Page 1

operating instructions

betriebsanleitung

notice d’utilisation

handleiding

brugsanvisning

bruksanvisning

Page 2

DualDrive · December 2002

2

Precautionary measures,

which protect from possible

accident, injury or danger to

life, or which prevent possible

damage to the bicycle.

These instructions contain important

information on your DualDrive

system.

Cycling with DualDrive is easy. It’s

true. It may surprise you just how

many features your DualDrive

system has.

To make the best possible use of

your DualDrive please take the time

to read these operating instructions

carefully.

Your DualDrive system is almost

maintenance-free. Should you have

any queries that are not answered in

these operating instructions, your

qualified bicycle specialist will be

pleased to help you.

Have a nice time and enjoy

”dualdriving”.

Special advice to assist in

the better handling of the

operation, control and adjustment procedures.

Please take particular note of the

following:

© Copyright SRAM Corporation 2002

Publ. No. 5000 E/D/F/Nl/Dk/Sv

Information may be enhanced

without prior notice.

Released December 2002

SRAM Technical Documentation,

Schweinfurt/Germany

Shimano is a trademark of Shimano Inc., Japan.

Page 3

DualDrive · December 2002

3

E

CONTENTS

THE DUALDRIVE SYSTEM 4

OPERATION 7

MAINTENANCE AND CARE

» Gear adjustment 8

» Remove and fit rear wheel 10

» Cleaning and Lubrication 11

» Cable change 12

ASSEMBLY OF COMPONENTS 14

TECHNICAL DATA 18

ADDRESSES 110

Page 4

DualDrive · December 2002

4

THE DUALDRIVE SYSTEM

WHAT IS DUALDRIVE

The general perception is that shifting

requires a Zen-like touch from years

of trial and error . . . mostly error.

Many riders wanted something

easier. We really love this kind of

challenge. And DualDrive exceeds

all the expectations.

DualDrive is a drive train consisting

of a self-energized internal hub and

rear derailleur for smooth adjustment.

It’s the market’s most revolutionary

transmission.

OPERATING PRINCIPLE

Single-side shifting allows the rider to

use one-hand to easily click through

a 27-, 24- or 21 gear option. And

DualDrive’s superior gear indication,

featuring three intuitive riding modes,

creates a smooth, comfortable ride

for novice and masters alike. Easy

shifting.

Advanced performance. Mission

accomplished.

RIDING MODES

DualDrive has 3 intuitive shifting

modes. Hill mode, standard mode, and

fast mode. Each mode is designed to

allow the rider to be in the proper

mode wherever you go.

H

i

l

l

S

t

a

n

d

a

r

d

F

a

s

t

Page 5

DualDrive · December 2002

5

E

THE DUALDRIVE SYSTEM

DualDrive hub and cassette

Super light shifting forces,

load shiftable. Stand-still shifting

(mode selector): easy re-start at

a traffic light

DualDrive single-sided shifter

Simple gear indication:

one view for all information.

Intuitive logical shifting.

DualDrive rear derailleur

Light, precise shifting.

Larger pivots, links and cages:

increased rigidity and durability.

DualDrive Clickbox

Easy wheel removal:

pre-adjusted gears for simplicity.

Page 6

DualDrive · December 2002

6

THE DUALDRIVE SYSTEM

HOW LONG DID IT

TAKE TO FINISH

DUALDRIVE?

A big team of 25 engineers from all

around the world worked for two

years on this project.

HOW DID WE TEST

DUALDRIVE?

Enthusiastic trekking riders did test

the system under all weather circumstance for more than a year.

Within these tests we finetuned the

function of the system to perform to

100% of the comfort trekking riders

expectations.

WHAT PARTS DO I NEED

TO COMPLETE A DUALDRIVE TRAIN?

A DualDrive train contains the

following products:

» DualDrive hub: in either without

brake and disc brake version.

» Cassette: 11-34 teeth, 9 speed for

DualDrive 27 or 11-32 teeth, 8

speed for DualDrive 24 or 12-32

teeth, 7 speed for DualDrive 21.

» Derailleur: DualDrive 9 speed for

DualDrive 27, DualDrive 8 speed

for DualDrive 24 or DualDrive 7

speed for DualDrive 21.

» Shifter with Clickbox: 27 speed

with gear indication window or

24 and 21 speed without gear

indication window.

» Spoke protector: There are two

versions available: in versions for

36 or 32 spoke hole hubs.

» Crank: DualDrive cranks offer the

best performance with the DualDrive system.

I BELIEVE A DUALDRIVE SYSTEM HAS

TO BE HEAVIER THAN

A NORMAL EXTERNAL

DRIVE SYSTEM!

In fact the DualDrive system weighs

around 250 gr less than a standard

derailleur drive train system.

WHAT IS THE BENEFIT

OF THE SINGLE SIDED

SHIFTER?

It is more intuitive due to the riding

modes which explain the driver

directly what mode to use in which

terrain.

Page 7

DualDrive · December 2002

7

E

OPERATION

RIDING MODES

Use the thumb shifter to

choose the gear ratio. You can

operate it in stand still or while

riding. The smoothest and fastest

gear change happens when

changing gears while pedaling.

DERAILLEUR

Use the rotating grip (to the

right) to change gear of the

derailleur system. The smoothest

and fastest gear change happens

when changing gears while

pedaling with low force.

1

2

1

2

Page 8

DualDrive · December 2002

8

4

5

MAINTENANCE AND CARE

GEAR ADJUSTMENT

GEAR HUB

Place thumb shift lever

in standard mode.

Match up the yellow marks in

the Clickbox viewing window

by twisting the barrel adjuster.

DERAILLEUR

Limit screw adjustment:

View the rear derailleur and

pulleys from behind the rear of

the bicycle.

» Turn the limit screw marked ’H’ on

the outer link of the derailleur to

align the upper guide pulley center with the outboard edge of the

smallest cog – clockwise moves

the guide pulley inboard towards

the wheel.

» While turning the crank, push the

rear derailleur towards the larger

cogs by hand.

» Align the upper guide pulley under

the largest cog, by turning the

limit screw marked ’L’ on the outer

link – clockwise moves the guide

pulley outboard away from the

spokes.

3

5

3

4

Page 9

DualDrive · December 2002

9

E

MAINTENANCE AND CARE

GEAR ADJUSTMENT

Chain gap adjustment:

Chain gap is the distance between the

upper guide pulley and the cog the

chain is riding on. Optimal chain gap

allows quick, efficient shifts.

» While turning the crank, push the

rear derailleur inboard by hand to

the largest cog.

» Hold the derailleur in this position

while making the following adjustment.

Use a 3 mm hex wrench, turn

the b-adjust screw until the

chain gap equals approximately

6 mm (

1

/4”).

– Turn the b-adjust screw clock-

wise to increase the chain gap.

– Turn the b-adjust screw

counterclockwise to decrease

the chain gap.

Do not use the b-adjust screw

to adjust the rear derailleur

to act as a chain-tensioning device

or to prevent chain suck. This

increases the chain gap causing

poor shifting performance.

Index shifting adjustment:

» Make sure the chain is located on

the smallest sprocket.

» Shift the chain to the second cog.

– If the chain hesitates or does not

shift, increase the cable tension

by turning the shifter barrel

adjuster counterclockwise.

–

If the chain shifts beyond the

second cog,

decrease the cable

tension by turning the shifter

barrel adjuster clockwise.

» Repeat the two former steps until

shifting and cable tension is

accurate.

» While turning the crank, shift the

chain up and down the cassette

several times to ensure that your

derailleur is indexing smoothly.

3 mm

6 mm

(

1

/

4

")

6

6

Page 10

DualDrive · December 2002

10

MAINTENANCE AND CARE

REMOVE AND FIT REAR WHEEL

REMOVE REAR WHEEL

» Rotate the twist shifter to the hig-

hest gear position (speed „7/8/9“).

Place thumb shift lever

in hill riding mode.

Push Clickbox button down.

» Pull Clickbox off the axle.

» Dismantle wheel.

Unscrew shifting rod (1)

FIT REAR WHEEL

» Fit wheel in frame dropouts.

Place retaining washers (2) on

both sides of the axle – the

serrations must bear against the

dropout (washers with lugs: these

must engage in the dropout slots).

» Tighten up axle nuts. Tightening

torque 30 – 40 Nm (266 – 350 in. lbs.).

» Screw shifting rod (1) into the hub

axle and thigthen it with 0.2 Nm

(1.8 in. lbs.).

» Push on Clickbox to the stop on

the hub axle. The thumb shift lever

must be positioned in the hill riding

mode and Clickbox button must be

pushed down.

» Bring Clickbox button back to initial

setting by pushing it up from underneath.

» Check the gear settings.

7

8

9

7

8

9

9

1

0,2 Nm

2

Page 11

DualDrive · December 2002

11

E

MAINTENANCE AND CARE

CLEANING AND LUBRICATION

CLEANING

Your DualDrive components

are well protected against

adverse environmental influences.

In order to avoid malfunction due

to water penetration, pressurized

jets (high pressure cleaners etc.)

should not be used when cleaning

the bicycle.

» When using the bike during the

winter more frequent cleaning is

necessary to prevent damage

caused by de-icing salt.

» Do not use solvants or corrosive

materials to clean the components.

» Clean dirty chains before oiling.

Do not use any grease-dissolving

or acidic agents. Cleaning agent

must be rinsed off after a few

minutes with water. Apply oil after

chain is completely dried.

LUBRICATION

» DualDrive hubs are provided with

permanent lubrication and

maintenance-free under normal

conditions.

Lubricate the shifting joints

regularly. Grease any cable

guides (e.g. beneath the bottom

bracket).

» Regular lubrication will extend the

chain’s service life.

10

11

11

10

Lubricate the

shifting joints

regularly

Page 12

DualDrive · December 2002

12

13

14

12

MAINTENANCE AND CARE

CABLE CHANGE

CABLE CHANGE

Leave the shifter on the

handlebar.

» No need to move other components.

The shifter does not need to be

opened.

» Use only new high quality cable

(stainless) and compressionless

cable housing with end caps.

Twist shifter (rear derailleur):

» Detach the cable from the

derailleur.

» Cut cable off 15 cm (6") from

shifter barrel adjuster. Discard old

cable and cable housing.

Remove screw (1) and pull open

the cable change sleeve (2).

Rotate the shifter fully in the

cable release direction (gear

position “7/8/9“). Look for cable

head entry (3).

» Push cable up/out of the shifter

and discard.

» Feed the new cable through the

cable entry.

Pull cable snug.

Install cable change sleeve (2)

and fit screw (1).

2

1

3

4

5

12

13

12

Page 13

» Install Clickbox (see Page 10).

» Adjust gearshift.

15

» Feed the cable through the new

cable housing and frame stops.

» Attach cable to the derailleur and

adjust indexing.

Thumb shifter (gear hub):

Place thumb shift lever

in hill riding mode.

» Remove Clickbox from the axle

(see Page 10).

Snap open Clickbox-cover (6)

as shown.

» Unscrew clamping bolt (7), hex

wrench 4 mm.

Remove the shifter escape

hatch (4).

» Remove and discard the old cable.

» Feed the new cable through the

cable entry (5), the new cable

housing and pull the cable snug.

» Attach the escape hatch.

Pull the cable tight and

position it under the cable

anchor washer (8).

» Tighten the 4 mm hex cable anchor

bolt to 2.5 – 4 Nm (22 – 35 in.lbs.).

» Cut off cable end to 1 – 2 mm.

» Snap in Clickbox-cover.

15

7

15

14

MAINTENANCE AND CARE

CABLE CHANGE

DualDrive · December 2002

13

E

REPAIR WORK

Arrange for any work, which

may become necessary on

the DualDrive gear hub and shifter

to be carried out by your qualified

specialist dealer.

» Non-authorized work on your

DualDrive system could put you in

danger and also lead to the loss of

your guaranteed rights.

» If you have questions or problems

please contact your qualified

specialist dealer.

6

7

8

4 mm

2.5 – 4 Nm

22 – 35 in.lbs.

Page 14

1

0,2 Nm

2

3

17

ASSEMBLY

OF COMPONENTS

DualDrive · December 2002

14

ASSEMBLY HUB

»

Spoke the hub as normal.

Place spoke protector disc (1)

on shoulder of hub, fit

cassette (2) onto driver profile.

Screw lock nut (3) with cassette

tool (Park Tool FR-5 or SRAM Part

No. 4624 411 010), tightening

torque: 40 Nm (350 in.lbs.).

Screw shifting rod (1) into the

hub axle and tighten it with

0.2 Nm (1.8 in.lbs.).

» Fit wheel in frame dropouts.

Place retaining washers (2) on

both sides of the axle – the

serrations must bear against the

dropout.

– Version for horizontal dropouts (2):

the lug must engage in the

dropout slot.

– Version for vertical dropouts (3):

without lug.

» Tighten up axle nuts. Tightening

torque 30 – 40 Nm (266 – 350 in. lbs.).

16

3

2

1

16

17

17

Page 15

18

5 mm

8 – 10 Nm

70 – 85

in.lbs.

(4 links)

ASSEMBLY

OF COMPONENTS

DualDrive · December 2002

15

E

ASSEMBLY DERAILLEUR

Check the rear derailleur

hanger alignment. A bent rear

derailleur hanger will result in

inaccurate index shifting.

Attach the rear derailleur to

the frame’s rear derailleur

hanger.

Check that the b-adjust

washer tab (b-adjust screw at

DualDrive 24 and 21) is clear of the

rear derailleur dropout tab.

» Tighten the 5 mm hex hanger bolt

to 8 – 10 Nm (70–85 in.lbs.).

CHAIN LENGTH

Bypassing the rear derailleur,

run the chain around the

largest cog chainring combination. Add 4 LINKS or 3 links +

connecting link to this length for

proper chain length.

» For rear suspension frames,

position the rear suspension for

the greatest chain length

required.

18

19

DualDrive 24 / 21

DualDrive 27

19

20

20

Page 16

ASSEMBLY

OF COMPONENTS

DualDrive · December 2002

16

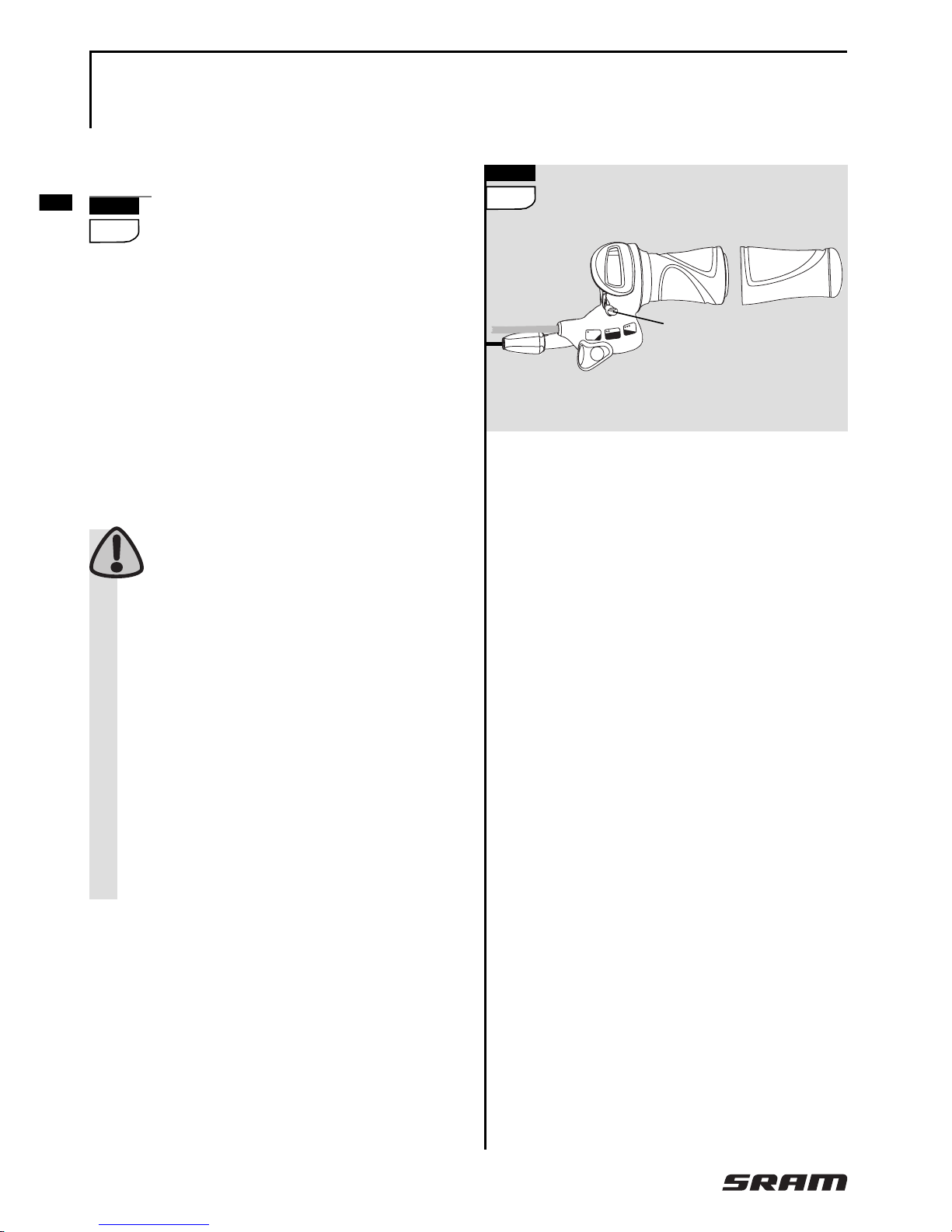

ASSEMBLY SHIFTER

Slide the shifter (5) onto the

handlebar.

» Rotate the shifter until the barrel

adjuster (6) is beneath (but out of

the way of) the brake lever.

» Tighten the 3 mm hex clamp bolt (7)

to 1.9 – 2.5 Nm (17 – 22 in.lbs.).

» Slide the handlebar grip (8) onto

the handlebar.

Never use lubricants or

solvents to install handlebar

grips. Handlebar grips provide an

axial safety function. For this

reason, they should be mounted in

such a way as to make sure they

do not slip off handlebar.

» Check that the shifter and brake

lever function properly and are

unobstructed.

» Never ride without the handlebar

grips, this can result in severe

injury or death.

21

21

5

6

7

8

Page 17

ASSEMBLY

OF COMPONENTS

DualDrive · December 2002

17

E

INSTALLING CLICKBOX

» Fit the cable and avoid small

radius.

» Cable housing must be movable

inside attachment.

Place thumb shift lever

in hill riding mode.

Push Clickbox

button down.

» Push on Clickbox to the stop on

the hub axle.

» Bring Clickbox button back to initial

setting by pushing it up from

underneath.

GEAR ADJUSTMENT

See MAINTENANCE AND CARE

22

23

22

23

Page 18

DualDrive · December 2002

18

TECHNICAL DATA

DualDrive 27 DualDrive 24 DualDrive 21

Over Locknut Dim. 135 mm

Length 182.6 mm

Ends Diameter FG 10.5

Holes 36 or 32

Hole Diameter 2.6 mm

Hole Ref. ø 67 mm

Flange Dist. to 1/2OLD

33 mm / 18 mm

Totally 576% 542 % 509 %

Totally hub 186 %

Speed 1

73

%

Speed 2

100

%

Speed 3

136

%

Chainline 45 mm 45 mm 42 mm

Crankset 33 / 38 Teeth

Cogset 9 / 8 / 7 speed, 11-34 / 11-32 / 12-32 Teeth

Cogset Compatib. DualDrive 27 DualDrive 24 DualDrive 21

Shifter Compatib. DualDrive 27 DualDrive 24 DualDrive 21

Tandem compatib.

Not suitable for tandems and delivery bicycles

Axle

Spoke

Ratio

67

18

Chain line

67,5

135

182,6

4,6 / 4,6 / 9,5

33

GEAR HUB

Page 19

DualDrive · December 2002

19

E

TECHNICAL DATA

DualDrive 27 DualDrive 24 DualDrive 21

Speeds 98 7

Shifter Compatibility DualDrive 27 DualDrive 24 DualDrive 21

Cage Length Short, 75 mm Short, 75 mm Short, 75 mm

Sprocket, max. 34 Teeth 32 Teeth 32 Teeth

Sprocket, min. 11 Teeth 11 Teeth 11 Teeth

Pulleys Exchangea. / Bushing

Direct Mount ●● ●

➔

DualDrive 27 DualDrive 24 DualDrive 21

Shifter Type SRS Twistring-Thumbshifter-Combo (2in1)

Gear Hub DualDrive

Derailleur DualDrive 27 DualDrive 24 DualDrive 21

Gear Indication Der. Window Printed Printed

Riding Mode Indic. Printed Printed Printed

Barrel Adj. Derailleur Index

Clamping Diameter 22,3 mm

Handlebar, Straight Area

Minimum length = 150mm

Cable Routing, Gear Hub

Continuous housing (preassembled)

Cable Routing, Der. Open or continuous

Com-

pat.

DualDrive 27 DualDrive 24 DualDrive 21

Largest Cog 34 Teeth 32 Teeth 32 Teeth

Speeds 98 7

Cogs 11/34 11/32 12/32

Spacers Blue Black Grey

Chain compatib.

9spd, SRAM/Shim. 8spd, SRAM/Shim.

7spd, SRAM/Shim.

CASSETTE

DERAILLEUR

SHIFTER

Page 20

ADDRESSES

DualDrive · December 2002

110

DANMARK

Dan Agentur

Stationsvej 77

5792 Årslev

Tel.: +45 65 99 24 11

Fax: +45 65 99 28 42

DEUTSCHLAND

Epple Zweirad GmbH

Mittereschweg 1

87700 Memmingen

Tel.: +49 (0) 83 31 7 51 411

Fax: +49 (0) 83 31 7 51 450

Hermann Hartje KG

Deichstraße 120-122

27318 Hoya/Weser

Tel.: +49 (0) 42 51 81 12 40

Fax: +49 (0) 42 51 81 12 49

ESPAÑA

Casa Masferrer, s.a.

Pol. Ind. Congost.Avda.

San Julian, s/n

E-08400 Granollers (Barcelona)

Tel.: +34 9 38 46 60 51

Fax: +34 9 38 46 53 56

FRANCE

Savoye, S.A.

Rue de l’industrie

01470 Serrières de Briord

Tel.: +33 4 74 36 13 77

Fax: +33 4 74 36 15 14

ITALIA

A.M.G. s.r.l.

Via Piave 10

23871 Lomagna (Como)

Tel.: +39 039 5 30 11 67

Fax: +39 039 9 22 02 70

NEDERLAND

Koch Kleeberg B.V.

Dukdalfweg 25

1332 BJ Almere

Tel.: +31 36 532 05 04

Fax: +31 36 532 25 48

Vertex Cycle Systems BV

Delfweg 12

2211 VM Noordwijkerhout

Tel.: +31 252 340611

Fax: +31 252 345030

EUROPE

Page 21

ADDRESSES

DualDrive · December 2002

111

UNITED KINGDOM

Fisher Outdoor Leisure Plc

Unit 8/9 Brick Knoll Park

Ashley Road Industrial Estate

Ashley Road

St. Albans, Hertfordshire

AL1 5UG

Tel.: +44 1727 798345

Fax: +44 8009 807129

World Headquarters

Chicago, Illinois U.S.A.

SRAM Corporation

1333 North Kingsbury, 4th floor

Chicago, Illinois 60622

Tel.: +1-312-664-8800

Fax: +1-312-664-8826

UNITED STATES

ÖSTERREICH

KTM Fahrrad GmbH

Harlochnerstrasse 13

5230 Mattighofen

Tel.: +43 7742 409 10

Fax: +43 7742 409 172

SCHWEIZ

Amsler & CO AG

Lindenstraße 16

8245 Feuerthalen

Tel.: +41 5 26 47 36 36

Fax: +41 5 26 47 36 66

SUOMI

J. Syväranta Oy

Nervanderinkatu 5E 47/PL 64

F-00101 Helsinki

Tel.: +358 9 434 2030

Fax: +358 9 493 890

SVERIGE

Vartex AB

Batterivägen 14

43232 Varberg

Tel.: +46 340 64 60 00

Fax: +46 340 61 11 90

Page 22

WORLD HEADQUARTERS

Chicago, Illinois U.S.A.

SRAM Corporation

1333 North Kingsbury, 4th floor

Chicago, Illinois 60622

phone: +1-312-664-8800

fax: +1-312-664-8826

EUROPEAN HEADQUARTERS

Amersfoort, The Netherlands

SRAM Europe

Basicweg 12-D

3821 BR Amersfoort

The Netherlands

phone: +31-33+-450-6060

fax: +31-33-457-0200

ASIAN HEADQUARTERS

Taichung, Taiwan

SRAM Taiwan

No. 1598-8 Chung Shan Road

Shen Kang Hsiang, Taichung

County 429

Taiwan R.O.C.

phone: +886-4-2561-3678

fax: +886-4-2561-3686

www.sram.com

Loading...

Loading...