This page was intentionally left blank.

Altivar Process 600

Introduction

variable speed drives

Target Markets

Applications

The Altivar Process 600 series of variable speed drives has over 30

functions dedicated to pumping applications as well as functions for fan

and simple material handling applications.

The Altivar Process was designed for the following markets and

applications.

Water & Wastewater applications

Ŷ Water Intake - surface pumps

- borehole pumps

Ŷ Treatment - aeration blowers

- disinfection dosing pumps

- ventilation fans

Ŷ Storage & Transportation - distribution pumps

- pressure booster pumps

Ŷ Lift Station - submersible pumps

Ŷ Plant Influent - submersible pumps

- screw pumps

Ŷ Treatment - aeration blowers

- sludge conveying

- gas compression

- dosing pumps

- odor ventilation

Oil & Gas applications

Ŷ Extraction - submersible pumps

- liquid injection pumps

Ŷ Treatment - liquid treatment pumps

- refinery pumps

- ventilation fans

Ŷ Storage - distribution pumps

- pressure booster pumps

Ŷ Transport - pipeline booster pumps

- compressors

Mineral, Mining & Metals applications

Ŷ Extraction - ventilation fans

- de-watering pumps

- mine shaft pumps

Ŷ Treatment - filtration pumps

- refinery pumps

- cooling fans

- induced draft fans

- mixers

- exhaust fans

Food & Beverage applications

Ŷ Material receiving - ventilation fans

- simple conveying

Ŷ Processing - mixing pumps

- boiler pumps

- condensate pumps

- solids handling

- ventilation fans

- liquid pumps

- cooling tower fan

- dryer fans

Ŷ Transport - pipeline booster pumps

- compressors

5

Altivar Process 600

Introduction

variable speed drives

Product Range

Product range

The Altivar Process 600 series of variable speed drives are available in a variety of

enclosures and cover a wide range of motor power ratings.

The Altivar Process 630 range, packaged in 6 frame sizes, is a global offer available

worldwide and designed to meet worldwide standards and certifications.

The range includes:

Ŷ 200 - 240Vac, 1-60 HP, UL Type 1 rating

Ŷ 200 - 240Vac, 75-100 HP, IP00 rating, UL Type 1 rating with option conduit kit

Ŷ 400 - 480Vac, 1-125 HP, UL Type 1 rating

Ŷ 400 - 480Vac, 150 - 250 HP, IP00 rating, UL Type 1 rating with option conduit kit

The Altivar Process 660 range, with availability beginning in 3rd quarter 2015, is a

regional offer designed to meet standards and certifications applicable in the USA.

The range includes:

Ŷ 200 - 240Vac, 1-60 HP, available with

- UL Type 1, UL Type 12, or UL Type 3R enclosures

Ŷ 400 - 480Vac, 1-125 HP, available with

- UL Type 1, UL Type 12, or UL Type 3R enclosures

Ŷ 400 - 480Vac, 150 - 1100 HP

- UL Type 1, UL Type 12

Options for the Altivar Process 660 range include circuit breaker disconnects, service

entrance ratings, options for push buttons, pilot lights, and other items required for

the targeted markets.

6

Altivar Process 600

Introduction

variable speed drives

Energy dashboard

Presentation

Integrated Functions

Operational Intelligence delivers value through process visibility.

The Altivar Process incorporates features that provide process monitoring and

visibility.

- Power measurement capable of 5% accuracy for energy management.

- Advanced integrated web server.

- Web server secured with Achilles Level 2 certification.

- Web pages can be quickly customized with ready-to-use-widgets to create different

dashboards.

- Process data and status tables, charts and graphs can be accessible with any

HTML5 browser.

- Data can be logged for export in .csv formatted files.

- Accepts 5 operating points and the BEP (Best Efficiency Point) of a pump curve to

provide feedback on operating efficiency.

Through system and equipment condition monitoring, Altivar Process can help ensure

applications are performing at optimum efficiency.

Embedded Guidance provides direction that improves uptime

Built-in functions simplify set-up and provide quick understanding.

- A Simply Start menu guides the operator through the initial set-up.

- ‘My Menu’ allows users to select their key parameters to store in this menu.

- A ‘Modified Parameters’ menu stores the last 10 parameters that have been

modified.

- Parameters are grouped by application configuration, motor parameters, commun-

cation setting parameters and display parameters. Any single or multiple parameter

group can be copied into the keypad to be downloaded into other drives.

- Integrated pump functions and pump protection features can be quickly config ured.

- Error codes can be date and time stamped to aid in diagnostics.

- QR code access to technical documentation, and diagnostic information on mobile

devices.

- A static QR code located on the drive provide part number specific information.

- The drive’s ability to dynamically generate QR codes based on error conditions

helps solve issues immediately by directing operators to specific technical

information and support information.

- These QRs can also assist in making contact with a Schneider Electric Customer

Care center when needed.

This embedded guidance can speed up start-up, troubleshooting and maintenance

while reducing downtime and its related costs.

A Reliable and Sustainable platform for long-term dependable service

The Altivar Process represents the latest in reliable and sustainable design technology. The drive complies with all aspects of Schneider Electric’s industry leading

“Green PremiumTM” standard for sustainable and eco conscious product design,

incorporating 70 percent or greater of recyclable materials and is in compliance with

RoHS 2 and REACH standards. Other key aspects are:

- Conformal coatings to provide resistance to chemical pollution. This provides

resistance against: sea salts, sulphur dioxide, hydrogen sulphide, chlorine, hydro gen chloride, hydrogen fluoride, ammonia, ozone, and nitrogen oxides.

- Conformal coatings to provide resistance to air born pollution. This provides resis tance against debris such as dust and sand.

- Stop and Go capability: Power consumption can be reduced up to 60%,

depending on the power size, while the drive is in standby, waiting for a run

command. This is accomplished by powering down cooling fans, display

backlighting, and the power section of the drive.

- Integrated safety inputs minimize external components and wiring.

- Ability of the drive to continuously operate at 50 degrees Celsius.

Long operating life and reliable service have been lasting hallmarks of the Altivar

drives family for more than 30 years. That tradition continues with the Altivar Process

drive.

8

Altivar Process 600

Introduction

variable speed drives

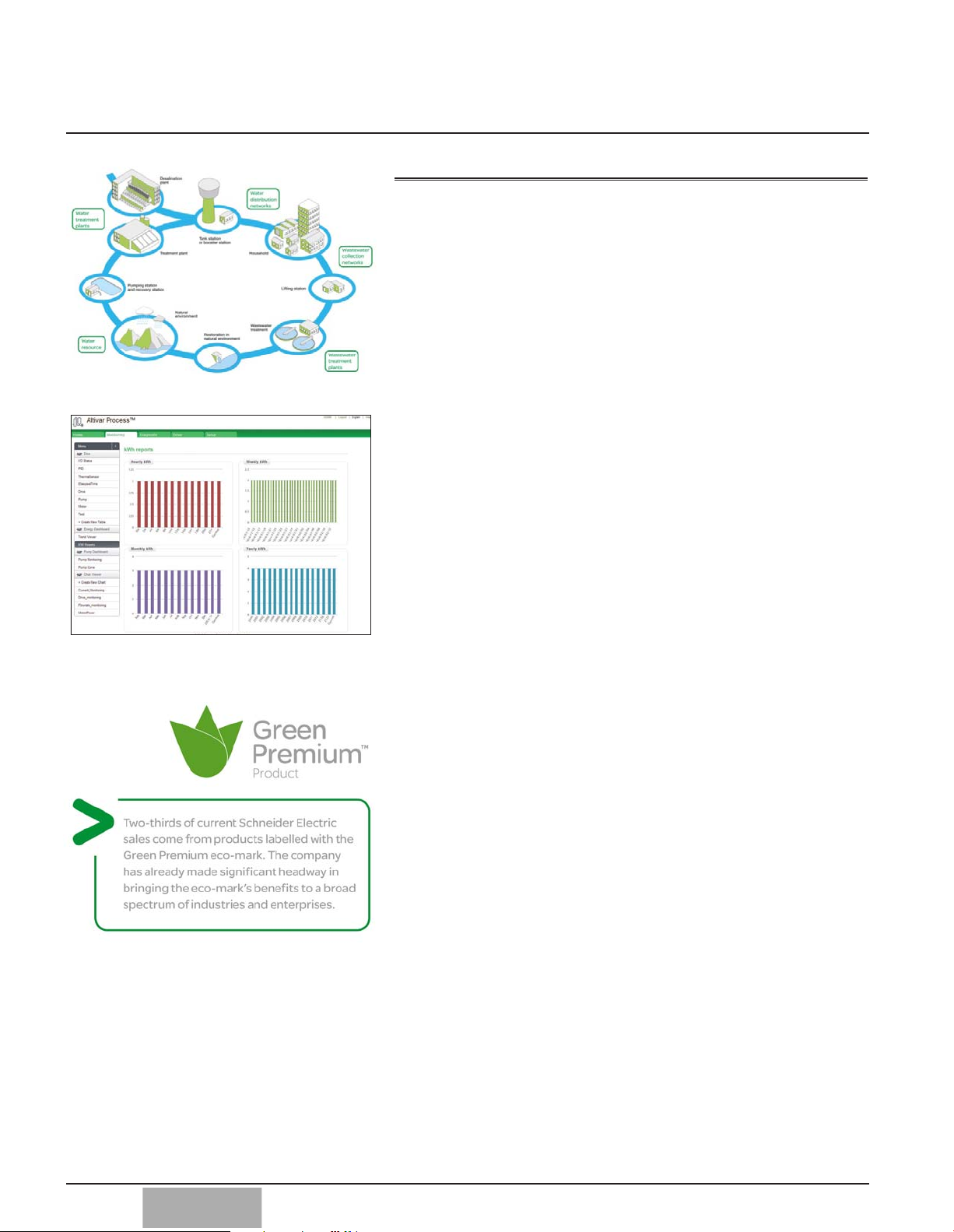

Login screen

Customizable widgets

Presentation

Web Server

Presentation

The Web server can be accessed:

Ŷ For a drive not connected to an Ethernet network:

- Direct connection via an Ethernet cable or the Schneider Electric

dongle (the drive then appears as a network device)

Ŷ For a drive connected to an Ethernet network:

- from any point on the network by entering the drive IP address

Ŷ The Web server is used for::

- Commissioning the drive (setting configuration parameters and enabling the

main functions)

- Monitoring energy and process data, as well as drive and motor data

- Diagnostics (drive status, file transfer, detected errors and warnings logs)

Description

The Web server is structured around 5 tabs.

Ŷ “My dashboard” tab:

- Configurable using a wide choice of widgets; groups all the information

selected by the user on one page

Ŷ “Display” tab:

- Monitors energy indicators, efficiency, and performance

- Displays process data such as optimum pump operation

- Monitors drive parameters and status

- Shows the I/O state and assignment

TM

WiFi

Pump curves

Ŷ “Diagnostics” tab:

- Drive status

- Time and date-stamped warning and detected errors logs

- Network diagnostics

- Access to drive self-tests

Ŷ “Drive” tab:

- Access to the main drive adjustment parameters with contextual help

Ŷ “Setup” tab:

- Network configuration

- Access management

- Transferring and retrieving drive configurations

- Exporting data acquisition files and logs

- Customizing pages (colors, logos, etc.)

Ŷ Other characteristics:

- Ease of connection via the RJ45 port or WiFi connection

- Password-protected authentication (modifiable password; access rights can

be configured by administrator)

- No downloads or installation necessary

- Web server can be disabled

Ŷ Works in a similar way on PCs, iPhones, iPads, Android systems, and the main web

browsers:

- Internet Explorer

- Google Chrome

- Mozilla Firefox

- Safari

®

(version 5.1.7 or higher)

®

(version 8 or higher)

®

(version 11 or higher)

®

(version 4 or higher)

9

Altivar Process 600

Introduction

variable speed drives

Altivar Process DTM in Unity

Presentation

DTM

Presentation

Using FDT/DTM technology it is possible to configure, control, and diagnose Altivar

Process drives directly in Unity Pro and SoMove software by means of the same

software brick (DTM).

FDT/DTM technology standardizes the communication interface between field devices

and host systems. The DTM contains a uniform structure for managing drive access

parameters.

Specific functions of the Altivar Process DTM

Ŷ Offline or online access to drive data

Ŷ Drive firmware updates

Ŷ Transfer of configuration files from and to the drive

Ŷ Customization (dashboard, My Menu, etc.)

Ŷ Acces to drive parameters and option cards

Ŷ Oscilloscope function

Ŷ Graphic interface to assist with configuration of the Altivar Process pump

functions

Ŷ Energy and process dashboards

Ŷ Graphic display of system operation and comparison with optimum operation

(pump curves)

Ŷ Detected errors and warnings logs (with timestamping)

SoMove software

Ŷ Advantages of the DTM library in Unity Pro:

- Single tool for configuration, commissioning, and diagnostics

- Network scan for automatic recognition of network configuration

- Ability to add/remove, copy/paste configuration files from other drives in

the same architecture

- Single input point for all parameters shared between the ePAC

(programmable automation controller) and the Altivar Process drive

- Creation of drive profiles for implicit communication with the ePAC as well

as dedicated profiles for programs with DFBs (derived function blocks)

- Integration in the fieldbus topology

- Drive configuration is an integral part of the Unity Pro project file (STU) and

the archive file (STA)

- Advantages of the DTM library in SoMove:

- Drive-oriented software environment

- Wired connection to the Ethernet communication port

- Standard cable (file transfer performance)

- Third-party software and downloads:

- The Altivar Process DTM library is a flexible, open, and interactive tool that

can be used in a third-party FDT.

- DTMs can be downloaded from our website

10

Altivar Process 600

Introduction

variable speed drives

Pump Functionality

Flow Limitation

Allows user to limit the flow of the system to a configured value.

Sleep/Wake Up

Manages periods where demand is low and main pumps do not need to remain

running. It saves energy and prevents premature aging. The user can select the

sleep mode activation: on sensor value, on switch or external condition, on speed,

or on power level.

Sleep Boost

When entering in Sleep mode, a boosting phase allows increasing pressure just

before stopping the pump. It prevents from quick restart in case of low demand.

Low Demand

Define periods of the application where water demand is low in order to save

energy.

Jockey Pump Control

During Sleep mode, a Jockey pump can be started to maintain emergency service

pressure or to meet a low demand.

Anti-Jam

Removes clogging substances from the pump impellers with quick forward and

reverse operation. It can be triggered automatically or manually.

Advance Sleep Checking

Used to periodically monitor demand when pump curve is flat and flow switch or

meter isn’t installed

Pipe Cleaning

Used to start the pump periodically to avoid sedimentation in the pump housing.

Centrifugal Pump Start & Stop

Defines speed profile & control the start & stop of the pump.

Multi-Pump Control (Booster) Drive to Drive

Define control of several pumps

Sensor Management

Define how the drive I/O will be used to manage pressure sensor or flow sensor

inputs.

Process Control (PID)

Maintains a process at a given pressure or flow reference in the water network.

Level Control

Used to manage an upper level limit or lower level limit of a liquid in a tank.

Friction Loss Compensation

Helps to maintain constant pressure by monitoring flow in order to compensate

pressure losses over pipes by estimating the pressure drop due to friction.

Application Modes

Define running modes of the application, control inputs and monitoring outputs

related to application.

Priming Pump Control

The priming pump maintains a supply to the inlet of the main pump by running

before the lead pump starts.

Pipe Fill

Used on the start cycle to prevent water hammer and associated mechanical

stresses in pipes when a system is filled in too quickly.

Outlet Pressure Protection

Min Pressure (detection of Pipe Burst, low outlet pressure while pump is loaded)

Max Pressure (prevention of Pipe Burst, detect running outside normal working

area)

11

Altivar Process 600

Introduction

variable speed drives

Pump Functionality

Application Units

Define units used in applications, including pressure, flow rate, temperature, and

currency.

Centrifugal Pump Characteristics

Define characteristics & configuration of a centrifugal pump

Sensorless Flow Estimation

Provides flow estimation using predefined pump curves HQ (head vs flow) or PQ

(power vs flow) entered by the user. It’s designed to work on single pump systems

without external sensor input.

PID Auto Tuning

Auto tuning of PID parameters.

Pump Cyclic Start Protection/ Pump Cycle Monitoring

Limits the number of restarts in a dedicated time period in order to avoid excess

wear to the pump.

12

Altivar Process 600

Introduction

variable speed drives

Pump Functionality

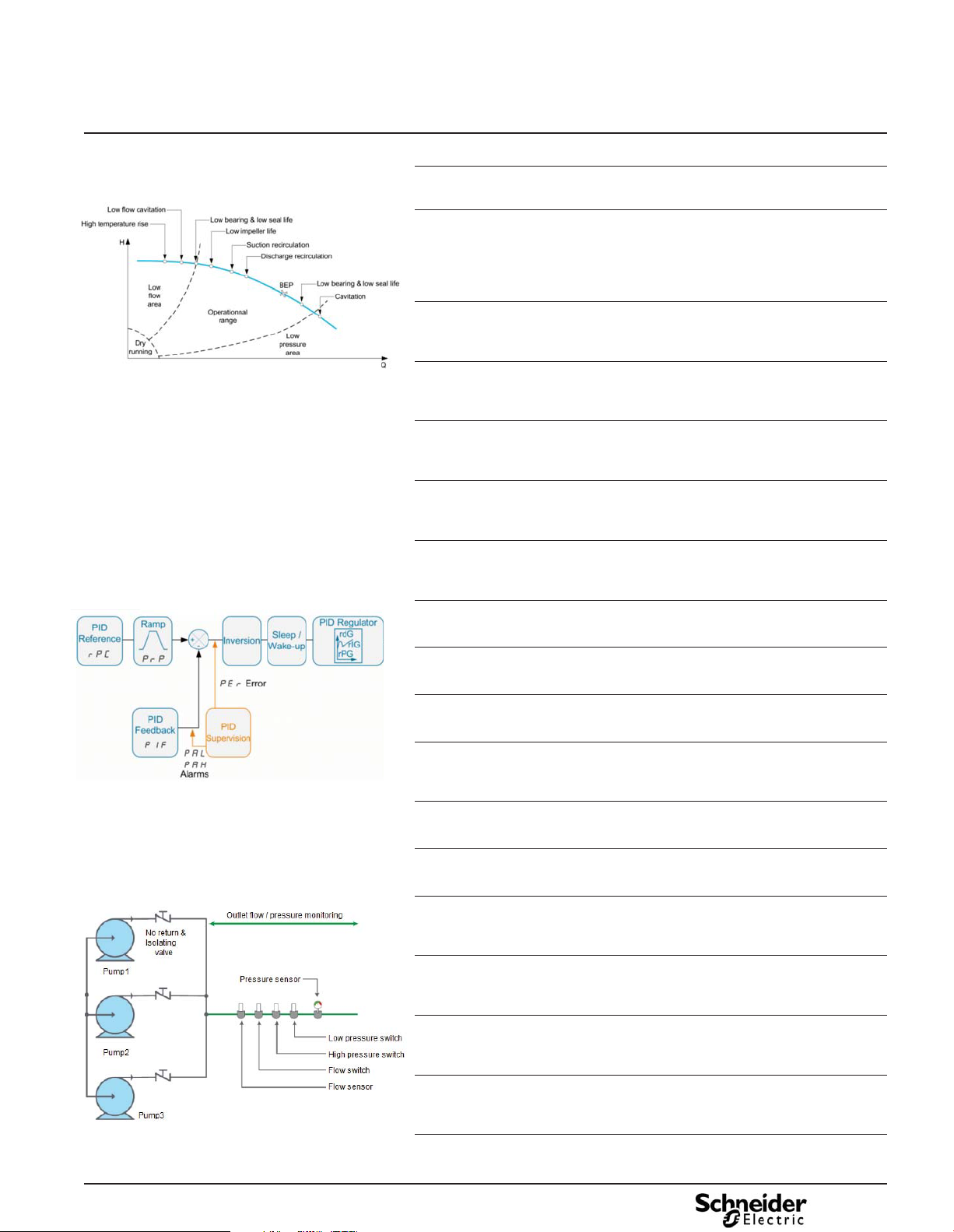

Cavitation Pump Protection

Functions used to prevent cavitation which can damage the pump impeller, reduce

flow, create vibration, and increase energy consumption.

Dry Running Pump Protection

Detects pump operation in a dry running condition to avoid severely damaging or

destroying the pump.

No Flow/ Low Flow Pump Protection

Detects pump operation at no flow or low flow to avoid severely damaging or

destroying the pump by overheating

PID Feedback Supervision

Keep pump running point in right running area. Prevention of burst pipe

High Flow Protection

Detection of Pipe Burst. Detect running outside normal working area

Inlet Pressure Protection

Protects the pump against low inlet pressure. When the inlet pressure goes below

the settable pressure, the applied pressure setpoint is decreased by the drive itself

to prevent cavitation. If the pressure setpoint is reduced, the pump speed will also

decrease.

Outlet Pressure Protection

This protection provides outlet “high pressure” and “low pressure” alarms. Used to

prevent pipe system damage or to detect burst pipes.

Low Pressure Pump Protection

Detects pump operation at low pressure in order to avoid pump damage due to

cavitation.

13

Altivar Process 600

Introduction

variable speed drives

Pump Functionality

Total Quantity

The estimated total cumulated quantity (volume or mass) when a flow rate sensor is

used. Installation related Cumulated Values & Counts are recorded for the full life of

the installation and can be reset or modified (e.g. in case of device replacement) by

customer.

Outlet Pressure

The measured pressure at outlet/discharge of the pump system or installation.

Inlet Pressure

The measured pressure at inlet/suction of the pump system or installation.

Level

The measured level of the installation when level control is activated.

Installation Flow Rate

The measured total flow rate of the installation.

Pump Status

Status of the pump controlled by VSD (Running, Stopped, Anti-Jam, Fault detected)

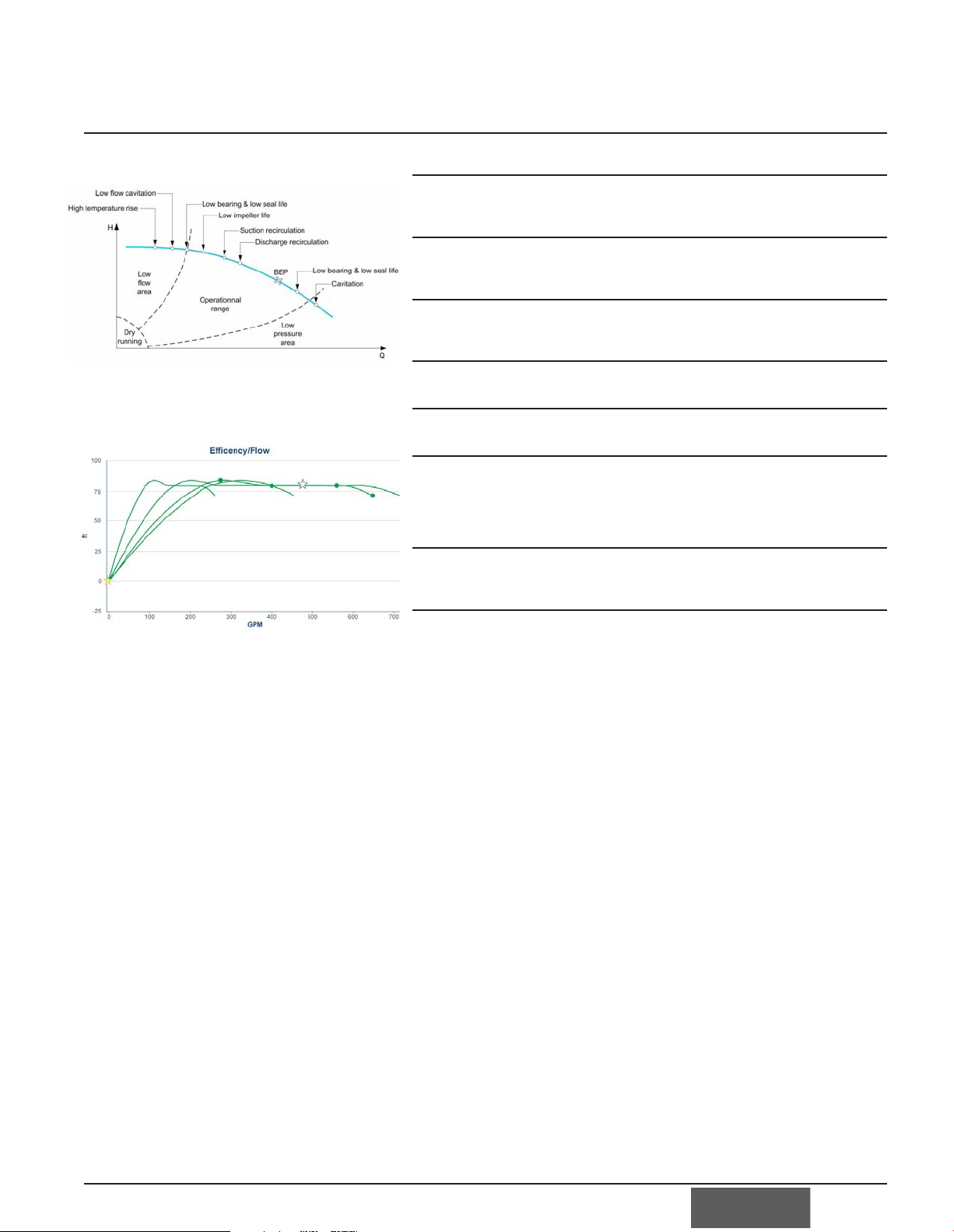

Pump Curves

User has the possibility to input 6 points from a pump curve (including BEP) for

better control and monitoring of the process. Curves can be in Head vs Flow,

Power vs. Flow, or Power vs Speed

Energy Consumption

Allows the display of several values: Instantaneous input power, Input energy

consumed, Instantaneous output power, Cumulated output energy consumed. They

can be logged and viewed by hour, week, month, and year. It can also estimate the

energy bill based on usage and rate as input by the user.

Power Drift Detection

Can manage alarms to alert user when power consumed is either too low or too high

compared to expected value

Energy Saved

The drive will display energy saved while the motor is running.

Pump Thermal Monitoring

Helps prevent equipment damage due to high temperature by monitoring the real

temperature by the drive.

Motor Thermal Monitoring

Helps prevent motor damage from overheating by an estimation of the thermal state

of the motor.

14

Altivar Process 600

Specifications

variable speed drives

Electrical Specifications

Input power

Drive output voltages

Output frequency range

Configurable switching

frequency

Speed range

Speed accuracy

Torque accuracy

Braking torque

Maximum transient

current

Voltage V 200 - 15%...240 + 10% three-phase for ATV 630pppM3

Frequency Hz 50 - 5%...60 + 5%

ATV630U07M3...D45M3

ATV630075N4…D75N4

ATV630U07M3...D22M3

ATV630U07N4...D45N4

ATV630D30M3...D45M3

ATV630D55N4...D90N4

ATV630D55M3...D75M3

ATV630C11N4...C16N4

For a torque variation of 0.2

Tn to Tn

Normal Duty Rating 110% of the nominal drive current for 60 s (typical value) with a minimum duty cycle of 10 minutes.

Electrical

380 - 15%...480 + 10% three-phase for ATV 630ppppN4

500 - 15%…690 + 10% three-phase for ATVpppY

V Maximum three-phase voltage equal to line supply voltage

Hz 0.1...500 Hz

kHz Nominal switching frequency: 4 kHz without derating in continuous operation.

Adjustable during operation from 1…16 kHz

Above 4 kHz, see the derating curves in the Installation Manual.

kHz Nominal switching frequency: 2.5 kHz without derating in continuous operation.

Adjustable during operation from 1…8 kHz

Above 2.5 kHz, see the derating curves in the Installation Manual.

kHz Nominal switching frequency: 2.5 kHz without derating in continuous operation.

Adjustable during operation from 2.5…8 kHz

Above 2.5 kHz, see the derating curves in the Installation Manual.

Asynchronous motor:

Ŷ 1…100 in open-loop mode without encoder feedback

Synchronous motor:

Ŷ 1…50 in open-loop mode without encoder feedback

± 10% of nominal slip, without encoder feedback

± 15% in open-loop mode without encoder feedback

30% of nominal motor torque without braking resistor (typical value)

130% of the nominal drive current for 2 s (typical value)

Motor control profiles

Heavy Duty Rating 150% of the nominal drive current for 60 s (typical value) with a minimum duty cycle of 10 minutes.

170% of the nominal drive current for 2 s (typical value)

Asynchronous motor:

Ŷ Voltage/frequency: quadratic, or 2 point or 5 points

Ŷ Voltage/frequency optimized for energy savings

Synchronous motor:

Ŷ Vector control for permanent magnet motors

15

Altivar Process 600

Specifications

variable speed drives

Electrical Specifications (continued)

Slip compensation

Drive noise level

ATV630D11M3 dBA 65

ATV630D15M3...D22M3 dBA 75

ATV630D30M3...D45M3 dBA 78

ATV630D55M3...D75M3 dBA 76

ATV630D15N4...D22N4 dBA 65

ATV630D30N4...D45N4 dBA 75

ATV630D55N4...D90N4 dBA 78

ATV630C11N4...C16N4 dBA 76

Indicator

Electrical impedance

Motor protection

Dielectric strength

ATV630U07M3...U55M3

ATV630U07N4...C13N4

ATV630U75M3...D55M3

ATV630C16N4

ATV630D75M3 Integrated DC choke

Electrical isolation

Acceleration and deceleration ramps

Braking to a standstill

Main drive protection and protection

features

ATV630pppM3 Between ground and power terminals: 2830 V c

Electrical

Automatic. Can be suppressed or adjusted.

Conforming to directive 86-188/EEC

1 LED red for presence of voltage

4 LEDs dual color for communication module status

3 LEDs dual color for embedded communication status

3 LEDs for local diagnostic

Integrated DC Choke

Inductance of approximately 1.5-2%

Integrated DC choke

Inductance of approximately 2.5-3%

Inductance of approximately 4%

Between power and control (inputs, outputs, power supplies)

Ramp profiles:

Ŷ Linear, can be adjusted separately from 0.01 to 9000 s

Ŷ S, U or customized

Automatic adaptation of deceleration ramp time if braking capacities exceeded,

programmable inhibition of this adaptation.

By DC injection:

Ŷ By a command on a programmable logic input

Ŷ Automatically as soon as the estimated output frequency drops to < 0.1 Hz, period

adjustable from 0 to 60 s or continuous, current adjustable from 0 to 1.1 In. for

normal duty rating and 0 to 1.4 In. for heavy duty rating.

Thermal protection:

Ŷ Drive overtemperature

Ŷ On the power stage

Protection against:

Ŷ Internal short-circuits between motor phases

Ŷ Overcurrents between output phases and ground

Ŷ Overvoltages on the DC bus

Ŷ Loss of follower signal

Ŷ Exceeding maximum speed setting

Ŷ Line supply overvoltage and undervoltage

Ŷ Input phase loss, with three-phase input

Class 10 motor thermal protection integrated in drive via continuous calculation of I

taking speed

into account:

Ŷ The motor thermal state is saved when the drive is powered down.

Ŷ Function can be modified depending on the type of

motor (force-cooled or self-cooled).

Protection against motor phase loss

Protection with user supplied PTC probes Safe Torque Off

2

t

Insulation resistance to ground

Frequency resolution

16

ATV630ppppN4 Between ground and power terminals: 3535 V c

Between ground and power terminals: 3110 V c

> 1 M:(electrical isolation) 500 V c for 1 minute

Display units Hz 0.1

Analog inputs Hz 0.012/50 Hz (12 bits)

Altivar Process 600

Specifications

variable speed drives

Environmental

Environmental Specifications

Vibration resistance

Shock resistance

Maximum ambient

pollution

Definition of insulation

Environmental

conditions

Around the device

Relative humidity

Ambient air

temperature around the

device

Maximum operating

altitude

Operating position Vertical position +/- 10 degrees

ATV630U07M 3...D45 M3

ATV630U07N 4...D 90 N4

ATV630D55M3...D75M3

ATV630C11N4...C16 N4

ATV630U07M3...D45M3

ATV630U07N4...D90N4

ATV630D55M3...D75M3

ATV630C11N4...C16N4

ATV630U07M3...D75M3

ATV630U07N4...C16N4

ATV630U07M3...D75M3,

ATV630U07N4...C16N4

ATV630U07M3...D75M3

ATV630U07N4...C16N4

Operation °C - 10…+ 50 without derating

Storage °C - 40…+ 70

ATV630U07M3...D75M3

ATV630U07N4...C16N4

1.5 mm peak to peak from 2…13 Hz, 1 gn from 13…200 Hz, conforming to IEC/EN 60068-2-6

1.5 mm peak to peak from 3…10 Hz, 0.6 gn from 10…200 Hz, conforming to IEC/EN 60068-2-6

15 gn for 11 ms conforming to IEC/EN 60068-2-27

7 gn for 11 ms conforming to IEC/EN 60068-2-27

Degree 2 conforming to IEC/EN 61800-5-1

Degree 3 in accordance with UL marking conforming to UL840

Chemical pollution resistance to class 3C3 per EN/IEC 60721-3-3.

This provides resistance against: sea salts, sulphur dioxide, hydrogen sulphide, chlorine,

hydrogen chloride, hydrogen fluoride, ammonia, ozone, and nitrogen oxides.

Air borne debris pollution resistance to class 3S3 per EN/IEC 60721-3-3.

This provides resistance against air borne debris such as dust and sand.

% 5…95% without condensation or dripping water conforming to IEC 60068-2-3

Up to 60 with derating per the derating curves in the Installation Manual.

m 1000 without derating

1000…4800 derating the current by 1% per additional 100 m.

Limited to 2000 m for the “Corner Grounded” distribution network

17

Altivar Process 600

Specifications

variable speed drives

Certifications and Compliance

Certifications and Compliance

Conformity to

standards

Protection UL508C (Standard for Power Conversion Equipment)

Conducted

EMC

emissions for

drives

ATV630U07M3...D75M3 No integrated EMC filter

ATV630U07N4...C16N4 Integrated EMC filter meets IEC/EN 61800-3:

e marking The drives are marked e according to the European low voltage (2006/95/EC) and EMC

Product certifications

Altivar Process drives have been developed to conform to the strictest standards and the

recommendations relating to electrical industrial control devices (UL,IEC, EN), in particular:

UL508C, UL50, IEC/EN 61800-5-1, and IEC/EN 61800-3.

UL 50 (Standard for Enclosures for Electrical Equipment)

IEC 61000-3-12 (Harmonic standard)

IEC/EN 61800-3, Environments 1 and 2 (EMC requirements and specific test methods)

IEC/EN 61000-4-2 level 3 (electrostatic discharge immunity test)

IEC/EN 61000-4-3 level 3 (radiated, radio-frequency, electromagnetic field immunity test)

IEC/EN 61000-4-4 level 4 (electrical fast transient/burst immunity test)

IEC/EN 61000-4-5 level 3 (surge immunity test)

IEC/EN 61000-4-6 level 3 (immunity to conducted disturbances, induced by radio-frequency

fields)

IEC/EN 61000-4-11 (voltage dips, short interruptions and voltage variations immunity tests)

EN/IEC 61800-5-1 (Standard for Adjustable Speed Electrical Power Drive Systems)

EN/IEC 62061 EN ISO 13849-1 (functional safety)

IEC 61508 (functional safety)

IEC 60721-3 (classification of environmental conditions)

IEC/EN 61800-3, environments 1 and 2, categories C2 and C3

Ŷ Category C3 with up to 150 m of cable

(89/336/EEC) dir

UL 508C, UL File E116875, CSA, TUV, REACH

ectives

Degree of protection

ATV630U07M3...D45M3

ATV630U07N4...D90N4

ATV630D55M3...D75M3 w/ optional

conduit kit

ATV630C11N4...C16N4 w/ optional

conduit kit

ATV630D55M3...D75M3

ATV630C11N4...C16N4

UL Type 1 conforming to UL 50: Standard for enclosures for Electrical Equipment.

IP 21 conforming to IEC 60529

IP21 conforming to IEC 61800-5-1

IP 00 conforming to IEC 60529

IP 00 conforming to IEC 61800-5-1

18

Altivar Process 600

Specifications

variable speed drives

I/O and Control Specifications

Description Terminal Electrical Characteristics

Available internal

supplies for analog

inputs

For external + 24 V

power supply

Analog input

Analog I/O

Common

Analog output

Analog I/O

Common

10 V, 24 V Output supply for Analog Input:

P24 External input supply +24 Vdc

0 V 0 V for P24

AI1, AI2, AI3 Software-configurable V/A : voltage or current analog input

COM 0 V for analog inputs

Other inputs Available on I/O option cards

AQ1, AQ2 AQ: Analog output software-configurable for voltage or current

COM 0 V for analog outputs

I/O and Control Specifications

10 V

Ŷ 10.5 Vdc

Ŷ Tolerance ± 5%

Ŷ Current: maximum 10 mA

Ŷ Short circuit protected

24 V

Ŷ +24 Vdc

Ŷ Tolerance: minimum 20.4 Vdc, maximum 27 Vdc

Ŷ Current: maximum 200 mA for both 24 Vdc terminals

Ŷ Terminal protected against overload and short-circuit

Ŷ In Sink Ext position, this supply is powered by external PLC supply

Ŷ Tolerance: minimum 19 Vdc, maximum 30 Vdc

Ŷ Current: maximum 1.25 A

Ŷ Voltage analog input 0...10 Vdc, impedance 30 k:,

Ŷ Current analog input X-Y mA by programming X and Y from 0...20 mA, with impedance 250 :

Ŷ Maximum sampling time: 5 ms ± 1 ms

Ŷ Resolution 12 bits

Ŷ Accuracy: ± 0.6% for a temperature variation of 60°C

Ŷ Linearity ± 0.15% of maximum value

Software-configurable for sensor inputs: PT1000 or KTY84 or PTC or Water level

sensor

Ŷ PT100

v 1 or 3 thermal sensors mounted in series (configurable by software)

v Sensor current: 5 mA

v Range –20/200°C

v Accuracy +/– 4°C for a temperature variation of 60°C

Ŷ PT1000

v 1 or 3 thermal sensors mounted in series (configurable by software)

v Thermal sensor current: 1 mA

v Range –20/200°C

v Accuracy +/– 4°C for a temperature variation of 60°C

Ŷ KTY84

v 1 thermal sensor

v Thermal sensor current: 1 mA

v Range –20/200°C

v Accuracy +/– 4°C for a temperature variation of 60°C

Ŷ PTC

v 6 sensors maximum mounted in series

v Sensor current: 1 mA

v Nominal value: < 1.5 k:

v Overheat trigger threshold: 3k:

v Overheat reset threshold: 1.8 k:

v Protected for low impedance < 50 :

Ŷ Water Level Sensor

Sensitivity: 0...1 M:, adjustable by softwar

v

v W

ater level sensor current: 0.3 mA...1 mA maximum

v Adjustable delay: 0...10 s

Ŷ Voltage analog output 0...10 Vdc, minimum. Minimum load impedance 470 :,

Ŷ Current analog output X-Y mA by programming X and Y from 0...20 mA, maximum load impedance 500 :

Ŷ Maximum sampling time: 10 ms ± 1 ms

Ŷ Resolution 10 bits

Ŷ Accuracy: ± 1% for a temperature variation of 60°C

Ŷ Linearity ± 0.2%

e

19

Altivar Process 600

variable speed drives

Specifications

Integrated communicaton ports

Modbus protocol

Type of connection Modbus RJ45 port on face of product Modbus RJ45 network port

Structure

Services

Physical interface 2-wire RS 485

Transmission mode RTU

Transmission speed Configurable via the display keypad or the

Format Fixed = 8 bits, even parity, 1 stop Configurable via the display keypad or the

Polarization No polarization impedances

Address 1 to 247, configurable via the terminal or the SoMove PC software.

Device profiles 2 profiles: CiA 402 (“Device Profile Drives and Motion Control”) and I/O profile

Messaging Read Holding Registers (03) 63 words maximum

Communication monitoring Can be inhibited.

TM

SoMove

9600 bps or 19200 bps

These should be provided by the wiring system (for example, in the master)

3 addresses can be configured in order to access the drive data, the “Controller Inside”

programmable card and the communication card respectively.

These 3 addresses are identical for the connector and network ports.

Write Single Register (06)

Write Multiple Registers (16) 61 words maximum

Read/Write Multiple Registers (23) 63/59 words maximum

Read Device Identification (43)

Diagnostics (08)

“Time out,” which can be set between 0.1 s and 30 s

PC software:

Configurable via the display keypad or the

SoMove PC software:

4800 bps, 9600 bps, 19200 bps or 38.4 kbps

SoMove PC software:

- 8 bits, odd parity, 1 stop

- 8 bits, even parity, 1 stop

- 8 bits, no parity, 1 stop

- 8 bits, no parity, 2 stop

CANopen protocol

Structure

Services

Physical Interface RJ45

Application Modbus TCP

Transport TCP/UDP

Network IP protocol V4 and V6

Link Ethernet

Transmission Speed 10/100 Mbits/s

Connections Up to 32 concurrent TCP/IP and/or TCP/UDP connections

Operating Modes Fixed, BOOTP, or DHCP

Messages DHCP?

I/O Scanning 32 in, 32 out, configurable contiguous memory locations

Profiles Native CiA402 - IEC61800-7, I/O profile

FDR Automatic data configuration for replaced devices

Web Server Configuration and diagnostics via defined page:

My Dashboard: allows customer defined views

Display: data views in table and graphical formats

Diagnostics: error code and self-evaluation

Drive: parameter configuration

Set-up: guided set-up configurations

21

Altivar Process 600

variable speed drives

Additional Application Information

Using Altivar Process 600 drives with

synchronous motors

Using special motors at high-speed

Using a motor at overspeed

Power of self-cooled motor greater than the

drive power

Connecting motors in parallel

Using a motor at constant torque up to

87/104 Hz

Altivar Process drives are also suitable for powering synchronous motors with sinusoidal electromotive force. This

drive/motor combination makes it possible to obtain remarkable accuracy and maximum torque.

The design and construction of synchronous motors are such that they offer enhanced power density, high efficiency,

and high-end torque in a compact footprint.

Driving a synchronous motor with sinusoidal electromotive force without speed feedback.

The entire range of Altivar Process variable speed drives can be used to power a synchronous motor with sinusoidal

electromotive force without speed feedback. The performance level achieved is then comparable to that obtained

with an asynchronous motor in sensorless flux vector control.

These motors are designed for constant torque applications with high frequency ranges. The Altivar Process drive

supports operating frequencies of up to 500 Hz. Through their design, this type of motor is more sensitive to

overvoltages than a standard motor.

Various solutions are available:

Ŷ Overvoltage limitation function

Ŷ Output filters

The drive’s 5-point voltage/frequency control ratio is particularly well-suited as it avoids resonance.

When using a standardized asynchronous motor at overspeed, check the mechanical overspeed characteristics of

the selected motor with the manufacturer. Above its nominal speed corresponding to a frequency of 50/60 Hz, the

motor operates with a decreasing flux, and its torque decreases significantly. The application must be able to permit

this type of low-torque, high-speed operation.

1. Machine torque (degressive torque)

2. Machine torque (low motor torque)

3. Continuous motor torque

Typical applications: wood-working machinery, polishing and cutting machines.

This motor-drive combination makes it possible to use a self-cooled motor for a greater speed range in continuous

operation. The use of a motor with a higher power rating than that of the drive is only possible if the current drawn by

this motor is less than or equal to the nominal drive current.

Note: Limit the motor power to the standard rating immediately above that of the drive.

Example: On a single machine, the use of a 2.2 kW drive combined with a 3 kW motor means that the machine can

operate at its nominal power (2.2 kW) at low speed.

1. Motor power = drive power = 2.2 kW

2. 2.2 kW drive combined with a 3 kW motor: greater speed range at 2.2 kW

The nominal current of the drive must be greater than or equal to the sum of the currents of the motors to be controlled.

In this case, provide external thermal protection for each motor using probes or thermal overload relays. For cable

runs over a certain length, taking account of all the tap links, it is advisable either to install an output filter between the

drive and the motors or to use the overvoltage limitation function.

If several motors are used in parallel, there are two possible scenarios:

Ŷ The motors have equal power ratings, in which case the torque characteristics will remain optimized after the

drive has been configured

Ŷ The motors have different power ratings, in which case the torque characteristics will not be optimized for all the

motors

A 400 V, 50 Hz motor in

In this particular case, the initial motor power and the power of the first associated drive are multiplied by (it is

therefore important to select a drive with a suitable rating).

Example: A 2.2 kW 50 Hz motor in

Note: Check the overspeed operating characteristics of the motor.

Application Information

Çconnection can be used at constant torque up to 87 Hz if it is in U connection.

Ç connection supplies 3.8 kW at 87 Hz with a U connection.

22

Altivar Process 600

variable speed drives

Application Information

Using special motors

ATEX motors in an explosive atmosphere

explosive

Resistive rotor asynchronous motors

Switching the motor at the drive output

Test on a low power motor or without a

motor

Special brake motors: tapered rotor or flux bypass

The magnetic field releases the brake. This type of operation with the Altivar Process drive requires application of the

voltage/frequency ratio.

Note: The no-load current may be high, and operation at low speed can only be intermittent.

Use of the STO safety function enables the variable speed drive to provide thermal protection in the event of

excessive temperature rise of the ATEX motor, but it does not enable it to control and regulate the temperature of the

ATEX motor.

All motor types ATEX certified for use in zones 1, 21, 2 or 22, which are equipped with ATEX thermal sensors, can be

protected by the Altivar Process variable speed drive.

Different motor control ratios available on the Altivar Process drive make it possible to apply specific settings when

using high-slip motors.

The drive can be switched when locked or unlocked. If the drive is switched on-the- fly (drive unlocked), the motor is

controlled and accelerates until it reaches the reference speed smoothly following the acceleration ramp. This use

requires configuration of the automatic catching a spinning load (“catch on the fly”) and the motor phase loss on

output cut functions.

Typical applications: loss of run circuit at drive output, bypass function, switching of motors connected in parallel.

On new installations, it is recommended that the STO safety function is used.

In a test or maintenance environment, the drive can be tested without having to use a motor with the same rating as

the drive (particularly useful in the case of high power drives). This use requires deactivation of the output phase loss

function.

23

Altivar Process 600

Application Information

variable speed drives

Motor cable length

Motor Cable Length

Impact of Long Motor Cable Lengths

Long motor cable lengths between a drive and motor may cause over current

conditions, causing the drive to trip on short circuit or ground fault errors or cause

over voltage conditions that cause premature wear on the motor. These

phenomenon are often underestimated at the design and installation stage. Left

un-checked, this neglect can lead to motor breakdown and unexpected down time.

Over current conditions may be caused by capacitive coupling between motor

cables, generating enough current flow to ground, which causes the drive to trip on

ground fault errors. Also capacitive coupling between motor cable may cause the

drive to detect and trip on short circuit errors.

Over voltage conditions may be caused by the mismatched impedance of the cable

and the motor. This mismatch of impedences causes the switching frequency pulsed

output voltage from the drive to reflect back from the motor terminals. The result can

be voltages at twice the level of the DC bus or higher, which can stress the drive,

cable, motor windings and motor bearings.

Generally, longer motor cables yield higher voltages. This effect is amplified when by

using shielded cable.

Preventative Measures

There are several steps provided below, beginning with the least costly, that can be

taken to reduce nuisance trip errors and improve the life of the motor.

Ŷ Reduce the switching frequency of the drive to 2.5kHz or less.

Ŷ Use un-shielded motor cables.

Ŷ Specifiy a drive, like the Altivar Process, that has software functionality to help

manage voltage wave reflection.

Ŷ Specify motors that are NEMA MG1 Part 31 or IEC60034-25 compliant.

Ŷ Specify output load reactors (also known as motor chokes) to limit voltage rise

time

Ŷ Specify dV/dt filters to further limit voltage rise time

Ŷ Specify Sine wave filters (also known as sinus filters) that allow a smooth, lower

voltage output wave form to the motor

Recommendations Additional Filters

The following table provides guidelines when to specify additional filters

Motor Cable Length

(unshielded cable)

1 m (3.3 ft.) < Lm <50 m (164 ft.) Filter not required dV/dt filter

50 m (164 ft.) < Lm < 100 m (328.1 ft.) Filter not required Sinus filter

100 m (328.1 ft.) < Lm < 300 m (984.3 ft.) Filter not required Sinus filter

300 m (984.3 ft.) < Lm < 500 m (1640.4 ft.) dV/dt filter Sinus filter

500 m (1640.4 ft.) < Lm < 1000 m (3280.8 ft.) Sinus filter Sinus filter

Note: When calculating cable lengths for the purpose of guarding against these overvoltage situations, a shielded

cable should count as twice the length of an unshielded cable. For example, if a shielded cable is 100 meters in

actual length, it should be considered to be equal to a 200 meter length standard cable in the calculation.

Note: In applications where one drive is used to power multiple motors in parallel, the appropriate cable length

should be calculated based on the sum of all the cables. For example, if three motors in parallel are connected to

a single drive, each with a 20 meter (66 foot) cable, the total length that should be calculated in not 20 meters, but

should be 60 meters (197 feet). Precautions must be taken to protect the VSD from any unexpected tripping.

Motor Conforming to

NEMA MG1 Part 31

Motor Not Conforming to

NEMA MG1 Part 31

24

Altivar Process 600

Graphic Display

variable speed drives

Remote graphic display terminal

(example shows dynamic pump

operation in relation to its optimum

operation)

Detected fault: the screen’s red

backlight is activated

automatically

Keypad

Graphic display Keypad

This graphic display keypad is supplied with the Alivar Process drive. This keypad

can be:

Ŷ Connected and mounted on the front of the drive

Ŷ Connected and mounted on an enclosure door using a remote mounting

accessories

Ŷ Connected to a PC to exchange files via a Mini USB/USB connection

Ŷ Connected to several drives in multidrop mode

This keypad is used to:

Ŷ Control, adjust, and configure the drive

Ŷ Display current values (motor, I/O, and process data)

Ŷ Display graphic dashboards such as the energy consumption monitoring

dashboard

Ŷ Store and download configurations (several configuration files can be stored in the

16 MB memory)

Ŷ Duplicate the configuration of one powered-up drive to another powered-up drive

Ŷ Copy configurations from a PC or drive and duplicate them on another drive (the

drives must be powered on for the duration of the duplication operations)

Other keypad characteristics:

Ŷ Integrated languages covering many countries around the world

Ŷ 2-color backlit display (white and red); if an error is detected, the red backlight is

activated automatically (This function can be disabled if needed)

Ŷ Operating range: -15...50 °C/+5...122 °F

Ŷ Type 12/ IP 65 protection

Ŷ Trend curves: graphic display of changes over time in monitoring variables, energy

data, and process data

Ŷ Graphic display of a pump’s dynamic operation in relation to its optimum operation

Ŷ Embedded dynamic QR codes for providing contextual, instantaneous access to

online help (diagnostics and settings, etc.) using a smartphone or tablet

Ŷ Real-time clock with backup battery for providing data acquisition and event

timestamping functions even when the drive is stopped

Embedded dynamic QR codes for

contextual, instantaneous access to

online help

Scanning the QR code from a

smartphone or tablet

Instant access to online help

Description

Display:

Ŷ 8 lines, 240 x 160 pixels

Ŷ Displays bar charts, gauges, and trend charts

Ŷ 4 function keys to facilitate navigation and provide contextual links for enabling

functions

Ŷ “STOP/RESET” button: local control of motor stop command/clearing detected

faults

Ŷ “RUN” button: local control of motor run command

Ŷ Navigation buttons:

Ƒ OK button: saves the current value (ENT)

Ƒ Capacitive wheel dial ±: increases or decreases the value, goes to the next or

previous line

Ƒ “ESC” button: aborts a value, parameter, or menu to return to the previous

selection

Ƒ home: root menu

Ƒ information (i): contextual help

Part Number

Description Part Number Weight

Graphic display

keypad (supplied with

drive)

VW3A1111 0.200/0.441

kg/lb

27

Altivar Process 600

Accessories & Options

variable speed drives

Mounting Options

Kit for mounting heat sink & power section

external to enclosure

This kit can be used to mount the power section of the drive outside the enclosure,

which reduces the power dissipated into the enclosure.

Kits are available for frame sizes 1-5:

ATV630U07M3...ATV630D45M3

ATV630U07N4...ATV630D90N4

With this type of mounting, the enclosure size can be reduced as the enclosure

surface area needed to dissipate the heat in the enclosure is minimized. See the

selection tables for dissipated power of the drive and power dissipated in the

enclosure when using this kit to mount the heat sink and power section out the back of

the enclosure.

The back of the enclosure must be cut to accept the metal frame that comes with the

kit.

The kit includes:

b A metal frame of the right frame size for the drive rating

b Seals

b Mounting screws

b Instruction sheet

For drives Frame Size Part number Weight

ATV630U07M3...ATV630U40M3

ATV630U07N4...ATV630U55N4

ATV630U55M3...ATV630U75M3

ATV630U75N4...ATV630D11N4

ATV630D11M3

ATV630D15N4...ATV630D22N4

ATV630D15M3...ATV630D22M3

ATV630D30N4...ATV630D45N4

ATV630D30M3...ATV630D45M3

ATV630D55N4...ATV630D90N4

lbs kg

1

2

3

4

5

NSYPTDS1

NSYPTDS2

NSYPTDS3

NSYPTDS4

NSYPTDS5

6 2.7

6.8 3.1

8.2 3.7

10.1 4.6

10.8 4.9

UL Type 1 Conduit Kit

This kit can be used with the frame size 6 Altivar Process 630 to obtain a UL Type

1 rated enclosure installation. This is kit is field installed. Frame sizes 1-5 of the

Altivar 630 range come standard with a UL Type 1 rated enclosure.

This kit is available for:

ATV630D55M3…ATV630D75M3

ATV630C11N4…ATV630C16N4.

This kit provides numerous conduit entrance knockouts to properly separate incoming line power cables, output motor cables, control wiring, and any communication

cabling.

The kit includes:

Ŷ Metal casing to fit up to the bottom of the frame size 6 Altivar Process 630

Ŷ Conduit knock-outs on the bottom of the casing

Ŷ Mounting screws

Ŷ Instruction sheet

For drives Frame Size Part number Weight

lbs kg

ATV630D55M3...ATV630D75M3

ATV630C11N4...ATV630C16N4

6 VW3A9704 - -

30

Altivar Process 600

Accessories & Options

variable speed drives

VW3A3203

Maximum Wire Size: 1.0 mm2 (AWG 16)

VW3A3203

Pin Terminal Function Electric Characteristics

Soe-configurable Voltage, current, PT100,

1 SHLD Shield connection AI4

2 AI4+

Differential Analog Input 4

Depending on SW configuration

Differential Voltage measurement

3 AI4-

4 AI4+L

5 SHLD Shield connection AI5

6 AI5+

7 AI5-

8 AI5+L

PTx measurement

0...20mA measurement

AI4- reference potential for AI4+

3 wire PTx compensation

connection

Differential Analog Input 5

Depending on SW configuration

Differential Voltage measurement

PTx measurement

0...20 mA measurement

AI5- reference potential for AI5+

3 wire PTx compensation

connection

PT1000, KTY84,

PTC measurement: Voltage differential input

circuit:

Ŷ Range: -10 Vdc...+10Vdc

Ŷ Impedance: 20k:

Ŷ Resolution: 11 bit + sign bit

Ŷ Accuracy: +/- 0.6% for a temperature

variation of 60°C

Ŷ Linearity: +/- 0.15% of max. value

Current measurement:

Ŷ Range: X-Y mA by programming X and Y

from 0 to 20 mA

Ŷ Impedance: 250:

Ŷ Resolution: 10 bit

Ŷ Accuracy: +/- 0.6% for a temperature

variation of 60°C

Ŷ Linearity: +/- 0.15% of max. value

Ŷ Sampling period: 1 ms

PTx measurement: Type of PTx and mode

selected via parameter PT100, PT1000, PTC,

KTY84

Ŷ PT100:

Ƒ 1 or 3 thermal sensors mounted in series

(configurable by software)

Ƒ Thermal sensor current: 7,5 mA max

Ƒ Range: -20...200°C

Ƒ Accuracy: +/- 3°C final for a temperature

variation of 60°C

Ŷ PT1000, KTY84:

Ƒ 1 or 3 thermal sensors mounted in series

(configurable by software)

Ƒ Thermal sensor current: 1 mA max

Ƒ Range: -20...200°C

Ƒ Accuracy: +/- 3°C final for a temperature

variation of 60°C

Ŷ PTC:

Ƒ 3 or 6 thermal sensors mounted in series

(configurable by software)

Ƒ Thermal sensor current: 1 mA max

Ƒ Nominal value: <1.5 k:

Ƒ Overheat trigger threshold: 3 k:

Overheat reset threshold: 1.8 k:

Ƒ

otected for low impedance: <50 :

Ƒ pr

Ƒ detection of high impedance: >100k:

9 DQ12 Digital output 12

10 DICOM

11 DI11 Digital input 11

12 DI12 Digital input 12

13 DI13 Digital input 13

14 DI14 Digital input 14

15 DI15 Digital input 15

16 DI16 Digital input 16

17 DQCOM

18 DQ11 Digital output 11

Digital input common

Reference potential for the digital

inputs

Digital output common

Reference potential for the digital

outputs

Note: Only one VW3A3203 can be installed for one drive

The levels of the digital 24 Vdc output signals

DQ, comply with IEC/EN61131-2 standard

Ŷ Logic Type selected via DQCOM wiring

Ŷ Output voltage: d 30Vdc

Ŷ Switching current: d 100mA

Ŷ Voltage drop at 100 mA load: d 3Vdc

Ŷ Sampling period: 1 ms

The levels of the digital 24 Vdc input signals

DI, comply with IEC/EN61131-2 standard

Ŷ Logic Type selected via DICOM wiring

Ŷ Positive logic (Source): State 0 if d 5Vdc,

state 1 if t11Vdc

Ŷ Negative logic (Sink): State 0 if t16Vdc,

state 1 if d 10Vdc

Ŷ Maximum voltage: 30 Vdc

Ŷ Input current (typical): 2.5 mA

Ŷ Sampling period: 1 ms

The levels of the digital 24 Vdc output signals

DQ, comply with IEC/EN61131-2 standard

Ŷ Logic Type selected via DQCOM wiring

Ŷ Output voltage: d 30Vdc

Ŷ Switching current: d 100mA

oltage drop at 100 mA load: d

Ŷ V

Ŷ Sampling period: 1 ms

3Vdc

33

Altivar Process 600

Accessories & Options

variable speed drives

VW3A3204

Maximum Wire Size: 1.5 mm2 (AWG 16)

VW3A3204

Pin Terminal Function Electric Characteristics

Programmable Output Relay 4:

1 R4A

NO contact of relay R4

2 R4C

3 R5A

NO contact of relay R5

4 R5C

5 R6A

NO contact of relay R6

6 R6C

Note: Only one VW3A3204 can be installed for one drive

Ŷ Min. switching current: 5 mA for 24 Vdc

Ŷ Max. switching current on resistive load:

(cos =1): 3 A for 250 Vac and 30 Vdc

Ŷ Max. switching current on inductive load:

(cos =0.4 and L/R= 7 ms): 2 A for 250 Vac and

30 Vdc

Ŷ Refresh time: 5 ms +/- 0.5 ms

Ŷ Service life: 100,000 operations at max

switching power

Programmable Output Relay 5:

Ŷ Min. switching current: 5 mA for 24 Vdc

Ŷ Max. switching current on resistive load:

(cos =1): 3 A for 250 Vac and 30 Vdc

Ŷ Max. switching current on inductive load:

(cos =0.4 and L/R= 7 ms): 2 A for 250 Vac and

30 Vdc

Ŷ Refresh time: 5 ms +/- 0.5 ms

Ŷ Service life: 100,000 operations at max

switching power

Programmable Output Relay 6:

Ŷ Min. switching current: 5 mA for 24 Vdc

Ŷ Max. switching current on resistive load:

(cos =1): 3 A for 250 Vac and 30 Vdc

Ŷ Max. switching current on inductive load:

(cos =0.4 and L/R= 7 ms): 2 A for 250 Vac and

30 Vdc

Ŷ Refresh time: 5 ms +/- 0.5 ms

Ŷ Service life: 100,000 operations at max

switching power

34

Altivar Process 600

Accessories & Options

variable speed drives

PF140354

Communication Networks

Communication buses and networks

Altivar Process drives have 3 built-in RJ45 communication ports as standard:

Ŷ 1 Ethernet port

Ŷ 2 serial ports

Integrated communication protocols

Altivar Process drives integrate the Modbus TCP and Modbus serial link

communication protocols as standard.

Ŷ Ethernet port

This offers standard services regularly used in industrial networks:

Ƒ Modbus TCP message handling is based on the Modbus protocol and is used to

exchange process data with other network devices (e.g., a PLC). It provides

Altivar Process drives with access to the Modbus protocol and to the high

performance of the Ethernet network, which is the communication standard for

numerous devices.

Ƒ SNMP (Simple Network Management Protocol) offers standard diagnostics

services for network management tools.

Ƒ The FDR (Fast Device Replacement) service allows automatic reconfiguration of a

new device installed to replace an existing device.

Ƒ Possibility to reinforce device security by disabling some unused services as well

as managing a list of authorized devices.

Ƒ Setup and adjustment tools (SoMove, Unity with DTM) can be connected locally

or remotely.

Ƒ The embedded Web server is used to display operating data and dashboards as

well as configure and diagnose process elements from any web browser.

- These numerous services offered by the Ethernet port mean that Altivar

Process drives can be integrated into Schneider Electric solutions.

Ŷ Serial ports

Ƒ One port dedicated to field network operation for exchanging data with other

devices via the Modbus protocol

Ƒ A second dedicated port for the multidrop connection of the following HMIs and

configuration tools:

- the remote graphic display terminal supplied with the drive

- a Magelis industrial HMI terminal

- a PC with SoMove or Unity setup software

1

The detailed specifications for the Ethernet or serial communication ports, and the

Modbus and Modbus TCP protocols are available on our website

2

3

4

Description

5

6

1 RJ45 Ethernet port

2 RJ45 serial port

3 Slot A for I/O expansion or communication cards

4 Slot B for I/O expansion cards

5 Removable screw terminal blocks for 24 V c power supply and integrated I/O

6 RJ45 serial link for HMI (remote graphic display terminal, Magelis terminal, etc.)

Altivar Process drives can only take one communication card, in slot A 3 only.

They cannot take 2 cards of the same type (e.g., 2 logic and analog I/O cards or 2

relay output cards).

The drives can take one logic and analog I/O card and one relay output card in either

slot A 3 or slot B 4.

Note: The user manuals and description files (gsd, eds, xif) for devices on the

communication buses and networks are available on our website www.schneider

electric.com.

-

35

Altivar Process 600

Accessories & Options

variable speed drives

Communication Card Options

Optional communication cards

Altivar Process drives can also be connected to other industrial communication buses

and networks using one of the communication cards available as an option.

Communication cards are supplied in “cassette” format for ease of mounting/removal.

Dedicated communication cards:

Ŷ EtherNet/IP and Modbus TCP dual port

Ŷ CANopen:

Ƒ RJ45 daisy chain

Ƒ SUB-D

Ƒ Screw terminals

Ŷ ProfiNet

Ŷ PROFIBUS DP V1

Ŷ DeviceNet

ProfiNet and PROFIBUS DP V1 cards also support the Profidrive and CiA402 profiles.

It is possible to maintain communication using a separate power supply for the control

and power sections. Monitoring and diagnostics are possible via the network even if

there is no power supply to the power section.

Functions

All drive functions can be accessed via the various communication networks:

Ŷ Configuration

Ŷ Adjustment

Ŷ Control

Ŷ Monitoring

Altivar Process drives offer a high degree of interfacing flexibility with the possibility to

assign, by configuration, the different control sources (I/O, communication networks,

and HMI terminal) to control functions in order to meet the requirements of complex

applications.

Network services and parameters are configured using the SoMove drive setup

software, or in Unity software if the drive is being integrated into a PlantStruXure

architecture.

Communication is monitored according to the specific criteria for each protocol.

However, regardless of the protocol, it is possible to configure how the drive responds

to a detected communication interruption, as follows:

Ŷ Define the type of stop when a communication interruption is detected

Ŷ Maintain last command received

Ŷ Fallback position at preset speed

Ŷ Ignore the detected communication interruption

36

Altivar Process 600

variable speed drives

Outline of Test Process and Procedures

Printed circuit board testing, dielectric testing, preliminary memory and functional test, unit operation with burn-in testing, and final

verification testing are conducted at various points in the manufacturing process for each drive. All aspects of these tests during the

assembly are logged electronically for internal tracking purposes. Each unit is checked and product conformance status is recorded

at each test station. Appropriate conformance information is carried in nonvolatile memory within each unit. The sequence of testing

is monitored. Each test station requires a successful bar code scan on entry to validate that each drive has successfully completed

any prerequisite test stations.

In addition to the processes and procedures detailed below, each test station has a visual quality inspection check list. This check list

includes a physical inspection for proper connections, power component polarities, proper assembly torques, mechanical integrity,

and proper documentation.

Quality Assurance

Quality Assurance

This document communicates a summary of the processes, procedures and

quality assurance

Altivar Process 600 drives are produced in ISO certified facilities. Customers can

be assured that these

by third party representatives verify documented processes and procedures are

followed

assurance processes and procedures to verify the integrity of components and

the assembly process. Data is gathered on each unit and tracked via the

serial number of each unit during the manufacturing process. The document

was not intended

communicated externally nor that a written report is generated for each product.

and

that

are in place for the manufacturing of the Altivar Process 600.

processes

provide certification to ISO 14001. Schneider Electric utilizes quality

to

imply this data is available in a format that could be easily

and procedures are followed. Audits

conducted

unique

Printed Circuit Board Testing

Printed circuit boards used in the assembly of the ATV61 undergo testing as a part of the board assembly. These tests include:

Ŷ In-circuit, component level testing

Ŷ Functional power-on testing

Ŷ Thermal-cycle stress testing

Ŷ High-potential test applied to high voltage boards

Dielectric Testing (Hi Pot Test)

This test verifies the dielectric withstand between customer connection points and ground to validate that required isolation barriers

are intact. Isolation barriers are typically tested for a duration of one (1) second during which a high voltage is applied according to

lEC 61800-5-1 standard. This station is also used to verify placement of the power circuit connections.

Preliminary memory and functional testing

During this test, the unit’s on-board communication port is utilized to read internal memory and set aside a portion of memory to track

the processes preformed on the drive and its main components. Each tracked process must have been completed successfully to

proceed. These include:

Ŷ Supplier preformed tests of printed circuit boards with on-board memory.

Ŷ Successful drive hi-pot test.

A preliminary test is run to verify:

Ŷ Heatsink ground screw presence

Ŷ RFI filter jumper setting

Ŷ DC bus jumper presence

Ŷ EEPROM test

Ŷ Product rating verification

Ŷ Initial rating verification

Ŷ Analog input calibration

Ŷ Analog output calibration

Ŷ Self test (verification of the display board and control terminal board.)

Ŷ Pre-motor test

42

Loading...

Loading...