SPRT®

POS Thermal printer user manual

(SP-POS88Ⅵ)

(Ver 1.01)

Beijing Spirit Technology Development

Co., Ltd

PDF created with pdfFactory trial version www.pdffactory.com

Contents

Brief Introduction..............................................................................................................................3

Chapter 1 Feature and Performance.....................................................................................................3

1.1 Print Performance...................................................................................................................3

1.2 Print Paper...........................................................................................................................4

1.3 Print Font................................................................................................................................4

1.4 Interface.................................................................................................................................4

1.5 Print Control Commands.........................................................................................................5

1.6 Power Supply..........................................................................................................................6

1.7 Operation Environment...........................................................................................................6

1.8 Outline Dimension...............................................................................................................6

1.9 Model classification.................................................................................................................6

Chapter 2 Operation instruction...........................................................................................................7

2.1 Printer Appearance.................................................................................................................7

2.2 Paper Installation....................................................................................................................8

2.2.1 Paper Loading..........................................................................................................8

2.2.2 Solution to Paper Jam..............................................................................................9

2.3 Interface.................................................................................................................................9

2.3.1 Serial Interface .............................................................................................................9

2.3.2 Parallel Interface......................................................................................................12

2.3.3 Cash Drawer Interface.................................................................................................13

2.3.4 Power Connection ...................................................................................................14

2.4 Indicator, buzzer and button..................................................................................................15

2.5 Turn on the printer................................................................................................................17

2.6 Self-test.................................................................................................................................18

2.7 Hexadecimal Printing.............................................................................................................18

Appendix A: Parameter setting ...........................................................................................................20

PDF created with pdfFactory trial version www.pdffactory.com

Brief Introduction

POS88Ⅵ printer is a new type line thermal printer, which features in fast speed

print, low print noise, high reliability, perfect print quality and ribbon

needless, avoiding the vexation of regular maintenance.

POS88Ⅵprinter: small in outline dimension, simple operation, and

extensive application, especially suitable for commercial cash register, PC-POS,

bank POS and all kinds of receipts print.

Warning

This is a class A product. In a domestic environment this product may cause radio inter

ference in which case the user may be

required to take adequate measures.

Chapter 1 Feature and Performance

1.1 Print Performance

●

Print method: direct thermal

Print paper width: 79.5±0.5mm●

Print density: 8 dots/mm, 576 dots/line●

Print speed: ● max 220mm/sec.

Reliability●

(1)Print head life: 100km

Using condition:

* Print 12 × 24 ASCII characters, print 50 lines each time, intermittent print repeatedly

* Use specified thermal paper

(2)Cutter life: 500,000 cuts. Using condition: less than 30 cuts/minute

PDF created with pdfFactory trial version www.pdffactory.com

Valid print width: 72mm●

1.2 Print Paper

●Thermal paper roll model:TF50KS-E(Japan paper co.ltd)

AF50KS-E(JUJO THERMAL)

●Thermal paper roll: Width--- 79.5±0.5mm

Outer Diameter --- 80mm(max.)

Inner Diameter--- 13mm(min.)

Thickness --- 0.06mm~0.08mm

1.3 Print Font

●ANK Character Set :

12×24 dots,1.5(W)×3.00(H)mm

●GB2312-80(Chinese):

24×24 dots,3.00(W)×3.00(H)mm

1.4 Interface

●RS-232C Serial Interface:

DB-25 socket (female), supports XON/XOFF and TR/DSR protocols.

Baud rate: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200bps

adjustable.

Data structure: 1start bit + (7 or 8) data bits + 1 stop bit.

Parity checking: no parity or odd, even parity optional.

PDF created with pdfFactory trial version www.pdffactory.com

●Parallel Interface:

36-pin,8-bit parallel interface,BUSY/ACK handshaking protocol, TTL

signal level.

●Ethernet Interface:

Standard Ethernet interface.

●USB Interface::

Standard USB interface

●Cash Drawer Control:

DC24V,1A,6-pin RJ-11 socket.

1.5 Print Control Commands

●Character print commands: support double-width, double height print of

ANK characters, user-defined characters and Chinese characters, the

character line spacing is adjustable.

●Graphics print commands: support the print of bit-map graphics and

download bit-map graphics with different density。

●GS bar code print commands: support UPC-A,UPC-E,EAN-13,EAN-8,

CODE39,ITF,CODEBAR,CODE93,CODE128,PDF417,QR bar code print.

PDF created with pdfFactory trial version www.pdffactory.com

1.6 Power Supply

●DC24V±10%,2A,A-1009-3P power socket.

1.7 Operation Environment

●Operation temperature: 5~50; Relative humidity: 10℃ ~80%

● Storage temperature: -40~55; Relative humidity: 10℃ ~90℃

1.8 Outline Dimension

212● (L)mm×150(W)mm×135(H)mm

1.9 Model classification

Model Interface

SP-POS88SFⅥ

SP-POS88SⅥ

RS-232C Serial Interface

SP-POS88PFⅥ

SP-POS88PⅥ

Parallel Interface

SP-POS88EFⅥ

SP-POS88EⅥ

Ethernet Interface

SP-POS88UFⅥ

SP-POS88UⅥ

USB Interface

PDF created with pdfFactory trial version www.pdffactory.com

Chapter 2 Operation instruction

2.1 Printer Appearance

Paper Cover

Power Indicator(green

Status Indicator (red)

Paper-end Indicator (red)

Paper Feed

Decap button

Paper-out slot

Cutter cover

PDF created with pdfFactory trial version www.pdffactory.com

2.2 Paper Installation

2.2.1 Paper Loading

POS88 Ⅵadopts 79.5mm width thermal paper roll.

Steps of Loading Thermal Paper Are as below:

Hold down the upper cover button on the left side, open the movable

upper cover, draw a certain length of the paper roll, put the paper end on

the print head, close the upper cover and press it downwards lightly.

1.Pay attention to the direction of loading paper,make the printing

surface face to the print head.

2.Please don’t feed or draw the paper forwards or backwards with

hands.

Power Switch

Cash driver interface

Interface socket

Power socket

!Caution!

PDF created with pdfFactory trial version www.pdffactory.com

3.Keep clean of the print head, avoid to influence the printing quality.

2.2.2 Solution to Paper Jam

If cutter jam, turn off the power, and turn on again, the cutter will be

back to original position. If paper jam, open the paper storage cover, and

take out the paper. If the cutter can not be back to the original position,

open the cover of it, and turn the white plastic gear by the direction

suggestive on the cutter by hand to make the cutter be back to the original

position.

2.3 Interface

2.3.1 Serial Interface

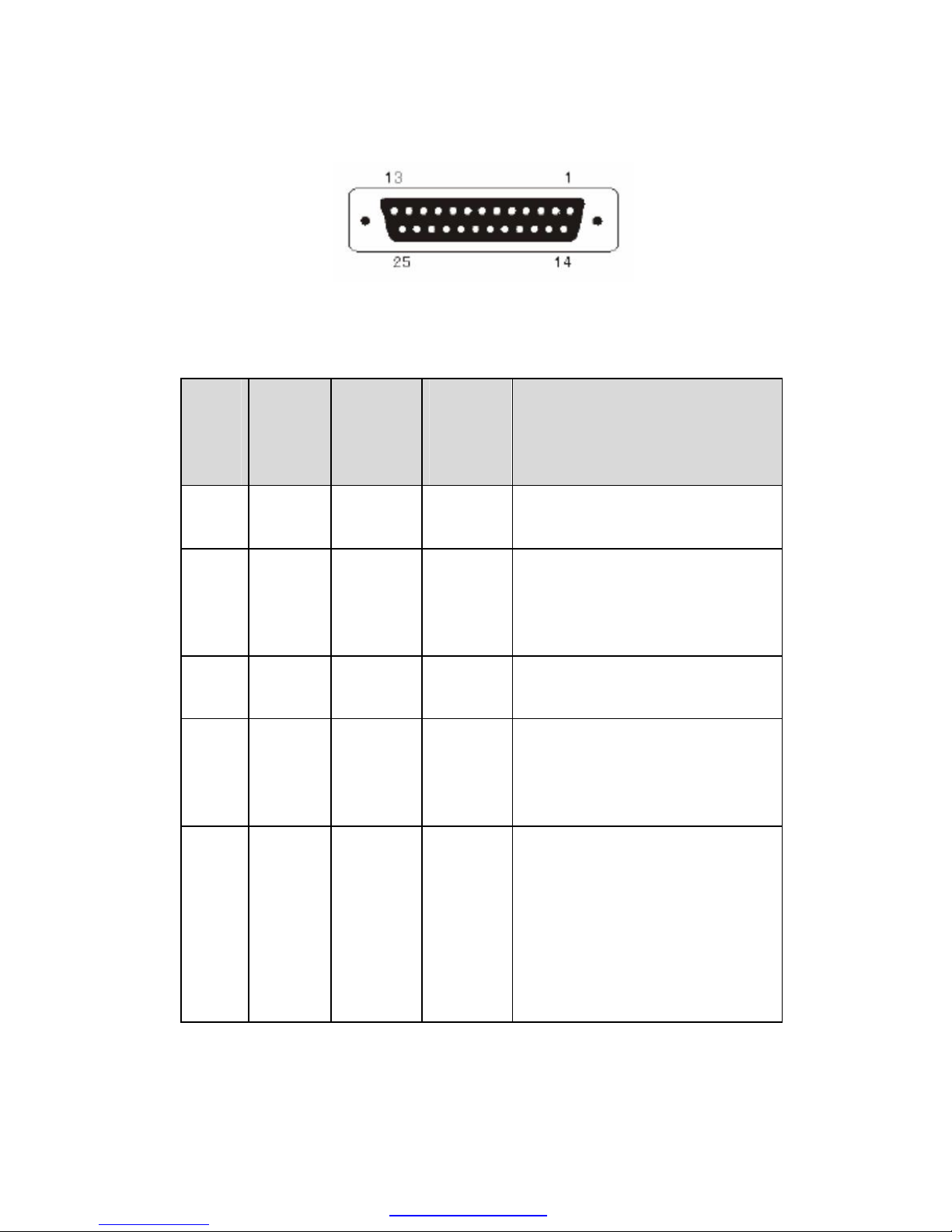

The serial interface of SP-POS88VI printer is compatible with RS-232C,

supports DTR/DSR and XON/XOFF handshaking protocols, uses DB25 socket

(female). The pin order of the serial port is as Fig.2-2 shows:

PDF created with pdfFactory trial version www.pdffactory.com

Fig.2-2 Pin Order of Serial Port

The pin assignment of serial interface is shown in Fig. 2-3:

Pin

No.

Signal

Name

Signal

Direction

Sourc

e

Description

1 FG —— —— Cover ground

2 TXD Output Printer Printer transmits control code

X-ON/X-OFF and data to host

3 RXD Input Host Printer receives data from host

4 RTS Output Printer The same with 20pins DTR

signal

6 DSR Input Host Signal “MARK” means the host

is busy and can not receive

data.Signal “SPACE” means the

host is ready to receive data.

PDF created with pdfFactory trial version www.pdffactory.com

7 GND —— —— Signal Ground

20 DTR Output Printer Signal “MARK” means the host

is busy and can not receive

data.Signal “SPACE” means the

host is ready to receive data.

Fig. 2-3 The pin assignment of serial interface

Note: (1)“Source” denotes the source that signal come from;

(2)Logical signal level is EIA.

The baud rate and data structure in serial interface mode is 9600bps, 8-bit

data bits, no parity bit and 1 stop bit.

The serial interface of SP-POS88VI can be connected to standard RS-232C

interface. When it is connected to IBM PC or its compatible machine,

connection can accord to Fig.2-4.

Fig.2-4 Connection between SP-POS88VI and IBM PC Serial Interface Sketch Map

Printer

25PIN

IBM PC

DB9

Printer

25

PIN

IBM PC

DB25

PDF created with pdfFactory trial version www.pdffactory.com

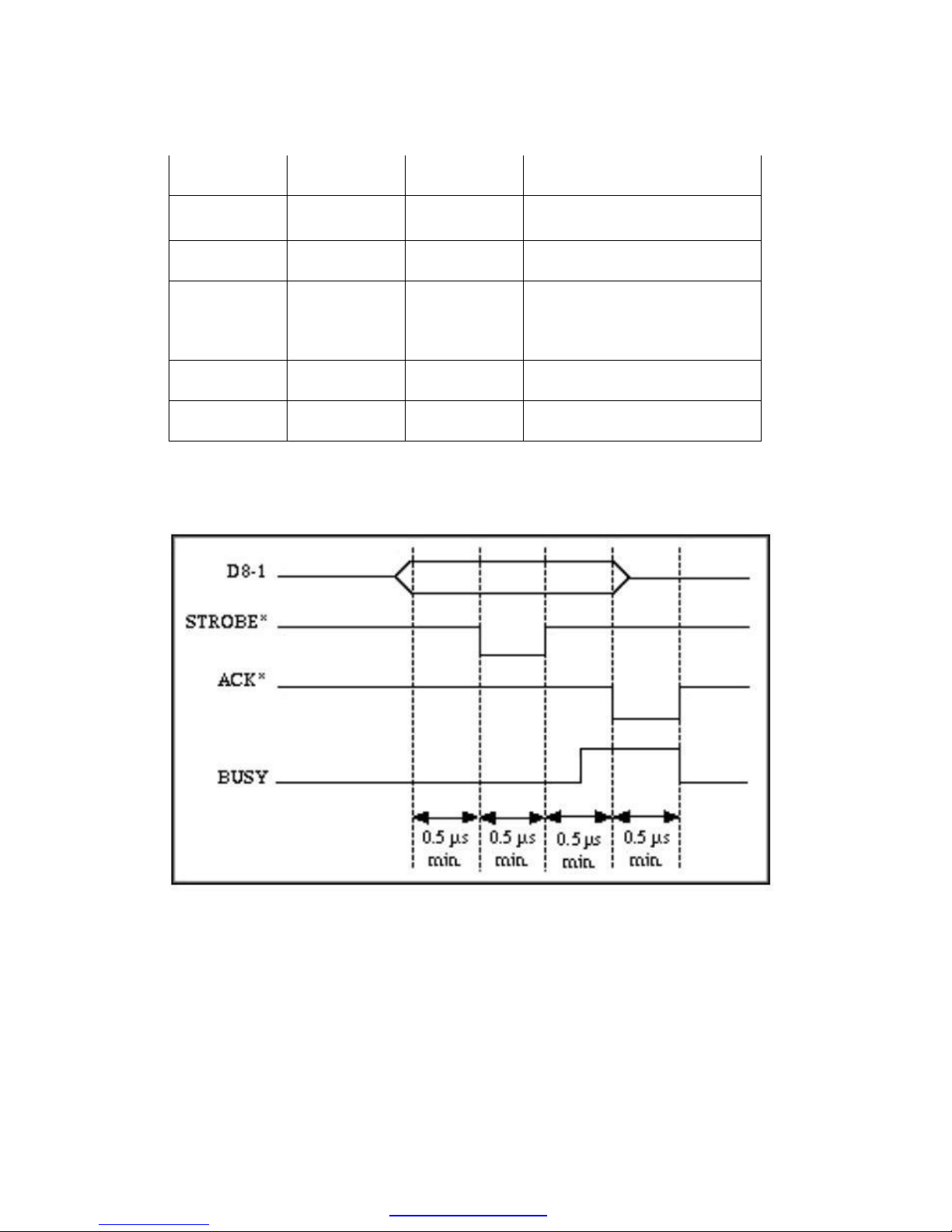

2.3.2 Parallel Interface

The parallel interface of POS88VI printer is compatible with CENTRONICS,

supports BUSY or ACK handshaking protocol,

The pin assignment of 36PIN parallel interface is as Fig. 2-5 shows:

Pin No. Signal Direction Description

1 STROBE In Strobe pulse to latch data, Reading

occurs at falling edge.

2 D1 In

3 D2 In

4 D3 In

5 D4 In

6 D5 In

7 D6 In

8 D7 In

9 D8 In

These signals represent the 1st bit

to 8th bit of the parallel data

representatively, each signal is at

HIGH level when data is logic 1,

and LOW when data is logic 0.

10 ACK Out Answer pulse, LOW level signal

indicates that data have already

been received and the printer gets

ready to receive the next data.

11 BUSY Out HIGH level signal indicates that the

printer is BUSY and can not

receive data.

12 PE Out HIGH level signal indicates that

paper is end.

13 SEL Out Pulling up to HIGH level signal by a

resistor

17 FG --- Signal Cover

PDF created with pdfFactory trial version www.pdffactory.com

18 Logic-H --- Logic “1” level

32 nFault Out Low level means the printer is at

fault

14,15,17

18,34,36 NC --- No connection

16,19~30, 33 GND --- Grounding logical 0 level

35 +5V --- +5V power

Fig.2-6 Signal Timing Chart of Parallel Interface:

2.3.3 Cash Drawer Interface

The cash drawer interface of POS-POS88VI adopts RJ-11 6-pin socket, as

Fig.2-7 shows:

PDF created with pdfFactory trial version www.pdffactory.com

Fig.2-7 Cash Drawer Interface

The pin assignment is as below:

Pin No. Signal Direction

1 Chassis Ground ——

2 Cash drawer driver signal 1 Out

3 Cash drawer on/off status signal In

4 +24VDC ——

5 Cash drawer driver signal 2 Out

6 Signal ground ——

2.3.4 Power Connection

POS88 Ⅵuses the external power supply adopter as 24V±10%、2A,

power socket is A-1009-3P model, as Fig. 2-10 shows:

PDF created with pdfFactory trial version www.pdffactory.com

Pin No. Signal

1 +24VDC

2 Ground

3 NC

The pin assignment is as above:

2.4 Indicator, buzzer and button

There is one button, one buzzer and three indicators on POS88VI printer.

【FEED】is paper feed button. The function of this button is on/off can be set

by print command. When the function of this button is on, press【FEED】

button to feed paper; release【FEED】button to stop feeding button.

The buzzer can indicate the error and cutter status. Through parameters

setting, the buzzer can be set into error alarm, paper-cut indicating or both

above. The types of error status are same as ERROR indicator.

The green POWER light is the power indicator. POWER indicator lighting

means the printer is power on.

PDF created with pdfFactory trial version www.pdffactory.com

The red ERROR light is error status indicator. It is off when the printer works

normally; while it flashes or persismently lights when the printer has

abnormal alarm.

If ERROR indicator flashes or persismently lights and the buzzer sounds, it

means the printer has error.

According to different flashing types, the different errors of printer are

indicated:

1. Un-recoverable error: the times of indicator flashing and buzzer sound

indicate the error type, then indicator persismently light.

2. Recoverable error: the times of indicator flashing and buzzer sound

indicate the error type, then indicator is persismently off.

3. Automaticly recoverable error: the indicator flashes and the buzzer sounds

continuously.

4. Paper out: the indicator lights and the buzzer sounds persismently.

The details are as below,

a. Un-recoverable error, the indicator flashes several times, then persismently

lights. Then cycle. The times of flashing means the error type.

Error type Description Types of ERROR

flashing

LED flashes once : Memory

read - write errors

Un-recovera

ble error

LED flash twice:

Over-voltage

PDF created with pdfFactory trial version www.pdffactory.com

LED flashes three times: the

voltage is lack

LED flashes four times : CPU

Execution error (wrong

address )

LED flashes five times : UIB

error

LED flashes eight times :

temperature detection of

circuit is wrong

b. Recoverable error: the indicator continuously flashes and persisment off for

a period.

Error type Prescription Type of flash

Recoverable

error

LED flashes once .the place

of cutter is wrong

c. Automaticly recoverable error: the indicator flashes continuously.

Error type Description Type of flash

Automaticly

recoverable

error

LED continues flashing :

the temperature of printing

head is over high and the

cover is wrong

2.5 Turn on the printer

When the printer is off and paper case cover is closed, press the POWER

button to turn on the printer. The status indicator and Paper Out indicator

flashes twice alternatively, then indicator off. The printer enters into the

normal working mode.

PDF created with pdfFactory trial version www.pdffactory.com

2.6 Self-test

The self-test will check the condition of printer, if the printer prints out the

self-test receipt correctly, it means the printer works normally except interface

with host. Otherwise it needs to repair.

The self-test will print out: Manufacturer name, printer model, software

version, interface type, default value of printer parameters, 96 ANK characters

in ASCII code, content of default codepage (if language is set English) or

name of Chinese character library (if the language is set Chinese), barcode

type.

Way of self-test: hold down【FEED】button and turn on the printer, At this time,

printer will print out self-test receipt. The content is as below picture 2-9:

2.7 Hexadecimal Printing

Turn on the printer according to the steps below, it will enter the mode of

Hexadecimal Printing

1.Open the cover;

2.Hold down【FEED】button,and connect with power;

3.Close the cover, the printer will print out 3 lines as below:

Hexadecimal Dump

PDF created with pdfFactory trial version www.pdffactory.com

To terminate hexadecimal dump,

Press FEED button three times.

This means the printer has entered hexadecimal printing mode, and

under this mode, all of the input will be printed out as hexadecimal number,

feed one line with single-click of “FEED” button, after 3 times, it will print out

“*** Completed ***”,and exit hexadecimal printing mode.

2.8 Printer parameter Settings

This function is for the setup of parameters.

Steps for setting parameters: When printer power is off, open paper case

cover firstly, then press the 【FEED】 button and turn on the printer. After

status indicator and paper out indicator flash twice alternatively, press

【FEED】 button twice, then close pape case cover. Printer enters into

parameter setting mode and print out the first set parameter and its default

value. The details method of setting parameter can refer to Appendix A.

Steps for exiting of parameter setup: open paper case cover and press the

【FEED】 button; then close paper case cover and release the 【FEED】

button. The printer will save the setup of parameters, exit setting mode and

enter the normal working mode.

The data will not be saved if turn off the printer directly.

2.9 Enter the program upgrade mode

When printer power is off,open paper case cover, hold down the【FEED】

button, then turn on the printer. After the status indicator and paper out

indicator flash alternatively, release【FEED】 button. Then press 【FEED】

button five times and printer enters into the program upgrading mode. At this

time, the indicator flashes once each second.

Quick method of entering this mode: when printer power is off, open paper

case cover, hold down the【FEED】 button, then turn on the printer and release

the【FEED】 button. Printer enters into the program upgrading mode. At this

time, the indicator flashes once each second.

Notice: After printer enters into Program Upgrading Mode, if paper out

indicator lights, it means this interface can’t support program upgrading. Only

serial interface or USB interface can support program upgrading online.

PDF created with pdfFactory trial version www.pdffactory.com

Appendix A: Parameter setting

This appendix is the method to set default parameters of printer by buttons.

Setup instruction: use the button of【paper case cover】 to choose the setting

items, change the item by press the button【paper case cover】, and print out

the current value. Use the button of 【FEED】to set the parameter, the

parameter will be changed by press the 【FEED】 button.

Summary setting:

Paper case paper case paper case paper case

Cover cover cover cover

Paper case paper case paper case paper case cover

Cover cover cover

Baud rate:

FEED FEED FEED

FEED FEED

FEED FEED FEED

Language:

FEED FEED

FEED

Font dots:

FEED

FEED

Print Density :

FEED FEED

FEED

China

English

12×24 9×17

中 低 高

China-BIG5

Baud rate

Density

Speed

Font dots

Language

Buzzer

function

Print function

for out of paper

Black label

option

9600 57600 38400 19200

4800 115200 1200 2400

PDF created with pdfFactory trial version www.pdffactory.com

Print speed:

FEED FEED FEED

FEED

Buzzer:

FEED FEED FEED

FEED

Re-printing lack of paper:

FEED

FEED

Black label mode:

FEED

FEED

220mm/s 150mm/s

250mm/s 200mm/s

OFF Cut ON

Error ON ALL ON

OFF ON

off on

PDF created with pdfFactory trial version www.pdffactory.com

Loading...

Loading...