Page 1

MINI KEGERATOR

MODEL: BD-0538

INSTRUCTION MANUAL

Please read the instruction manual carefully before installing and operating the

beer cooler, and keep it for future reference.

Page 2

INTRODUCTION

This is a household beer cooler, equipped with a CO2 cartridge pressure system to

keep beer fresh. It brings the beer to the best temperature for cold storage (0 to 4ºC /

32 to 39ºF) within 19-21 hours.

The beer cooler can keep the 5L Keg cool for an almost indefinite period. We do,

however, suggest that you initially cool your beer keg for at least 12 hours in your

refrigerator before placing it into the beer cooler.

IMPORTANT SAFETY INSTRUCTION

We have provided many important safety messages in the instruction manual for the

beer cooler. Before use, please read and obey all safety rules and operating

instructions; and keep the instruction manual in a safe place for future reference.

Safety Instruction

Before use, check whether the power cord is well connected; if not, please do not

use and call service center.

If the supply cord is damaged, it must be replaced by the manufacturer, service

agent or a similarly qualified person in order to avoid a hazard.

Before use, check rating and confirm voltage. Dedicated circuit is recommended.

Check that the plug conforms with the socket; if not, please do not use and contact

a qualified electrician.

Do not connect or disconnect the electric plug when your hands are wet.

Place the beer cooler on a dry and horizontal surface.

To ensure proper ventilation for the beer cooler, make sure the beer cooler is at

least 5 inches away from walls/cabinets on all sides to allow proper ventilation.

Do not place near heat sources such as ovens, grills or direct sunlight.

Never cover the beer cooler when it is in operation.

The beer cooler must be installed in an area protected from the elements, such

wind, rain, water spray or drips.

Always turn the unit off and unplug from outlet before cleaning. Failure to do so can

result in electric shock or death.

Do not immerse the beer cooler or power plug in water or other liquid.

Do not use coarse cloth, abrasive stuff to clear the beer cooler

Do not remove beer keg from the beer cooler if the keg is not empty.

Do not remove the CO2 cartridge until the CO2 cartridge is completely empty.

Do not use the CO2 cartridge if the room temperature is over 49ºC/120ºF. Failure to

do so can result in explosion or death.

Never allow children to operate, play with or crawl inside the beer cooler.

This unit is not intended for use by persons, including children, with reduced

physical, sensory or mental capabilities.

This unit is not intended to be used by children. Children should be supervised to

ensure that they do not play with this product.

Page 3

HOW TO SELECT A KEG

Sealed 5L universal mini keg and Heineken mini keg applies only

Pay close attention to safety and storage messages about the keg / on the keg.

Check that the keg is neither damaged, nor out-of-date before purchasing.

Protect the top surface from being damaged. Otherwise it could be difficult to attach

the suction tube.

Keep the keg in a rather cold place for 12 hours, but not freezing (e.g. refrigerator),

until next use.

Never shake the keg before use

Never put the beer keg in direct sunlight

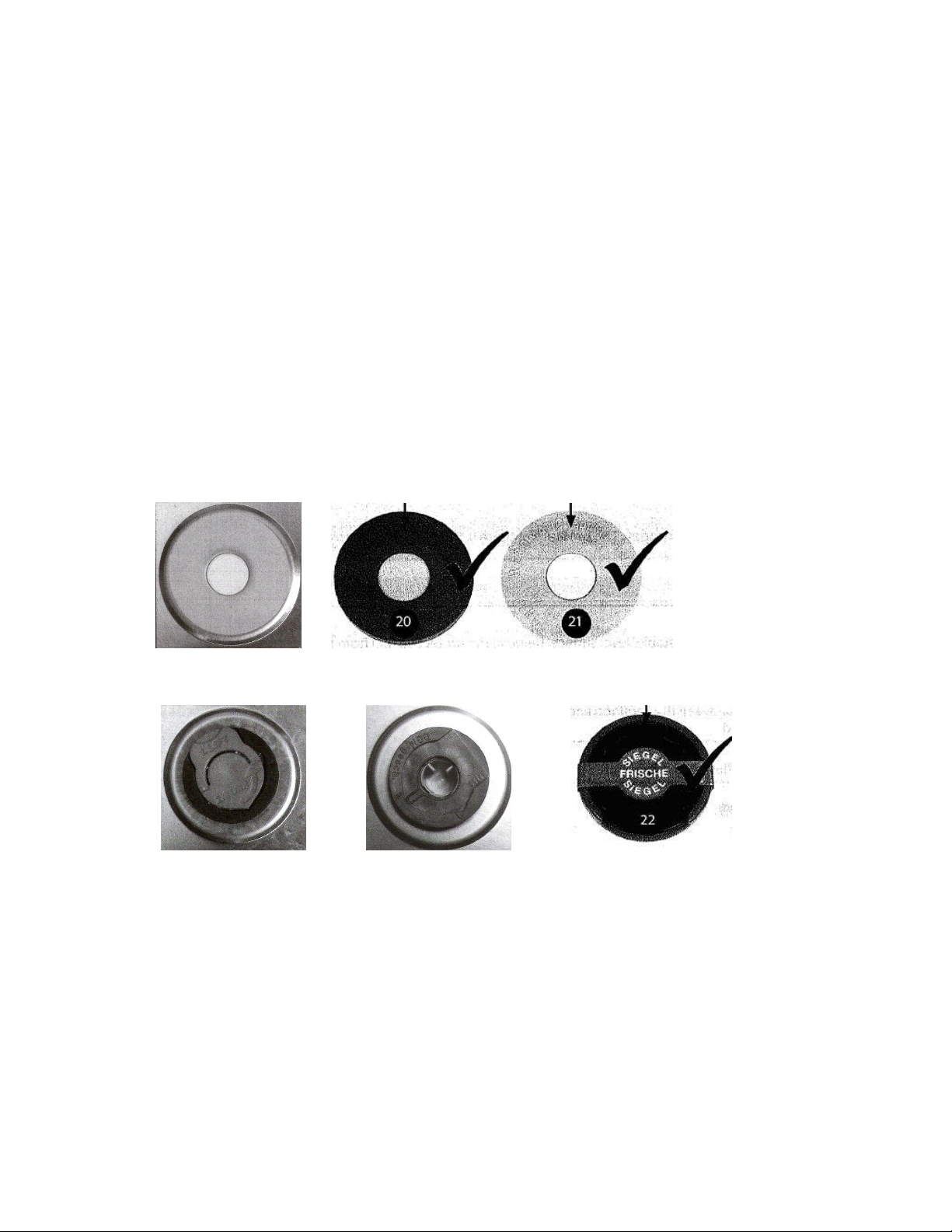

BEER KEG SEALANT

5-Liter beer kegs come with various plug sealants. You can use them with the beer

cooler, however, you should follow the information below for installation.

*The sealants with code No. 20 and 21 can be pierced simply by the cooler piercing

pin.

*The sealants with code No. 22 need to be removed off the marking ring from the

sealant and pierce the keg by cooler piercing pin. (Show as figure 1)

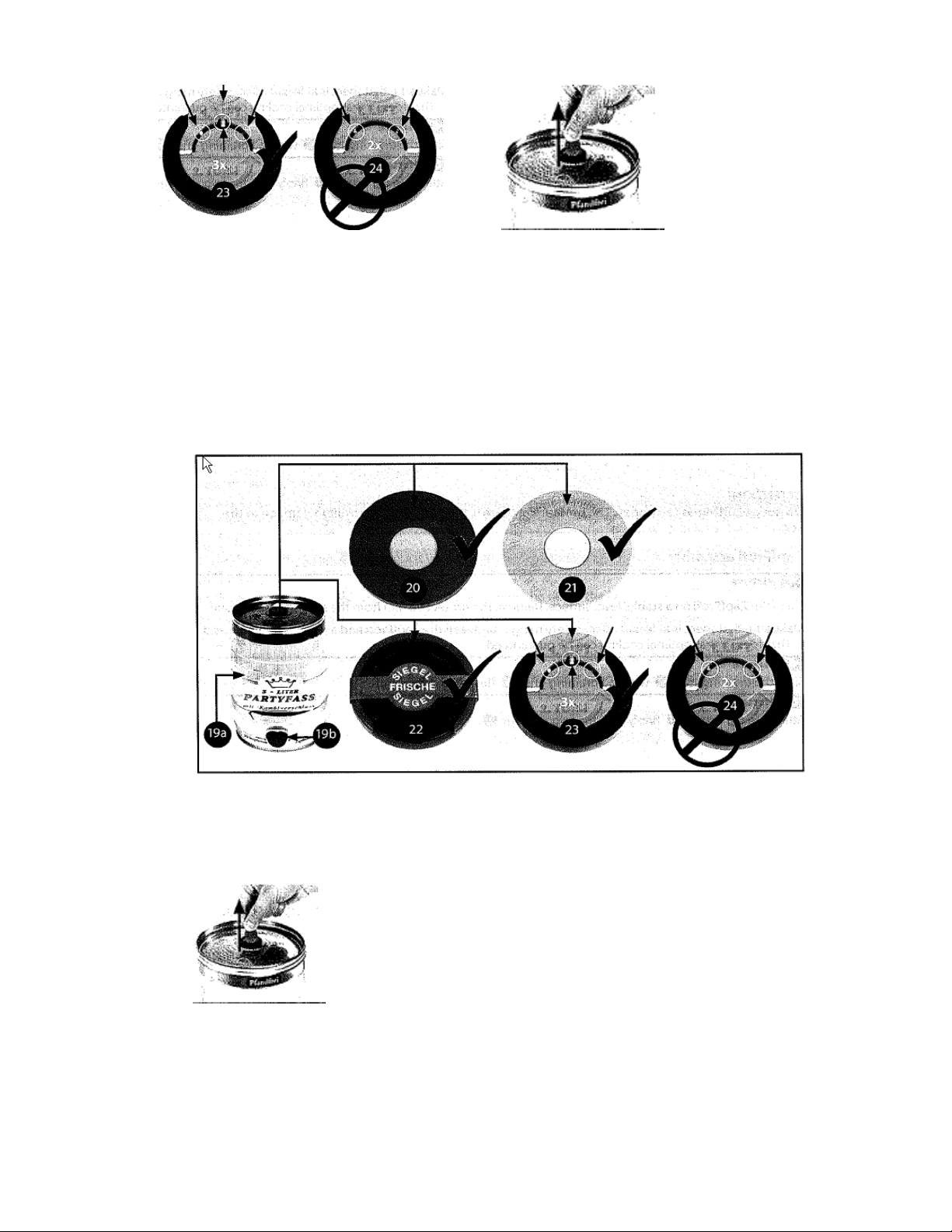

*The difference between code No 23 and 24 is the safety clasp quantity. Pull up the

safety clasp carefully, turn around and take it out from the keg; replaced it by the

sealant (like code No 2 sealant) provided in the beer cooler, attach it to the beer keg,

and pierce it by cooler piercing pin. (Show as Figure 3).

Page 4

Figure 1

(Important: Before replacing the sealants or piercing the cooler kit, you must always

follow the instructions marked on the keg to eliminate the excess gas and ensure that

the keg has rested long enough to avoid foam coming out through the cooler piercing

pin /tap faucet. There is no need to release the gas and replace the seal rubber if you

use Heineken keg, because Heineken keg has its own CO2 pressure inside. You do

not need to connect the CO2 pressure system with the Heineken keg.

Figure 2

Figure 3

Page 5

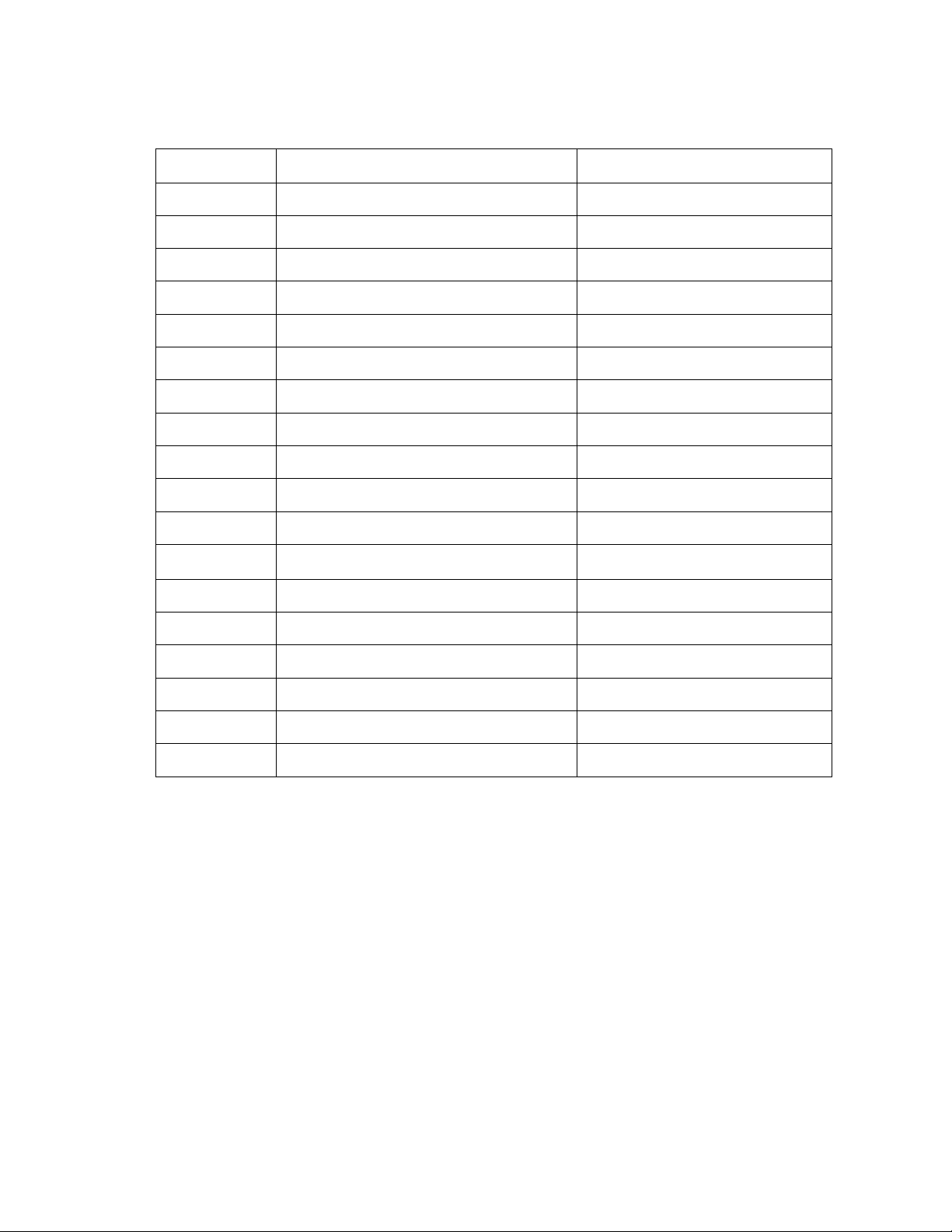

SPECIFICATIONS

Item Descriptions Specification

1 Voltage AC 110-120V/60Hz

2 Available capacity 5 liter beer keg

3 Rated operating power 65W

4 Cooling performance 36°F-53°F / 2°C-12°C

5 Noise level

6 Dimensions 10.71W*16.3D*16.93H in

7 Net weight 13.89 lb

8 CO2 pressure out unit √

9 Stainless steel appearance

10 Aluminum radiator system

11 Semi-conductor cooling technology

12 Water conduction cooling system

13 LED display function

14 Manual drainage outfit

15 Detachable water drip tray

16 Temperature adjustable

17 Cool preservation system

18 Climate type

≤38dB(A); (ambient noise ≤25dB(A))

√

√

√

√

√

√

√

√

PU insulation / Weight 310±5g

N/SN

Page 6

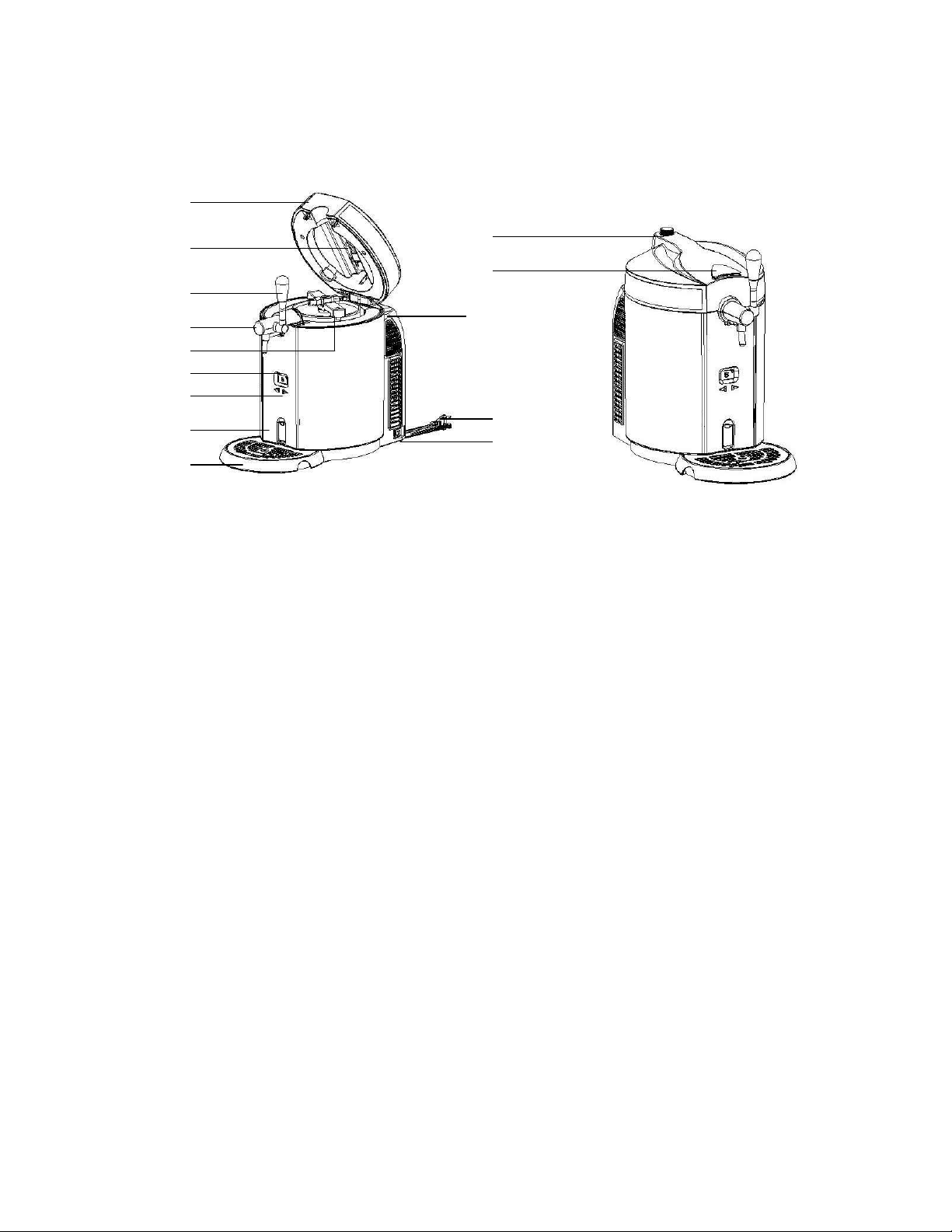

PARTS & FEATURE

1

2

3

4

5

6

7

8

9

Figure four Figure five

1. Top cover 8. Drain switch

2. CO2 cartridge sheath 9. Drip tray

3. Tap handle 10. CO2 pressure relief valve/ knob

4. Tap 11. Door lock button

5. Keg lifter 12. Rear cover

6. LED display 13. Power cord & plug

7. Digital control button 14. AC power switch

10

11

12

13

14

Page 7

T

he max water level

Make sure the drain

”

line

INSTALLATION & OPERATION

A.

INSTALLATION

1. Take the beer cooler out from its package. Place the beer cooler on a sturdy

horizontal (flat) surface. Make sure the beer cooler is at least 5-inches/10 cm away

from other appliances and walls on each side to allow proper ventilation.

Figure 6 Figure 7

2. Install the tap handle to the faucet by turning clockwise, make sure both end fit

together perfectly. (Show as Figure 6)

3. Set the water drip tray into the notch provided.(Show as figure 7)

4. Plug-in the beer cooler.

Note: Do not connect or disconnect the electric plug when your hands are wet. Before

using it, make sure the voltage conforms to the plug mark. Check whether the power

cord is well connected or not; if not, please don’t use it, and call the service center;

5. Put 800ml (27-oz) of water into the cooling cavity. Do not pour the water past the

max mark. (Show as figure 8) Unit can work without water, but cooling performance is

best when used with water.

Note: Make sure the drain switch is at “Off” position, and no extra objects in the cooling

cavity.

Handle

Faucet

switch is at “OFF

position.

Drip tray

Figure 8 Figure 9

Page 8

、、、、

B

OPERATION

Universal 5L beer keg

1. Before piercing the plug on the top of the keg, you must always follow the

instructions marked on the keg to eliminate the excess gas and ensure that the keg has

rested long enough to avoid foam coming out through the tap faucet.

2. With the keg upright, place the piercing pin against the sealant on the upper center

of the keg (you may need to tear off the marking ring or change a proper sealant),

press the piercing pin/keg lifter to poke the seat and then push the piercing pin into the

keg quickly. Press the tap mechanism until you hear a “click” sound that will indicate

the tap mechanism is fixed on the beer keg. (Show as figure 10). Make sure both sides

are securely attached.

Beer dispensing unit

Beer connector

Keg Seal

Figure 10 Figure 11 Figure 12

beer keg

CO2 connector

3. Open the beer cooler, by pressing the door latch button, and place the assembled

keg into the cooling cavity; Connect the CO2 connector tube and beer outlet tube to the

keg lifter tube connector.

NOTES: make sure all connection of tap mechanism is well connected, and without

damage. And make sure tap valve is on close status, and the CO2 pressure regulator

knob is at “Off” status.

排水开关

Close

Open

Figure 13 Figure 14

Page 9

CO2 bottle

4. Loosen the CO2 bottle sheath (Show as figure 15), insert a non-threaded 16 gram

CO2 cartridge in the sheath (Figure 16), and screw the sheath tightly until you hear it

“click” or “pop” (Figure 17), which indicates that the cartridge seal has been pierced

and the CO2 gas can flow into the keg freely. Make sure the CO2 bottle sheath is fixed

tightly to avoid CO2 leakage. Then put CO2 bottle sheath into the top cover.

Regulator assembly

Cover assembly

16gCO2

sheath

Figure 15 Figure16

Figure 17 Figure 18

5. Close the top cover of the beer cooler. When dispensing beer, turn the knob on the

top cover to “+” position to release the CO2 (you will hear a hissing noise). When

done, turn knob back to “-“ position to close the CO2. Please refer to the notice label on

the top cover.

6. Turn on the power switch to “I” position to power on the beer cooler. (“0” position is

off).

NOTES:

Please make sure your hands are dry when you operate the beer cooler, to

avoid electric shock.

1. Connector

2. Switch is on ‘off” status

Figure 19

Page 10

7. It will take 19-21 hours to cool the beer down to 35-50°F at 72-75°F ambient

temperature. And it can keep the temperature as set and displayed on the LED. (The

LED will display the real temperature of the beer). We do, however, suggest that you

initially cool your beer keg for at least 12 hours in your refrigerator before placing it into

the beer cooler, especially when the ambient temperature is higher than 77°F.

Page 11

8. You can set the temperature to fit your taste. The temperature can be set from 36°F

to 53°F (2°C to 12°C). Use the temperature adjustin g buttons (+ and -) located next to

the temperature display. The PCB has memory function, when you power on the cooler,

it memorizes the last set temperature.

The LED will default display the real temperature of beer. You can see the set

temperature by pressing “+” button, it will display the set temperature for 3 seconds

then resume to display the real temperature.

Preset Temperature

The beer cooler has 6 preset temperatures.

Press “-” button 3 seconds, it enter the 6 preset temperatures, then you can press “-”

button to choose a certain preset temperature, 40F, 46F, 48F, 50F, 52F and 54F.

Press “+” button 3 seconds,

9. Adjust the CO2 pressure regulator knob to “+” position, to pour the beer out by

pulling down the tap mechanism, and you can adjust the pressure regulator knob to

control the beer flow rate and beer bubble;

Note: Clean the glass before pouring beer into it, if the beer cup/glass is in high

temperature or if the beer is not cold enough, many bubbles will form when dispensing.

10. When taping the beer, lean your beer glass against the pouring spout and slowly

straighten it up as the beer rises, then open the tap mechanism completely to avoid too

much foam; It is advisable to pour half-glass, make a short pause before continuing the

rest.

NOTES:

Remember to lock the tap after finishing pouring.

11. It is normal to have more foam when pouring the first 3 cups of beer.

12. There will be a sharp and high-speed jet when pouring the last cup of beer from

Please adjust the CO2 pressure regulation knob to “-” position to close the CO2 supply

and reserve the CO2.

Never immerse the pouring spout into the beer glass to avoid excess foam;

keg.

Figure 20

Temperature Scale Display

Press and hold “+” button for 3 seconds to switch temperature display between

Fahrenheit and Celsius.

Page 12

C、

C、

Heineken Keg

C、C、

Heineken kegs are pre-charged with CO2 and do not require the use of a regulator. Do

not install the CO2 cartridge. Leave the control knob in the off, “-”, position

Figure 21

1. The Heineken connectors that come with your beer cooler can work with all

Heineken 5 liter kegs. However you must use a flat head screwdriver to remove the

green base from the keg, if it is already installed, in order to install the new connector

provided with the beer cooler.

2. When installing our connector to the Heineken keg, you must first install the clear

beer connector tube to the connector and one end to the tap mechanism, snap the

beer connector to the Heineken keg adapter then place the adaptor onto the keg.

Figure 22 Figure 23

CO2 connector position

Heineken Adaptor

Heineken keg

Page 13

Note: Please take out the Heineken adaptor with

collect ways, Press it according the arrow

Figure 24 Figure 25

3. Close the top cover; operate it as above step 6-12, as the universal 5 liter keg, but

step 9 is exception.

Beer

connector

、、、、

D

TO CHANGE A NEW BEER KEG

(5 liter universal keg)

When the beer keg runs out follow the instructions below before installing a new

beer keg.

1. Adjust the CO2 pressure regulation knob to “-“ switch to shut off the CO2 supply

and reserve the CO2.

2. Open the top cover of the beer cooler, pull down the tap handle to release the

remaining gas in the keg (there may be some beer bubble).

3. Disconnect the CO2 and Beer connectors from the Piercing Pin/Keg Lifter by

pressing the white release buttons as shown on figure 26.

4.Use the keg lifter and remove the keg from the dispenser.

5.Disconnect the piercing pin from the keg (see figure 27).

6. It is recommended to clean the tap mechanism when changing the beer keg each

time. Please refer to the below contents about cleaning.

7. Follow installation instructions for new keg.

Page 14

n you take out the beer connector and CO2

You must take out

the right fastener at

first, then push the

left fastener out as

arrow indication,

you can pull out

the dispensing unit

When you take out the fastener of beer

dispensing unit, you can move this unit

towards arrow indication

Whe

connector, please press the white button down

Figure 26 Figure 27

E

E.

TO CHANGE THE CO2 CARTRIDGE

EE

Please change the CO2 cartridge when beer cannot be dispensed - the CO2 pressure

knob is at “on” position and there is beer in keg.

1. Turn the CO2 pressure knob to “-“ position to close the CO2 supply.

2. Open the top cover, loosen the cartridge sheath by rotating left (counter-clockwise),

and take out the empty CO2 cartridge.

Insert a new 16g CO2 cartridge in the sheath, and screw the sheath tightly until you

hear a “pops”, which indicates that the cartridge seal has been pierced and the CO2

gas can flow into the keg. Make sure the bottle sheath is fixed tightly to prevent the

CO2 from leaking. Then put CO2 bottle sheath into the top cover.

3. Close the top cover of beer cooler;

3. Turn the CO2 pressure knob to “+“ position to turn on the CO2 supply, cooler is now

ready to dispense beer.

Reminder:

each 16g CO2 cartridge can pressure more than 5 liter of beer.

(Not needed for Heineken keg)

finally.

Page 15

Warning:

B

down

Water

1. Please use a qualified and approved CO2 cartridge. It should be Beverage

grade.

The CO2 cartridge information below is for your reference. Never use a Nitrogen gas

cartridge in the beer cooler to avoid an explosion, because of its much higher pressure.

Also do not use CO2 cartridges designed for air guns as they may contain oils.

2. Do not use any CO2 cartridges that may have been tampered with or are

damaged. Any misuse may cause serious injury.

16g CO2 Cartridge

NW

(g)

15.5

│

16.5

Volume

(ml)

20

GW

(g)

57.0

│

58.6

Cartridge

Weight

(g)

42.0

│

42.6

. A

(mm) B (mm) C (mm) D (mm)

Ø8.6

Ø8.9

88.0

│

89.0

Ø21.7

│

│

Ø22.0

10

│

11

Pressure

(Kgf/cm2)

60 450

Blast

pressure

(bar)

F

F:

REPLACE WATER INSIDE THE COOLING CAVITY

FF

It is recommended to replace the water inside the cavity once a week. (There is no

need to replace the water when switching the beer keg)

Open the drain switch, water flows into the S shape drainpipe from this end

Water flow into drip tray from this end

Figure 28(Sketch map of drain construction)

Lower the drain switch

to a horizontal line.

will start to drain.

Drip tray

Page 16

Cleaning

Beer connector must

dispensing

Please open the faucet when

you are cleaning the beer

Dispensing

unit

connector must connect with

1. Open the drain switch to drain out the water from the cavity into the drip tray. Make

sure the drip tray is inserted into the notch to avoid spilling water on the counter. The

drip tray can hold 15oz (450ml) water so you may need to do this twice.

2. After all the water has drained out, lift the drain switch to closed and put 800ml fresh

water into the cavity.

NOTE: Alternatively, instead of using the drip tray, you may place the drain hole above

your sink or other similar location that allows you to drain all the water at once.

Warning: Clean water is necessary. Make sure the drip tray is inserted into the notch

after draining.

CLEANING BEER TAP MECHANISAM

The Beer cooler hoses should be cleaned often for best results and to avoid any health

hazards. They need to be cleaned before the first use and after long periods of time

between uses. Clean the outside of the machine with dry cloth. Recommended

cleaning steps as follows:

1. Fill the cleaning bottle with warm water.

2. Connect to the end of the piercing pin, squeeze the water into the pin to clean the pin

tube and push the water out from the beer tube. Repeat this until the beer tube is

clean (need 3 bottles warm water at least).

3. Clean the beer tap mechanism as figure 30. Note: Please open the tap when

cleaning. (Show as figure 29)

connect with

unit

This

cleaning bottle

tube

Figure 29 Figure 30

Warning:

Never put the tap mechanism parts in the washing machine or dishwasher;

Never use a chemical cleaning detergent to clean the parts, warm or purified water is

recommended.

bottle

Page 17

CHANGE SPARE PARTS

assembly

ACCESSORIES INCLUDED WITH YOUR BEER COOLER

Items Name Qty. Installment Picture Spare parts

1 Connector seal 6 Regulator valve

5pcs

2 CO2 connector 2 Regulator valve

1pcs

3 Beer tube 2 Beer-out connector

4 Tube seal circle 4 Beer-in pipe

5 Keg seal 2 Standard tub

6 Heineken adaptor 2 Heineken tub

7 CO2 cartridge 3 Regulator valve

assembly

8 Cleaning bottle 1

1pcs

3pcs

2pcs

1set

3pcs

1pcs

、、、、

A

Cartridge Regulator valve: CO2 connector and Connector seal washer

CO2 Cartridge piercing probe and connector seal washer maybe damaged when used

improperly, from general wear and tear, and other reasons.

1、First, pick out the connector seal washer with a tiny metal stick(Show as figure 31),

and take out Cartridge piercing probe. Be careful not damage other parts of regulator.

2、Install a new cartridge piercing probe in the regulator (leave the sharp end facing

outwards), and install the seal washer (Show as figure 32). Don’t remove other parts

of the regulator in the replacing process.

Regulator

Page 18

Empty CO2

Cartridge

connector

Seal circle

Slim metal stick

cartridge

Figure 31 Figure 32

Warning: Remember press the seal circle with empty cartridge instead of new

cartridge, or will cause hazard.

、、、、

B

TO CHANGE BEER TUBE(show as figure 33)

Please replace the beer tube if beer tube is damaged and leaking.

1. Loosen the tube from connection: 1, Pull out the lock setting. Once off, draw the

tube out. (you may need to wiggle the lock setting while pulling)

2. Unscrew the nut at connection 2, and draw the tube out.

3. Replace a new beer tube, and install the beer tube according with reverse

procedure.

NOTES: Don’t move other screws when processing tube replacement, otherwise, it

may cause the beer leakage or gas leakage

1. Lock setting

2. Connector nut

Figure 33

、、、、

C

Replace the seal circle of beer tube(Show as figure 34)

Replace the seal circle of beer tube if the connector has a leak

1. Unscrew the beer tube as indicated in the below figure

2. Take out the seal circle of beer tube

3. Replace a new seal circle in the same position

4. Turn the seal circle tightly to avoid any leakage

Seal circle

Page 19

Beer tube

Figure 34

MAINTENANCE

If the beer cooler does not work properly, please call the service center;

To save time and money, before you call for service, check the Troubleshooting Guide.

It lists cause of minor operation problems that you can correct yourself.

Troubleshooting

Trouble Cause Troubleshooting

The tap does not

work / can’t pour beer

out

Too much bubble

pouring out

Beer flows out too

slowly

1. The pouring tube has a poor

connection or CO2 supply is cut off

2. No keg or no beer in the keg;

3. No gas in the CO2 cartridge

4. The CO2 pressure regulator knob is

closed

1. Use a wrong way to pour beer out

2. The beer temp is high (better at

3-5C)

3. The keg was shaken before usage

4. Almost no beer in the keg

5. Too much pressure in the keg

1. inside CO2 pressure isn’t high

enough

2. The connection tube or pouring

tube is leaking

1. Reconnect the pouring tube and CO2

supply

2. Change a new keg

3. Change a new CO2 cartridge

4. Turn the CO2 pressure regulator knob

on “+” position

1. Use the right way to pour beer out

2. Cool the beer down to 3-5C

3. Put the beer keg aside a while till no

bubble inside

4. Change a new keg

5. Adjust the pressure knob to

“-“ direction to decrease the pressure or

close the knob

1. Adjust the pressure knob to release

more CO2 pressure or replace with a

new one.

2. Check whether the tube is leaking or

not, if so replace the tube

Page 20

Your Guarantee

If this product is found to be faulty as a result of faulty materials or workmanship within one

year from date of purchase, it will be repaired free of charge.

This guarantee is subject to the following terms:

• Sunpentown must be notified of the fault.

• Proof of purchase must be presented to Sunpentown’s nominated representative.

•

The warranty will be void if the product if modified, misused or repaired by an unauthorized

person.

• The warranty after repair will not be extended beyond the original one-year period.

• All replacement parts will be new or reconditioned.

• Parts, which are replaced, become the property of Sunpentown.

•

The warranty applies for the use of the product in the USA only.

What is NOT COVERED:

• Warranty does not include freight charges.

• Damage due to installation error, product abuse and/or misuse.

•

Incidental or consequential damage caused by possible defects with this product.

•

Labor cost incurred for the installation and/or removal of a possible defective unit.

• Damage to product caused by improper power supply voltage, accident, fire, floods or acts of

nature.

• Failure of product resulting from unauthorized modifications to the product.

•

Improper installation or failure to perform the necessary maintenance.

•

Normal wear and tear on parts or replacement of parts designed to be replaced.

• Damage to personal property from use of product.

• Replacement or repair of household fuses, circuit breakers, wiring or plumbing.

This GUARANTEE is in addition to your Statutory Rights

SUNPENTOWN INTERNATIONAL INC.

14625 Clark Ave. City of Industry, CA 91745

Tel: 800-330-0388

service@sunpentown.com

www.sunpentown.com

Loading...

Loading...