SPT SPT1019AIN, SPT1019BIN Datasheet

SPT1019

8-BIT, HIGH SPEED D/A CONVERTER

FEATURES

• 275 MWPS Conversion Rate - Version A

• 165 MWPS Conversion Rate - Version B

• Compatible with the HDAC10181

with Improved Performance

• RS-343-A Compatible

• Complete Video Controls: Sync, Blank, Bright

and Reference White (Force High)

• 10KH, 100K ECL Compatible

• Single Power Supply

• Registered Data and Video Controls

• Differential Current Outputs

• Stable On-Chip Bandgap Reference

• ESD Protected Data and Control Inputs

GENERAL DESCRIPTION

The SPT1019 is a monolithic 8-bit digital-to-analog converter

capable of accepting video data at a 165 or 275 MWPS rate.

Complete with video controls (Sync, Blank, Reference White

[Force High], Bright), the SPT1019 directly drives doublyterminated 50 or 75 ohm loads to standard composite video

levels. The standard setup level is 7.5 IRE. The SPT1019 is

APPLICATIONS

• High Resolution Color or Monochrome Raster

Graphics Displays

• Medical Electronics: CAT, PET, MR Imaging Displays

• CAD/CAE Workstations

• Solids Modeling

• General Purpose High-Speed D/A Conversion

• Digital Synthesizers

• Automated Test Equipment

• Digital Transmitters/Modulators

pin-compatible with the HDAC10181 with improved performance. The SPT1019 contains data and control input registers, video control logic, reference buffer, and current

switches.

The SPT1019 is available in a 24-lead PDIP package in the

industrial temperature range. Contact the factory for military

temperature and /883 versions.

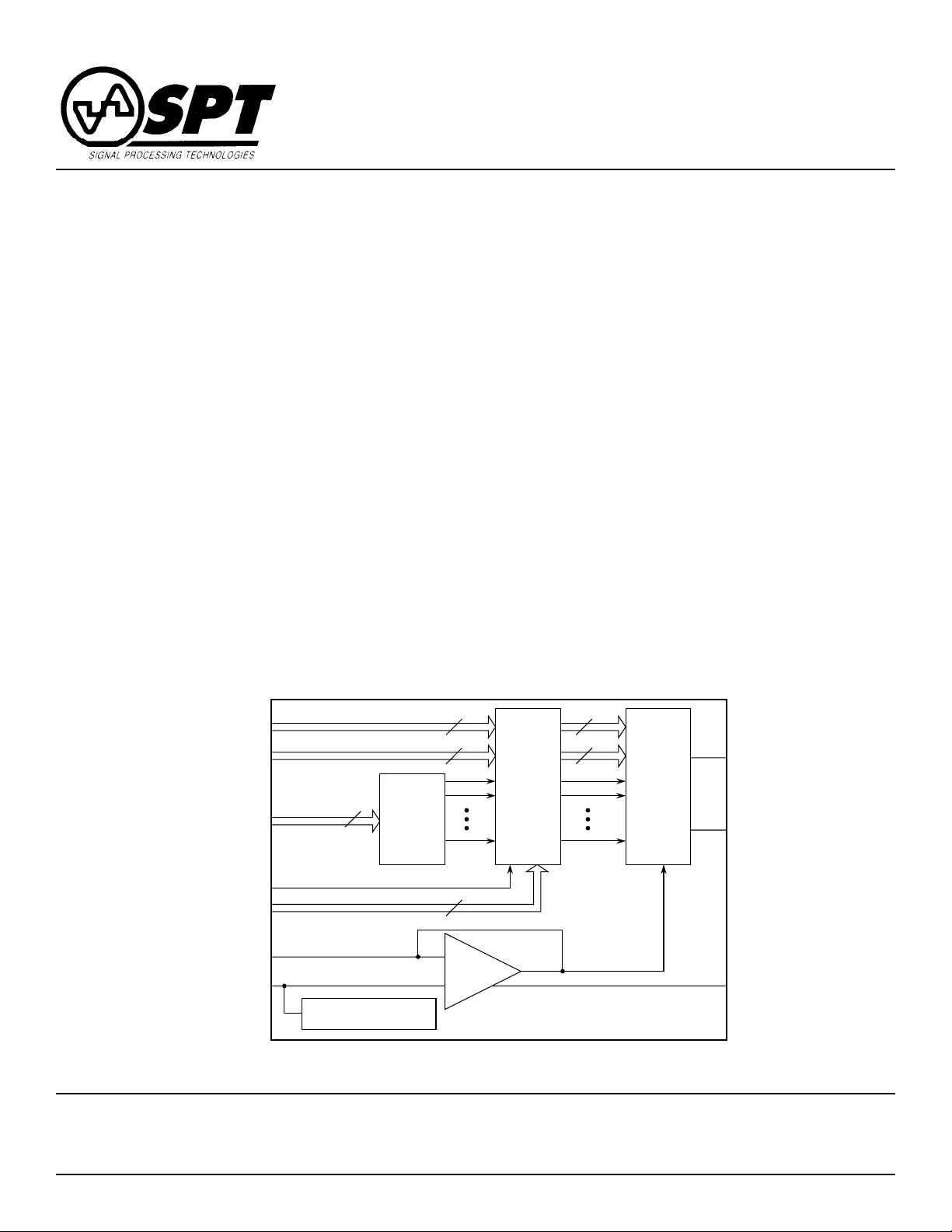

BLOCK DIAGRAM

Video Controls In

Video Data In

Video Data In

Feedthrough

Convert

I

Set

Ref Out

Sync, Blank, Bright, Ref - High

D0 - D3

4 To 15

Decode

D4 - D7

(MSBs)

4

Bandgap

Reference

4

4

2

Ref

Buffer

Register

4

4

Output

Current

Switches

Out +

Out -

Comp

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: (719) 528-2300 FAX: (719) 528-2370

ABSOLUTE MAXIMUM RATING (Beyond which damage may occur)

1

Supply Voltages

VEE (measured to VCC) ............................... -7.0 to 0.5 V

Temperature

Operating, ambient ...............................-25 to + 85 °C

junction........................................ + 175 °C

Input Voltages

CONV, Data, and Controls .......................... VEE to 0.5 V

Lead, Soldering (10 seconds)............................ + 300 °C

Storage ....................................................-60 to + 150 °C

(measured to VCC)

Ref+ (measured to VCC) ..............................VEE to 0.5 V

Ref- (measured to VCC)............................... VEE to 0.5 V

Note: 1. Operation at any Absolute Maximum Ratings is not implied. See Electrical Specifications for proper nominal applied

conditions in typical applications.

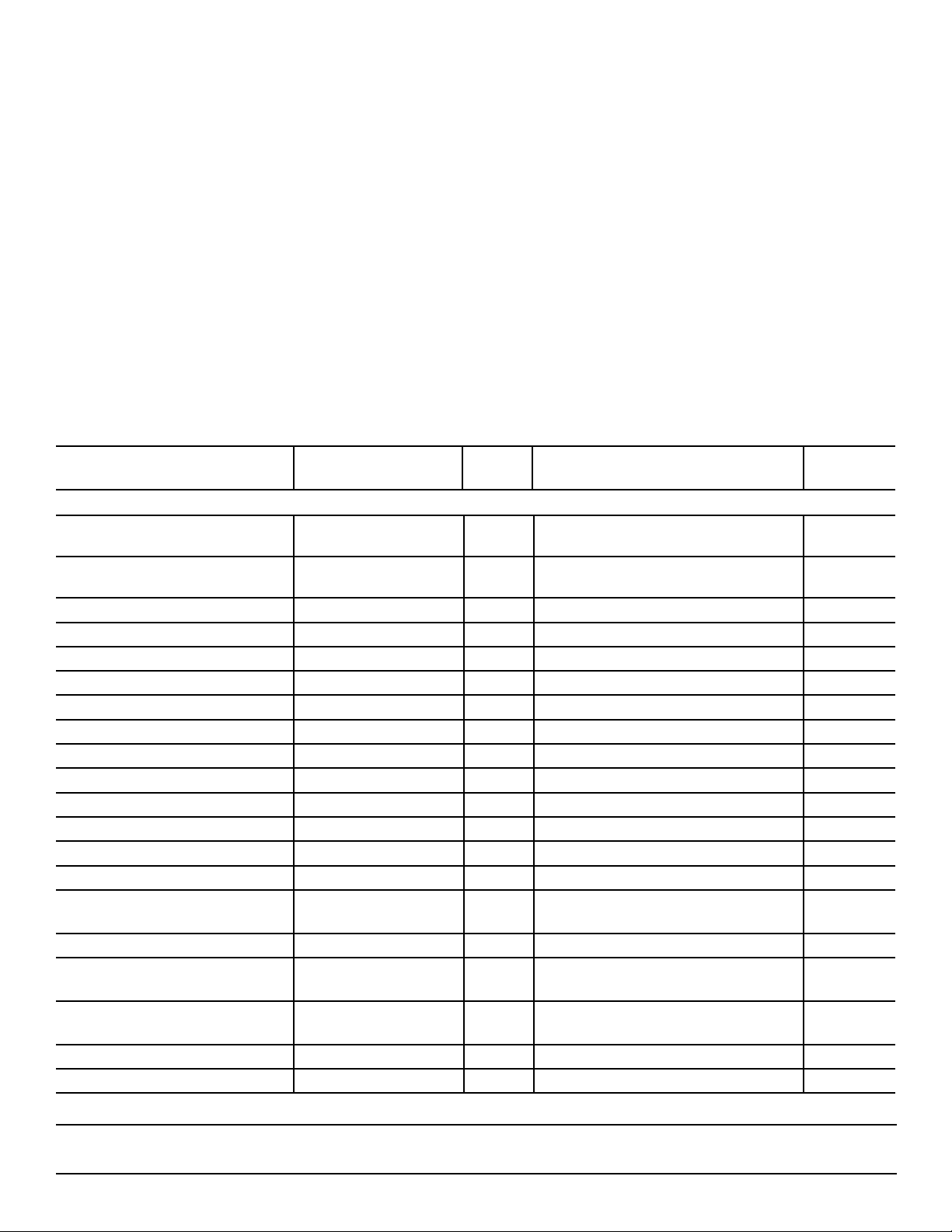

ELECTRICAL SPECIFICATIONS

VCC =ground, VEE = -5.2 V ±0.3 V, TA =T

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

DC ELECTRICAL CHARACTISTICS

Integral Linearity Error 1.0 mA<I

Differential Linearity Error 1.0 mA<I

Gain Error VI -19 +19 % Full Scale

Gain Error Tempco V 150 PPM/°C

Input Capacitance, Ref Out, I

Compliance Voltage, + Output VI -1.2 1.5 V

Compliance Voltage, - Output VI -1.2 1.5 V

Equivalent Output Resistance VI 20 kΩ

Output Capacitance V 12 pF

Maximum Current, + Output IV 45 mA

Maximum Current, - Output IV 45 mA

Output Offset Current VI 0.05 0.5 LSB

Input Voltage, Logic HIGH VI -1.0 V

Input Voltage, Logic LOW VI -1.5 V

Convert Voltage, IV -0.5 -2.5 V

Common Mode Range (V

Convert Voltage, Differential (V

Input Current, Logic LOW, VI 35 120 µA

Data and Controls

Input Current, Logic HIGH, VI 40 120 µA

Data and Controls

Input Current, Convert VI 2 60 µA

Bandgap Tempco V 100 PPM/°C

Set

ICM

IDF

to T

MIN

)

) IV 0.4 1.2 V

, CC = 0 pF, I

MAX

TEST TEST

<1.3 mA VI -.37 +.37 % Full Scale

Set

<1.3 mA VI -0.2 +0.2 % Full Scale

Set

= 1.105 mA, unless otherwise sprecified.

Set

V5pF

-.95 +.95 LSB

-0.5 +0.5 LSB

SPT

SPT1019

2 5/14/97

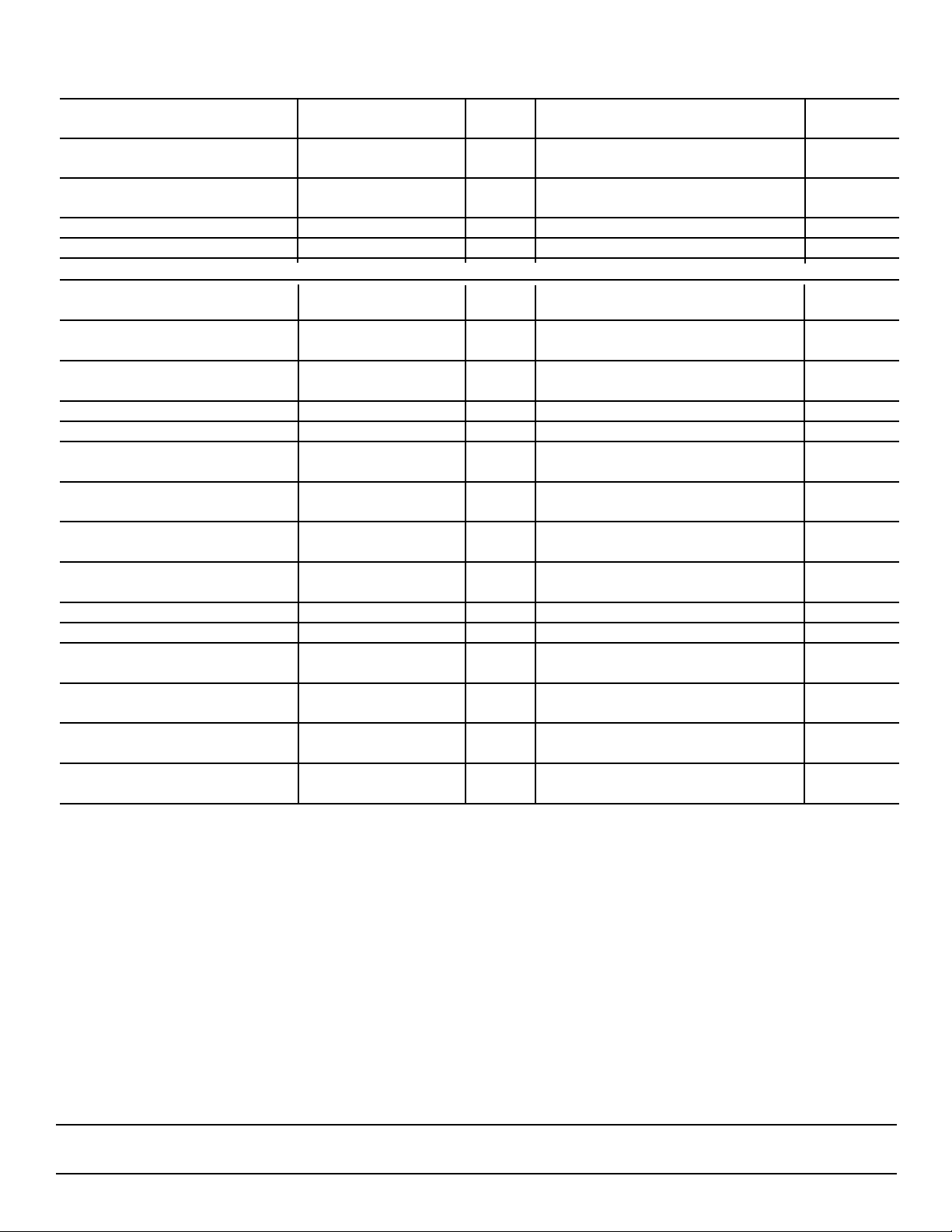

ELECTRICAL SPECIFICATIONS

VCC =ground, VEE = -5.2 V ±0.3 V, TA =T

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Reference Voltage

Measured to V

Input Capacitance, V 3.0 pF

Data and Controls

Power Supply Sensitivity VI -120 20 +120 µA/V

Supply Current VI 155 220 mA

CC

DYNAMIC CHARACTERISTICS (R

Maximum Conversion Rate B Grade IV 165 MWPS

Rise Time 10% to 90% G.S. IV 1.6 ns

Rise Time 10% to 90% G.S. V 1.0 ns

Current Settling Time, Clocked Mode To 0.2% G.S. V 7.0 ns

Current Settling Time, Clocked Mode To 0.8% G.S. V 5.5 ns

Current Settling Time, Clocked Mode To 0.2% G.S. V 4.5 ns

t

SI

Clock to Output Delay, Clocked Mode IV 2.2 4.0 ns

t

DSC

Data to Output Delay, IV 3.2 6.0 ns

Transparent Mode t

Convert Pulse Width, ( LOW or HIGH) B Grade IV 3.0 ns

t

, t

PWL

PWH

Glitch Energy Area = 1/2 VT V 4 pV-s

Reference Bandwidth, -3 dB V 1.0 MHz

Setup Time, Data and Controls IV 1.0 ns

t

S

Hold Time, Data and Controls IV 0.5 ns

t

H

Slew Rate 20% to 80% G.S. IV 390 V/µS

Clock Feedthrough IV -48 dB

DST

to T

MIN

= 37.5 ohms, CL = 5 pF, TA = 25 °C, I

L

, CC = 0 pF, I

MAX

TEST

A Grade IV 275 MWPS

TA = T

RL = 25 ohms

RL = 25 Ω

TA = T

A Grade IV 1.8 ns

TA = T

TA = T

TA = T

TA = T

MIN

MIN

MIN

MIN

MIN

MIN

to T

to T

to T

to T

to T

to T

= 1.105 mA, unless otherwise specified.

Set

VI 1.3 -1.2 1.0 V

= 1.105 mA)

Set

MAX

MAX

MAX

MAX

MAX

MAX

IV 2.0 ns

IV 4.5 ns

IV 6.0 ns

IV 1.0 ns

IV 0.5 ns

IV 325 V/µS

IV -48 dB

TEST LEVEL CODES

All electrical characteristics are subject to the

following conditions:

All parameters having min/max specifications

are guaranteed. The Test Level column indicates the specific device testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification is not

tested at the specified condition.

SPT

TEST LEVEL

I

II

III

IV

V

VI

3 5/14/97

TEST PROCEDURE

100% production tested at the specified temperature.

100% production tested at TA = +25 °C, and sample

tested at the specified temperatures.

QA sample tested only at the specified temperatures.

Parameter is guaranteed (but not tested) by design

and characterization data.

Parameter is a typical value for information purposes

only.

100% production tested at TA = +25 °C. Parameter is

guaranteed over specified temperature range.

SPT1019

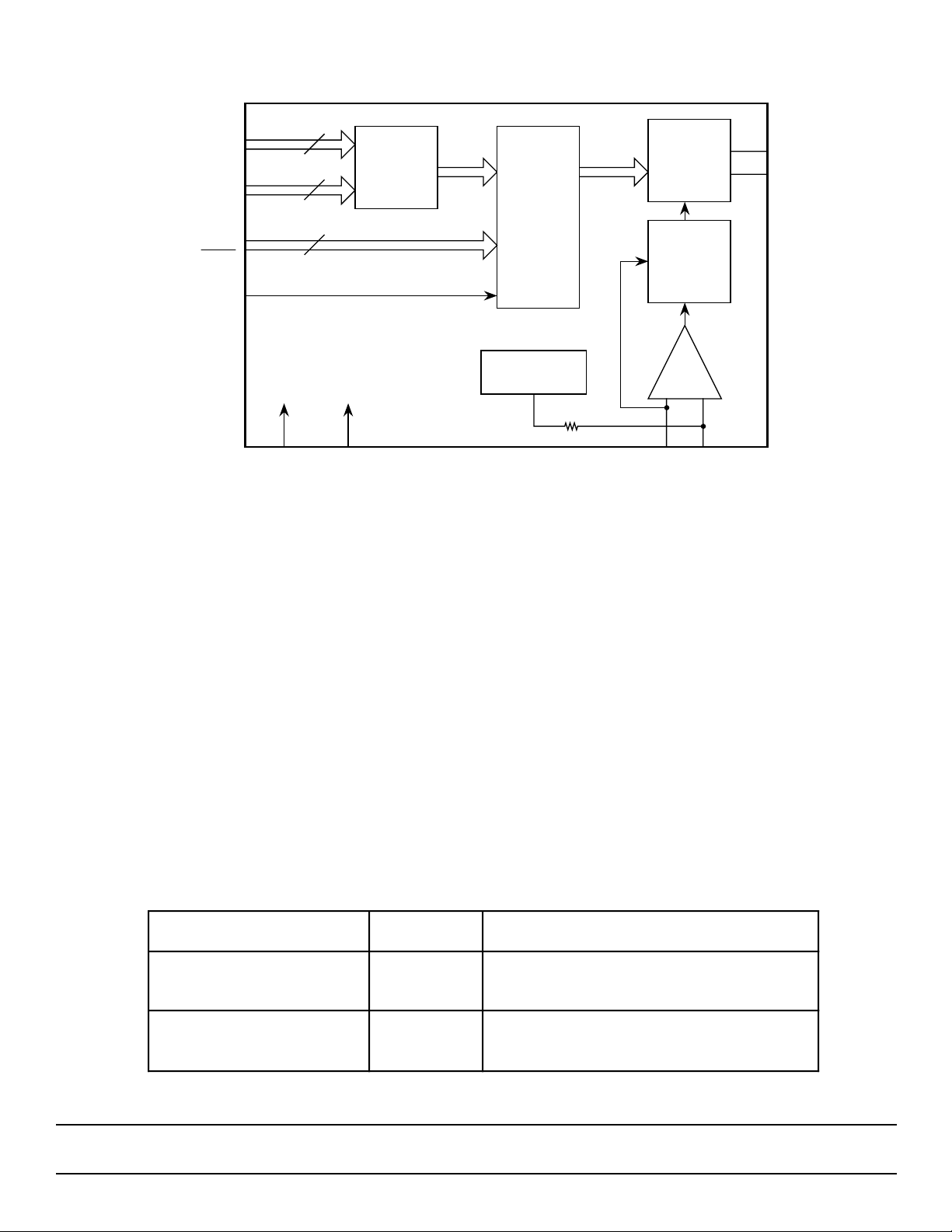

Figure 1 - Functional Diagram

D0 - D7

Composite

Video Controls

CONV

CONV

Feedthrough

8

4

2

V

EE

V

CC

Decoding

Logic

APPLICATION INFORMATION

The SPT1019 is a high speed video digital-to-analog converter capable of conversion rates of up to 275 MWPS. This

makes the device suitable for driving 1500 X 1800 pixel

displays at 70 to 90 Hz update rates.

Data

Registers

Bandgap

Reference

Current

Sources

And

Switches

Current

Source

Biasing

Amp

+-

I

Ref Out

Set

Out +

Out -

coarse output levels. The remaining four LSBs drive four

binary weighted current switches.

The MSB currents are then summed with the LSBs, which

provide a one-sixteenth of full scale contribution, to provide

the 256 distinct analog output levels.

The SPT1019 is separated into different conversion rate

categories as shown in table I.

The SPT1019 has 10 KH and 100K ECL logic level compatible video controls and data inputs. The complementary

analog output currents produced by the devices are proportional to the product of the digital control and data inputs in

conjunction with the analog reference current. The SPT1019

is segmented so that the four MSBs of the input data are

separated into a parallel thermometer code. From here,

fifteen identical current sinks are driven to fabricate sixteen

Table I - The SPT1019 Family and Speed Designations

PART NUMBER UPDATE COMMENTS

SPT1019A 275 MWPS Suitable for 1200 X 1500 to 1500 X 1800

SPT1019B 165 MWPS Suitable for 1024 X 1280 to 1200 X 1500

The video control inputs drive weighted current sinks that are

added to the output current to produce composite video

output levels. These controls, Sync, Blank, Reference White

(Force High), and Bright are needed in video applications.

Another feature that similar video D/A converters do not have

is the Feedthrough Control. This pin allows registered or

unregistered operation of the video control and data inputs.

In the registered mode, the composite functions are latched

to the pixel data to prevent screen-edge distortions generally

found on unregistered video DACs.

displays at 60 to 90 Hz update rate.

displays at 60 to 90 Hz update rate.

SPT

SPT1019

4 5/14/97

Loading...

Loading...