Page 1

DualDrive · December 2002

1

E

D

F

Nl

Dk

Sv

user manual

betriebsanleitung

notice d’utilisation

handleiding

brugsanvisning

bruksanvisning

Page 2

i-MOTION 3 · June 2006

2

Precautionary measures,

which protect from possible

accident, injury or danger to

life, or which prevent possible

damage to the bicycle.

These instructions contain

important information about your

SRAM i-MOTION 3 System.

Please take the time to read these

operating instructions carefully.

Your SRAM i-MOTION 3 System is

almost maintenance-free. Should

you have any queries that are

not answered in these operating

instructions, your qualified bicycle

specialist will be pleased to help

you.

Have a nice time and enjoy your

SRAM i-MOTION 3.

Special advice to assist in the

better handling of the operation, control, and adjustment

procedures.

Please note:

© Copyright SRAM Corporation 2006

Publ. No. 5300 E/D/F/Nl/Dk/Sv

Information may be enhanced

without prior notice.

Released June 2006

SRAM Technical Documentation,

Schweinfurt/Germany

Page 3

i-MOTION 3 · June 2006

3

E

THE SRAM i-MOTION 3 SYSTEM

4

OPERATION

5

MAINTENANCE AND CARE

» Gear adjustment 6

» Remove and fit rear wheel 7

» Cleaning and lubrication 10

» Repair work / wear parts 11

ASSEMBLY OF COMPONENTS

12

TECHNICAL DATA

18

TABLE OF CONTENTS

Page 4

i-MOTION 3 · June 2006

4

A modern bicycle derailleur should

be sporty, load shiftable, intuitive

to use and durable! With the new

i-MOTION 3, SRAM delivers an

internal gear hub that meets and

exceeds all these requirements!

i-MOTION 3 shifter

Intuitive gear indication, highquality design.

i-MOTION 3 gear hub

Load shiftable. Light shifting

forces. Shifting during standstill is possible: Easy re-start

e.g. at a traffic light.

i-MOTION 3 connecting link

Easy wheel removal:

The gear adjustment remains

unchanged.

THE SRAM i-MOTION 3 SYSTEM

Page 5

i-MOTION 3 · June 2006

5

E

OPERATION

SHIFTING

1

Shift gears by turning the

rotating grip.

» You can shift while standing still

or while riding your bicycle.

» When approaching inclines shift

down in good time.

» The smoothest and fastest gear

change happens when changing

gears while pedaling with low

force.

BRAKING

On long and steep downhill roads,

simultaneously use rear and front

brakes to avoid heating up of the

brakes.

Excessive heating of the hub

with the back pedal brake

may result in loss of lubricant and

braking too hard. This will lead to a

trip to the repair shop.

Read the applicable user

manual for each bicycle

equipped with i-BRAKE or band

brakes.

1

Page 6

i-MOTION 3 · June 2006

6

MAINTENANCE AND CARE

GEAR ADJUSTMENT

2

Shift the twist shifter to the

3rd gear.

The shift cable must be with-

out play in 3rd gear. That

means it must be pulled out of the

hub as far as it will go.

3

While pulling the plastic re-

tainer (1), it should not be possible to pull the shift cable further

out of the hub.

– Shift cable has too much play:

Shift the twist shifter to the 1st

gear.

4

Reduce play of the shift

cable by turning the barrel

adjuster (2) at the shifter.

– Shift cable is too taut:

The shifter won‘t shift into 3rd

gear or the hub doesn‘t shift in

1st gear or will permanently

switch between 1st and 2nd

gear.

Shift the twist shifter to the 1st

gear.

4

Decrease shift cable tension by turning the barrel

adjuster (2) at the shifter.

» Shift the twist shifter to the 3rd

gear and check again, until there

isn‘t any play in the shift cable.

2

4

2

1

3

Page 7

i-MOTION 3 · June 2006

7

E

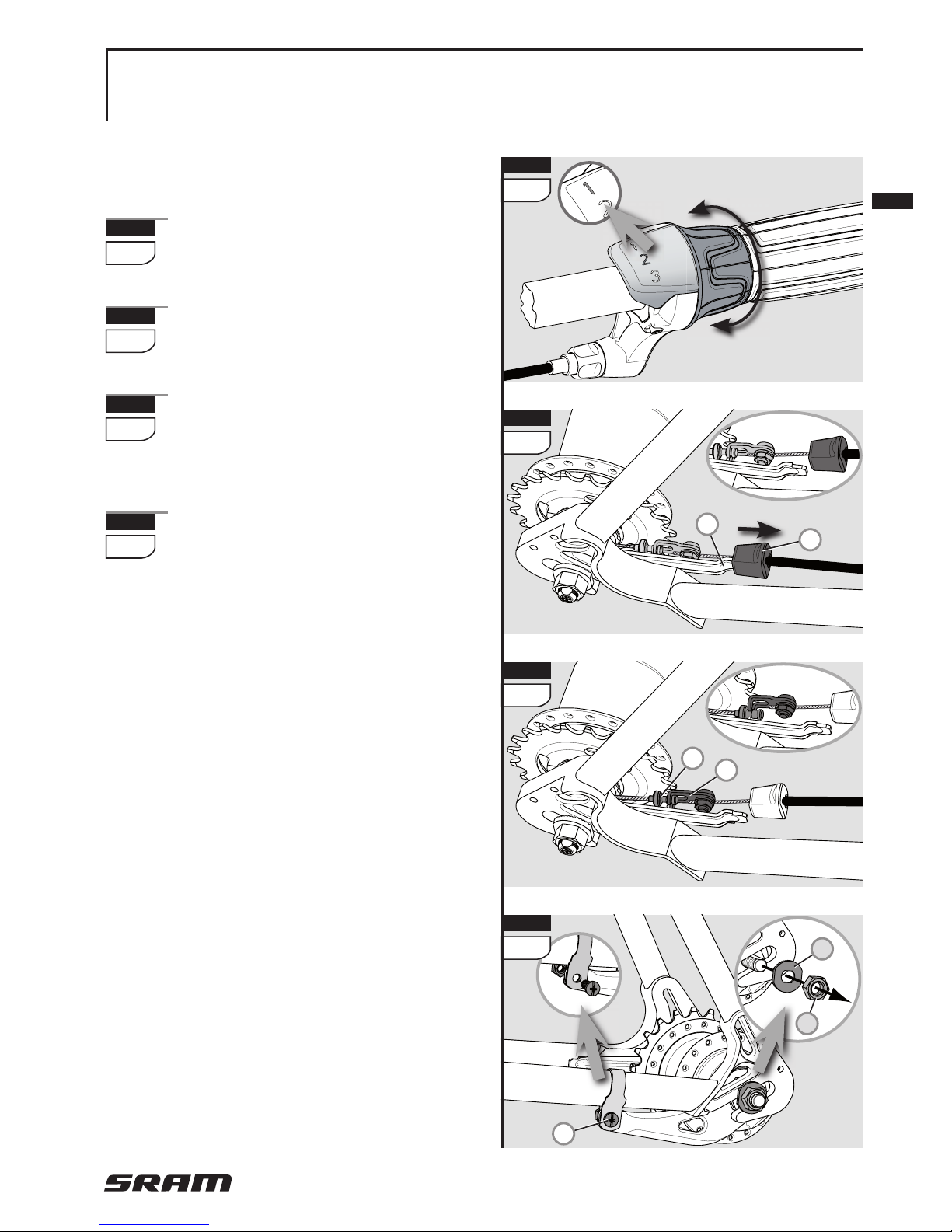

5

MAINTENANCE AND CARE

REMOVE AND FIT REAR WHEEL

REMOVING THE REAR

WHEEL

5

Shift the twist shifter to the 1st

gear.

6

Pull the plastic retainer (1) off

the cable stop bracket (2).

7

Disconnect the shift cable by

disengaging the link (3) of the

cable nipple (4).

8

Loosen the axle nuts (5) and

remove the nuts and the retaining washers (6) underneath

them.

If applicable, unscrew the frame

clamp connection (7) of the brake

lever.

» Remove the rear wheel.

1

2

6

3

4

7

8

7

5

6

Page 8

i-MOTION 3 · June 2006

8

FITTING THE REAR

WHEEL

» Place the rear wheel into the rear

frame.

9

Slide one retaining washer

each (1) onto each axle end.

The serrations of the retaining

washer must bear against the

dropout of the frame.

10

Align the cable stop bracket (2)

parallel to the frame stay (3).

11

Mount the axle nuts (4) and

tighten them alternately with

a torque of 30 – 40 Nm (266 – 350

in.lbs.).

12

If applicable, mount the brake

lever (5) between the two

straps of the frame clamp (6).

The frame clamp must be

seated on the frame with no

play. Use only self-locking nuts!

Tightening torque: 2 – 3 Nm (18 –

27 in.lbs.).

MAINTENANCE AND CARE

REMOVE AND FIT REAR WHEEL

1

9

4

11

5

6

12

2

10

3

Page 9

i-MOTION 3 · June 2006

9

E

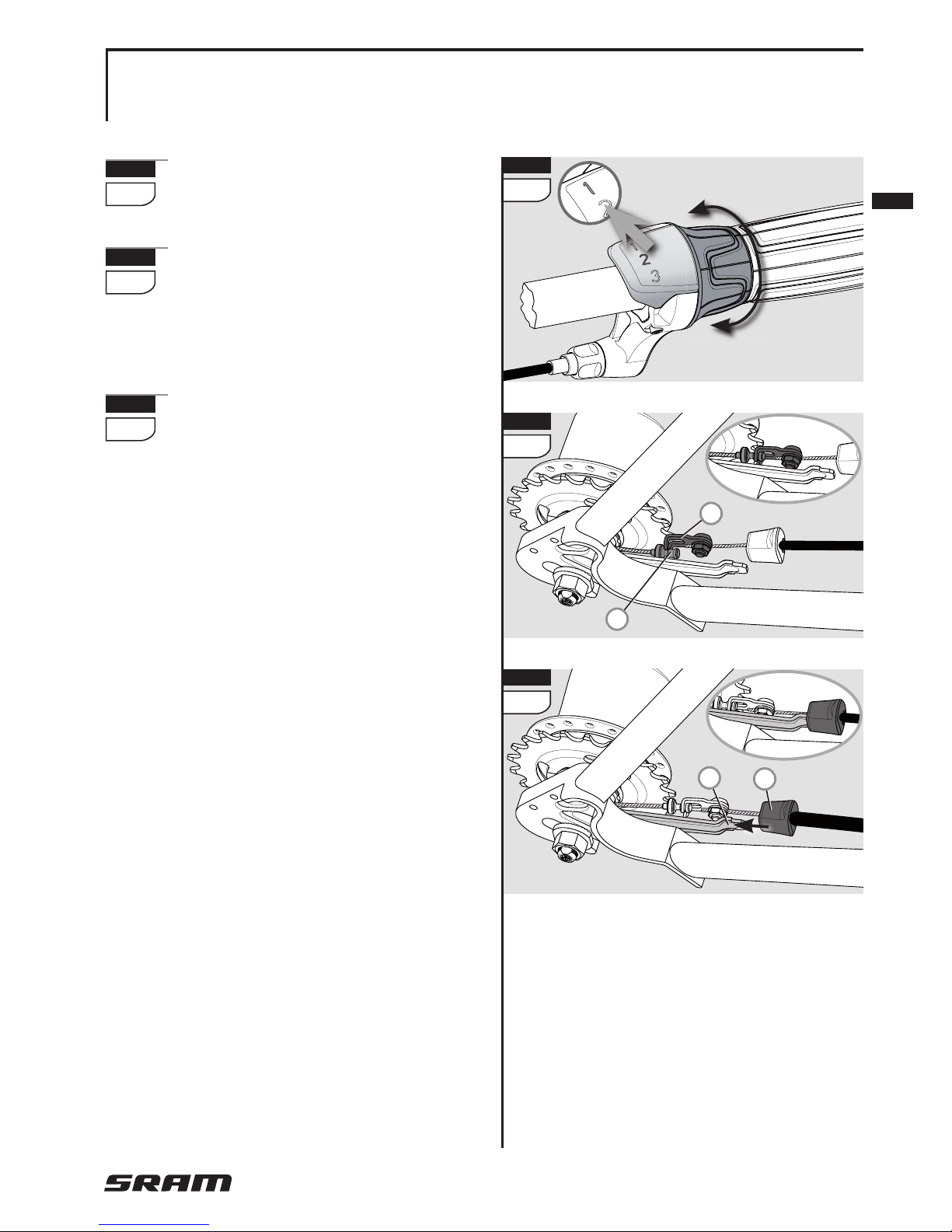

13

13

Make sure that the shifter is

set to the 1st gear.

14

Make the cable connection by

hooking in the link (7) of the

shift cable to the cable nipple (8)

on the hub.

15

Slide the plastic retainer (9)

completely onto the cable stop

bracket (10).

MAINTENANCE AND CARE

REMOVE AND FIT REAR WHEEL

7

8

14

9

10

15

Page 10

i-MOTION 3 · June 2006

10

CLEANING

» Your SRAM i-MOTION 3 compo-

nents are well protected from

external evironmental impacts.

However, do not use water under

pressure (such as pressure washers or water jets) for cleaning to

prevent malfunctions due to water

penetration.

» During the winter season, you

should clean your bicycle in

shorter intervals so that winter

road salt cannot cause any dam-

age.

» Do not use agressive cleaners.

» Clean dirty chains before oiling.

Let cleaner set for only a few

minutes and rinse with water. Do

not oil chain until completely dry.

LUBRICATION

» The rear wheel hub is provided

with permanent lubrication and

maintenance-free under normal

conditions.

» Regular lubrication will extend the

chain's service life.

MAINTENANCE AND CARE

CLEANING AND LUBRICATION

Page 11

i-MOTION 3 · June 2006

11

E

REPAIR WORK

Only a qualified bike dealer

should perform any necessary

work on the gear hub, shifter, and

brakes.

» Unauthorized work on your

i-MOTION 3 system could endanger you and your warranty may

become void.

» Please contact your qualified bike

dealer regarding any questions or

problem you may have.

Back pedal brake

If the back pedal brake is braking

too hard, the brake jacket has to be

lubricated with special grease. This

work must be performed by a qualified bike dealer.

Cable Change

If a cable must be replaced (shifter

cable or brake cable), contact your

qualified dealer.

WEAR PARTS

Brake liners or brake jackets, brake

cables, shift cables, handlebar

grips, sprockets, and bike chains

are wear parts. Please check these

parts regularly and replace them

timely.

MAINTENANCE AND CARE

REPAIR WORK / WEAR PARTS

Page 12

i-MOTION 3 · June 2006

12

ASSEMBLY HUB

» Spoke the hub as normal.

16

Set the dust cover (1) onto the

driver. The curve must point to

the outside.

17

Set the sprocket (2) onto the

driver.

If an offset sprocket will be used,

mount the sprocket with the curve

pointing to the outside.

18

Mount the sprocket retaining

ring (3) onto the driver. Check

proper seat of the retaining ring.

19

Slide the cable stop bracket (4)

onto the axle end of the

sprocket side. Thereafter mount

the washer with rubber insert (5)

to fix the the cable stop bracket.

» Place the rear wheel into the rear

frame.

ASSEMBLY

OF COMPONENTS

3

1

2

18

17

16

19

4

5

Page 13

i-MOTION 3 · June 2006

13

E

20

Slide one retaining washer

each (6) onto each axle end.

The serrations of the retaining

washer must bear against the

dropout of the frame.

21

Align the cable stop bracket (7)

parallel to the frame stay (8).

22

Mount the axle nuts (9) and

tighten them alternately with

a torque of 30 – 40 Nm (266 – 350

in.lbs.).

23

If applicable, mount the brake

lever (10) between the two

straps of the frame clamp (11).

The frame clamp must be

seated on the frame without

play. Use only self-locking nuts!

Tightening torque: 2 – 3 Nm (18 –

27 in.lbs.).

ASSEMBLY

OF COMPONENTS

7

21

8

6

20

9

22

10

11

23

Page 14

i-MOTION 3 · June 2006

14

ASSEMBLY

OF COMPONENTS

ASSEMBLY SHIFTER

24

Slide the shifter (1) onto the

handlebar.

25

Slide the handlebar grip (2)

onto the handlebar.

26

Align the shifter on the han-

dlebar grip and position the

shifter according to your needs.

Tighten the clamp bolt (3).

2.5 mm Allen wrench, torque 1.7 Nm

(15 in.lbs.).

Never use lubricants or sol-

vents to install handlebar

grips. Handlebar grips provide an

axial safety function and may not

become separated from the handlebar.

» Make sure that the shifter and

brake lever function properly and

are unobstructed (re-adjust if

needed).

» Never ride without the handlebar

grips. The turning grip of the twist

shifter could become loose. This

can result in severe injury.

3

2

1

24

25

26

2.5 mm

1.7 Nm

(15 in.lbs.)

Page 15

i-MOTION 3 · June 2006

15

E

28

ASSEMBLY

OF COMPONENTS

ASSEMBLY SHIFT

CABLE

Make sure that the cable

housing length is sufficient to

allow an extreme turning angle.

» Also consider the influence of

adjustable handlebars and stems

on the cable housing length.

27

Fasten the cable housing on

the frame.

The cable housing must be

movable at the fastening

points.

» Avoid tight bends when install-

ing the shift cable.

28

Make sure that the shifter is

set to the 1st gear.

29

Make the cable connection by

hooking in the link (1) of the

shift cable to the cable nipple (2)

on the hub.

30

Slide the plastic retainer (3)

completely onto the cable stop

bracket (4).

27

1

2

29

3

4

30

Page 16

i-MOTION 3 · June 2006

16

GEAR ADJUSTMENT

» Shift the gears up and down re-

peatedly before setting the shifter

so that the shift cable can settle.

31

Shift the twist shifter to the

3rd gear.

The shift cable must be with-

out play in 3rd gear. That

means it must be pulled out of the

hub as far as it will go.

32

While pulling the plastic re-

tainer (1), it should not be possible to pull the shift cable further

out of the hub.

– Shift cable has too much play:

Shift the twist shifter to the 1st

gear.

33

Reduce play of the shift

cable by turning the barrel

adjuster (2) at the shifter.

– Shift cable is too taut:

The shifter won‘t shift into 3rd

gear or the hub doesn‘t shift in

1st gear or will permanently

switch between 1st and 2nd

gear.

Shift the twist shifter to the 1st

gear.

33

Decrease shift cable tension by turning the barrel

adjuster (2) at the shifter.

ASSEMBLY

OF COMPONENTS

2

33

1

32

31

» Shift the twist shifter to the 3rd

gear and check again, until there

isn‘t any play in the shift cable.

Page 17

i-MOTION 3 · June 2006

17

E

ASSEMBLY

OF COMPONENTS

Page 18

i-MOTION 3 · June 2006

18

TECHNICAL DATA

i-MOTION 3 with back pedal brake

Speeds 3

Brake With back pedal brake

Over Locknut Dim., OLD 130 mm

Length, L 168 and 178 mm

Ends Diameter M 10x1

Dropout Width Dim., A

min. 4 mm / max. 8 mm

Holes 28 / 32 / 36

Hole Diameter 3.0 mm

Hole Ref. ø, HR 70 mm

Flange Dist. to 1/2 OLD F1 = 27.3 mm / F2 = 27.6 mm

Total Ratio 186 %

Gear jump 1 to 3 36% / 36%

Chainline, CL 44.0 mm (straight spr.) / 40.5 mm (off-set spr.)

Dimension

1

/2" x 1/8" and 1/2" x 3/32"

Sprocket 16 / 17 / 18 T. (straight) / 19 / 20 / 21 T. (off-set)

Shifter SRAM i-MOTION 3

Tandem

not suitable for tandems and transport bicycles

Axle

Spoke

ChainCompat-

ibility

GEAR HUB

i-MOTION 3 shifter

Shifter type

Twist shifter

Assembly location Right side of handlebar

Gear indication Window

Barrel adjuster Indexed

Clamp diameter 22.3 mm

Straight handlebar ends

Length = min. 150 mm

Cable laying Continuous cable housing (pre-assembled)

SHIFTER

Page 19

i-MOTION 3 · June 2006

19

E

TECHNICAL DATA

OLD

19

A

3

A

3

2.8 2.8

F

1

F

2

M 10x1

1

0

0

M 10x1

L

HR

78

124.5

CL

straight

CL

off-set

1

/

2

OLD

Ø

3.0

Ø

7.3

Version with back pedal brake

Page 20

WORLD HEADQUARTERS

Chicago, Illinois U.S.A.

SRAM Corporation

1333 North Kingsbury, 4th floor

Chicago, Illinois 60622

phone: +1-312-664-8800

fax: +1-312-664-8826

EUROPEAN HEADQUARTERS

Amersfoort, The Netherlands

SRAM Europe

Basicweg 12-D

3821 BR Amersfoort

The Netherlands

phone: +31-33-450-6060

fax: +31-33-457-0200

ASIAN HEADQUARTERS

Taichung, Taiwan

SRAM Taiwan

No. 1598-8 Chung Shan Road

Shen Kang Hsiang, Taichung

County 429

Taiwan

phone: +886-4-2561-3678

fax: +886-4-2561-3686

www.sram.com

Loading...

Loading...