Spy®

model 670

po rtab le wet sponge

h o l i day detector

o p e r at i n g

instructions

PIPELINE INSPECTION COMPANY

picltd.com

2

pi clt d.co mpi clt d.co m

3

welcome

Thank you for purchasing the SPY® Model 670 Wet Sponge Holiday

Detector.

Pipeline Inspection Company and our SPY

®

brand of coating inspection,

jeep meter and pig tracking equipment has been serving companies all

over the world for over 60 years. With the purchase of this high precision

instrument you can now enjoy access to worldwide service and support

only SPY® and our vast Distributor network can offer.

For more information about SPY® brand equipment please visit our

website at picltd.com.

Tab le of contents

Unit Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Principles of Wet Sponge Holiday Detection . . . . . . . . . . . . 5

670 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Optional Accessories . . . . . . . . . . . . . . . . . . . . . 10

Battery Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controls & Testing Instructions . . . . . . . . . . . . . . . . . . . . . . 12

670 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance & Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Electrode Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Related Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wet Sponge Inspection Kit . . . . . . . . . . . . . . . . . . . . . . . . 24

The SPY® Model 670 Holiday Detector meets the Electromagnetic

Compatibility and Low Voltage Directive. This product is a Class B,

Group 1 ISM equipment according to CISPR 11. Group 1 ISM product: A

product in which there is intentionally generated an d/or used conductively

coupled radio -frequency energy which is necessary for the internal

functioning of the equipment itself. Class B products are suitable for use

in domestic establishments and in establishments directly connected to

a low voltage power supply network which supplies buildings used for

domestic purpose.

is a registered trademark of Pipeline Inspection Company,

Houston, Texas 77055, United States.

A copy of this Operating Instructions Manual can be downloaded on our

website at picltd.com.

4

pi clt d.co mpi clt d.co m

5

unit calibration principles of wet Sponge

h o l i day detection

As the operator of this unit you require accurate, safe, and reliable equipment to

perform coating inspections at the proper output voltage.

Prior to leaving our manufacturing facility Pipeline Inspection Co. certifies

that SPY

®

Model 670 Wet Sp onge Holiday Detectors has b een calibrated and

demonstrates the ou tput voltage of 67.5 volts (+/- 5%). Since output voltage is

regulated, this toler ance is maintained regardless of load.

Your unit comes with a Factory Calibration Certificate and a Factory

Authorized Calibration Decal applied to the bottom of the unit both with the

date your unit was calibrated.

Our units do not tend to drift but it is recommended that this unit be calibrated at

least once per year or more frequently based on heav y usage. Recal ibration of

our equ ipment should be perfo rmed ONLY at a SPY

®

Authorized Service

Cente r due to the uniq ue calibration proces s; test equi pment util ized and

prope rly trained SPY

®

technicians.

We DO NOT recommend using any other calibration ser vice other than a SPY

®

Authorized Ser vice Center; using an outside service with technicians not trained

to work on SPY

®

brand equipment could damage the unit and if the enclosure is

opened will void the warranty.

When calibration is needed please return your unit to a SPY

®

Authorized Service

Center or SPY

®

manufacturing facility located at:

Pipeline Inspection Company

Attn: Calibration

1919 An toine Dr.

Houston, T X 77055

Please include: Company Name and Contac t Information. For a complete list of

Authorized Ser vice Centers please visit our website at picltd.com. If a copy of the

Calibration C ertificate on file is needed it may be obtained by emailing a request to

sales@picltd.com.

Wet Sponge Holiday Detectors are used for the detection of discontinuities

(holidays) in thin film coatings (1-20 mils) of paint, epox y or any non-con ductive

material applied to a conductive material. This t ype of detector uses 67.5 volts

DC for a test voltage, w hich is applied to the test surfac e via a wet sponge. The

fluid media (usually water) in the wet sponge fills the voids in the surface to be

tested and allows low current (micro-amps) to flow into any ho lidays in the test

area. The current moves through the holiday and into the conductive substrate

which activates a horn to indicate the presence of the holiday.

6

pi clt d.co mpi clt d.co m

7

670 overview

The NEW SPY Model 670 Wet Sponge Holiday Detector operates on a

single 9 volt alkaline battery. Unit output voltage is 67.5 volts DC. This

voltage makes the detector highly sensitive and accurate. Compact and

light weight with no bulky battery packs allowing for non destructive

inspection of paints, epoxy paints and coatings 1-20 Mils.

Inspect larger surfaces faster and with less operator fatigue using a

quick attach, easy to use roller sponge electrode. (Optional Accessory).

•

New Ergonomic, Balanced, Lightweight Hand held Design

•

New Rugged, Durable Construction

•

67.5 Volt DC, Sensitive and Accurate

•

New Quick Change Battery Compartment

•

A New Wide Range of Quick Change Accessories

•

New Inspections Kit w/Carrying Case (Optional)

1 Standard Large Sponge

2 Standard 14.5” Wand Shaft

3 Quick Connect Points for

Optional Accessories

4 Built-In 8 0Kohm and 100Kohm

Calibration Test Buttons

5 Water Proof Power Switch

6 Audible Holiday Indicator

7 Visual Holiday and Low Battery

Indicator

8 Shoulder Strap Connection

9 Quick Change Batter y

Compartment

10 Ground Cable Connection

9

10

3

3

5

6

7

8

4

2

1

8

pi clt d.co mpi clt d.co m

9

con necting accessories

STEP 3. CO NNECTING T HE GROUND CABL E. The ground cable at tach

point is on the backside of the 670, untwist the black knob to expose the hole in

the ground connector, thread the ground wire through the hole and then tighten the

black ground connector knob tightly with your hand only.

CAUTION! DO NO T TOUCH Make sure the switch is in the OF F position

prior to connecting any accessory.

STEP 1. CONN ECTING THE E LECTRODE WAND. Screw the wand onto the

base of the 670 holiday detector and firmly tighten with your hand only.

STEP 2. CO NNECTING T HE ELECTROD ES. The flat sponge ele ctrode comes

standard with t he 670 and is already attac hed to the wand. However, if you purchased

the optional roller sponge electrode just unsc rew the flat sponge electrode from the

top of the wand and screw on the optional roller sponge elec trode. You can adjust

the flat sponge o r roller sponge electrode by simply holding the knurled k nob firmly

and twisting the electrode to the desired position.

CAUTION! DO NO T TOUCH THE ELECTRODE WHILE T HE DETECTOR

IS OPERATING.

CAUTION! DO NO T TOUCH THE ELECTRODE WHILE T HE DETECTOR

IS OPERATING.

PROPER GROUNDING. Make sure the ground c able is uncoiled and

extended.

DIAGRA M 1: Shows the method of completing a circuit is by connecting

the ground cable of the 670 holiday detector to the unco ated part of the metal

substrate of the test piece using the alligator clip. This allow s the circuit to

complete directly from the detector through the holiday into the substrate back

into the detec tor.

1

2

3

DIAGRAM 1

WET SPONGE GROUND

CABLE

METAL

NON-CONDUCTIVE

COATING

ALLIGATOR

CLIP

PINHOLE

HO LIDAY

10

pi clt d.co mpi clt d.co m

11

battery

Instructions

connecting optional

accessories

For a range of optional accessories and spare parts that enhance and

expand the capabilities of the SPY 670 SPY offers an Optional 670

Inspection Kit. See the Accessories page in this manual or call your SPY

distributor or manufacturer to order.

STEP 5. (OPT IONAL) CONNECTING THE SHOULDER STRAP.

Attach the strap clips tabs on each side of the 670 detector. Adjust strap

for comfort. The strap comes with the optional 670 Inspection Kit which

offers the option of attaching a light weight foam handle wand to use

while operating rather than holding the weight of the complete unit.

STEP 6. (OPTIONAL) CONNECTING ADDITI ONAL 14.5”

WAND EXTENSION RODS. With the 670 turned off simply unscrew

the electrode from the wand and screw on the number of 14.5” wand

extensions you need for the job, once complete add the electrode back

to the end of the wand. The optional 670 Inspection Kit comes with

2-14.4” wand extensions to give the 670 detector added length for hard

to reach test areas

STEP 7. (OPTIONAL) CONNECTING WAND LEAD CABLE.

With the 670 turned off disconnect the wand from the base of the unit,

screw the knurled portion knob of the wand lead cable to the base of the

unit and plug the other end of the wand lead cable to the end of the foam

handle wand. Unscrew the electrode from the stock wand electrode and

screw it on the foam hand wand.

The NEW SPY® Model 670 Wet Sponge Holiday Detector operates on

a single 9 volt alkaline battery. Unit output voltage is 67.5 volts DC. This

voltage makes the detector highly sensitive and accurate.

STEP 1: Make sure the detector switch is in the off position.

STEP 2: The battery compartment is located on the left side of the unit,

using the notch on the bottom of the batter y compartment lift up and

pull out to slide the battery tray out.

STEP 3: Insert a new 9V battery into the battery tray and push the

battery tray firmly back into the unit making sure it locks back into place.

If the battery discharges to a low level the detector will begin to tone

continuously, at this point the detector is not properly detecting holidays

and the battery should be changed to a new 9V battery.

Low Battery

12

pi clt d.co mpi clt d.co m

13

controls

testing

instructions

No Signal adjustment is necessary with the 670 Wet Sponge Holiday

Detector. The unit can easily be tested by means of the test buttons

located on the front operating panel.

The test is performed by turning the 670 on and by pressing the 80 Kohm

button, the signal will become active causing the horn and LED to be

activated. Release the 80 Kohm button then press the 100 Kohm, the

signal should NOT activate the horn and LED. This test indicates the unit

sensitivity is within calibration.

670 operation

STEP 1: Insert a new 9V battery in the battery box and push the

battery box firmly back into the unit making sure the battery box locks

back into place.

STEP 2: Attach the electrode wand and electrode.

STEP 3: Attach the ground cable to the conductive substrate of the test

surface (the uncoated bare metal portion of the surface). See Diagram

1 on page 8.

STEP 4: Wet the electrode sponge with clean tap water to where it is

damp or moist to the touch and apply SPY

®

wetting agent.

STEP 5: Keeping the detector away from the test surface and turn the

detector to the on position.

IMPORTANT! While the electrode sponge must be damp or

moist to the touch it should not be saturated to the point water

is running from the sponge. This can result in the water migrating and

causing the current to flow away from the sponge down the test surface

to holidays further down the test sur face or even on the support surface

causing false holiday indications.

IMPORTANT! When the coating thickness is between 11– 20

mils, a low sudsing wetting agent such as KODAK Photo-flo

™

should be applied to the water (test media). This will allow for a lower

surface tension, which will help the test media to penetrate the thicker

coatings. You can order Kodak Photo-flo

™

direct from SPY®.

14

pi clt d.co mpi clt d.co m

15

STEP 6: Place the electrode sponge on the coated surface and begin

passing the sponge across the surface (See Diagram 2 Below). Several

passes should be made over the test area to ensure that moisture has

penetrated any possible holiday. If the sponge passes across a pinhole

in the coated surface an audible horn from the detector will begin to

sound and the red light on the control panel will light up. The audible

and visual alert will stop once the electrode moves away from the

pinhole. For more precisely locating the holiday use the corner of the

sponge in the area the holiday occurred.

IMPORTANT! Care should be made to ensure that the sponge

stays as clean as possible. Dirt or other contamination of the test

surface adds resistance, which impedes the current flow capability of

the sponge. This can result in missing holidays in the test piece.

troubleshooting guide

PROBLEM POSSIBLE SOLUTION CORRECTION MET HOD

HOLIDAY

DETECTOR

WILL NOT

DETECT

HOLIDAY S

Test Buttons Push the 80k test button,

the horn should sound.

Push the 100k test button,

the horn WILL NOT sound.

Detection Testing Touch electrode/wand

directly to bare ground

cable to test that the unit is

functioning properly.

The horn will sound and the

light on the control panel

will light up.

If the detector does not

detect then ensure ground

cable and electrode wand

are correctly connected.

If the detector still fails

to detect a defect in the

coating a repair may be

needed, contact Pipeline

Inspection Company for

support.

TROUBL ESHOOTING G UIDE CONTIN UED ON THE NE XT PAGE...

DIAGRAM 2

CONNE CT GROUND CA BLE TO UNCOATED ME TAL SUBSTR ATE.

16

pi clt d.co mpi clt d.co m

17

troubleshooting guide troubleshooting guide

PROBLEM POSSIBLE SOLUTION CORRECTION MET HOD

HOLIDAY

DETECTOR

WILL NOT

DETECT

HOLIDAY S

Check Detector Ground

Connection

With the detector OFF

remove the ground

cable, clean banana plug

connection point and

reconnect ground.

Ensure both ends of the

ground cable are clean.

Ensure the clip end of the

ground cable is securely

connected to metal

substrate.

Check Electrode/

Wand Connection

With the detector OFF

unscrew the wand,

clean connections and

reassemble.

Ensure wand and electrode

connection points are clean.

PROBLEM POSSIBLE SOLUTION CORRECTION MET HOD

DETECTOR

HORN

CONSTANT

SOUND

Check Battery When the battery is

low the horn will sound

continuously to let you

know it needs to be

replaced. Replace with

new battery.

Test Buttons Stuck Check that the test buttons

are not stuck by pressing

each several times to

disengage.

DETECTOR

DOES NOT

TURN ON

Switch Check the power switch to

make sure its full toggled

on.

Battery Batter y is low. Replace

battery.

18

pi clt d.co mpi clt d.co m

19

technical

specifications

If maintained the Model 670 Wet Sponge Holiday Detector will offer you

years of dependable operation. Regular care and maintenance of the unit

is a requirement of good quality preventative maintenance practices.

WARN ING! This detector does not contain any user-serviceable

parts; your warranty will be voided if the SPY

®

unit is opened

by anyone other than a SPY

®

Authorized Service Center or SPY®

manufacturing facility.

In the event the unit fails to operate properly please return your unit to a

SPY Authorized Ser vice Center or SPY manufacturing facilit y located at:

Pipeline Inspection Company

Attention: Repair

1919 Antoine Dr.

Houston, Texas 77055

Please include: Company name, contact information and a short

description of the problem with the unit. For a complete list of

Authorized Service Centers please visit our website at picltd.com.

ELECTRODES AND ACCESSORIES

Sponge electrodes and all attached accessories are prone to wear and

tear and will eventually need to be replaced, timing of replacement

will depend on how they are maintained and the coatings that they are

used on.

maintenance & repair

MODEL 670

Voltage Type DC

Voltage Range (k V) 67.5 Volts

Voltage Output Accuracy ±5%

Coating Rang e (Min-Max ) 1 - 20 mils

Operating Temperature 33°F to 148°F

Holiday Indic ator Type Audible/Visual

Battery 9 Volt Battery

Battery L ife 8-12 Hours

Low Battery Indicator Yes

Unit Weight Only 0.9 lbs

Unit Weight With Battery Only 1.8 lbs

Unit Dimensions (LxWxH) 9” x 4.5” x 3.25”

With Wand 25” x 4.5” x 8”

Domestic/International Standards NACE SP0188 -2006

Unit Complies W ith

Factory Warranty 3 Month

20

pi clt d.co mpi clt d.co m

21

Pipeline Inspection Company, hereafter referred to as (SPY®) warrants

that SPY

®

‚ Model 670 Series Holiday Detectors shall, under normal use

and service, be free from defects in material and workmanship. SP Y

®

‘s

entire warranty oblig ation shall be limited to, at SPY

®

’s option, the repair or

replacement free of charge to the buyer of any defective equipment or parts

thereof which prove to be defective in material and workmanship under

normal use and ser vice.

Claims for defective par ts must be made in writing within three (3) months

after shipment of the equipment from the works of SPY

®

. Fast wearing and

consumable par ts including, but not limited to, electrodes and ground cables,

are expressly excluded from the warranty. SPY

®

shall have the option to

require return of a claimed defective part to SPY

®

’s manufacturing facility in

the U.S.A ., freight prepaid by buyer for examination to establish buyer’s claim.

Except with SPY

®

’s prior written approval, SPY® shall not be liable (a) for

the cost of repairs, alterations or replacements or any expense connected

therewith made or incurred by the buyer or its designers, or (b) for defects

resulting from alterations or repairs made by others than SPY

®

‚ or its

approved representatives.

SPY

®

shall not be liable for dam ages, including but not limited to direct , special,

indirect or consequential, resulting from the handling, or use, whether alone

or in combination with other products, or any SPY

®

equipment or third par ty

designed or manufactured equipment, including without limitation, any loss

or damage sustained or caused by the operation and use of the equipment

which is improperly operated or its successful operation is impaired by

natural elements after its delivery to the buyer.

The foregoing warrant y is exclusive and in lieu of all other warranties

whether written, oral or implied (including without limitation, any warranty

of merchantability or fitness for purpose).

warranty

FL AT SP ONG E

3” X 2” X 2”

INTERNAL SPONGE

2”- 28” (5 0–711mm)

ROLLER SPONGE

INTERNA L

SPONGE PU LL

CABLE

Electrode types

The Model 670 uses cellulose sponge electrodes that vary in form and

size and fit a wide range of coating inspection projects. If we don’t carry

it we can custom build an electrode to fit your project needs.

Different types of electrodes can be used with different units. The most

common electrode is a flat sponge electrode wand. The Model 670

wand utilizes a 2”x 4” x 8” (51mm x 102mm x 203mm) size flat sponge.

Roller sponges are also available to increase the surface area in contact

and the speed at which the test piece can be tested.

Please call our office at (713) 681-5837 or email us at sales@picltd.com

for more product details or to place an order.

IMPORTANT! SPY uses ONLY cellulose sponges for our wet

sponge units. DO NOT use rubber or urethane sponges!

22

pi clt d.co mpi clt d.co m

23

accessories

The Model 670 has a wide variety of accessories to assist you with your

coating inspection project.

Please call our office at (713) 681-5837 or email us at sales@picltd.com

for more product details or to place an order.

related equipment

GROUND CABLE

(2 5 FT. )

ITEM #11927

SHOULDER

STRAP

ITE M #10187

16 OZ. BOTTLE O F

WET TING AGENT

ITE M #1400 1

ROLLER SPONGE

WAND

ITE M #14160

4 OZ. BOTTLE O F

WET TING AGENT

ITE M #1398 5

14.5” EXTENSION

ROD FOR WAND

ITE M #14162

SPY

®

MODEL 673

WET S PONGE

DETEC TOR

FL AT SPO NGE

WAND

ITE M #14159

ROLLER SPONGE

REPLAC EMENT

PACK S

AVAIL ABLE IN

PACKS O F 3, 5 OR 7

Please call our office at (713) 681-5837 or email us at sales@picltd.com

for more product details or to place an order.

24

pi clt d.co mpi clt d.co m

25

wet sponge inspection kit optional 670 inspection kit

For added operator comfort & inspection capability

KIT INCLUD ES:

1 - CAR RYING/SHI PPING CASE

1 - ROLL ER SPONGE AXL E

3 - SPARE RO LLER SPONGES

2 - 14.5” EX TENSION SHA FTS

1 - SPARE FL AT SPONGE

(4” X 8” X 2”)

1 - 35FT G ROUND CABLE

1 - FOAM WAND H ANDLE

1 - WAND SIGN AL CABLE

1 - 4OZ. WE TTING AGENT

2 - 9 VOLT BATTERI ES

1 - SHOULD ER STRAP

ITE M #670 KIT (DE TECT OR NOT

INCLU DED)

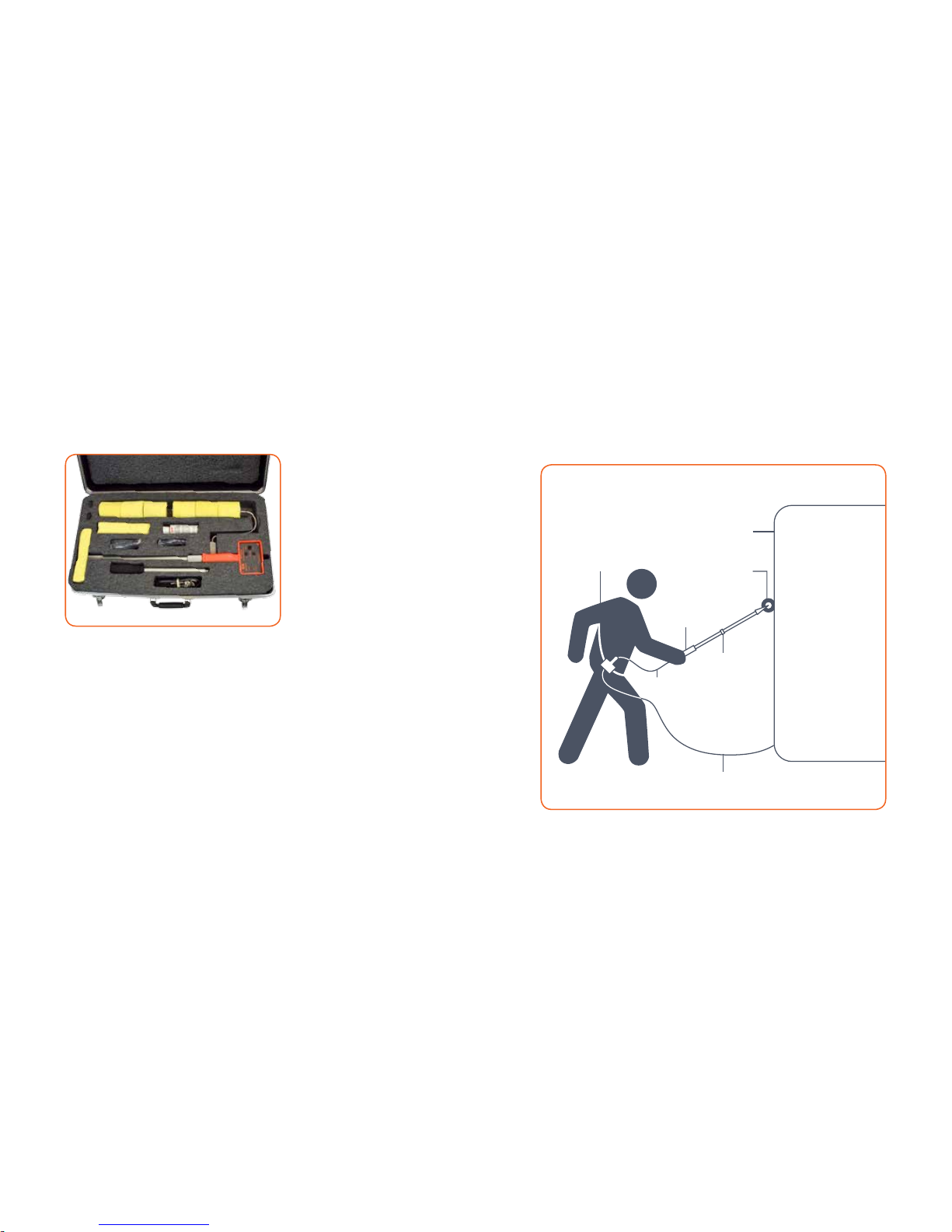

Foam Grip Wa nd

Handle for Ad ded

Comfort

Any La rge

Coated Surface

12” Roller Spong e

to Reduce Surface

Resistance

2 - 14.5” Add- On

Extensions for

Added Reach

35’ Ground C able to Help Inspect

Larger Co ating Areas

Wand Signal

Cable

Adjustable Shoulder

Strap to Carr y 670

and Reduce Operator

Fatigue

26

pi clt d.co mpi clt d.co m

27

User Notes User Notes

PIPELINE INSPECTION COMPANY

picltd.com

Loading...

Loading...