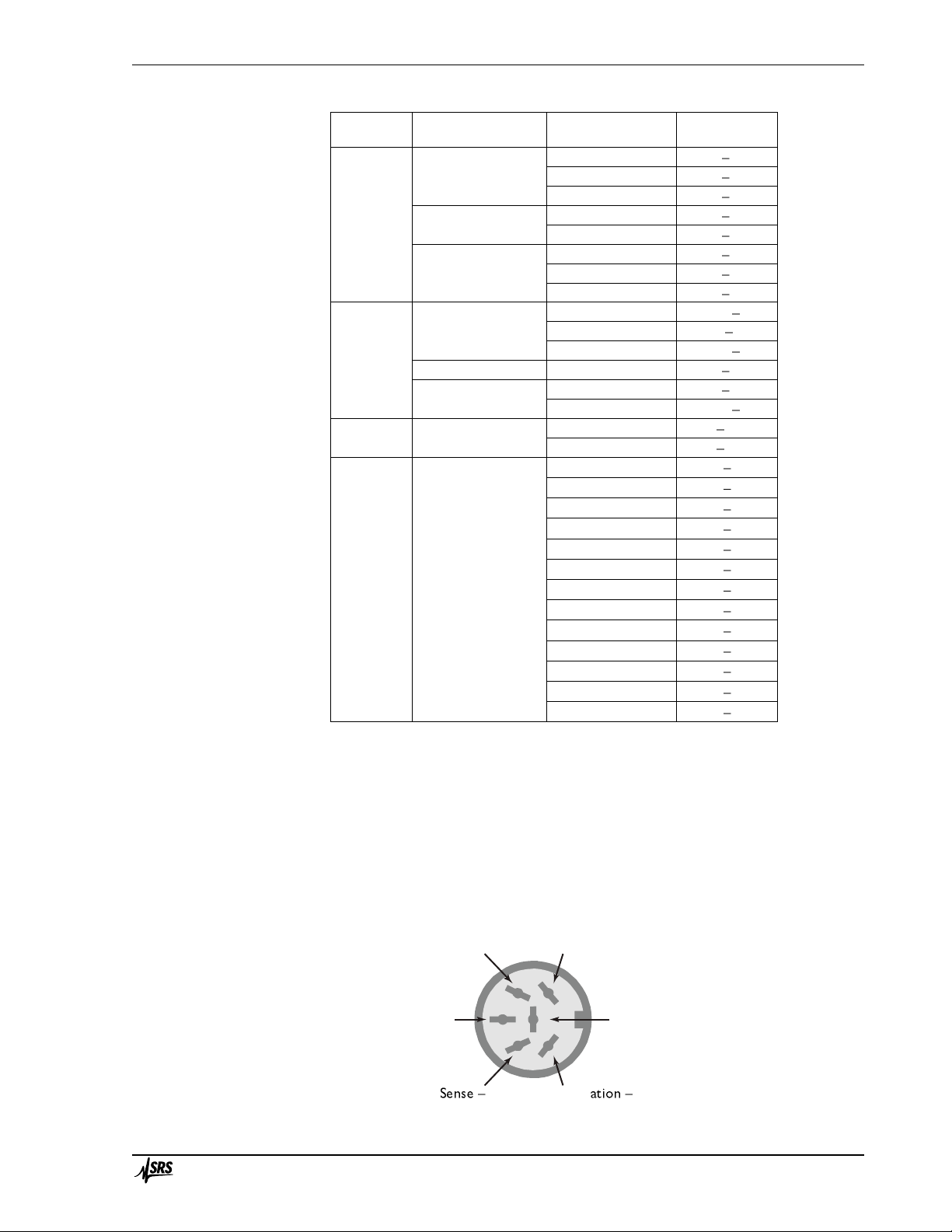

Standard calibration curves are included for the following sensors.

the range of the standard calibration curve; outside this range, no reading appears for the sensor. It

may be possible to obtain a larger range by uploading a custom calibration curve.

Page 19

Introduction 3

PTC10 Programmable Temperature Controller

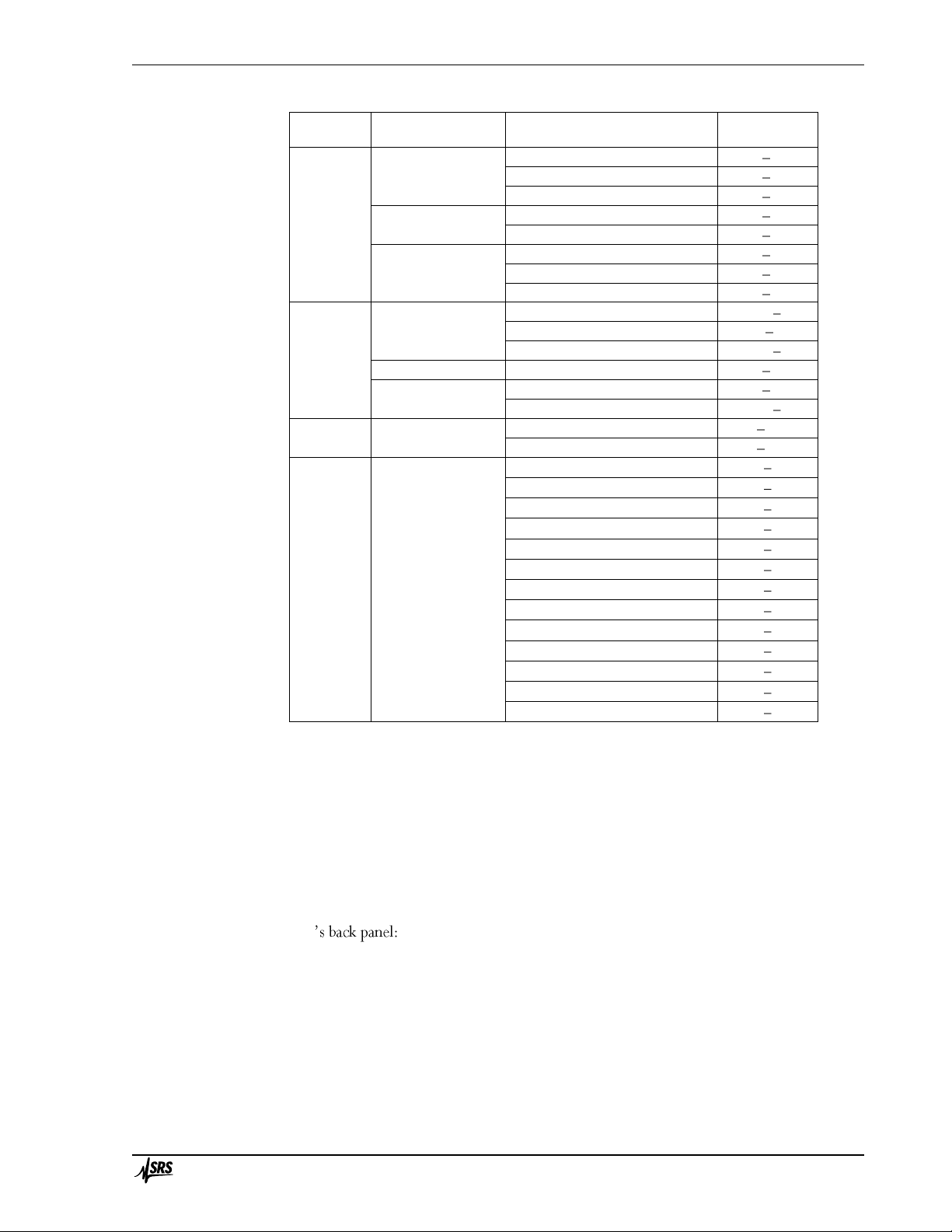

Sensor

class

Manufacturer

Calibration

type

Range,

K

Diode

Scientific Instruments

Si410

1.0 450

Si430

1.0 400 Si440

1.0 500

LakeShore; Omega

DT-470 (=CY7)

1.4 475

DT-670 (=CY670)

1.4 500

Cryo-Con

S700

1.5 475

S800

1.4 385

S900

1.5 500

Ruthenium

oxide

LakeShore

RX-102A

0.050 40

RX-103A

1.2 40

RX-202A

0.050 40

Scientific Instruments

RO600

1.0 300

Cryo-Con

R400

2.0 273

R500

0.050 20

RTD

All

IEC751 (DIN43760)

48.15 1173.15

US

48.15 1173.15

Thermistor

Measurement

Specialties,

Inc.

(formerly YSI);

Omega

100

193.15 373.15

300

193.15 373.15

1000

193.15 373.15

2252

193.15 523.15

3000

193.15 523.15

5000

193.15 523.15

6000

193.15 523.15

10000 type B

193.15 523.15

10000 type H

193.15 523.15

30 k

233.15 523.15

100 k

233.15 423.15

300 k

298.15 423.15

1 M

298.15 423.15

Other resistive and diode sensors can be used with the PTC320, but require custom calibration

curves. For example, rhodium-iron, germanium, and carbon-glass sensors have too much sensorto-sensor variability to use a standard curve, and therefore must be custom-calibrated.

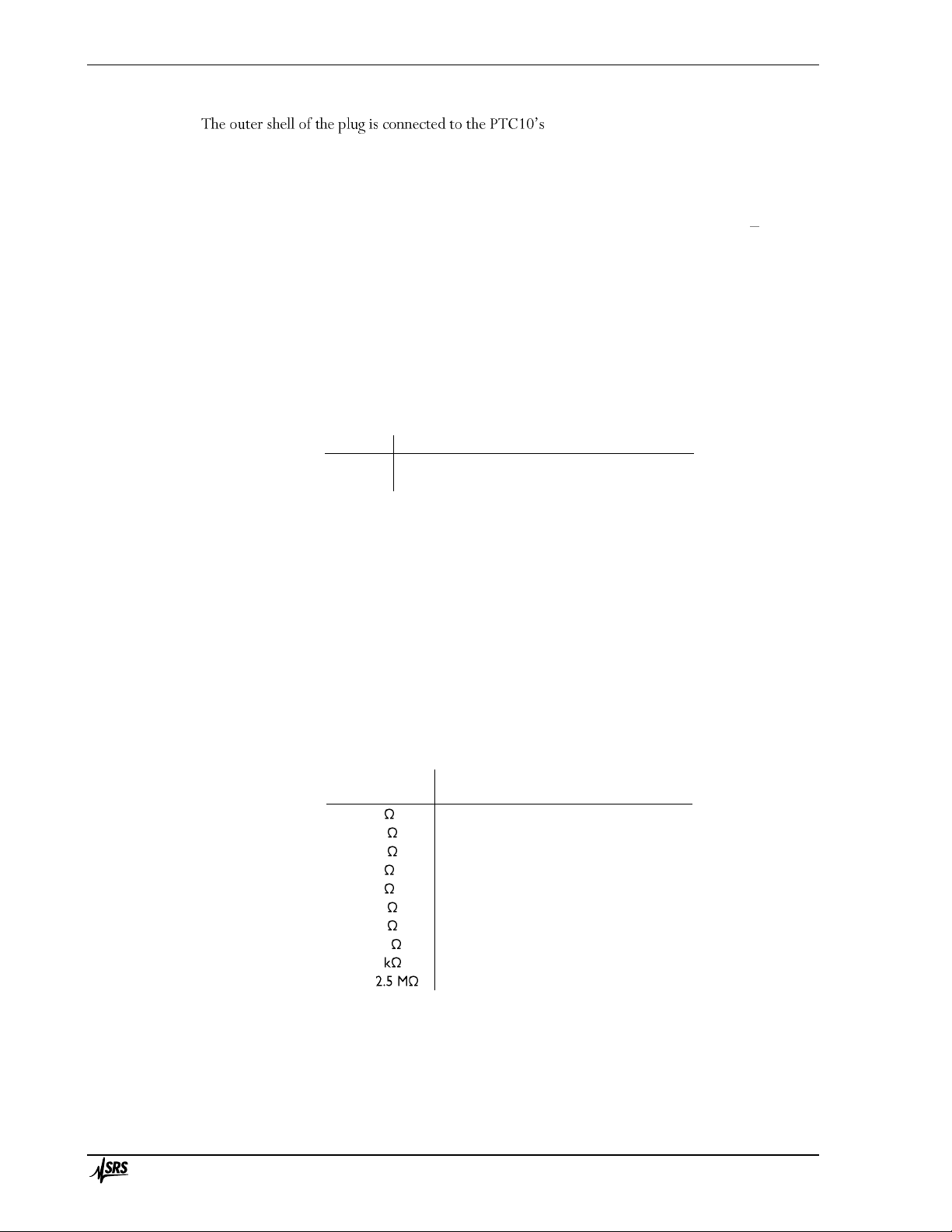

Connecting the sensor

The PTC320 has a 6-pin DIN socket that mates with standard 6-pin push-pull DIN plugs (i.e.

Digi-Key CP-1060-ND). This is the pinout of the socket, as it appears when looking at the back

panel:

1

5

4

2

6

3

Not connected

Excitation +Sense +

Ground

Excit

Page 20

Introduction 4

PTC10 Programmable Temperature Controller

chassis.

The PTC320 passes an excitation current through the attached RTD, thermistor, or diode, and

senses the induced voltage. For the most accurate results all sensors should be read with a four-wire

configuration, using separate sense and excitation leads. However, for convenience the PTC320

can also read sensors attached with only two leads.

To make a two-wire measurement, connect one end of the sensor to pin 1 (Excitation ) and the

other to pin 5 (Excitation +). An inaccuracy is introduced because the resistance of the leads affects

the measurement; however, some thermistors have such a high resistance that the lead resistance

may be negligible in comparison.

A four-wire measurement eliminates the effect of lead resistance. In the four-wire configuration,

two of the wires carry the excitation current, while the other two wires sense the voltage that the

current produces across the sensor. RTDs sold with four wires normally have two wires of one

color, both attached to one side of the RTD, and two of a different color attached to the other side.

In this case, the RTD should be wired to the PTC320 in one of the following two ways (assuming

the leads are white and black):

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Option 1

White

White

Unconnected

Black

Black

Option 2

Black

Black

Unconnected

White

White

RTDs with two wires can be modified by connecting two additional wires, one on each side of

the sensing element and as close to the sensing element as possible.

The higher the resistance of a sensor, the more its leads pick up noise from ambient

electromagnetic radiation. The noise level of high-resistance thermistors in particular can often be

improved by using a shielded cable and connecting the shield to pin 3.

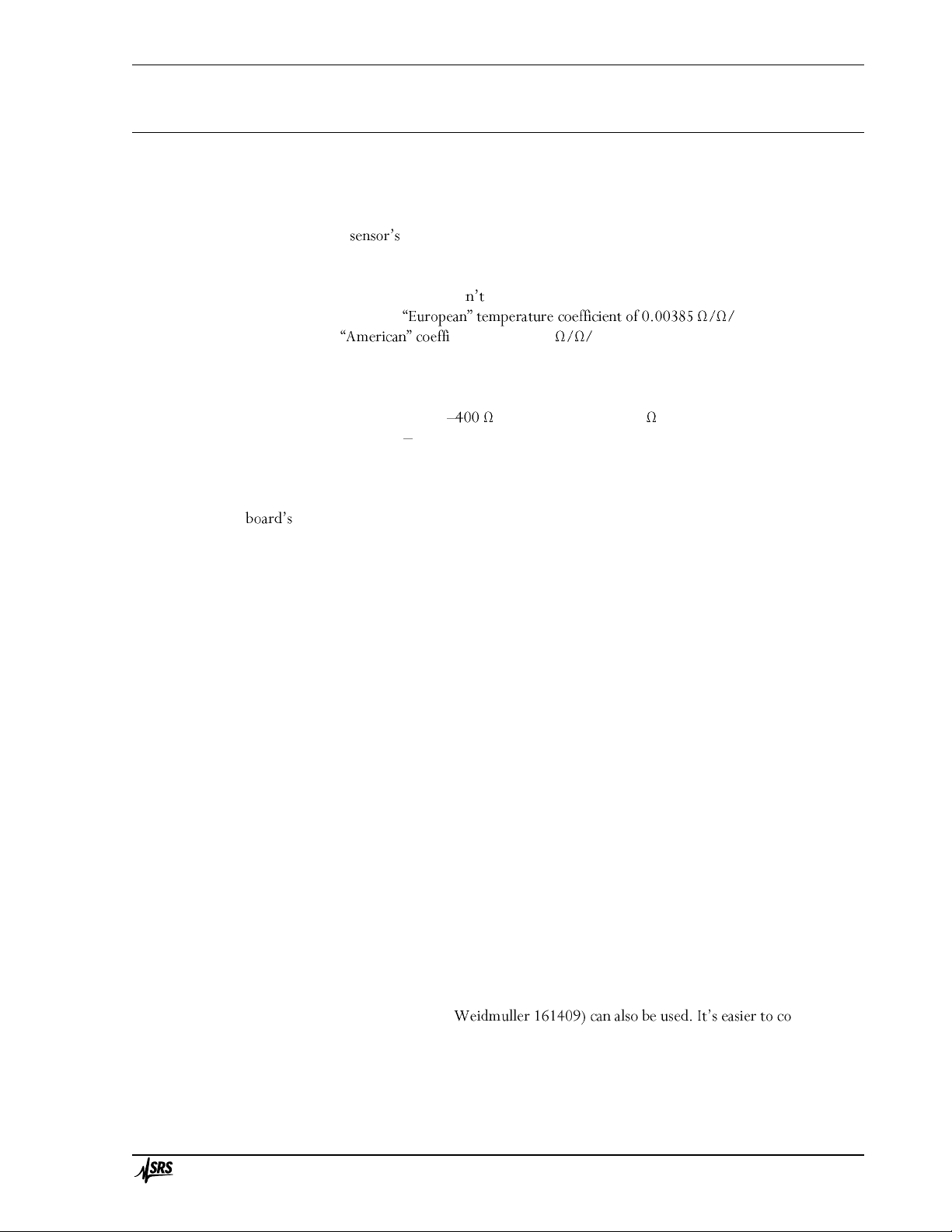

Excitation current

The excitation current provided to the sensor is automatically determined by the PTC320. For

resistive sensors, the current is determined by the type of sensor and the measurement range as

shown in the table below. When a diode sensor is in use, the card always produces a 10 µA

excitation.

Measurem ent

range

RTD

excitation

Therm istor

excitation

Diode

excitation

30

5 mA

200 µA

100

2 mA

100 µA

300

1 mA

50 µA

1 k

500 µA

30 µA

3 k

200 µA

20 µA

10 k

100 µA

10 µA

30 k

50 µA

5 µA

100 k

10 µA

3 µA

300

5 µA

2 µA

2.5 V ( )

1 µA

1 µA

10 µA

Excitation current produced by the PTC320

The thermistor excitation current results in about 1 µW of power being dissipated in the

thermistor at the high end of each measurement range. Therefore, if the dissipation constant of the

thermistor is above 1 mW/°C, the measurement error due to self-heating should be less than 1

mK.

Page 21

Introduction 5

PTC10 Programmable Temperature Controller

PTC321 RTD reader

Resistance temperature detectors (RTDs) use the resistance of a metal wire or film to indicate

temperature. RTDs are usually made of platinum which, being very non-reactive, produces sensors

with exceptional long-term stability. However, platinum RTDs are also expensive and have a

limited temperature range.

Typically, the resistance is measured by passing an excitation current through it and

measuring the resulting voltage drop. A four-wire RTD has two wires to carry the current and two

to measure the voltage. Negligible current flows through the voltage-measuring wires, ensuring

that the resistance of the wires does affect the measured voltage.

RTDs usually have the °C (IEC751

standard). The cient of 0.00392 °C is less common, even in America.

The PTC321 RTD reader reads up to four 100 ohm platinum RTDs with a 1 mA excitation

current. The current through the RTD can be reversed with each reading to null out parasitic

thermocouple voltages.

The PTC321 has a range of 10 , allowing it to read 100 European-type platinum RTDs

in the temperature range 215 to 850°C. RTDs with other base resistances can also be used, but

over a smaller temperature range.

The PTC321 is calibrated at ambient temperatures of 25 and 35°C. An on-board temperature

sensor continuously interpolates between these two calibrations to account for thermal drift of the

electronic components. Since the PTC10 enclosure is usually elevated 2 to 3 degrees above

ambient temperature, the accuracy of the PTC321 may be reduced if the ambient temperature rises

above about 32°C.

To further improve measurement stability, the PTC321 can control the main enclosure fan to

keep the card at a constant temperature (see the Channel.PCB button).

A narrow flange is available for the PTC321. With this flange mounted, the card can be plugged

into either slot 5 (normally occupied by the analog I/O card) or slot 6 (normally occupied by the

digital I/O card). Since all six slots of the PTC are identical except for their width, the I/O cards

can be arranged in any order as long as they fit into the slots. To order the narrow flange from SRS,

contact sales and ask for part number 7-01920-720.

Connecting the RTDs

RTDs are connected to the PTC321 with removable 5-pin, 3.5 mm terminal plugs (e.g.,

Weidmüller part number 169045). The supplied plugs use a tension clamp to hold the RTD wires.

To install the RTD wires:

1. Hold the plug such that the row of five small holes is on the right and the five larger holes are

on the left.

2. Each pair of holes is blocked by a metal clip. Place a small screwdriver into one of the small

holes and firmly push it into the narrow gap to the right of the clip. The screwdriver should

go in about half an inch and push the clip to the left.

3. The larger hole should open up. Place a stripped wire into the hole and remove the

screwdriver.

Plugs with screw clamps (e.g., nnect the

RTD wires to these plugs, but the wires often come loose, resulting in noisy temperature

measurements. The tension clamps are a little more difficult to install but produce a more reliable

connection.

Page 22

Introduction 6

PTC10 Programmable Temperature Controller

On each connector, the top two pins receive the resistance signal, the middle pin is a ground that

can be connected to a shield or left unconnected, and the lower two pins provide the excitation

current.

Commercial 4-wire RTDs usually have two wires of the one color connected to one end of the

resistive sensor, and two of a different color connected to the other end. There is normally no

shield. In this case, the RTD plug should be wired in one of the following ways (assuming black and

white wires):

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Option 1

White

Black

Unconnected

White

Black

Option 2

Black

White

Unconnected

Black

White

If the plug is wired any other way, no reading appears when the sensor is plugged into the RTD

reader.

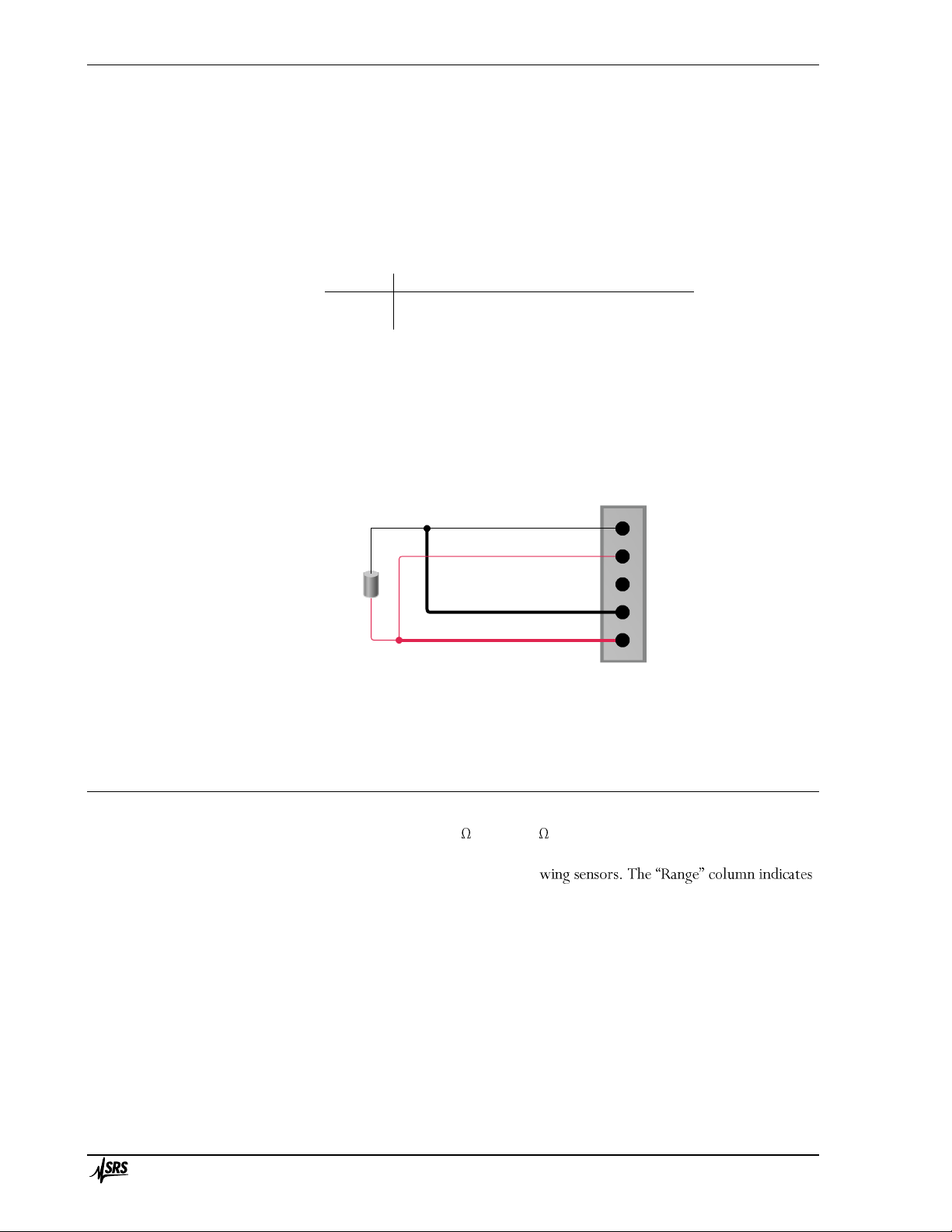

RTDs with two wires must be modified by soldering two additional wires to the existing wires,

one on each side of the sensing element and as close to the sensing element as possible. The diagram

below shows how to connect the wires to the PTC321.

Connecting a 2-wire RTD to the PTC321 RTD reader

PTC323 2-channel thermistor/diode/RTD card

The PTC323 is a two-channel, multi-range input card that can read a variety of temperature

sensors. It can read resistances between 1 and 2.5 M , and can also read diode temperature

sensors.

Standard calibration curves are included for the follo

the range of the standard calibration curve; outside this range, no reading appears for the sensor. It

may be possible to obtain a larger range by uploading a custom calibration curve.

Connect the two wires that

came with the sensor (thin lines)

to the Signal inputs

Solder two additional wires (thick lines)

to the sensor and connect them

to the Excitation inputs

RTD

sensing

element

Signal

Signal

Ground

Excitation

Excitation

Page 23

Introduction 7

PTC10 Programmable Temperature Controller

Sensor

class

Manufacturer

Calibration

type

Range,

K

Diode

Scientific Instruments

Si410

1.0 450

Si430

1.0 400 Si440

1.0 500

LakeShore; Omega

DT-470 (=CY7)

1.4 475

DT-670 (=CY670)

1.4 500

Cryo-Con

S700

1.5 475

S800

1.4 385

S900

1.5 500

Ruthenium

oxide

LakeShore

RX-102A

0.050 40

RX-103A

1.2 40

RX-202A

0.050 40

Scientific Instruments

RO600

1.0 300

Cryo-Con

R400

2.0 273

R500

0.050 20

RTD

All

IEC751 (DIN43760)

48.15 1173.15 US

48.15 1173.15

Thermistor

Measurement

Specialties,

Inc.

(formerly YSI);

Omega

100

193.15 373.15

300

193.15 373.15

1000

193.15 373.15

2252

193.15 523.15

3000

193.15 523.15

5000

193.15 523.15

6000

193.15 523.15

10000 type B (32.66 k at 0°C)

193.15 523.15

10000 type H (29.49 k at 0°C)

193.15 523.15

30 k

233.15 523.15

100 k

233.15 423.15

300 k

298.15 423.15

1 M

298.15 423.15

Other resistive and diode sensors can be used with the PTC320, but require custom calibration

curves. For example, rhodium-iron, germanium, and carbon-glass sensors have too much sensorto-sensor variability to use a standard curve, and therefore must be custom-calibrated.

Connecting the sensor

The sensors are connected via a 9-pin D-sub (DB9) socket that mates with any standard DB9

plug, such as Amphenol L717SDE09P with backshell 17E-1657-09. One plug and backshell is

provided with each PTC323. Here is a wiring diagram of the socket as it appears when looking at

the PTC10

Page 24

Introduction 8

PTC10 Programmable Temperature Controller

A four-wire connection is used so that the PTC323 measures the resistance of the sensor and not

the wires going to the sensor. The +I and I pins provide a small current and should be connected

to the temperature sensor with two wires, preferably a shielded twisted pair. The +V and V pins

measure the voltage produced across the sensor and should be connected to +I and -I as close as

possible to the sensor.

Resistive sensors: Four-wire resistive sensors usually have two wires of one color attached to

one side of the RTD, and two of a second color attached to the other side. Two wires of the same

co

wires of the other color should be connected to the V and I pins.

Two-wire sensors can be converted to four-wire sensors by soldering two additional wires to the

existing leads, one on each side of the sensing element and as close to the sensing element as

possible. Soldering is essential; the wires should not be connected to the sensor by pressure alone

(e.g. crimping or clamping), as any resistance within the joint becomes part of the measured sensor

resistance.

The higher the resistance of an RTD or thermistor, the more sensitive it is to ambient

electromagnetic noise and the greater the need for shielded cables.

Diode sensors: Diode sensors can be connected in either direction. If no reading appears,

change the current direction from Forward to Reverse.

Diode sensors are especially susceptible to electromagnetic noise because the diode rectifies any

noise picked up by the sensor leads, increasing the measured voltage. It may be necessary to place

the sample within an electromagnetically shielded enclosure and to put EMI filters not only the on

the sensor leads but also on all other leads entering the enclosure. The filters should be located at

the point where the wires enter the enclosure, and the enclosure itself should be grounded. D-sub

and circular connectors with built-in filters, as well as individual filters, can be obtained from

Spectrum Advanced Specialty Products. We have found their 4000 pF pi filters to be effective.

These filters include capacitors to ground, which should be connected either to the ground pin (pin

3) of the sensor input connector or to chassis ground.

AD590 sensors: The PTC323 can read AD590 sensors if the sensor is connected in series with a

2 k resistor as shown below. Note that the diagram shows the sensor connected to channel A, but

it can also be connected to channel B. The diagram shows the back of the DB9 connector, that is,

the side that you solder to, with pin 1 in the bottom-right corner.

sistors

have a TCR of about 100 ppm/°C, which means that the sensor reading will drift upward by about

30 mK for each 1°C rise in ambient temperature. Thermal drift can be reduced substantially by

AD590

+I

1

6

5

9

+V

+

Page 25

Introduction 9

PTC10 Programmable Temperature Controller

using a 5 ppm/°C resistor available from SRS; ask for part number 4-02502-457. For even better

stability, a 1 ppm/°C resistor such as the Riedon USR2G-2KX1, available from Digi-Key, can be

used. In any case, to minimize noise and drift, the resistor should be soldered directly to the pins on

the DB9 plug and covered up with the backshell.

Because AD590 sensors are highly sensitive to electromagnetic interference, the AD590 wires

and package must be shielded, with the shield connected to pin 3 of the DB9 connector.

Excitation current

The PTC323 measures the resistance of the sensor by passing an excitation current through it.

The larger the excitation, the less noise the temperature reading will have. However, if the

excitation is too large it will heat the sensor and cause higher than expected readings. Therefore,

e

Low power: minimizes sensor heating. This option is mainly for use with thermistors in

cryogenic applications. To compensate for the fact that heat conductivity decreases (and

thermistor resistance increases) as the temperature approaches absolute zero, the amount of

power that the sensor dissipates decreases as the measurement range is increased.

High power: minimizes noise. Power dissipation is kept roughly constant as the

measurement range is increased. This option is for use with RTDs or with any kind of sensor

at non-cryogenic temperatures.

Auto power: uses low power if the sensor type is set to thermistor or ROX, or high power

if the sensor type is set to RTD.

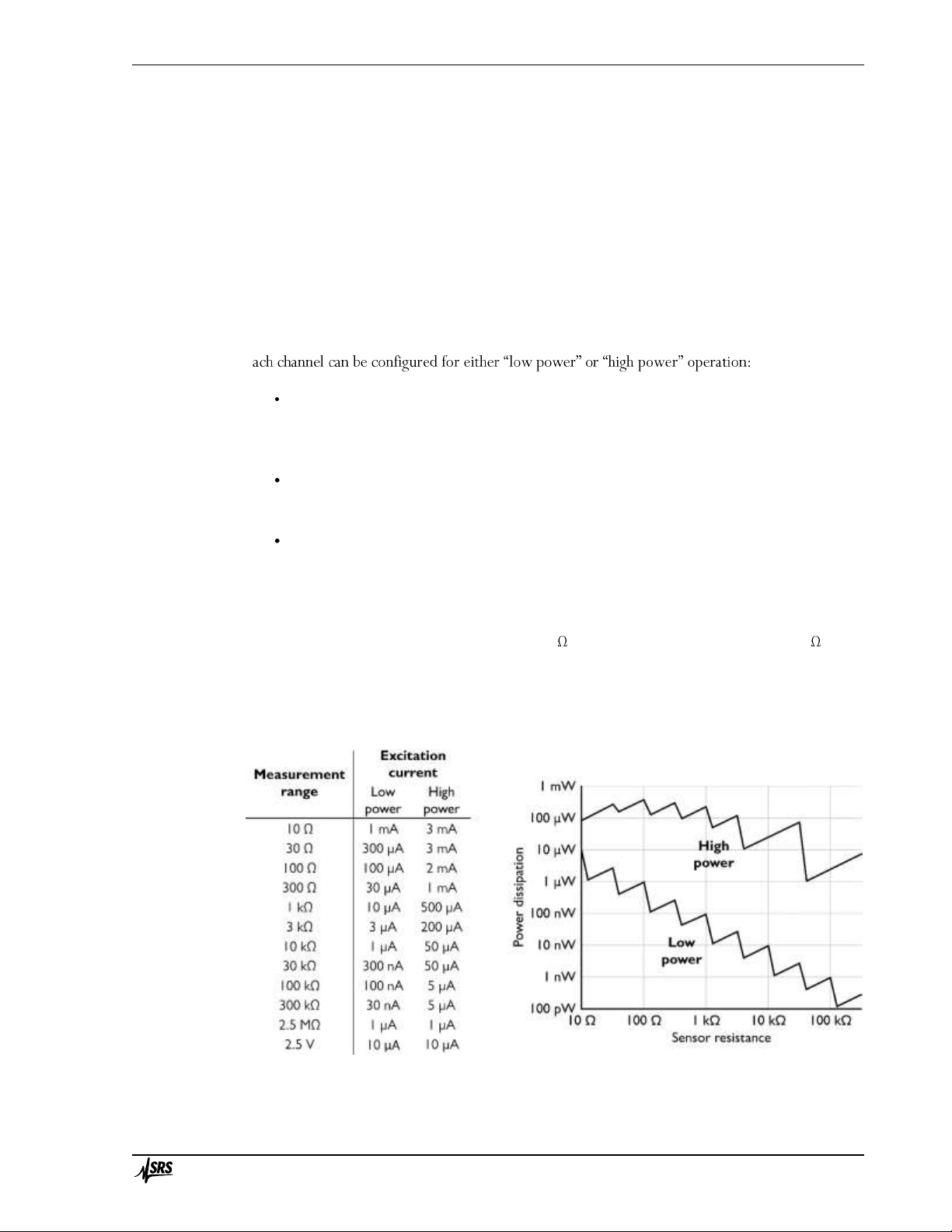

The PTC323 has 12 measurement ranges. Within any given range, it generates a constant

excitation current as shown in the table below. Note that the range has to be greater than the

sensor resistance, so if the sensor resistance is 10 k , for example, the range should be 30 k .

For diode sensors the range is always 2.5V and the excitation current is always 10 µA.

The graph below shows how the amount of power dissipated by the sensor depends on the range

and power settings. Sensor heating (degrees above the ambient temperature) is proportional to

power dissipation.

Left: the amount of current passed through the sensor by the PTC10; right:

the amount of power that the sensor dissipates due to that current

Page 26

Introduction 10

PTC10 Programmable Temperature Controller

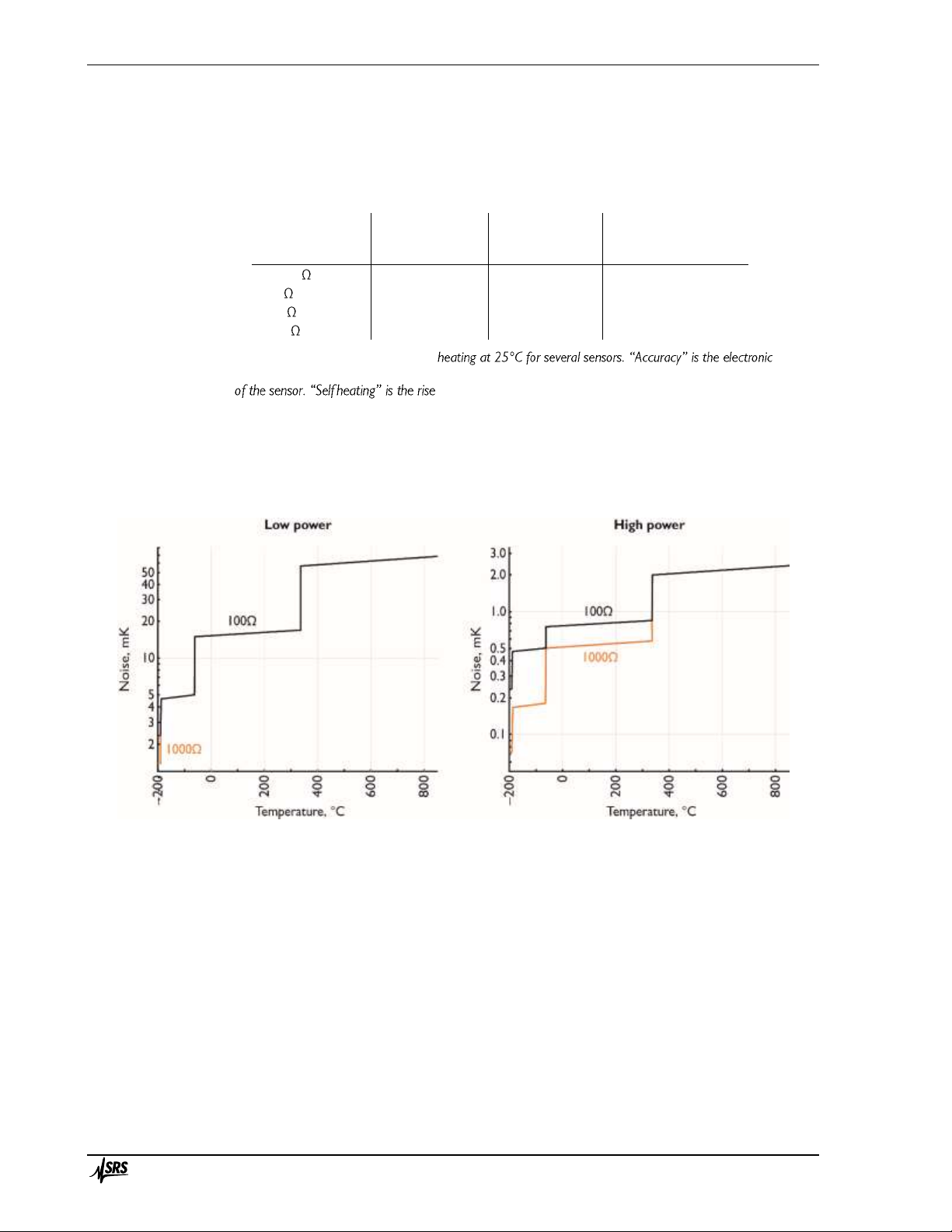

The table below shows some representative noise, electronic accuracy, and self-heating values for

free-standing sensors at room temperature. Note that the amount of self-heating can vary

dramatically depending on the thermal conductivity of whatever the sensor is attached to or

immersed in.

Noise

Accuracy

Self-heating

Low

power

High

power

Low

power

High

power

Low

power

High

Power

100 RTD

20 mK

0.8 mK

640 mK

40 mK

0.09 mK

100 mK

1 k thermistor

2 mK

0.08 mK

60 mK

3 mK

0.009 mK

40 mK

10 k thermistor

2 mK

0.02 mK

50 mK

2 mK

0.0009 mK

25 mK

100 k thermistor

9 mK

0.04 mK

220 mK

3 mK

0.00009 mK

2.5 mK

Noise, accuracy, and amount of self-

accuracy of the PTC10 immediately after calibration and does not account for self-heating or the accuracy

- above ambient temperature of a ~1 mm diameter sensor hanging

by its leads in still air (dissipation constant 1 mW/°C).

The graphs below show how electronic noise varies with temperature for several types of

sensors.

RMS noise levels for 100Ω and 1000Ω platinum RTD sensors as a function of temperature. At low power, the 100Ω

and 1000Ω sensors have about the same noise level.

Page 27

Introduction 11

PTC10 Programmable Temperature Controller

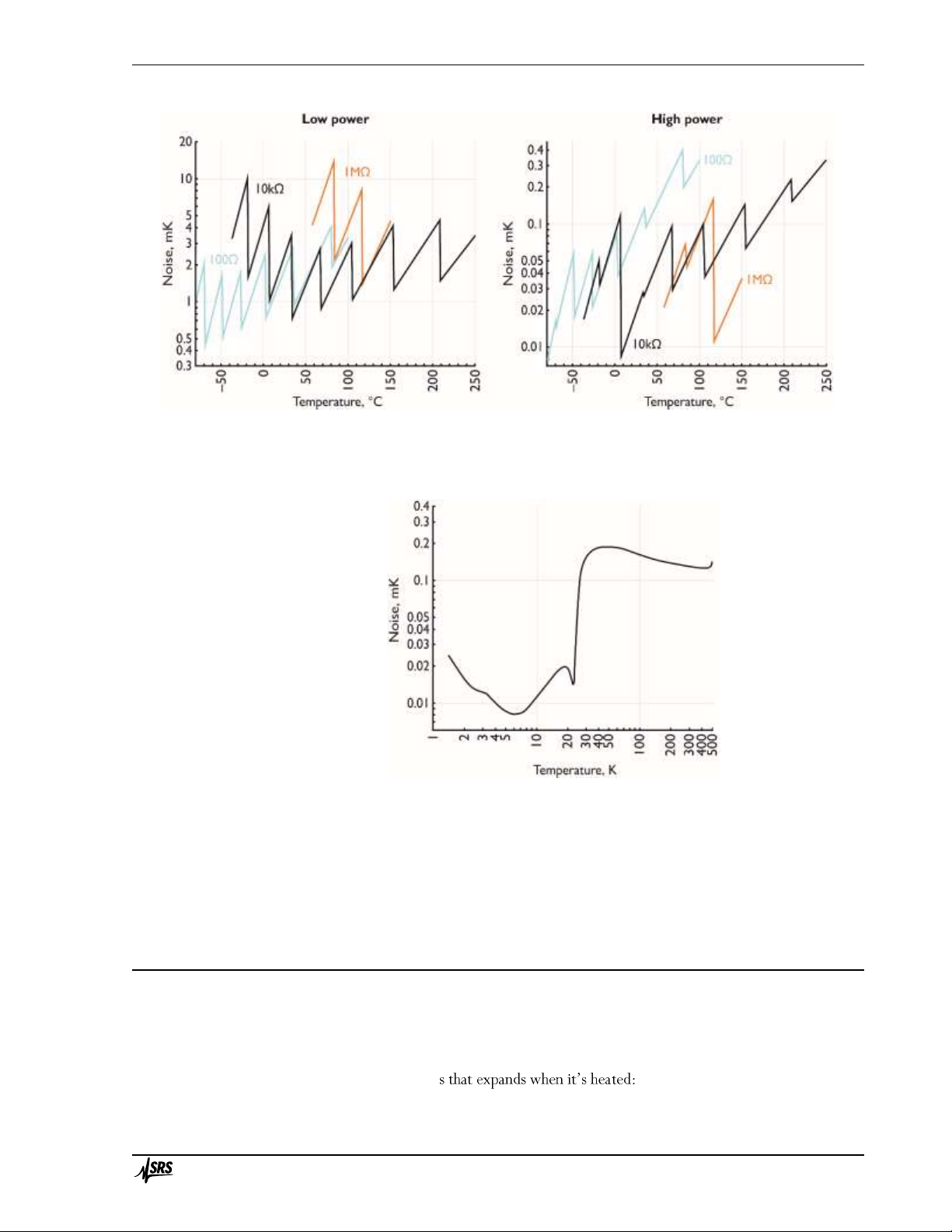

RMS noise levels for 100Ω, 10kΩ, and 1MΩ (at 25°C) thermistors as a function of temperature

RMS noise for DT-670 diode sensor as a function of temperature.

The direction of the excitation current can be set by the user to forward, reverse, or AC

(switching between forward and reverse with each sample). AC current is recommended for

resistive sensors to reduce noise and drift. AC current cannot be used with diode sensors.

PTC330 thermocouple reader

How thermocouples work

If the two ends of a metal wire are held at different temperatures, the electrons at the hot end

move faster than those at the cold end. Since the electrons are free to diffuse throughout the wire,

they behave somewhat like a ga the hot end of the wire develops a

lower density of electrons relative to the cold end. As a result, the hot end has a slight positive

Page 28

Introduction 12

PTC10 Programmable Temperature Controller

charge and the cold end a slight negative charge, producing a voltage difference. The exact voltage

depends on the temperature at each end and the composition of the wire.

A thermocouple has two wires that develop different voltages in response to a given temperature

difference. The wires are welded together at one end ) and the voltage difference

is measured at the other junction . If we know the cold junction temperature and if each

wire has a perfectly homogeneous composition, we can calculate the hot junction temperature.

Normally, we measure the cold junction temperature with another sensor such as an RTD or a

thermistor.

Thermocouple calibration tables generally assume that the cold junction is at 0 °C. Therefore, to

convert the thermocouple voltage to a temperature, to calculate what the

thermocouple voltage would be if the cold junction were at 0°C. For example, say a type K

thermocouple is used to measure the temperature of some liquid nitrogen. The thermocouple

reader measures a voltage of -6.829 mV and also determines that the cold junction is at 25°C. The

calibration table indicates that the voltage of a type K thermocouple at 25°C is 1.000 mV. So we

add 1 mV to the reading and look up the result, -5.829 mV, in the calibration table. The result is

the temperature of the inaccurately named -196°C.

Choosing a thermocouple

Thermocouples are inexpensive and can sense a wide range of temperatures, but without

frequent calibration they are accurate to no more than 1°C, partly because they tend to oxidize or

otherwise react with gases in their environment. Thermocouples made from thinner wires oxidize

more quickly and therefore exhibit more calibration drift than heavier-gauge thermocouples.

When selecting a thermocouple type, t s generally a tradeoff between sensitivity and

stability. That is, thermocouples that produce the largest voltages also have the most calibration

drift. With the excep he letters that describe thermocouples (E, J, K, etc.) appear

to be assigned in order of increasing long-term stability, with type C being the least stable and type

T the most. Therefore, if your application requires low noise, it might be best to choose type E; for

the best absolute accuracy, type T might be more appropriate.

Each PTC330 input supports one of the following thermocouple types:

Type E thermocouples have one chromel (90% nickel, 10% chromium) and one constantan

(60% copper, 40% nickel) wire. It has a large voltage change per degree (68 µV/°C), resulting in

excellent signal-to-noise ratio. However, its long-term stability is not very good. Type E

thermocouples are resistant to oxidation, but corrode if used in a vacuum or other reduced-oxygen

environment.

Type J thermocouples have one iron and one constantan wire. Above 500°C, oxidation of the

iron results in poor stability. This thermocouple is mainly used in legacy applications.

Type K thermocouples have one chromel and one alumel (95% nickel, 2% manganese, 2%

aluminum, 1% silicon) wire. With a wide temperatur s the most

popular type of thermocouple. Type K thermocouples are resistant to oxidation, but corrode if

used in a vacuum or other reduced-oxygen environment.

Type N thermocouples and 1% silicon) and one

and 0.1% magnesium) wire. They are designed for high stability,

especially at temperatures above 500°C. However, their sensitivity is low.

Type T thermocouples have one copper and one constantan wire. They are very accurate and

can be used in reducing atmospheres, but their temperature range is limited.

The following table summarizes some properties of thermocouples. Two temperature ranges are

given: the range that the thermocouple itself can withstand without losing its calibration, and the

built-in calibration tables, assuming that the cold junction

ng

Page 29

Introduction 13

PTC10 Programmable Temperature Controller

appears on the display and any feedback loops for which the thermocouple is an input do not

function.

-2 standard for thermocouple-to-thermocouple

material variation. Not all commercial thermocouples may follow this standard; for example,

Omega specifies an accuracy of 2.2°C for its type J and K thermocouples. Greater accuracy is

possible if your thermocouple is custom calibrated. The accuracy values in this table only apply to

the thermocouple itself and

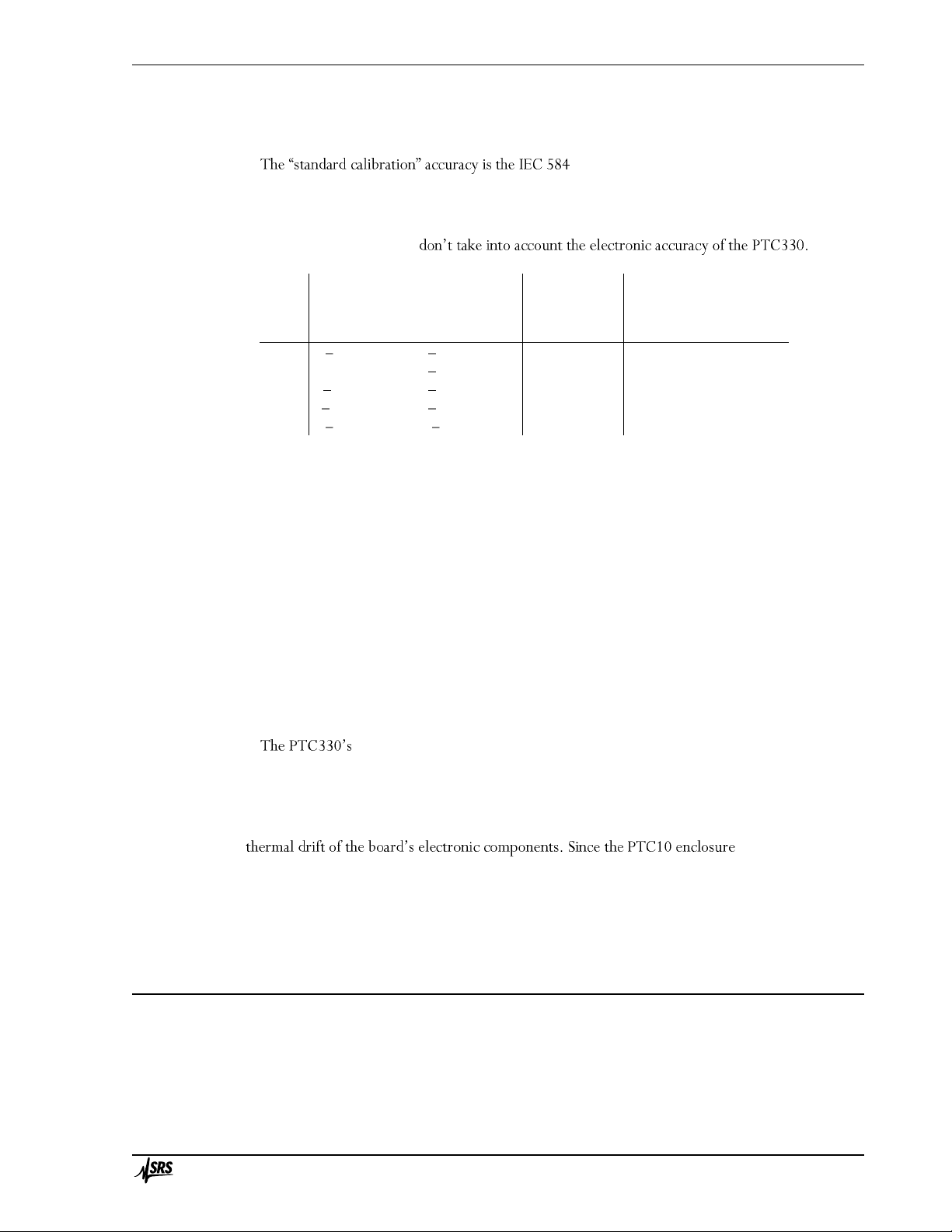

Tem perature range, °C

Accuracy

Type

Thermocouple

PTC10, cold

junction at 25°C

Sensitivity,

µV/°C at 25°C

Standard

calibration,

°C, at 0°C

Custom

calibration,

°C, <300°C

E

200 to 870

245 to 1025

60.9

1.7

1

J

0 to 760

185 to 1225

51.7

1.5

0.1

K

200 to1260

245 to 1395

40.6

1.5

0.1

N

270 to 1300

245 to 1325

26.5

1.5

T

200 to 350

245 to 425

40.6

0.5

0.1

Connecting thermocouples to the PTC330

The PTC330 thermocouple reader is factory-configured to read one of the above thermocouple

types. The thermocouple must be equipped with a miniature jack such as Omega part number

SMPW-J-M for type J, SMPW-K-M for type K, etc. The jacks on the PTC330 are color coded

according to the American (ANSI) color coding scheme, i.e. type J jacks are black, type K jacks are

yellow, etc. The colors may not conform to the standard colors used in other countries.

The thermocouple jacks are connected with thermocouple extension wires to a cold junction

block inside the PTC10. The cold junction temperature is measured with a platinum RTD

temperature sensor. The cold junction temperature is recorded so that if unexpected drift or other

artifacts appear in the thermocouple readings, it can be determined whether the artifacts are due to

erratic behavior of the cold junction. If readings are displayed in sensor units (see the

System.Other.Units button), the raw thermocouple EMFs are displayed in millivolts, not corrected

for the cold junction temperature, and the cold junction temperature is displayed in ohms.

inputs are optically isolated and the thermocouples can come in direct contact

with electrically live metal. In this case, however, the noise level and accuracy of the measurement

may be affected.

The PTC330 hardware is calibrated at ambient temperatures of 25 and 35°C. An on-board

temperature sensor continuously interpolates between these two calibrations to account for

is usually elevated 2

to 3 degrees above ambient temperature, the accuracy of the PTC330 may be compromised if the

ambient temperature rises above about 32°C.

To further improve measurement stability, the PTC330 can control the main enclosure fan to

keep the card at a constant temperature (see the manual entry for the Channel.PCB control).

PTC420 AC output card

The PTC420 AC output card has a solid-state relay that delivers mains current to the heater. It is

intended for control of large heaters including heating mantles, heating tape, and heating blankets.

The relay is either on or off; when on, the full AC mains voltage appears on the output. To vary the

output power, the PTC420 switches the relay on and then off once every 10 seconds (by default)

with a variable duty cycle.

Page 30

Introduction 14

PTC10 Programmable Temperature Controller

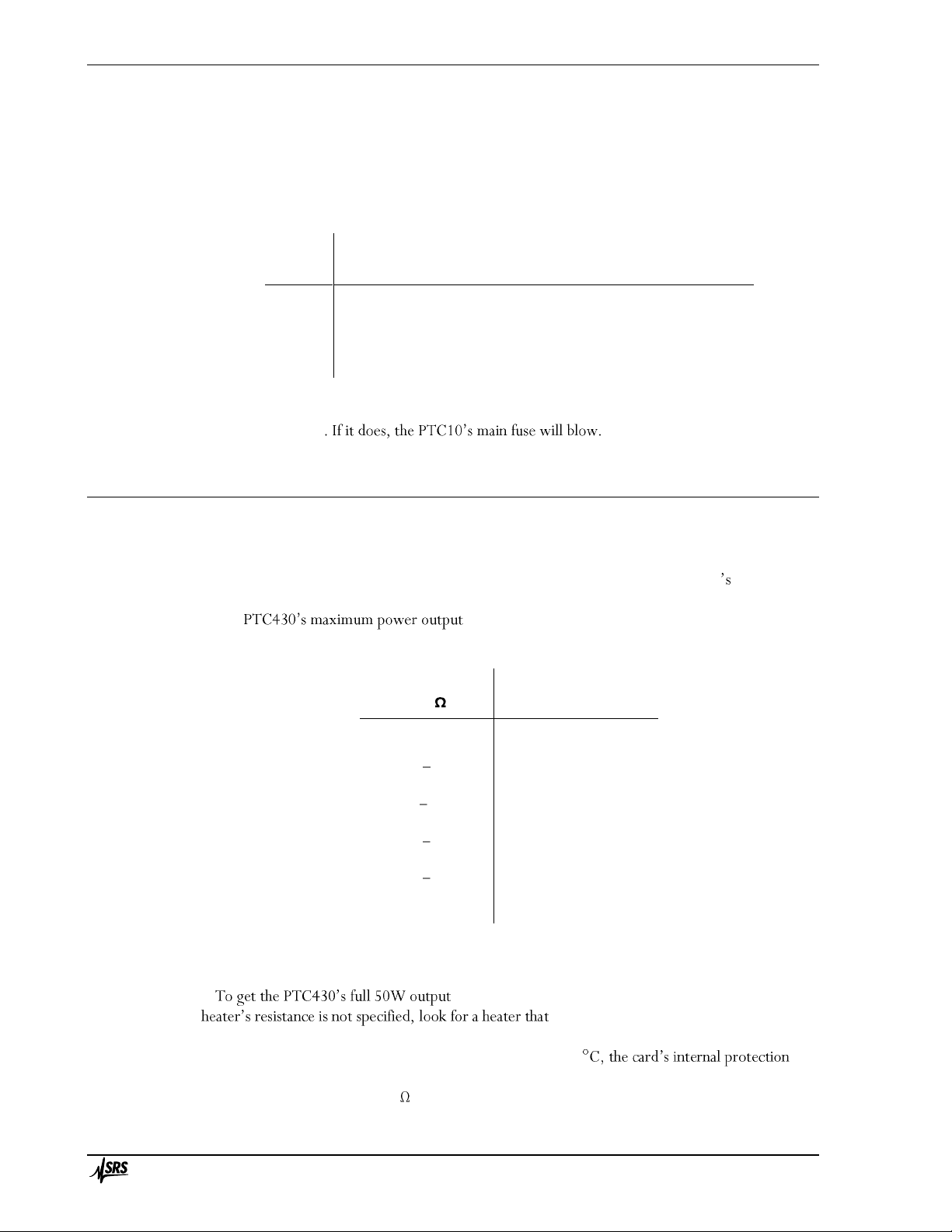

The card can deliver at most 5 A of current. If the resistance of the heater is too small, the card

delivers more than its rated current and may be shut down by its internal protection circuitry. In

some cases the card may be damaged. The minimum permissible heater resistance depends on the

AC line voltage as shown in the table below. The table also shows the maximum power that the

card can deliver.

Line

voltage,

V

Exam ple

locations

Min heater

resistance,

ohm s

Max power at

min heater

resistance, W

Max power

at heater

resistance R, W

100

Japan

20

500

10000 / R

120

Canada, US

24

600

14400 / R

220

Russia

44

1100

48400 / R

230

Europe

46

1150

52900 / R

240

China, Australia

48

1200

57600 / R

The total AC current delivered at any one time by the all the PTC420 cards in a single chassis

cannot exceed 10 A

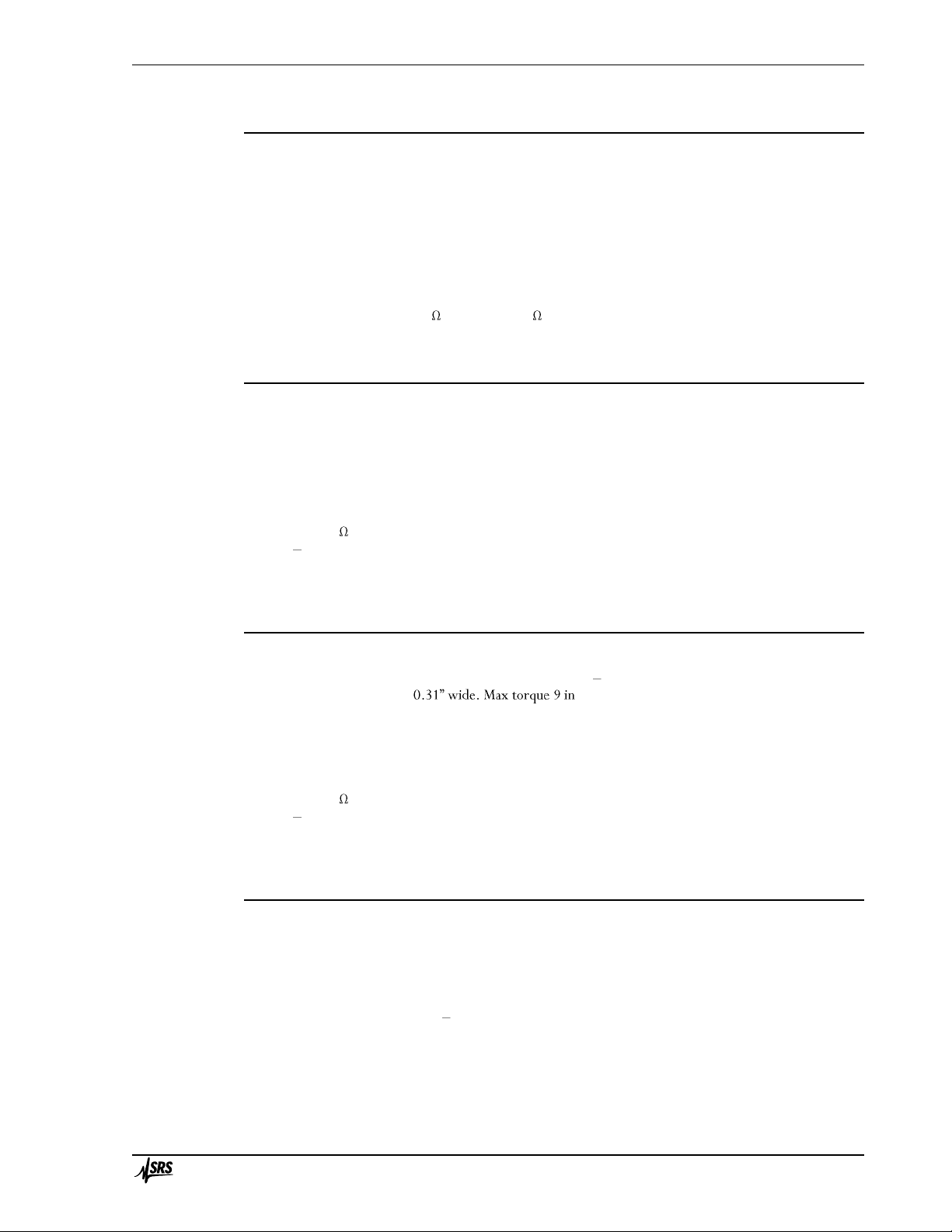

PTC430 50 W DC output card

The PTC430 DC output card can deliver up to 50 W of power and is intended for precise

control of small heaters. The card offers two voltage ranges (50 V and 20 V) and three current

ranges (1A, 0.5A, and 0.1A). An auto-range feature continuously adjusts the current and voltage

ranges to the smallest values needed to achieve the power specified with the channel Hi Lmt

setting.

The depends on the resistance of the heater; see the table

below.

Heater resistance

(R),

Optimum

output

range

Maximum

power, W

> 500

50 V 0.1 A

2500/R

500

50 V 0.1 A

5

100 500

50 V 0.5 A

2500/R

100

50 V 0.5 A

25

50 100

50 V 1 A

2500/R

50

50 V 1 A

50

20 50

50 V 1 A

R

20

20 V 2 A

20

10 20

20 V 2 A

400/R

10

20 V 2 A

40

< 10

20 V 2 A

4R

Maximum output power and optimum output range as a function of

heater resistance

, the heater must have a resistance of 50 ohms. If the

produces about 265W at 115V or 1060W

at 230V.

If the heatsink temperature of a DC output card exceeds 60

circuitry shuts down the output. This is likely to occur if one of the 50V output ranges is used when

the heater resistance is under 20 ; if the ambient temperature outside the chassis is above 30°C; if

Page 31

Introduction 15

PTC10 Programmable Temperature Controller

and/or if the system fan is turned off or not working. If the heater

resistance is less than 20 , select the 20 V ranges to prevent thermal

shutdown.

The temperature of the heatsink can be monitored by setting the System.Display.Monitors

PCB temperature display

should appear on the Select screen directly underneath the current value of the DC output card. If

the temperature

If the 50 V 1 A range is used and the average heater resistance is less than 65 , up to three DC

output cards can be installed in a single chassis and run at full power simultaneously. If four DC

output cards are installed and the average output current at any given moment exceeds 0.8A, a

system reset may occur to protect the power supply from overload.

If any other range is used or the average heater resistance is greater than 65 , up to four DC

output cards can be installed in a single chassis and run at full power.

Hardware faults

The PTC430 continuously monitors for unsafe operating conditions. If such a condition occurs

and persists for more than 2 seconds, the In addition, one of the

following error messages appears in a pop- :

Ground fault: on, and the current s

positive terminal is not the same as the current flowing into the negative terminal. This error

can occur if one of the leads is shorted to an external ground.

Unexpected output current off, but current is flowing into

the negative terminal anyway. This error may indicate that the heater is shorted to a power

source other than the PTC430. It can also i

circuitry.

DC output card overheated: Either the resistance of the heater is too low; the positive

and negative terminals are shorted to each other

off; or the chassis fan is no longer functioning. Try reducing the maximum output voltage or

current, and make sure the front panel fan is running.

To re- key, then

re-enable the outputs by pressing the Output Enable key twice.

PTC431 100W DC output card

The PTC431 DC output card can deliver up to 100 W of power and is intended for precise

control of small heaters. The card offers two voltage ranges (50 V and 20 V) and three current

ranges (2A, 0.6A, and 0.2A). An auto-range feature continuously adjusts the current and voltage

ranges to the smallest

setting.

The 20V range can be used to limit the output voltage for safety purposes. Selecting this range

does not otherwise affect the performance of the card. On the other hand, the 0.6A and 0.2A

current ranges offer lower noise levels and are intended to be used when very precise temperature

control is needed.

The maximum power that the PTC431 can deliver depends on the resistance of the heater as

shown below.

Page 32

Introduction 16

PTC10 Programmable Temperature Controller

Maximum output power as a function of output range and heater resistance

at 230V.

circuitry shuts down the output. This is likely to occur if the heater resistance is under 10 ; if the

ambient temperature outside the chassis is above 30°C; and/or if the system fan is turned off or not

working. The PCB temperatures can be monitored by going to the System screen and setting the

Monitors control to Show.

Although up to four PTC431 cards can be installed in a chassis, only two can be run at full power

at any given time. If more than two PTC431 cards are installed, their output should be limited to

half their maximum value, either by using the 20V range or by setting the upper limit to 50W.

Hardware faults

The PTC431 can detect certain unsafe operating conditions. If such a condition occurs and

-enable the output,

disable all outputs by pressing the Output Enable key, then re-enable the outputs by pressing the

Output Enable key twice). In addition, one of the following error messages appears in a pop-up

Measured heater current differs from desired value: The ,

and the current at the positive terminal differs from the desired current by more than 0.25A.

This error can occur if the card is out of calibration. It can also mean that the card has been

damaged and is no longer capable of correctly regulating its output current or of producing

its rated output current.

Current at + and heater terminals is different , and the

current at the positive terminal differs from the current at the negative terminal by more

than 0.25A. This error can occur if one of the leads is shorted to an external ground.

Output is off but heater current was detected: current is flowing into the negative

. This error may

indicate that the heater is shorted to a power source other than the PTC10. It can also

i

Output card overheated: Either the resistance of the heater is less than 10 ohms; the

positive and negative terminals are shorted to each other; the ambient temperature is too

Page 33

Introduction 17

PTC10 Programmable Temperature Controller

or current, and make sure the front panel fan is running.

PTC440 TEC driver

The PTC440 includes a current source to drive a thermoelectric cooler and a sensor input for a

thermistor, RTD, or IC temperature sensor. The card has a single 15-pin D-sub connector for both

sections. The pinout and wiring diagram are shown below. Only pins 1 and 3 need to be connected

to power a TEC device, and only pins 8 and 14 need to be connected to read a temperature sensor.

The other pins are optional.

TEC driver section

A thermoelectric cooler (TEC), also referred to as a Peltier device, is a solid-state electric heat

pump that can both heat and cool, depending on the direction of current flow. Thermoelectric

coolers are generally used for precise temperature control of small objects in the range of -100

100°C.

With its high-current, low-voltage output, its ability to change the direction of current flow, and

circuitry to protect the TEC from excessive voltages, the PTC440 is primarily intended to drive

TEC devices. However, it can also drive low-resistance (optimally 2.4 ohm) resistive heaters. In

this case, the lower output limit should be set to 0 A and the heater should be connected to pins 1

and 3.

If the TEC is unplugged while current is flowing, or if the current is turned on when no TEC is

is

feature ensures that the voltage between the output terminals is always zero when a TEC is plugged

in. A nonzero voltage would produce a destructive current spike when the TEC is plugged in.

Therefore, if the PTC440 does not produce any output current, turn the current off and back on

three times or setting the output

value to zero with the Channel.value control.

Connecting the TEC

Connect the + and leads of the TEC to pins 1 and 3, respectively. Pins 2 and 4 can also be

connected to reduce contact resistance.

The PTC440 is a current source, that is, it has direct control over the current that passes through

the TEC but not the voltage. Since thermoelectric coolers are easily destroyed by both voltages and

currents even slightly above their rated maximum, the PTC440 provides a voltage input (Vmon) to

Page 34

Introduction 18

PTC10 Programmable Temperature Controller

monitor the TEC voltage. The connections for this input are the TEC sense + and TEC sense

pins. If these leads are connected to the TEC + and leads, as close to the TEC as possible, Vmon

shows the voltage across the TEC. If the leads are not connected, Vmon shows the voltage at the

.

If only a small current passes through the TEC even at its maximum voltage, the TEC may have

been damaged by excessive current or voltage.

Maximum TEC voltage

The TEC driver has four voltage ranges: 3, 6, 9, and 12V. In general, the lowest possible voltage

range should be used; besides potentially damaging the TEC, the larger voltage ranges create excess

heat inside the PTC chassis and ca

However, when selecting a voltage range, it's important to account for the resistance of the wires

you've used to connect the TEC. This resistance can significantly reduce the voltage available to the

TEC. For example, if the wires have a resistance of 0.5 ohms and a 5A current is flowing through

them, the wires will reduce the available voltage by 2.5V. Therefore, if the 3V range is selected,

the maximum voltage across the TEC will only be 0.5V. If the TEC sense leads have been

connected, this is the maximum voltage that will appear in the Vout display.

To minimize such voltage losses, heavy-gauge wires should be used to connect the TEC. Standard

DB-15 cables in particular should not be used because their thin wires absorb most of the PTC440's

output power.

The Vmon channel has a voltage limit, Vmax. If the voltage at the TEC exceeds Vmax, the

PTC440's output is shut off. The output will remain disabled until it is set to zero using either the

Output Enable key or the If the sense leads have been

connected, the lead resistance does not have to be taken into account when setting Vmax.

In some cases, the output may exceed Vmax every time the PID feedback is enabled. To avoid

this, temporarily set the ramp rate to a low value (i.e. 1 °C/s) when enabling the feedback.

Temperature input section

The PTC440 has a sensor input that can read thermistors, RTDs, AD590, and

LM135/LM235/LM335 temperature sensors. t is not intended for

precision applications and should only be used when temperature stability of ~0.1°C is acceptable.

For more demanding applications the sensor should be read with a dedicated input card such as the

PTC320 (for thermistors, RTDs, and diodes), PTC321 (for 100 RTDs only), or PTC330

(thermocouples). These cards provide lower noise and greater accuracy than the PTC440.

Connecting the temperature sensor

RTDs: 4-wire RTDs should be used to ensure accuracy. Two of the wires are normally white

and are connected to one end of the resistive sensor, while the other two are black, red, or yellow

and are connected to the other end. There is normally no shield. In this case, the RTD should be

wired in one of the following ways (assuming black and white wires):

Pin 7

Pin 8

Pin 14

Pin 15

Option 1

White

Black

White

Black

Option 2

Black

White

Black

White

Thermistors: Two-wire thermistors should be connected to pins 8 and 14.

Page 35

Introduction 19

PTC10 Programmable Temperature Controller

LM135/LM235/LM335: The LM135, LM235, and LM335 are integrated circuit temperature

sensors. If an excitation current between 400 µA and 5 mA is passed through the sensor, the

voltage drop across the sensor is 10 mV/K. The three models have different temperature ranges,

with the LM135 having the largest range and the LM335 the smallest. For the best possible

accuracy the sensors can be connected in a 4-wire configuration, just like an RTD. However, it is

more common to connect the device in a 2-wire configuration, leavings pins 14 and 15 of the

PTC440 unconnected. The first row of the table below lists the four sensor input pins on the

s show which leads of the LM135/235/335

should connect to those pins.

Pin 7

Pin 8

Pin 14

(optional)

Pin 15

(optional)

8-pin SOIC

Pin 8

Pin 4

Pin 8

Pin 4

Other packages

+ +

AD590/AD592: The AD590 and AD592 are an integrated circuit temperature sensors. When a

/K flows

through the device. The two models have different packages and temperature ranges, with the

AD590 having a range of -55 150°C and the AD592 a range of -25 125°C. The AD590/592

can be connected in a 2- or 4- wire configuration as shown in the table below. For the 2-wire

configuration, leave PTC440 pins 14 and 15 disconnected.

Pin 7

Pin 8

Pin 14

(optional)

Pin 15

(optional)

8-pin SOIC

Pin 2

Pin 3

Pin 2

Pin 3

Other packages

+ +

Sensor excitation current

The excitation current provided to resistive sensors can be set to 10 µA, 100 µA, 1 mA, or auto.

In auto current mode, the sensor resistance is continuously monitored and the excitation current is

adjusted whenever the sensor resistance rises above or drops below the levels shown in the table

ion when a diode sensor is in use, or 1

mA when an LM335 or AD590 sensor is in use.

Sensor

resistance

Excitation

current

<2 k

1 mA

1 20 k

100 µA

>10 k

10 µA

TEC driver (for resistive sensors only)