Page 1

This is a non-approved rough

draft document. Do not share

outside of SRAM. Procedures,

illustrations, and technical

information may not be correct

and should not be used for any

service or installation.

Page 2

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

eTap Systems

User Manual

95-XXXX-XXX-XXX Rev X

© 2015 SRAM, LLC

Page 3

Grease

Tools and Supplies Tools and Supplies Tools and Supplies

Tools and Supplies Tools and Supplies Tools and Supplies

Tools and Supplies Tools and Supplies Tools and Supplies

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

5 4

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

T25

T25

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

Highly specialized tools and supplies are

required for the installation of your SRAM

components. We recommend that you have

a qualified bicycle mechanic install your

SRAM components.

5

4

24 22

C

25 TPI

8 8 8

400 Grit

2

Page 4

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

SAFETY INSTRUCTIONS

You must read and understand

the safety and warranty document

before proceeding with installation.

Improperly installed components are

extremely dangerous and can result in

severe and/or fatal injuries. If you have

any questions on the installation of

these parts, consult a qualified bicycle

mechanic. This document is also

available on www.sram.com.

3

Page 5

Battery Charging Battery Charging Battery Charging

Battery Charging Battery Charging Battery Charging

Battery Charging Battery Charging Battery Charging

1

2

4

3

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove the battery cover from the

battery.

NOTICE

Do not discard the derailleur battery

cover. Install the derailleur battery

cover on the battery when it is not on

the charger or derailleur.

Remove Retirer Retire

Entfernen Rimuovere

Quitar Verwijderen

Install Installer Instalar

Einbauen Installare

Instalación Monteren

Adjust Régler Ajustar

Einstellen Regolare

Ajustar Afstellen

4

Page 6

1

2

4

3

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Install the battery into the charger with

the battery foot seated in the base

first.

The LED lights are amber while the

battery is charging and turns green

when the charging is complete.

Remove Retirer Retire

Entfernen Rimuovere

Quitar Verwijderen

Install Installer Instalar

Einbauen Installare

Instalación Monteren

Adjust Régler Ajustar

Einstellen Regolare

Ajustar Afstellen

5

Page 7

1

2

4

3

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Press the button on the charger base

to release the battery.

NOTICE

Immediately install the derailleur

battery cover or install the battery

on the derailleur. Failure to cover the

battery connection points could result

in damage to the battery.

Remove Retirer Retire

Entfernen Rimuovere

Quitar Verwijderen

Install Installer Instalar

Einbauen Installare

Instalación Monteren

Adjust Régler Ajustar

Einstellen Regolare

Ajustar Afstellen

6

Page 8

System Pairing System Pairing System Pairing

System Pairing System Pairing System Pairing

System Pairing System Pairing System Pairing

1

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

NOTICE

The rear derailleur is the master device,

and the pairing session begins with

the master device. The LED on the rear

derailleur and the device being paired

will blink quickly when the device is

successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

NOTICE

The rear derailleur is the master

device, and the pairing session begins

with the master device. The LED on

the rear derailleur and the device

being paired will blink quickly when

the device is successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

Begin the pairing session

at the rear derailleur. Press

and hold the function button

on the rear derailleur until

the green LED blinks slowly,

then release.

NOTICE

The rear derailleur is the master device,

and the pairing session begins with

the master device. The LED on the rear

derailleur and the device being paired

will blink quickly when the device is

successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

NOTICE

The rear derailleur is the master device,

and the pairing session begins with

the master device. The LED on the rear

derailleur and the device being paired

will blink quickly when the device is

successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

NOTICE

The rear derailleur is the master device,

and the pairing session begins with

the master device. The LED on the rear

derailleur and the device being paired

will blink quickly when the device is

successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

The rear derailleur is the master

device, and the pairing session begins

with the master device. The LED on

the rear derailleur and the device

being paired will blink quickly when

the device is successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

The rear derailleur is the master

device, and the pairing session begins

with the master device. The LED on

the rear derailleur and the device

being paired will blink quickly when

the device is successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

NOTICE

NOTICE

NOTICE

The rear derailleur is the master device,

and the pairing session begins with

the master device. The LED on the rear

derailleur and the device being paired

will blink quickly when the device is

successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

NOTICE

The rear derailleur is the master device,

and the pairing session begins with

the master device. The LED on the rear

derailleur and the device being paired

will blink quickly when the device is

successfully paired.

Steps 2-4 can be done in any order.

The rear derailleur LED light will blink

when it has received and executed a

command.

Install

Einbauen

Instalación

Installer

Installare

Monteren

Instalar

7

Page 9

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on the front

derailleur until the green

LED blinks quickly, then

release.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and hold the function

button on one shifter

until the green LED blinks

quickly, then release.

Repeat on the other shifter.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Press and release the

function button on the rear

derailleur to end pairing,

or wait 30 seconds for the

pairing session to time out.

The green LED will stop

blinking.

Measure

Messen

Medir

Mesurer

Misurare

Meten

Medir

Remove

Entfernen

Quitar

Retirer

Rimuovere

Verwijderen

Retire

8

Page 10

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

Verify the system is paired

by shifting the derailleurs

in both directions. If the

derailleurs do not respond,

repeat the pairing process.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

NOTICE

Any time a new device is added,

the entire pairing process must be

repeated for all devices. For example, if

the right shifter is replaced, the entire

system will need to be paired again.

9

Page 11

Shifting Shifting Shifting

Shifting Shifting Shifting

Shifting Shifting Shifting

1

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

2

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the left shifter paddle to move the

rear derailleur inboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

Press the right shifter paddle to move the

rear derailleur outboard. Press and hold the

paddle for multiple shifts.

10

Page 12

3

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

Press both shifter paddles simultaneously

to move the front derailleur inboard or

outboard.

11

Page 13

Shifter Installation Shifter Installation Shifter Installation

Shifter Installation Shifter Installation Shifter Installation

Shifter Installation Shifter Installation Shifter Installation

5

1

5

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

2

6-8 N·m

(53-70 in-lb)

2

6-8 N·m

(53-70 in-lb)

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

Use a 5 mm

hex bit socket

to torque thte

shifter bolt to 6-8

N·m

(53-70 in-lbs).

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Install the shifter

assembly onto

the handlebar

and set it to your

desired position.

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

Use a 5 mm hex

bit socket to

torque the shifter

bolt to 6-8 N·m

(53-70 in-lbs).

3

4

+

Measure

Messen

Medir

Mesurer

Misurare

Meten

Medir

Install

Einbauen

Instalación

Installer

Installare

Monteren

Instalar

Torque

Drehmoment

Momento

Valeur de couple

Coppia

Aandraaimoment

Momento de torção

12

Page 14

5

2.5

Install

Einbauen

Instalación

Installer

Installare

Monteren

Instalar

13

Page 15

Front Derailleur Installation Front Derailleur Installation Front Derailleur Installation

Front Derailleur Installation Front Derailleur Installation Front Derailleur Installation

Front Derailleur Installation Front Derailleur Installation Front Derailleur Installation

Direct Mount Direct Mount Direct Mount

Direct Mount Direct Mount Direct Mount

Direct Mount Direct Mount Direct Mount

Clamp Mount Clamp Mount Clamp Mount

Clamp Mount Clamp Mount Clamp Mount

Clamp Mount Clamp Mount Clamp Mount

1

After step 4.

Nach Schritt 4.

Después del paso 4.

Après l’étape 4.

Dopo il punto 4.

Na stap 4.

Depois do passo 4.

Po kroku 4.

Efter trin 4.

Po provedení kroku 4.

Μετά το βήμα 4.

După pasul 4.

1

5-7 N·m

4

2

(44-62 in-lb)

5-7 N·m (44-62 in-lb)

4

2

1

5-7 N·m

4

(44-62 in-lb)

4-5 N·m

4

(35-44 in-lb)

14

Page 16

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

The tip of the tallest

chainring teeth must

appear within the

setup line when viewed

directly from the side.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

Align the tooth tips of

the large chainring with

the guide marks on the

derailleur.

15

Page 17

Rear Derailleur Installation Rear Derailleur Installation Rear Derailleur Installation

Rear Derailleur Installation Rear Derailleur Installation Rear Derailleur Installation

Rear Derailleur Installation Rear Derailleur Installation Rear Derailleur Installation

5

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

3

1

2

8-10 N·m

(70-88 in-lb)

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

Press and hold the left

shift paddle to shift the

rear derailleur until it is

fully extended.

NOTICE

Do not manually force the

derailleur to move inboard

or outboard. Forcing the

derailleur to move will

damage the motor.

NOTICE

Do not manually force the

derailleur to move inboard

or outboard. Forcing the

derailleur to move will

damage the motor.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

NOTICE

NOTICE

Do not manually force the

derailleur to move inboard

or outboard. Forcing the

derailleur to move will

damage the motor.

16

Page 18

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

Align the pulley wheel with the largest

cog by performing a micro-adjust.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm. Continue

to hold and shift to perform multiple

micro-adjusts.

17

Page 19

Mid Cage

26/28T

= 6 mm

2.5

=

=

6

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

Use your fingers to

adjust the low limit

screw so that it lightly

contacts the inner link of

the rear derailleur.

18

Page 20

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

Press and hold the right

shift paddle to shift the

rear derailleur until it is

fully compacted.

NOTICE

Do not manually force the

derailleur to move inboard

or outboard. Forcing the

derailleur to move will

damage the motor.

NOTICE

Do not manually force the

derailleur to move inboard

or outboard. Forcing the

derailleur to move will

damage the motor.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

NOTICE

Do not manually force

the derailleur to move

inboard or outboard.

Forcing the derailleur

to move will damage

the motor.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

NOTICE

Do not manually force the

derailleur to move inboard

or outboard. Forcing the

derailleur to move will

damage the motor.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the

high limit screw until it

lightly touches the inner

link of the rear derailleur.

19

Page 21

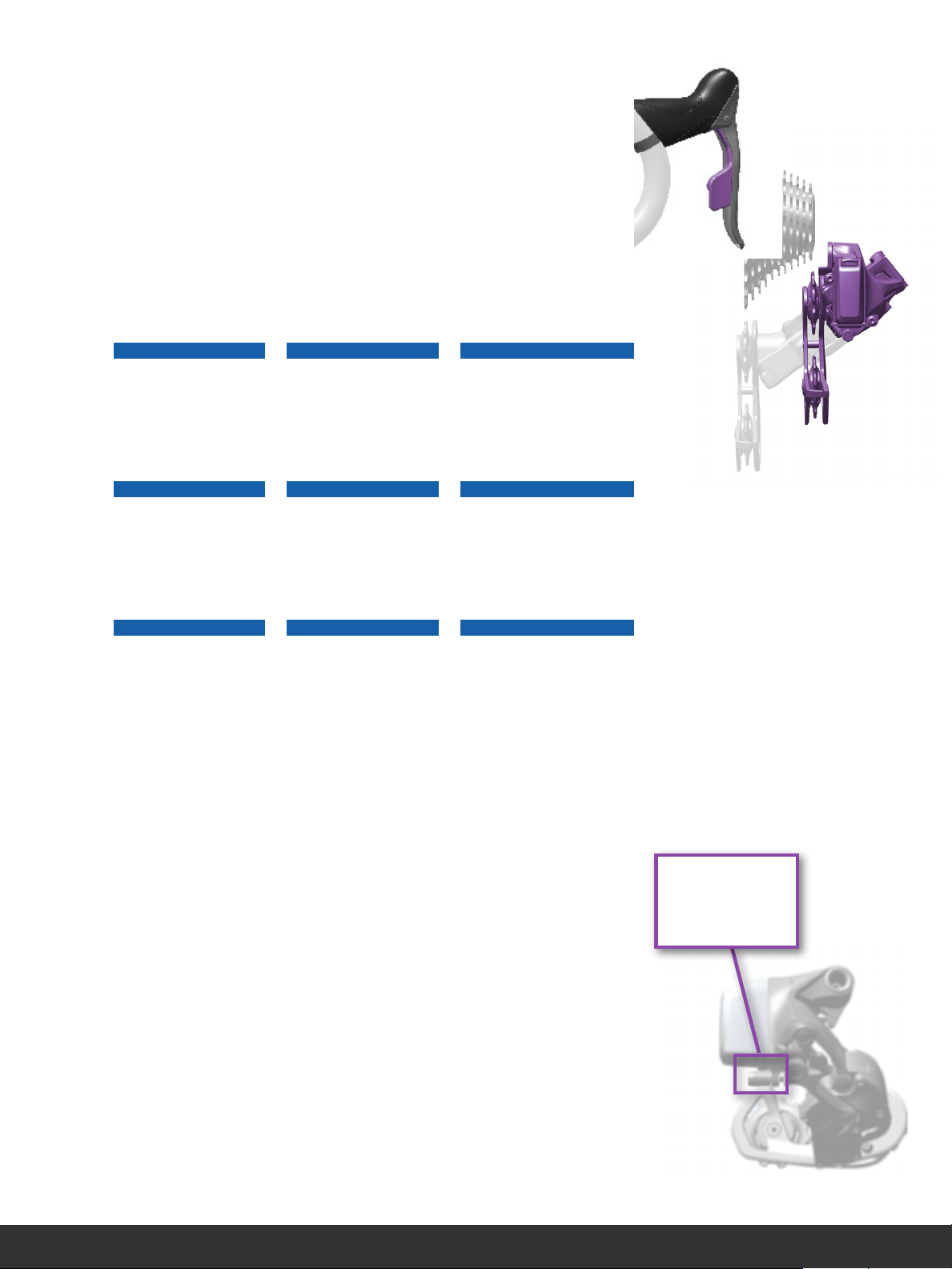

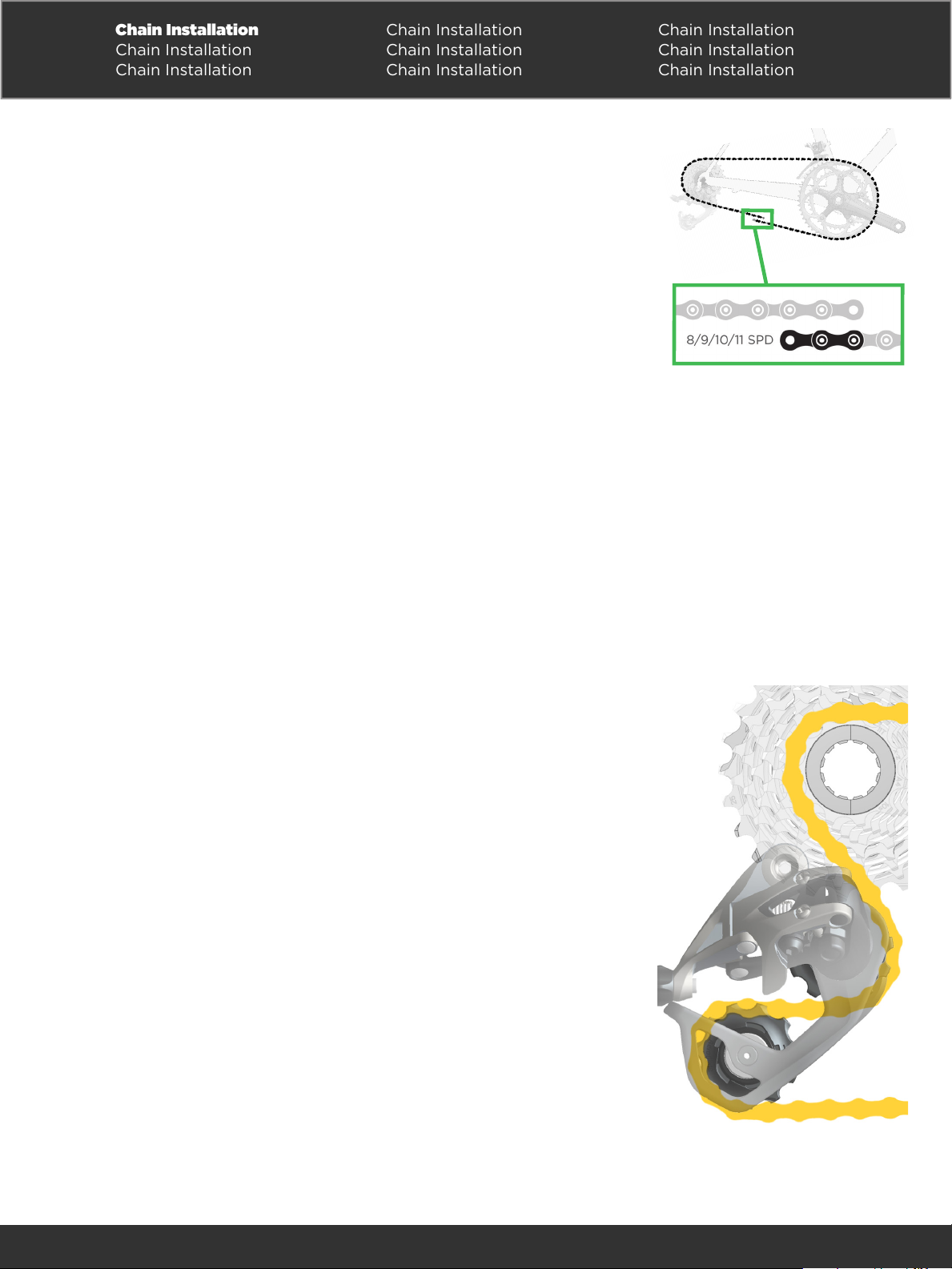

Chain Installation Chain Installation Chain Installation

Chain Installation Chain Installation Chain Installation

Chain Installation Chain Installation Chain Installation

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Route the chain through

the rear derailleur.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Route the chain through

the rear derailleur.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Wrap the chain around

the largest cog on the

rear derailleur and the

large chainring. From

where the chain meets,

add one inner and one

outer link. Use a chain

tool to remove the

excess chain.

Route the chain through

the rear derailleur.

Route the chain through

the rear derailleur.

Route the chain through

the rear derailleur.

Route the chain through

the rear derailleur.

Route the chain through

the rear derailleur.

Route the chain through

the rear derailleur.

Route the chain through

the rear derailleur.

20

Page 22

Install the

PowerLock.

Install the

PowerLock.

Install the

PowerLock.

Install the

PowerLock.

Install the

PowerLock.

Install the

PowerLock.

Install the

PowerLock.

Install the

PowerLock.

Install the

PowerLock.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

Squeeze the brake

lever while pushing the

crankarm down to lock

the PowerLock into

place.

21

Page 23

Front Derailleur Adjustment Front Derailleur Adjustment Front Derailleur Adjustment

Front Derailleur Adjustment Front Derailleur Adjustment Front Derailleur Adjustment

Front Derailleur Adjustment Front Derailleur Adjustment Front Derailleur Adjustment

Use a 2.5 mm hex

L

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

12

0.5 mm

2.5

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

Use a 2.5 mm hex

wrench to adjust the low

limit screw so there is .5

mm between the chain

and the outside edge of

the rear derailleur.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

13

1-2 mm

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

Measure the gap

between the tallest teeth

of the large chainring

and bottom edge of the

outer cage plate. The

gap must be 1-2 mm.

If it is not, adjust the

height of the derailleur

(_ & _), then repeat steps

_, __, and __.

22

Page 24

With the chain as

H

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

With the chain as

illustrated, use a 2.5 mm

hex to turn the high limit

screw until there is 1 mm

of clearance between

the inside of the outer

derailleur cage plate and

the chain.

C

2.5

B

1 mm

D

23

Page 25

Fine Tuning Fine Tuning Fine Tuning

Fine Tuning Fine Tuning Fine Tuning

Fine Tuning Fine Tuning Fine Tuning

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

Fine-tune the rear derailleur shifting

performance by using microadjustments.

Inboard: Press the left shifter function

button while actuating the shift paddle

to micro-adjust the rear derailleur

inboard 0.25 mm.

Outboard: Press the right shifter

function button while actuating the

shift paddle to micro-adjust the rear

derailleur outboard 0.25 mm.

24

Page 26

Maintenance Maintenance Maintenance

Maintenance Maintenance Maintenance

Maintenance Maintenance Maintenance

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

Periodic cleaning is recommended.

Use a damp cloth to wipe the

components until clean.

25

Page 27

Firmware Update Dongle Firmware Update Dongle Firmware Update Dongle

Firmware Update Dongle Firmware Update Dongle Firmware Update Dongle

Firmware Update Dongle Firmware Update Dongle Firmware Update Dongle

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer. The

dongle will automatically install the

necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer. The

dongle will automatically install the

necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer. The

dongle will automatically install the

necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer. The

dongle will automatically install the

necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer.

The dongle will automatically install

the necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer.

The dongle will automatically install

the necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer. The

dongle will automatically install the

necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer. The

dongle will automatically install the

necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

Use the Firmware Update Dongle to

communicate the firmware update

between your components and the

computer.

Install the Firmware Update Dongle

into a USB drive on your computer.

The dongle will automatically install

the necessary drivers.

Go to www.sram.com/registration to

download the firmware update, then

follow the prompts to update the

component's firmware.

For software updates related to your

products, please register online at

www.sram.com/registration.

26

Page 28

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

WARNING

Do not use or clean the components without

connector wires or dummy plugs installed.

Moisture will damage the components.

Use and store the device within the

temperature ranges specified in the

Declaration of Conformity, and Hazards and

Warnings document at

www.sram.com.

Avoid chemical cleaners and solvents that

can damage plastic components.

Do not submerge the components in liquid

of any kind.

Do not clean the components with a power

washer.

27

Page 29

The LED color indicates the battery life

Battery Status Lights Battery Status Lights Battery Status Lights

Battery Status Lights Battery Status Lights Battery Status Lights

Battery Status Lights Battery Status Lights Battery Status Lights

remaining, and lights up when a shift is

performed.

The LED color indicates the battery life

remaining, and lights up when a shift is

performed.

The LED color indicates the battery life

remaining, and lights up when a shift is

performed.

The LED color indicates the battery life

remaining, and lights up when a shift is

performed.

The LED color indicates the battery life

remaining, and lights up when a shift is

performed.

The LED color indicates the battery life

remaining, and lights up when a shift is

performed.

The LED color indicates the battery life

remaining, and lights up when a shift is

performed.

60-15 hours 60-15 hours 60-15 hours

60-15 hours 60-15 hours 60-15 hours

60-15 hours 60-15 hours 60-15 hours

15-6 hours 15-6 hours 15-6 hours

15-6 hours 15-6 hours 15-6 hours

15-6 hours 15-6 hours 15-6 hours

5-1 hours 5-1 hours 5-1 hours

5-1 hours 5-1 hours 5-1 hours

5-1 hours 5-1 hours 5-1 hours

The LED color indicates the battery life

remaining, and lights up when a shift is

performed.