SPRSUN CGK/C-XX(L) Series, CGK/C-XX(LHC) Series, CGK/D-XX(L) Series, CGK/D-XX(LHC) Series, CGK/C-XX(H) Series User Manual

...

Heat Pump User Manual

Comprehensive version

(EVI heat pump and High temp. heat pump)

Version: CG2017111601

This manual is suitable for below heat pumps:

No Abbreviations Details Model

1 EVI-HW EVI air source heat pump hot

water series

CGK/C-XX(L),

CGK/D-XX(L)

2

EVI-HH EVI air source heat pump

heating + hot water series

3 EVI-HC EVI air source heat pump

heating and cooling series

4 HT Air source high temperature

heat pump

Note: Abbreviations name will be used in the below content, pls check the

related content for your heat pump referring to the form above.

CGK/C-XX(L),

CGK/D-XX(L)

CGK/C-XX(LHC),

CGK/D-XX(LHC)

CGK/C-XX(H),

CGK/D-XX(H)

Contents

Part 1. Before use …….…………………………………………………2-6

A. Attentions ...............................................................................................2

B. Installation ............................................................................................4-6

Heat pump installation location and attentions……………………………….….4

Installation diagram and tips…………………………...………………………...5

Pre-stat up………………………………………………………………………..6

Part 2. Use …………………………………………….….……………….7-21

Operation and display…………………………………………………..…….9-12

Data query and setting……………………………………………………...…..13

Error code………………………………………………………………………14

Working modes…………………………………………………………………19

Electrical component controlling……………………………………….………21

Part 3.Maintenance and Reparing ………………………………...23-26

Warranty card………………………………………………………………...26

P1

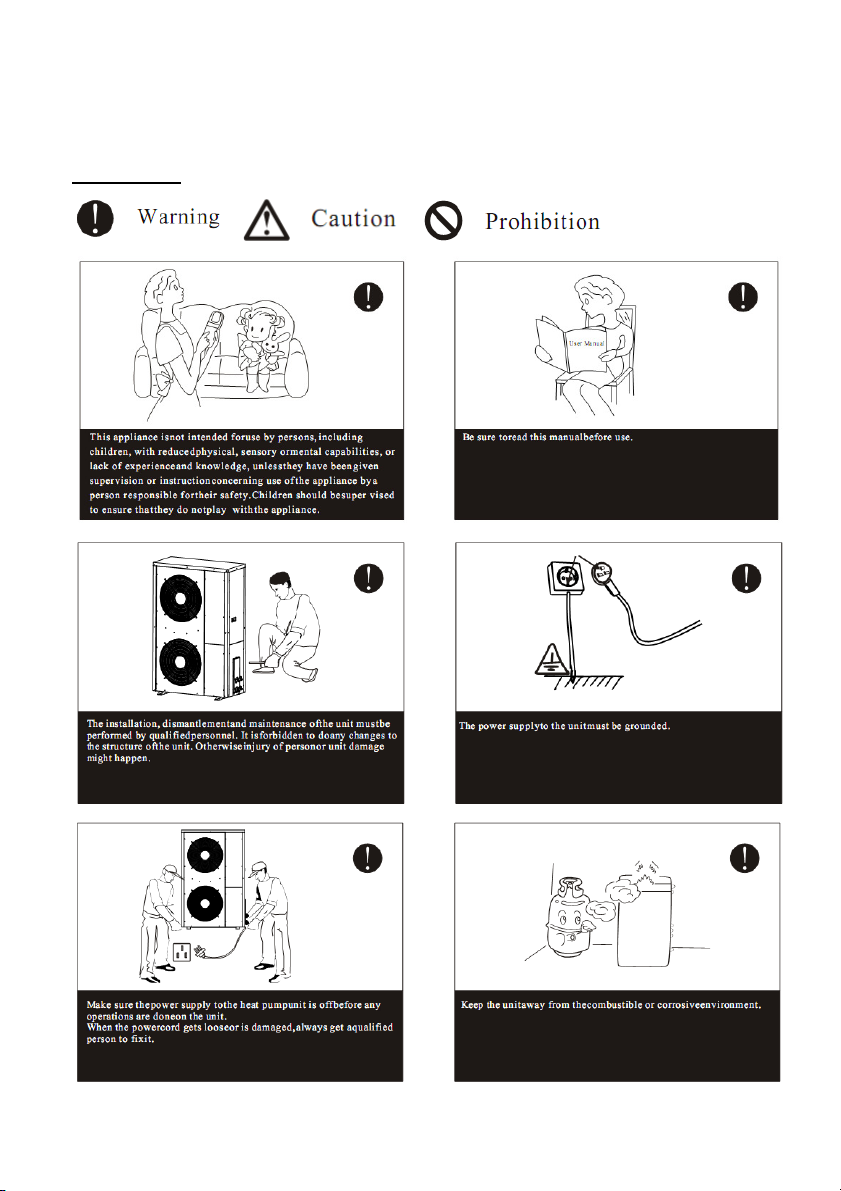

Part 1 Before Use

Attentions

P2

P3

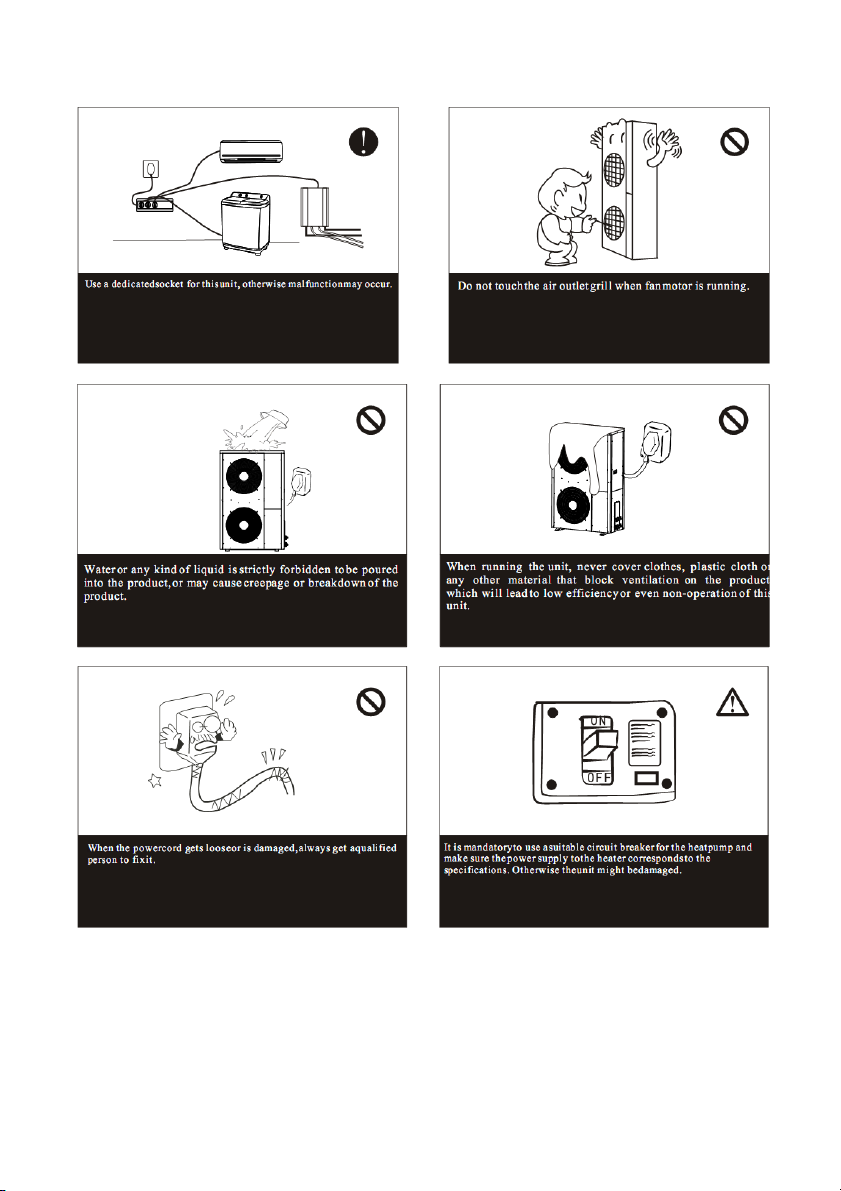

2.Installation

A. Heat pump installation location and attentions

*. Heat pump is not allowed to be installed in the place where combustible gas

may leaks.

*. Heat pump is not allowed to be installed in the place where there is oil or

corrosion gas released.

*. Heat pump should be installed in a open space, and good ventilating.

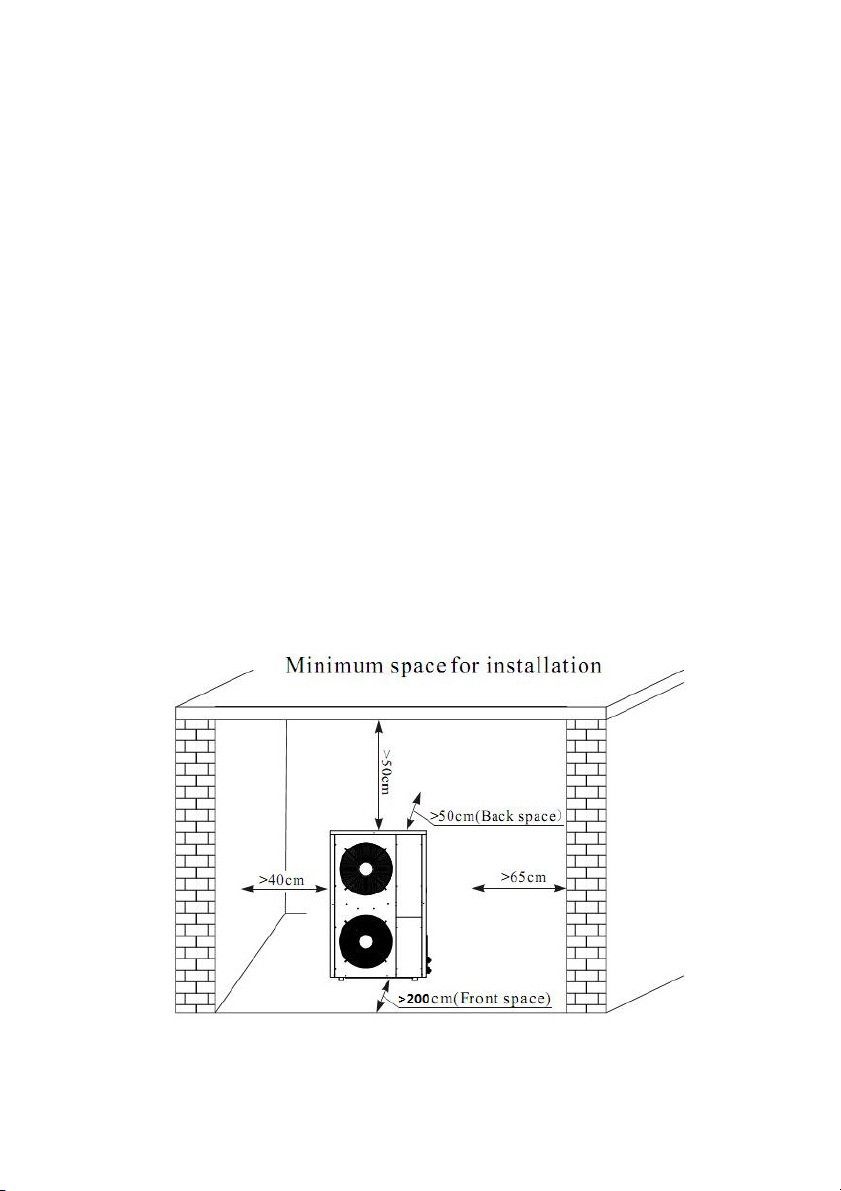

*. Heat pump each side to wall or barrel should be keep certain distance, air

outlet to barrel distance should ≥2m, air inlet distance to wall or barrel≥0.5m,

bottom distance to ground ≥0.5m, other side distance should be enough for

installation or repairing.

*. Heat pump should be installed on concrete basic or steel bracket, and

anti-shock pad should be put between heat pump and basic or bracket. Then use

expansion bolt to fix heat pump on bracket.

* Water drainage pipe and ditch should be set around heat pump and water pipes

and water tank. When testing or repairing, maybe need drain plenty of water, and

when heat pump is working, there are some condensed water flow down.

B. Installation diagram ( it is only for reference,the actual installation shall be

based on actual project)

P4

* for hot water and floor heating

*for heating/cooling

P5

Tips for installation related to the water pipe part:

*Install a valve at the highest point of each water circulations for releasing air

from water system.

* A Y filter is very important in front of circulating water pump of heat pump.

* If more heat pumps installed in one water pipe system, the connection of these

heat pumps can’t be in series, only can be in parallel or independent.

C. Pre-start up

1.Checking before pre-start up

* Check if the water pipe are connected well and if there is any leakage. The

water supply valve are open.

* Make sure the water flow is enough and meet the demand of the heat pump

selected and water flow smoothly without air . In cold area, pls make sure that

the water flow is without freezing

* Check if the power cable is connected well and properly grounded.

* Check if fan blade is blocked by the fixing plate of fan blade and fan blade

protecting grill.

* Check if the tank has been filled with water or enough water volume that can

meet the demand of heat pump running

Pre-start up

After check completely and confirm no problem for installation, the unit can be

power to start up .

After connect power supply, heat pump delay 3 mins to start. Check carefully

is there is some abnormal noise or vibration or if the working current is normal

or if water temp increasing is normal.

After the unit is working properly for 10 minutes without any problem, then the

pre-start up is usefully completed. If not, pls refer to Service and Maintenance

Chapter to solve the problem.

P6

Part 2. Use

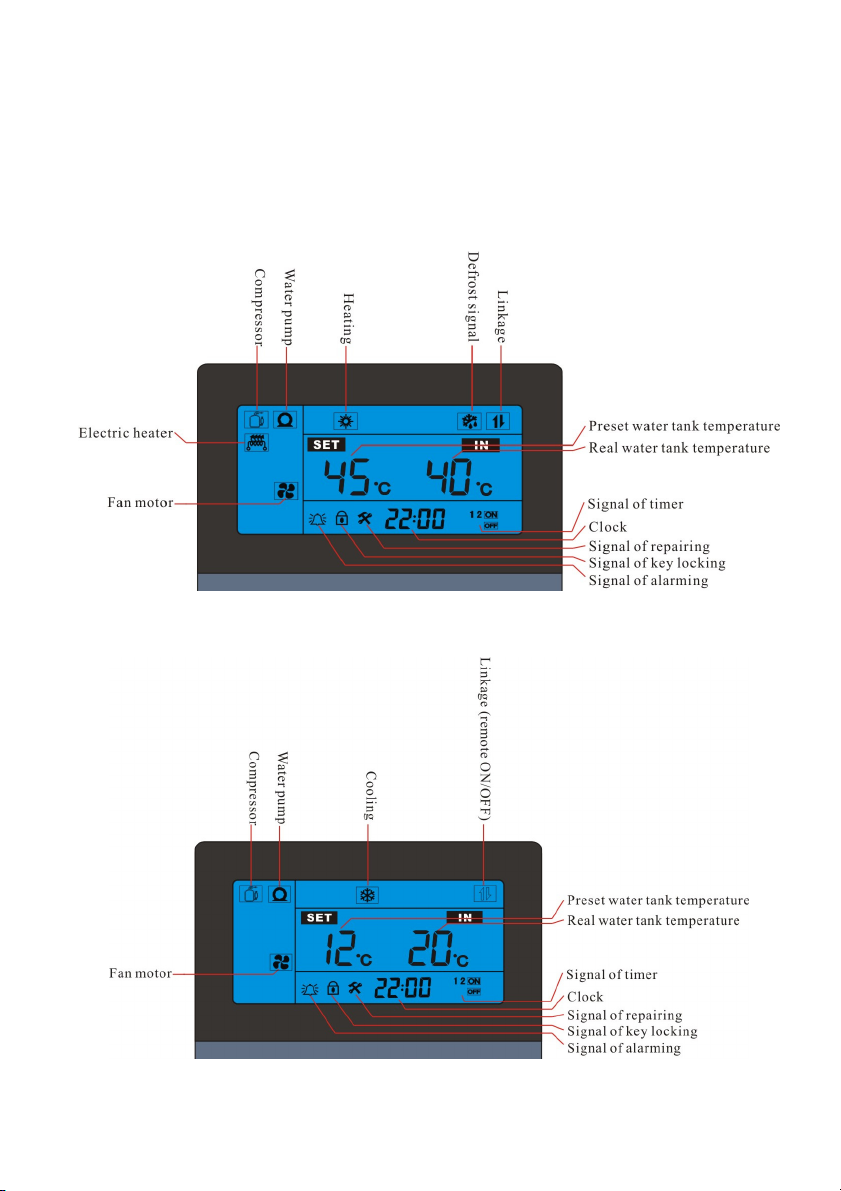

Operating panel display

EVI-HC

A. Heating mode

B. Cooling mode

P7

EVI-HH

A. Only hot water mode

B. Heating + hot water mode

P8

EVI-HW

HT series

P9

Buttons function

↓ ↓ ↓ ↓ ↓

Clock M + - power

“Power” button

2.1.1 Under unlock state, press this button for 1second, can turn on and turn off

heat pump.

2.1.2 Under other state, press this button, can return main interface.

2.1.3 Under locking state, press this button for 5 seconds, can unlock buttons.

“M” button

Under main interface, press “M” button, can query the working status

parameters

“+”and “-“ button

2.3.1 Turns page, change value

2.3.2 Combine with “M” button, can query and set parameter

2.3.3 Under power on state, press “+”and “-“button, can set current working

mode water temperature (except heating + hot water mode).

“Clock” button

2.4.1 Press this button for 10seconds, enter clock setting interface

2.4.2 Press this button, can enter timer of ON/OFF setting, combine “+”and

“-“button, can set timers.

Operating

Operating panel get electricity

When heat pump power supply is supplied, operating panel and PC board will

get electricity, then display panel displays, background light is very weak, all

buttons are locked now, any touching is invalid.

Unlock buttons

Press “power” button for 3sec, when hear “Du” voice, move finger, now

background light is strong, all buttons are unlocked, the lock symbol disappear.

P10

(if there is not operating on buttons for 60sec, buttons will be locked

automatically, and displays lock symbol)

Turn on/off heat pump.

Press “power” button, if operating panel shows off state, will turn on heat pump.

If operating panel shows on state, will turn off heat pump.

Water tank temperature setting (L3 or L4)

Except EVI-HH and HH series, other series have two way to set water tank

temperature:

Way 1:

Under on state and main interface, press “+” and “-“ button, can adjust current

working mode water tank preset temp. The preset water tank temp is the left one

temperature, the real water tank temp is the right one temperature. When setting,

the left temp will change, and display L3 or L4 below it.

Way 2:

Refer to “Table 3: user parameters query and setting” in P15. All user parameters

can be set by the same way. Floor heating water temperature only can be set by

this way.

Parameters query and setting operation

① Working status parameters and history error code query

How to enter? Under main interface, press ”M” button, can query the working

status parameters and history error codes

Working status parameters (table 1)

P11

Table 1: heat pump working status parameters query

Code Meaning Note

A0 Water tank temperature

A1 Outlet water temperature

A2

A3

A4

Air heat exchanger 1 lowest

tube temp

Inlet gas temperature of

compressor 1

Outlet gas temperature of

compressor 1

Same meaning for all series

Same meaning for all series

Same meaning for all series

A5 Ambient air temperature Same meaning for all series

A6 Inlet economic unit 1 Same meaning for all series

A7 Outlet economic unit 1

A8

Return water temperature of

water tank

Inlet water temp For EVI-HC

For EVI-HW and HT series

For EVI-HH and HH series

Floor heating water temp

(displayed on main interface, the

left one temperature)

A9 Compressor 1 current Same meaning for all series

For HW and HH and SP-H series,

rated heating capacity less than

52KW models

Same meaning for all series

A10

A11

Primary electronic expansion

valve opening degree 1

Secondary electronic expansion

valve opening degree 1

A12 After throttling1 temperature

A13 Air heat exchanger 2 lowest Same meaning for all series

P12

tube temp

A14 Outlet gas temperature of

Same meaning for all series

compressor 2

A15

Inlet gas temperature of

compressor 2

Same meaning for all series

A16 After throttling 2 temperatures

A17 Inlet economic unit 2

A18 Outlet economic unit 2

A19 Compressor 2 current Same meaning for all series

A20

Primary electronic expansion

valve opening degree 2

For HW and HH and SP-H series,

rated heating capacity less than

52KW models

A21

A22

Secondary electronic expansion

valve opening degree 2

Air conditioning (floor heating)

inlet the water temperature

Same meaning for all series

A23 User return water temperature

E1~

E6

History error code Same meaning for all series

Note:

1.A23 return water temperature:

It is the return temperature of hot water mode, the temp sensor need to be

installed in the water tank on the return pipe, used to control the return valve;

2. about water tank temp sensor, installation position in each series is

different.

A. EVI-HW: should be installed in hot water tank by installer

B. EVI-HH series: hot water tank temp sensor should be installed in hot water

tank by installer. (Floor heating water temp sensor should be installed in floor

heating water tank or on floor heating system return water pipe)

C. EVI-HC series: water tank temp sensor has been installed on inlet water pipe

by factory (if project has A/C water tank, installer can move the sensor to tank

from heat pump)

P13

Table 2: Error code

Code Meaning Method

Er 01

Wrong phase error

Exchange phase sequence

Er 02 Lack phase error

Er 03 Water flow switch error

Er 04

Er 05 System (1) High pressure

Er 06 System (1) Low pressure

A/C side of the water flow

switch

Er 07 System (2) High pressure

Er 08 System (2) Low pressure

Er 09 Communication error

Er10 Tank temp sensor

Er 11

Er 12

Time limit for locking heat

pump reached

System (1)

pressure of compressor 1 is

Outlet gas

Check the power supply

Check the hot water side of the water

flow is sufficient or the water flow

switch wiring, such as damage please

replace

Check the hot water side of the water

flow is sufficient or the water flow

switch wiring, such as damage please

replace

Check water flow is too small; check

the dust of fin heat exchanger

Check water flow is too small; check

whether the refrigerant leak

Check the PC board and control panel

line is connected, if damaged please

replace

Please cancel setting time of

running

P14

too high

System (2)

Er 13

pressure of compressor 2 is

too high

Er 14 Throttling temperature 1

Er 15 Throttling temperature 2

Er 16

Er 17

Er 18

Er 19

Air heat exchanger 1 coil

temp sensor

Air heat exchanger 2 coil

temp sensor

Outlet gas temp sensor 1 of

compressor error

Outlet gas temp sensor 2 of

compressor error

Outlet gas

Check the sensor contact is good;

replace the temp sensor

as above

as above

Er 20 Ambient air temp sensor error as above

Er 21

Er 22 HE

Er 23

A/C Return water temp

sensor

outlet water temp sensor as above

Inlet gas temp sensor 1

Er 24 Inlet gas temp sensor 2

Er 25

Er 26

Er 27

Er 28

Er 29

The economic unit 1 inlet

the sensor error

The economic unit 2 inlet

the sensor error

The economic unit 1 outlet

the sensor error

The economic unit 2 outlet

the sensor error

Compressor 1 current too

high protection

Er 30 Compressor 2 current too

as above

as above

as above

as above

Check the current and voltage are

stable

P15

high protection

Er 31 Water level switch error

Ambient temp too low

Er 32

protection

Outlet water temp too high

Er 33

error at heating mode

Air conditioning supercooling

Er 34

protection

Return water temp sensor error

Er 35

of water tank

Hot water symbol flashing Anti-freeze protection for hot water side

Heating symbol flashing Anti-freeze protection for heating side

Check the wiring contact is good; replace

the pressure switch

Beyond the normal operating temperature

range of the heat pump

Check the sensor contact is good; replace

the temperature sensor

Check if the air conditioning water pump

is low water

Check the sensor contact is good; replace

the temperature sensor

②User parameters query and setting (both ON and OFF state can set)

How to enter?

◆ Under main interface, press “M” for 3seconds, enter user parameter query

interface, then press “+”and “-“ button , can query L0 to L9value.

◆ Under user parameter query interface, press “M” button, enter setting interface,

press “+”and “-“ button, to set the value of current parameter, press “M” button

again, return query interface.

◆ Under user parameters query interface and setting interface, if there is not

operation for 30seconds constantly, system will quit user parameter query or setting

interface automatically, and return to main interface, press “power” button can return

main interface too.

Table 3: user parameters query and setting

P16

Code Meaning

L0

L1

L2

L3

Compressor restart temperature

of hot water drop

Preset water tank temperature of

heating mode

Compressor restart temperature

cooling drop

Preset water tank temperature of

cooling mode

L4 Heating drop

L5 Heating set the temperature

Ambient air temperature below

L6

which electric heater is allowed

Setting

range

2℃─18℃

20℃─58℃

2℃─18℃

10℃─32℃

2℃─18℃

12℃─99℃

─30℃─35

℃

Factory setting

3℃

1. HT series: 75℃

2. EVI-HC series: 45℃

3. Other series: 55℃

5℃

12℃

5℃

45℃

0℃

to start

L7 Return water temperature

L8

Water compensate temperature

L9 Compressor current

20℃─80℃

20℃-80℃

0~48A

30℃

48℃(20℃ no need

water compensate)

0A(0A: will not detect

current)

Note:

L1, L3 is the water tank setting temperature . Water tank temperature is directly

displayed on PC board. The left side is the setting temperature, the right side is the

actual temperature.

For heating, User need put the temp sensor into blind tube which is installed on

water tank.

The pool temp sensor is installed on a titanium tube heat exchanger by factory

The water temp sensor of the heating and cooling mode is installed in the return pipe

of the heat pump by factory.

Other operation

P17

①Clock setting

A. At main interface, press “clock” button for 5 seconds, enter clock setting interface

B. At clock interface, press “clock” button, then “hour” flash, press “+”or “-”button,

can set hour.

C. After finish setting hour, press “clock” button, then “minute” flash, now press

“+”or“-”button,can set minute.

D. After finish setting minute, press “clock” button, to confirm clock setting, and

back to main interface.

E. At clock setting interface, if there is not operation within 30seconds, system will

confirm clock setting and back to main interface automatically.

F. At clock setting interface, press “power” button, can confirm current clock setting

and back to main interface.

②Timer setting and cancelling (ON/OFF timer)

A. At main interface, press “clock” button, enter timer group setting.

Now press “+”or“-”button, can switch timer groups, there are 4 groups ON/OFF

timer.

B. When group 1 ON timer flashing, press “clock” button, enter group 1 ON timer

“hour” setting interface, “hour” flash, then press “+”or“-”button,then can set “hour”

for group 1 ON timer.

C. After finish setting “hour”, press “clock” button, then “minute” flash, then press

“+”or“-”button,can set “minute” for group 1 timer.

D. After finish setting group 1 ON timer “minute”, press “clock” button, enter group

1 OFF timer setting, same way like ON timer setting.

E. After finish setting group 1 ON/OFF timer, press “clock” button, confirm group 1

setting, and enter group 2 ON/OFF timer setting, same way like group 1 setting.

F. At timer interface, if there is not operation within 30seconds, then confirm current

timer setting, and back to main interface (this setting can be remembered if

electricity is cut off)

G. At timer interface, press “power” button, confirm current timer setting, and back

to main interface.

H. Other groups ON/OFF timer setting are same way like group1.

Remarks: groups 1 and 2 are heat pump ON/OFF timer, group 3 is return water timer,

group 4 is cool water compensating timer.

P18

group 3 and 4 only valid for EVI-HW, HT series.

I. How to cancel timer?

At timer interface, press “clock” button for 5seconds, when the ON and OFF signal

disappear, then press “power” button to confirm, can cancel current group ON/OFF

timer.

③③③③Forced defrosting

◆ At ON status, press “-” for 3seconds, enter forced defrost.

◆ To quit forced defrost, there are two ways.

a. Automatic quitting: when defrost time reach preset quitting temperature, can quit

forced defrost.

b. Forced quitting: Press “power” button,after power off, 3minutes later, will quit

forced defrost completely.

④④④④Remove history error code

At the interface of query history error code, press “power” and “M” button together

for 5seconds, can remove all the history error code.

⑤⑤⑤⑤Change working mode

Press “+” button for 5seconds, can change the working mode For EVI-HC series,

change working mode between heating mode and cooling mode.

For EVI-HH series, change working mode between hot water mode and heating +

hot water mode.

C. Working mode

1. EVI-HW, HT series

The three series mainly used to supply hot water, (sometimes used for house

heating), have only one working mode: hot water mode.

1.1 The unit start and stop based on the hot water tank temp. and setting temp.

2. EVI-HH series

The two series mainly used to supply hot water and heating house, have two

working mode: Hot water mode and hot water + heating mode.

2.1 Hot water mode controlling, the unit start and stop based on the hot water tank

temp. and the setting temp.

2.2 Hot water + heating mode controlling

2.2.1 Hot water mode: working same as 2.1

P19

2.2.2 Heating mode

The unit start and stop based on the heating return temp. and the setting temp.

2.2.3 Hot water + floor heating controlling logic

◆ Hot water is priority, before hot water reach preset temp, 3-way valve doesn’t

have electricity

◆ When hot water reach preset temp, heat pump stop, then check heating side

water temp automatically, if heating side water temp doesn’t reach preset temp, then

3-way valve will get electricity, and meanwhile heat pump start. When heating

system water temp reach preset temp, heat pump stop to standby. In the process, if

check hot water tank temp dropped lower then setting temp., then heat pump stop

and 3-way valve loss electricity, then heat pump restart to heat hot water.

3. EVI-HC series

The three series are all heating and cooling type. User can change the working mode

between heating mode and cooling mode.

3.1 Heating mode

The unit start and stop based on the setting temp. and real water tank temp.

3.2 Cooling mode

The unit start and stop based on the setting temp. and the real water tank temp.

4. Defrosting:

Defrost only valid at heating or/and hot water mode.

When defrost, the display panel will display defrost symbol.

Fan motor doesn’t work.

Compressor stops first, then start.

Circulating water pump doesn’t stop.

D. Each electrical component controlling

1. Compressor (installed inside heat pump)

1.1 Compressor start / stop according to water tank (or heating system) real

temperature and preset temp.

1.2 After compressor stops, should need at least 3min, then it can restart again.

1.3 After compressor start, should work at least 2min first, then can stop. (Except

turned off or there is error).

1.4 There is not 3min protection for the first time starting.

P20

2. Four - way valve (installed inside heat pump)

2.1 At heating or hot water mode, 4-way valve lose electricity.

2.2 When cooling or defrosting, four-way valve get electricity.

2.3 Four way valve delay 2min change direction after compressor stop when change

working mode.

2.4 When defrosting and forced defrosting, 4-way valve get electricity.

3. Circulating water pump

3.1 EVI-HW, EVI-HC, HT series:

Circulating water pump start / stop together with compressor.

3.2 EVI-HH series

If change to hot water mode, circulating water pump start/stop together with

compressor.

If change to hot water + heating mode, circulating water pump doesn’t stop.

4. Fan motor (installed inside heat pump)

4.1 Normally, fan motor start in advance than compressor, and stop at the same time

as compressor.

4.2 When defrosting, fan motor doesn’t work.

5. Auxiliary electrical heater

5.1 Starting conditions::::

5.1.1 At heating or hot water mode

5.1.2 Ambient temperature ≤ L6

5.1.3 Water tank temperature < water tank setting temp. – L0

5.1.4 Low level switch connects.

When all of above conditions are met, electric heater starts.

5.2 Stopping conditions:

5.2.1 Water tank temp ≥ water tank setting temp..

5.2.2 Water tank temp sensor damaged and controller show error code.

5.2.3 Ambient temp ≥L6+2℃;

5.2.4 Water level switch has error

5.2.5 Low level switch disconnects

Any of above condition is met, electric heater stops.

5.3 When defrosting, forced defrosting, secondary anti-freeze, electric heater is

forced to start.

P21

5.4 Except there is water level error, hot water tank temp sensor error, when there

is other temp error, high and low pressure error protection, electric heater will start.

Remarks: EVI-HH series, only hot water side has electric heater function, heating

side doesn’t have.

6. Three-way valve

6.1 Only EVI-HH and HH heat pump have three-way valve function. Installer need

install three-way valve on outlet water pipe of heat pump.

6.2 When switch to hot water side, 3-way valve lose electricity. When switch to

heating side, 3-way valve get electricity.

6.3 Before 3-way valve switch the direction, circulating water pump should stop first

10 seconds in advance.

7. Return water valve

Only EVI-HW, HT series has return water valve function.

7.1 Condition of return water valve open (all below condition should be met):

7.1.1 Low water level switch connects

7.1.2 Water tank temp ≥L7 + 5

7.1.3 Return water temp ≤ L7 – 5

7.2 Condition of return water valve closes (any below condition met):

7.2.1 Low water level switch disconnects

7.2.2 Water tank temp < L7 + 5

7.2.3 Return water temp > L7

8. Linkage switch

8.1 Linkage switch is input OF/OFF signal, heat pump can be turned on/off by the

signal.

8.2 When operating panel is under on state, if linkage signal is on, heat pump keep

on state. If linkage signal is off, heat pump will be turned off.

8.3 When operating panel is under off state, if linkage signal is off, heat pump keep

off state. If linkage signal is on, heat pump will be turned on.

9. RS485 Connection

P22

Part 3. Maintenance and repairing

A. Daily maintenance

Heat pump is high automatic equipment, if can check and maintain periodically, the

stability and lifetime of heat pump will increase greatly.

1. When using and maintain the heat pump, please note: all security device have

been set before leave factory, please don’t adjust anymore.

2. Check if power cable and other cables connection is firm, if electrical unit work is

abnormal, if yes, repair or replace at once.

3. Check periodically if water system leaks water, if insulation damaged.

4. Check if the air around is clean and dry, if ventilation is good.

5. Don’t put debris around heat pump, avoid blocking air inlet and outlet.

6. If need stop heat pump for long time, should drain the water in the system, and cut

off the power supply. Before restart, check the system completely.

7. When there is error codes, or heat pump work abnormally, please call local

servicer to repair.

B. Some error code and repairing

When below error happen, controller will alarm and display error code.

Error Possible reason Method to repair

1. Check if water tank temp probe

is installed correctly

2.1 Release air from highest

position of circulation.

2.2. Open Y type filter to check if

there is impurity on the net.

3. Drain refrigerant and vacuum

and refill refrigerant according to

nameplate.

1. Check leaking point and repair

and refill refrigerant

2. Change fan motor or blade

3. Wash fin of air heat exchanger or

High pressure

error

Low pressure

error

1. Real water temp is too

high but probe can’t

detect real temp

2. Water flow is too small

3. Refrigerant is

excessive

1. Lack of refrigerant

2. Fan motor doesn’t run

3. Air flow is blocked

P23

1. Lack of refrigerant

2. Water pump is too

Outlet gas temp

too high error

Outlet water

temp too low

protection when

cooling

Outlet water

temp too high

protection when

heating (hot

water)

Compressor

current is too

large

small

3. Water pipe is too small

4. Air entered water

system

1. Circulating water

pump is too small

2. Air entered water

system

3. There is impurity in

water filter.

1. Circulating water

pump is too small

2. Air entered water

system

3. There is impurity in

water filter.

1. The current detector is

damaged

2. Compressor damaged

3. Compressor doesn’t

start

C. Other problem and repairing

remove barrier close air inlet or

outlet.

1. Repair leakage and refill

refrigerant

2. Change a bigger water pump

3. Change bigger size water pipe

4. Release air in water system

1. Change a bigger water pump

2. Release air from water system

3. Clean the filter

1. Change a bigger water pump

2. Release air from water system

3. Clean the filter

1. Change the detector

2. Change compressor

3. Check if the compressor cable is

loose

No Error Possible reason Method

1

Heat pump

doesn’t run

1. Power supply cable is

loose

2. The fuse of power

P24

1. Cut off the power

supply to check and

repair.

supply is fused. 2. Change the fuse.

Heating capacity

2

is too small

Compressor

3

doesn’t run

Compressor noise

4

is loud

Fan motor

5

doesn’t run

Compressor run,

6

but not heat

1. Refrigerant is not

enough

2. Water system insulating

is not good

3. Air heat exchanger is

dirty

4. Water heat exchanger

scaled

1. Power supply has error

2. Cable connecting is

loose

3. Compressor is overheat

1. Expansion valve

damaged lead to liquid

entering compressor

2. The internal parts of

compressor damaged

3. Compressor lack of oil

1. Fan blade fixing screw

is loose

2. Fan motor damaged

3. Fan motor capacitance

damaged

1. There is not refrigerant

at all

2. Compressor damaged

P25

1. Check leakage and

repair and refill gas

2. Improve the

insulation

3. Clean air heat

exchanger

4. Clean water heat

exchanger

1. Check reason and

solve

2. Check loose and

repair

3. Check reason and

repair

1. Change expansion

valve

2. Change compressor

3. Compensate oil for

compressor

1. Tight the screw

2. Change fan motor

3. Change the

capacitance

1. Check leakage and

repair

2. Change compressor

Warranty card

Product model: Bar code:

Buyer Address

Invoice No. Date

Repair date Repair record Repairer

Items of warranty:

1. Warranty term: ; Within

warranty, any problem because of quality, we repair for free.

2. When need repair, please show the warranty card and invoice of order

or other proof.

P26

3. We don’t afford the problem that is caused by re-fitment or adding

other function by user.

4. Warranty card and invoice or other purchasing proof will be invalid if

alerted.

5. Please keep the warranty card and invoice or other purchasing proofs

good, we will not supply service if these documents are lost.

6. We will not repair for free for below condition:

①without proof;

②Errors caused by re-fitment or not correct operating;

③Damage caused by not professional people operating;

④faulty by moving or falling;

⑤Faulty caused by natural disaster.

Product Model:…………………………………

CERTIFICATE

Bar code:………………………………………….

Checking result:…………………………………

P27

Loading...

Loading...