Page 1

Squirrel Workstation 8

SQ-2020

Operator and Service

Manual

Revision 1.0

Page 2

Preliminary Release

Caution: Changes or modifications to this equipment, not expressly approved by the

manufacturer could void the user’s authority to operate the equipment.

Information in this document is subject to change without

notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or

mechanical, for any purpose, without the express written

permission of Squirrel Systems.

© 2003 Squirrel Systems. All rights reserved.

Page 3

Squirrel Workstation 8

Records of Revision

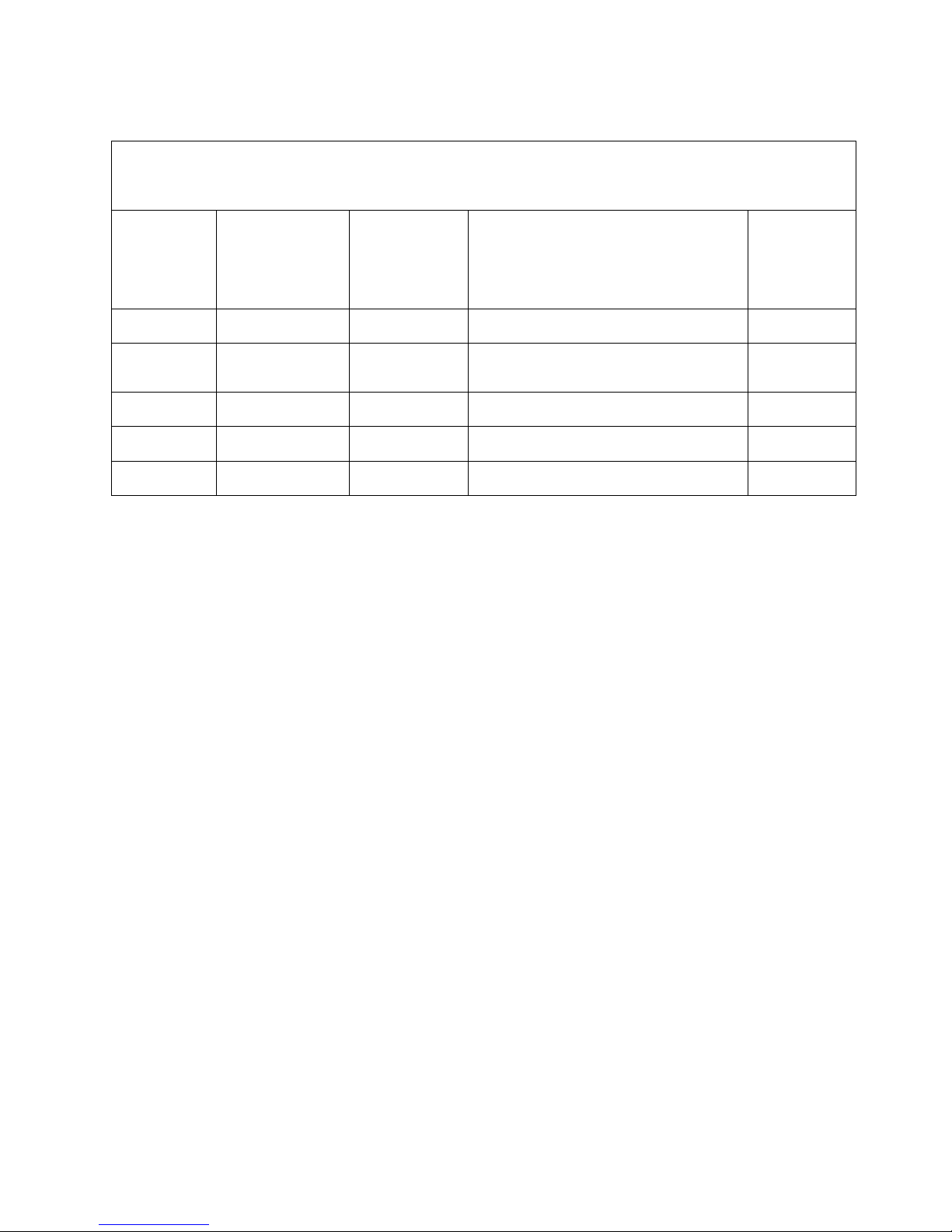

Date

Reference:

Page,

Paragraph,

Revision

No.

Comments

Check

and

Approval

Drawing No.

Mar 31/05 Rev 1.0 Initial Release D. O’Brien

Page 4

TABLE OF CONTENTS

CHAPTER 1: GENERAL INFORMATION................................... 1-1

INTRODUCTION............................................................................................ 1-1

SPECIFICATIONS ......................................................................................... 1-2

ACCESSORIES ............................................................................................. 1-4

WORKSTATION 8 DIMENSIONS ................................................................. 1-5

PRODUCT DESCRIPTION............................................................................ 1-7

CHAPTER 2: DISASSEMBLY and ASSEMBLY........................ 2-1

General Servicing Precautions................................................................... 2-1

Service Equipment and Parts List.............................................................. 2-1

Removing the Front Cover......................................................................... 2-5

Replacing the Front Cover ......................................................................... 2-7

Removing the Mag Swipe Reader.............................................................. 2-7

Removing the ISIS Badge Reader (Optical Reader) ................................. 2-8

Removing the ‘DG41 LCD Assembly (Mounting Bracket) from the Rear

Internal Shield Assembly

Disassembly of the ‘DG41 LCD Assembly...............................................2-13

Removing the Touch Screen Sensor (Overlay) ............................. 2-13

Reassembling/Replacing the Touch Screen Sensor (Overlay) ..... 2-14

Removing the ‘DG41 LCD from the LCD Mounting Bracket.......... 2-14

Disconnecting the LCD Data Cable ............................................... 2-16

Removing the Open Frame Inverter...............................................2-16

Reassembly.................................................................................... 2-17

Base Bottom Disassembly ....................................................................... 2-18

Disconnecting the Power Switch Cable from the Motherboard ..... 2-18

Disassembly of the Internal Shield Assembly ................................ 2-19

Removing the Motherboard from the Internal Shield Housing2-21

Resetting CMOS for Squirrel Defaults ................................... 2-22

Removing the Card Guide Rails............................................. 2-23

TABLE OF CONTENTS

.......................................................................... 2-11

Removing the Internal Shield Assembly out of the Base Bottom

Plastics

Removing the Power Switch Cable and the Power Switch....2-19

Removing the Intake Fan....................................................... 2-20

................................................................................... 2-19

CHAPTER 3: INSTALLATION ................................................... 3-1

I Preliminary Release 3/24/05/R1.0

GENERAL GUIDELINES............................................................................... 3-1

ELECTRICAL POWER REQUIREMENTS.................................................... 3-2

LOCATION AND MOUNTING POSITIONS .................................................. 3-2

Page 5

TABLE OF CONTENTS

PROPER INSTALLATION OF MOUNTING HARDWARE............................3-3

Tilt Stand (92-205) Installation....................................................................3-3

Adjusting the Tilt Stand...............................................................................3-6

Mounting the Workstation 8 to a Wall Bracket (92-207).............................3-8

Wall Mount........................................................................................3-8

Counter Sunk Mount.........................................................................3-9

HOST/SERVER COMMUNICATION PROTOCOL........................................3-9

ISIS BADGE READER CONFIGURATION .................................................3-10

CABLE LOCATION LABEL - I/O INTERFACE..........................................3-10

TYPICAL WORKSTATION & PERIPHERAL SETUP.................................3-12

FINAL TESTING OF THE INSTALLATION.................................................3-13

Powering it On...........................................................................................3-13

Screen Contrast........................................................................................3-14

Volume Control .........................................................................................3-14

CHAPTER 4: MAINTENANCE....................................................4-1

CARING FOR THE WORKSTATION 8..........................................................4-1

General Cleaning........................................................................................4-1

Cleaning the Credit Card Reader ...............................................................4-2

CHAPTER 5: TROUBLESHOOTING .........................................5-1

CHAPTER 6: APPENDICES.......................................................6-1

APPENDIX A: ESD WORK-STATION...........................................................6-1

Maximum Allowable Resistances and Discharge Times for Static Safe

Operations

ESD Work-station Do’s and Don’ts.............................................................6-2

Prime Sources of Static Electricity in an Electronics Work Area................6-3

Field Service - ESD Prevention ..................................................................6-4

Field Service Kit..........................................................................................6-4

APPENDIX B: LCD HANDLING ....................................................................6-5

ESD Protection............................................................................................6-5

Mechanical Force and Strength..................................................................6-5

Handling the LCD........................................................................................6-5

Cleaning......................................................................................................6-6

Storage........................................................................................................6-6

Ingestion and Injury Warning......................................................................6-7

..............................................................................................6-2

APPENDIX C: HANDLING CIRCUIT BOARDS ............................................6-8

APPENDIX D: PORT SIGNAL PIN ASSIGNMENT.......................................6-9

II Preliminary Release 3/24/05

Page 6

TABLE OF CONTENTS

APPENDIX E: TOUCHSCREEN SENSOR ................................................. 6-10

Cleaning ................................................................................................... 6-10

Specifications ........................................................................................... 6-10

APPENDIX F: MOTHERBOARD PREPARATION ..................................... 6-12

Foil Taping the Rear Shield Casing (89-541)...........................................6-13

Foil Tape Specifications........................................................................... 6-14

APPENDIX G: ............................................................................................ 6-15

Connector Descriptions............................................................................ 6-15

Jumper Descriptions................................................................................. 6-16

Jumper Settings Information .................................................................... 6-17

APPENDIX H: BUTTERFLY SHIELD SCREW.......................................... 6-21

APPENDIX I: LCD BRACKET PREPARATION FOR MOUNTING THE

LQ121S1DG41 DISPLAY

............................................................................ 6-22

3/24/05 Preliminary Release III

Page 7

CHAPTER 1: GENERAL INFORMATION

The General Information Chapter includes three sections:

• Introduction

• Specifications

• Accessories

• Product Dimensions

• Product Description

GENERAL INFORMATION

INTRODUCTION

This publication is intended to provide technical support information for Squirrel

systems installers, field service technicians and depot service technicians.

Information in this manual includes:

• Specifications for electrical power requirements and interface

installation.

• Installation guidelines for mounting hardware and procedures pertaining

to the Wall Bracket and Tilt Stand

• Assembly and disassembly procedures.

cable

Only authorized SQUIRREL personnel with proper training and equipment such as

Anti-static Kits should attempt the disassembly procedures described in this manual.

1-1 R1.0 Preliminary Release 3/24/05

• Configuration and adjustment of communication protocol, display

attributes and other features.

• Troubleshooting and repair procedures.

Page 8

SPECIFICATIONS

GENERAL INFORMATION

Standard SBC

Functions

PROCESSOR

BIOS

SYSTEM CHIPSET

SECOND LEVEL OF CACHE

RAM

PARALLEL PORT

SERIAL PORTS

Intel Celeron 850 MHz or Pentium 3 up

to 1GHz

- Socket 370

- Standard Award® PC 256 KB Flash

BIOS

- Includes ETHERNET LINUX boot

ROM

VIA VT82C694/VT82C686

On-board 512KB

- two 168 - pin DIMM sockets

(supports up to 512MB SDRAM)

- One parallel port (LPT2)

onboard/internal access, supporting

SPP/EPP/ECP/ parallel mode.

- COM 1 & 2 External

RJ11: RS-232

- COM 4 External

RJ11: RS232 & supports +5V

power

Ethernet Interface

KEYBOARD CONNECTOR

PS/2 MOUSE CONNECTOR

VIDEO CONNECTOR

WATCHDOG TIMER

USB

CHIP

ETHERNET INTERFACE

- COM 1,2 & 3 Onboard

2x5 Header: RS-232

Mini-DIN keyboard connector

PS/2 mouse – onboard/internal access

Internal shrouded header to support a

CRT monitor

Software enable/disable. Time interval of

1.6 seconds generates system reset in

the event of program failure

Two onboard/internal access USB1.1

RTL8139C

10/100 BASE-T/TX, RJ45

1-2 Preliminary Release 3/24/05

Page 9

GENERAL INFORMATION

Flat Panel / PCI

SVGA Interface:

Touchscreen

Interface

Cash Drawer

Interface:

Peripherals Devices

Software

Compatibility

CHIPSET

DISPLAY MEMORY

DISPLAY TYPE

C & T 69000

- 2 MB integrated memory

2 MB on-board memory

- 12.1” Color TFT – Hi Brightness LCD

- Resolution: 800x600

OVERLAY

5 Wire 12.1” ELO-Touch Analogue

Resistive overlay

CASHDRAWERS

Supports 2 cash drawers.

(RJ11 connector)

MAGNETIC SWIPE

SOFTWARE POS SquirrelOne

Bi-directional read Track 1 & Track 2

External Power

Supply Adaptor

INPUT REQUIREMENTS

OUTPUT REQUIREMENTS

POWER CORD LENGTHS

SIZE (DIMENSIONS)

- 100 VAC – 240 VAC

- 50-60 Hz (International)

- UL and CE

- +12V, DC @ 5.5 Amps

- maximum power rating: 60 WATTS

CONT.

- input approx.: 40” (1016mm)

- output approx.: 72” (1830mm)

- L x W x D:

132”(5.20mm)x58”(2.29mm)x

30”(1.18mm)

- Weight: 0.66 lbs (300g)

3/24/05 Preliminary Release 1-3

Page 10

Mechanical and

Environmental

OPERATING TEMPERATURE

OPERATING HUMIDITY

GENERAL INFORMATION

50° to 105.8° F (10° to 40° C)

5% to 95% relative humidity

ACCESSORIES

WEIGHT

ETHERNET CABLE

CHECK PRINTER COMMUNICATION

CABLE

EXTERNAL POWER SUPPLY WITH

POWER CORD

CASH DRAWER CABLE

CUSTOMER DISPLAY TOWER CABLE

ADJUSTABLE TILT STAND

MAG SWIPE (CREDIT CARD

READER)

12.47 lbs (5.64 kg) WS on stand

7.10 lbs (3.22 kg) WS only

Standard

Standard

Standard

Optional

Optional

Standard

Optional

1-4 Preliminary Release 3/24/05

Page 11

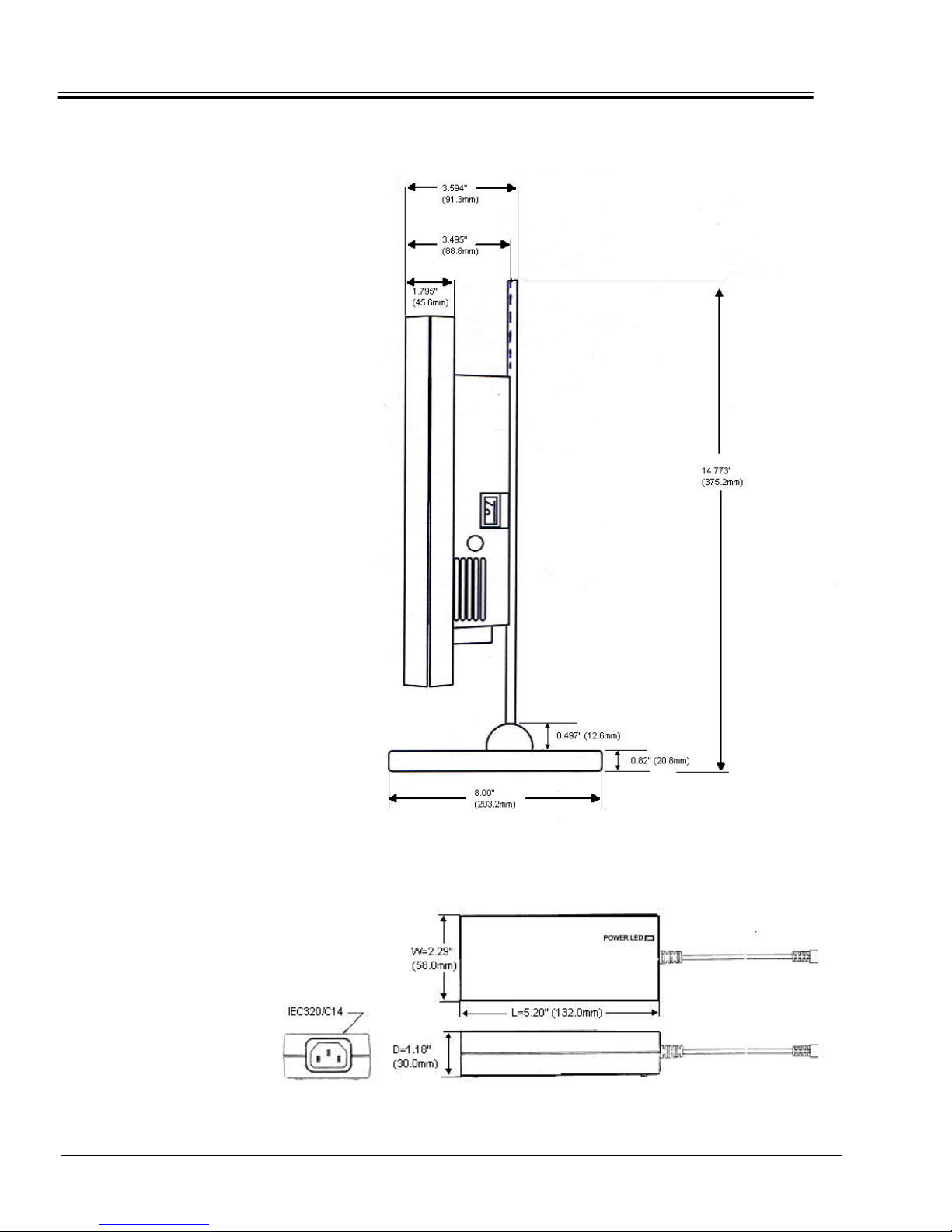

WORKSTATION 8 DIMENSIONS

GENERAL INFORMATION

3/24/05 Preliminary Release 1-5

Page 12

Side Dimensions

GENERAL INFORMATION

External Power Supply Dimensions

1-6 Preliminary Release 3/24/05

Page 13

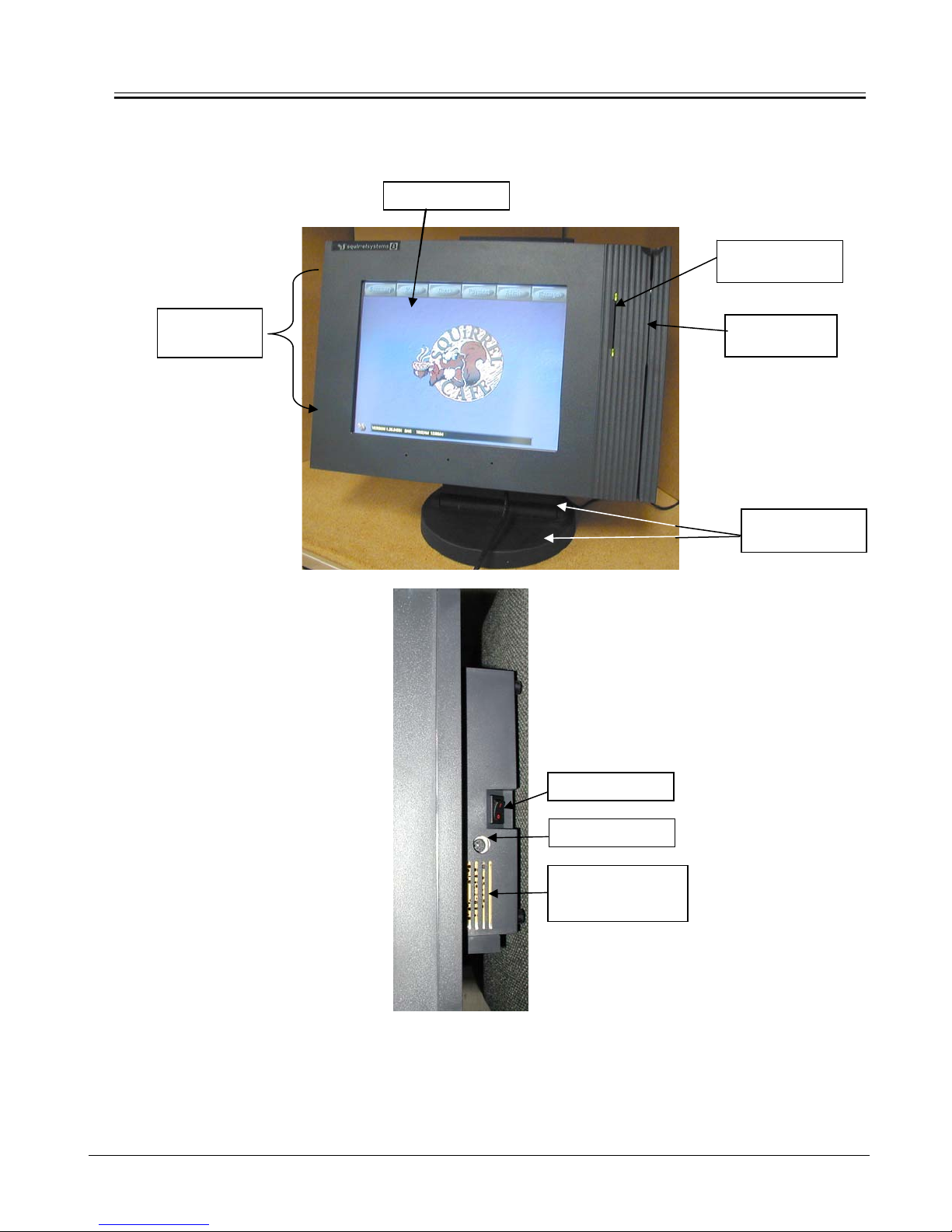

Product Description

Air Exhaust

Area

GENERAL INFORMATION

Touchscreen

Power Switch

Keyboard Port

Internal Intake

Fan Vents

Optical ID Reader

Badge Card Slot

Magswipe

Reader/Slot

Adjustable Stand

and Backplate

3/24/05 Preliminary Release 1-7

Page 14

Serial Number

Label

Workstation’s Ethernet

MAC Address

Sales & Service

Label

GENERAL INFORMATION

6 5 4 3 2 1

1. Power Jack – AC/DC Power Supply Adaptor is connected here.

2. Ethernet Port – 10/100 Base – T/TX, RJ45 Jack for SquirrelOne Network

Connection.

3. COM 4 – RJ12 Interface Jack configured for default Customer Display

Tower.

4. Cashdrawer Port – RJ12 Jack provides Dual Cashdrawer Output.

5. COM 2 – RJ12 Interface Jack configured for default POS printer.

6. COM 1 – RJ12 Interface Jack configured for default POS printer.

Refer to Appendix D for port signal pin assignment.

Wall Mounting Bracket Slots

Cable Location Label

Stand Back

Plate Mounting

Holes

1-8 Preliminary Release 3/24/05

Page 15

DISASSEMBLY AND ASSEMBLY

CHAPTER 2: DISASSEMBLY AND ASSEMBLY

General Servicing Precautions

The following are general precautions that should be taken by technicians when

servicing the Workstation 8 product. Please refer to APPENDICES at the back of

the manual for a detailed explanation.

• A safe EDS protected work area is required to service the

Workstation 8 product to prevent damage to sensitive

components from static discharge. Refer to APPENDIX A.

• Extra care needs to be exercised when handling and cleaning

the LCD to prevent any damage. Refer to APPENDIX B.

• Circuit boards need to be handled and stored with care to

prevent any ESD damage. Refer to APPENDIX C.

• Opening & Closing – all cabling needs to be arranged so that

they will not be pinched or interfere when you open and close

the workstation case for servicing.

Service Equipment and Parts List

The following equipment is required to service the WORKSTATION 8 according

to this manual:

• Anti-static mat with ground-wire and wrist strap – safe ESD work

area

• Side cutters

• #1 and #2 Phillips screwdrivers

• Multimeter

• Magnetic head cleaning card (SQ-2940 pkg of 10

pkg of 50)

• Scissors

Disassembly Instructions

When disassembling the workstation make sure the workstation is turned off and

disconnected from all cabling and peripherals.

OR SQ-2941

3/24/05 R1.0 Preliminary Release 2-1

Page 16

DISASSEMBLY AND ASSEMBLY

Reassembly Instructions

Reassembling is the reverse of the disassembly process. Use care to ensure

that all cables and screws are returned to their proper positions. Check that no

loose parts have been left inside and everything is properly installed and

tightened.

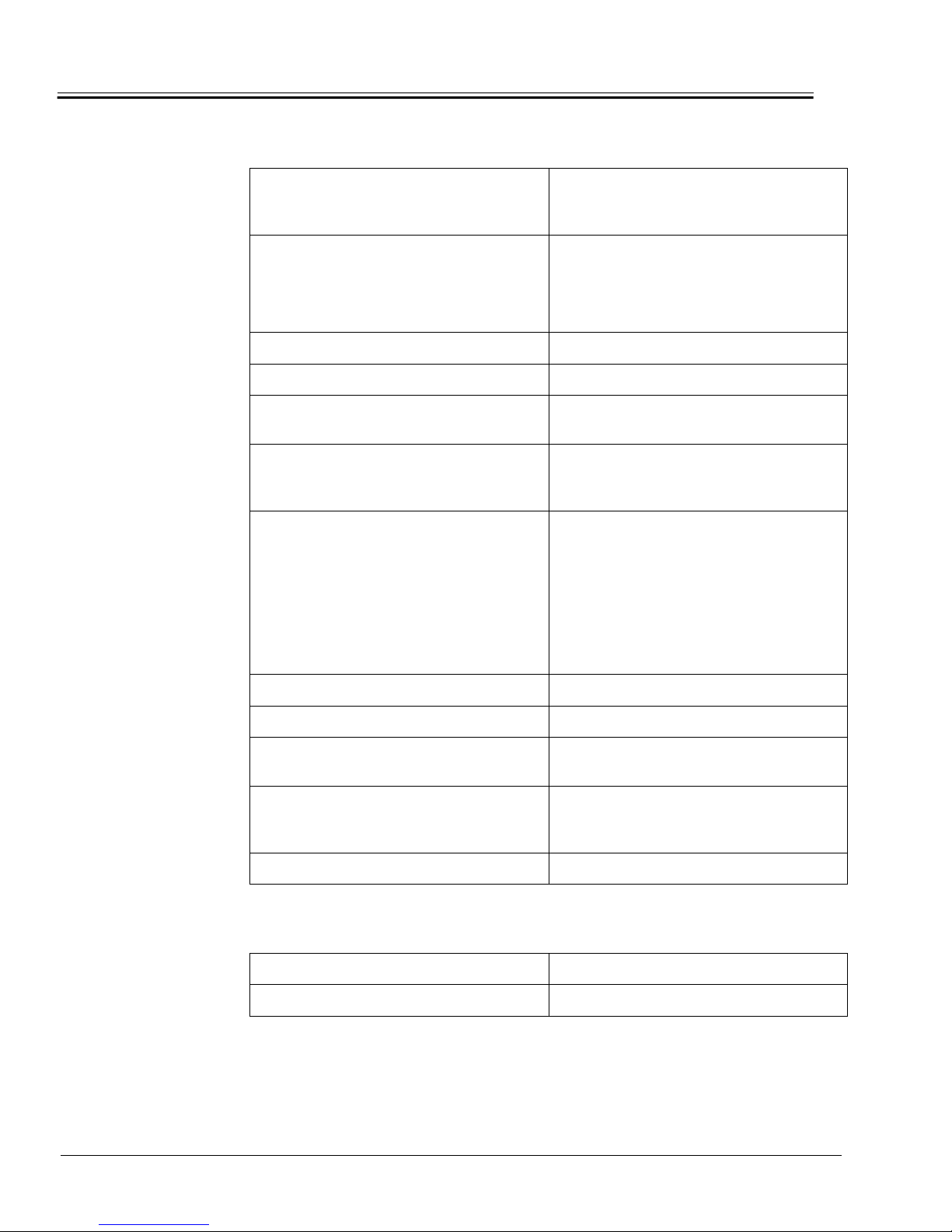

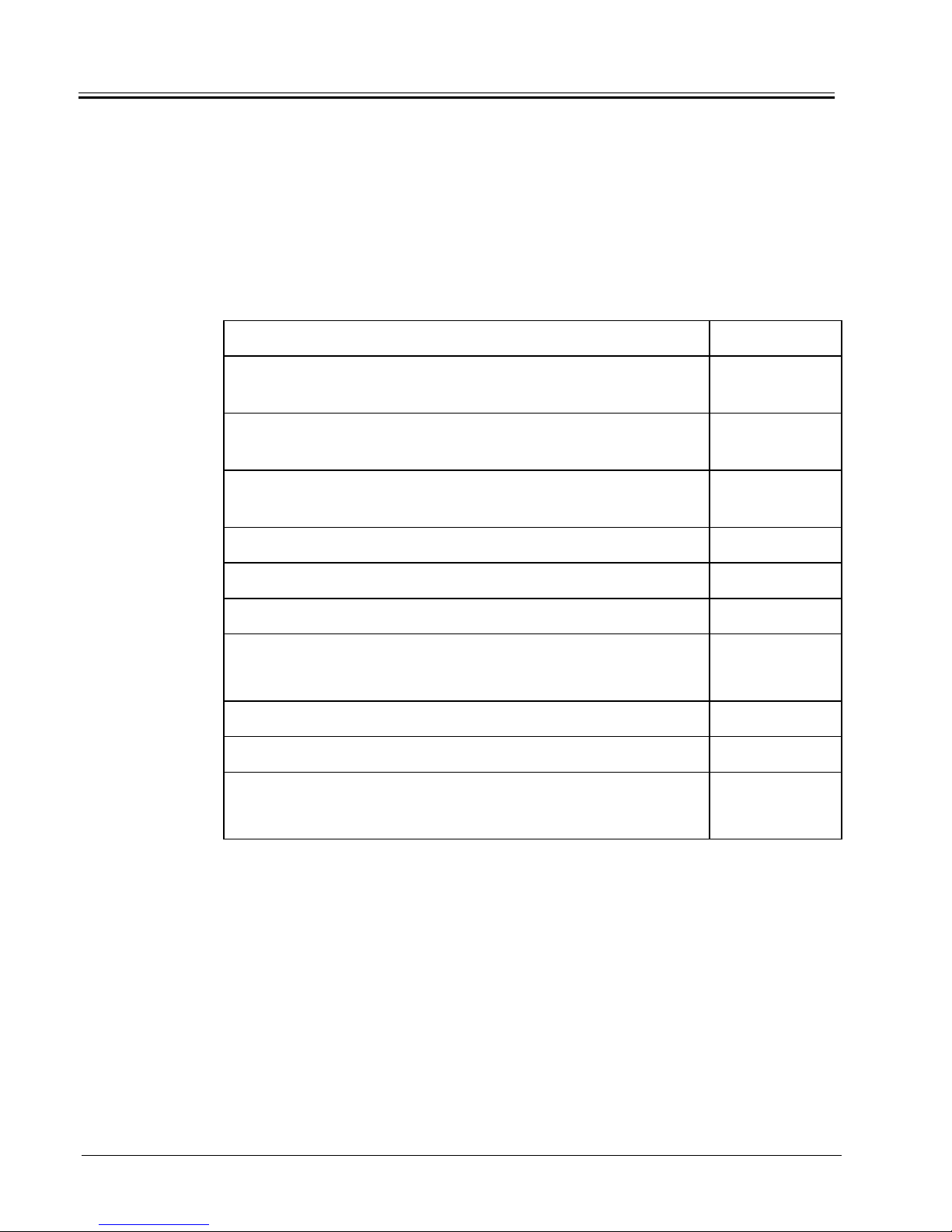

A list of modules and/or their sub-assemblies:

Module / Sub-Assembly

Workstation 8 for SquirrelOne with Power Supply and

Stand

Workstation 8 for SquirrelOne with Power Supply and no

Stand

Workstation 8 for SquirrelOne without Power Supply and

Stand

AC / DC Power Supply (no AC cable)

AC Power Supply Cord

Touchscreen Overlay/Sensor

LCD Assembly (LQ121S1DG41 LCD) & Shield Top

Note: Primarily for field servicing

ISIS Badge Reader Kit

Magswipe Reader

Part Number

SQ-2020

SQ-2021

92-800

31-038

78-010

SQ-2523

92-241

SQ-2899C

SQ-2902

Motherboard – SBC

Comes with 64M RAM

Table 2.1 Module / Sub-Assembly Parts List

2-2 Preliminary Release 3/24/05

SQ-6593

Page 17

DISASSEMBLY AND ASSEMBLY

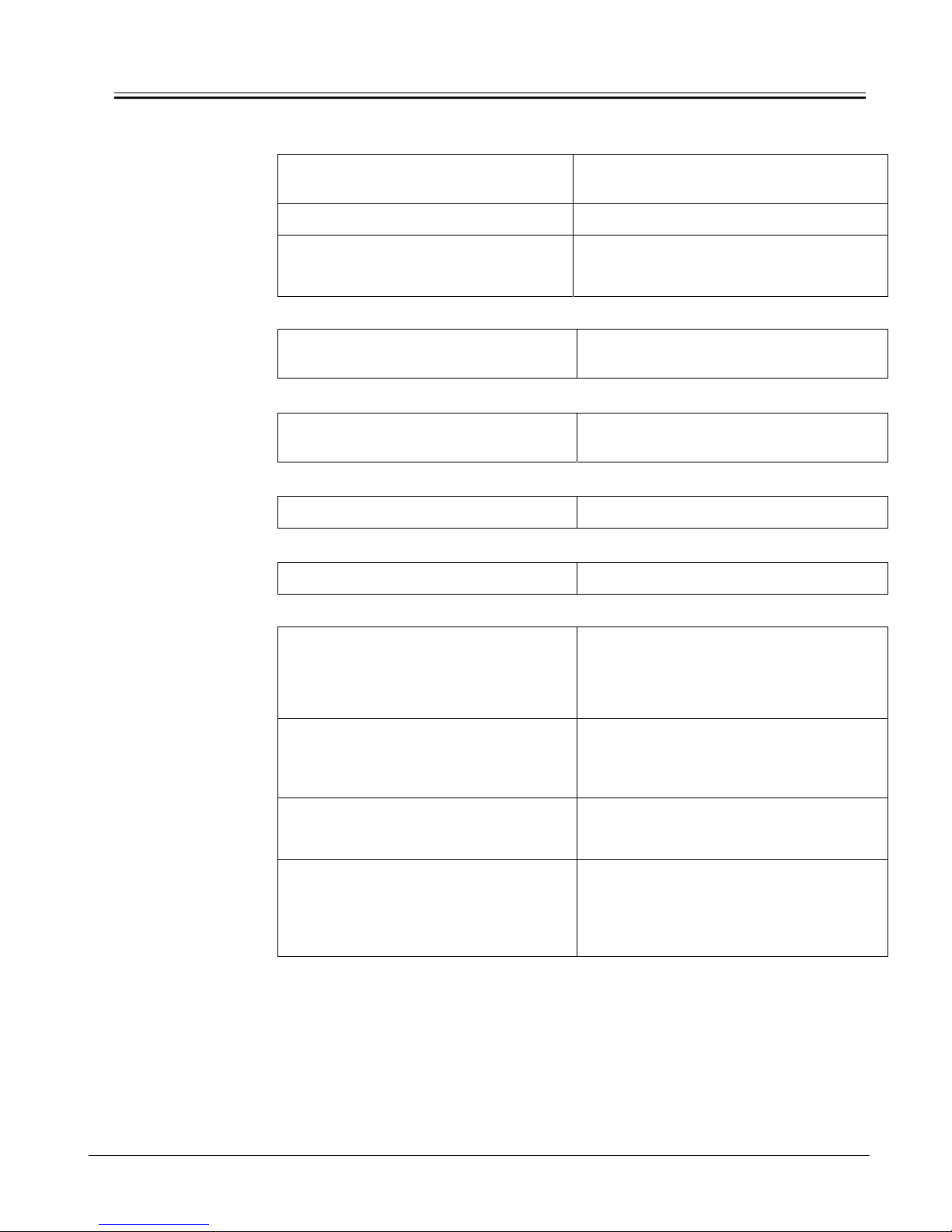

Various cables, screws and miscellaneous parts

Part Description Part Number

Cable RJ12 to RJ12 Interface

Use: COM1

COM2

COM4

Cable CATS Ethernet Patch

Use: SquirrelOne

Cable RJ12 to RJ45 Printer Interface

Use: COM2

Cable Cash Drawer

Use: DRW

Dual Cash Drawer Adaptor

Plastic Split Tubing (per foot)

#6-32 X 1” Pan Head Phillips Screw

Front to back housing

#4 Star Washer

For LCD mounting and motherboard

Screw #4-40 x ¼

- LCD to mounting bracket

- Motherboard to rear shield

- Inverter to LCD mounting bracket

SQ-7035

SQ-7706

SQ-7345

SQ-7175

95-026

77-040

82-009

83-003

82-004

Screw #4 x ¼

For card guide rails

Screw #4 x 3/8

To secure magswipe reader

Display Backplate

Rear Internal Shield

LCD Data Cable

LCD Back Light Cable

82-068

82-067

89-540

89-541

76-245

76-208

Table 2.2 Miscellaneous Parts List

3/24/05 Preliminary Release 2-3

Page 18

DISASSEMBLY AND ASSEMBLY

Power Switch

74-020

Power Switch Cable

Plastic Card Guide

Black Cable Tie

Fan

ISIS Cable

Adjustable Stand with Weight Assy

Base

Back Plate

Wall Mount Bracket

Rear Workstation 8 Plastic Housing

Top Workstation 8 Plastic Cover

WS8 High Touch Strip

ISIS Badge Rdr Kit

76-338

99-608

86-015

91-070

76-301

92-205

92-195

99-604

92-207

99-618

99-622

99-623

SQ-2899C

#6-32x1/2” Phil Black Screw

For Fan to Rear Shield

82-608

Table 2.2 Miscellaneous Parts List

2-4 Preliminary Release 3/24/05

Page 19

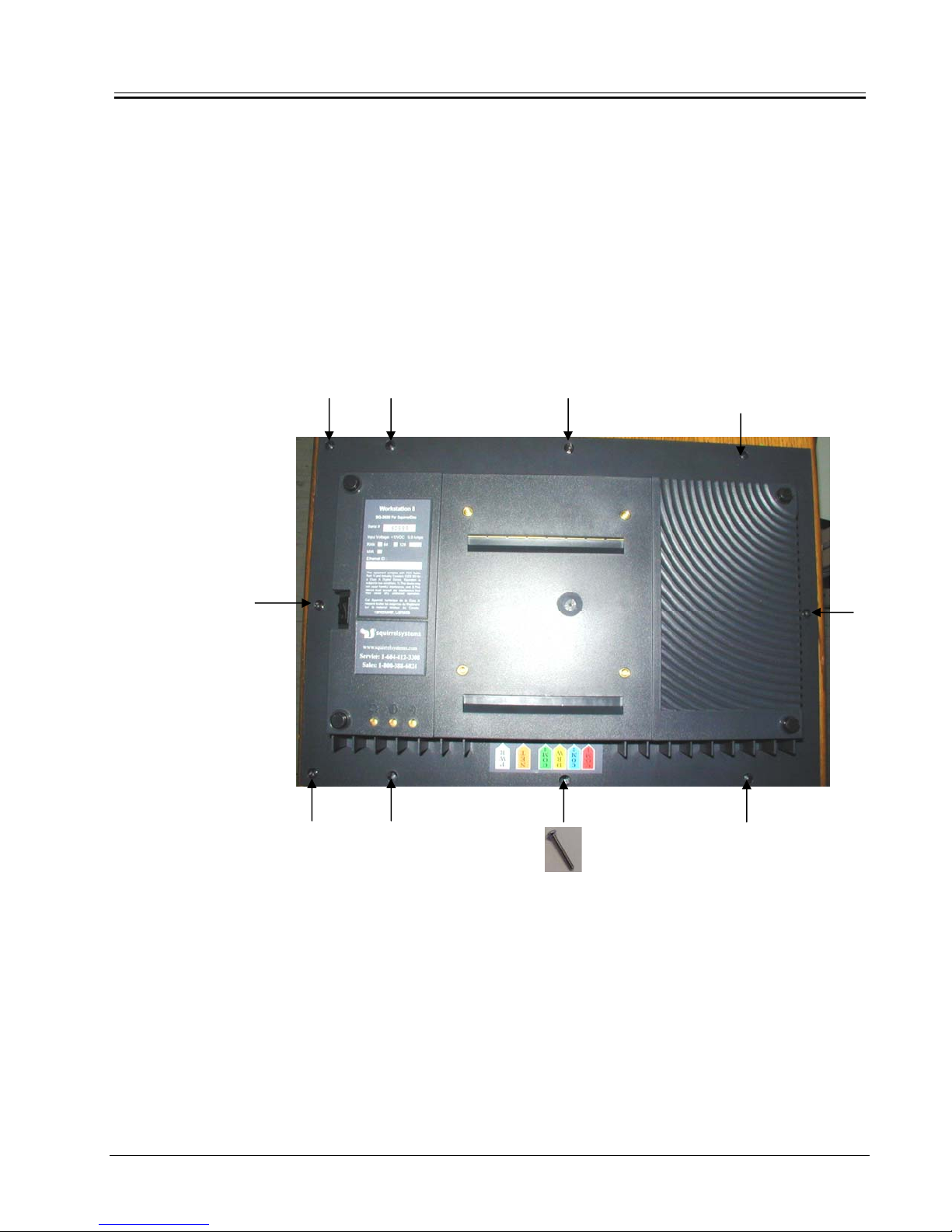

DISASSEMBLY AND ASSEMBLY

Removing the Front

Cover

To remove the Front Cover:

This procedure requires a #2 Phillips screwdriver.

1. Place the WORKSTATION 8’s front of the unit face down on the

anti-static mat. Ensure that the mat is clean of debris that could

scratch or damage the workstation.

2. Remove all 10 screws that secure the front cover to the bottom

housing as shown in the picture below.

3. Carefully hold the front and rear housing together and turn the

unit over right side up.

4. Carefully lift off the front cover to expose the internal

assemblies.

3/24/05 Preliminary Release 2-5

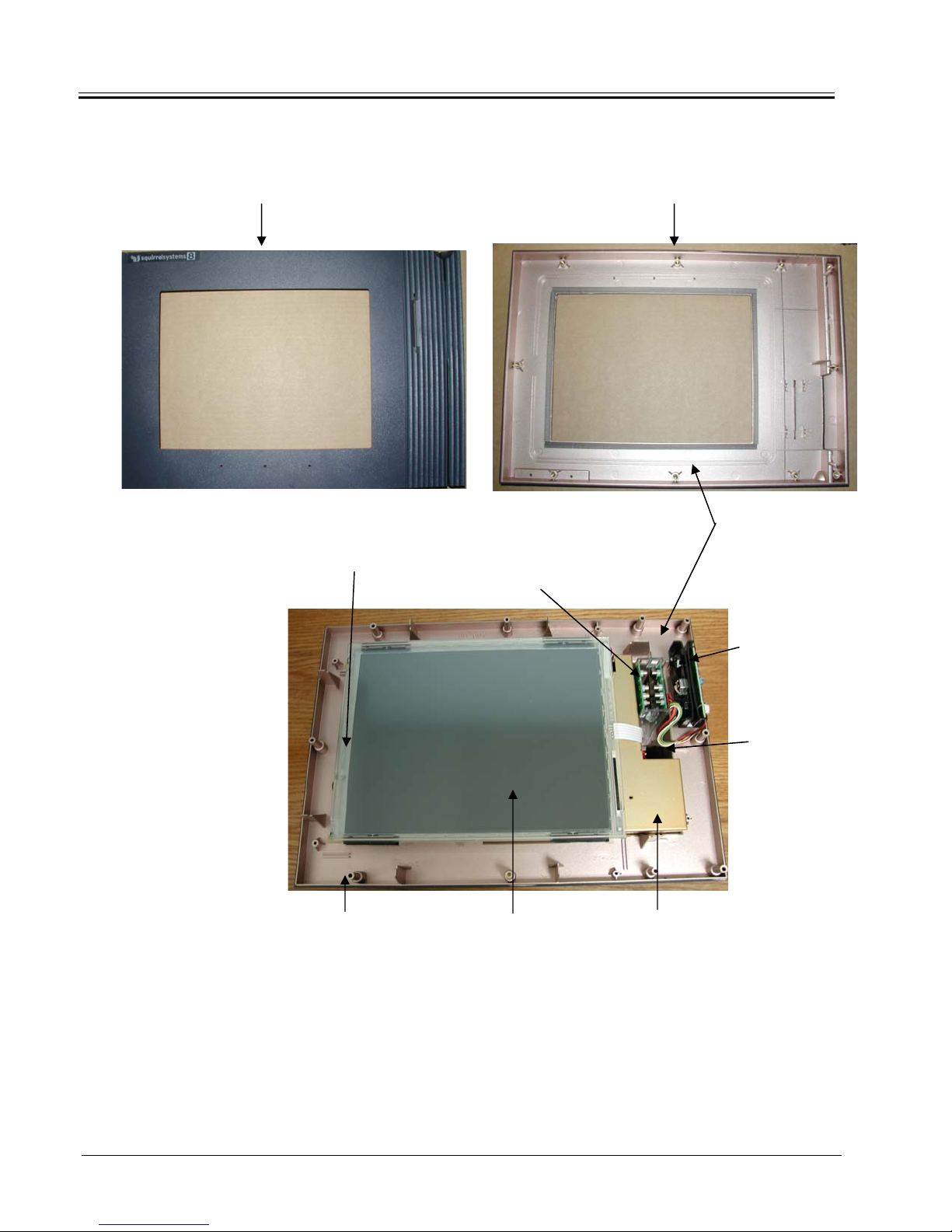

Page 20

DISASSEMBLY AND ASSEMBLY

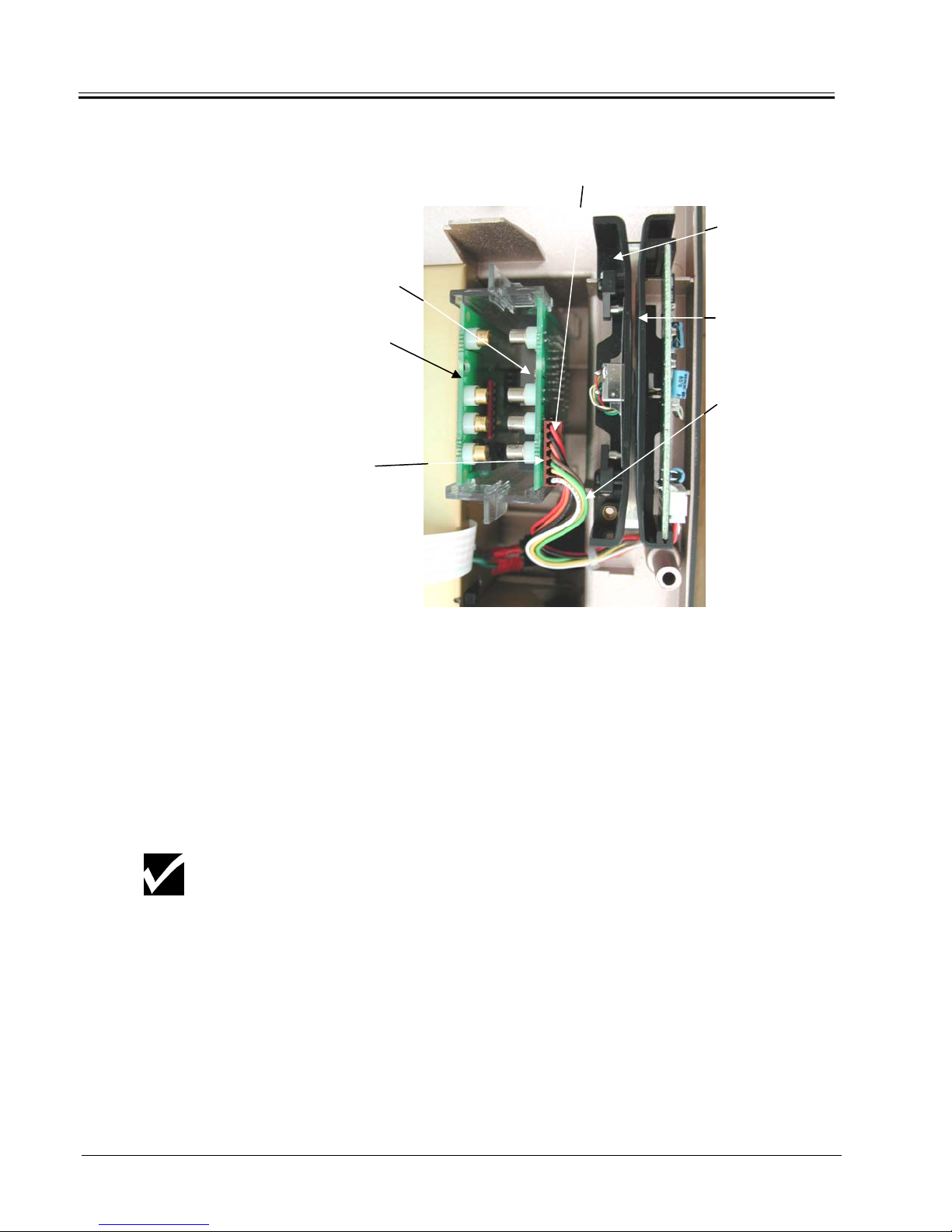

Front/Top Cover Front/Top Cover

Front View Back View

LCD Optical ID Reader

(Isis Badge Reader)

Base Bottom Housing Sensor/Overlay LCD Mounting

Bracket

Spray coated with

copper loaded paint for

EMI/RFI shielding

Magswipe

Reader

Power Switch

2-6 Preliminary Release 3/24/05

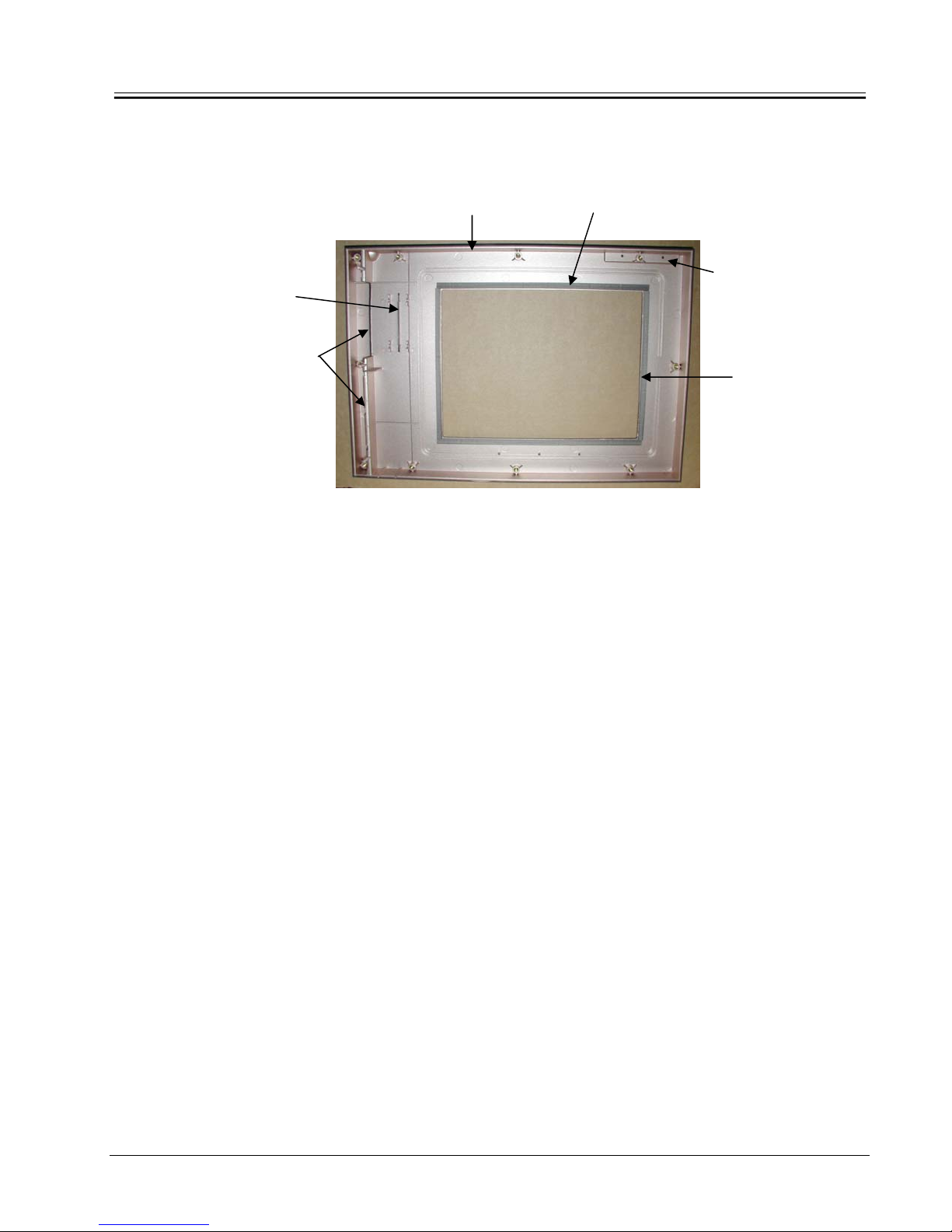

Page 21

DISASSEMBLY AND ASSEMBLY

(

)

Replacing the Front

Cover

Badge Card Slot

Magswipe Card Slot

In the event the top cover is damaged and is required to be replaced, it should

be noted that the top cover consists of the following: Top cover plastic, RF

Gasket Strips and the Touch Strip located in front of the cover.

Front/Top Plastic Cover 10.25” RF Gasket Strip (2 pcs)

(99-622) (88-053-1)

Touch strip

(on front side)

(99-623)

7.35” RF Gasket Strip

(2 pcs)

88-053-2

Backside View

When ordering, all 3 items need to be ordered at the same time. The gasket

and Touch Strip are not reusable. When installing the gasket, DO NOT stretch

the gasket during application.

Reassembling the top cover to the bottom housing is the reverse of the

disassembly process. When the top cover is fitted over the bottom housing,

make sure the Badge Reader’s Card Guides fit into place in the Badge Card

Slot located in the Font Cover.

Removing the

Magswipe Reader

1. To remove the Magswipe Reader a #1 Phillips screwdriver is

required.

2. When disconnecting the interface cable from the ISIS

Detector board, attention should be paid as to how the

connector is oriented and connected to the right angle

connector on the detector board.

3/24/05 Preliminary Release 2-7

Page 22

DISASSEMBLY AND ASSEMBLY

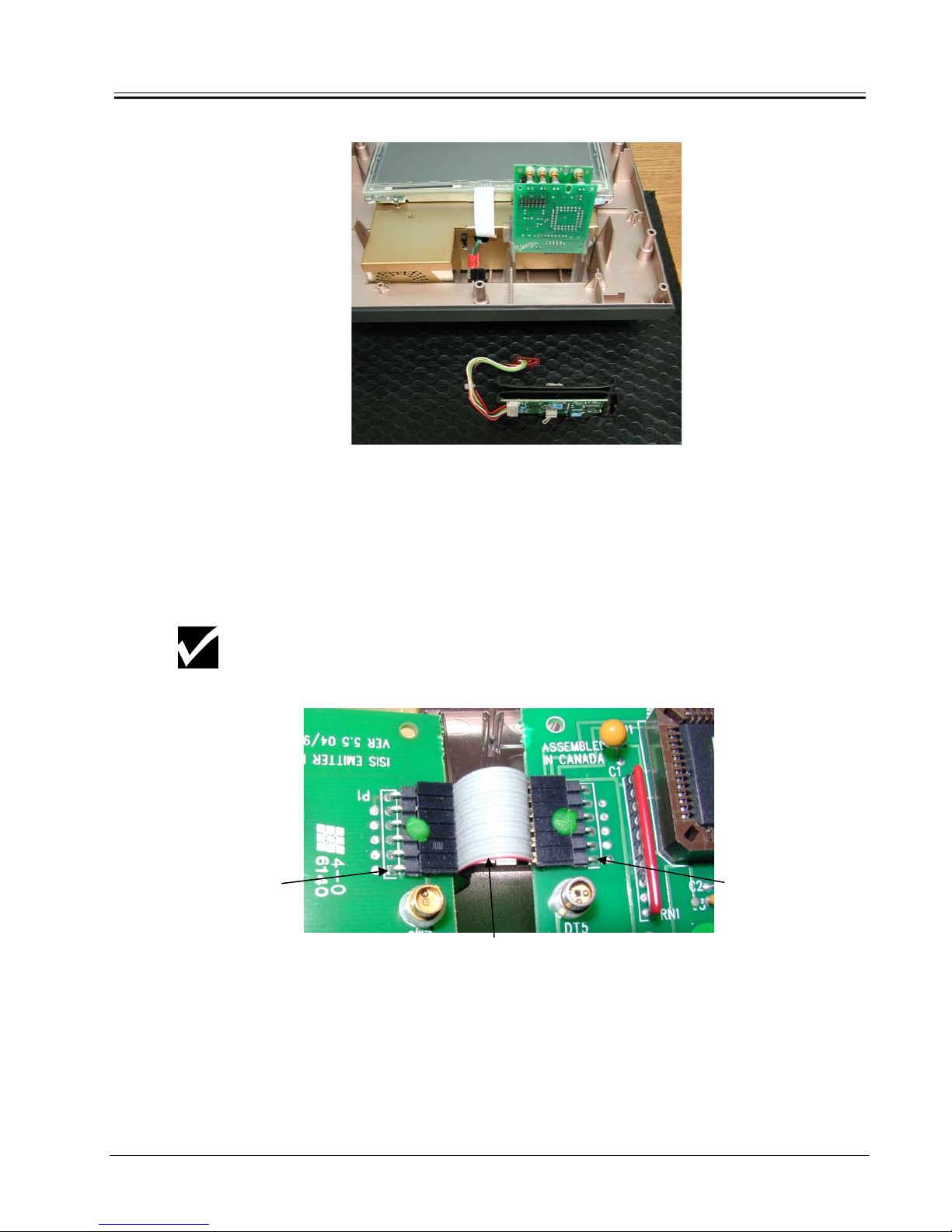

ISIS Detector PCB

ISIS Emitter PCB

2. Disconnect

Red Wire

1. Remove Screw

Magswipe Reader

Interface Cable

Removing the ISIS

Badge Reader

(Optical Reader)

NOTE

1. Without touching the emitter (emitting diode) and detector

(phototransistor) components (these will either be gold or

silver), carefully grasp the top edges of the emitter and

detector boards and gently slide them (together) upwards

and out of the card guides.

Care should be taken when handling these boards as the emitter &

detector components have been aligned for optimal performance.

Accidentally shifting these components can cause the reader to not read

the badge cards.

2-8 Preliminary Release 3/24/05

Page 23

DISASSEMBLY AND ASSEMBLY

Removing the ISIS Reader

NOTE

2. Both the detector & emitter boards need to be disconnected

from the ribbon cable. Always handle these boards by

holding their edges and avoiding touching the components

and circuitry.

The ribbon cable can only be disconnected from the Motherboard after the

LCD Mounting Bracket is disassembled from the Internal Shield Housing.

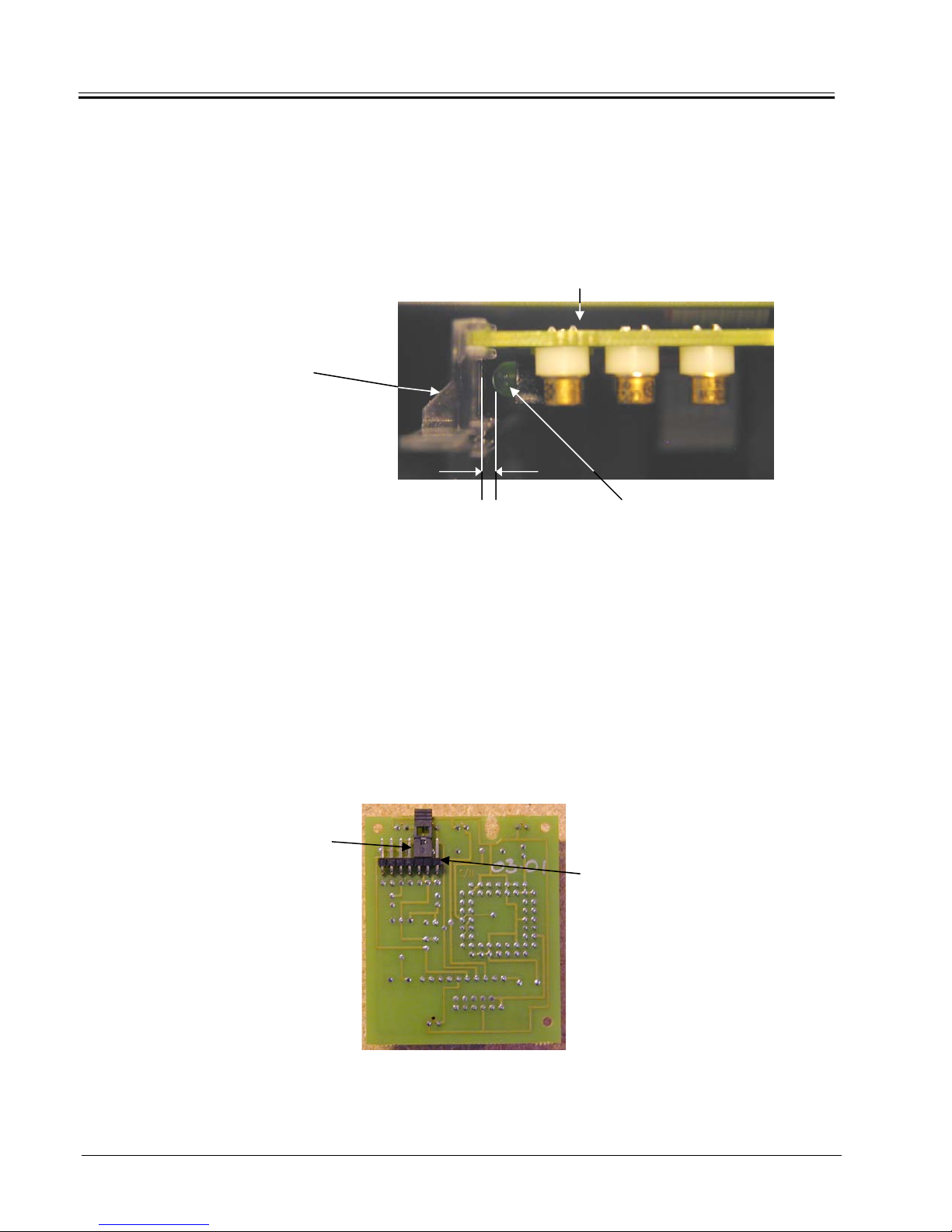

Pin 1

Red wire

Pin 1

Replacing these boards is the reverse of removing and care should be

exercised when reconnecting and reinserting into the card guides. The

red wire of the ribbon cable connects to Pin 1 on both P1 connectors of

both boards. Both cards need to be slid down the card guide rails

completely and should be seated properly.

3/24/05 Preliminary Release 2-9

Page 24

DISASSEMBLY AND ASSEMBLY

3. Ensure that each green LED on the ISIS Badge Reader

PCBs are properly aligned with the card guide lightpipes as

shown below. The LED should not touch the card guide but

should be about 1/16” (1 mm) away.

Card

Guide/Lightpipe

1/16” Green LED

(1 mm)

ISIS PCB

Badge Reader LEDs

If the LED is not properly positioned or the lightpipe is dim and uneven the LED

can be carefully bent into a better position, ensuring that the LED does not

touch the card guide.

In the event the workstation being serviced does not have a Magswipe

Reader, the ISIS detector board will have a jumper installed on the right angle

connector located at the back of the board as shown below.

Jumper

Pin 1

ISIS Detector PCB

2-10 Preliminary Release 3/24/05

Detector PCB Jumper Setting

Page 25

DISASSEMBLY AND ASSEMBLY

Removing the ‘DG41

LCD Assembly

(Mounting Bracket)

from the Rear Internal

Shield Assembly

The ‘DG41 LCD Panel requires an Open Frame Inverter

(DMA23058) which is mounted to the backside of the LCD

NOTE

Mounting Bracket.

The LCD Mounting Bracket is merely resting on top (acting as a lid)

of the Rear Internal Shield Assembly. No tools are required when

removing the LCD Mounting Bracket from the Rear Internal Shield

Assembly.

1. Carefully lift off the LCD Mounting Bracket a few inches, as

there is the Touchscreen Sensor Cable, Backlight Cable and

LCD Data Cable attached to the Motherboard.

Carefully lift off

the LCD

Mounting Bracket

a few inches

3/24/05 Preliminary Release 2-11

Page 26

DISASSEMBLY AND ASSEMBLY

2. Disconnect the Touchscreen Sensor Cable, Backlight Cable

and LCD Data Cable from the Motherboard and lift the LCD

Mounting Bracket clear away from the Rear Internal Shield

Assembly.

Backlight Cable

LCD Data Cable

D

Touchscreen

Sensor Cable

After the LCD Mounting Bracket has been completely removed, the ISIS

NOTE

cable can now be disconnected from the Motherboard.

When disconnecting the cables, attention should be paid as to how the

cables are connected to the Motherboard and the orientation of the cables’

NOTE

connectors. When disconnecting cables,

Remove/disconnect the cables by pulling on their connector or pull-tab.

Reassembling the LCD Mounting Bracket to the Rear Internal Shield Assembly

is the reverse of the disassembly process. A visual inspection should be done

after to make sure the LCD Mounting Bracket is resting properly (on all sides)

on top of the Rear Shield Assembly.

Top View of LCD Mounting Bracket

DO NOT PULL on the cable itself.

Rear View of LCD Mounting Bracket

2-12 Preliminary Release 3/24/05

Page 27

NOTE

DISASSEMBLY AND ASSEMBLY

Make sure the Touch-screen cable tail is positioned properly in

between the notch of the rear metal casing before resting the LCD

Mounting Bracket on top of the casing. The Touch-screen cable tail

should also be bent with a radius as it is channeled through the

notch and should move freely through the notch.

Disassembly of the

‘DG41 LCD Assembly

Removing the Touch Screen Sensor (Overlay)

To disassemble the LCD assembly a #1 Philips screwdriver and

side cutters are required

.

The LCD panel is very sensitive to pressure and can be damaged.

Keep dirt and debris away from the LCD panel. Refer to

APPENDIX B on Handling the LCD.

1. Carefully hold the side edge of the sensor where the flat flex

cable is and lift off slowly to disengage the Velcro. Then

disengage the Velcro from the other side of the sensor/LCD.

2. Handle the touchscreen with reasonable care when not

integrated onto the LCD.

3. DO NOT PULL OR STRESS THE FLAT FLEX CABLE.

Refer to APPENDIX E for Cleaning & Specifications.

3/24/05 Preliminary Release 2-13

Page 28

DISASSEMBLY AND ASSEMBLY

Reassembling/Replacing the Touch Screen Sensor (Overlay)

Before mounting the Touchscreen Sensor, the face of the LCD display must

be clean of any dust or debris. Refer to APPENDIX B LCD Handling. The

backside of the Touchscreen Sensor must also be cleaned of any fingerprints.

Refer to APPENDIX E Touchscreen Sensor. The space between the

Touchscreen Sensor and the LCD face must be clean and free of any foreign

objects.

The Touchscreen Sensor is secured to the LCD via a 3M Hook and Loop

product (Velcro). Tiny, stiff hooks mesh with pliable loops for quick secure

fastening. 4 pieces of this tape are applied, 2 to the top edge and 2 to the

bottom edge of the backside of the Touchscreen Sensor. The adhesive tape

is set back slightly from the edge of the active area of the Touchscreen. When

the Top Plastic cover is reassembled, the mounting tape should not be visible.

When mounting the Touchscreen Sensor to the LCD, the Active Area Border

of the Touchscreen Sensor must be aligned to the LCD’s Display Area Border.

Once positioned, gently press the Touchscreen firmly against the LCD.

Removing the ‘DG41 LCD from the LCD Mounting Bracket

1. Make sure the ESD protected work area has no debris on the

antistatic mat.

2. Turn the LCD Mounting Bracket over and place the assembly face

down on the antistatic mat.

3. Cut the cable tie that is securing the backlight cable (cable tail from

LCD) to the cable tie mount.

Exercise care not to scratch the LCD’s display surface. Refer to APPENDIX B

LCD Handling.

NOTE

4. Disconnect the backlight cable from the Open Frame Inverter’s

interface connectors.

5. Cut the cable tie that is securing the LCD Data Cable to the tie

mount.

6. Carefully pull back the RF Gasket just enough to loosen the

adhesive (do not completely remove) so that the LCD Data Cable

can be passed through later.

When disconnecting cables,

Remove/disconnect the cables by pulling on their connector or pull-tab.

NOTE

2-14 Preliminary Release 3/24/05

DO NOT PULL on the cable itself.

Page 29

4. Disconnect the

Backlight Cable

DISASSEMBLY AND ASSEMBLY

3. Cut cable tie securing backlight cable

5. Cut the cable tie

that is securing the

LCD Data Cable

6. Carefully pull

back the RF

Gasket (do not

completely

remove).

7. Carefully turn the LCD Mounting Bracket over, right side up.

NOTE

Be careful not to touch the LCD’s display surface when turning the LCD

Mounting Bracket over.

8. Using a Phillips #1 screwdriver remove the 4 screws and

washers that secure the LCD to the LCD Mounting Bracket.

#4-40x1/4 Screw

#4 Star

Washer

9. Carefully lift off the LCD at the same time slowly passing the

backlight cable and the LCD data cable through the cutouts

in the LCD Mounting Bracket.

3/24/05 Preliminary Release 2-15

Page 30

DISASSEMBLY AND ASSEMBLY

Disconnecting the LCD Data Cable

When disconnecting the LCD data cable from the LCD connector, attention

should be paid to how the data cable is oriented and connected to the LCD

NOTE

connector.

Removing the Open Frame Inverter

83-006

#6 NYLON WASHER

Turn the LCD Mounting Bracket over. Using a #1 Phillips screwdriver

unscrew the 2 screws securing the Inverter to the LCD Mounting

Bracket.

82-004

#4-40x1/4 Screw

32-017

Inverter – DMA23058

82-004

#4-40 x 1/4 SCREW

WARNING

Shock hazard

if powered!

76-208

Backlight Cable

Refer to Appendix I for LCD bracket preparation for the mounting of the

LQ121S1DG41 display.

NOTE

2-16 Preliminary Release 3/24/05

Page 31

DISASSEMBLY AND ASSEMBLY

Reassembly

Reassembly is almost the opposite process of disassembly.

1. Make sure the LCD Data Cable is connected in the proper orientation to

the LCD and Torque Seal has been applied to either side of the data

cable connector.

Use the following method when connecting the LCD data cable to the

LCD.

A) Correct connection

ispersedStress is d

Base (horizontal film base) is required

B) Incorrect connection

Stress is dispersed

Base (horizontal film base) is required

2. When mounting the LCD, carefully pass the backlight cables and the

LCD data cable through the openings in the LCD Mounting Bracket.

3. Line up the LCD’s Mounting Holes to the stand-offs.

4. Install the washers and the screws. Do not over tighten the screws at

this point.

3/24/05 Preliminary Release 2-17

Page 32

DISASSEMBLY AND ASSEMBLY

5. Adjust and position the LCD, then tighten the screws using a

crisscross pattern. DO NOT USE POWER TOOLS, ONLY HAND

TIGHTEN THE MOUNTING SCREWS.

Binding Torque Value: 0.196N x m (2.0Kgf x cm)

NOTE

6. The pink and blue wires of the LCD’s backlight cable connect to Pin

1 of interface connectors J2 & J3 on the Inverter Board.

Base Bottom Disassembly

Disconnecting the Power Switch Cable from the Motherboard

1. Disconnect the power switch cable from the quick tabs located on

the motherboard.

2. Cut the cable tie strap securing the ferrite bead to the Rear Internal

Shield Casing.

1. Disconnect the power

switch cable from the

quick tabs.

When disconnecting cables, DO NOT PULL on the cable itself.

Remove/disconnect the cables by pulling on their connector or pull-

NOTE

tab.

2. Cut the cable

tie strap securing

the ferrite bead

3. Pull back the power switch cable until the cable is clear of the

slot/channel on the Rear Internal Shield Casing.

Attention needs to be paid as to how the power switch cable was

routed and how the ferrite bead was positioned when secured to

NOTE

2-18 Preliminary Release 3/24/05

the Rear Internal Shield Casing.

Page 33

Reassembly

Reassembly is the reverse of the disassembly process.

Disassembly of the Internal Shield Assembly

Removing the Internal Shield Assembly out of the Base Bottom Plastics

1. The Internal Shield Assembly sits inside the Base Bottom Plastic

Housing and is not secured to the Bottom Plastic Housing in any way.

To remove the Internal Shield Assembly, grasp the assembly as shown

in the picture below and carefully lift the assembly straight out of the

base bottom evenly.

DISASSEMBLY AND ASSEMBLY

Reassembly

Reassembly is the reverse of the disassembly process. Simply align the

Internal Shield Assembly to the Base Bottom Housing and carefully lower

the Internal Shield Assembly into the Base Bottom Housing. Check to make

sure the Internal Shield Housing is sitting evenly inside the Base Bottom

Housing.

Removing the Power Switch Cable and the Power Switch

1. Disconnect the power switch cable from the tabs of the power switch.

When disconnecting cables, DO NOT PULL on the cable itself.

Remove/disconnect the cables by pulling on their connector or pull-tab.

NOTE

3/24/05 Preliminary Release 2-19

Page 34

DISASSEMBLY AND ASSEMBLY

2. Gently push the switch through the Base Bottom Housing until the

switch pops out.

Reassembly

Reassembly is the reverse of the disassembly process.

Removing the Intake Fan

1. Disconnect the fan’s 3-pin connector plug from the 3-pin header

(Reference Designator: CN2) on the motherboard.

2. The fan is secured via two #6-32x1/2” Phil screws (as depicted below)

onto PEM Head Standoffs located inside the Shield Housing. To remove

the fan use a #1 Phillips screw driver and carefully unscrew the top screw

first followed by the remaining screw.

82-608

6-32x1\2” Phil Screw (x2) Black

Located on top corner (unscrew first)

& bottom corner (unscrew last)

CN2

FAN ASSEMBLY

2-20 Preliminary Release 3/24/05

Page 35

Reassembly

Reassembly is the reverse of the disassembly process.

Make sure the cable tail from the fan is of the correct length. If not then any

excess cable needs to be bunched neatly together and cable tied to achieve

NOTE

the proper cable length.

Removing the Motherboard from the Internal Shield Housing

1. Using a Phillips #1 screwdriver, remove the 9 screws and

washers that secure the motherboard to the Internal Shield

Casing.

DISASSEMBLY AND ASSEMBLY

2. Removing the motherboard out of the Rear Shield Housing should

be done with care and without any stress to the board. To remove

the motherboard, carefully lift the end of the motherboard where the

hard drive mounting area (Reference Designator: HD1) is located.

This will cause the board to come up at an angle. Once the board

has cleared the Rear Metal Casing’s wall, slide the board

completely out carefully. Care should be taken not to damage the

foil tape located on the inside wall of the metal casing near the

fan/keyboard area.

3/24/05 Preliminary Release 2-21

Page 36

DISASSEMBLY AND ASSEMBLY

Reassembly

Reassembly of the same motherboard in the Shield Housing is the reverse

of the disassembly process.

1. Inserting the motherboard into the Rear Shield Housing should be

done with care and without any stress to the board.

2. When reassembling, angle the motherboard so that the

keyboard/fan end of the board goes in first. Gently lower the board

down when in position.

3. Once the board is sitting inside the casing, shift the board around to

make sure there is some play to ensure proper placement. Check

front side of the metal casing’s area where the I/O connectors are

exposed to make sure the I/O connectors are properly aligned with

the metal casing’s I/O connector openings. Also check that the

keyboard connector is aligned properly to the metal casing’s

opening before securing board down.

NOTE

4. Install screws and washers to secure the motherboard to the shield

casing.

Screws have two purposes: one, to secure the motherboard into

place, particularly around I/O areas where user interaction causes

NOTE

additional stress; and two, the screws are the means of electrically

connecting the metal shield to the chassis ground source on the

motherboard. Be sure to use all screws.

Refer to APPENDIX F for the following:

• New Motherboard Preparation

NOTE

• Foil Taping the Rear Shield Casing

• Foil Tape Specifications

Refer to APPENDIX G for Motherboard Connector Descriptions, Jumper

Descriptions & Settings.

Resetting CMOS for Squirrel Defaults

The WS8 product now offers the feature where by resetting CMOS

to factory defaults will reset CMOS to Squirrel’s required Default

NOTE

Settings.

To reset CMOS:

2-22 Preliminary Release 3/24/05

Page 37

- Turn power on or re-boot system and press the “DEL” key on

the keyboard to access CMOS.

- When the CMOS main menu appears select “Load Optimized

Defaults” to load Squirrel’s Default Settings.

- Save settings and exit CMOS for changes to take effect.

Removing the Card Guide Rails

• Using a Phillips #1 screwdriver remove the two screws

(one on each Card Guide) securing the Card Guides to

the Base Bottom Plastics.

Reassembly

• Reassembly of the Card Guide Rails to the Base Bottom

Plastics is the reverse of the disassembly process.

DISASSEMBLY AND ASSEMBLY

• Make sure the Card Guides are properly in place before

securing the rails.

3/24/05 Preliminary Release 2-23

Page 38

CHAPTER 3: INSTALLATION

Installation of the SQUIRREL WORKSTATION 8 involves the

following recommendations:

• General guidelines

• Electrical Power Requirements

• Location and mounting positions

• Proper installation of the mounting hardware

• Host/Server Communication Protocol

• ISIS Badge Reader Configuration

• Cable Location Label - l/O Interface

• Typical Workstation & Peripheral Setup

INSTALLATION

General Guidelines

• Final testing of the installation

1. The Workstation should have sufficient clearance to allow

access to the power switch and cables.

2. Account for the Workstation’s dimensions when selecting an

installation location or enclosure. Refer to Chapter 1 for product

dimensions.

3. Workstation must be placed/mounted at a comfortable working

level and yet will not block traffic flow in the restaurant when in

use.

4. Consider locations for accessories such as AC power outlets

and lighting for installation and maintenance convenience.

5. Location should have adequate ventilation (2 inches) and

measures should be taken to avoid obstructing the airflow to

allow for maximum cooling. Note air intake and exhaust

locations – see page 1-7.

6. Location must allow for credit card reader swiping action and

7. Workstation should be located where the possibility of food or

3-1 R1.0 Preliminary Release 3/24/05

badge reader insertion.

beverage spillage is at a minimum risk.

Page 39

INSTALLATION

8. Workstation should be kept away from high heat sources such

as grills, fryers and heat lamps.

9. Location should have adequate space for the external power

supply; check printer and cash drawer installation. The external

power supply must have 1" clearance on all sides.

Electrical Power Requirements

The power line for the Workstation 8 must be kept in accordance

with the SQUIRREL POWER SPECIFICATION GUIDE. This

means the Workstation as well as all locally connected peripherals

will be plugged into a SQUIRREL Dedicated Isolated Ground

receptacle.

Location and Mounting Positions

The WORKSTATION 8 can be mounted in a variety of locations

and positions using the Tilt Stand or Wall Bracket as shown below.

The General Guidelines and Power Requirements mentioned

above must be taken into consideration during customer

consultation for the best locations and mounting methods.

SUSPENDED UNDER COUNTER MOUNT

3-2 Preliminary Release 3/24/05

Page 40

INSTALLATION

ANGLED WALL MOUNT SIDE WALL MOUNT

“TRADITIONAL”

COUNTER TOP

COUNTER SUNK

(Using Wall Bracket)

Proper Installation of the Mounting Hardware

Tilt Stand (92-205) Installation

The Tilt Stand can be used to suspend the Workstation 8 from a

shelf, rack, wall, or to support the Workstation on a countertop in a

traditional fashion.

By aligning the Workstation in different positions on the Back Plate

of the Tilt Stand, these options can be obtained.

When the Workstation 8 is mounted vertically on the Back Plate,

the Tilt Stand attaches as in Figure 3-1. The tubing and cables can

then be routed through the hole in the Back Plate.

FLUSH WALL MOUNT

(Using Wall Bracket)

3/24/05 Preliminary Release 3-3

Page 41

INSTALLATION

Tilt Stand

Back Plate

Figure 3-1. WORKSTATION 8 with Tilt Stand

Similarly, the Workstation 8 can be secured to the Back Plate

sideways except when attached from the left. Use only two screws

as shown in Figure 3-2.

Tilt Stand

Back Plate

Figure 3-2.Workstation 8 with Tilt Stand (Sideways from Left)

3-4 Preliminary Release 3/24/05

Page 42

INSTALLATION

For counter top mounting where the Tilt Stand is not to be screwed

to the countertop, a weight can be attached to the base of the Tilt

Stand as shown in Figure 3-3. The base weight is shipped

standard with the Workstation 8.

Figure 3-3. Tilt Stand with Weight

There are three screw holes for securing the base to the mounting

surface. It is important that the correct screws be used for the

surface where the base is being installed. Long wood screws

should be used for wood paneling and shelves and "butterfly shield"

screws MUST be used for a surface such as gyproc.

Ensure that wood screws are secured into wall studs when wall

mounting the Workstation. If they are not secured properly, then the

weight of the Workstation will cause the Workstation to pull out of

the wall and fall, causing damage to the restaurant’s wall and the

Workstation itself. A commercially available stud locator (available

at hardware stores) should be used during installation.

3/24/05 Preliminary Release 3-5

Page 43

INSTALLATION

Adj

usting the Tilt Stand

BASE

SCREWS

(3)

To adjust the angle of the Tilt Stand:

1. Remove the three base screws that secure the stand to the wall,

countertop or shelf if necessary. See Figure 3-5. The

Workstation may have to be removed in order to do this.

TILT STAND

BACK PLATE

BASE

Figure 3-5. Tilt Stand Base Screws.

2. Locate the three setscrews on the backside of the Tilt Stand

Base as shown in Figure 3-6.

3-6 Preliminary Release 3/24/05

Page 44

INSTALLATION

Set Screws (3)

(1/8” Allen key)

Figure 3-6. Tilt Stand Base Setscrews.

3. Using a 1/8" Allen Key, loosen these screws just enough so that

the back-plate of the stand begins to move. While holding the

stand against the mounting surface, adjust the back-plate to the

angle desired. On a piece of masking tape placed on the raised

portion of the base by the back-plate, mark the desired backplate angle with a felt pen. The back-plate angle can now be set

by tightening the setscrews using the mark on the tape as a

guide for the desired angle. (Don't forget to remove the tape

afterwards.)

4. If needed, the tilt angle range can be switched over to the

opposite side of the base. Remove the setscrews and lift the

back from the base. Flip the back 180° and re-install it into the

base. Replace the washers, adjust the back to the desired angle

and tighten the setscrews.

5. Place the stand in its previous location and fasten the base

screws.

6. Install/mount the Workstation 8.

3/24/05 Preliminary Release 3-7

Page 45

INSTALLATION

g

)

Mountin

the Workstation 8 to a Wall Bracket (92-207

The Wall Bracket can be used in two ways: to attach the

Workstation to a wall, or to provide a slight tilt for a flush countermount installation.

WALL MOUNT

Mounting screws MUST be secured into the wall stud. (Two

screws are sufficient for vertical studs.) “Butterfly Shield screws”

must be used for gyproc to ensure that the bracket doesn’t pull

away from the wall causing the Workstation to fall.

See Appendix H for the use of “Butterfly shield” type screw.

Mounting flanges on the Wall Bracket hold and support the

Workstation. A foam insert is included as a spacer to prevent

unintended dislodging of the WS from the bracket, while still

allowing easy service access. Place the Workstation on the

bracket as shown in Figure 3-7.

Foam Insert

(“Bump-off”

Preventer)

Foam Insert

#98-302

#98-302

Figure 3-7. Wall Mount

The rubber feet on the backside of the Workstation may have to be

removed for it to be wall mounted.

3-8 Preliminary Release 3/24/05

Page 46

INSTALLATION

COUNTER SUNK MOUNT

The Wall Bracket can be attached to the back of the Workstation to

provide a slight tilt when the unit is mounted on a counter top.

The four mounting screws used to secure the Workstation 8 to the

Tilt Stand can be used to attach the Wall Bracket to the Workstation

as shown in Figure 3-8.

Figure 3-8. Attaching the Wall Bracket to the Workstation 8.

Host/Server Communication Protocol

The standard communication protocol between the Host/Server and

the WS8 product is Ethernet 10/100 Base-T. TCP/IP (Transfer

Control Protocol/Internet Protocol) is the standard used for

SquirrelOne (POS) to communicate between Host/Server and

workstation.

3/24/05 Preliminary Release 3-9

Page 47

INSTALLATION

–

ISIS Badge Reader Configuration

The ISIS badge reader can be configured for the type of ISIS

Badge Card series used. Series 1 was the original badge type.

Series 2 was developed to extend the range of ID numbers. See

STN 073 for more detailed information.

To configure the series type:

1. Power on the workstation and load SquirrelOne software.

2. Once POS is loaded and the Workstation has initialized,

insert the badge card of the desired series.

3. The badge reader will automatically configure itself to the

series of badge card inserted after power-on.

Cable Location Label

4. To reconfigure the badge reader to a different series type,

power off the Workstation and perform steps 1 to 2 again.

I/O Interface

The Cable Location Label is located right above the Multi RJ12-I/O

connector, RJ45 Ethernet connector and Power Jack.

Refer to Chapter 1 “Product Description” for I/O Connector

description.

3-10 Preliminary Release 3/24/05

Page 48

INSTALLATION

Multi I/O Connector Label

The color scheme on the Cable Location Label developed for

earlier Squirrel Workstation models for each port/connector

descriptor still holds for the WS8 product. This color scheme was

introduced to aid in connecting peripherals to their respective I/O

port connectors. Interface cables used to connect the peripherals

to their respective ports and communication cables also have

corresponding matching color bands.

3/24/05 Preliminary Release 3-11

Page 49

INSTALLATION

y

r

r

y

pical Workstation & Peripheral Setup

T

Matching Color

Band

SQ-7035

Note: depending on

peripheral, COM port can

be configured to support

the following:

Printer

OR

Tower

OR

Weigh Scale

OR

Bar Code Reader

Printer

SQ-7035

SQ-7175

Cash Drawe

SQ-7035

Tower

OR

Weigh Scale

OR

Bar Code Rd

SQ-7706

Power Suppl

Ethernet Patch Cable

The power connector is friction lock. To prevent the plug from

becoming dislodged, attach tie wrap and loop cord to secure.

3-12 Preliminary Release 3/24/05

Page 50

INSTALLATION

g

All interface cables EXCEPT the Power Supply connection can be

made while the Workstation is powered on. Hence any

communication cables can be replaced without powering down the

Workstation.

Final Testin

Powering It On

of the Installation

Once the power, ethernet and peripherals have been interfaced to

the Workstation, it is now ready to be powered on. The Workstation

8 can be powered on without having the Squirrel POS software

activated on the host.

To power on the Workstation 8 while Squirrel POS is active:

1. Ensure that power and Ethernet communication lines to the host

are connected.

2. Turn the power switch ON.

3. On power up, the screen will go white for a few seconds and the

ISIS Badge Reader LEDs will also turn on. The following chain

of events will take place:

o POST (Power On Self Test)

o Will get IP Address

o Will load Linux Image – Spinning Wheel

o POS will load

LOADING DATA PAGE 0

LOADING IMAGE 1

o POS session will start.

For SquirrelOne software initially the Workstation will look for the

server.

4. If the POS program is active on the Host Server, the

Workstation should now load PROGRAM and DATA pages

automatically. If the POS program in not active, then select the

START BUSINESS DAY option within the Squirrel program on

the Host Server. Consult the software manuals for further

information on host to terminal operations.

3/24/05 Preliminary Release 3-13

Page 51

INSTALLATION

5. Once POS is loaded onto the Workstation and the Workstation

has initialized, insert a badge card into the Badge Reader to

configure the reader for the type of badge series to be used.

Screen Contrast

The Workstation 8 is designed so that the screen contrast is preset

to the maximum setting and thus eliminating the need for contrast

control.

Volume Control

The Workstation 8 is designed so that the volume control is also

preset to the maximum setting and thus eliminating the need for

volume control.

3-14 Preliminary Release 3/24/05

Page 52

CHAPTER 4: MAINTENANCE

There is relatively little general maintenance for the SQUIRREL

WORKSTATION 8, but disregarding maintenance will result in long

term problems for the user.

Caring for the WORKSTATION 8

The WORKSTATION 8 and its associated cables and peripherals

should not be immersed in liquids. The risk of liquids spilling on or

around the Workstation should be prevented. The WORKSTATION

8 is designed to be water-resistant, NOT waterproof.

The WORKSTATION 8 should be kept away from high heat

sources such as grills, fryers and heat lamps. Any area that is too

hot for prolonged exposure of your hand (more than a minute) is

too hot for the Workstation.

MAINTENANCE

General Cleaning

Cleaning solvents such as gasoline, turpentine and alcohol also

should NOT be used on the Workstation.

Routine cleaning can be performed by wiping the WORKSTATION

8 with a clean, soft damp cloth to remove dust and minor stains.

Soap and warm water can be used carefully with a rag to clean

stains. Make certain that the Workstation is powered OFF and that

NO water can drip from the cloth into the openings of the

Workstation. The touch-screen display can be cleaned with a

common household glass cleaner applied with a clean, soft cloth.

Examine the screen area, especially the gaps on the border of the

screen between the touch-screen surface and the plastic housing.

Carefully clean out any crumbs or other debris that could be

“touching” the screen. (An employee badge can be carefully used

to clean out the screen border areas.)

Exhaust vent and fan intake vents must be kept clean of dust

buildup. Clumps of dirt or ‘dust bunnies’ can block airflow and

restricted airflow causes overheating inside your Workstation.

When components overheat, they become stressed and eventually

fail. Overheating caused by dust is the primary cause of equipment

failure over time.

4-1 R1.0 Preliminary Release 3/24/05

Page 53

MAINTENANCE

Cleaning the Credit Card Reader

Regular use of the Credit Card Reader results in a residue buildup

on the magnetic head within the reader. This degrades

performance and will lead to the eventual failure of the credit card

reader. Regular cleaning of the reader will prevent this problem

from occurring.

Disposable cleaning cards are available from SQUIRREL for

cleaning the Credit Card Reader. A card should be used to clean

the reader every 2 - 4 weeks depending on usage. If the credit card

reader performance starts to degrade (i.e. credit cards take several

swipes to read) the reader should be cleaned.

To use the disposable cleaning card, simply follow the directions

that accompany it.

4-2 Preliminary Release 3/24/05

Page 54

CHAPTER 5: TROUBLESHOOTING

If the WORKSTATION 8 is required to be serviced on site (restaurant), it is

advisable that the service technician bring along a fully functional Workstation

in the event that the Workstation in question requires more than a simple

service. Swapping Workstations should be carried out in order to minimize

disruption to the site.

Troubleshooting on Workstations can be carried out using the Diagnostic

feature available in the SquirrelOne POS software. Reference can be made to

the V1.3x Functions document or the V1.3x Managers Guide for detailed

information regarding the Diagnostic feature.

The Workstation 8 has thus far proven to be a very reliable product. However,

there is always a chance that you may experience some problems. Listed

below are some common problems and possible solutions.

TROUBLESHOOTING

Problem Possible Solutions

Workstation is ‘ON’ but the screen is

blank/dark.

No touch in some areas of the screen

and recalibration doesn’t fix the

problem.

Touch the screen or insert a badge

card to activate the backlight. If there

hasn’t been any activity on the

Workstation for approximately 2

minutes, the software turns off the

backlight to conserve power.

Check to make sure the touch-screen

sensor is connected properly to the

motherboard.

Connect another touch-screen sensor

to see if the problem is rectified.

Component failure in the touch-screen

sensor circuitry on the motherboard.

Send unit to Repair Depot for

servicing/replacement.

5-1 R1.0 Preliminary Release 3/24/05

Page 55

TROUBLESHOOTING

Problem Possible Solutions

Badge Reader will not read Badge

Cards.

Top LED of the Badge Reader

is either continuously flashing

or off.

Check that the Badge Reader function

is enabled in the POS software.

Refer to the software manual on

Badge Reader setup.

If the Badge Reader function is

enabled in POS and the problem still

persists, check to make sure Badge

Cards are being inserted properly.

Check to make sure the ISIS cable is

seated properly on the Motherboard

and connected properly to the ISIS

reader. Also check to make sure both

LEDs (Detector & Emitter boards)

light when unit is powered.

Check the alignment of the emitter

and detector components.

Swap with another known working

Badge Reader and check if problem is

rectified.

The Credit Card Reader (Mag Swipe

Reader) requires several swipes to

read the card information or will not

read the cards at all.

The Magnetic Swipe Reader is a bidirectional reader allowing the card to

be swiped in either direction. Ensure

that when the card is being swiped,

the magnetic stripe is oriented

correctly into the reader (magnetic

stripe goes into the reader facing

towards the LCD screen), and the

card is not being swiped too fast.

Using a Mag Stripe Reader Cleaning

Card, swipe the Cleaning Card

through the Credit Card Reader to

help eliminate residue buildup on the

magnetic head.

5-2 Preliminary Release 3/24/05

Page 56

TROUBLESHOOTING

Problem Possible Solutions

Check that the ISIS LED goes off for

a short period while a M/R card is

being swiped. Does this happen? If

not, check that the Mag Reader’s

cable is connected/seated properly to

the right angle connector located at

the back of the ISIS Detector boards.

Also inspect the cable for any

damage.

Communication problems.

Printer not printing or printer

communication problems.

Check the Host Server to make sure

the Workstation’s IP Address is

entered correctly.

Check that the interface patch cable

is connected properly at the

Workstation and to the termination

block.

Swap the interface patch cable with a

known working cable.

Swap in a known working Workstation

and if the problem still persists then

the problem lies in the wiring or the

Host Server.

Make certain that there is proper

electrical power (refer to the Squirrel

Power Specification Guide).

Check to make sure that the interface

cable is connected properly at the

Workstation and on the correct port,

as well as at the printer end.

3/24/05 Preliminary Release 5-3

Make certain that the printer is

powered on.

Make certain that the printer routing is

done correctly in the Squirrel POS.

Make certain that the printer port’s

jumpers on the Motherboard are

configured correctly for RS232

communication protocol.

Page 57

TROUBLESHOOTING

Problem Possible Solutions

Swap in a known working printer and

if the problem still persists then the

problem lies with the Workstation.

Problem could be component related

on the Motherboard.

Cash Drawer will not open.

The Squirrel Diagnostic feature

available in the SquirrelOne software

can be used in conjunction with a

Squirrel Cash Drawer Tester (SQ-

9870) to test the Cash Drawer port.

The tester consists of two LED

indicators that briefly pulse ON when

the Cash Drawer function is selected

in the Diagnostic utility. If the tester

reveals that neither one of the LEDs

is triggered then the problem could be

component related on the

Motherboard. If both LEDs pulse ON,

then proceed to other Possible

Solutions listed below.

Check to make sure that the interface

cable between the Cash Drawer and

Terminal are connected properly.

Swap in a known working Cash

Drawer interface cable.

LCD backlight not working or too dark.

5-4 Preliminary Release 3/24/05

Check to make sure the Cash Drawer

is powered.

Check that the backlight cable is

connected properly at the

Motherboard and LCD end.

Faulty or damaged backlight interface

cable or cables from the LCD itself.

Burnt out backlight tube(s). Note:

depending on the LCD panel, some

models permit replacing backlight

tubes in the field and some don’t.

Contact Squirrel for details or to

inquire.

Page 58

TROUBLESHOOTING

Problem Possible Solutions

Inverter board component level

failure.

LCD screen unreadable; Character

missing pixels; Screen abnormal;

Wrong color displayed; Horizontal or

vertical lines displayed.

NOTE: a few pixel abnormalities may

be normal. Refer to note on page 6-7

‘Appendix B’.

Workstation does not power up – no

video; no fan sound; Badge Reader’s

LED off.

Check that the LCD data cable is

seated properly at the LCD and

Motherboard end.

Damaged or defective LCD data

cable.

Swap in another LCD (same model)

to determine if the LCD is faulty.

Check that the Power Supply is

connected properly at the Workstation

and wall outlet end.

Check wall outlet with a Wall Socket

Circuit Tester or Multimeter to make

sure there is power.

Check the Power Supply’s end

connectors to make sure they are in

good condition.

Swap in a known working Power

Supply. If the unit powers then the

problem is with the Power Supply, if it

doesn’t then the problem lies within

the Workstation (component or board

circuit level).

3/24/05 Preliminary Release 5-5

Check resettable fuse FS4 on the

Motherboard.

Page 59

CHAPTER 6: APPENDICES

APPENDIX A

3. Wrist Strap

A two-part device

including a wristband

and a coil cord that

connects a person’s

skin to ground.

2. Common

Ground Cord

A cable and

connector that

connect a table

mat and one or

two wrist straps

to ground.

1. Table Mat

A work surface

that dissipates

static from

conductive items

placed on it.

Air Ionizer

An Air Ionizer is an optional piece of equipment for the ESD Work-station and is

costly, but will give you the added protection you need. Nonconductive

materials, such as plastic and synthetic fabrics, cannot be grounded. Only

ionized air can neutralize their static charge. The air ionizer should be turned on

immediately after the wrist strap is attached. If you are applying or removing

pressure sensitive tape, do so directly under the blower, using a slow, steady

motion.

ESD Work-station

Work-station Components

4. Floor Mat

A walking surface that

dissipates static

charge from

conductive items

placed on it.

5. Floor Mat

Ground Cord

A cable and

connector that

connect a floor

mat to ground.

Constant Monitor

An electronic device that continuously

checks the connections of the coil cord,

wristband and person.

APPENDICES

6. ESD Awareness Sign

A sign that provides

warning text and symbol

to indicate special static

control precautions are

required in the area.

7. Heel Straps

A device for

connecting a

walking or

standing person

to ground by

using the

moisture in the

shoe as a body

connection and

a conductive

rubber tread as

a connection to

a grounded mat

or floor.

6-1 R1.0 Preliminary Release 3/24/05

Page 60

APPENDIX A

Maximum Allowable Resistances and Discharge Times for Static Safe

Reading from Operator

through:

Floor mat to ground 1000 megohms Less than 1 sec.

Table mat to ground 1000 megohms Less than 1 sec.

Wrist strap to ground 100 megohms Less than 0.1 sec.

*Minimum resistance to ground for each is 500 kilohms.

ESD Work-station Do’s and Don’ts

Do Don’t

• Test the wrist strap/operator combination

for continuity daily or install constant

monitors.

• Test the mats quarterly.

• Clean the mats with a cleaner designed

for static mats

• Remove all nonessential plastic items

from the workstation area. Insulative

plastic items can store large amounts of

static charge that is not removed when

placed on a mat or grounded. Examples

include: Styrofoam cups, plastic lunch

bags and containers, combs and brushes.

• Require personnel that wear heel

grounders to also wear a wrist strap when

they sit at a workbench. Most people lift

their feet or heels off the floor at some

point while seated.

• Use GFCI outlets when working with

energized items.

• Avoid parallel ground paths. The only

connection to ground for an operator at

an ESD workstation should be the wrist

strap, heel grounders or work surface.

Other uncontrolled ground paths could

create a shock hazard.

• Equipment and tools in the working area

must be grounded

Maximum Tolerable*

Resistance

APPENDICES

Operations

Maximum Acceptable

Discharge Time

• Do not ground the mat by

one snap and connect the

wrist strap to the other snap.

This adds the resistance of

the mat to the ground path.

• Do not “daisy chain” mats

together. Each mat must be

connected to the ground

point - not connected to the

ground point through another

mat.

• Do not use commercial

cleaners on mats. The

cleaners may leave a residue

that prevents the mat from

draining away charge.

6-2 Preliminary Release 3/24/05

Page 61

APPENDICES

APPENDIX A

Prime Sources of Static Electricity in an Electronics Work Area

1. People: Walking, rocking in a chair, getting up from a chair, putting on or removing

work smocks - any brisk or repetitive motion.

2. Clothing: Clean room smocks, synthetic shirts, sweaters, pants etc. Shoes with

synthetic (such as neoprene, foam rubber) soles and heels.

3. Chairs: Vinyl covered, fiberglass, finished (such as varnished, shellacked,

polyurethane coated), waxed.

4. Workbench tops: Plastic, vinyl, covered, finished wax.

5. Floors: Vinyl, finished wood, sealed concrete, waxed floors.

6. Parts bins, trays, tote boxes: Plastic, finished wood or metal.

7. Packaging material Plastic foam, bubble pack, cushioning, polyethylene bags, vials,

containers, Styrofoam pellets (shells, peanuts).

8. Tools: Plastic solder suckers, hand tools (coated handles), soldering irons (with

ungrounded tips), heat guns (used bar heat shrink tubing, drying conformal coating,

etc.), solvent brushes (synthetic bristles).

9. Manufacturing Equipment and Processes: Drying ovens, degreasers,

sandblasters, temperature chambers, solder flow machines, integrated circuit

handlers or loaders, spraying conformal coating, spray painting and cleaning, fault

isolation, cryogenic sprays.

Many of the components you come in contact with, including all those in the chart

below, are susceptible to damage from static discharge. In the case of the most

sensitive, it can take as little as 30 volts to degrade or completely destroy the

component.

What do you have to do to build up a potentially destructive charge? It can take as

little as sitting up straight or lifting one foot off the floor. Walking across a vinyl floor

can generate 4,000 volts; a carpeted floor 8,000 volts.

6-3 Preliminary Release 3/24/05

Page 62

NOTE

APPENDICES

APPENDIX A

Field Service – ESD Prevention

Field service technicians are required to take appropriate steps to make sure they are

properly grounded before handling any circuit boards. If a field service technician is at a

site and is not equipped with a portable ESD field service kit, the technician must keep

in mind that touching a metal chassis whether grounded or not will only temporarily

bring the technician to the same potential as the chassis. This is a common

misconception by a lot of field people, that touching ground will make you safe…it will

only while your are touching ground…once you disengage that connection, you put all

sensitive ESD devices at risk.

Field Service Kit

A typical field service kit provides a complete portable static safe workstation for

personnel working with electronics in the field. To stop static electricity from damaging

electronic cards, a static safe work area is essential for Field Service Technicians

performing in-field repair or installation of cards. A field service kit folds to fit into most

tool cases and comprises of the following: 24”x24” mat with 2 pockets, wrist strap,

ground cord and instructions.

Field Service Kit

6-4 Preliminary Release 3/24/05

Page 63

APPENDICES

APPENDIX B

LCD Handling

ESD Protection

• LCD’s are very susceptible to electrostatic discharge failure and so extra care should

be exercised when handling these devices. When working with an LCD, be sure to

ground your body and any electrical equipment you may be using.

• Treat the LCD the way you would treat most active electronic components such as IC,

etc. The original packaging material that ship with the product is static proof and would

offer basic ESD protection. However, when assembling the LCD into the workstation,

ESD precautions must be taken in order to prevent damage.

• Avoid the use of work clothing made of synthetic fibers. It is recommended to use

cotton clothing or other conductivity-treated fibers.

• Slowly and carefully remove the protective film from the LCD module, since this

operation can generate static electricity.

It is strongly recommended that the protective film be kept on as long as possible

in the assembly process in order to protect the polarizer. Impact, scratching or

rubbing the LCD’s surface can easily damage the polarizer and can degrade the

display quality.

Mechanical Force and Strength

• Do not touch the display surface of the LCD as it is made of glass and a polarizer that

is sensitive to pressure and can be easily scratched or damaged.

• Avoid stacking material on top of the LCD display.

• The LCD should be mounted properly to prevent movement to the LCD during normal

use and shipment.

• Both the top and bottom side of the LCD should be protected from excessive force as

this may crack the glass.

Handling the LCD

• Handle the module from the bezel’s edge. Avoid touching the LCD panel.

• If the LCD module has its circuitry PCB(s) on the rear side of the panel, care should

be exercised not to stress the PCB(s).

• Make sure the workstation is powered down when connecting or disconnecting the

LCD data cable.

• When mounting the LCD on the LCD bracket, never secure the LCD by using Hand

Power Tools. It is strongly recommended that the mounting screws be tightened using

hand tools and using the “Crisscross Method”.

• Never connect or disconnect the module from the workstation while power is being

supplied.

6-5 Preliminary Release 3/24/05

Page 64

APPENDICES

APPENDIX B

LCD Handling

Do not disassemble or modify the LCD module as this can cause permanent

damage and should be strictly avoided. Any non-authorized modifications,

ampering or physical damage will void the manufacturer’s warranty. t

The cold cathode fluorescent lamp in the LCD panel contains a small amount of

Caution!

mercury. Please follow local ordinances or regulations for disposal.

Cleaning

Even though most people understand that the LCD is constructed of glass as its major

components, most people do not know that extended exposure to moisture and water

can damage the LCD.

• Remove condensation/water immediately as water can stain, swell or cause the

polarizer to fade.

• To clean the surface of the LCD, use a forced air device if available, to blow any dust

and debris off the surface of the display. An alternative to a forced air device would be

to gently wipe (DO NOT scrub hard) the LCD surface with a nonabrasive soft, dry

cloth.

• DO NOT use organic solvents to clean the display panel off, as these solvents may be

adverse to polarizers.

• Petroleum benzene is preferred for cleaning the surface of the LCD to remove most

stains and smudges.

Storage

• Avoid using or storing the module under conditions where high temperature and

humidity may exist.

• When storing, the LCD should be packaged in a conductive polyethylene bag and

direct sunlight or light from fluorescent lamp should be avoided.

• Protect the LCD modules from excessive external forces.

• Use original cartons and trays (packaging material) for storage and for repackaging

defective modules.

• If stored at temperatures below the specified storage temperature, the Liquid Crystal

may freeze and deteriorate. If the storage temperature exceeds the specified rating,

the molecular orientation of the Liquid Crystal may change to that of a liquid, and

may not revert to its original state. Always store at normal room temperature and

normal humidity in a dark place.

Storage Temperature (Tstg):

Tstg = -25°C ~ +60°C

Humidity: 95% RH Max, at Ta (Ambient temp.) ≤ 40°C

Maximum wet-bulb temperature at 39°C or less at Ta>40°C

No condensation.

6-6 Preliminary Release 3/24/05

Page 65

APPENDIX B

LCD Handling

Ingestion and Injury Warning

LCD is composed of glass, liquid crystal, spacer dust and many other chemicals.

Should the display break, caution must be taken to avoid contact with liquid crystal.

When there is case of skin contact, wash immediately with soap & water and make

sure that there are no glass chips remaining on the skin. The liquid crystal may also

leak out, since liquid crystal is composed of over 20 different chemicals, avoid

ingestion of liquid crystal and glass particles.

Pixel Abnormalities (AQL)

Modern LCDs frequently have up to a few pixel abnormalities even as brand new,

and this is normal. Some years ago the industry, in a never ending drive to reduce

LCD costs, recognized that there could be an acceptable quality level (AQL), not

completely flawless parts but completely usable nonetheless. This allowed

manufacturing yield profile to go up during the LCD manufacture process and thus

lowered average unit cost (since the previously thought to be unusable LCDs were

discarded and considered an overall cost of business).

APPENDICES

6-7 Preliminary Release 3/24/05

Page 66

APPENDICES

APPENDIX C

Handling Circuit Boards

Measures should be taken to ensure that technicians are properly grounded before

handling the Motherboard (SBC) or any other circuit boards. Certain components on

the Motherboard are sensitive to static electricity and can be damaged by discharge.