Page 1

Model SR2555 Stand-On Scale Rev 991222

PART No. MAN2555

S

by SR Instruments, Inc.

SR Instruments, Inc. 600 Young Street, Tonawanda, NY 14150

Tel: 1.716.693.5977 Fax: 1.716.693.5854 URL: www.srscales.com email: sri@srinstruments.com

Model SR2555

Stand-On Scale

Operating Manual

Page 2

Model SR2555 Stand-On Scale Rev 991222

S

by SR Instruments, Inc.

Table of Contents

SECTION I

System Description 1.0

Intended Use 1.1

Specifications 1.2

Theory of Operation 1.3

Assembly 1.4

SECTION II

Button Functions & Basic System Operation 2.0

Special Features – Continuous Weigh/ Auto-Hold 2.1

SECTION III

Calibration 3.0

Periodic Calibration Check 3.1

ESD 3.2

Calibration Procedure 3.3

Calibration Tolerance Table 3.4

Maintenance, Care and Cleaning 3.5

Schematic Diagram 3.6

Parts List 3.7

Component Layout 3.8

Product Labeling 3.9

Page 3

Model SR2555 Stand-On Scale Rev 991222

SECTION I S S

MODEL SR2555

SYSTEM DESCRIPTION and SPECIFICATIONS

1.0 SYSTEM DESCRIPTION - The SR2555 Scale

System employs the latest in microprocessor

and load cell technology to provide accurate

and repeatable weight data. Four (4)

identically matched transducers are

strategically placed to ensure an accurate

representation of the patient's weight

regardless of weight distribution.

The low power microprocessor circuitry allows

the SR2555 to derive it’s power from six (6)

common “C” cell alkaline batteries which will

provide up to 10,000 weight readings before

needing replacement. This eliminates the

need for an external battery charger or the

danger of an A.C. power supply.

The patient’s weight is displayed on a large 2 x

24 character dot matrix L.C.D. capable of

displaying information in many different

languages. With the push of a button, weight

data may be viewed in both POUNDS and

KILOGRAMS with a displayed resolution of 0.1

LB or 100 grams.

1.1 INTENDED USE The SR2555 is designed for use

as a portable patient weighing system for

ambulatory patients only.

1.2 SPECIFICATIONS

1.2.01 Maximum Weight Capacity - The SR2555 has

a maximum weight capacity of 1000 Lbs. /

450 Kgs. This strength is due in part to the one

piece, solid aluminum cast base.

1.2.02 Platform Size –An generous standing area of

22” x 15” / 55 x 25 cm will accommodate

most all of your patients special needs.

1.2.03 Display Type - The display is a large 2 x 24

Character Dot Matrix L.C.D. with green L.E.D.

back lighting. Highly visible in all light

conditions, you may select one of 7 different

languages to view weight data : ENGLISH

FRANÇAIS ESPAÑOL DEUTSCH ITALIANO

DANSK NEDERLANDS

1.2.04 Display Resolution – The SR2555 will display

weight data in both POUNDS and KILOGRAMS

with a resolution of 0.1 Lb. or 0.1 Kg.

1.2.05 Accuracy - The accuracy of the displayed

weight is 0.1% +/- 1 digit of the displayed

resolution for calibrated range. Refer to the

Calibration Certificate supplied with the scale

for the calibrated range.

1.2.06 Zero - One button Auto-Zero

1.2.07 Memory / Recall - The feature Freezes display

and stores the data in memory. The button is

pressed once again to recall last stored

weight.

1.2.08 Auto Power Down – The system will

automatically power down in 30 seconds to

conserve battery life.

1.2.09 Averaging – An Automatic Digital Filter

samples the weight data to filter motion.

1.2.10 Power Supply - Six LR 14 (“C” cell )Alkaline

Batteries.

1.2.11 Warranty 2 YEAR LIMITED WARRANTY - Each

S scale system is manufactured

with high quality components. SR Instruments,

Inc. warrants that all new equipment will be

free from defects in material or workmanship,

under normal use and service, for a period of

two years from the date of purchase by the

original purchaser. Normal wear and tear,

injury by natural forces, user neglect and

purposeful destruction are not covered by this

warranty. Warranty service must be performed

by the factory or an authorized repair station.

Service provided on equipment returned to the

factory or authorized repair station includes

labor to replace defective parts. Goods

returned must be shipped with transportation

and/or broker charges prepaid. SR Instruments

obligation is limited to replacement of parts

which have been so returned and are

disclosed to SR Instruments satisfaction to be

defective. The provisions of this warranty clause

are in lieu of all other warranties, expressed or

implied, and of all other obligations or liabilities

on SR Instruments part and it neither assumes

or authorizes any other person to assume for SR

Instruments any other liabilities in connection

with the sale of said articles. In no event shall

SR Instruments be liable for any subsequent or

special damages. Any misuse, improper

installation or tampering, shall void this

warranty.

1.2.12 Calibration - Calibration is traceable to NIST

Standards.

1.2.13 Operating Conditions – Care has been taken

in the design of this product to provide

accurate and reliable information under

normal operating conditions. When proper

care is exercised, your scale will provide many

years of reliable service. Normal conditions for

this product would be : Temperature Range:

20oC to 30oC (68o to 85of) Humidity Range:

0%-95%. Avoid exposure to high pressure

water or steam.

1.2.14 Transport and Storage – To maintain proper

operation of this instrumentation transport and

storage conditions should not vary outside the

following conditions: Humidity: 0% to 99%,

Ambient Temp:-200C to +500C

1.2.15 Patient Applied Part Classification – TYPE B

1.2.16 Accessories – The SR2555 is available with

optional handrails for 3-Sided support (part no.

FG3070) and a Height Gauge (part no. 3086)

107 – 203 cm / 42” – 80”.

Page 1

Page 4

Model SR2555 Stand-On Scale Rev 991222

Figure 2. Force Cell bending with applied weight (displacement exaggerated for clarity)

SECTION I S S

SR2555 Theory of Operation

1.3 The SR2555 patient weighing system is a digital weigh scale. Four strain-gauge force cells convert the force of a patient’s

weight into an analog signal. This signal is amplified by a chopper-stabilized operational amplifier and converted to a digital signal

by a quad slope analog to digital converter. The digital signal is transferred to a micro-controller where it is filtered, converted to

appropriate units and displayed on a dot-matrix liquid crystal display.

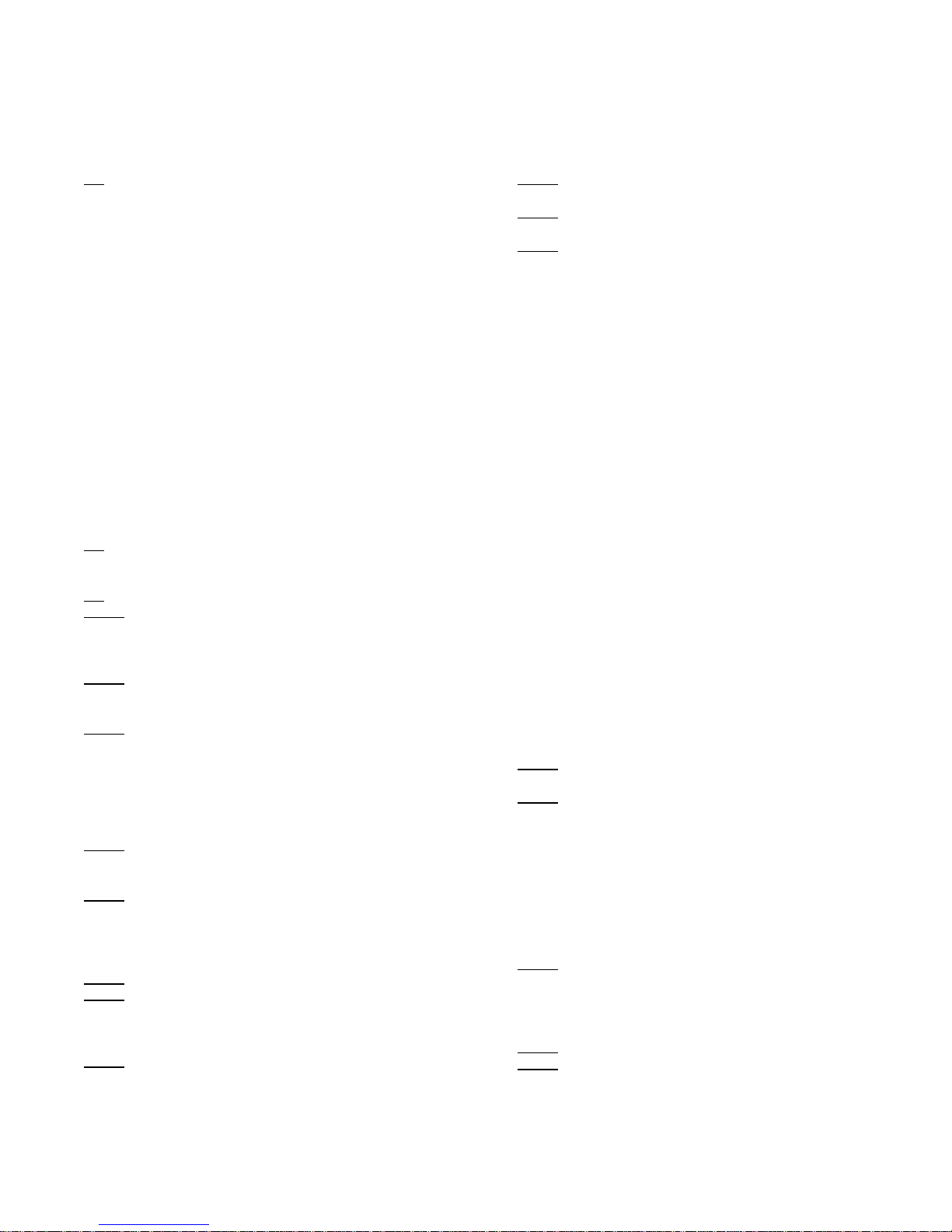

The base of the SR2555 patient weighing system contains four strain gauge based

force cells (Analog board J1..4). Each cell contains four strain gauges mounted in a full

Whetstone-bridge configuration (Figure 1.) These bridges convert the physical bending of the

force cell (Figure 2.), due to the patient’s mass on the system, into minute changes in

electrical resistance. These changes in resistance produce a voltage difference across the

Whetstone Bridge, which is amplified by the chopper-stabilized operational amplifier (Analog

board U1). The amplifier is configured to current sum the output of each cell, with

potentiometers (Analog board R1, R2, R4, R5) serving to adjust the sensitivity (voltage out per

unit of weight applied) of each bridge. The offset potentiometer (Analog board R3) produces

a small current, which nulls the output of the amplifier for a n unloaded system.

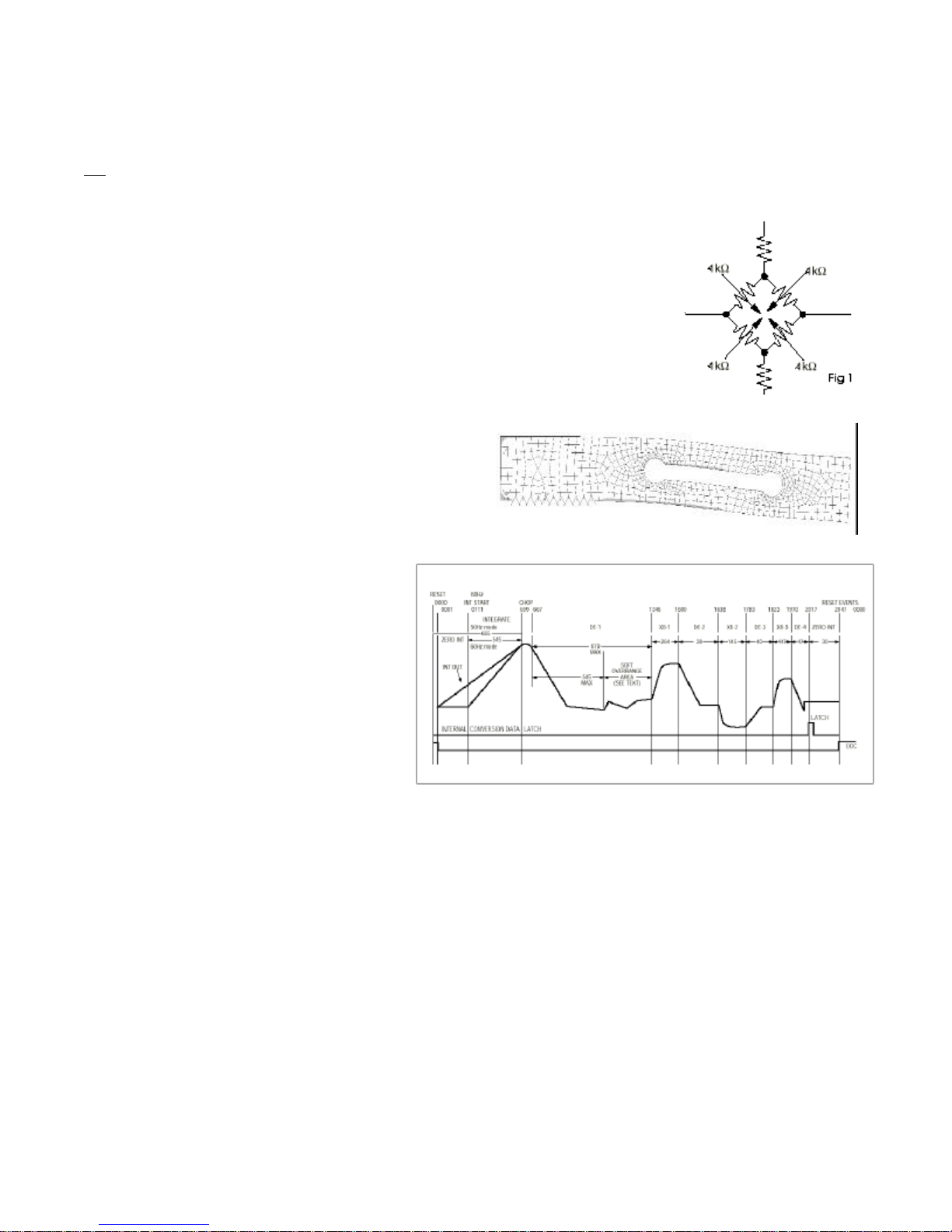

The output of the operational amplifier is digitized by the quad

slope analog to digital converter (Analog board U5). The

converter integrates the analog signal onto the integrating

capacitor (Analog board C9) over a short interval. The

integrating capacitor is then discharged at a rate proportional

to the reference voltage applied to the converter

(Analog board C11 and C10). The residual voltage

on the integrating capacitor (Analog board C9) is

then multiplied by a factor of eight and again

discharged at a rate proportional to the reference

voltage (Figure 3.). The residual voltage from this

discharge is again multiplied by eight and again

discharged. The time taken to discharge the

capacitor is proportional to the voltage from the

operational amplifier, which is proportional to the

weight on the force cells. The time is stored as a

binary number in the analog to digital converter

and is transferred to the micro-controller when the

conversion is complete.

The micro-controller (Readout U1)

averages and filters the digital output of the

analog to digital converter, subtracts the value

saved during the system tare operation and scales

the filtered output to the appropriate units (Kg or

Lb.) then displays the result on the dot-matrix liquid crystal display. The micro-controller performs a rolling average of two seconds

of data for continuous weigh and, for AutoHold, the micro-controller averages two seconds of data, minimum, before locking in

on the reading. If the data variance is greater than 0.1% in the AutoHold mode, the micro-controller will reset the filter and start a

new averaging period.

The micro-controller can be placed in a calibration mode (Readout J5), where the system can be re-calibrated. In the

calibration mode, the result of the weigh operation is scaled to match the value entered by the decimal keypad. This new

calibration factor is then stored in the non-volatile memory (Analog board U4).

Figure 3. Analog to digital converter timing diagram (from Maxim MAX132 data sheet).

Page 2

Page 5

Model SR2555 Stand-On Scale Rev 991222

1.4 ASSEMBLY

IMPORTANT: All of the scale systems

are calibrated at our factory as a

complete system. Components should

not be interchanged with other

systems. To assure optimal accuracy

and reliability, make sure the serial

numbers on the readout (2) and the

base (1) match.

1. Insert mast(5) into base assembly

(1) as shown.

2. Remove the 4 set screws (10) from

the base collar and apply loctite

®

to all set screws

3. Make sure the mast is seated firmly

in the base assembly. Re-install the

set screws and tighten.

4. Slide the cable from the display

assembly (2) down the mast (5)

and out through the base.

5. Insert the mast (5) into the collar of

the display assembly (2) and seat

firmly. Turn the readout assembly

(2) so that it is aligned with the

base assembly.

6. Apply loctite® to all set screws and

tighten display assembly in place.

7. Plug the display assembly cable

into the base assembly as shown

and secure the cable in place with

the strain relief clamp provided at

the bottom of the collar in the

base assembly. Make sure the

excess cable is fed back into the

mast (5) before tightening the

strain relief clamp.

8. Remove the battery cover (8) and

install the 6 “LR14” (C cell) batteries

provided. Replace the cover.

OPTIONAL HANDRAILS –

Install the handrails with the hardware

provided. Be sure to use the lock

washers (12) and apply loctite® to all

screws.

1. Attach the LEFT and RIGHT handrails (3,4) to the bottom of the readout assembly (2) first and then to the base (1)

as shown.

OPTIONAL HEIGHT BAR –

1. Insert the Height Bar (6) from the top making sure it is seated firmly at the base.

2. Align the top extension perpendicular to the readout

3. Apply loctite® to all set screws and tighten in place

Page 3

Page 6

Model SR2555 Stand-On Scale Rev 991222

))

0.0

/

SECTION II S S

2.0 BUTTON FUNCTIONS and BASIC OPERATION

2.0.1 LANGUAGE SELECT

..

))

))

The language button allows you to select one of the following languages to display weight data

and system messages –

ENGLISH FRANÇAIS ESPAÑOL DEUTSCH ITALIANO DANSK NEDERLANDS

Procedure for Weighing Standing Patients

2.0.2 ZERO – Press the “0” button to set the system tare to ZERO. The displayed message will indicate

“PLEASE WAIT – HANDS OFF” / “ZEROING SCALE”. Make sure that nothing is in contact with the scale

system during this process. In a few seconds the display will indicate “WEIGHT = 0.0 POUNDS” (or

KILOGRAMS).

The Patient may now step up onto the scale platform to view the weight data.

NOTE: It is recommended that you press “0” before each weighing to assure optimal accuracy.

2.0.3 WEIGH - If the display shuts off before you are able to view the weight data, simply press the “WEIGH”

button to wake the display and view the patient’s weight. The display will indicate “CURRENT WEIGHT

= XXX.X POUNDS“ (or KILOGRAMS).

W

2.0.4 MEMORY/RECALL - Pressing the “MEMORY/RECALL” button will freeze the displayed weight data and

store it away in memory. To recall the stored weight data, wait until the system has automatically shut

off then press the “MEMORY/RECALL” button. The display will indicate “LAST WEIGHT = XXX.X

POUNDS” (or KILOGRAMS).

Pressing the “0.0” button will clear the last stored weight from memory.

2.0.5 POUNDS / KILOGRAMS -Weight data may be viewed in either POUNDS or KILOGRAMS. Pressing the

button allows you to switch between display modes quickly and easily.

LB

2.0.6 IMPORTANT – Be sure not to touch the patient or the scale during the weighing process. By design,

Both modes will display patient weight with 0.1 units of resolution. ( 0.1 Lb. or 0.1 Kg. )

the entire scale assembly is weight sensitive so that the patient may use the structure for support

should their condition dictate.

Page 4

Page 7

Model SR2555 Stand-On Scale Rev 991222

0.0

SECTION II S S

2.1 Special Features

CONTINUOUS WEIGH and AUTO-HOLD

The SR2555 has the capability of displaying patient weight in two different ways.

2.1.01 CONTINUOUS WEIGH - When the SR2555 is shipped it comes in the Continuous Weigh Mode. This means

that when the patient is being weighed, the weighing surface remains ACTIVE and the display may show

variations depending on the movement of the patient. To LOCK the displayed reading you must press

the "MEMORY/RECALL" button. This will also store the weight data in memory if you wish to recall it.

2.1.02 AUTO-HOLD - The Auto-Hold Mode will automatically LOCK the displayed weight data and store it in

memory as the last weight. The Auto-Hold Mode is activated as follows:

Press and Hold the "MEMORY/RECALL" button for approximately 5 sec. until the display indicates

"AUTO-HOLD ENABLED" then release the button.

To return to the Continuous Weigh Mode simply repeat the same procedure. The display will indicate

"CONTINUOUS WEIGH ENABLED".

2.1.03 Procedure for Weighing Patients in AUTO-HOLD mode

1. Press the "0" button to set the zero.

2. Position the patient on to the scale.

W

If the display turns off before you view the weigh data or if you wish to re-weigh the patient simply press the "WEIGH"

button once again while the patient is still on the scale.

IMPORTANT:

3. When the patient's motion has stabilized, press the "WEIGH" * button.

* Note: In the Auto-Hold mode you MUST press the "WEIGH" button to display the weight.

If after the display turns off you wish to recall the last stored weight you MUST press the

"MEMORY/RECALL" button FIRST. Otherwise the last stored weight will be reset.

Page 5

Page 8

Model SR2555 Stand-On Scale Rev 991222

1

2

3

6987045

SECTION III

SS

3.0 CALIBRATION

3.1 Periodic Calibration Check - IMPORTANT : The following calibration procedure should only be performed by

qualified service personnel. The SR2555 load cell, itself, has no user serviceable components and should not be

tampered with for any reason.Re-calibration is generally not required, but should be verified periodically to ensure

accuracy. Our recommendation for calibration check is at least once every 12 months or as your maintenance

policy requires.

3.2 ESD – The integrated circuits and semiconductors on the printed circuit boards may be damaged by electrostatic

discharge (ESD). Be sure to use proper handling precautions at all times.

3.3 CALIBRATION PROCEDURE - NOTE: Make sure that nothing is in contact with the scale system during this procedure.

Be sure to remove your hands from the system when noting the displayed calibration results.

1. The Calibration Slide Switch (J5) is located on the bottom side of the display

P.C. board. Expose the Calibration Jumper by removing the two (2) screws on

the bottom side of the display housing and lifting the face plate up and off.

2. Move the calibration switch to the CAL ON position. The display will read

"CALIBRATION MODE".

3. When in the Calibration Mode, press "T" button to zero the display.

4. Place known calibrated weights on to the weighing surface and compare it to

the displayed reading. Note: For best results use around 200 lbs / 90 kgs of

T

7. Press the “SAVE” button to save the calibration data. The display will indicate “SAVING CALIBRATION” – “HANDS OFF / PLEASE

WAIT”. DO NOT touch the scale system during this process. NOTE: If you make an error of wish to abort your changes, simply

move the calibration switch to the CAL OFF position. DO NOT PRESS “SAVE”

8. Move the calibration switch to the CAL OFF position.

9. Re-assemble the display electronics.

known calibrated weights.

5. Use the Key Pad to enter the proper weight. The displayed value should be

within 0.1% of the calibrated weight plus or minus 1 digit of reading.

6. Remove the weight and repeat steps 3 – 5 to be sure of consistent results.

3.4 CALIBRATION TOLERANCE TABLE

LOW APPLIED HIGH

LIMIT LOAD LIMIT

99.9 100.0 100.1

199.8 200.0 200.2

299.7 300.0 300.3

399.6 400.0 400.4

499.5 500.0 500.5

599.4 600.0 600.6

699.3 700.0 700.7

799.2 800.0 800.8

899.1 900.0 900.9

999.0 1000.0 1001.0

3.5 MAINTENANCE, CARE and CLEANING - The readout and transducer housing for the SR2555 Scale System is made of

an epoxy powder-coated aluminum casting with stainless steel riser posts. You need only exercise caution when

cleaning the display window of the electronics as this is made of clear polyester . We recommend mild soap and

water for general cleaning and disinfecting.

3.5.01 WARNING: DO NOT use pressurized water or steam. The scale system contains microprocessor circuitry and strain

gage sensors that may be adversely affected by exposure to such an environment.

3.5.02 STORAGE – If storing this equipment for periods longer than 3 months remove the batteries. Observe storage

conditions in section 1.2.14

3.5.03 BATTERY REPLACEMENT – When battery replacement is needed the display will indicate “CHANGE BATTERIES”. When

replacing batteries ALWAYS replace all six batteries at the same time. Use only LR 14 or “C” cell type alkaline

batteries.

Page 6

Page 9

Model SR2555 Stand-On Scale Rev 991222

SECTION III

SS

3.6 SCHEMATIC DIAGRAM

Page 7

Page 10

Model SR2555 Stand-On Scale Rev 991222

SECTION III

3.7 PARTS LIST

No_ Description Quantity per Position Position 2 Position 3

EPCB980811C PC BOARD 980811C 1

FCKMDL-8S-AS KYCON MINI-DIN 90DEG PCB 8PIN 1 J5

EV50K89PR 50K POTENTIOMETER 89PR50K 5 R1,R2,R3,R4 ,R5

ER21005QF 100 OHM 1/4 WATT 5% RESISTOR 2 R30,R31

ER31005QF 1K 1/4 WATT 5% RESISTOR 5 R22,R23,R24 ,R25,R26

ER51005QF 100K 1/4 WATT 5% RESISTOR 4 R16,R18,R19 ,R20

ER31001EJ 1K 1/8 WATT 1% J RESISTOR 8 R7,R8,R9,R1 0,R11,R12, R13,R17

ER51003EJ 100K 1/8 WATT 1% J RESISTOR 1 R21

ER54991EJ 499K 1/8 WATT 1% J RESISTOR 2 R6,R34

ER43921EJ 39.2K 1/8 WATT 1% J RESISTOR 2 R15, R14

ER46041EJ 60.4K 1/8 WATT 1% J RESISTOR 1 R33

ER43011EJ 30.1K 1/8 WATT 1% RESISTOR 2 R32,R35

ER41005QF 10K 1/4 WATT 5% RESISTOR 3 R27,R28,R29

EC710RE016 10MFD #UVX1C100MDA (NICHICON) 4 C1,C2,C3, C4

EC510RM050 .1MFD #R68104J63B (NISSEI) 4 C10,C11,C6, C5

EC210AP 100PF POY CAP.#09WX7747 1 C7

EC510RF 0.1MFD #SR205C104KAA (AVX) 1 C8

ECP3272 .0027MFD RADIAL, POLY 50V 1 C9

EC547J63 .47MFD #168474J63F (MALLORY) 1 C12

ETBSS110 TRANSISTOR (FAIRCHILD)MOS-FET 1 Q1

EITSC7652C IC #TC7652CPA 1 U1

ET55RP500 REGULATOR (TELCOM) 5V 1 U2

EIMAX660CP IC #MAX660CPA 1 U3

EINM24C02EN IC #NM24C02EN 1 U4

EIMAX132CN IC #MAX132CNG (MAXIM) 1 U5

EITLE2426C IC #TLE2426CLP (TEXAS INSTR.) 1 U6

EXSE3331 CRYSTAL 96.000KHz (DIGI-KEY) 1 X1

ED1N5817 DIODE 1N5817 1 D1

ESRUE090 SWITCH, POLY (RAYCHEM) #RUE090 1 F1

ED1N914 DIODE 1N914 0

EIDIP8 SOCKET 8 PIN (BURNDY) 4

No_ Description Quantity per Position Position 2 Position 3

EPCB980812C P.C.BOARD S/M (EUROPE) 1

ECV1H104KBW .1 MFD 50 V CERAMIC CHIP CAP 18 C1,THRU C18

ER1K18W5 1.0K 1/8W 5% RESISTOR-SURFACE 27 R31R33R35R36R32 R34R17R18R37R39,R10 R15R16R19R24R23R38R9

ER10018W5 100 OHM 1/8W 5% RESISTOR SURFA 2 R40,R41

ER1M18W5 1.0MEG 1/8W 5% RESISTOR-SURFAC 7 R45R44R43 R46R42R47 R48

ER10OHM18W5 10 OHM 1/8W 5% RESISTOR-SURFAC 1 R1

ER100K18W5 100K 1/8W 5% RESISTOR-SURFACE 14 R11R14,R8 R13R12R6R5 R7R4R3R49R50R51R52

ER770101 RESISTOR NETWORK 100K #770-101 1 R60

EC722SM016 22MFD #PCS3226CT SURFACE MT. 2 C19,C20

ETNDS9955 SM XITSOR NDS9955CT(FAIRCHILD 2 Q1A,Q1B

EICHD64F3437 HD64F3437FLH15 Hitatchi Micro 1 U1

EIMAX3320ACAP Maxim MAX3320ACAP 1 U2

EIMAX662ACSA Maxim MAX662ACSA 1 U3

EIADP3367AR IC - LOW DROPOUT LINEAR VOL. 1 U4

ELBRT1209 BUZZER #BRT1209-PF12 1 SPK1

TSW10913TSRE TSW109-13-TS-RE,13 PIN 90'HEAD 1

FCTSW11312 TERMINAL STRIP TSW113-12-T-S-R 1 J6

ESMMS12 SWITCH #MMS12 (ALCO) 2 SW-1,SW-2

ESP8060S SWITCH,PANASONIC #P8060S-ND 1 SW3

FCCLH108FD TERMINAL STRIP CLH-108-F-D-TE 1

EXPBRC4 #PBRC-4.00B CERAMIC RESONATOR 1 X1

EIDIP16 SOCKET,16 PIN DILB-16P-223T 1

SS

0 R27,R26,R28 R30R29R25 R21R20R22

Page 8

Page 11

Model SR2555 Stand-On Scale Rev 991222

SECTION III

SS

3.8 COMPONENT LAYOUT

Page 9

Page 12

Model SR2555 Stand-On Scale Rev 991222

3.9 PRODUCT LABELING

Page 13

Model SR2555 Stand-On Scale Rev 991222

Tel: 716.693.5977 Fax: 716.693.58 54 www.srscales.com email: sri@srinstruments.com

S

By SR Instruments, Inc.

600 Young Street, Tonawanda, NY 14150

Loading...

Loading...