SPT SPT2110SCT Datasheet

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: (719) 528-2300 FAX: (719) 528-2370

SPT2110

NTSC/PAL VIDEO DECODER

FEATURES

• NTSC/PAL Video System Compatible

• Dual 9-Bit Wide Data Paths for Video Processing

• Composite or Component Video Inputs

• Supports Three Video Sampled Modes: Square Pixel,

ITU-R BT.601 (CCIR-601), and 4Fsc (NTSC Only)

• Sync Detector and Complete Timing Generator

• Comb Filters (NTSC)

• Two Output Formats: YCrCb (4:2:2), RGB (4:4:4)

• Picture Quality Adjustment Functions:

Luminance Signal: Peaking Compensation,

Contrast, Brightness

Chrominance Signal: Hue, Saturation

• MPU Interface Control

• 100-Lead PQFP Package

• +3.3 V Single Power Supply

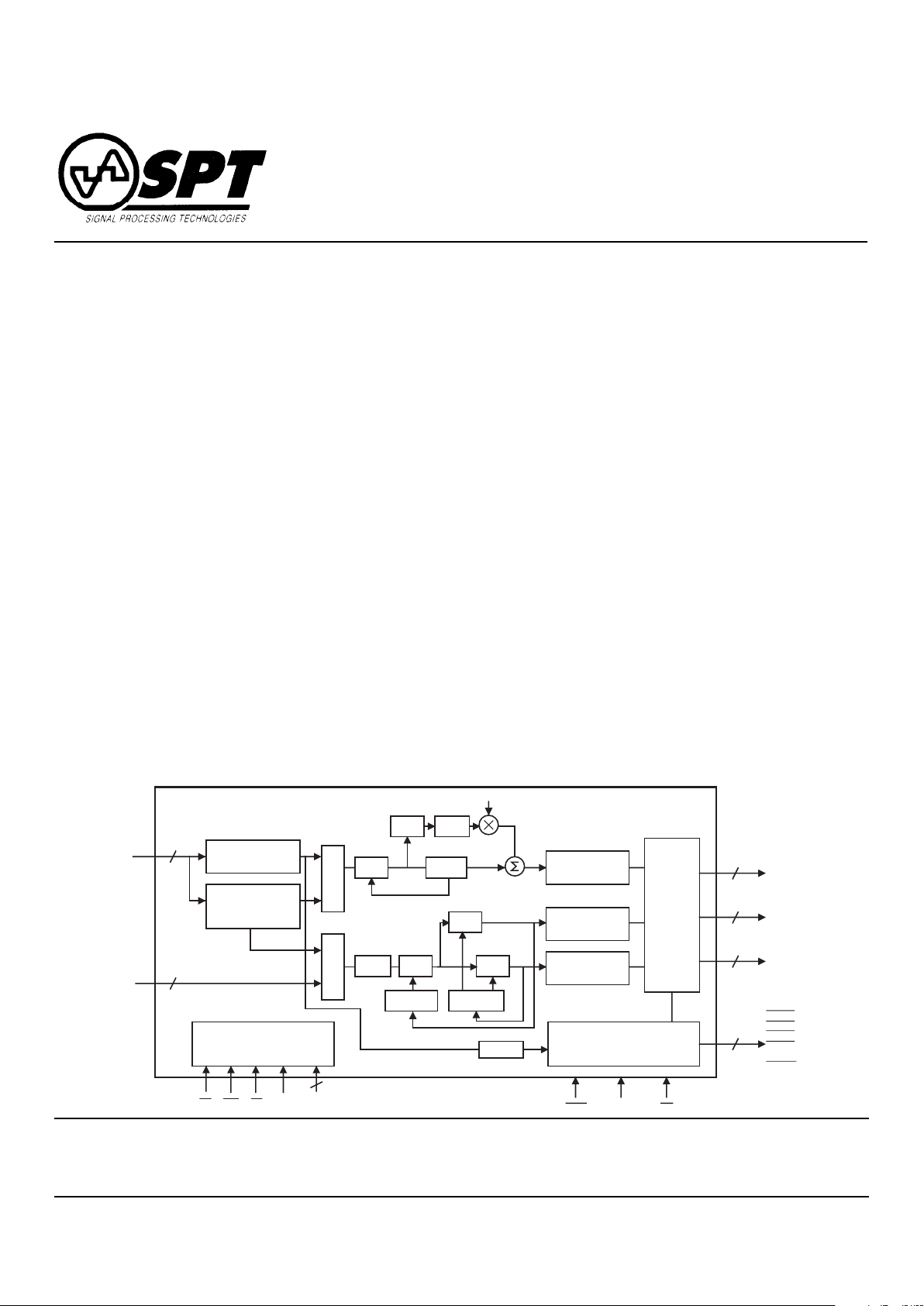

BLOCK DIAGRAM

APPLICATIONS

• High-End NTSC or PAL Video Decoding

• S-Video Decoding

• Composite Video Decoding

• Video Frame Grabbers

• Video Projection and Displays

• Digital VCRs

• Digital Video Transmitters

• Video Printers

• Image Filing Systems

• Multimedia PCs

• Advanced Set-Top Boxes

• Security Cameras

GENERAL DESCRIPTION

The SPT2110 is a high-performance video digital signal

processor for NTSC and PAL applications. It processes 9-bit

composite digitized video or two 9-bit component digitized

video signals. All internal processing is done at 9 or more bits.

The decoder outputs the image data in YCrCb (4:2:2) or RGB

(4:4:4) formats. This product has many advanced internal

features not found in other decoder products. These features

include full 9-bit processing, AGC on both luminance and

chrominance processing, exceptional picture quality controls, complete timing generation and a simple MPU interface. All these features provide for easy digital video design

and produce digital image data that is free from dot error and

color noise. The SPT2110 video decoder is ideal for composite or S-Video applications requiring high quality signal decoding.

M

u

x

Trap Filter

M

u

x

Y/C Separator

(Comb)

Sample Alignment

Sample Alignment

Timing Generation

Control Parameter Registers

Color

Space

Conversion

MPU Interface

HSYNC

VSYNC

HBLNK

VBLNK

ODD

STATUS

9

9

CHR8 - 0

8

R Y

G Cr/Cb

B

5

8

8

8

Sample Alignment

CS WR RD RS D7-0

ClockReset OE

CBPF ACC

Demod

Demod

DTO

Burst

Comp

Sync Det

AGC

BPF

Coring

Peaking

LUM8 - 0

SYNC

SEP

SPT

2 3/27/98

SPT2110

The SPT2110 is part of a three-chip solution for high quality

video signal decoding. The companion integrated circuits are

the SPT9210, a dual analog video processor, and the

SPT7852, dual 10-bit ADC. The SPT9210 provides internal

DC restoration and Automatic Gain Control (AGC) of the

video signal. The SPT7852 provides 10-bit resolution video

digitization.

The SPT2110 operates from a single +3.3 V supply. It is

available in a 100-lead PQFP package and operates over the

commercial temperature range.

GENERAL OVERVIEW

The SPT2110 video decoder is compatible with NTSC or PAL

video standards. It has two 9-bit digitized video inputs busses

and three 8-bit video data output busses with sync, blank,

field indicator and chrominance data indicator output signals.

The SPT2110 is fully programmable through the command

registers. Each command register is accessed by a single

address register. The control lines and the bidirectional 8-bit

data bus provide access to the command and address

registers.

DIGITAL VIDEO INPUT DATA BUSSES

The two 9-bit digital video input data busses have 3.3 volt

compatible logic levels. In composite mode, the composite

digital video is input through the LUM8…0, 9-bit data bus. In

component mode, the luminance component is input through

the LUM8…0, 9-bit data bus while the chrominance component is input through the CHR8…0, 9-bit data bus. Register 1

selects whether composite or component video input data will

be processed. The input busses expect valid data on each

rising edge of the clock input. Refer to the timing diagram,

figure 1.

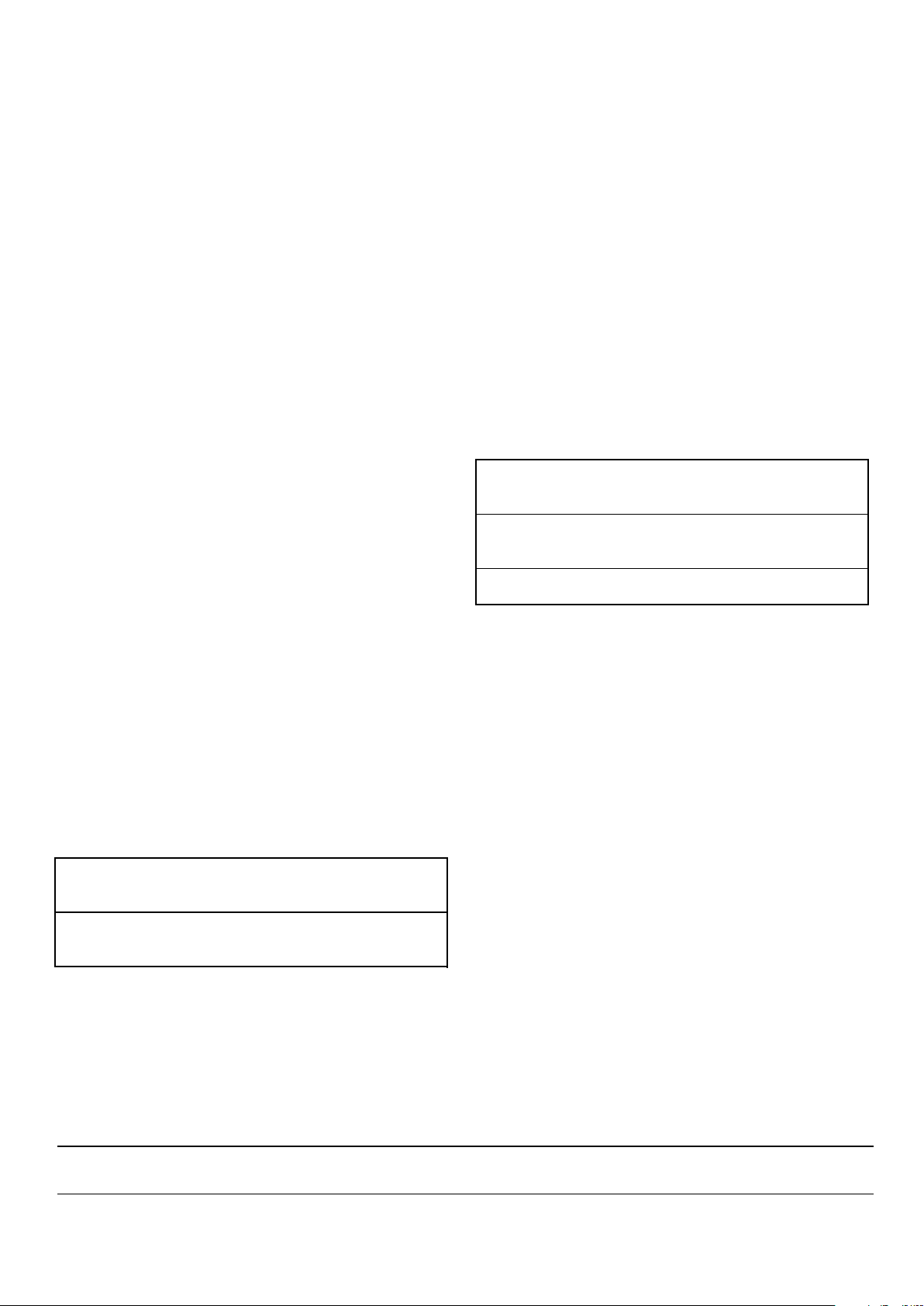

Table I - Digital Image Input Busses Description

Bus Label Description

LUM8...0 Digitized video data for composite

video or the luminance signal input.

LUM8 is the MSB, and LUM0 is the LSB.

CHR8...0 Digitized video data for the chromi-

nance signal input. CHR8 is the MSB,

and CHR0 is the LSB.

DECODED DIGITAL VIDEO OUTPUT DATA

BUSSES

The three 8-bit digital video output data busses on the

SPT2110 have 3.3 volt compatible logic levels. All three

busses are used for RGB digital video data output. Two

busses are used for YC (YCrCb) digital video data. The RGB

data is NTSC or PAL video that has been translated to RGB

(4:4:4) format. The YC data is NTSC or PAL video that has

been translated to YCrCb (4:2:2) format. The luminance

portion of the YCrCb output (Y) is output on the Y/R7…0 bus,

and the color difference signal data (Cr and Cb) is output on

the C/B7…0 bus. Cr and Cb are alternately output every other

clock cycle. All three busses may be programmed to a tristate level. Refer to the timing diagram, figure 1.

Table II - Digital Video Output Busses Description

Bus Label Description

Y/R7...0 Decoded video data for Y (luminance) or R

(red). Y/R7 is the MSB, and Y/R0 is the

LSB.

C/G7...0 Decoded video data for C (chrominance)

or G (green). C/G7 is the MSB, and C/G0

is the LSB.

B7...0 Decoded video data for B (blue). B7 is

the MSB, and B0 is the LSB.

VIDEO TIMING OUTPUT SIGNALS

The video timing output signals have 3.3 volt compatible logic

levels. They produce the temporal information that identifies

the spacial position of the video signal. They are used

downstream to synchronize signals and for odd/even field

identification. These discrete output timing control signals

may be programmed as positive or negative true logic or they

may be tri-stated.

The video timing output signals are described in table III. The

signal names are horizontal sync, vertical sync, horizontal

blank, vertical blank, odd/even field indicator and chrominance flag. Refer to timing diagrams 1, 3 and 4.

SPT

3 3/27/98

SPT2110

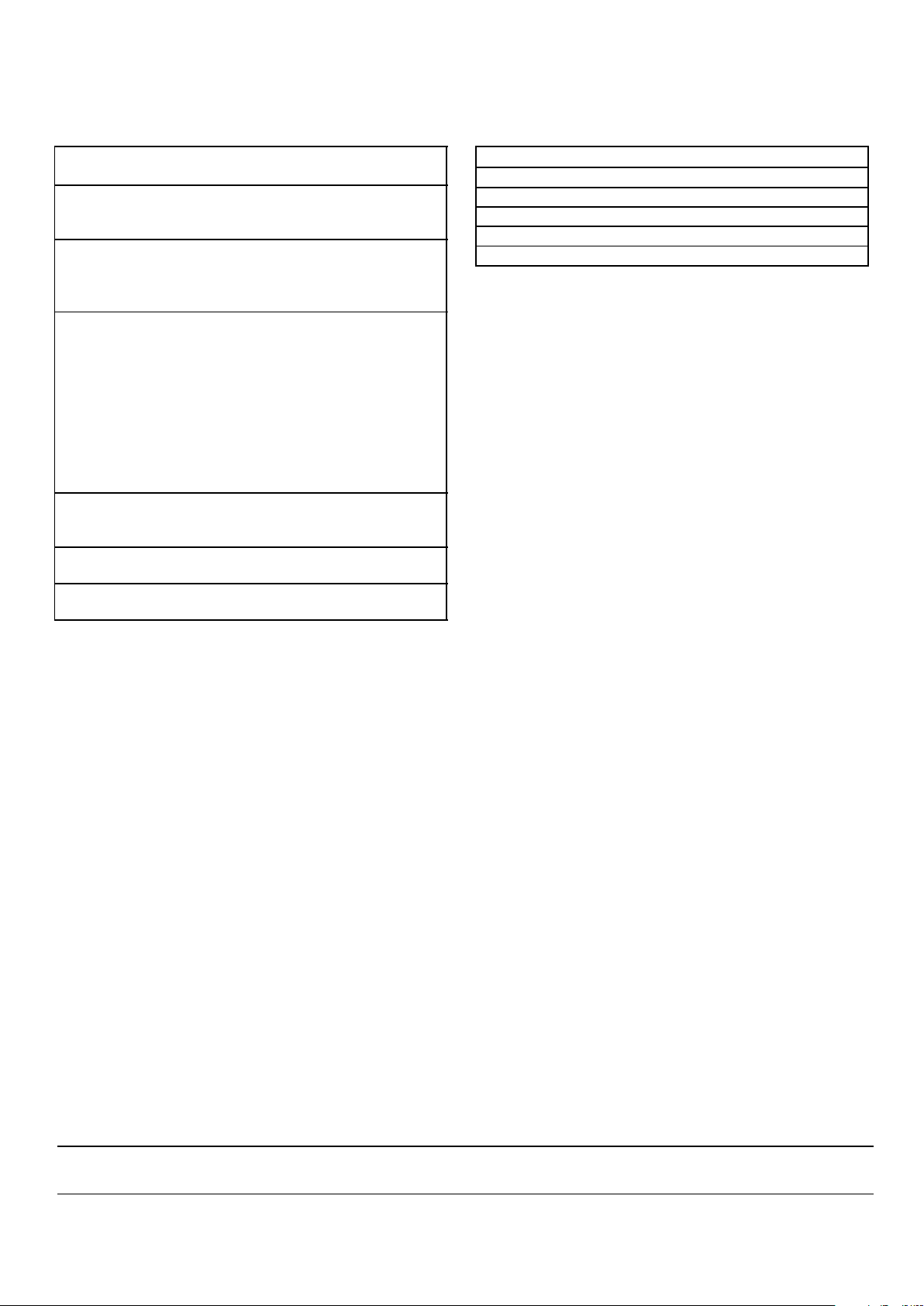

Table III - Timing Control Signal Description

Signal

Label Description

HSYNC This is the horizontal synchronizing signal; its

width is equal to the width of the incoming

digitized video signal.

VSYNC This is the vertical synchronizing signal. 3H time

for NTSC starting after the three H lines of

equalizing pulses and 2.5H time for PAL starting

at beginning of line 1 and line 312.5.

HBLNK This is the horizontal blanking signal. Registers

DH and EH control the start and stop locations

of the active pixels. When this signal is

deasserted the following number of active video

pixels is displayed for the various sampling

modes.

- ITU-R BT.601 720 active pixels

- NTSC square pixel 640 active pixels

- NTSC4Fsc 768 active pixels

- PAL square pixel 768 active pixels

VBLNK This is the vertical blanking signal. Registers FH

and 10H control the start and stop locations of

the active lines.

ODD When active, this signal indicates that the odd

field is being output from the decoder.

CFLAG This signal indicates whether Cb or Cr data is

active.

Note: Due to asynchronous sampling of the video signal, a

periodic deviation of the sync width by one pixel clock may

be generated in HSYNC, VSYNC, HBLNK, VBLNK and

ODD signals.

CLOCK SIGNAL

The clock (CLK) input has is 3.3 volt compatible logic. The

clock is the master time-base controller for the SPT2110. The

SPT2110 synchronizes data input, data output, control signal

out, address and command register modifications and data

processing to the clock. A stable, jitter-free clock signal

should be used.

Table IV - Sample Mode Clock Frequencies

Sampling Mode Input Frequency (MHz)

NTSC Square Pixel 12.2727

NTSC ITU-R (CCIR-601) 13.500

NTSC 4 Fsc 14.3182

PAL Square Pixel 14.7500

PAL ITU-R (CCIR-601) 13.5000

MPU INTERFACE

The SPT2110 provides for microprocessor unit (MPU) based

programming and control through a 3.3 V compatible logic

interface. The MPU interface is comprised of a bidirectional

8-bit data bus and four discrete control registers. A description of this interface is shown in table V.

COMMAND AND ADDRESS REGISTERS

The SPT2110 operational performance is controlled by internal command registers that are accessed through the MPU

interface described above. There is one address register and

20 command registers (0H - 13H). All registers have read/

write capability.

The address register is used to identify the command register

to be operated. This register must be written to first with the

address of the target command register before a read/write

operation can be performed on the command register. Tables

VI and VII describe the normal operation for reading and

writing to the address register.

Most of the command registers control multiple functions, i.e.,

each bit or group of bits within a register controls a chip

function. When modifying a register a read of the register

should be performed first. Then alter the bit(s) while maintaining the rest of the bits in their present state. Finally, write the

modified data back into the register.

Tables VIII and IX describe the operation for reading and

writing to a selected command register. All registers have a

default setting when the STP2110 is reset. For a detailed

description of the functions of each register, refer to table XIII,

Command Register Description Table.

SPT

4 3/27/98

SPT2110

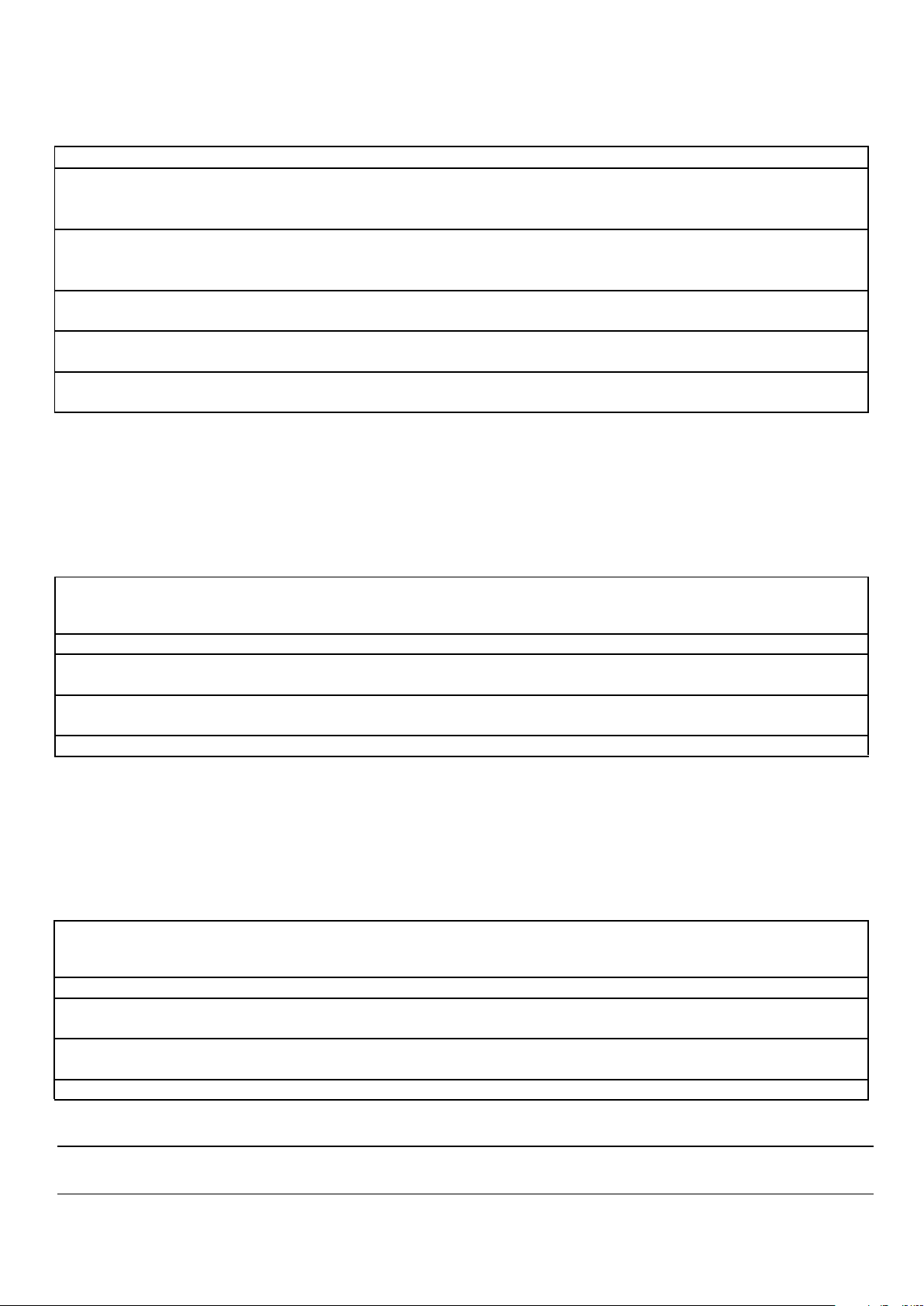

Table V - MPU Interface Description

Signal Name Abbreviation Description

CHIP SELECT CS_ The Chip Select signal (active low logic) enables further action by the chip from the other

control lines This means the chip needs to process (recognize) one of the following

control signals: RS, WR_ or RD_.

REGISTER RS The Register Select signal (active high logic) enables access to the Command Register

SELECT that the address register is holding. When this signal is low it enables the address data

register.

WRITE WR_ The Write signal (active low logic) transfers the data on the data bus into the address or

command data register (depending on the level of RS).

READ RD_ The Read signal (active low logic) transfers the data in the address or command data

register (depending on the level of RS) onto the data bus.

DATA(7-0) D7-0 This is the 8-bit bidirectional data bus for transferring data to and from the SPT2110. The

direction is dictated by the WR_ (input) and RD_ (output) signals.

Refer to the Electrical Specification Table for correct interfacing of the SPT2110. Note the assert times required for each of

the control lines. The times must be a numerical multiple of the clock that operates the SPT2110.

The accessing of a Command register(s) is performed as shown in table VI below.

(Note that 1 defines logic high, 0 is logic low, X is defined as don’t care and D is valid data)

Table VI - Write Address Register

CONT.

STATE\

STEP CS_ WR_ RD_ RS DATA (7-0) COMMENTS

1 0110DDh

2 0010DDh Data needs to be valid on the data bus for minimum setup time

(relative to the WR_ signal).

3 0110DDh Data needs to remain valid on the data bus for minimum hold

time (relative to the WR_ signal).

4 111XXXh Completed Address Write

The address write sequence described above is a normal write sequence. A write can be performed by asserting

CS_ and RS (to logic low). Observe the minimum setup time before asserting WR_. Hold CS_ and RS for the hold

time and then release CS_ and RS. Then set the data bus to the valid address for the minimum setup time before

the rising edge of WR_. Then hold the data bus for the hold time required. Note that the WR_ assert time is a

multiple of the clock. This sequence will perform a valid write to the address register. The following read write

functions may be performed in a manner similar to the normal sequences outlined in the tables VII and VIII.

Table VII - Read Address Register

CONT.

STATE\

STEP CS_ WR_ RD_ RS DATA (7-0) COMMENTS

1 0110XXh

2 0100DDh Data is valid on the data bus after output delay time (relative to

the RD_ signal).

3 0110XXh Data continues to remain valid for output hold time delay (relative

to the RD_ signal).

4 111XXXh Completed Address Read.

SPT

5 3/27/98

SPT2110

The following assumes the address register is already set.

Table VIII - Write Command Register

CONT.

STATE\

STEP CS_ WR_ RD_ RS Data (7-0) Comments

1 0111DDh

2 0011DDh Data needs to be valid on the data bus for minimum setup time

(relative to the WR_ signal).

3 0111DDh Data needs to remain valid on the data bus for minimum hold

time (relative to the WR_ signal).

4 111XXXh Completed Command Write.

Table IX - Read Command Register

CONT.

STATE\

STEP CS_ WR_ RD_ RS Data (7-0) Comments

1 0111XXh

2 0101DDh Data is valid on the data bus after output delay time (relative to

the RD_ signal).

3 0111XXh Data continues to remain valid for output hold time delay (relative

to the RD_ signal).

4 111XXXh Completed Command Read.

If the address already contains the correct address of the register to be accessed, it is not necessary to perform

an address register write. Only a command register acquisition is required to write or read the command register.

OTHER DISCRETE SIGNALS

The other signals not discussed are the Reset, Status and OE signals. The following table describes these functions.

Table X - Other Discrete Signals

Signal Input/

Name Output Description

RESET_ INPUT This signal is an input active low. It requires three or more input clocks while the signal

is active to reset the device. It resets all registers to their default states and clears all

data within the device.

STATUS_ OUTPUT This signal is an output active low signal. It will be asserted whenever video sync is

being detected and will go inactive when sync is not detected.

OE_ INPUT When asserted, this signal enables the output signals. This is an active low logic signal.

It tri-states the outputs when deasserted and enables them when asserted. The signals

that are controlled are the data output busses (RGB/YC), HSYNC, VSYNC, HBLNK,

VBLNK, ODD and CFLAG.

SPT

6 3/27/98

SPT2110

LUMINANCE PROCESSING

LUMINANCE SEPARATION

For composite video the luminance needs to be separated

from chrominance in the baseband video. Each is processed

separately. Selection of the separation method is determined

by register 3H. Separation of the luminance from the chrominance is performed by a 2H comb, 1H comb or trap filter.

Comb filtering is available for NTSC signal processing only.

The comb is the best filter method for composite video. The

trap filter method of separation reduces the dynamic performance of the luminance signal above 2.3 MHz due to the filter

transfer function.

This separation is not necessary for component (Y/C, S-Video).

The comb filtering is inhibited, and the digitized data is sent

on to the luma processing circuitry.

SYNC SEPARATOR

The sync signals are separated from the luminance component and sent to the timing control circuit. The sync pulses are

used to synchronize the timing of the number of pixels per

line, number of lines, and odd field identification.

LUMINANCE MUX

A 2:1 mux is used to multiplex the digital luminance component data to either the trap filter or comb filter.

AGC

Automatic Gain Control (AGC) for the luminance signal is

derived from the amplitude of the sync signal. The video

luminance is scaled by the value derived from the sync signal

value. This is a very important feature for nonstandard video

signal values. In addition, the sync is removed from the

luminance signal at this stage before further luminance

processing.

PICTURE QUALITY FUNCTIONS

LUMINANCE SIGNAL CORRECTION

Luminance signal correction is composed of three luminance

digital signal processing functions. These functions include

selecting a frequency pass band that will be further enhanced, a coring function and a peaking function. The peaking function must be set to a compensation value (other than

zero, default) for either of the other two functions to be

enabled. The Pass-Band (PBAND) Filter is controlled by

register 6H. It sets the lower limit of the pass band filter. These

frequencies will be peaked further downstream. The coring

function provides a hysteresis effect on pixel-to-pixel data

value changes based on a threshold coring level set by the

core register 7H. Coring is performed on the pre-peaked

signal levels. With the pass-band and the coring levels set,

the peaking compensation value is applied to those luminance signals that fit in the selected profile. Peaking is a

multiplicative factor that gains up the selected frequencies.

The higher the peaking factor the more gain provided for

those selected frequencies. Peaking is controlled by register

8H.

Brightness is controlled by register 12H. This puts an additive

value to the luminance signal. This additive value is plus or

minus 32 LSBs of the luminance signal. It is a DC value for the

luminance signal. Brightness is applied after luminance signal correction is performed.

Contrast is controlled by register 11H. This setting applies a

multiplying factor to the luminance signal. The coefficient

multiplies the luminance value after it has been corrected.

SYNC REINSERTION

The sync signals are reinserted into the luminance signal

after all luminance signal processing is performed.

LUMINANCE SAMPLE ALIGNMENT

Sample alignment circuitry ensures the same number of

pixels per line and field/frame. Counting registers control this

process based on the mode of operation. They determine the

number of pixels per line and the number of lines per field.

LUMINANCE COLOR SPACE CONVERSION

The color space conversion block uses the luminance signal’s

value to transform from the NTSC or PAL system format that

was originally digitized to either RGB of YCrCb. This process

requires the values of both luminance and chrominance be

synchronized in time to make this conversion correctly. The

transformation to RGB or YCrCb is performed using the

luminance and color difference signal data.

CHROMINANCE PROCESSING

COLOR SEPARATION

For composite video, the chrominance needs to be separated

from luminance in the baseband video. Each is processed

separately. Selection of the separation method is determined

by register 3H. Separation of the chrominance from the

luminance is performed by a 2H or 1H comb filter or the trap

filter. The comb separation is the best separation method for

composite video. Comb filtering is available for NTSC signal

processing only.

For component (Y/C, S-Video), this separation is not necessary. The comb filter is inhibited and the digitized chrominance data is sent on for chroma processing.

Loading...

Loading...