Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 1 of 16

by S Instruments, Inc.

Model SR775L

Wheelchair Scale System

Operating and Service

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

Manual

Serial Numbers: 1035+

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 2 of 16

TABLE OF CONTENTS

TABLE OF FIGURES ......................................................................................................................2

PACKING CHECKLIST - SR775L ................................................................................................3

ASSEMBLY.......................................................................................................................................4

SYSTEM DESCRIPTION AND INTENDED USE .......................................................................5

MAINTENANCE AND CLEANING ..............................................................................................5

STORAGE AND TRANSPORTATION ........................................................................................6

SPECIFICATIONS...........................................................................................................................7

BUTTON FUNCTIONS ...................................................................................................................8

BASIC SYSTEM OPERATION ......................................................................................................9

DISPLAY ERROR CODES ...........................................................................................................10

BATTERY REPLACEMENT .......................................................................................................10

THEORY OF OPERATION .........................................................................................................11

CALIBRATION ..............................................................................................................................12

WARRANTY...................................................................................................................................15

TABLE OF FIGURES

Figure 1: Scale Assembly................................................................................................................ 4

Figure 2: Battery Compartment Cover ........................................................................................ 4

Figure 3: Button Display ................................................................................................................ 8

Figure 4: Battery Compartment .................................................................................................. 10

Figure 5: Calibration Switch........................................................................................................ 12

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 3 of 16

PACKING CHECKLIST - SR775L

Wheelchair Scale System

DESCRIPTION Qty

√

MAST ASSEMBLY 1 ea

BASE ASSEMBLY 1 ea

NYLON INSERT LOCK NUTS 4 ea

PACKAGE OF SIX (6) “D” CELL BATTERIES 6 ea

QUALITY CONTROL CHECKLIST 1 ea

CALIBRATION CERTIFICATE 1 ea

MODEL SR775L MANUAL 1 ea

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 4 of 16

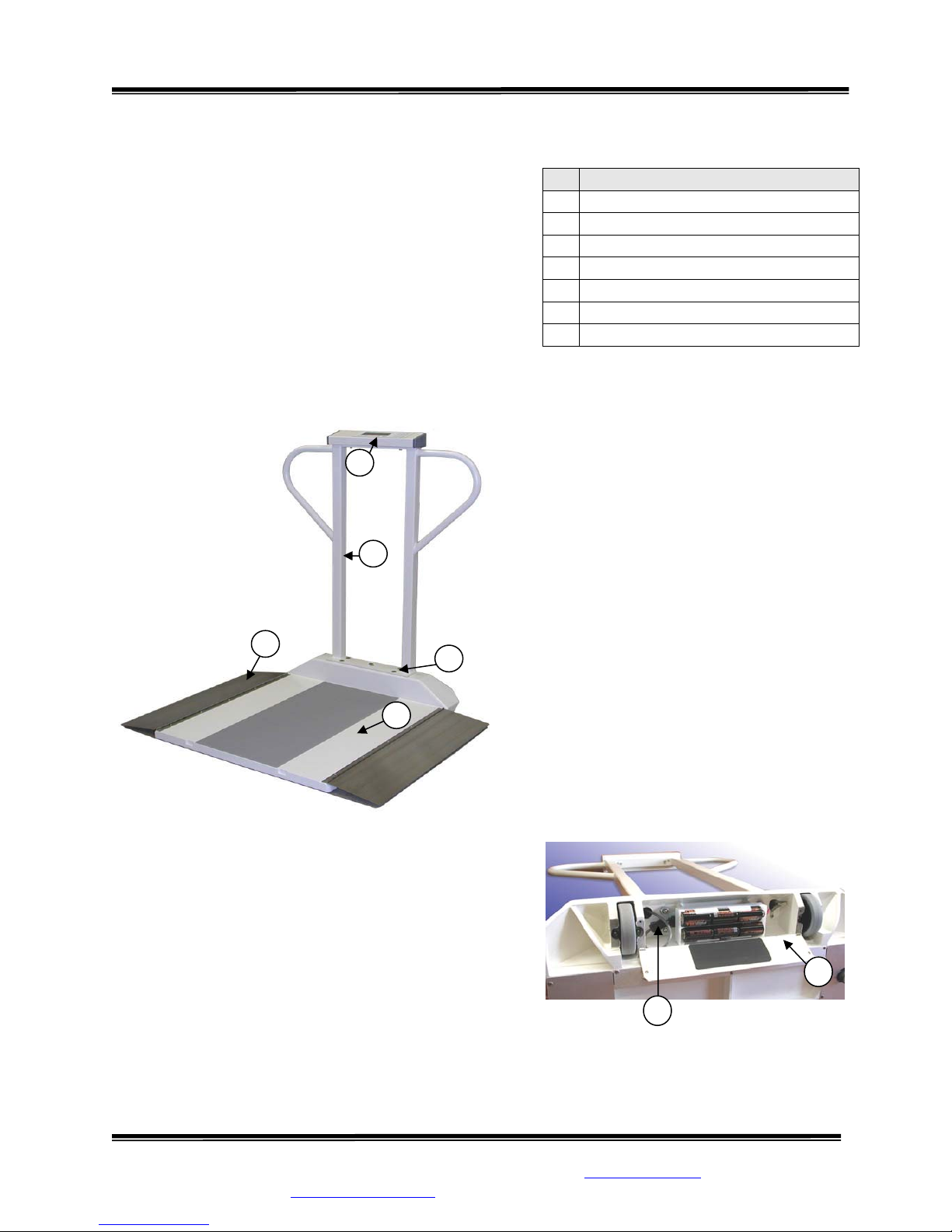

ASSEMBLY

STEP 1: Unpack the scale system and check parts

against the PACKING CHECKLIST. If there are

any missing or damaged parts, call the local sales

representative.

STEP 2: Verify that the serial number on the Display

Assembly (1) and the Base Assembly (3) match.

IMPORTANT: All of the scale systems are calibrated

at the factory as a complete system. Components

should not be interchanged with other systems.

1

# PART NAME

Display Assembly

1

Mast Assembly

2

Base Assembly

3

Ramps

4

Flat Socket Head Cap Screws (4)

5

Battery Compartment Cover

6

Display Assembly Cable Connector

7

STEP 3: (Figure 1) Place the Mast

Assembly (2) onto the Base Assembly as

shown. Note: Be sure to put Display

Assembly Cable Connector (7) through

corresponding hole in Base Assembly.

2

4

5

3

Figure 1: Scale Assembly

TEP 6: Plug the Display Assembly Cable Connector

S

(7) into its mate in the battery compartment.

STEP 7: Insert the six (6) “D” cell batteries

following

directions on the Battery Compartment Cover. Close and

sec u r e l y s cre w th e B a t t e r y Co mpa r t m e n t Cover into place.

STEP 8: Gently return scale to an upright, level position

on the f

loor.

STEP 4: Insert the four 3/8” Flats Socket

Head Cap Screws (5) provided, to attach

the Mast Assembly to the Base Assembly.

STEP 5: Gently position the scale system

on its side. Lo o s e n t h e battery compartment

cover screws to open the Battery

Compartment Cover (6) (Figure 2).

6

7

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

Figure 2: Battery Compartment Cover

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 5 of 16

SYSTEM DESCRIPTION and INTENDED USE

SYSTEM DESCRIPTION

The SR775L Scale System employs the latest in microprocessor and load cell technology to

provide precise and repeatable weight data.

The low power microprocessor circuitry derives its power from batteries that will provide up to

400 hours of weight readings before needing replacement. This eliminates the need for an external

battery charger or the danger of a plug-in power supply.

The SR775L also incorporates a keypad tare, which allows the caregiver to preset a predetermined tare value that can represent the weight of the wheelchair, walker, chair, etc., to be

used when weighing the patient. This amount will be automatically subtracted from the gross

weight of patient and equipment so only the net weight of the patient will be displayed and stored

in memory.

The scale comes equipped with dual side ramps to facilitate access when using wheelchair bound

patients. When not in use, or when moving the scale, the dual ramps are folded up and onto the

scale surface.

INTENDED USE

The SR775L is designed for use as a portable patient

weighing system for ambulatory and non-ambulatory

wheelchair bound patients, or those that need to be

supported by a chair or walker. Maximum weight

capacity must not exceed 1000 pounds or 454

kilograms gross weight.

MAINTENANCE and CLEANING

Exercise caution when cleaning the display

window of the SR775L as it is made of

clear polyester and can be scratched by

abrasive cleaners. It is recommended to use

mild soap and water for general cleaning

and disinfecting. DO NOT use vinegar to

clean the display.

DO NOT use pressurized water or steam. The

scale system contains microprocessor circuitry

and strain gauge sensors that may be adversely

affected by exposure to such an environment.

WARNING

DO NOT EXCEED

MAXIMUM WEIGHT LIMIT OF

1000 LB / 454 KG

WARNING

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 6 of 16

STORAGE and TRANSPORTATION

STORAGE

If storing this equipment for extended periods or longer than three (3) months, remove the

batteries. To maintain proper operation of this instrumentation, storage and transport conditions

should not vary outside the following conditions: Relative Humidity 0% to 85%, Ambient

Temperature -10°C to +50°C.

TRANSPORTATION

To transport the SR775L, tilt the scale back and roll on the built-in wheels to another location.

Gently return the scale system to an upright, level position.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 7 of 16

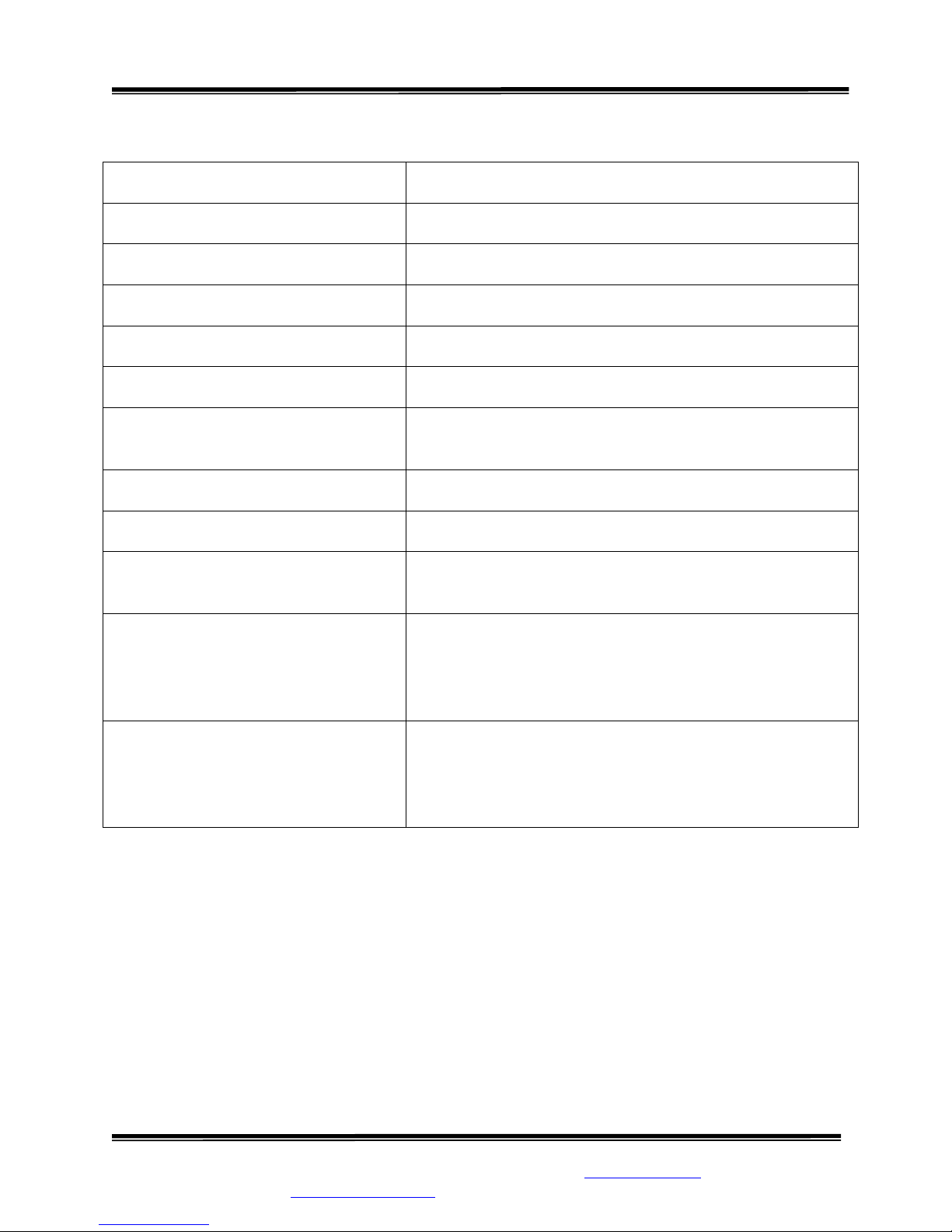

SPECIFICATIONS

MAXIMUM WEIGHT CAPACITY

PLATFORM SIZE

DISPLAY TYPE

DISPLAY RESOLUTION

ACCURACY

AUTO ZERO

KEYPAD TARE

AUTOMATIC SHUT OFF

AVERAGING

POWER SUPPLY

1000 lb or 454 kg

28 in x 28 in

1 in LCD display screen

0.1 lb/0.1 kg

0.1% +/- 1 digit reading over 200 g

One button operation

Pre-programmable TARE value to allow patient’s net

weight to be viewed

Programmable to (OFF / 60 / 120 / 180) seconds

Automatic digital filter

Six (6) “D” cell batteries

Low battery indicator on Display

OPERATING CONDITIONS

TRANSPORT and STORAGE

Normal operating conditions for this product:

Ambient Temperature Range: 5°C to 35°C

Relative Humidity Range: 0% to 85% (non – condensing)

Avoid exposure to high-pressure water or steam.

Storage and transport conditions should not vary outside

the following conditions: Relative Humidity 0% to 85%,

Ambient Temperature -10°C to +50°C. Remove batteries

if storing for an extended period of time.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

y

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 8 of 16

BUTTON FUNCTIONS

Figure 3: Button Displa

ZERO

The “ZERO” button activates scale display and sets the system to zero. When the system

0

is turned on, the display lights all segments on the LCD, shows the software revision level,

and the local gravitational constant. Scale will be in GROSS WEIGHT mode and display

will zero.

LB/KG MODE

The “LB/KG” button factory default setting allows user to toggle between viewing data in

pounds or kilograms. Alternative options can display “pounds only” or “kilograms only”,

deactivating the “LB/KG” button.

WEIGH

The “WEIGH” button starts the scale and displays the pa t i e n t ’ s w e i g h t . T h e display lights

all segments on LCD, shows the software revision level, and the local gravitational

constant, and starts up in the same mode (NET or GROSS) it was in prior to Automatic

Shut Off. Tare data will not be compromised.

HOLD

The “SET TARE” button stores the weight of object prior to that object and patient being

placed together on the scale.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 9 of 16

BASIC SYSTEM OPERATION

SETTING SYSTEM ZERO

Before placing anything on the scale, ensure it is level and press the “ZERO” button.

0

When the system starts up, the display will quickly test all segments, indicate the software

revision level, and the local gravitational constant. All tare values will be erased and the scale will b e

in GROSS WEIGHT mode. Display will zero. When both the ZERO and STABILITY DETECTION

display symbols are visibl e, weighing ca n proceed. Ambulatory patient can walk on the scale and

the weight will appear on the display. Non-ambulatory patients should not be placed on the scale

until tare is set for any equipment needed by the patient, i.e. wheelchair/chair/walker etc. Refer to

SETTING TARE.

WEIGH

When the system has been set to zero, the “WEIGH” button can be used after the patient is

positioned on the scale. Lock the patient’s wheelchair brake to prevent movement. The

display will indicate the patient’s weight. After Automatic Shut Off, simply press the

“WEIGH” button to re-activate the scale.

Do not leave patient unattended on the scale platform.

CAUTION

SETTING TARE

Place the empty wheelchair/chair/walker (with any blankets or

pillows that the patient may have with them) on the scale platform.

Press the “ZERO” button to tare the object’s weight. The display

will read “0.0”. Remove the wheelchair from the platform. Place

the patient in the wheelchair. Place the wheelchair on the platform. Lock the patient’s wheelchair

brake to prevent movement. Press the “WEIGH” button to display the patient’s weight.

When tare is known for an object, the amount can be pre-set via the keypad. Press the “ENTER”

button to activate the keypad and display any pre-set tare data residing in memory. Enter the numeric

value of the weight of the current tare object. For example, 12.5 kilograms will be entered as 125

(decimal remains fixed).

Press the “ENTER” button again to save the data. The PRE-SET TARE and NET W EI GH T display

symbols will light on the display. The pre-set tare value will be indicated as a negative number until the

patient is positioned on the scale.

The “CLEAR” button, or an Automatic Shut Off, will cancel the pre-set operation if the “ENTER”

button has not already saved tare to memory.

The “WEIGH” button will re-activate the scale after Automatic Shut Off without compromising the tare

data.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 10 of 16

DISPLAY ERROR CODES

CODE DEFINITION RESOLUTION

Err 1

Excessively large or small

gravitational constant is stored

during calibration

Use a known gravitational constant for the location

of the scale.

Err 2

LoBat

^^^^

vvvv

Excessively large or small Full

Scale is stored during calibration

Re-calibrate using a known calibrated weight.

Battery resource is critically low Batteries must be replaced.

Data input to electronics too high

Remove any weight that may be on the scale,

ensure that the scale is level, and re-zero.

Data input to electronics too low Check the Display Assembly Cable Connection

BATTERY REPLACEMENT

STEP 1: When the batteries are low and need to be replaced, the

LOW BATTERY display symbol will light up on the display.

STEP 2: Gently position the scale system on its side to access the

Battery Compartment.

STEP 3: (Figure 4) Unscrew the two screws holding the Battery

Compartment Cover in place.

STEP 4: Open the Cover and remove and replace ALL of the batteries at

the same time. Replace with six (6) “D” cell batteries following the

instruction on the Battery Compartment Cover.

STEP 5: Check to make sure the display is working correctly by pressing

the “ZERO” or “WEIGH” button to activate the display screen.

STEP 6: Close the Battery Compartment Cover and securely screw into

place.

STEP 7: Gently return the scale to the upright, level position.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

Figure 4: Battery

Compartment

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 11 of 16

THEORY OF OPERATION

SR Instruments patient weighing systems are digital scales. Strain-gauge force cells convert the force

of an applied weight into an analog signal. This signal is amplified by an operational amplifier and

converted to a digital signal by an analog to digital converter. The digital signal is transferred to a

micro-controller where it is filtered, converted to appropriate units, and displayed on a liquid crystal

display.

Strain-gauge force cells each contain four strain gauges mounted in a full Wheatstone-bridge

configuration. These bridges convert the physical movement of the force cell, due to the applied mass

on the system, into minute changes in electrical resistance. These changes in resistance produce a

voltage difference across the Wheatstone-bridge. The output of the Wheatstone-bridge is digitized by

a sigma-delta analog to digital converter. The data is transferred to the micro-controller.

The micro-controller averages and filters the digital output of the analog to digital converter, subtracts

the value saved during the system zero operation, and scales the filtered output and then displays the

result on the liquid crystal display. The micro-controller performs a rolling average of data for

continuous weigh and then micro-controller averages the data before locking in on the reading. The

micro-controller can be pl aced in a calibration mode, where the system can be re-calibrated. In the

calibration mode, the calibration, local gravitational constant, and duration of “on” time can be

adjusted. The new factors are stored in non-volatile memory.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 12 of 16

CALIBRATION

IMPORTANT

CALIBRATION CHECK – A certified technician should perform this procedure.

The load cell and integrated electronics have no user serviceable components and

should not be tampered with for any reason. Re-calibration must be performed

when the seal is broken. Recommendation for calibration check is at least once

every 12 months, or as individual maintenance policy requires.

INITIAL SYSTEM SETUP

When initially set up, calibration is factory set and re-calibration is not needed. The Local

Gravitational Acceleration may have to be re-set for the current geographical location. Automatic

Shut Off is shipped with a factory default of 60 seconds. If a longer period of time (120 or 180

seconds) is desired, then it will need to be re-set. Both of these procedures are found below.

ACCESS SYSTEM SETUP

Ensure scale is level before proceeding. To access all settings below, break the Calibration Seal and

open the right hand end cap. Seal must be replaced by a certified technician. Push the cali brati on

swi t c h right to the “CAL” position (Figure 4) using the eraser end of a pencil or similar item. Display

arrow on the top right will light up.

CAUTION

ESD: The integrated circuits and

semiconductors on the printed circuit boards

may be damaged by electrostatic discharge).

Be sure to use proper handling precautions at

all times.

SETTING GRAVITATIONAL ACCELERATION

STEP 1: Select number “1” on the numeric keypad. The 2ND

display arrow down on the right will light up.

STEP 2: The factory default setting will appear on the display.

Using the keypad, enter in the local gravitational acceleration value if

desired.

STEP 3: Press the “ENTER” button to save the selection or

the “CLEAR” button to exit the menu without saving. The

display arrow will return to the 2

right.

STEP 4: (Figure 5) Select another menu item, or push the

calibration switch left to the “RUN” position to exit

CALIBRATION mode.

ND

display arrow down on the

Figure 5: Calibration Switch

Continued next page

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 13 of 16

CALIBRATION cont’d

CALIBRATION PROCEDURE

Note: Ensure scale is level and make sure that nothing is in contact with the scale during this

procedure. Remove hands from scale when noting displayed calibration results.

STEP 1: Press number “2” on the numeric keypad. The 2ND

display arrow down on the right will light up. System is now in

mode to set Calibration Gravitational Acceleration.

If value is already correct, press the “ENTER” button to save and continue with calibration.

STEP 2: Using the keypad, enter in the local gravitational acceleration value if desired.

STEP 3: Press “ENTER” button to save and continue with calibration. The 4TH display arrow

down on the right will light up.

STEP 4: Press “ZERO” button to set the display to zero. The

ZERO and STABILITY DETECTION display symbols will light

up. At that time, place calibrated weight(s) onto the scale. It is

recommended that the full 280 kilograms be used for calibration.

STEP 5: Using the numeric keypad, enter the value of the total

calibrated weight placed on the scale.

STEP 6: Press the “ENTER” button to save the selection or the “CLEAR” button to exit the

menu without saving. The top right display arrow will light up.

STEP 7: Select another menu item, or push the calibration switch left to the “RUN” position to

exit CALIBRATION mode.

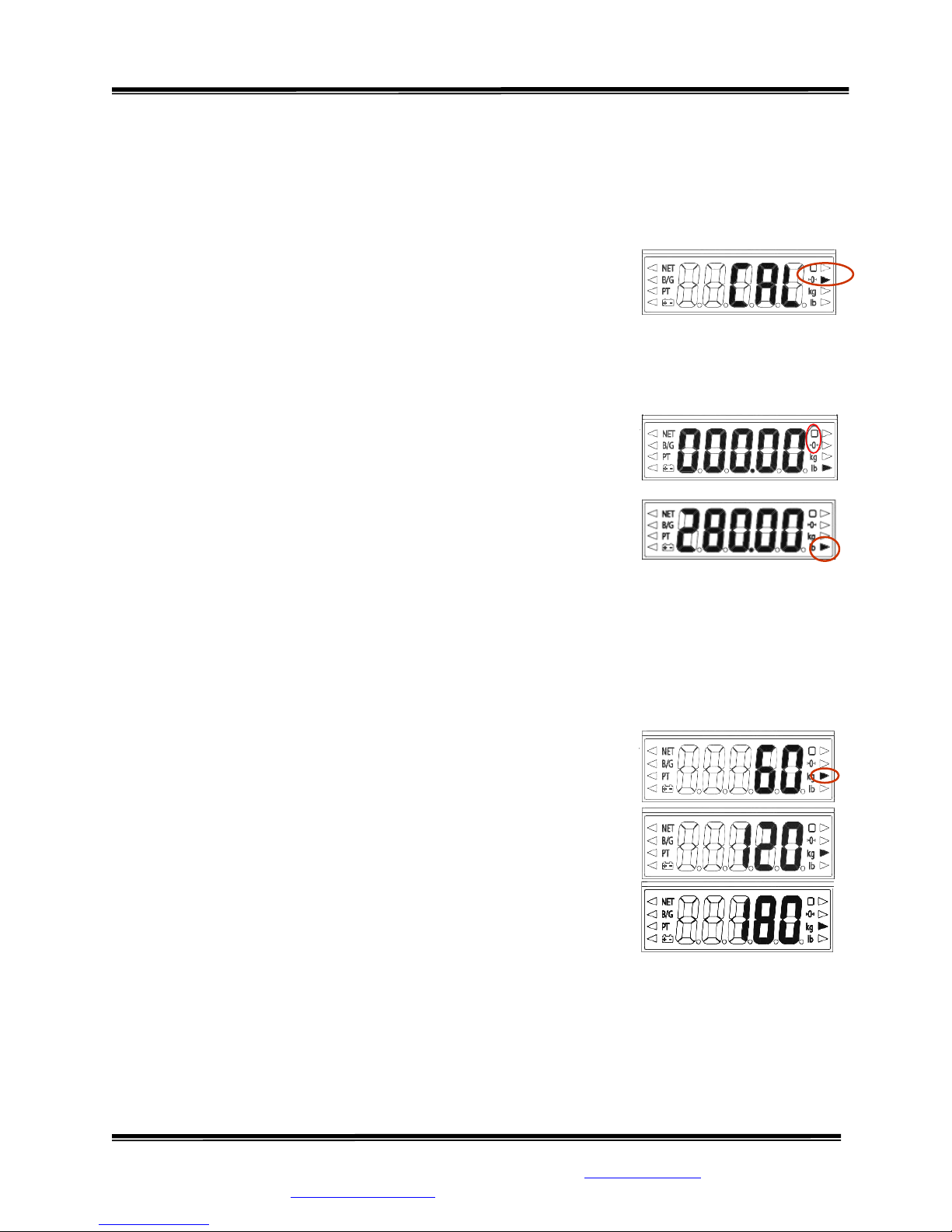

AUTOMATIC SHUT OFF TIMER SETTING

STEP 1: With the calibration switch is in the “CAL” position,

select number “3” on the numeric keypad. The 3RD display arrow

down on the right will light up.

STEP 2: Repeatedly press number “3” on the numeric keypad to

toggle selection for “60” seconds (default), “120” seconds, “180”

seconds, or “--” (off).

STEP 3: Press “ENTER” button to save the new value or

“CLEAR” button to return to the menu without saving. Default (60

seconds) will remain in effect.

STEP 4: Select another menu item, or push the calibration

switch left to the “RUN” position to exit CALIBRATION mode.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

Continued next page

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 14 of 16

DISPLAY UNIT OPTIONS SETTING

STEP 1: With the calibration switch is in the “CAL” position, select number “4” on the numeric

TH

keypad. The 4

display arrow down on the left will light up.

STEP 2: Repeatedly press number “4” on the numeric keypad to toggle unit display selections

as follows:

KG/LB (factory default setting). When selected, both display symbols will light up.

Weight readings will display in either pounds or kilograms. Pressing the “kg/lb” button

toggles between display units at any time during the weigh process.

LB only. When selected, the “lb” display symbol will light. Weight readings will display

in pounds only. The “kg/lb” button is deactivated.

KG only. When selected, the “kg” display symbol will light. Weight readings will display

in kilograms only. The “kg/lb” button is deactivated.

STEP 3: Press “ENTER” button to save t he new value or “CLEAR” button to return to the menu

without saving. Default will remain in effect.

STEP 4: Select another menu item, or push the calibration switch left to the “RUN” position to

exit CALIBRATION mode.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 15 of 16

WARRANTY

FOUR YEAR LIMITED WARRANTY

Each S system is manufactured with high quality components. SR Instruments, Inc.

warrants that all new equipment will be free from defects in material or workmanship, under

normal use and service, for a period of four (4) years from the date of purchase by the original

purchaser. Normal wear and tear, injury by natural forces, user neglect, and purposeful

destruction are not covered by this warranty. Warranty service must be performed by the factory

or an authorized repair station. Service provided on equipment returned to the factory or

authorized repair station includes labor to replace defective parts. Goods returned must be shipped

with transportation and/or broker charges prepaid. SR Instruments, Inc.’s obligation is limited to

replacement of parts that have been so returned and are disclosed to SR Instruments, Inc.’s

satisfaction to be defective. The provisions of this warranty clause are in lieu of all other

warranties, expressed or implied, and of all other obligations or liabilities on SR Instruments,

Inc.’s part, and it neither assumes nor authorizes any other person to assume for SR Instruments,

Inc. any other liabilities in connection with the sale of said articles. In no event shall SR

Instruments, Inc. be liable for any subsequent or special damages. Any misuse, improper

installation, or tampering, shall void this warranty.

DAMAGED SHIPMENTS

Title passes to purchaser upon delivery to Transportation Company. Any claims for shortage or

damage should be filed with the delivery carrier by purchaser.

RETURN POLICY

All products being returned to SR Instruments, Inc. require a Return Goods Authorization number

(RGA). To receive an RGA, call our Technical Service Team at 716-693-5977 or toll-free in the

USA and Canada at 800-654-6360.

When inquiry is made, please supply model and serial numbers, purchase order, if the scale was

bought on contract, and reason for return.

Generally, deleted, damaged, and outdated merchandise will not be accepted for credit. A

minimum restocking charge of 15% will be assessed on return of current merchandise.

All returns are to be shipped FREIGHT PREPAID to: SR Instruments, Inc., 600 Young Street,

Tonawanda, NY 14150.

RESTOCKING FEE

• 15% fee for any scale that has been opened and used

• 10% fee for any scale returned that has been ordered incorrectly or refused delivery with

no model change

• 5% fee if an error in ordering has been made and a different model exchanged

• No fees will be charged if the scale is returned because of an error on the part of SR

Instruments, Inc.

• No returns accepted after 60 days.

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Model SR775L

Service Manual - S/N 1035+

Part No. MAN775L_100929 Page 16 of 16

By SInstruments, Inc.

Precision & Technology in

Perfect Balance

™

SInstruments, Inc.

Tel: 716-693-5977 Fax: 716-693-5854 URL: www.srscales.com

email: sri@srinstruments.com

, 600 Young Street, Tonawanda, NY 14150

Copyright 2010 SInstruments, Inc.

Loading...

Loading...