Page 1

2014

ROAM 60/50

RAIL 50

Service Manual

Page 2

SRAM LLC WARRANTY

EXTENT OF LIMITED WARRANTY

Except as otherwise set forth herein, SRAM warrants its products to be free from defects in materials or workmanship for a period of

two years after original purchase. This warranty only applies to the original owner and is not transferable. Claims under this warranty

must be made through the retailer where the bicycle or the SRAM component was purchased. Original proof of purchase is required.

Except as described herein, SRAM makes no other warranties, guaranties, or representations of any type (express or implied), and

all warranties (including any implied warranties of reasonable care, merchantibility, or fitness for a particular purpose) are hereby

disclaimed.

LOCAL LAW

This warranty statement gives the customer specific legal rights. The customer may also have other rights which vary from state to

state (USA), from province to province (Canada), and from country to country elsewhere in the world.

To the extent that this warranty statement is inconsistent with the local law, this warranty shall be deemed modified to be consistent

with such law, under such local law, certain disclaimers and limitations of this warranty statement may apply to the customer. For

example, some states in the United States of America, as well as some governments outside of the United States (including provinces in

Canada) may:

a. Preclude the disclaimers and limitations of this warranty statement from limiting the statutory rights of the consumer

(e.g. United Kingdom).

b. Otherwise restrict the ability of a manufacturer to enforce such disclaimers or limitations.

For Australian customers:

This SRAM limited warranty is provided in Australia by SRAM LLC, 1333 North Kingsbury, 4th floor, Chicago, Illinois, 60642, USA. To

make a warranty claim please contact the retailer from whom you purchased this SRAM product. Alternatively, you may make a claim

by contacting SRAM Australia, 6 Marco Court, Rowville 3178, Australia. For valid claims SRAM will, at its option, either repair or replace

your SRAM product. Any expenses incurred in making the warranty claim are your responsibility. The benefits given by this warranty

are additional to other rights and remedies that you may have under laws relating to our products. Our goods come with guarantees

that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and for

compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the

goods fail to be of acceptable quality and the failure does not amount to a major failure.

LIMITATIONS OF LIABILITY

To the extent allowed by local law, except for the obligations specifically set forth in this warranty statement, in no event shall SRAM or

its third party suppliers be liable for direct, indirect, special, incidental, or consequential damages.

LIMITATIONS OF WARRANTY

This warranty does not apply to products that have been incorrectly installed and/or adjusted according to the respective SRAM user

manual. The SRAM user manuals can be found online at sram.com, rockshox.com, avidbike.com, truvativ.com, or zipp.com.

This warranty does not apply to damage to the product caused by a crash, impact, abuse of the product, non-compliance with

manufacturers specifications of usage or any other circumstances in which the product has been subjected to forces or loads beyond its

design.

This warranty does not apply when the product has been modified, including, but not limited to any attempt to open or repair any

electronic and electronic related components, including the motor, controller, battery packs, wiring harnesses, switches, and chargers.

This warranty does not apply when the serial number or production code has been deliberately altered, defaced or removed.

This warranty does not apply to normal wear and tear. Wear and tear parts are subject to damage as a result of normal use, failure to

service according to SRAM recommendations and/or riding or installation in conditions or applications other than recommended.

Wear and tear parts are identified as:

• Dust seals

• Bushings

• Air sealing o-rings

• Glide rings

• Rubber moving parts

• Foam rings

• Rear shock mounting hardware

and main seals

• Upper tubes (stanchions)

• Stripped threads/bolts

(aluminium, titanium,

magnesium or steel)

• Brake sleeves

• Brake pads

• Chains

• Sprockets

• Cassettes

• Shifter and brake cables (inner

and outer)

• Handlebar grips

• Shifter grips

• Jockey wheels

• Disc brake rotors

• Wheel braking surfaces

• Bottomout pads

• Bearings

• Bearing races

• Pawls

• Transmission gears

• Spokes

• Free hubs

• Aero bar pads

• Corrosion

• Tools

• Motors

• Batteries

Notwithstanding anything else set forth herein, this warranty is limited to one year for all electronic and electronic related components

including motors, controllers, battery packs, wiring harnesses, switches, and chargers. The battery pack and charger warranty does not

include damage from power surges, use of improper charger, improper maintenance, or such other misuse.

This warranty shall not cover damages caused by the use of parts of different manufacturers.

This warranty shall not cover damages caused by the use of parts that are not compatible, suitable and/or authorised by SRAM for use

with SRAM components.

This warranty shall not cover damages resulting from commercial (rental) use.

Page 3

TABLE OF CONTENTS

ROAM 60 & RAIL 50 Front Wheel Service .................................................................................................................................... 5

Parts and Tools .......................................................................................................................................................................................................................................5

ROAM 60 & RAIL 50 End Cap Replacement ............................................................................................................................................................................. 6

ROAM 60 & RAIL 50 Front Hub Bearing Replacement .......................................................................................................................................................10

ROAM 50 Front Wheel Service ..................................................................................................................................................... 16

Parts and Tools .....................................................................................................................................................................................................................................16

ROAM 50 End Cap Replacement .................................................................................................................................................................................................. 17

ROAM 50 Front Hub Bearing Replacement .............................................................................................................................................................................18

ROAM 60/50 & RAIL 50 Rear Wheel Service ............................................................................................................................. 24

Parts and Tools ....................................................................................................................................................................................................................................24

ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement ................................................................................................................................................ 25

Tubeless Rim Tape ...........................................................................................................................................................................36

Parts and Tools ....................................................................................................................................................................................................................................36

Tubeless Rim Tape Installation ......................................................................................................................................................................................................36

Valve Stem Installation .....................................................................................................................................................................................................................38

Wheel Build & Spoke Replacement .............................................................................................................................................. 39

Replacement Parts .............................................................................................................................................................................................................................39

3Table of Contents

Page 4

SAFETY FIRST!

We care about YOU. Please, always wear your safety glasses and

protective gloves when servicing SRAM products.

Protect yourself! Wear your safety gear!

Page 5

ROAM 60 & RAIL 50 Front Wheel Service

We recommend that you have your SRAM wheels serviced by a qualified bicycle mechanic. Servicing SRAM products requires

knowledge of bicycle components as well as the special parts and tools for service.

For exploded diagram and part number information, please refer to the Spare Parts Catalog available on our web site at www.sram.com.

For order information, please contact your local SRAM distributor or dealer.

Information contained in this publication is subject to change at any time without prior notice. For the latest technical information,

please visit our website at sram.com.

Your product's appearance may dier from the pictures/diagrams contained in this publication.

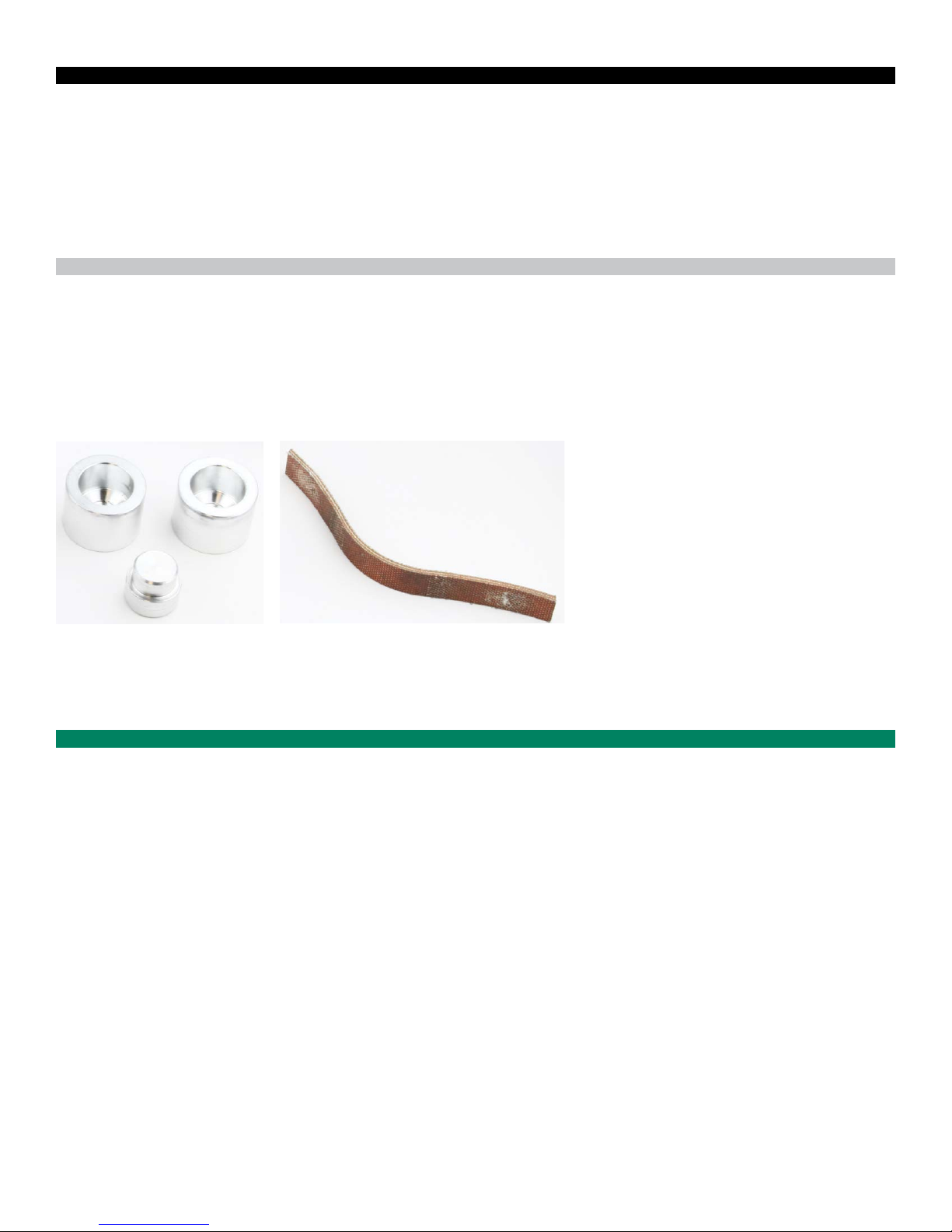

Parts and Tools

• Nitrile gloves

• Apron

• Clean, lint-free rags

• Isopropyl alcohol

• Multipurpose bicycle grease and brush

• Bench vise

DT Swiss Toolkit HWTXXX00NTK24S

• FR/440 Front Hub Tools

• Small Stepped Tool

• Fabric Strap tool

SAFETY INSTRUCTIONS

Always wear nitrile gloves when working with bicycle grease.

• (2) 5 mm hex wrenches

• (2) 22 mm open end wrenches

or

(2) Adjustable wrenches

• Torque wrench

• Rubber mallet

5ROAM 60 & RAIL 50 Front Wheel Service

Page 6

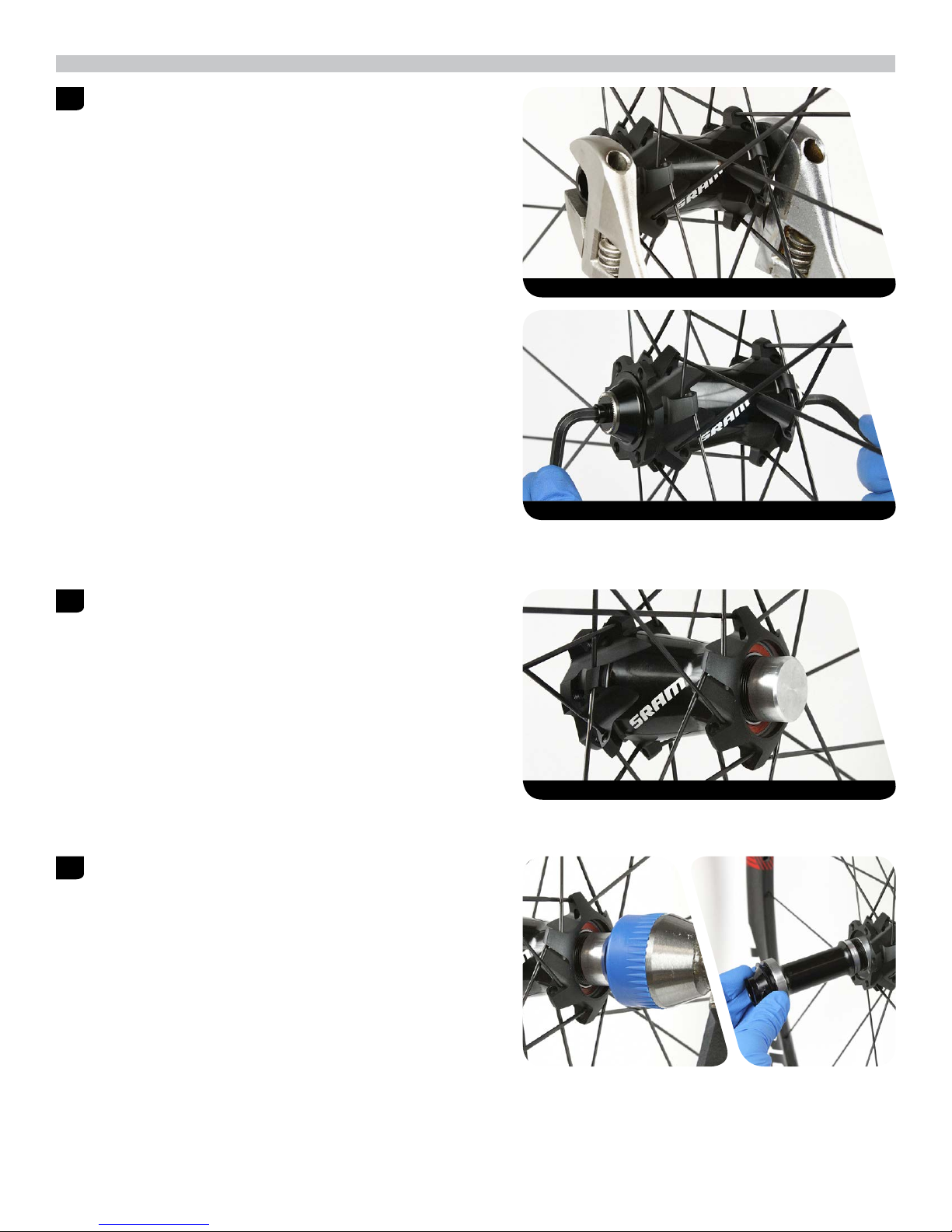

ROAM 60 & RAIL 50 End Cap Replacement

22 mm 20 mm or 15 mm Thru Axle 22 mm

5 mm hex Quick Release 5 mm hex

Small Stepped Tool

20 mm or 15 mm thru axle end caps: use 2x 22 mm open end

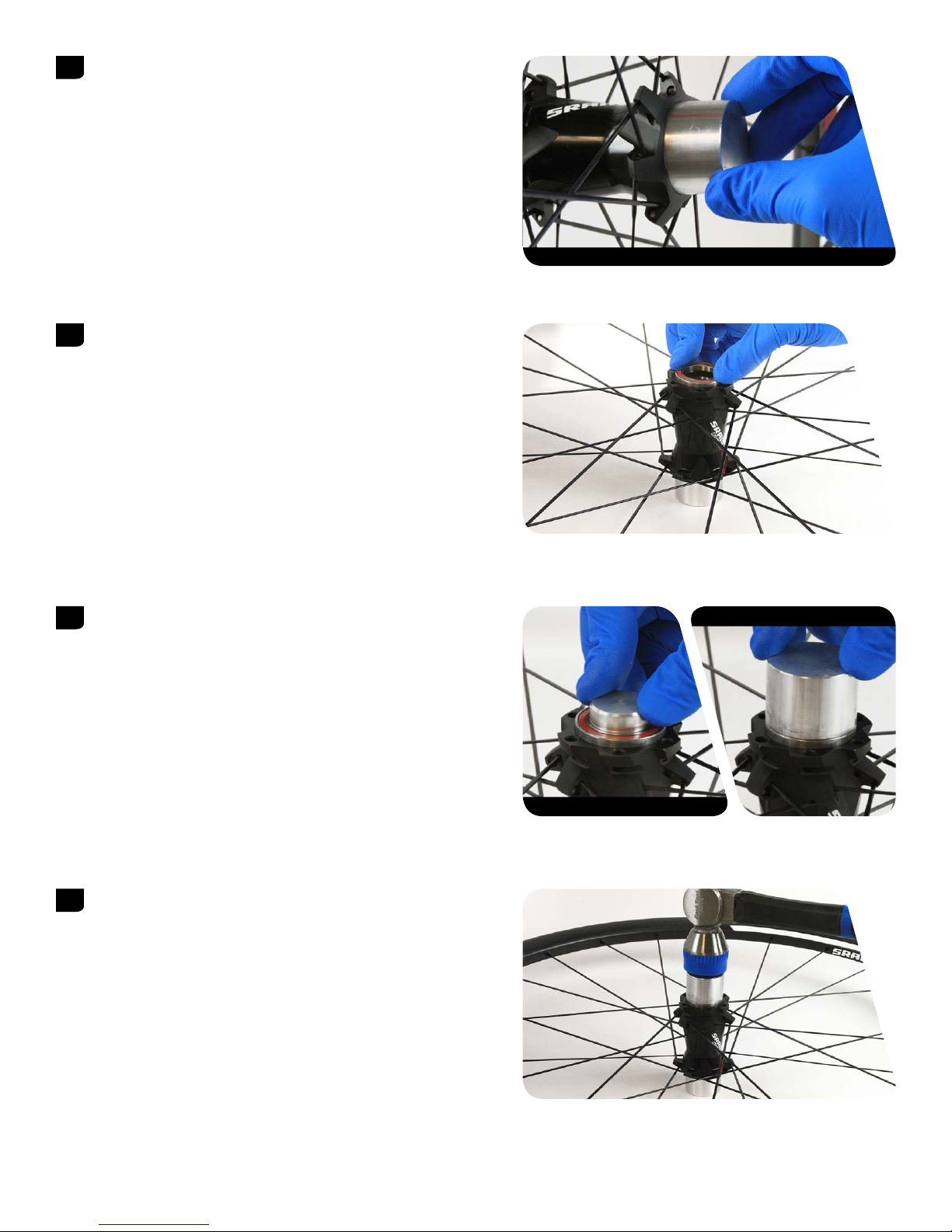

1

wrenches or adjustable wrenches.

Quick release (QR) end caps: use 2x 5 mm hex wrenches.

Hold one wrench stationary and turn the other wrench

counterclockwise. One end cap will unthread from the hub and the

other will remain on the axle.

Insert the Small Stepped Tool into the open end of the axle.

2

Use a soft face mallet to tap out the axle from the hub.

3

6ROAM 60 & RAIL 50 End Cap Replacement

Page 7

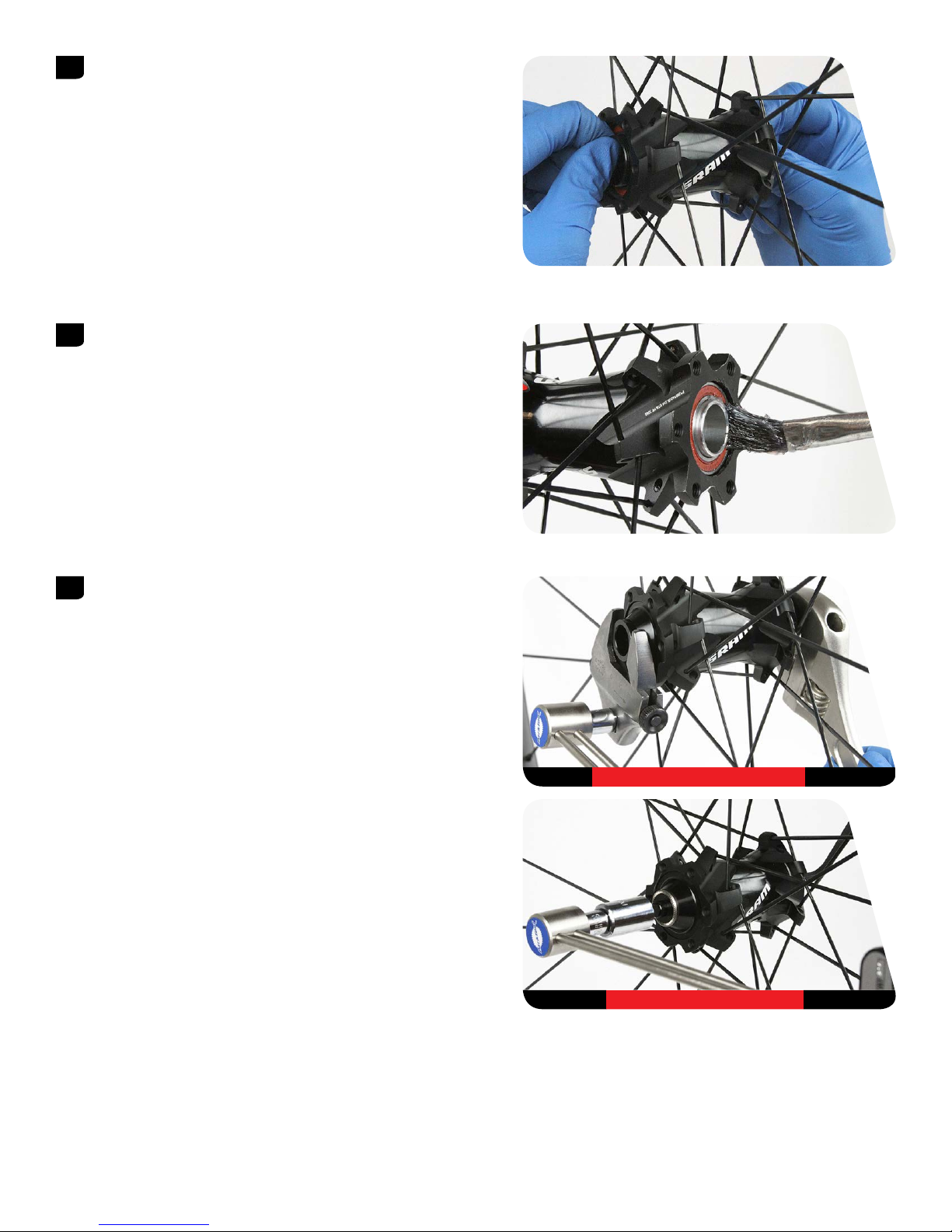

Wrap the Fabric Strap Tool tightly around the axle. Pull down

Fabric Strap Tool

22 mm 20 mm or 15 mm Thru Axle

5 mm hex QR

4

firmly on the strap while clamping the strap in the vise.

NOTICE

Only use the Fabric Strap Tool to secure the axle in the vise. Do

not clamp the axle directly in the vise.

Remove the end cap. If the axle rotates in the strap tool, remove

5

it from the vise and pull the strap tighter. Make sure the bearing

does not come o of the axle.

Lightly grease the bearing bores.

6

Install the axle into the hub and bearing.

7

7ROAM 60 & RAIL 50 End Cap Replacement

Page 8

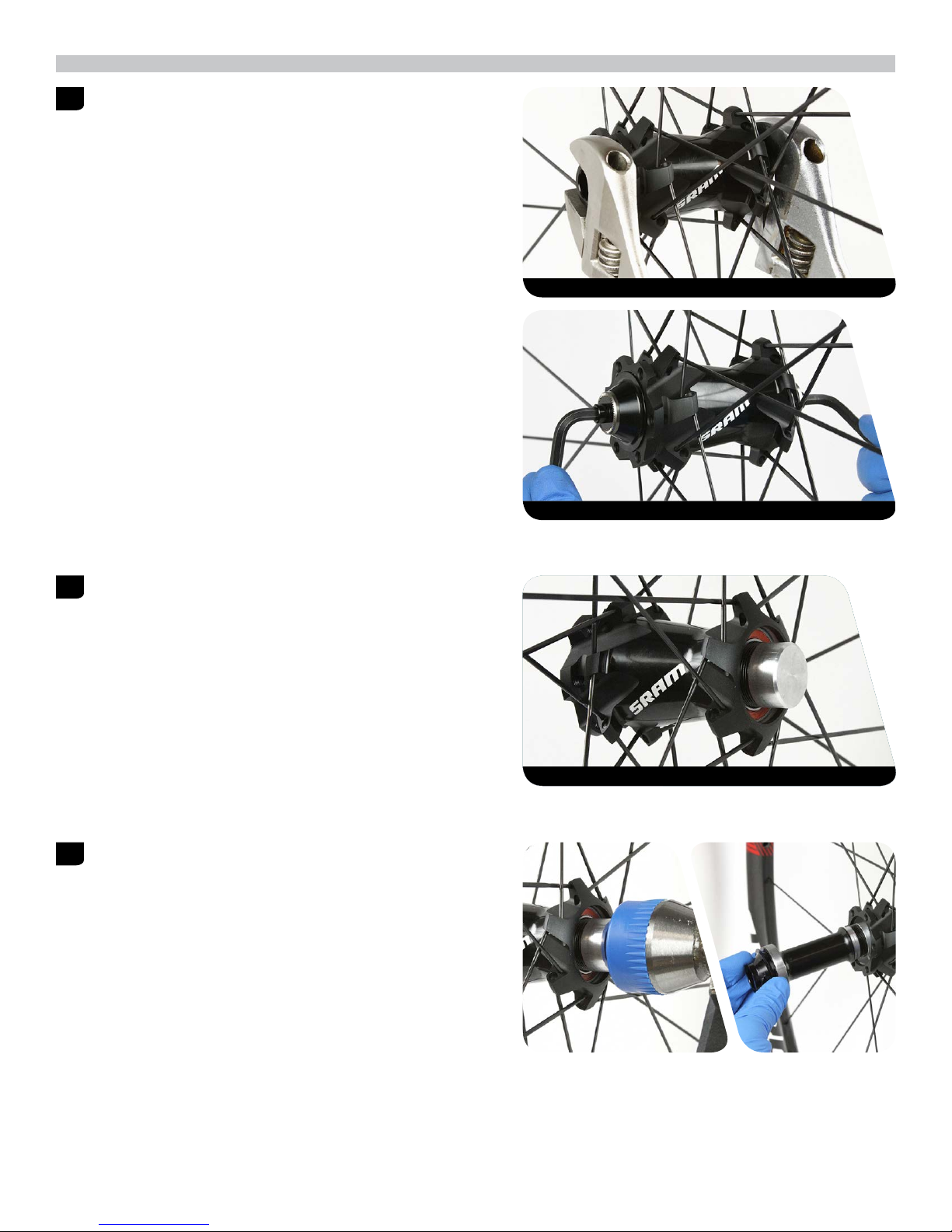

Insert one of the FR/440 Front Hub Tools into the hub against the

FR/440 Front Hub Tool

Small Stepped Tool

FR/440 Front Hub Tool

8

face of the installed bearing.

Place the FR/440 Front Hub Tool and wheel onto a bench. Install

9

the other bearing onto the axle with the red seal facing away from

the hub.

Insert the Small Stepped Tool into the axle and bearing. Install the

10

other FR/440 Front Hub Tool onto the Small Stepped Tool and

against the bearing face.

Strike the FR/440 Front Hub Tool with a soft face mallet until the

11

bearing is firmly seated into the bearing pocket.

8ROAM 60 & RAIL 50 End Cap Replacement

Page 9

Check the axle for play by pushing and pulling it in the hub. If any

22 mm 15 N•m (133 in-lb) 22 mm

5 mm hex 15 N•m (133 in-lb) 5 mm hex

12

play is detected, repeat steps 8-11.

Lightly grease the face of each bearing.

13

Thread the new end caps onto the axle. Tighten the end caps to

14

15 N•m (133 in-lb).

9ROAM 60 & RAIL 50 End Cap Replacement

Page 10

ROAM 60 & RAIL 50 Front Hub Bearing Replacement

22 mm 20 mm or 15 mm Thru Axle 22 mm

5 mm hex Quick Release 5 mm hex

DT Swiss Tool #DT Swiss Tool Kit HWTXXX00NTKFRS

Small Stepped Tool

20 mm or 15 mm thru axle end caps: use 2x 22 mm open end

1

wrenches or adjustable wrenches.

Quick release (QR) end caps: use 2x 5 mm hex wrenches.

Hold one wrench stationary and turn the other wrench

counterclockwise. One end cap will unthread from the hub and the

other will remain on the axle.

Insert the Small Stepped Tool into the open end of the axle.

2

Use a soft face mallet to tap the axle from the hub.

3

10ROAM 60 & RAIL 50 Front Hub Bearing Replacement

Page 11

Wrap the Fabric Strap Tool tightly around the axle. Pull down

Fabric Strap Tool

22 mm

5 mm hex

4

firmly on the strap while clamping the strap in the vise.

NOTICE

Only use the Fabric Strap Tool to secure the axle in the vise. Do

not clamp the axle directly in the vise.

Remove the end cap. If the axle rotates in the strap tool, remove it

5

from the vise and pull the strap tighter.

6

7

Remove the bearing from the axle.

Insert one end of the axle into the hub and into the installed

bearing. Press the axle in as far as possible until it comes out of

the bearing.

11ROAM 60 & RAIL 50 Front Hub Bearing Replacement

Page 12

Insert the Small Stepped Tool into the axle. Strike the axle with a

Small Stepped Tool

8

soft face mallet to remove the bearing from the hub.

Remove the bearing from the axle and discard. Install a new

9

bearing onto the axle with the red seal facing away from the axle.

Clean the hub using isopropyl alcohol and a rag.

10

12ROAM 60 & RAIL 50 Front Hub Bearing Replacement

Page 13

Lightly grease the bearing bores.

FR/440 Front Hub Tool

FR/440 Front Hub Tool

11

Insert the axle and bearing into the disc brake side of the hub.

12

Install one of the FR/440 Front Hub Tools over the axle end and

against the bearing.

Place the FR/440 Front Hub Tool and wheel onto a bench.

13

Install the other FR/440 Front Hub Tool over the axle and into

14

the hub. Strike the tool with a soft face mallet until the bearing is

firmly seated into the bearing pocket

13ROAM 60 & RAIL 50 Front Hub Bearing Replacement

Page 14

Remove the upper LFR/440 Front Hub Tool from the axle. Install a

Small Stepped Tool

FR/440 Front Hub Tool

15

new bearing onto the axle with the red seal facing away from the

hub.

Insert the Small Stepped Tool into the end of the axle. Install the

16

other FR/440 Front Hub Tool on top of the Small Stepped Tool.

Strike the FR/440 Front Hub Tool with a soft face mallet until the

17

bearing is firmly seated into the bearing pocket.

Check the axle for play by pushing and pulling it in the hub. If any

18

play is detected, repeat steps 16 and 17.

14ROAM 60 & RAIL 50 Front Hub Bearing Replacement

Page 15

Lightly grease the face of each bearing.

22 mm 15 N•m (133 in-lb) 22 mm

5 mm hex 15 N•m (133 in-lb) 5 mm hex

19

Thread the new end caps onto the axle. Tighten the end caps to

20

15 N•m (133 in-lb).

15ROAM 60 & RAIL 50 Front Hub Bearing Replacement

Page 16

ROAM 50 Front Wheel Service

We recommend that you have your SRAM wheels serviced by a qualified bicycle mechanic. Servicing SRAM products requires

knowledge of bicycle components as well as the special parts and tools used for service.

For exploded diagram and part number information, please refer to the Spare Parts Catalog available on our web site at www.sram.com.

For order information, please contact your local SRAM distributor or dealer.

Information contained in this publication is subject to change at any time without prior notice. For the latest technical information,

please visit our website at sram.com.

Your product's appearance may dier from the pictures/diagrams contained in this publication.

Parts and Tools

• Nitrile gloves

• Apron

• Clean, lint-free rags

• Isopropyl alcohol

• Multipurpose bicycle grease and brush

• Bench vise

DT Swiss Toolkit HWTXXX00NTK24S

• Large Diameter Hub Tools

• Long Stepped Tool

SAFETY INSTRUCTIONS

Always wear nitrile gloves when working with bicycle grease.

• Park Tool AV-4 axle vise

• Torque wrench

• Rubber mallet

16ROAM 50 Front Wheel Service

Page 17

ROAM 50 End Cap Replacement

Park Tool AV-4

Pull the end caps from the hub by hand. A Park Tool AV-4 Axle

1

Vise can be used if the end caps are dicult to remove.

Press the new end caps onto the hub by hand.

2

NOTICE

The tall end cap is installed on the disc brake side of the hub.

17ROAM 50 End Cap Replacement

Page 18

ROAM 50 Front Hub Bearing Replacement

Park Tool AV-4

Long Stepped Tool

Pull the end caps from the hub by hand. A Park Tool AV-4 Axle

1 1

Vise can be used if the end caps are dicult to remove.

Install the Long Stepped Tool into one side of the axle.

2

Use a soft face mallet to tap out the axle from the hub.

3

18ROAM 50 Front Hub Bearing Replacement

Page 19

Remove the bearing from the axle and discard.

Long Stepped Tool

4

Insert one end of the axle through the hub and into the installed

5

bearing.

Install the Long Stepped Tool into the axle. Strike the axle with a

6

soft face mallet to remove the bearing from the hub.

Remove the bearing from the axle and discard.

7

19ROAM 50 Front Hub Bearing Replacement

Page 20

Clean the inside of the hub using isopropyl alcohol and a rag.

8

Lightly grease the bearing bores.

9

Install a new bearing onto the long end of the axle with the red

10

seal facing away from the axle.

Install the axle into the hub through the disc brake side of the hub.

11

20ROAM 50 Front Hub Bearing Replacement

Page 21

Install one of the Large Diameter Hub Tools into the non-brake

Large Diameter Hub Tool

Large Diameter Hub Tool

12

side of the hub. This will help maintain the alignment of the axle.

Place the Large Diameter Hub Tool and wheel onto a bench with

13

the disc brake side facing up.

Install the other Large Diameter Hub Tool over the axle end

14

and into the hub. Strike the tool with a soft face mallet until the

bearing is firmly seated into the bearing pocket.

21ROAM 50 Front Hub Bearing Replacement

Page 22

Turn the wheel over so that the Large Diameter Hub Tool and

Large Diameter Hub Tool

15

installed bearing are on the work bench. Install a new bearing onto

the axle.

Install the other Large Diameter Hub Tool over the axle and into

16

the hub. Strike the tool with a soft face mallet until the bearing is

firmly seated into the bearing pocket. Periodically check bearing

alignment in the hub.

Check the axle for play by pushing and pulling it in the hub. If any

17

play is detected, repeat steps 12-16.

Apply a light layer of grease to each bearing face. Use a rag or

18

paper towel to remove any grease from the ends of the axle.

22ROAM 50 Front Hub Bearing Replacement

Page 23

Press the end caps onto the hub by hand.

19

NOTICE

The tall end cap is installed on the disc brake side of the hub.

23ROAM 50 Front Hub Bearing Replacement

Page 24

ROAM 60/50 & RAIL 50 Rear Wheel Service

We recommend that you have your SRAM wheels serviced by a qualified bicycle mechanic. Servicing SRAM products requires

knowledge of bicycle components as well as the special parts and tools used for service.

For exploded diagram and part number information, please refer to the Spare Parts Catalog available on our web site at www.sram.com.

For order information, please contact your local SRAM distributor or dealer.

Information contained in this publication is subject to change at any time without prior notice. For the latest technical information,

please visit our website at sram.com.

Your product's appearance may dier from the pictures/diagrams contained in this publication.

Parts and Tools

• Nitrile gloves

• Apron

• Clean, lint-free rags

• Isopropyl alcohol

• Multipurpose bicycle grease and brush

• Bench vise

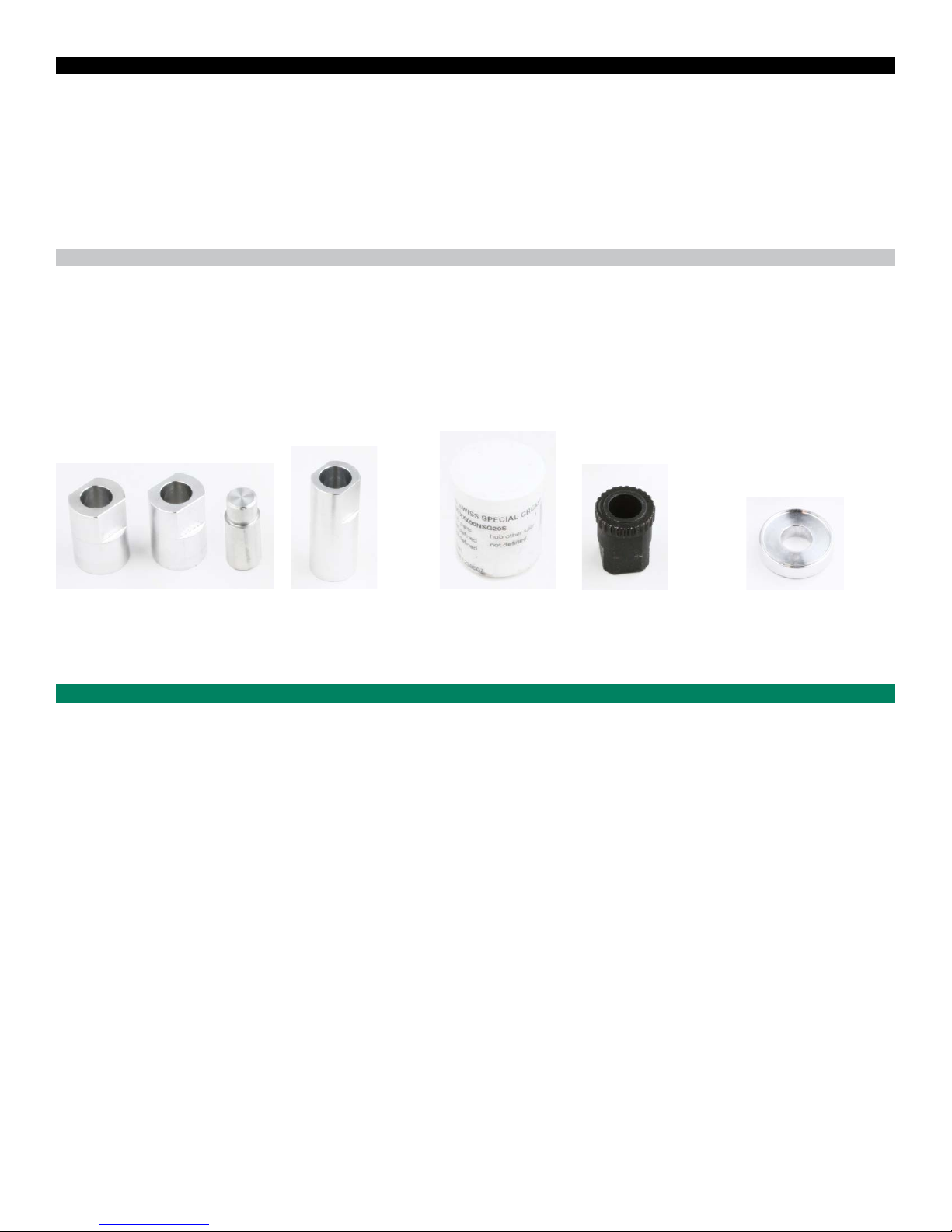

DT Swiss Toolkit HWTXXX00NTK24S

• Short Installation Cylinders

• Long Stepped Tool

• Long Installation

Tool

SAFETY INSTRUCTIONS

Always wear nitrile gloves when working with bicycle grease.

• Torque wrench

• Soft face mallet

• Metal Pick

• DT Special Grease

• Ring Nut Installation

Tool

• Seal Installation

Tool

24ROAM 60/50 & RAIL 50 Rear Wheel Service

Page 25

ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Park Tool AV-4

Pull the end caps from the hub by hand. A Park Tool AV-4 Axle

1 1

Vise can be used if it the end caps are dicult to remove.

NOTICE

Removal of 9/10 speed driver body is the same as for XD driver

body.

Pull the driver body and spring from the hub by hand. Remove the

2

two star ratchets.

Use a pick to remove the internal spring from the hub.

3

25ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 26

Remove the aluminum spacer from the axle.

Ring Nut Installation Tool

4

Strike the axle with a soft face mallet to remove the disc brake

5

side bearing from the hub.

Remove the bearing from the axle and discard.

6

To remove the ring nut, first install the Ring Nut Installation Tool

7

into a vise.

26ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 27

Install the drive side of the hub onto the Ring Nut Installation Tool.

8

Press down firmly and rotate the wheel to make sure that the teeth

of the tool engage with the ring nut.

Press down firmly and rotate the wheel counter-clockwise to

9

remove the ring nut from the hub. The rotor seal will also be

removed, and may fall over the ring nut tool onto the vise.

Remove the ring nut from the tool. Clean the ring nut and inspect

for any damage. Replace the ring nut if it is damaged.

Use a pick to remove the shim ring from the hub.

10

27ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 28

Insert the short end of the axle through the disc brake side of the

11

hub and into the drive side bearing.

Strike the axle with a soft face mallet to remove the bearing from

12

the hub.

Remove the bearing from the axle and discard.

13

Clean the inside of the hub using isopropyl alcohol and a rag.

14

28ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 29

Lightly grease the bearing bores.

Short Installation Cylinder

15

Install one of the Short Installation Cylinders into a vise. Install a

16

new bearing onto the long end of the axle with the red seal facing

away from the axle.

Install the long end of the axle into the Short Installation Cylinder.

17

Firmly press down on the axle to seat the bearing onto the axle.

Install the drive side of the hub onto the axle and bearing.

18

29ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 30

Install the other Short Installation Cylinder over the axle and into

Short Installation Cylinder

Ring Nut Installation Tool

19

the hub. Strike the Short Installation Cylinder with a soft face

mallet until the bearing is firmly seated into the bearing pocket.

To install the ring nut, first install the Ring Nut Installation Tool into

20

a vise so that the teeth are level with the top of the vise.

Place the ring nut onto the Ring Nut Installation Tool with the

21

recessed edge facing up. Apply a light layer of grease to the

threads of the ring nut. Place the the shim ring on top of the

ring nut.

30ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 31

Insert the axle into the Ring Nut Installation Tool. Carefully turn the

Short Installation Cylinder

Seal Installation Tool

Long Installation Tool

22

wheel clockwise to thread the ring nut into the drive side of the

hub. Do not overtighten the ring nut.

NOTICE

After the ring nut has engaged the threads inside the hub, you will

need to raise the Ring Nut Installation Tool in the vise to prevent

the vise from scratching the hub shell.

Install one of the Short Installation Cylinders into a vise. Install the

23

disc brake end of the axle into the Short Installation Cylinder.

Place the rotor seal onto the Seal Installation Tool with the rubber

24

seal facing the tool. Place the tool onto the axle with the rotor seal

facing toward the hub.

NOTICE

If the rotor seal shows any signs of damage, it must be replaced

with a new rotor seal.

Place a Long Installation Tool onto the axle. Strike the Long

25

Installation Tool with a soft face mallet until the rotor seal is seated

in the hub shell.

31ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 32

Install the Ring Nut Installation Tool in a vise. Install the drive side

Ring Nut Installation Tool

Short Installation Cylinder

26

of the axle into the Ring Nut Installation tool and press down

firmly to make sure that the teeth of the tool engage the teeth of

the ring nut.

Pull the axle out of the hub about 2 cm. Install a new bearing onto

27

the axle with the red seal facing away from the hub.

NOTICE

You may need to remove the axle from the hub, install the bearing

onto the axle, and then reinstall the axle into the hub and Short

Installation Cylinder.

Install a Short Installation Cylinder onto the axle and bearing.

28

Strike the Short Installation Cylinder with a soft face mallet until

the bearing is firmly seated into the bearing pocket.

Check the axle for play by pushing and pulling it in the hub. If any

29

play is detected, repeat step 28.

32ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 33

Apply a light layer of grease to the face of the non-drive side

DT Special Grease

30

bearing. Use a rag or paper towel to remove any grease from the

end of the axle.

Apply a very thin layer of DT Special Grease to the teeth of the

31

ring nut.

Install the spacer onto the axle as far as possible.

32

Install the spring onto the axle and over the spacer. The wide

33

opening of the spring is toward the hub.

33ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 34

Clean both star ratchets and inpect for damage. If either star

DT Special Grease

DT Special Grease

34

ratchet is damaged, the damaged part must be replaced. Apply

a very thin layer of DT Special Grease to all surfaces of both star

ratchets.

NOTICE

Only use DT Special Grease on the star ratchets. Using any other

grease, or applying too much DT Special Grease can prevent the

ratchets from engaging. If the ratchets do not engage properly,

clean them and reapply a thin layer of DT Special Grease.

Install the two star ratchets onto the axle.

35

Clean the driver body and install the spring into the driver body.

36

The wide opening of the spring is against the driver body.

Installation of the 9/10 speed driver body is the same as for XD

driver body.

Install the driver body onto the axle. Firmly press the driver body

37

against the hub to make sure the teeth of the driver body are

engaged with the teeth of the star ratchets and ring nut.

NOTICE

34ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 35

Apply a thin layer of grease to the driver body bearing. Use a rag

38

or paper towel to remove any grease from the ends of the axle.

Press the end caps onto the hub by hand.

NOTICE

Only use the end cap labeled "XD Compatible" when installing an

XD driver body.

35ROAM 60/50 & RAIL 50 Rear Hub Bearing Replacement

Page 36

Tubeless Rim Tape

We recommend that you have your SRAM wheels serviced by a qualified bicycle mechanic. Servicing SRAM products requires

knowledge of bicycle components as well as the special parts and tools used for service.

For exploded diagram and part number information, please refer to the Spare Parts Catalog available on our web site at www.sram.com.

For order information, please contact your local SRAM distributor or dealer.

Information contained in this publication is subject to change at any time without prior notice. For the latest technical information,

please visit our website at sram.com.

Your product's appearance may dier from the pictures/diagrams contained in this publication.

Parts and Tools

• ROAM 50/60 = 26 mm width rim tape

• RAIL 50 = 28 mm width rim tape

• Nitrile gloves

• Apron

• Clean, lint-free rags

Tubeless Rim Tape Installation

Install the wheel into a truing stand. Remove any existing rim strips

1

or rim tape from the rim. Remove the valve stem. Thoroughly clean

the rim with isopropyl alcohol and a clean rag. Make sure that the

rim is dry and free of alcohol. Spinning the wheel rapidly in the

truing stand can help remove alcohol from the spoke holes.

• Wheel truing stand

• Isopropyl alcohol

• Small flashlight

• Small knife

• Scissors

Apply the beginning section of tape between the two spoke holes

2

that are 180 degrees opposite from the valve stem hole. Press 4-5

inches (10-13 cm) of tape into the channel of the tire bed.

36Tubeless Rim Tape

Page 37

Apply tension to the tape by rotating the wheel away from you

3

while rapidly "shaking" the tape from side to side about 2-3 inches

(5-8 cm). This will seat the tape into the channel and keep it

centered in the rim.

NOTICE

The tubless tape must be seated into the channel to create an

adequate seal. If the tape is not seated into the channel, the tire

may leak air.

Continue the process of rotating the wheel and shaking the tape

4

side to side while keeping an even tension on the tape roll until

the tape meets the beginning edge of tape from step 2. Overlap

the beginning edge with another 12 inches (31 cm) of tape to the

wheel.

Cut the tape. Use your fingers or a tire lever to press the leading

5

edge of tape against the rim. This will help prevent sealant from

getting under the tape.

12 in (31 cm)

37Tubeless Rim Tape Installation

Page 38

Valve Stem Installation

Shine a flashlight through the rim to illuminate the valve stem hole.

1

Use a small knife to cut the tape from the valve stem hole.

Remove the nut and o-ring from the valve stem. Install the valve

2

stem into rim.

Install o-ring onto the valve stem.

Install nut onto valve stem and o-ring, with the recessed area

toward rim.

Press the valve stem into the channel and hand tighten the nut.

38Valve Stem Installation

Page 39

Wheel Build & Spoke Replacement

Replacement Parts

For part numbers, please refer to the SRAM Wheels Spare Parts List in the Service section of www.sram.com.

Front

Wheel

Rear

ROAM 60

Wheel

Front

Wheel

Rear

ROAM 50

Wheel

Front

Wheel

Rear

RAIL 50

Wheel

Spoke

Count

24 2 Cross 268 mm 280 mm 298 mm

24 2 Cross 268 mm 280 mm 298 mm

24 2 Cross 270 mm 281 mm 300 mm

24 2 Cross 270 mm 281 mm 300 mm

24 2 Cross 270 mm 281 mm 300 mm

24 2 Cross 270 mm 281 mm 300 mm

Lacing

Pattern

Spoke Length 26 Spoke Length 27.5 Spoke Length 29 Final Spoke Tension

110 kgf ± 10 kgf (1079 N ± 98 N)

on Brake side

110 kgf ± 10 kgf (1079 N ± 98 N)

on Drive side

110 kgf ± 10 kgf (1079 N ± 98 N)

on Brake side

110 kgf ± 10 kgf (1079 N ± 98 N)

on Drive side

110 kgf ± 10 kgf (1079 N ± 98 N)

on Brake side

110 kgf ± 10 kgf (1079 N ± 98 N)

on Drive side

39Wheel Build & Spoke Replacement

Page 40

www.sram.com

GEN.0000000004463 Rev A © 2013 SRAM, LLC

Loading...

Loading...