ype S Contactors and Starters

T

Class 8536/8502/8736/8702/8810/8811/8812

CONTENTS

Description

Magnetic Contactors and Starters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Reversing Magnetic Starters and Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Motor Starters Multi-Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Page

Contents

SECTION 1 – MAGNETIC CONTACTORS AND STARTERS

Application Data – Class 8502, 8536. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Selection – Class 8502 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Selection – Class 8536 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Application Data – Class 8502, 8536. . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Approximate Dimensions, Shipping Weights – Class 8502, 8536 . . . . 17-22

Application Data – Class 8502 Vacuum Contactors. . . . . . . . . . . . . . . . . .23

Selection and Pricing – Class 8502 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5/98

© 1998 Square D All Rights Reserved

1

Full Voltage Contactors and Starters — NEMA

Application Data – Class 8502, 8536

Type SCO2

Size 1, 3-Pole Contactor

Type SCO3

Size 1, 3-Pole Starter

Starter with MOTOR LOGIC

Starter with Melting Alloy

AC MAGNETIC CONTACTORS CLASS 8502

General Information

Class 8502 Type S magnetic contactors are used

to switch heating loads, capacitors, transformers,

and electric motors where overload protection is

separately provided. Class 8502 contactors are

available in NEMA Sizes 00-7. Type S contactors

are designed for operation at 600 Volts, AC 50-60

Hertz.

Holding Circuit Contact

A normally open holding circuit contact for three

wire control is provided on all contactors as

standard. Siz es 00-2 contactors use a Class 9999

SX11 auxiliary contact as the holding circuit

contact. Sizes 3-7 contactors use a Class 9999

SX6 auxiliary contact as the holding circuit

contact. See Class 9999 for the holding circuit

contact electrical ratings. On Size 00-1 single

phase contactors, a power pole is used as the

holding circuit contact and therefore has the same

rating as the power contacts.

Enclosures

Class 8502 magnetic contactors are available in

the following enclosures:

• NEMA Type 1 General Purpose

• NEMA Type 4 & 4X Watertight and Dusttight

Stainless Steel

• NEMA Type 4X Watertight, Dusttight, and

Corrosion Resistant Glass — Polyester

• NEMA Type 7 & 9 Bolted and Spin-Top for

Hazardous Locations

• NEMA Type 12 Dusttight and Driptight for

Industrial Use

The NEMA Type 4 & 4X stainless steel enclosure

(Sizes 0-5) has a brushed finish. For an

electropolished finish, specify Form G16 and add

15% to the price of the standard device.

Also, NEMA Type 12 devices are available UL

Listed for use in Class II, Division 2, Group G and

Class III, Divisions 1 and 2 locations. Request

Form G21, no additional charge.

Separate enclosures are available, see Class

9991.

AC MAGNETIC STARTERS CLASS 8536

General Information

Class 8536 Type S magnetic starters are used for

full voltage starting and stopping AC squirrel cage

motors. Motor overload protection is provided by

melting alloy type thermal overload relays. Class

8536 starters are available in NEMA Sizes 00-7.

Type S starters are designed f or operation at 600

Volts AC, 50-60 Hertz.

Holding Circuit Contact

A normally open holding circuit contact for three

wire control is provided on all contactors as

standard. Siz es 00-2 contactors use a Class 9999

SX11 auxiliary contact as the holding circuit

contact. Sizes 3-7 contactors use a Class 9999

SX6 auxiliary contact as the holding circuit

contact. See Class 9999 for the holding circuit

contact electrical ratings.

Overload Relays with Melting Alloys

Class 8536 Type S Sizes 00-6 starters are

provided with a melting alloy thermal overload

relay as standard. Interchangeable thermal units

are available in standard trip (Class 20) Sizes

00-6, quick trip (Class 10) Sizes 00-4, and slow

trip (Class 30) Sizes 00-3. Single-phase starters

use one thermal unit, 3-phase starters use three

thermal units.

Class 8536 Size 7 starters are provided with solid

state Motor Logic which has selectable trip

Class10/20, Ground fault detection, and

Communication capabilities for future

enhancement. The solid state overload relay is

ambient insensitive and features phase loss,

phase unbalance and over-current protection.

MOTOR LOGIC™ Solid State Overload Relay (SSOLR)

Solid state overload relays are a vailab le f or Siz es

00 – 7 starters. These ambient insensitive

overload relays provide phase loss protection,

phase unbalance protection and a LED power

indicator. For additional inf ormation, see the Class

9065 catalog section. To order Type S starters

with solid state overload relays, see Factory

Modification (FORMS).

Bimetallic overload relays are also available for

Sizes 0-6. Ambient Compensated and Noncompensated versions are supplied with manual

2

© 1998 Square D All Rights Reserved

5/98

Full Voltage Contactors and Starters — NEMA

Application Data – Class 8502, 8536

and automatic reset, trip current adjustment, and

an alarm contact on Sizes 0-2. For additional

information, see the Class 9065 catalog section.

To order Type S starters with bimetallic overload

relays, see Factory Modifications (FORMS).

Enclosures

Class 8536 magnetic starters are available in the

following enclosures.

• NEMA Type 1 General Purpose Enclosure

• NEMA Type 3R Rainproof, Sleet Resistant for

Outdoor Use

• NEMA Type 4 & 4X Watertight and Dusttight

• NEMA Type 4X Watertight, Dusttight, and

Corrosion Resistant Glass – Polyester

• NEMA Type 7 & 9 Bolted and Spin-Top for

Hazardous Locations

• NEMA Type 9 Bolted for Hazardous Locations

• NEMA Type 12 Dusttight and Driptight for

Industrial Use

The NEMA Type 4 & 4X stainless steel enclosure

(Sizes 0-5) has a brushed finish. For an

electropolished finish, specify Form G16 and add

15% to the price of the standard device. Sizes 6 &

7 are painted sheet steel and are rated NEMA 4

ONLY.

Also NEMA Type 12 devices are available UL

Listed for use in Class II, Division 2, Group G and

Class III, Divisions 1 and 2 locations. Specify

Form G21, no additional charge.

Coil V oltages

AC coils are available for application on 50-60

Hertz. NEMA Sizes 00-5 are supplied with coils

that are designed to operate satisfactorily on line

voltages of 85% – 110% of rated voltage. NEMA

Size 6 and 7 contactors are supplied with a DC

coil operated by a solid state rectifier circuit that is

powered by an AC source.

Please note that

added to the Type designations in order to

improve customer service. It is necessary to

include the Voltage Code when ordering

contactors and starters. Also , 120 Volt Polyphase

contactors and starters will be wired for separate

control.

Auxiliary Contacts

Additional auxiliary contacts may be added to

Type S contactors. See Page 15 for maximum

number of auxiliary units and Form designations

for factory installed auxiliary contacts.

Type S Accessories

Additional accessories such as power poles,

pneumatic timer attachments, and cover mounted

control stations are available as factory or field

modifications.

Voltage Codes

have been

5/98

Separate enclosures are available, see Class

9991.

© 1998 Square D All Rights Reserved

3

24 q

q

f

j

t

Full Voltage Contactors — NEMA

Selection – Class 8502

3-Pole Polyphase — 600 Volts AC Maximum — 50-60 Hertz

Continuous

Current

Ratings

Size 6 and 7 are painted sheet steel rated NEMA Type 4 only.

120 Volt Polyphase contactors are wired for separate control.

Coil voltage code must be specified to order this product. Refer to standard voltage codes listed below and insert as shown in How to Order.

Type SC02

Size 1, 3-Pole Contactor

NEMA

Size

00 9

018

127

245

390

4 135

5 270

6 540

7 810

Coil V oltage Codes

NEMA Type 4 & 4X

Watertight, Dusttight

Brushed Stainless

Steel Enclosure

(Size 0-5)

Motor Volts Max. HP

t

Coil Volta ge

Open Type

NEMA Type 1

General

Purpose

Enclosure

Type Type Type

Separate Control j

200 1

230 1

460 2 480 SAO12V06 SAG12V06

575 2 600 SAO12V07 SAG12V07

Separate Control j

200 3 208 SBO2V08 SBG2V08 SBW12V08

230 3 240 SBO2V03 SBG2V03 SBW12V03

460 5 480 SBO2V06 SBG2V06 SBW12V06

575 5 600 SBO2V07 SBG2V07 SBW12V07

Separate Control

200 7

230 7

460 10 480 SCO2V06 SCG2V06 SCW12V06

575 10 600 SCO2V07 SCG2V07 SCW12V07

Separate Control j

200 10 208 SDO2V08 SDG2V08 SDW12V08

230 15 240 SDO2V03 SDG2V03 SDW12V03

460 25 480 SDO2V06 SDG2V06 SDW12V06

575 25 600 SDO2V07 SDG2V07 SDW12V07

Separate Control j

200 25 208 SEO2V08 SEG2V08 SEW12V08

230 30 240 SEO2V03 SEG2V03 SEW12V03

460 50 480 SEO2V06 SEG2V06 SEW12V06

575 50 600 SEO2V07 SEG2V07 SEW12V07

Separate Control j

200 40 208 SFO2V08 SFG2V08 SFW12V08

230 50 240 SFO2V03 SFG2V03 SFW12V03

460 100 480 SFO2V06 SFG2V06 SFW12V06

575 100 600 SFO2V07 SFG2V07 SFW12V07

Separate Control j

200 75 208 SGO2V08 SGG2V08 SGW12V08

230 100 240 SGO2V03 SGG2V03 SGW12V03

460 200 480 SGO2V06 SGG2V06 SGW12V06

575 200 600 SGO2V07 SGG2V07 SGW12V07

Separate Control j

200 150 208 SHO2V08 SHG2V08 SHW12V08

230 200 240 SHO2V03 SHG2V03 SHW12V03

460 400 480 SHO2V06 SHG2V06 SHW12V06

575 400 600 SHO2V07 SHG2V07 SHW12V07

Separate Control j

200 . . . 208 SJO2V08 SJG2V08 SJW12V08

230 300 240 SJO2V03 SJG2V03 SJW12V03

460 600 480 SJO2V06 SJG2V06 SJW12V06

575 600 600 SJO2V07 SJG2V07 SJW12V07

1

⁄

2

1

⁄

2

j

1

⁄

2

1

⁄

2

120 SAO12V02S SAG12V02S

208 SAO12V08 SAG12V08

240 SAO12V03 SAG12V03

120 SBO2V02S SBG2V02S SBW12V02S

120 SCO2V02S SCG2V02S SCW12V02S

208 SCO2V08 SCG2V08 SCW12V08

240 SCO2V03 SCG2V03 SCW12V03

120 SDO2V02S SDG2V02S SDW12V02S

120 SEO2V02S SEG2V02S SEW12V02S

120 SFO2V02S SFG2V02S SFW12V02S

120 SGO2V02S SGG2V02S SGW12V02S

120 SHO2V02S SHG2V02S SHW12V02S

120 SJO2V02S SJG2V02S SJW12V02S

USE Size 0

f

4

File E78351

CCN NLDX

File LR12751

Class 3211-04

File 60905

Class 3211-04

IEC 947-4-1

Sizes 00-5 only

Voltage

60 Hz 50 Hz

120 110 VO2

208 . . . VO8

240 220 VO3

480 440 VO6

600 550 VO7

Specify Specify V99

24 V coils are not availab le on Sizes 4-7. On Sizes 00-3, where 24 V

coils are available, Form S (separate control) must be specified.

. . . VO1

Code

How to Order:

To Order Specify: Catalog Number

• Class Number

• T ype Number

• Coil Voltage Code

• Form(s)

Class Type Coil

8502 SBG2 VO2 P1S

Voltage

Code

© 1998 Square D All Rights Reserved

Form(s)

Factory Modifications (FORMS) ...............Refer to Catalog 9999CT9701

Application Data ...................................................................Pages 13-16

Dimensions ...........................................................................Pages 17-20

Separate Enclosures (Class 9991) ...........Refer to Catalog 9999CT9701

Replacement Parts (Class 9998) ..............Refer to Catalog 9999CT9701

Type S Accessories (Class 9999) .............Refer to Catalog 9999CT9701

5/98

3-Pole Polyphase — 600 Volts AC Maximum — 50-60 Hertz

j

c

t

24 q

q

Full Voltage Contactors — NEMA

Selection – Class 8502

NEMA Type 4X

Watertight, Dusttight,

Corrosion-Resistant

NEMA

Size

Continuous

Current

Ratings

Motor

Volts

Max.

HP

t

Coil

Voltage

Glass-Polyester

Enclosure

Type

Separate Control j 120

00 9

018

127

245

390

4 135

5 270

6 540

7 810

120 Volt Polyphase contactors are wired for separate control.

Limited to one Pilot Light and a Selector Switch or Start-Stop Push Button.

Coil voltage code must be specified to order this product. Ref er to standard coil voltage codes listed in selection tab le abov e or additional standard voltage codes belo w and insert as shown

in the HOW TO ORDER block.

200 1

230 1

460 2 480

575 2 600

Separate Control j 120 SBW22V02S SBT2V02S SBT42V02S SBR2V02S SBA2V02S

200 3 208 SBW22V08 SBT2V08 SBT42V08 SBR2V08 SBA2V08

230 3 240 SBW22V03 SBT2V03 SBT42V03 SBR2V03 SBA2V03

460 5 480 SBW22V06 SBT2V06 SBT42V06 SBR2V06 SBA2V06

575 5 600 SBW22V07 SBT2V07 SBT42V07 SBR2V07 SBA2V07

Separate Control j 120 SCW22V02S SCT2V02S SCT42V02S SCR2V02S SCA2V02S

200 7

230 7

460 10 480 SCW22V06 SCT2V06 SCT42V06 SCR2V06 SCA2V06

575 10 600 SCW22V07 SCT2V07 SCT42V07 SCR2V07 SCA2V07

Separate Control j 120 SDW22V02S SDT2V02S SDT42V02S SDR2V02S SDA2V02S

200 10 208 SDW22V08 SDT2V08 SDT42V08 SDR2V08 SDA2V08

230 15 240 SDW22V03 SDT2V03 SDT42V03 SDR2V03 SDA2V03

460 25 480 SDW22V06 SDT2V06 SDT42V06 SDR2V06 SDA2V06

575 25 600 SDW22V07 SDT2V07 SDT42V07 SDR2V07 SDA2V07

Separate Control j 120 SEW22V02S

200 25 208 SEW22V08 SET42V08 SER2V08 SEA2V08

230 30 240 SEW22V03 SET42V03 SER2V03 SEA2V03

460 50 480 SEW22V06 SET42V06 SER2V06 SEA2V06

575 50 600 SEW22V07 SET42V07 SER2V07 SEA2V07

Separate Control j 120 SFW22V02S

200 40 208 SFW22V08 SFT42V08 SFR2V08 SFA2V08

230 50 240 SFW22V03 SFT42V03 SFR2V03 SFA2V03

460 100 480 SFW22V06 SFT42V06 SFR2V06 SFA2V06

575 100 600 SFW22V07 SFT42V07 SFR2V07 SFA2V07

Separate Control j 120

200 75 208 SGR2V08 SGA2V08

230 100 240 SGR2V03 SGA2V03

460 200 480 SGR2V06 SGA2V06

575 200 600 SGR2V07 SGA2V07

Separate Control j 120

200 150 208 SHA2V08

230 200 240 SHA2V03

460 400 480 SHA2V06

575 400 600 SHA2V07

Separate Control j

200 — 208 SJA2V08

230 300 240 SJA2V03

460 600 480 SJA2V06

575 600 600 SJA2V07

Coil V oltage Codes

1

⁄

208

2

1

⁄

240

2

1

⁄

208 SCW22V08 SCT2V08 SCT42V08 SCR2V08 SCA2V08

2

1

⁄

240 SCW22V03 SCT2V03 SCT42V03 SCR2V03 SCA2V03

2

Use Size 0 Use Size 0 Use Size 0 Use Size 0

. . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . .

Explosion Proof Units

NEMA Type 7 & 9

Hazardous Locations

Class I, Groups C & D

Class II, Groups E, F, & G

Bolted Type

Cast Iron c

. . .

. . .

Cast

Aluminum

SET42V02S SER2V02S SEA2V02S

SFT42V02S SFR2V02S SFA2V02S

NEMA Type 12

Dusttight & Driptight

Industrial Use Enclosure

SPIN TOP

Type

SGR2V02S SGA2V02S

®

Type

SHA2V02S

SJA2V02S

Voltage

60 Hz 50 Hz

120 110 VO2

208 . . . VO8

240 220 VO3

480 440 VO6

600 550 VO7

Specify Specify V99

24 V coils are not availab le on Sizes 4-7. On Sizes 00-3, where 24 V

coils are available, Form S (separate control) must be specified.

Factory Modifications (FORMS) ...............Refer to Catalog 9999CT9701

Application Data ....................................................................Pages 13-16

Dimensions ............................................................................Pages 17-20

Separate Enclosures (Class 9991) ...........Refer to Catalog 9999CT9701

Replacement Parts (Class 9998) ..............Refer to Catalog 9999CT9701

Type S Accessories (Class 9999) ............Refer to Catalog 9999CT9701

. . . VO1

Code

5/98

File E78503

CCN NPKR

File LR60905

Class 3218-03

How to Order:

To Order Specify: Catalog Number

• Class Number

• T ype Number

• Coil Voltage Code

• Form(s)

© 1998 Square D All Rights Reserved

Class Type Coil

8502 SBA2 VO2 P1S

Voltage

Code

Form(s)

5

Full Voltage Contactors — NEMA

Selection – Class 8502

600 Volts AC Maximum — 50-60 Hertz

NEMA

Size

1-Pole Single Phase

018

127

2-Pole Single Phase

00 9

018

127

245

3 90 . . . . . .

4 135 . . . . . .

5 270 . . . . . .

6 540 . . . . . .

7 810 . . . . . .

4-Pole Polyphase

018

127

245

390

4 135

5-Pole Polyphase

018

127

245

390

4 135

f

j

t

Continuous

Current

Ratings

Size 6 and 7 are painted sheet steel rated NEMA Type 4 only.

120 Volt Polyphase contactors are wired for separate control.

Coil voltage code must be specified to order this product. Refer to standard voltage codes listed in selection table above or additional standard

voltage codes and insert as shown in the HOW TO ORDER block on Page 5.

t

NEMA Type 4 & 4X

Watertight, Dusttight

Brushed Stainless

Steel Enclosure

(Size 0-5)

Motor Volts Max. HP

Coil Volta ge

Open Type

NEMA Type 1

General

Purpose

Enclosure

Type Type Type

115 1 120 SBO5V02 SBG5V02 SBW15V02

230 2 240 SBO5V03 SBG5V03 SBW15V03

115 2 120 SCO5V02 SCG5V02 SCW15V02

230 3 240 SCO5V03 SCG5V03 SCW15V03

115

230 1 240 SAO11V03 SAG11V03

115 1 120 SBO1V02 SBG1V02 SBW11V02

230 2 240 SBO1V03 SBG1V03 SBW11V03

115 2 120 SCO1V02 SCG1V02 SCW11V02

230 3 240 SCO1V03 SCG1V03 SCW11V03

115 3 120 SDO1V02 SDG1V02 SDW11V02

230 7

Separate Control

200 3 208 SBO3V08 SBG3V08 SBW13V08

230 3 240 SBO3V03 SBG3V03 SBW13V03

460 5 480 SBO3V06 SBG3V06 SBW13V06

575 5 600 SBO3V07 SBG3V07 SBW13V07

Separate Control

200 7

230 7

460 10 480 SCO3V06 SCG3V06 SCW13V06

575 10 600 SCO3V07 SCG3V07 SCW13V07

Separate Control j

200 10 208 SDO3V08 SDG3V08 SDW13V08

230 15 240 SDO3V03 SDG3V03 SDW13V03

460 25 480 SDO3V06 SDG3V06 SDW13V06

575 25 600 SDO3V07 SDG3V07 SDW13V07

Separate Control j

200 25 208 SEO3V08 SEG3V08 SEW13V08

230 30 240 SEO3V03 SEG3V03 SEW13V03

460 50 480 SEO3V06 SEG3V06 SEW13V06

575 50 600 SEO3V07 SEG3V07 SEW13V07

Separate Control

200 40 208 SFO3V08 SFG3V08 SFW13V08

230 50 240 SFO3V03 SFG3V03 SFW13V03

460 100 480 SFO3V06 SFG3V06 SFW13V06

575 100 600 SFO3V07 SFG3V07 SFW13V07

Separate Control

200 3 208 SBO4V08 SBG4V08 SBW14V08

230 3 240 SBO4V03 SBG4V03 SBW14V03

460 5 480 SBO4V06 SBG4V06 SBW14V06

575 5 600 SBO4V07 SBG4V07 SBW14V07

Separate Control

200 7

230 7

460 10 480 SCO4V06 SCG4V06 SCW14V06

575 10 600 SCO4V07 SCG4V07 SCW14V07

Separate Control j

200 10 208 SDO4V08 SDG4V08 SDW14V08

230 15 240 SDO4V03 SDG4V03 SDW14V03

460 25 480 SDO4V06 SDG4V06 SDW14V06

575 25 600 SDO4V07 SDG4V07 SDW14V07

Separate Control j

200 25 208 SEO4V08 SEG4V08 SEW14V08

230 30 240 SEO4V03 SEG4V03 SEW14V03

460 50 480 SEO4V06 SEG4V06 SEW14V06

575 50 600 SEO4V07 SEG4V07 SEW14V07

Separate Control

200 40 208 SFO4V08 SFG4V08 SFW14V08

230 50 240 SFO4V03 SFG4V03 SFW14V03

460 100 480 SFO4V06 SFG4V06 SFW14V06

575 100 600 SFO4V07 SFG4V07 SFW14V07

1

⁄

3

1

⁄

2

j

j

1

⁄

2

1

⁄

2

j

j

j

1

⁄

2

1

⁄

2

j

120 SAO11V02 SAG11V02

240 SDO1V03 SDG1V03 SDW11V03

120 SEO1V02 SEG1V02 SEW11V02

240 SEO1V03 SEG1V03 SEW11V03

120 SFO1V02 SFG1V02 SFW11V02

240 SFO1V03 SFG1V03 SFW11V03

120 SGO1V02 SGG1V02 SGW11V02

240 SGO1V03 SGG1V03 SGW11V03

120 SHO1V02 SHG1V02 SHW1V02

240 SHO1V03 SHG1V03 SHW1V03

120 SJO1V02 SJG1V02 SJW1V02

240 SJO1V03 SJG1V03 SJW1V03

120 SBO3V02S SBG3V02S SBW13V02S

120 SCO3V02S SCG3V02S SCW13V02S

208 SCO3V08 SCG3V08 SCW13V08

240 SCO3V03 SCG3V03 SCW13V03

120 SDO3V02S SDG3V02S SDW13V02S

120 SEO3V02S SEG3V02S SEW13V02S

120 SFO3V02S SFG3V02S SFW13V02S

120 SBO4V02S SBG4V02S SBW14V02S

120 SCO4V02S SCG4V02S SCW14V02S

208 SCO4V08 SCG4V08 SCW14V08

240 SCO4V03 SCG4V03 SCW14V03

120 SDO4V02S SDG4V02S SDW14V02S

120 SEO4V02S SEG4V02S SEW14V02S

120 SFO4V02S SFG4V02S SFW14V02S

Use Size 0

f

6

© 1998 Square D All Rights Reserved

5/98

j

c

Full Voltage Contactors — NEMA

Selection – Class 8502

600 Volts AC Maximum — 50-60 Hertz

NEMA Type 4X

Watertight, Dusttight,

NEMA

Size

Continuous

Current

Ratings

Motor

Volts

Max.

HP

t

Coil

Voltage

Corrosion-Resistant

Glass-Polyester

Enclosure

Type

1-Pole Single Phase

018

127

2-Pole Single Phase

00 9

018

127

245

3 90 . . . . . .

4 135 . . . . . .

5 270 . . . . . .

6 540 . . . . . .

7 810 . . . . . .

4-Pole Polyphase

018

127

245

390

4 135

5-Pole Polyphase

018

127

245

390

4 135

120 Volt Polyphase contactors are wired for separate control.

Limited to one Pilot Light and a Selector Switch or Start-Stop Push Button.

Coil voltage code must be specified to order this product. Refer to standard coil voltage codes listed in selection table above or additional standard voltage codes and insert as shown in

the HOW TO ORDER block on Page 5.

115 1 120

230 2 240 SBT5V03 SBT45V03 SBR5V03 SBA5V03

115 2 120

230 3 240 SCT5V03 SCT5V03 SCR5V03 SCA5V03

115 1/3 120

230 1 240

115 1 120 SBW21V02 SBT1V02 SBT41V02 SBR1V02 SBA1V02

230 2 240 SBW21V03 SBT1V03 SBT41V03 SBR1V03 SBA1V03

115 2 120 SCW21V02 SCT1V02 SCT41V02 SCR1V02 SCA1V02

230 3 240 SCW21V03 SCT1V03 SCT41V03 SCR1V03 SCA1V03

115 3 120 SDW21V02 SDT1V02 SDT41V02 SDR1V02 SDA1V02

230 7

Separate Control j 120 SBW33V02S SBT3V02S

200 3 208 SBW33V08 SBT3V08 SBR3V08 SBA3V08

230 3 240 SBW33V03 SBT3V03 SBR3V03 SBA3V03

460 5 480 SBW33V06 SBT3V06 SBR3V06 SBA3V06

575 5 600 SBW33V07 SBT3V07 SBR3V07 SBA3V07

Separate Control j 120 SCW23V02S SCT3V02S

200 7

230 7

460 10 480 SCW23V06 SCT3V06 SCR3V06 SCA3V06

575 19 600 SCW23V07 SCT3V07 SCR3V07 SCA3V07

Separate Controlj120 SDW23V02S SDT3V02S

200 10 208 SDW23V08 SDT3V08 SDR3V08 SDA3V08

230 15 240 SDW23V03 SDT3V03 SDR3V03 SDA3V03

460 25 480 SDW23V06 SDT3V06 SDR3V06 SDA3V06

575 25 600 SDW23V07 SDT3V07 SDR3V07 SDA3V07

Separate Controlj120

200 25 208 SER3V08 SEA3V08

230 30 240 SER3V03 SEA3V03

460 50 480 SER3V06 SEA3V06

575 50 600 SER3V07 SEA3V07

Separate Control j 120

200 40 208 SFR3V08 SFA3V08

230 50 240 SFR3V03 SFA3V03

460 100 480 SFR3V06 SFA3V06

575 100 600 SFR3V07 SFA3V07

Separate Control j 120

200 3 208 SBA4V08

230 3 240 SBA4V03

460 5 480 SBA4V06

575 5 600 SBA4V07

Separate Control j 120

200 7

230 7

460 10 480 SCA4V06

575 10 600 SCA4V07

Separate Controlj120

200 10 208 SDA4V08

230 15 240 SDA4V03

460 25 480 SDA4V06

575 25 600 SDA4V07

Separate Control j 120

200 25 208 SEA4V08

230 30 240 SEA4V03

460 50 480 SEA4V06

575 50 600 SEA4V07

Separate Control j 120

200 40 208 SFA4V08

230 50 240 SFA4V03

460 100 480 SFA4V06

575 100 600 SFA4V07

1

⁄

240 SDW21V03 SDT1V03 SDT41V03 SDR1V03 SDA1V03

2

120 Consult Local Square D

240 SET41V03 SER1V03 SEA1V03

120 Consult Local Square D

240 SFT41V03 SFR1V03 SFA1V03

120

240 SGR1V03 SGA1V03

120

240 SHA1V03

120

240 SJA1V03

1

⁄

208 SCW23V08 SCT3V08 SCR3V08 SCA3V08

2

1

⁄

240 SCW23V03 SCT3V03 SCR3V03 SCA3V03

2

1

⁄

208 SCA4V08

2

1

⁄

240 SCA4V03

2

. . .

. . .

Use Size 0 Use Size 0 Use Size 0 Use Size 0

Field Office

Field Office

. . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . .

Consult Local Square D

Field Office

Consult Local Square D

Field Office

Consult Local Square D

Field Office

Consult Local Square D

Field Office

Consult Local Square D

Field Office

Consult Local Square D

Field Office

Consult Local Square D

Field Office

NEMA Type 7 & 9

Hazardous Locations

Class I, Groups C & D

Class II, Groups E, F, & G

Bolted Type

Cast Iron c

SBT5V02 SBT45V02 SBR5V02 SBA5V02

SCT5V02 SCT5V02 SCR5V02 SCA5V02

. . .

. . .

Consult

Local Square D

Field Office

Consult

Local Square D

Field Office

. . . . . . . . .

. . . . . . . . .

. . . . . . . . .

. . . . . . . . .

. . . . . . . . .

Cast

Aluminum

SET41V02 SER1V02 SEA1V02

SFT41V02 SFR1V02 SFA1V02

Consult

Local Square D

Field Office

Consult

Local Square D

Field Office

Consult

Local Square D

Field Office

Consult

Local Square D

Field Office

Consult

Local Square D

Field Office

SPIN TOP

Type

SGR1V02 SGA1V02

SBR3V02S SBA3V02S

SCR3V02S SCA3V02S

SDR3V02S SDA3V02S

SER3V02S SEA3V02S

SFR3V02S SFA3V02S

NEMA Type 12

Dusttight & Driptight

Industrial Use Enclosure

®

Type

SHA1V02

SJA1V02

SBA4V02S

SCA4V02S

SDA4V02S

SEA4V02S

SFA4V02S

t

5/98

© 1998 Square D All Rights Reserved

7

Full Voltage Starters — NEMA

Selection – Class 8536

3-Pole Polyphase—600 Volt AC Max. 50/60 Hz—Three Thermal Units Required

Continuous

NEMA

Current

Size

Ratings

00 9

018

127

245

390

4 135

5 270

6 540

7 810

f

Size 6 and 7 are rated NEMA Type 4 only.

j

120 Volt Polyphase starters are wired for separate control.

t

Coil voltage code must be specified to order this product. Ref er to standard coil voltage codes listed in selection table above or additional standard

voltage codes below and insert as shown in the HOW TO ORDER block.

Coil V oltage Codes

Motor

Volts

Max.

HP

t

Coil

Voltage

Open

Type

NEMA Type 1

General

Purpose

Enclosure

NEMA Type 4 & 4X

Watertight, Dusttight

Brushed Stainless

Steel Enclosure

(Size 0-5)

f

NEMA Type 4X

Watertight, Dusttight,

Corrosion-Resistant

Glass-Polyester

Enclosure

Type Type Type Type

Separate Control j 120 SAO12V02S SAG12V02S

200 1

230 1

460 2 480 SAO12V06 SAG12V06

575 2 600 SAO12V07 SAG12V07

Separate Control j 120 SBO2V02S SBG2V02S SBW12V02S SBW22V02S

200 3 208 SBO2V08 SBG2V08 SBW12V08 SBW22V08

230 3 240 SBO2V03 SBG2V03 SBW12V03 SBW22V03

460 5 480 SBO2V06 SBG2V06 SBW12V06 SBW22V06

575 5 600 SBO2V07 SBG2V07 SBW12V07 SBW22V07

Separate Controlj120 SCO3V02S SCG3V02S SCW13V02S SCW23V02S

200 7

230 7

460 10 480 SCO3V06 SCG3V06 SCW13V06 SCW23V06

575 10 600 SCO3V07 SCG3V07 SCW13V07 SCW23V07

Separate Control j 120 SDO1V02S SDG1V02S SDW11V02S SDW21V02S

200 10 208 SDO1V08 SDG1V08 SDW11V08 SDW21V08

230 15 240 SDO1V03 SDG1V03 SDW11V03 SDW21V03

460 25 480 SDO1V06 SDG1V06 SDW11V06 SDW21V06

575 25 600 SDO1V07 SDG1V07 SDW11V07 SDW21V07

Separate Control j 120 SEO1V02S SEG1V02S SEW11V02S SEW21V02S

200 25 208 SEO1V08 SEG1V08 SEW11V08 SEW21V08

230 30 240 SEO1V03 SEG1V03 SEW11V03 SEW21V03

460 50 480 SEO1V06 SEG1V06 SEW11V06 SEW21V06

575 50 600 SEO1V07 SEG1V07 SEW11V07 SEW21V07

Separate Control j 120 SFO1V02S SFG1V02S SFW11V02S SFW21V02S

200 40 208 SFO1V08 SFG1V08 SFW11V08 SFW21V08

230 50 240 SFO1V03 SFG1V03 SFW11V03 SFW21V03

460 100 480 SFO1V06 SFG1V06 SFW11V06 SFW21V06

575 100 600 SFO1V07 SFG1V07 SFW11V07 SFW21V07

Separate Control j 120 SGO1V02S SGG1V02S SGW11V02S

200 75 208 SGO1V08 SGG1V08 SGW11V08

230 100 240 SGO1V03 SGG1V03 SGW11V03

460 200 480 SGO1V06 SGG1V06 SGW11V06

575 200 600 SGO1V07 SGG1V07 SGW11V07

Separate Control j 120 SHO2V02S SHG2V02S SHW2V02S

200 150 208 SHO2V08 SHG2V08 SHW2V08

230 200 240 SHO2V03 SHG2V03 SHW2V03

460 400 480 SHO2V06 SHG2V06 SHW2V06

575 400 600 SHO2V07 SHG2V07 SHW2V07

Separate Control j 120 SJO2V02S SJG2V02S SJW2V02S

200 — 208 SJO2V08 SJG2V08 SJW2V08

230 300 240 SJO2V03 SJG2V03 SJW2V03

460 600 480 SJO2V06 SJG2V06 SJW2V06

575 600 600 SJO2V07 SJG2V07 SJW2V07

1

⁄

208 SAO12V08 SAG12V08

2

1

⁄

240 SAO12V03 SAG12V03

2

1

⁄

208 SCO3V08 SCG3V08 SCW13V08 SCW23V08

2

1

⁄

240 SCO3V03 SCG3V03 SCW13V03 SCW23V03

2

Use Size 0 Use Size 0

. . .

. . .

. . .

8

File E78351

CCN NLDX

File LR60905

Class 3211-04

IEC 947-4-1

Sizes 00-5 only

Voltage

60 Hz 50 Hz

24

q

120 110 VO2

208 . . . VO8

240 220 VO3

480 440 VO6

600 550 VO7

Specify Specify V99

q

24 V coils are not availab le on Sizes 4-7. On Sizes 00-3, where 24 V

coils are available, Form S (separate control) must be specified.

. . . VO1

Code

How to Order:

To Order Specify: Catalog Number

• Class Number

• T ype Number

• Coil Voltage Code

• Form(s)

Class Type Coil

8536 SBA2 VO2 P1S

Voltage

Code

© 1998 Square D All Rights Reserved

Form(s)

Factory Modifications (FORMS)

Application Data

Dimensions

Separate Enclosures (Class 9991)

Replacement Parts (Class 9998)

Type S Accessories (Class 9999)

...................................................................Pages 13-16

...........................................................................Pages 17-20

...............Refer to Catalog 9999CT9701

...........Refer to Catalog 9999CT9701

..............Refer to Catalog 9999CT9701

.............Refer to Catalog 9999CT9701

5/98

Full Voltage Starters — NEMA

Selection – Class 8536

3-Pole Polyphase — 600 Volts AC Maximum — 50-60 Hertz—Three Thermal Units Required

NEMA Type 7 & 9

Hazardous Locations

NEMA

Size

00 9

018

127

245

390

4 135

5 270

6 540

7 810

k For NEMA Type 3R enclosed devices (Sizes 0-4 only), change “A” in Type designation to “H”, no additional charge. Consult Factory for restrictions on available Forms in NEMA Type 3R

j 120 Volt Polyphase starters are wired for separate control.

c Limited to one Pilot Light and a Selector Switch or Start-Stop Push Button.

t Coil voltage code must be specified to order this product. Refer to standard coil voltage codes listed in selection table above or additional standard v oltage codes in tab le belo w and insert

Continuous

Current

Ratings

enclosures.

as shown in the HOW TO ORDER block.

Motor

Volts

Separate Controlj120

200 11⁄

230 11⁄

460 2 480

575 2 600

Separate Control

200 3 208 SBT2V08 SBT42V08 SBR2V08 SBE2V08 SBA2V08

230 3 240 SBT2V03 SBT42V03 SBR2V03 SBE2V03 SBA2V03

460 5 480 SBT2V06 SBT42V06 SBR2V06 SBE2V06 SBA2V06

575 5 600 SBT2V07 SBT42V07 SBR2V07 SBE2V07 SBA2V07

Separate Controlj 120 SCT3V02S SCT43V02S SCR3V02S SCE3V02S SCA3V02S

200 7

230 71⁄

460 10 480 SCT3V06 SCT43V06 SCR3V06 SCE3V06 SCA3V06

575 10 600 SCT3V07 SCT43V07 SCR3V07 SCE3V07 SCA3V07

Separate Controlj 120 SDT1V02S SDT41V02S SDR1V02S SDE1V02S SDA1V02S

200 10 208 SDT1V08 SDT41V08 SDR1V08 SDE1V08 SDA1V08

230 15 240 SDT1V03 SDT41V03 SDR1V03 SDE1V03 SDA1V03

460 25 480 SDT1V06 SDT41V06 SDR1V06 SDE1V06 SDA1V06

575 25 600 SDT1V07 SDT41V07 SDR1V07 SDE1V07 SDA1V07

Separate Controlj 120

200 25 208 SET43V08 SER3V08 SEE1V08 SEA1V08

230 30 240 SET43V03 SER3V03 SEE1V03 SEA1V03

460 50 480 SET43V06 SER3V06 SEE1V06 SEA1V06

575 50 600 SET43V07 SER3V07 SEE1V07 SEA1V07

Separate Controlj 120

200 40 208 SFT41V08 SFR1V08 SFE1V08 SFA1V08

230 50 240 SFT41V03 SFR1V03 SFE1V03 SFA1V03

460 100 480 SFT41V06 SFR1V06 SFE1V06 SFA1V06

575 100 600 SFT41V07 SFR1V07 SFE1V07 SFA1V07

Separate Controlj 120

200 75 208 SGT41V08 SGR1V08 SGE1V08 SGA1V08

230 100 240 SGT41V03 SGR1V03 SGE1V03 SGA1V03

460 200 480 SGT41V06 SGR1V06 SGE1V06 SGA1V06

575 200 600 SGT41V07 SGR1V07 SGE1V07 SGA1V07

Separate Controlj 120

200 150 208 SHA2V08

230 200 240 SHA2V03

460 400 480 SHA2V06

575 400 600 SHA2V07

Separate Controlj 120

200 — 208 SJA2V08

230 300 240 SJA2V03

460 600 480 SJA2V06

575 600 600 SJA2V07

Max.

HP

t

Coil

Voltage

208

2

240

2

j 120 SBT2V02S SBT42V02S SBR2V02S SBE2V02S SBA2V02S

1

⁄

208 SCT3V08 SCT43V08 SCR3V08 SCE3V08 SCA3V08

2

240 SCT3V03 SCT43V03 SCR3V03 SCE3V03 SCA3V03

2

Class I, Groups C & D

Class II, Class E, F, & G

Bolted Type

Cast Iron

USE Size 0 USE Size 0 USE Size 0 Use Size 0

. . .

. . .

. . .

. . . . . . . . . . . .

. . . . . . . . . . . .

Cast

c

Aluminum

SET43V02S SER3V02S SEE1V02S SEA1V02S

SFT41V02S SFR1V02S SFE1V02S SFA1V02S

SGT41V02S SGR1V02S SGE1V02S SGA1V02S

SPIN TOP

Type

NEMA Type 9

Hazardous Locations

Class II, Groups E, F, & G

®

Type Type

NEMA Type 12/3R

Dusttight & Driptight

Industrial Use

Enclosure

SHA2V02S

SJA2V02S

Coil V oltage Codes

k

Volta ge

60 Hz 50 Hz

24q . . . VO1

120 110 VO2

208 . . . VO8

240 220 VO3

480 440 VO6

600 550 VO7

Specify Specify V99

q 24 V coils are not a vailab le on Sizes 4-7. On Sizes 00-3, where 24 V

coils are available, Form S (separate control) must be specified.

Factory Modifications (FORMS)............... Refer to Catalog 9999CT9701

Application Data....................................................................Pages 13-16

Dimensions............................................................................Pages 17-20

Separate Enclosures (Class 9991)........... Refer to Catalog 9999CT9701

Replacement Parts (Class 9998).............. Refer to Catalog 9999CT9701

Type S Accessories (Class 9999)............Refer to Catalog 9999CT9701

Code

5/98

How to Order:

To Order Specify: Catalog Number

• Class Number

• T ype Number

• Coil Voltage Code

• Form(s)

© 1998 Square D All Rights Reserved

Class Type Coil

8536 SBA2 VO2 H3O

Voltage

Code

Form(s)

9

Full Voltage Starters — NEMA

Selection – Class 8536

2-Pole Single Phase — 600 Volts A C Maxim um — 50-60 Hertz Thermal Units —

One Thermal Unit Required

Continuous

NEMA

Current

Size

Ratings

00 9

018

127

1P 36

245

4-Pole, 2-Phase — 600 Volts AC Maximum — 50-60 Hertz — Two Thermal Units Required

Continuous

NEMA

Current

Size

Ratings

018

127

245

390

4 135

j 120 Volt Polyphase starters are wired for separate control.

t Coil voltage code must be specified to order this product. Refer to standard coil voltage codes listed in selection table above or additional standard

voltage codes below and insert as shown in the HOW TO ORDER block.

Coil V oltage Codes

Motor

Volts

115

230 1 240 SAO11V03 SAG11V03

115 1 120 SBO1V02 SBG1V02 SBW11V02 SBW21V02

230 2 240 SBO1V03 SBG1V03 SBW11V03 SBW21V03

115 2 120 SCO1V02 SCG1V02 SCW11V02 SCW21V02

230 3 240 SCO1V03 SCG1V03 SCW11V03 SCW21V03

115 3 120 SCO2V02 SCG2V02 SCW12V02 SCW22V02

230 5 240 SCO2V03 SCG2V03 SCW12V03 SCW22V03

115 3 120 SDO6V02 SDG6V02 SDW16V02 SDW26V02

230 7

t

Max.

Coil

HP

Voltage

1

⁄

120 SAO11V02 SAG11V02

3

1

⁄

240 SDO6V03 SDG6V03 SDW16V03 SDW26V03

2

Open

Type

Type Type Type Type

General

Purpose

Enclosure

NEMA Type 1

NEMA Type 1

Motor

Volts

Max.

HP

t

Coil

Voltage

Open

Type

General

Purpose

Enclosure

NEMA Type 4 & 4X

Watertight, Dusttight

Brushed Stainless

Steel Enclosure

Use Size 0 Use Size 0

NEMA Type 4 & 4X

Watertight, Dusttight

Brushed Stainless

Steel Enclosure

NEMA Type 4X

Watertight, Dusttight,

Corrosion-Resistant

Glass-Polyester

Enclosure

NEMA Type 4X

Watertight, Dusttight,

Corrosion-Resistant

Glass-Polyester

Enclosure

Type Type Type Type

Separate Controlj 120 SBO3V02S SBG3V02S SBW13V02S SBW23V02S

200 3 208 SBO3V08 SBG3V08 SBW13V08 SBW23V08

230 3 240 SBO3V03 SBG3V03 SBW13V03 SBW23V03

460 10 480 SBO3V06 SBG3V06 SBW13V06 SBW23V06

575 10 600 SBO3V07 SBG3V07 SBW13V07 SBW23V07

Separate Controlj 120 SCO4V02S SCG4V02S SCW14V02S SCW24V02S

200 7

230 71⁄

460 10 480 SCO4V06 SCG4V06 SCW14V06 SCW24V06

575 10 600 SCO4V07 SCG4V07 SCW14V07 SCW24V07

Separate Controlj 120 SDO2V02S SDG2V02S SDW12V02S SDW22V02S

200 10 208 SDO2V08 SDG2V08 SDW12V08 SDW22V08

230 15 240 SDO2V03 SDG2V03 SDW12V03 SDW22V03

460 25 480 SDO2V06 SDG2V06 SDW12V06 SDW22V06

575 25 600 SDO2V07 SDG2V07 SDW12V07 SDW22V07

Separate Controlj 120 SEO2V02S SEG2V02S SEW12V02S

200 15 208 SEO2V08 SEG2V08 SEW12V08

230 30 240 SEO2V03 SEG2V03 SEW12V03

460 50 480 SEO2V06 SEG2V06 SEW12V06

575 50 600 SEO2V07 SEG2V07 SEW12V07

Separate Controlj 120 SFO2V02S SFG2V02S SFW12V02S

200 40 208 SFO2V08 SFG2V08 SFW12V08

230 50 240 SFO2V03 SFG2V03 SFW12V03

460 100 480 SFO2V06 SFG2V06 SFW12V06

575 100 600 SFO2V07 SFG2V07 SFW12V07

1

⁄

208 SCO4V08 SCG4V08 SCW14V08 SCW24V08

2

240 SCO4V03 SCG4V03 SCW14V03 SCW24V03

2

Consult Local Square D

Field Office

10

File E78351

CCN NLDX

File LR60905

Class 3211-04

IEC 947-4-1

Volta ge

60 Hz 50 Hz

24q . . . VO1

120 110 VO2

208 . . . VO8

240 220 VO3

480 440 VO6

600 550 VO7

Specify Specify V99

q 24 V coils are not a vailab le on Sizes 4-7. On Sizes 00-3, where 24 V

coils are available, Form S (separate control) must be specified.

How to Order:

To Order Specify: Catalog Number

• Class Number

• T ype Number

• Coil Voltage Code

• Form(s)

Class Type Coil

8536 SCG1 VO2 P1

Code

Voltage

Code

Form(s)

© 1998 Square D All Rights Reserved

Factory Modifications (FORMS) ...............Refer to Catalog 9999CT9701

Application Data ................................................................... Pages 13-16

Dimensions ........................................................................... Pages 17-20

Separate Enclosures (Class 9991) ...........Refer to Catalog 9999CT9701

Replacement Parts (Class 9998) ..............Refer to Catalog 9999CT9701

Type S Accessories (Class 9999).............Refer to Catalog 9999CT9701

5/98

Full Voltage Starters — NEMA

Selection – Class 8536

2-Pole Single Phase — 600 Volts AC Maximum — 50-60 Hertz — One Thermal Unit Required

Devices require 1 thermal unit

NEMA Type 12/3Rf

Dusttight & Driptight

Industrial Use

Enclosure

NEMA Type 12

Dusttight & Driptight

Industrial Use

Enclosure

SBA3V02S

SCA4V02S

SDA2V02S

SEA2V02S

SFA2V02S

NEMA

Size

00 9

018

127

1P 36

245

Continuous

Current

Ratings

NEMA Type 7 & 9

Hazardous Locations

Motor

Volts

115

230 1 240

115 1 120 SBT1V02 SBT1V02 SBR1V02 SBE1V02 SBA1V02

230 2 240 SBT1V03 SBT1V03 SBR1V03 SBE1V03 SBA1V03

115 2 120 SCT1V02 SCT1V02 SCR1V02 SCE1V02 SCA1V02

230 3 240 SCT1V03 SCT1V03 SCR1V03 SCE1V03 SCA1V03

115 3 120 SCT2V02 SCT2V02 SCR2V02 SCE2V02 SCA2V02

230 5 240 SCT2V03 SCT2V03 SCR2V03 SCE2V03 SCA2V03

115 3 120 SDT6V02 SDT6V02 SDR6V02 SDE6V02 SDA6V02

230 71⁄

Max.

HP

1

⁄

t

Coil

Voltage

120

3

240 SDT6V03 SDT6V03 SDR6V03 SDE6V03 SDA6V03

2

Class I, Groups C & D

Class II, Groups E, F, & G

Bolted Type

Cast Ironc

USE Size 0 USE Size 0 USE Size 0 Use Size 0

Cast

Aluminum

SPIN TOP

Type

NEMA Type 9

Hazardous Locations

Class II, Groups E, F, & G

®

Type Type

4-Pole 2-Phase — 600 Volts AC Maximum — 50-60 Hertz —Two Thermal Units Required

NEMA Type 7 & 9

Hazardous Locations

NEMA

Size

018

127

245

390

4 135

j 120 Volt Polyphase contactors are wired for separate control.

f For NEMA Type 3R enclosed devices (2-Pole only), change ‘A’ in Type designation to ‘H’, no additional charge.

c Limited to one Pilot Light and Selector Switch or Start-Stop Push Button.

t Coil voltage code must be specified to order this product. Refer to standard coil v oltage codes listed in selection table abo ve or additional standard v oltage codes below and insert as shown

Continuous

Current

Ratings

in the HOW TO ORDER block.

Motor

Volts

Separate Controlj 120 SBT3V02S

200 3 208 SBT3V08 SBR3V08 SBA3V08

230 3 240 SBT3V03 SBR3V03 SBA3V03

460 5 480 SBT3V06 SBR3V06 SBA3V06

575 5 600 SBT3V07 SBR3V07 SBA3V07

Separate Controlj 120 SCT4V02S

200 7

230 7

460 10 480 SCT4V06 SCR4V06 SCA4V06

575 10 600 SCT4V07 SCR4V07 SCA4V07

Separate Controlj 120 SDT2V02S

200 10 208 SDT2V08 SDR2V08 SDA2V08

230 15 240 SDT2V03 SDR2V03 SDA2V03

460 25 480 SDT2V06 SDR2V06 SDA2V06

575 25 600 SDT2V07 SDR2V07 SDA2V07

Separate Controlj 120

200 25 208 SER2V08 SEA2V08

230 30 240 SER2V03 SEA2V03

460 50 480 SER2V06 SEA2V06

575 50 600 SER2V07 SEA2V07

Separate Controlj 120

200 40 208 SFA2V08

230 50 240 SFA2V03

460 100 480 SFA2V06

575 100 600 SFA2V07

Max.

HP

t

Coil

Voltage

1

⁄

208 SCT4V08 SCR4V08 SCA4V08

2

1

⁄

240 SCT4V03 SCR4V03 SCA4V03

2

Class I, Groups C & D

Class II, Groups E, F, & G

Bolted Type

Cast Ironc

Consult Local

Square D

Field Office

Consult Local

Square D

Field Office

Cast

Aluminum

Consult Local

Square D

Field Office

Consult Local

Square D

Field Office

Consult Local

Square D

Field Office

Consult Local

Square D

Field Office

Consult Local

Square D

Field Office

SPIN TOP

Type

SBR3V02S

SCR4V02S

SDR2V02S

SER2V02S

. . . . . .

NEMA Type 9

Hazardous Locations

Class II, Groups E, F, & G

®

Type Type

. . .

. . .

. . .

. . .

Coil V oltage Codes

Volta ge

60 Hz 50 Hz

24q . . . VO1

120 110 VO2

208 . . . VO8

240 220 VO3

480 440 VO6

600 550 VO7

Specify Specify V99

q 24 V coils are not a vailab le on Sizes 4-7. On Sizes 00-3, where 24 V

coils are available, Form S (separate control) must be specified.

Factory Modifications (FORMS)............... Refer to Catalog 9999CT9701

Application Data....................................................................Pages 13-16

Dimensions............................................................................Pages 17-20

Separate Enclosures (Class 9991)........... Refer to Catalog 9999CT9701

Replacement Parts (Class 9998).............. Refer to Catalog 9999CT9701

Type S Accessories (Class 9999)............Refer to Catalog 9999CT9701

Code

5/98

How to Order:

To Order Specify: Catalog Number

• Class Number

• T ype Number

• Coil Voltage Code

• Form(s)

© 1998 Square D All Rights Reserved

Class Type Coil

8536 SCA1 VO3 P1

Voltage

Code

Form(s)

11

Full Voltage Starters

Selection – Class 8536

Types SB-SD with Auxiliary Load Terminals – Class 8536

3-Pole Polyphase — Three Thermal Units Required

It is sometimes desirable to use the capacitors in motor branch circuits to improv e power factor . The Size

0-2 Type SB-SD starters listed included three auxiliary terminals to allow easy connection of power

factor correction capacitors. When capacitors are connected using these terminals, no adjustment on

the selection of thermal units is necessary.

These terminals are also available as a kit Class 9999 Type PFL for Type S NEMA Size 0, 1 and 2

Starters with Motor Logic overload relays. These terminals are av ailable for connection of power factor

(PF) correction capacitors. These kits are sold separately and are not factory installed.

NEMA Size Motor Volts Maximum HP Coil Voltage Open Type

Separate Controlj 120 SBTO2V02S

0

1

2

j 120 Volt polyphase starters are wired for separate control.

Extra Capacity Single Phase Starters

2-Pole Single Phase — 250 Volts AC Maximum — 50-60 Hertz

Thermal Units — Devices require 1 thermal unit. Standard trip.

200 3 208 SBTO2V08

230 3 240 SBTO2V03

460 5 480 SBTO2V06

575 5 600 SBTO2V07

Separate Controlj 120 SBTO3V02S

200 7

230 7

460 10 480 SBTO3V06

575 10 600 SBTO3V07

Separate Controlj 120 SDTO1V02S

200 10 208 SDTO1V08

230 15 240 SDTO1V03

460 25 480 SDTO1V06

575 25 600 SDTO1V07

1

⁄

2

1

⁄

2

208 SBTO3V08

240 SBTO3V03

NEMA Type 4X

Watertight

Corrosion Resistant

Class-Polyester

Enclosure

NEMA Type 12

Dusttight & Driptight

Industrial Use

Enclosure

Motor

Volts

Max.

HP

t

Coil

Voltage

Open

Type

NEMA Type 1

General Purpose

Enclosure

NEMA Type 3R

Rainproof, Sleet

Resistant, Outdoor

Use Enclosure

NEMA Type 4 & 4X

Watertight, Dusttight

Brushed Stainless Steel

Enclosure

(Sizes 0-5)

Type Type Type Type Type

115 5 120 SDO8V02

230 10 240 SDO8V03 SDH8V03

115 7

230 15 240 SEO6V03 SEG6V03 SEH6V03 SEW16V03 SEW26V03 SEA6V03

t Coil voltage code must be specified to order this product. Refer to standard coil voltage codes listed in selection tables above or additional standard voltage codes below and insert as

1

⁄

120 SEO6V02 SEG6V02 SEH6V02 SEW16V02 SEW26V02 SEA6V02

2

shown in the HOW TO ORDER bolck.

. . .

SDH8V02

. . . . . . . . .

Coil V oltage Codes

Volta ge

60 Hz 50 Hz

24 . . . VO1

120 110 VO2

208 . . . VO8

240 220 VO3

480 440 VO6

600 550 VO7

Specify Specify V99

Code

How to Order:

To Order Specify: Catalog Number

• Class Number

• T ype Number

• Coil Voltage Code

• Form(s)

Class Type Coil

8536 SEG6 VO3 P1

Voltage

Code

Form(s)

Factory Modifications (FORMS)...............Refer to Catalog 9999CT9701

Application Data ................................................................... Pages 13-16

Dimensions ........................................................................... Pages 17-20

Separate Enclosures (Class 9991)...........Refer to Catalog 9999CT9701

Replacement Parts (Class 9998) ..............Refer to Catalog 9999CT9701

Type S Accessories (Class 9999).............Refer to Catalog 9999CT9701

12

© 1998 Square D All Rights Reserved

5/98

Full Voltage Contactors and Starters — NEMA

Application Data – Class 8502, 8536

KVA Rating for Switching

Transformer Primaries at 50 or 60

PolyPhase

Cycles

Transformers

Having Inrush

Currents (Worst

Case Peak) of

Not More Than

20 Times Peak of

Continuous

Current Rating

Single

Phase

PolyPhase

Transformers

Having Inrush

Currents (Worst

Case Peak) of

Over 20 Through

40 Times Peak of

Continuous

Current Rating

Single

Phase

PolyPhase

3 Phase

Rating for

Switching

Capacitors

k

KVAR

NEMA

Size

Load

Volts

Maximum

Horsepower

Rating –

Nonplugging

and

Nonjogging

Duty

Maximum

Horsepower

Rating –

Plugging and

Jogging Duty j

Continuous

Current

Rating,

Amperes –

600 Volt

Max.

Service –

Limit

Current

Rating,

Amperes

t

Tungsten

and

Infrared

Lamp

Load,

Amperes –

250 Volts

Max.

Resistance

Heating Loads,

KW – Other

Than Infrared

Lamp Loads

u

a

Single

Poly-

Single

Phase

Poly-

Phase

Phase

1151⁄

200 . . . 11⁄

230 1 11⁄

00

380 . . . 11⁄

460 . . . 2 . . . . . . 9 11 . . . . . . . . . . . . . . . . . . . . . . . .

575 . . . 2 . . . . . . 9 11 . . . . . . . . . . . . . . . . . . . . . . . .

115 1 . . .

200 . . . 3 . . . 1

230 2 3 1 1

0

380 . . . 5 . . . 1

460 . . . 5 . . . 2 18 21 . . . . . . . . . 2.4 4.2 1.2 2.1 . . .

575 . . . 5 . . . 2 18 21 . . . . . . . . . 3.0 5.2 1.5 2.6 . . .

115 2 . . . 1 . . . 27 32 15 3 5 1.2 . . . 0.6 . . . . . .

200 . . . 7

230 3 7

1

380 . . . 10 . . . 5 27 32 . . . . . . 16.5 . . . . . . . . . . . . . . .

460 . . . 10 . . . 5 27 32 . . . 12 20 4.9 8.5 2.5 4.3 . . .

575 . . . 10 . . . 5 27 32 . . . 15 25 6.2 11.0 3.1 5.3 . . .

115 3 . . . 1

1P

230 5 . . . 3 . . . 36 42 24 . . . . . . . . . . . . . . . . . . . . .

115 3 . . . 2 . . . 45 52 30 5 8.5 2.1 . . . 1.0 . . . . . .

200 . . . 10 . . . 7

230 7

2

380 . . . 25 . . . 15 45 52 . . . . . . 28 . . . . . . . . . . . . . . .

460 . . . 25 . . . 15 45 52 . . . 20 34 8.3 14 4.2 7.2 16

575 . . . 25 . . . 15 45 52 . . . 25 43 10.0 18 5.2 8.9 20

115 . . . . . . . . . . . . 90 104 60 10 17 4.1 . . . 2.0 . . . . . .

200 . . . 25 . . . 15 90 104 60 . . . 31 . . . 12 . . . 6.1 . . .

230 . . . 30 . . . 20 90 104 60 20 34 8.1 14 4.1 7.0 27

3

380 . . . 50 . . . 30 90 104 . . . . . . 56 . . . . . . . . . . . . . . .

460 . . . 50 . . . 30 90 104 . . . 40 68 16 28 8.1 14 53

575 . . . 50 . . . 30 90 104 . . . 50 86 20 35 10 18 67

200 . . . 40 . . . 25 135 156 120 . . . 45 . . . 20 . . . 10 . . .

230 . . . 50 . . . 30 135 156 120 30 52 14 23 6.8 12 40

4

380 . . . 75 . . . 50 135 156 . . . . . . 86.7 . . . . . . . . . . . . . . .

460 . . . 100 . . . 60 135 156 . . . 60 105 27 47 14 23 80

575 . . . 100 . . . 60 135 156 . . . 75 130 34 59 17 29 100

200 . . . 75 . . . 60 270 311 240 . . . 91 . . . 41 . . . 20 . . .

230 . . . 100 . . . 75 270 311 240 60 105 27 47 14 24 80

5

380 . . . 150 . . . 125 270 311 . . . . . . 173 . . . . . . . . . . . . . . .

460 . . . 200 . . . 150 270 311 . . . 120 210 54 94 27 47 160

575 . . . 200 . . . 150 270 311 . . . 150 260 68 117 34 59 200

200 . . . 150 . . . 125 540 621 480 . . . 182 . . . 81 . . . 41 . . .

230 . . . 200 . . . 150 540 621 480 120 210 54 94 27 47 160

6f

380 . . . 300 . . . 250 540 621 . . . . . . 342 . . . . . . . . . . . . . . .

460 . . . 400 . . . 300 540 621 . . . 240 415 108 188 54 94 320

575 . . . 400 . . . 300 540 621 . . . 300 515 135 234 68 117 400

230 . . . 300 . . . . . . 810 932 . . . 180 315 . . . . . . . . . . . . 240

7f

460 . . . 600 . . . . . . 810 932 . . . 360 625 . . . . . . . . . . . . 480

575 . . . 600 . . . . . . 810 932 . . . 450 775 . . . . . . . . . . . . 600

Tables and footnotes are taken from NEMA Standards.

j Ratings shown are for applications requiring repeated interruptions of stalled motor current or repeated closing of high transient currents encountered in rapid motor reversal, in volving more

than five openings or closings per minute and more than ten in a ten-minute period, such as plug-stop, plug-reverse or jogging duty. Ratings apply to single speed and multi-speed

controllers.

t Per NEMA Standards paragraph ICS 2-321.20, the service-limit current represents the maximum ms current, in amperes, which the controller ma y be expected to carry for protracted periods

in normal service. At service-limit current ratings, temperature rises may exceed those obtained by testing the controller at its continuous current rating. The ultimate trip current of overcurrent (overload) relays or other motor protective devices shall not exceed the service-limit current ratings of the controller.

a FLUORESCENT LAMP LOADS – 300 VOLTS AND LESS – The characteristics of fluorescent lamps are such that it is not necessary to derate Class 8502 contactors below their normal

continuous current rating. Class 8903 contactors may also be used with fluorescent lamp loads . For controlling tungsten and infrared lamp loads, and resistance heating loads, Class 8903

ac lighting contactors are recommended. These contactors are specifically designed for such loads and are applied at their full rating as listed in the Class 8903 Section.

u Ratings apply to contactors which are employed to switch the load at the utilization voltage of the heat producing element with a duty which requires continuous operation of not more than

five openings per minute. Class 8903 Types L and S lighting contactors are rated for resistance heating loads.

k When discharged, a capacitor has essentially zero impedance. F or repetitive switching by contactor, sufficient impedance should be connected in series to limit inrush current to not more

than 6 times the contactor rated continuous current. In many installations, the impedance of connecting conductors ma y be sufficient f or this purpose. When switching to connect additional

banks, the banks already on the line may be charged and can supply additional available short-circuit current which should be considered when selecting the impedance to limit the current.

The ratings for capacitor switching above assume the following maximum available fault currents: NEMA Size 2-3: 5,000 A RMS Sym.; NEMA Size 4-5: 10,000 A RMS Sym.; NEMA Size

6-7: 18,000 A RMS Sym. If available fault current is greater than these values, connect sufficient impedance in series as noted in the previous paragraph.

f See Page 16 regarding operation rates for Size 6 & 7.

The motor ratings in the above table are NEMA standard ratings and apply only when the code letter of the motor is the same as or occurs earlier in the alphabet than is sho wn in

the table below. Motors having code letters occurring later in the alphabet may require a larger controller. Consult local Square D field office.

. . . . . . . . . 9 11 5 . . . . . . . . . . . . . . . . . . . . .

2

1

2

2

2

1

⁄

2

1

⁄

2

⁄

15 5 10 45 52 30 10 17 4.1 7.2 2.1 3.6 8

2

Phase

. . . . . . 9 11 5 . . . . . . . . . . . . . . . . . . . . .

. . . . . . 9 11 5 . . . . . . . . . . . . . . . . . . . . .

. . . . . . 9 11 . . . . . . . . . . . . . . . . . . . . . . . .

1

⁄

. . . 18 21 10 . . . . . . 0.6 . . . 0.3 . . . . . .

2

1

⁄

18 21 10 . . . . . . . . . 1.8 . . . 0.9 . . .

2

1

⁄

18 21 10 . . . . . . 1.2 2.1 0.6 1.0 . . .

2

1

⁄

18 21 . . . . . . . . . . . . . . . . . . . . . . . .

2

. . . 3 27 32 15 . . . 9.1 . . . 3.6 . . . 1.8 . . .

2 3 27 32 15 6 10 2.4 4.3 1.2 2.1 . . .

1

⁄

. . . 36 42 24 . . . . . . . . . . . . . . . . . . . . .

2

1

⁄

45 52 30 . . . 15.4 . . . 6.3 . . . 3.1 . . .

2

Single

Phase

Motor HP Rating

11⁄2-2 L

3-5 K

71⁄2 & above H

5/98

Maximum Allowable Motor

Code Letter

© 1998 Square D All Rights Reserved

13

Full Voltage Contactors and Starters — NEMA

Application Data – Class 8502, 8536

CLASS 8502 AND 8536 APPLICATION DATA

Power Contact Ratings

All contactors and starters are rated in

accordance with NEMA standards. The ratings

shown in the price tables are for normal service.

For complete data on power contact ratings , ref er

to Page 13.

Short Circuit Protection

According to the National Electrical Code branch

circuit overcurrent protection must be provided f or

each contactor or starter. For starters refer to

instructions furnished with the thermal unit

selection table. For contactors (Class 8502 or

8702) provide branch circuit overcurrent

protection in accordance with the National

Electrical Code, except do not exceed the

maximum protective device r atings in table belo w.

NEMA

Size

Maximum

Voltage

K5, RK5 or

RK1 Fuse

(Ampere)

Class

600 10

00

250 12

600 20

0

250 25 35

600 30

1

250 40 60

600

2

250 90

600 100

3

250 125 150

4 600 200 400 225

5 600 400 600 400

6 600 600 1200t 800

7 600 600 1600t 1200

t Class L Fuse only.

60 100

Capacitor Switching

The kilovar ratings of enclosed, three phase contactors

used as switches for capacitor loads , when only one

load appears on the secondary of a distribution system

are shown in the table on P age 13.

Coil Burdenq

NEMA

Size

00 2-3 . . . 165 . . . 33 . . . 6

0 & 1 1-5 232 245 26 27 7.7 7.8

2

3

4 2-5 . . . 973 . . . 81 . . . 25

5 2-3 2970 2970 250 212 42 39

6a 2-3 1495 1780 56 48 27 32

7a 2-3 . . . 1960 . . . 59 . . . 36

q Mean values.

a Size 6 and 7 have a DC coil. The values shown are f or the A C input

to the DC power supply that provides power to the coil.

Inrush VA Sealed V A Sealed Watts

No. of

50

Poles

Hertz60Hertz50Hertz60Hertz50Hertz60Hertz

2 & 3 296 311 36 37

4 & 5 429 438 37 38

2-3 676 700 47 46 15 14

4-5 1260 1185 89 85 23.4 22

Class

J or T

Fuse

(Ampere)

15 15

30

60

200

Inverse-Time

Circuit

Breaker

(Ampere)

20

40

80

125

12 14

Maintenance of Equipment

Class 9998 Repair Parts Kits are available for all

Class 8502 contactors and Class 8536 starters.

Service bulletins with a complete list of replaceable

parts are supplied with all enclosed devices.

Separate bulletins can be ordered and are listed

along with the appropriate contact parts kit.

Device

NEMA

Type Series

Type

00 SA

0 SB A & B

1 SC A & B

1P SC A 2 278AS SL3

2SDA

3SEA

4SFA

5SGA

6SH

7SJA

A 2-3 362AS SL2

B 2-3 556AS SJ1

A

B

Service

No. of

Bulletin

Poles

1-3

277AS

4

277AS & 250AS

5

277AS & 250AS

1-3

278AS

4

278AS & 250AS

5

278AS & 250AS

2-3

279AS

4

279AS & 293AS

5

279AS & 293AS

2 305AS SL6

3 305AS SL7

4 326AS (2)SL6

5 326AS (1)SL6 & (1)SL7

2 306AS SL8

3 306AS SL9

4 326AS (2)SL8

5 326AS (1)SL8 & (1)SL9

2 328AS SL10

3 328AS SL11

2 342AS SL25

3 342AS SL26

2 370AS SL25

3 370AS SL26

2

397AS

3 SL31

Replacement

Contacts

Class 9998 Type

SL2

SL12

(1)SL12 & (1)SL22

or

(1)SL2 & (2)SL22

SL3

SL13

(1)SL13 & (1)SL22

or

(1)SL3 & (2)SL22

SL4

SL14

(1)SL14 & (1)SL24

or

(1)SL4 & (2)SL24

SL30

Terminals

Power T erminals Control T erminals

NEMA

Type

SA, SB

& SC

Type

of Lug

Pressure

Wire

Parallel

Groove

Parallel

Groove

Size

00,

0 & 1

2 SD Box Lug #14-#4

3 SE Box Lug #14-1/0

4 SF Box Lug #8-250 kcmil

5 SG Box Lug #4-500 kcmil

6SH

7SJ

t Solid or stranded copper wire.

Wire

Sizest

Min.-Max.

#14-#8

One or two

250-500 kcmil

per phase

One to four

250-500 kcmil

per phase

Type

of Lug

Pressure

Wire

Pressure

Wire

Pressure

Wire

Pressure

Wire

Pressure

Wire

Pressure

Wire

Pressure

Wire

Wire

Sizest

Min.-Max.

#16-#12

#16-#12

#16-#12

#16-#12

#16-#12

#16-#12

#16-#12

14

© 1998 Square D All Rights Reserved

5/98

Full Voltage Contactors and Starters — NEMA

Application Data – Class 8502, 8536

Auxiliary Units

Auxiliary contacts, power poles, and timer

attachments can be added by the factory or in the

field on all Type S starters and contactors. The

table below shows the maximum number of

auxiliary units (in addition to the holding circuit

contact) that can be added to a given size starter

or contactor. In addition, it is possible to add a

second internal contact on NEMA Size 0, 1, and 2

contactors and starters.

No. of

Type

Poles of

Basic

NEMA

Size

Contactor

00 SA 2-3

SD

SG

SH

SJ

1, 2 or 3

4 or 5

2-5

(Size 3 & 4)

2-3

(Size 5)

2-3

0, 1 & 2SBSC

3, 4 & 5SESF

6 & 7

Maximum Number of External

Auxiliary Units (In addition to

holding circuit contact)

4 single circuit auxiliary contacts (N.O. or N.C.)

if second internal auxiliary contact is not used.

4 single circuit auxiliary contacts (N.O. or N.C.)

3 single circuit auxiliary contacts (N.O. or N.C.)

plus 1 attached timer (ON or OFF delay).

2 single circuit auxiliary contacts (N.O. or N.C.)

plus 1 power pole adder (1 or 2 poles, N.O. or

N.C.).

1 attached timer (ON or OFF delay) plus 1

power pole adder (1 or 2 poles, N.O. or N.C .)

plus 1 auxiliary contact.

2 single circuit auxiliary contacts (N.O. or N.C.)

1 timer attachment plus 1 auxiliary contact.

4 single circuit auxiliary contacts (N.O. or N.C.)

2 single circuit (Sizes 3 & 4) or 3 single circuit

(Size 5) auxiliary contacts plus 1 attached timer

(ON or OFF delay).

2 single circuit auxiliary contacts (N.O. or N.C.)

plus 1 NEMA Size 0-1 or Size 2 power pole

adder (1 or 2 poles, N.O. or N.C.)

4 single circuit auxiliary contacts (N.O. or N.C.)

3 single circuit auxiliary contacts (N.O. or N.C.)

plus 1 attached timer (ON or OFF delay).

2 single circuit auxiliary contacts (N.O. or N.C.)

plus 1 NEMA Size 0-1 or Size 2 power pole

adder (1 or 2 poles, N.O. or N.C.)

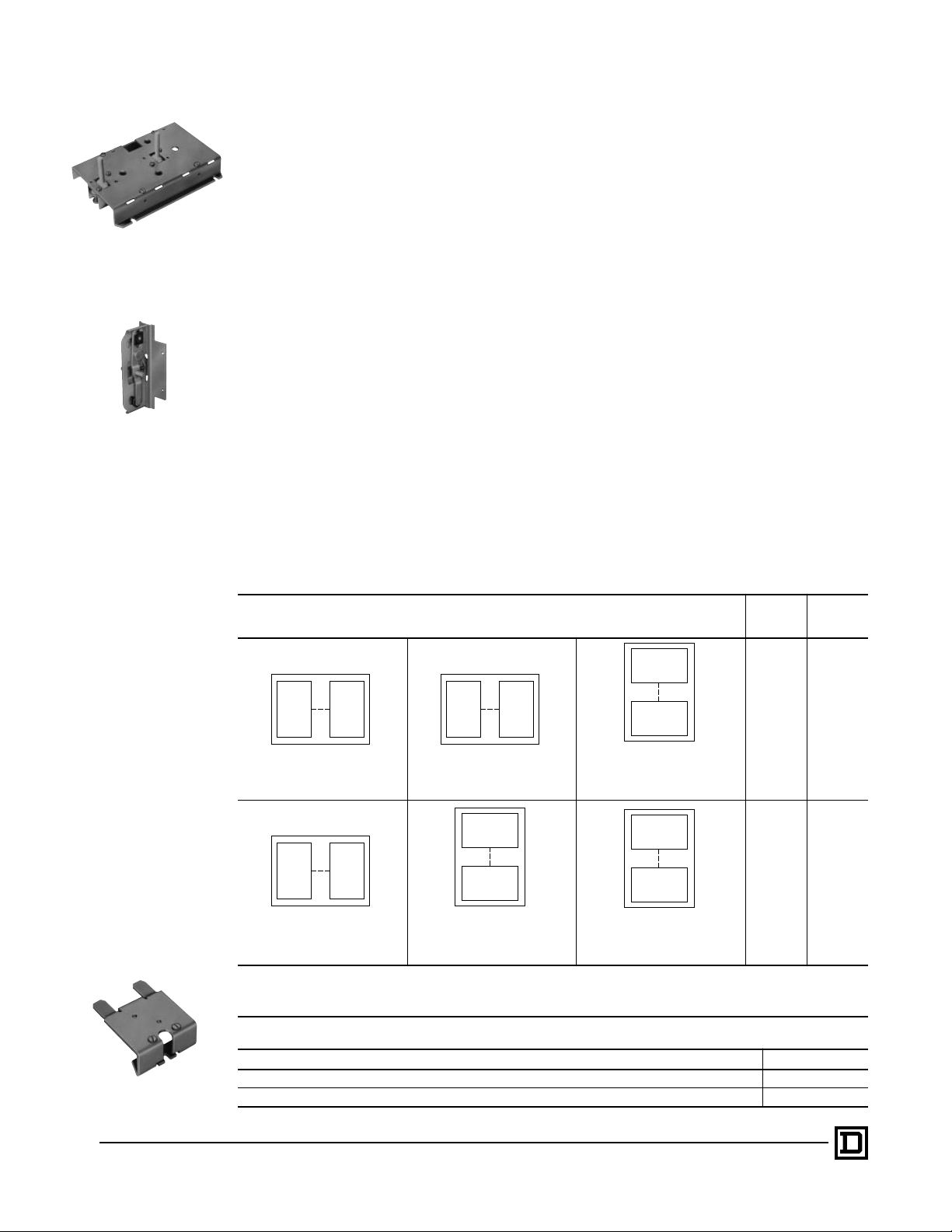

Factory Installed Auxiliary Contacts

Additional auxiliary contacts may be factory or

field added to any Type S contactor or starter. See

table above for maximum number of auxiliary

units. The tab le below lists the F orm designations

for factory installed electrical contacts.

See Class 9999 for field modification kits.

Form Number of Additional Auxiliary Contacts

When ordering factory installed auxiliary contacts,

the Form designations listed should be used.

Number of N.O.

Contacts

0

1

2

3 0 X30

3 1 X31

4 0 X40

Number of N.C.

Contacts

1 X01

2 X02

3 X03

4 X04

0 X10

1 X11

2 X12

3 X13

0 X20

1 X21

2 X22

Form Number

Control Circuit Transformers

Class 9070 Type T machine tool control

transformers are normally used when it is

necessary to provide a lower voltage to the control

circuit. This transf ormer with fused protection may

be ordered from the factory by specifying Form

F4T. The addition of a transformer often requires

the use of a larger enclosure. The table below

shows the transformer selection for given sized

starters and contactors with or without auxiliary

units.

NEMA

Size

0 & 1

0 & 1

0 & 1

Mechanically

Interlocked

Devices

2 SD 2-5 With or without attachments T100

3 SE 2-3 With or without attachments GO3j

3 SE 4 & 5 With or without attachments T300

4 SF 2-5 With or without attachments T300

5 SG 2-3 Any T500

6, 7

j Class 8502 & 8536 Type S, Size 3 standard NEMA T ype 1, 4 and 12

enclosures have space for field mounting a fused control circuit

transformer. A Class 9070 T ype GFT3 transformer and fuse block kit

is available for F orm F4T requirements in a NEMA Type 1 enclosure.

NEMA Type 4 and 12 enclosures utilize a Class 9070 T150

transformer and a Class 9999 SF4 fuse block.

u A Class 9070 transformer is an integral part of the Size 6 and Size 7

control circuit providing 120 volt control circuit voltage as standard.

No.

Type

of

Auxiliary Units

Poles

With max. of 2 auxiliary

contacts

SB

SC

SB

SC

SB

SC

SH,

SJ

With timer and maximum of

1-3

1 auxiliary contact

With 3 or 4 auxiliary

contacts with timer and 2 or

3 auxiliary contacts

With or without auxiliary

4 & 5

contacts or timer

1-5 With or without attachments T100

2-3 Any u

Transformer

Class 9070

Type

T50

T100

T100

Power Poles

Single or double circuit power pole adders ma y be

factory or field installed on 2 and 3 pole Type S

contactors and starters. The table below lists the

Form designation for factory installed power pole

adders. Only one power pole adder may be

installed per contactor.

Type NEMA Size

1 N.O.

1 N.C.

1 N.O., 1 N.C.

2 N.O.

2 N.C.

0, 1 SB6 Y428

2 SB11 Y436

0, 1 SB7 Y429

2 SB12 Y437

0, 1 SB8 Y435

2 SB13 Y440

0, 1 SB9 Y430

2 SB14 Y438

0, 1 SB10 Y434

2 SB15 Y439

Class 9999

Type

Form

Designation

5/98

© 1998 Square D All Rights Reserved

15

Full Voltage Contactors and Starters — NEMA

Application Data – Class 8502, 8536

Size 6 Starter 8536 SH

Size 7 Starter 8536 SJ

Size 6 Type SH and Size 7 Type SJ Contactors and Starters

Size 6 Type SH and Size 7 T ype SJ contactors and

starters have a DC coil operated by a solid state

rectifier circuit mounted on the device and

powered from an ac source. The Size 6 and 7 are

equipped as standard with a fused control circuit

transformer (Form F4T) rated 240/480-120 volts

60 hertz, 220/440-110 volts 50 hertz. The purpose

of this transformer is to provide an isolated 120

volts 60 hertz, 110 volts 50 hertz, supply for the

control circuit. Size 6 and 7 devices may be

ordered for other system voltages by specifying

the voltage and frequency desired.

Operation Rates

Continuous operation rate: 3 operations/minute

maximum. Jogging or Plugging Duty: 15

operations/minute – 3 minutes maximum.

Field conversion for other system voltages is

accomplished by one of the following methods,

NOT BY THE USUAL PRACTICE OF CHANGING

THE COIL:

1. If the factory wiring is indicated as being for

480 volts 60 hertz, 440 volts 50 hertz,

conversion to 240 volts 60 hertz, 220 volts 50

hertz, can be accomplished by reconnecting

the control transformer as illustrated on

instruction sheet supplied with the controller.

This is the same method that would be used

on Class 9070 control circuit transformers.

Conversion to any other voltage requires

replacement of the control transformer. For

other system voltages: i.e. 208, 277, 380, 600

volts, a new transformer with single voltage

primary must be selected from table at right.

Control transformer connections are

illustrated on the instruction sheet supplied

with the controller.

2. If the factory wiring is indicated as being for

any voltage other than 480 volts 60 hertz, 440

volts 50 hertz, conversion to any other voltage

requires replacement of the control

transformer. Refer to table at right.

3. The standard transformer supplied may be

used to power a maximum of five Class 9001

Type K illuminated operators powered with

transformer type light modules. When extra

capacity to power control relays or other

inductive loads is required, a second

transformer must be added. Extra capacity

can be purchased as Form F4T with additions

in 100 VA increments.

4. Standard controllers are wired for common

control and are not convertible for operation of

the control circuit from a separate source of

supply voltage. Controllers designated Form S

have special wiring designed for separate

control. They are furnished with an isolating

transformer, usually ha ving a 120 volt primary

and 120 volt secondary, that must not be

bypassed. Form S controllers are not

convertible for operation on common control.

The tables below give the replacement

transformers for Type S Sizes 6 and 7 contactors

and starters. To change voltages on these

devices, coils are not changed, instead

transformers with the desired voltage are

changed.

Replacement Control Transformers for Type S

Size 6

Voltage

60 Hertz 50 Hertz

240/480-120 220/440-110 EO3S2A

208-120 . . . EO3S2B

277-120 . . . EO3S2C

. . . 380-110 EO3S2D

600-120 550-110 EO3S2E

120-120 110-110 EO3S2F

240-120 220-110 EO3S2G

Class 9070 Type

Replacement Control Transformers for Type S

Size 7

Voltage

60 Hertz 50 Hertz

240/480-120 220/440-110 EO19S2A

208-120 . . . EO19S2B

277-120 . . . EO19S2C

. . . 380-110 EO19S2D

600-120 550-110 EO19S2E

120-120 110-110 EO19S2F

240-120 220-110 EO19S2G

Class 9070 Type

Auxiliary Contacts

A N.O. holding circuit contact and a N.C . auxiliary

contact are provided as standard. The holding

circuit contact may or may not be required for

either 3-wire or 2-wire control. Size 6 and 7

devices have an additional N.C. auxiliary contact

which is wired in the coil control circuit. DO NOT

USE THIS N.C. CONTACT FOR ANY OTHER

PURPOSE.

16

© 1998 Square D All Rights Reserved

5/98

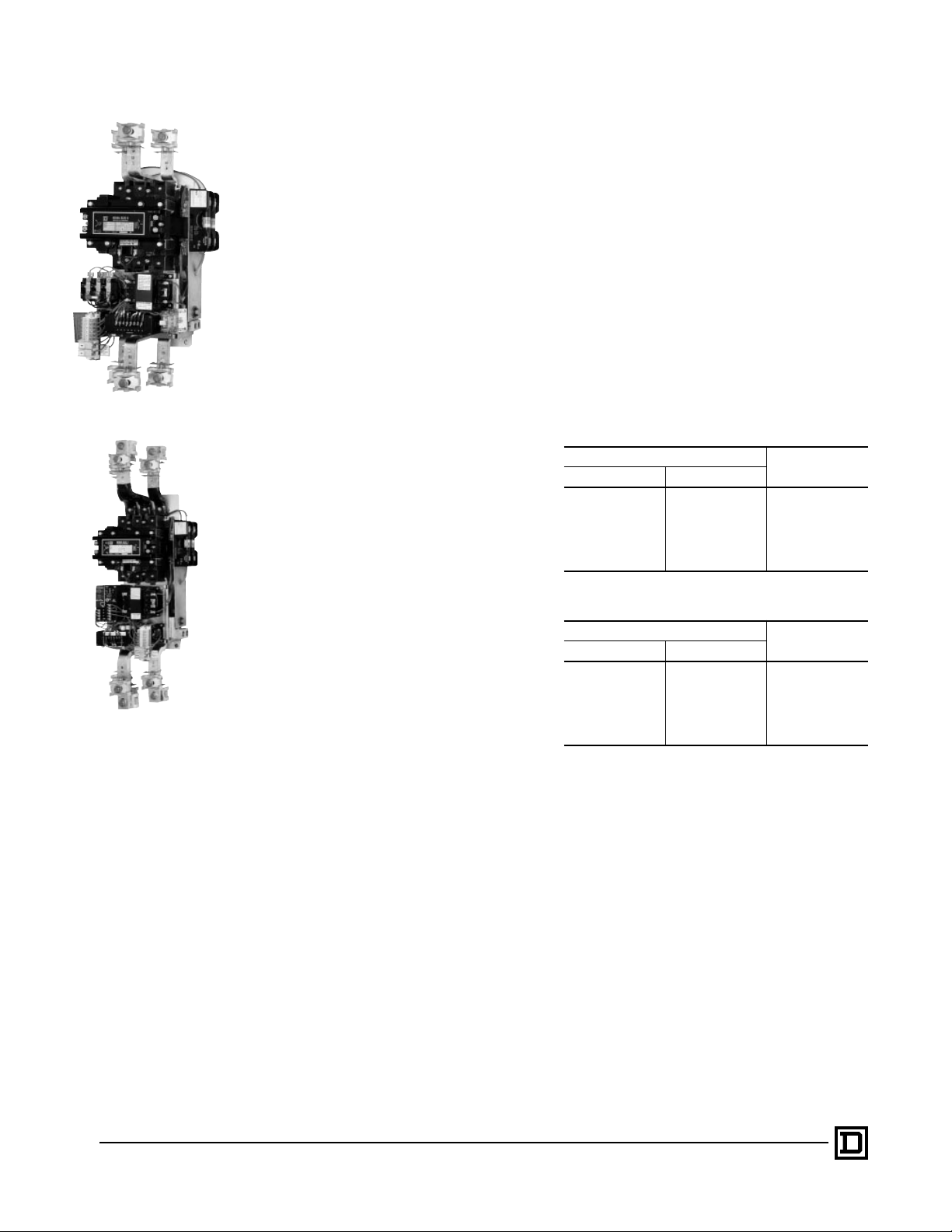

Full Voltage Contactors and Starters — NEMA

Approximate Dimensions, Shipping Weights – Class 8502, 8536

Class 8502 Open Type Class 8536 Open Type

RESET

A

F

G

B

H

D

E

C

I

A

D

I

Figure 1

E

F

B

G

H

C

Figure 2

No.

NEMA

Class

Size

00 SAO 2-3 1 (2) #10 3.22 82 4.34 110 4.22 107 1.63 41 1.63 41 .22 6 3.94 100 . . . . . . . . . . . . 4

0 SBO 1-3

1 SCO 4-5 4.25 108 4.34 110 4.22 107 1.63 41 2.63 67 .22 6 3.94 100 . . . . . . . . . . . . 41⁄

2 SDO

3 SEO

8502

4 SFO

5 SGO 2-3 1 (3) 1⁄2" 8.66 220 12.31 313 8.75 222 3.25 83 5.81 148 .63 16 11.13 283 4.75 121 7.25 184 45

6 SHO 2-3 1 (3) 1⁄2" 12.34 313 28.06 713 9.00 229 3.53 90 5.78 147 5.06 129 18.56 471 4.75 121 7.25 184 80

7 SJO 2-3 1 (3) 1⁄2" 12.34 313 37.25 946 10.88 276 3.53 90 5.78 147 7.22 183 22.38 568 4.75 121 7.25 184 135

00, 0, 1, 1P SAO-SCO 2-3 2 (3) #10 3.50 89 6.77 172 4.22 107 .50 13 1.00 25 1.61 41 .20 5 6.25 159 3.97 101 5

0, 1 SBO-SCO 4 2 (3) #10 4.53 115 6.77 172 4.22 107 .50 13 1.00 25 2.66 68 .20 5 6.25 159 3.97 101 51⁄

2 SDO

3 SEO

8536

4 SFO

5 SGO 3 2 (3) 1⁄2" 8.56 217 17.56 446 8.75 222 4.75 121 7.25 184 5.38 137 .63 16 16.38 416 6.00 152 62

6 SHO 3 2 (3) 1⁄2" 12.34 313 28.06 713 9.00 229 4.75 121 7.25 184 5.78 147 5.06 129 18.56 471 8.69 221 85

7 SJO 3 2 (3) 1⁄2" 12.34 313 37.25 946 10.88 276 4.75 121 7.25 184 5.78 147 7.22 183 22.38 568 9.00 229 140

Type

Fig.

of

No.

Poles

1 (2) #10

2-3

1 (3) #10

4-5 5.63 143 5.13 130 4.94 125 2.16 55 3.47 88 .22 6 4.59 117 .53 13 1.06 27 81⁄

2-3

1

4-5 (3)

2-3

1

4-5 (3) 5⁄16" 9.75 248 8.19 208 6.50 165 3.94 100 5.81 148 .31 8 7.00 178 4.53 115 9.06 230 22

2-3

2 (3) #10

4 5.63 143 7.81 198 4.94 125 .50 13 1.00 25 3.47 88 .20 5 7.34 186 4.06 103 91⁄

2-3

2

4 (3) 5⁄16" 9.75 248 12.13 308 6.50 165 1.81 46 1.75 44 5.81 148 .31 8 11.19 284 5.75 146 25

3

2

4 (3)

Dimensions – Inches/mm (Refer to Appropriate Figure)

Mtg.

ABCDEFGHI

Screws

IN mm IN mm IN mm IN mm IN mm IN mm IN mm IN mm IN mm

3.22 82 4.34 110 4.22 107 1.63 41 1.63 41 .22 6 3.94 100 . . . . . . . . . . . . 4

4.94 125 5.13 130 4.94 125 2.16 55 2.16 55 .22 6 4.59 117 .53 13 1.06 27 6

1

(3)

⁄4" 5.47 139 7.09 180 6.50 165 1.88 48 3.59 91 .31 8 6.03 153 3.25 83 4.75 121 14

5

⁄16" 9.75 248 7.88 200 6.50 165 3.94 100 5.81 148 .31 8 7.00 178 4.53 115 9.06 230 22

(3) 5⁄16" 6.00 152 8.19 208 6.50 165 2.06 52 3.94 100 .31 8 7.00 178 3.59 91 5.31 135 18

4.31 109 7.81 198 4.94 125 .50 13 1.00 25 2.16 55 .20 5 7.34 186 4.06 103 7

1

(3)

⁄4" 5.47 139 11.09 282 6.50 165 .88 22 1.75 44 3.59 91 .31 8 10.19 259 5.75 146 17

(3) 5⁄16" 6.00 152 12.88 327 6.50 165 1.81 46 1.75 44 3.94 100 .31 8 11.19 284 5.75 146 22

5