DE ........................ 10-22

Vor Inbetriebnahme der

Maschine unbedingt

Bedienungsanleitung

lesen!

UK ...................... 23-34

Read these instructions

carefully before

operating the machine!

SCHEURSAUGMASCHINE 10-22

FLOOR SCRUBBER DRYER 23-34

A

3

3

4

5

6

7

8

9

10

12

11

1

2

40

B

4

20 20 464623 23

22 22

21 21

13

14

15

16B

17

18

13

19 19

16

3 3

Model AC 230V

Model 2 x DC 12 V

Pb-Acido

Gel

C

22 23 20

20

5

6

D

24

28

31

25

26

27

29

30

7

BATTERY

LEVEL

Code 7.503.1808 rev. 00

Cod.7.503.1797-01

E

Model AC 230V Model 2 x DC 12 V

F

3333

3434

3535

37

36

38

39

3232

40

41

42

43

13

8

G

I

H

L

44

28

44

27

27

44

45

44

45

9

M

24

29

30

31

10

1. INHALTSVERZEICHNIS

2. ALLGEMEINE INFORMATIONEN

2.1 ZIELSETZUNG DES HANDBUCHS

2.2 ERKLÄRUNG DER SYMBOLE

2.3 PRODUKTINFORMATIONEN

2.4 BESTIMMUNGSGEMÄSSE VERWENDUNG

2.5 NORMENKONFORMITÄT

3. SICHERHEITSINFORMATIONEN

3.1 WICHTIGE HINWEISE

3.2 KÖRPERLICHE BELASTUNG

4. HANDLINGS-INFORMATIONEN

4.1 TRANSPORT DER MASCHINE

4.2 KONTROLLE BEI ANLIEFERUNG

4.3 AUSPACKEN

4.4 MONTAGE UND EINSTELLUNG DES

SCHUBBÜGELS

4.5 TRANSPORT DER MASCHINE,

BATTERIE UND BATTERIELADEGERÄT

5. TECHNISCHE INFORMATIONEN

5.1 BATTERIE

5.2 BATTERIELADEGERÄT

5.3 BEDIENELEMENTE UND FUNKTIONEN

5.4 BATTERIE

5.5 BATTERIELADEGERÄT

5.6 KONFIGURATION DES LADEGERÄTES

5.7 ZUBEHÖR

6. VOR DER INBETRIEBNAHME

6.1 BAT TERIE

6.2 INSTALLATION UND ANSCHLUSS DER

BATTERIE

6.3 KONFIGURATION DES LADEGERÄTS

6.4 VORBEREITUNG DER MASCHINE

7. BEDIENUNG

7.1 LADEN DER BATTERIEN

7.2 EIN- UND AUSBAU DER BÜRSTE

7.3 ABSTELLEN DER MASCHINE

7.4 EINBAU DES SAUGBALKENS

7.5 AUSBAU DES SAUGBALKENS

7.6 WECHSELN DER SAUGLIPPEN

7.7 EINSETZEN UND ABNAHME DES

SPRITZSCHUTZES

7.8 BEFÜLLEN UND ENTLEEREN DES

FRISCHWASSERBEHÄLTERS

7.9 ENTLEEREN DES SCHMUTZWASSERTANKS

7.10 DOSIERUNG DES FRISCHWASSERS

7.11 FAHREN DER MASCHINE

7.12 ARBEITSWEISE

7.12.1 VORBEREITUNG UND WARNHINWEISE

7.12.2 PRÜFUNG DES BATTERIELADEZUSTANDS

7.12.3 REINIGEN VON LEICHT VERSCHMUTZTEN

FLÄCHEN

7.12.4 REINIGEN VON STARK VERSCHMUTZTEN

FLÄCHEN

7.12.5 NACH DEM REINIGEN

7.13 GEBRAUCHSANWEISUNG FÜR DIE

230 VOLT NETZVARIANTE

8. WARTUNG

8.1 BEHÄLTER

8.2 FRISCHWASSERFILTER

8.3 SAUGSCHLAUCH

8.4 SAUGBALKEN

8.5 ZUBEHÖR

8.6 MASCHINE REINIGEN

8.7 BATTERIEN

8.8 REGELMÄSSIGE WARTUNG

8.9 EMPFOHLENE ERSATZTEILE

9 REINIGUNG / WARTUNG

9.1 STÖRUNGEN

9.1.1 DIE MASCHINE FUNKTIONIERT NICHT

9.1.2 FEHLERANZEIGEN AM DISPLAY

9.1.3 DIE BÜRSTEN DREHEN SICH NICHT

9.1.4 ES TRITT KEINE ODER NUR WENIG

REINIGUNGSLÖSUNG AUS

9.1.5 KEIN SAUGBETRIEB

9.1.6 ZU GERINGE SAUGKRAFT

9.1.7 DER BÜRSTENMOTOR ODER DER

SAUGMOTOR SCHALTEN NICHT AB

9.1.8 DER SAUGBALKEN REINIGT ODER TROCKNET

NICHT GUT

9.1.9 DAS BATTERIELADEGERÄT FUNKTIONIERT

NICHT

9.2 DIE BATTERIEN WERDEN NICHT GELADEN

ODER ENTLADEN SICH ZU SCHNELL

10. GARANTIE

10.1 ENTSORGUNG

11

2. ALLGEMEINE INFORMATIONEN

2.1 ZIELSETZUNG DES HANDBUCHS

Zum leichteren Nachschlagen und Lesen der gewünschten Informationen verwenden Sie bitte das

Inhalsverzeichnis.

Das vorliegende Handbuch stellt einen ergänzenden Teil des Produktes dar. Daher muss das

Handbuch über die gesamte Lebensdauer sorgfältig aufbewahrt werden.

Der Kunde hat sich zu vergewissern, dass das

Personal das Handbuch gelesen und den Inhalt

desselben verstanden hat, damit es die hier beschriebenen Anleitungen genau befolgen kann.

Nur das genaue Befolgen der in diesem Handbuch

enthaltenen Anleitungen gewährleistet beste Resultate hinsichtlich Sicherheit, Leistung, Wirksamkeit

und Lebensdauer ihres Produktes. Das Nichtbefolgen dieser Vorschriften kann eine potentielle

Gefahr für den Anwender, die Maschine, die gereinigte Oberfläche und die Umgebung darstellen.

Für daraus möglicherweise entstehende Schäden

kann der Hersteller nicht haftbar gemacht werden.

Die Batterien und das Batterieladegerät sind wichtige Komponenten um die Leistungsfähigkeit der

Maschine zu gewährleisten.

Nur die korrekte Kombination von Batterie und

Ladegerät gewährleistet optimale Leistungen

und verhindert kostspielige Schäden. Für detaillierte Informationen ist Bezug auf die spezifischen

Handbücher der Batterien und Batterieladegeräte

zu nehmen.

Das original Batterieladegerät gewährleistet in

Kombination mit der Original-Batterie die optimale

Funktionsweise

2.2 ERKLÄRUNG DER SYMBOLE

Für ein besseres Verständnis und zum Hervorheben der verschiedenen Aspekte der Anleitungen

wurden Begriffe und Symbole verwendet, die nachstehend definiert und abgebildet werden:

- Maschine. Dieser Begriff ersetzt die Handelsbezeichnung, auf die sich dieses Handbuch bezieht.

- Bediener. Person oder Personen, die die Maschine normalerweise bedienen und mit deren

Betrieb vertraut sind, aber nicht über die spezifische technische Kompetenz verfügen, die für die

Durchführung besonderer Eingriffe erforderlich ist.

- Techniker. Person, die über die Erfahrung, technische Ausbildung, Kenntnis der Gesetze und Vorschriften verfügen, die für die Durchführung von

Reparaturen erforderlich ist. Der Techniker ist in

der Lage, Gefahren zu erkennen und zu vermeiden,

die bei der Installation, dem Gebrauch, und der

Wartung der Maschine auftreten können.

- HINWEISSYMBOL ( ☞ ) Diese Informationen

sind besonders wichtig, um Maschinenstörungen

zu vermeiden.

- ACHTUNGSSYMBOL ( ) Diese Informationen

sind besonders wichtig, um schwere Maschinen

und Umweltschäden zu vermeiden.

- GEFAHRSYMBOL (

) Diese Informationen

sind besonders wichtig, um Personen-, Maschinenund Umweltschäden zu vermeiden.

2.3 PRODUKTINFORMATIONEN

Das unter dem Bedienteil angebrachte Leistungsschild enthält folgende Informationen:

- Angabe des Herstellers

- CE-Zeichen

- Modellnummer

- Modell

- Gesamt-Nennleistung

- Seriennummer (Kennnummer)

- Baujahr

- Gewicht bei max. Beladung

2.4 BESTIMMUNSGEMÄSSE

VERWENDUNG

Die Camira ist eine Scheuersaugmaschine.

Die Maschine kann zum Schrubben und Absaugen

von ebenen und hindernislosen Böden in Büround Industriegebäuden eingesetzt werden. Jeder

andere Einsatz ist verboten. Wir bitten Sie, die in

diesem Handbuch enthaltenen Sicherheitshinweise

strikt zu befolgen. Die Scheuersaugmaschine verteilt eine einstellbare Menge Reinigungslösung aus

Wasser und Reinigungsmittel auf dem zu behandelnden Boden, während die Bürsten den Schmutz

vom Boden entfernen. Mittels eines auf dem

Boden aufliegenden Saugbalken wird der Boden

getrocknet und der Schmutz aufgesaugt.

Durch eine korrekte Kombination der Reinigungsmittel mit den verschiedenen, verfügbaren

Bürstentypen (oder Schleifscheiben) kann die Maschine an alle Böden- und Verschmutzungen angepasst werden.

2.5 NORMENKONFORMITÄT

Diese Maschine wurde unter Berücksichtigung der

einschlägigen EU-Normen zur Gewährleistung der

Sicherheit und der Gesundheit des Anwenders

entwickelt und gebaut und ist daher mit dem

CE-Zeichen auf dem Leistungschild versehen. Die

EU-Normen, denen die Maschine entspricht, sind

in dieser Bedienungsanleitung innerhalb der Kon-

formitätsbescheinigung aufgeführt. Diese

Bescheinigung verliert ihre Gültigkeit, wenn sicherheitsrelevante Änderungen an der Maschine

vorgenommen werden.

Der Hersteller behält sich das Recht vor, jederzeit

und ohne Vorankündigung technische Änderungen am Produkt vorzunehmen, um das Produkt zu

aktualisieren oder technisch zu verbessern. Daher

kann die von Ihnen gekaufte Maschine in kleineren

Details leicht von den in unseren Katalogen oder im

vorliegenden Handbuch enthaltenen Informationen

und Abbildungen abweichen, ohne dass dadurch

12

die Sicherheit und die entsprechenden Informationen beeinträchtigt werden.

3. SICHERHEITSINFORMATIONEN

3.1 WICHTIGE HINWEISE

☞ Die “Bedienungsanleitung” ist vor dem

Einschalten, dem Gebrauch, der Wartung,

der ordentlichen Wartung und jeglichen

Eingriffen an der Maschine aufmerksam zu

lesen.

Alle im vorliegenden Handbuch und den

Handbüchern der Batterie und des Batterieladegeräts enthaltenen Anweisungen

sind strikt zu befolgen (insbesondere die

Achtungs- und Gefahrhinweise).

Der Hersteller haftet nicht für Personen- und/

oder Sachschäden, die auf das Nichtbeachten

der o.g. Vorschriften zurückzuführen sind.

☞ Vor dem Gebrauch der Maschine ist sicherzustellen, dass alle Bauteile korrekt montiert sind.

Die Maschine darf nur von Personen verwendet

werden, die bezüglich des Gebrauchs derselben

ausgebildet wurden, die zum Bedienen der Maschine fähig sind, und die ausdrücklich mit dem

Gebrauch der Maschine beauftragt wurden.

Der Gebrauch der Maschine ist nur volljährigen

Personen gestattet.

Die Maschine darf nicht für einen anderen als

den ausdrücklich vorgesehenen Zweck eingesetzt

werden. Bei dem Gebrauch der Maschine ist der

jeweilige Gebäudetyp zu berücksichtigen und es

sind die dort geltenden Sicherheitsbedingungen

strikt zu beachten.

Die Maschine darf nicht an schlecht beleuchteten Orten, in explosionsgefährdeter Umgebung, in

Verbindung mit gesundheitsschädlichem Schmutz

(Staub, Gas, usw.), auf öffentlichen Straßen und

Wegen sowie im Freien eingesetzt werden.

Die Maschine wurde für den Einsatz bei einer

Umgebungstemperatur zwischen +4°C und + 35°C

entwickelt; bei Nichtgebrauch ist die Maschine in

einer trockenen, nicht korrosiven Umgebung bei

einer Temperatur zwischen + 10°C und + 50°C

abzustellen.

Die für den Betrieb und die Lagerung der Maschine

zulässige Luftfeuchtigkeit liegt zwischen 30% und

95%.

Keine brennbaren oder explosiven Flüs-

sigkeiten, Gase, Trockenpulver, Säuren und

Lösemittel (z.B. Lösemittel zum Verdünnen

von Lack, Azeton, usw.) oder Benzin, Öl,

Treibstoff, usw. aufsaugen, auch nicht, wenn

diese verdünnt sind. Keine brennenden oder

glühenden Gegenstände aufsaugen.

Die Maschine nicht auf einem Gefälle über

10% oder auf Rampen mit einem Gefälle über

10% einsetzen. Die Maschine darf nicht quer zum

Gefälle eingesetzt werden. Auf Gefällstrecken ist

immer vorsichtig zu manövrieren und nicht zu

wenden. Beim Transport auf Rampen oder starken

Gefällen ist höchste Aufmerksamkeit erforderlich,

um ein Umkippen sowie eine unkontrollierte Beschleunigung zu vermeiden. Rampen und Gefälle

ausschließlich mit hochgefahrenen Bürsten und

Saugbalken befahren.

Die Maschine niemals an Gefällen parken.

Beim Gebrauch der Maschine ist auf anwesende

Drittpersonen, insbesondere Kinder in der Einsatzumgebung zu achten.

Die Maschine nicht zum Transportieren von Personen und/oder Gegenständen oder zum Schleppen

von Gegenständen verwenden. Die Maschine nicht

schleppen.

☞ Die Maschine nicht als Ablage für Gegenstände

verwenden.

Die Belüftungs- und Kühlöffnungen nicht bedecken

oder verstopfen.

Die Sicherheitsvorrichtungen nicht entfernen,

abändern oder umgehen.

Immer die für die Sicherheit des Bedieners erforderliche persönliche Schutzausrüstung verwenden.

Vor Arbeitsbeginn sind Armbänder, Ketten, Uhren,

Krawatten und andere Gegenstände abzulegen,

die eine potentielle Gefährdung darstellen und zu

schweren Unfällen führen können.

Nicht mit den Händen zwischen sich bewegende

Maschinenteile greifen.

☞ Keine anderen als die vorgesehenen Reinigungsmittel verwenden und die in den jeweiligen Sicherheitsblättern enthaltenen Vorsichtsmassnahmen und Vorschriften beachten. Wir empfehlen,

die Reinigungsmittel an einem Kindern unzugänglichen Ort aufzubewahren. Bei Kontakt mit den

Augen sind die Augen sofort gründlich mit Wasser

zu spülen. Bei Verschlucken der Reinigungslösung

ist sofort ein Arzt aufzusuchen.

Sicherstellen, dass die Steckdosen für die Stromversorgung des Batterieladegeräts geerdet und

abgesichert sind.

Die Anleitungen des Batterieherstellers sowie

die einschlägigen Normen sind zu befolgen. Die

Batterien immer sauber und trocken halten um

Kriechstrom zu vermeiden. Die Batterien vor Verschmutzungen, wie beispielsweise Metallstaub

schützen.

Keine Werkzeuge auf die Batterien legen:

Kurzschluss- und Explosionsgefahr.

Bei der Verwendung von Batteriesäure sind

die entsprechenden Sicherheitsvorschriften strikt

zu befolgen. In Anwesenheit von Magnetfeldern

sind die Auswirkungen auf die Geräteelektronik zu

überprüfen. Die Maschine auf keinen Fall mit Wasserstrahl reinigen.

☞ Die aufgenommenen Flüssigkeiten enthalten

Reinigungsmittel, Desinfektionsmittel, Wasser

sowie organisches und anorganisches Material, das

während der Arbeitens gelöst wurde: Daher müs-

13

sen diese Flüssigkeiten gemäß den anwendbaren

Gesetzen entsorgt werden.

Bei Defekten und/oder Betriebsstörungen ist die

Maschine sofort abzustellen (von dem Stromnetz

und/oder den Batterien trennen). Versuchen sie

nicht die Maschine selbst zu reparieren, sondern

kontaktieren sie einen Sprintus-Vertragshändler.

Alle Wartungsarbeiten müssen in gut beleuchteter

Umgebung durchgeführt werden, nachdem die Maschine durch Trennen des Batterieverbinders und/

oder des Netzsteckers von der Stromversorgung

getrennt wurde.

☞ Alle Eingriffe an der elektrischen Anlage sowie

alle Wartungs- und Reparatureingriffe (insbesondere die nicht ausdrücklich im vorliegenden

Handbuch beschriebenen Eingriffe) müssen in autorisierten Kundendienstcentern oder durch technisches Personal mit produktspezifischer Erfahrung

unter Beachtung der anwendbaren Sicherheitsvorschriften durchgeführt werden.

☞ Es ist ausschließlich der Einsatz von Originalersatzteilen zugelassen, die von Sprintus zu beziehen

sind. Nur Originalersatzteile gewährleisten einen

einwandfreien und sicheren Betrieb der Maschine.

Wenn die Maschine nicht mehr verwendet werden

soll, sind die Batterien auszubauen und gemäß den

Vorschriften der EU-Norm 91/157/EWG zu entsorgen oder einem autorisierten Batteriesammelcenter

zu übergeben.

Bei der Entsorgung der Maschine sind die im jeweiligen Anwendungsland geltenden Gesetze zu befolgen:

- Die Maschine vom Netz trennen, die Flüssigkeiten

ablassen und die Maschine reinigen;

- Dann wird die Maschine zerlegt um die verschiedenen Werkstoffe sortenrein zu entsorgen. Jede

Werkstoffgruppe wird gemäß den Wiederverwertungsgesetzen entsorgt.

Es wird empfohlen, die Bauteile der Maschine, von

denen eine Gefahr ausgehen kann, unschädlich zu

machen, damit insbesondere Kinder nicht gefährdet werden.

☞ Vor jedem Gebrauch ist die Maschine zu überprüfen. Insbesondere ist zu kontrollieren, dass

das Batterieladekabel und der Steckverbinder in

einwandfreiem Zustand sind, damit eine sichere Arbeit gewährleistet werden kann. Wenn diese Teile

nicht in einwandfreiem Zustand sind muss die Maschine vor einer weiteren Inbetriebnahme durch

einen zugelassenen Fachmann in Betrieb gesetzt

werden.

☞ Beim Austreten von Schaum oder Flüssigkeiten

ist der Saugmotor sofort abzustellen.

☞ Die Maschine nicht auf Textilböden, wie Teppichen, Teppichboden, usw. verwenden.

Der Gebrauch von Wachsen oder schäumenden

Reinigungsmitteln sowie Leckagen kann zu schweren Betriebsstörungen der Maschine sowie zum

Verstopfen der Leitungen führen.

3.2 MESSWERTE ZUR KÖRPERLICHEN

BELASTUNG

Geräusch- und Vibrationsdaten auf Seite 22.

4. HANDLINGS-INFORMATIONEN

4.1 TRANSPORT DER MASCHINE

Während des Hebens und des Transports ist sicherzustellen, dass die verpackte Maschine sicher

verankert wurde, damit sie nicht umkippen oder

abstürzen kann. Beim Laden/Abladen der Maschine auf/von Fahrzeugen ist für eine geeignete

Beleuchtung zu sorgen.

Beim Handling der verpackten Maschine sind

geeignete Mittel einzusetzen; dabei ist darauf zu

achten, dass die Verpackung keinen Stößen ausgesetzt ist und nicht beschädigt wird. Die verpackte

Maschine nicht auf den Kopf stellen und sie sanft

auf den Boden absetzen.

☞ Diese Anweisungen gelten auch für die Batterien

und das Batterieladegerät.

4.2 KONTROLLE BEI ANLIEFERUNG

☞ Bei der Lieferung der Ware (Maschine, Batterien, Batterieladegerät) durch den Spediteur ist

zu kontrollieren, dass die Verpackung und deren

Inhalt keine Beschädigungen aufweisen. Falls der

Verpackungsinhalt beschädigt sein sollte, ist der

Spediteur diesbezüglich zu unterrichten und es ist

schriftlich eine Schadensersatzforderung einzu reichen. Die Maschine in diesem Fall nur unter Vorbehalt annehmen.

4.3 AUSPACKEN

Beim Auspacken der Maschine ist folgendermaßen

vorzugehen:

In Karton verpackte Maschine:

- Die Kunststoffumreifungen mit einer Schere oder

einem Messer durchtrennen.

- Den Karton hochziehen und entfernen.

- Die Beutel aus dem Innenraum nehmen und

deren Inhalt überprüfen (Gebrauchs- und Wartungshandbuch, Steckverbinder für Anschluss an

das Batterieladegerät).

- Die Metallbügel oder Kunststoffumreifungsbänder

entfernen, die die Maschine an der Palette befestigen.

- Die Bürsten und Saugbalken aus der Verpackung

nehmen.

- Die Maschine nach hinten von der Palette schie-

ben, wozu eine gut an der Palette und am Boden

befestigtes, geneigtes Brett zu verwenden ist.

Nachdem das gesamte Verpackungsmaterial

entfernt wurde, können die Zubehörteile und Batterien gemäß den im spezifischen Abschnitt enthaltenen Anleitungen montiert werden.

Es wird empfohlen, alle Verpackungselemente

aufzubewahren, da sie zum Schützen der Maschine

und des Zubehörs bei einem weiteren Transport

an einen anderen Ort oder zu einem autorisierten

14

Kundendienstcenter verwendet werden können.

Andernfalls sind beim Entsorgen des Verpackungsmaterials die anwendbaren Gesetze zu befolgen.

4.4 MONTAGE UND EINSTELLUNG

DES SCHUBBÜGELS

- Den Griff in seinen Sitz einfügen.

- Fixieren Sie den Griff in der gewünschten Höhe

und ziehen Sie die 2 Knäufe an

(F oto B-21)

.

- Fügen Sie das Saugrohr in seinen Sitz am

Schmutzwassersammelbehälter ein

(Foto B-3)

.

- Stecken Sie den Anderson-Sicherheitsverbinder

(F oto B-18)

in seinen Anschluss

(F oto B-17)

.

4.5 TRANSPORT DER MASCHINE,

BATTERIE, BATTERIELADEGERÄT

Die Maschine nicht mit einem Hubwagen heben

da die Maschine hierfür nicht vorgesehen ist.

- Den Schmutzwasserbehälterälter und den Reinigungslösungsbehälter entleeren.

- Den Saugbalken und die Bürsten abnehmen.

- Die Batterien trennen und entfernen.

Die Maschine mittels geeigneter Auffahrhilfe auf die

Originalpalette (oder eine andere, dem Maschinengewicht und den Maschinenabmessungen entsprechenden Unterlage) schieben.

Die Maschine und den Saugbalken fest an der Palette verankern.

Die Palette mit der Maschine heben und auf das

Transportmittel laden.

Die Maschine und die Palette mit Seilen sichern und

im Transportfahrzeug befestigen.

Wenn man über eine Laderampe verfügt, kann

man die Maschine auch direkt ohne Palette auf die

Ladefläche des Transportfahrzeugs schieben. Dabei

ist jedoch darauf zu achten, dass die Maschine und

alle Komponenten während des Transports vor

Stößen, Feuchtigkeit, Erschütterungen und plötzliche Bewegungen geschützt sind.

5. TECHNISCHE INFORMATIONEN

5.1 BATTERI E

Unabhängig von dem Bautyp wird die Kapazität

einer Batterie in Ampere pro Stunde (Ah) ausgedrückt.

Die Maschine ist mit Gelbatterien ausgestattet.

Dieser Batterietyp ist wartungsfrei und benötigt

keine besonderen Räumlichkeiten zum Aufladen

(denn es werden keine schädlichen Gase abgegeben).

Es kann auf keinen Fall davon ausgegangen werden, dass nicht originale Batterien

und Batterieladegeräte die von SPRiNTUS zugesicherten Produkteigenschaften gewährleisten. Nur eine perfekte Kompatibilität

von Batterie und Ladegerät gewährleistet

erstklassige Leistungen, lange Lebensdauer,

Sicherheit und Wirtschaftlichkeit.

5.2 BATTERIELADEGERÄT

Das eingebaute Hochfrequenz-Batterieladegerät

gewährleistet ein optimales Laden der Batterie bei

hoher Batterie-Lebensdauer

Für nicht originale Batterien und Batterieladegeräte kann SPRiNTUS die zugesicherten

Produkteigenschaften nicht gewährleisten.

Nur eine perfekte Kompatibilität von Batterie und Ladegerät gewährleistet erstklassige

Leistungen, lange Lebensdauer, Sicherheit

und Wirtschaftlichkeit.

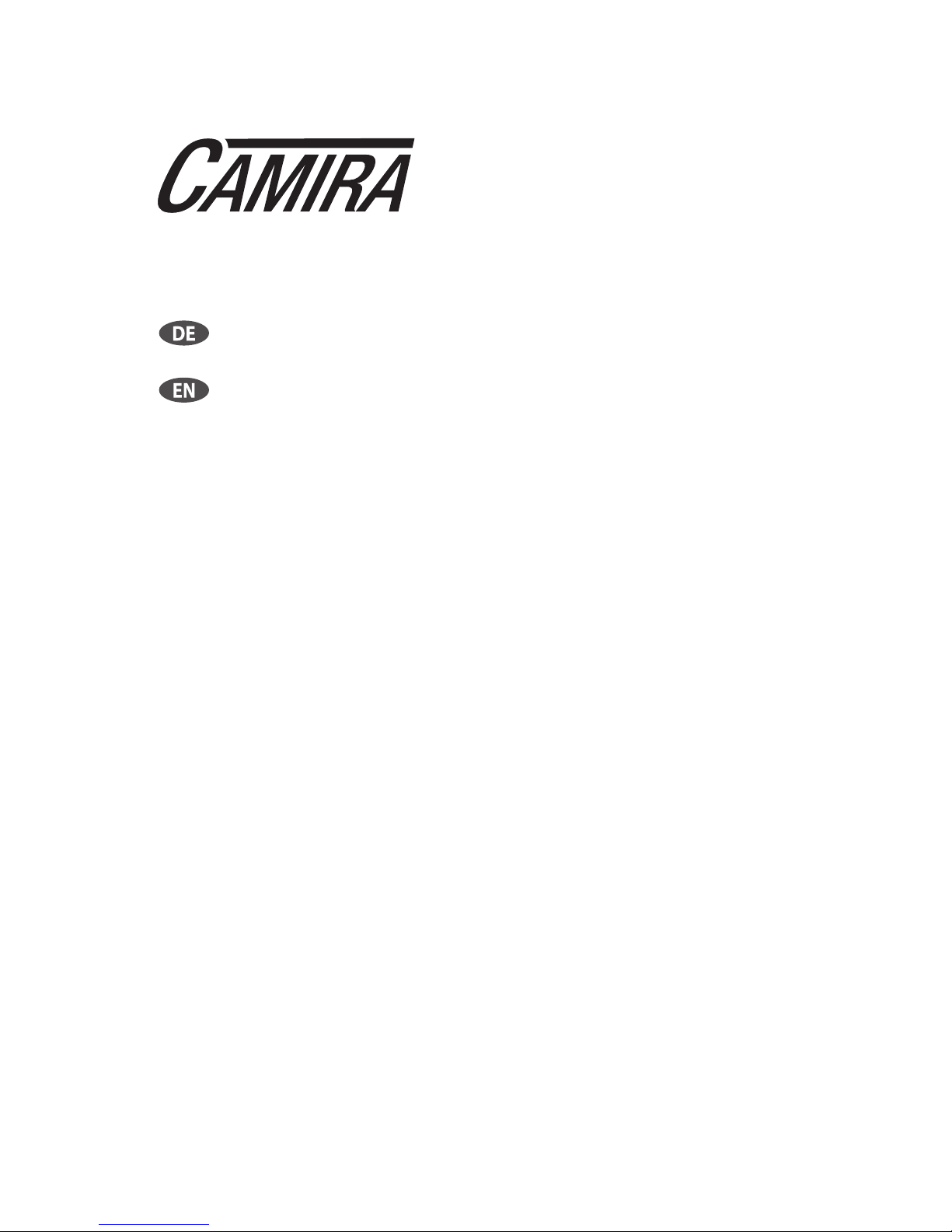

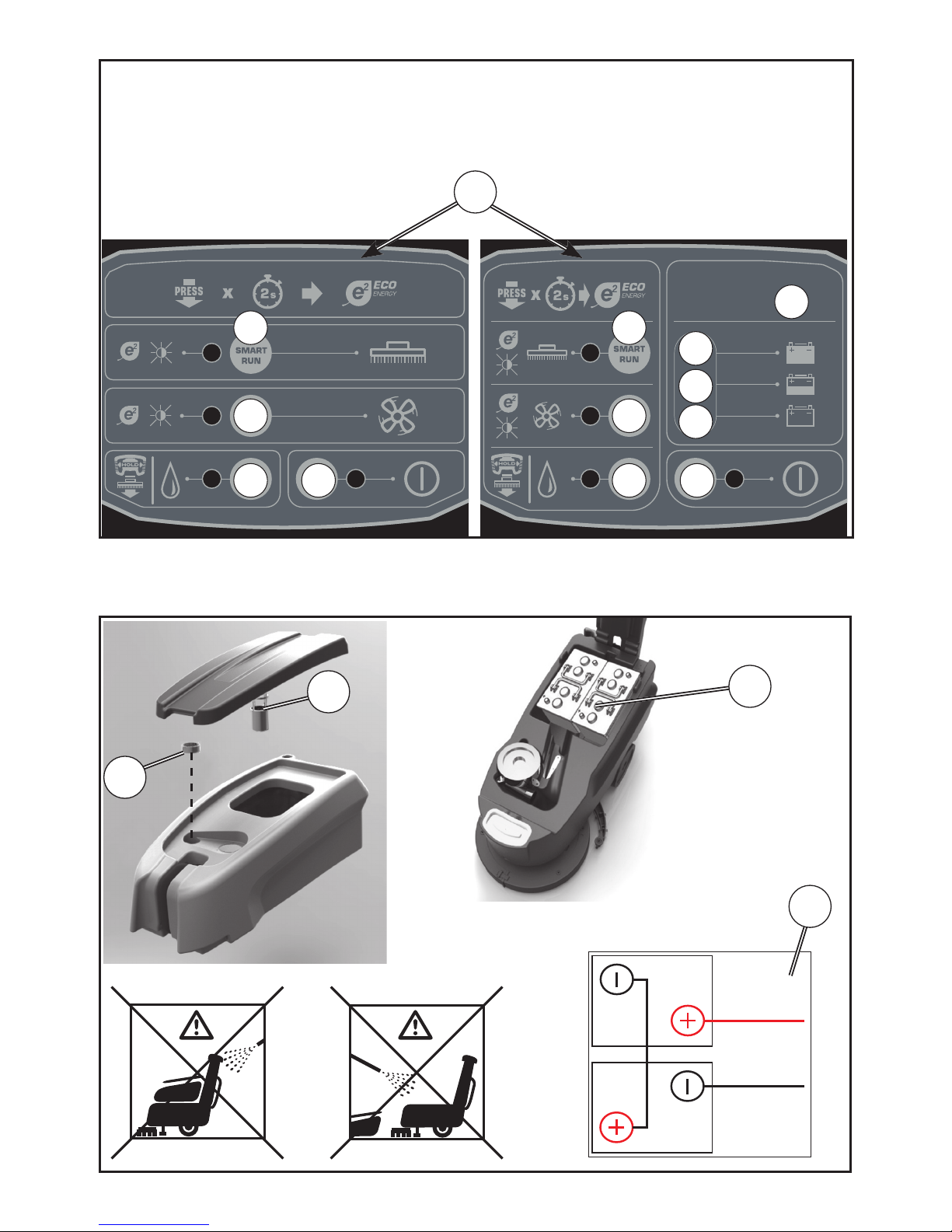

5.3 BEDIENELEMENTE UND SYMBOLE

Foto A

1 Lenker

2 Einschalter (Totmann)

3 Saugschlauch

4 Deckel des Schmutzwasserbehälters

5 Schmutzwassersammelbehälter

6 Frischwasserbehälter

7 Verschlusskappe für Ablassschlauch

8 Schmutzwasser-Ablassschlauch

9 Einfüllstutzen Frischwasserbehälter

10 Anpresswinkel Verstellung

11 Abweiser-Rad

12 Spritzschutz

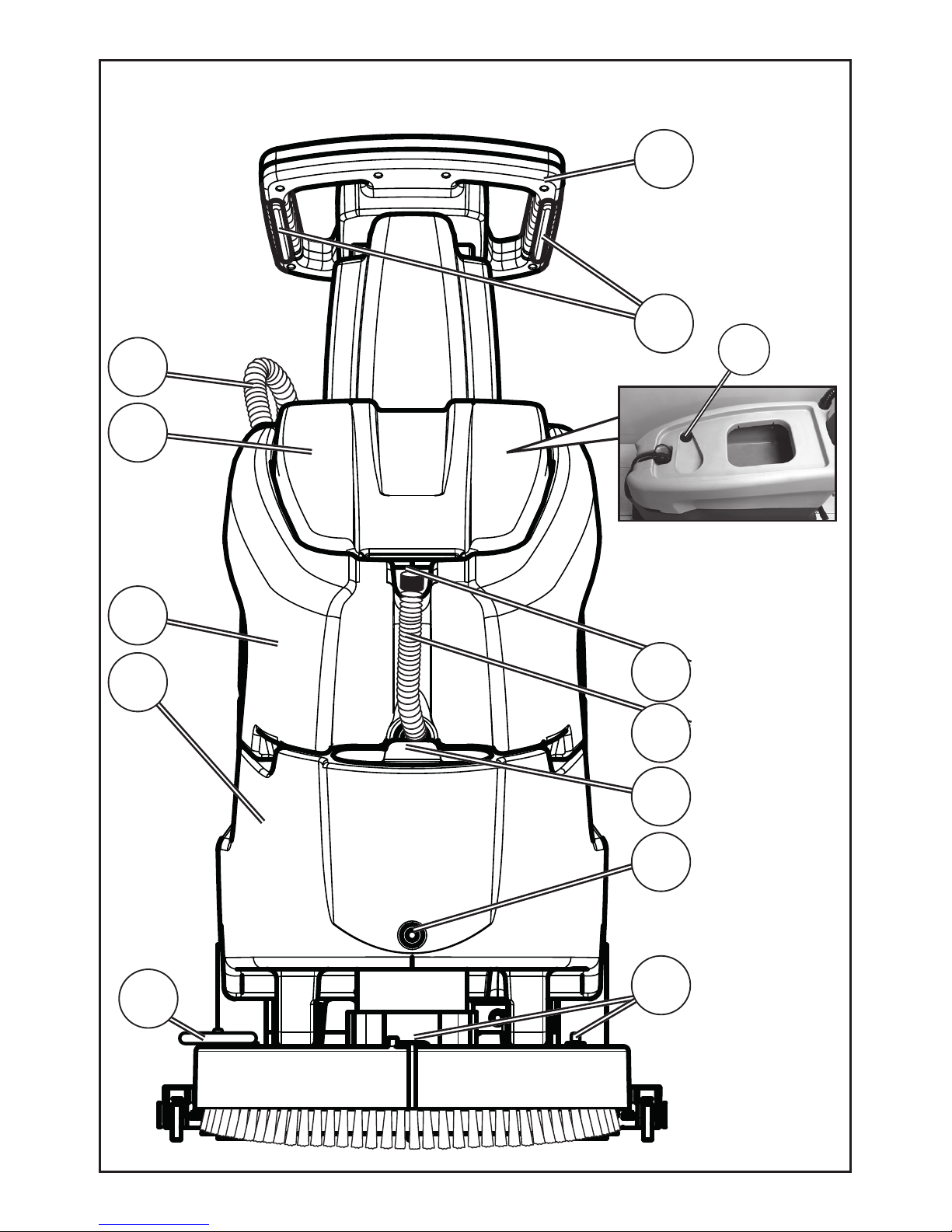

Foto B

13 Bedienpanel

14 Deckel Geräteelektronik

15 Eingebautes Ladegerät

16B Netzstecker des Ladegeräts

16 Netzkabel (Netzvariante AC230V)

17 Steckdose Batteriekabel

18 Batteriestecker (Anderson)

19 Fußhebel Saugbalken

20 Hinterrad

21 Einstellknäufe der Deichsel

22 Frischwasserregulierung

23 Frischwasserfilter

46 Ablass-Stutzen des Frischwasser-Behälters

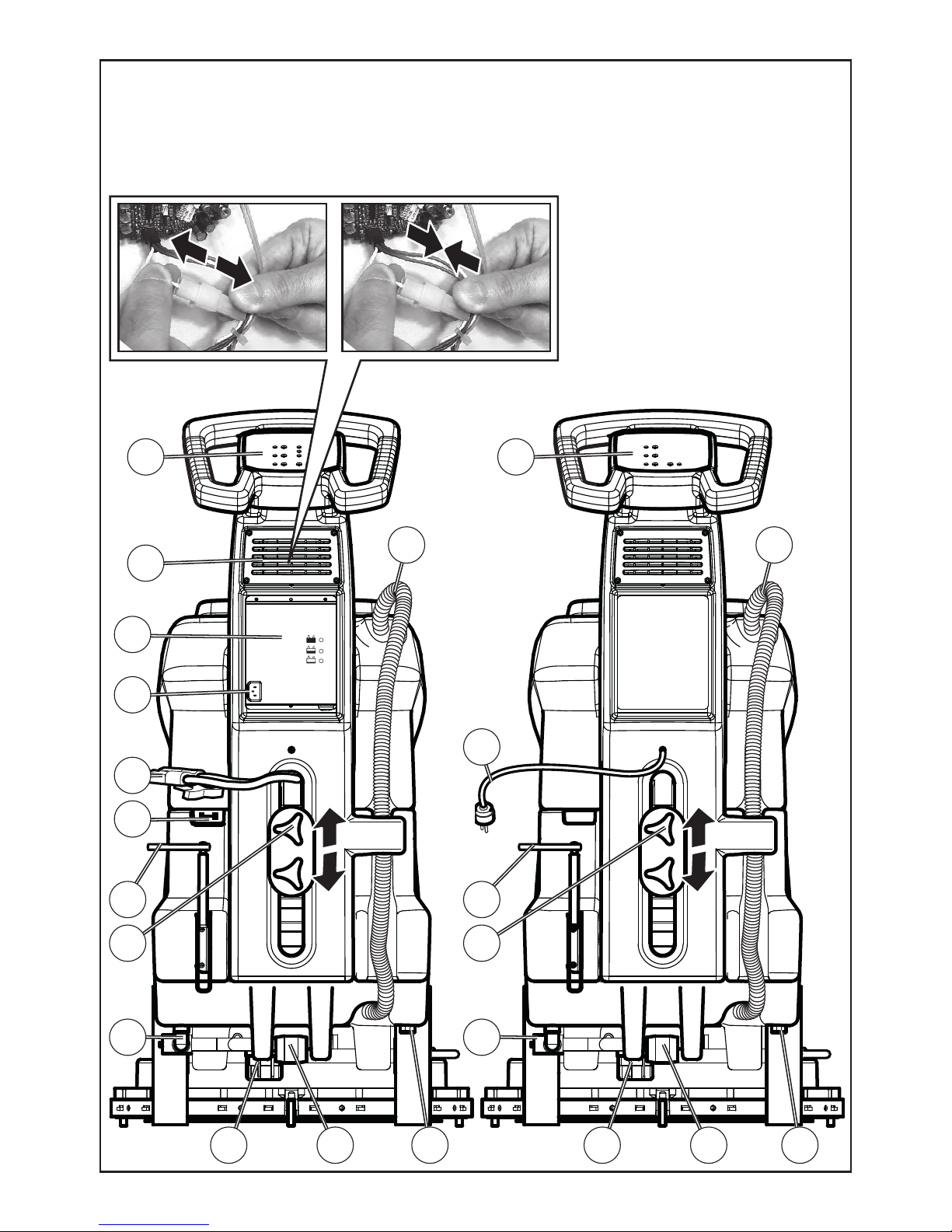

Foto C

20 Hinterrad

22 Frischwasserregulierung

23 Frischwasserfilter

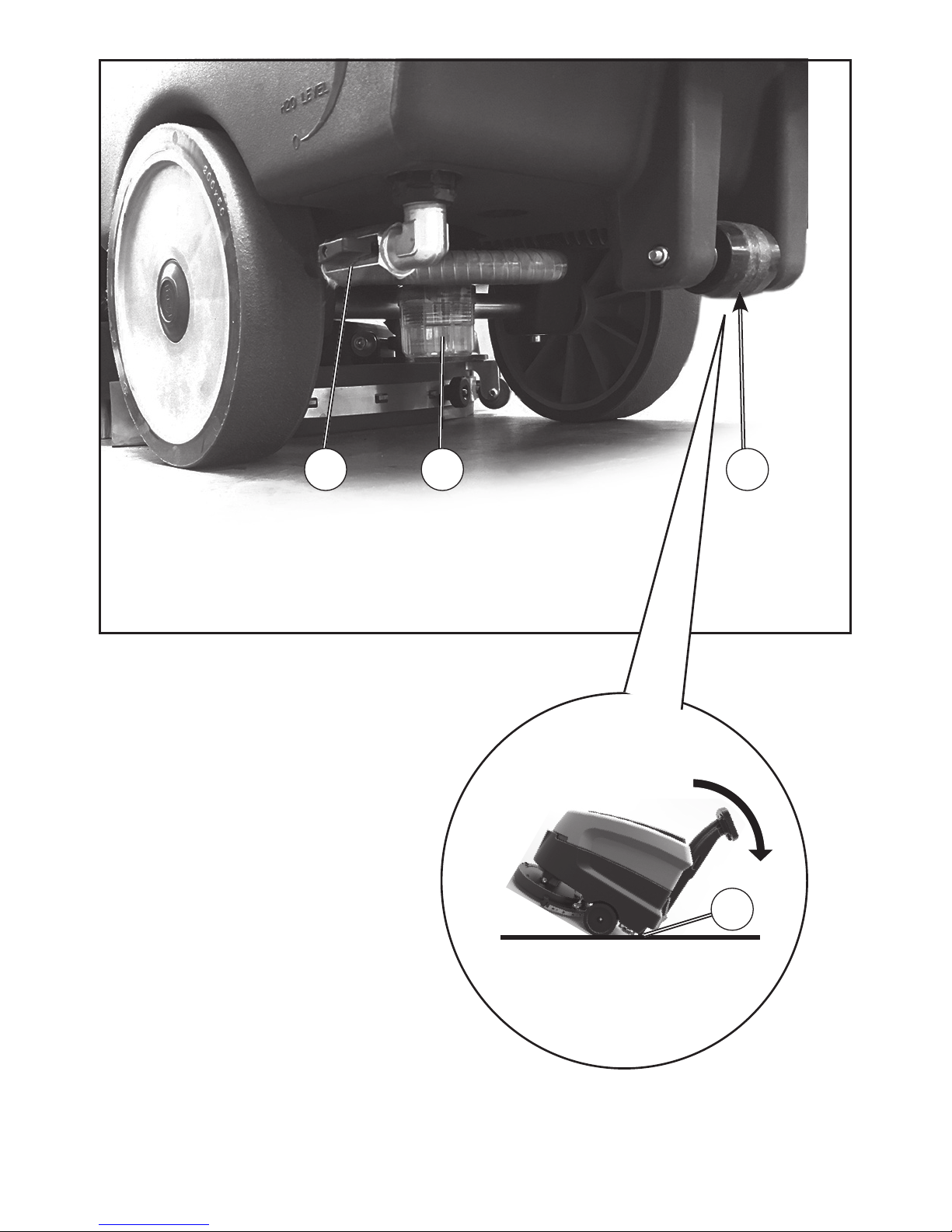

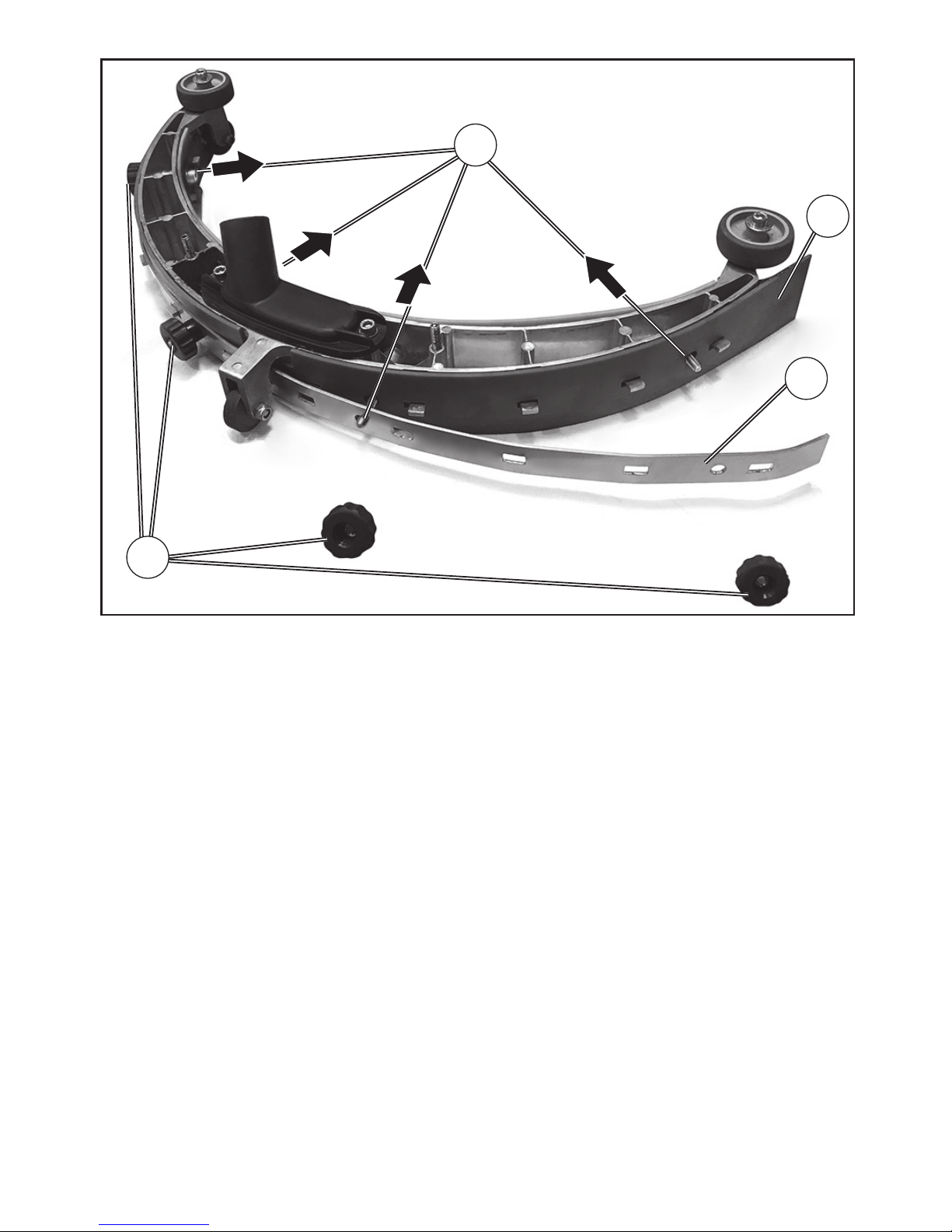

Foto D

24 Steckschrauben der Sauglippen

25 Befestigungsleiste Sauglippe

26 Vordere Sauglippe

27 Stutzen des Ansaugschlauchs

28 Befestigungsbolzen Saugstutzen

29 Hintere Sauglippe

30 Befestigungsleiste

15

Foto E

(13) Bedienpanel

32 AN / AUS Hauptschalter

Kontrolllampe an = EIN

33 Taster Bürstenmotor:

Kontrollleuchte an =EIN

Blinkende Kontrollleuchte = Eco-Funktion

Kontrollleuchte aus = AUS

34 Taster Absaugmotor:

Kontrollleuchte an =EIN

Blinkende Kontrollleuchte = Eco-Funktion

Kontrollleuchte aus = AUS

35 Taster Frischwasserzufuhr:

Kontrollleuchte ein = Frischwasserzufuhr

Kontrollleuchte aus = kein Frischwasser

Drücken des Tasters 35 + Einschalter 2

= Bürstenabwurf

36 Leuchtanzeige Batterieladezustand

37 Leuchtanzeige grün = Batterie geladen

38 Leuchtanzeige gelb = Batterie 50% geladen

39 Leuchtanzeige rot = Batterie entladen

Foto F

40 Ansaugstutzen

41 Batteriefach

42 Anschluss-Skizze der Batterien

43 Schwimmerschalter

Foto G

44 Halteblech des Saugbalkens

(28) Halterungsschraube des Saugbalkens

Foto H

45 Halterung des Saugbalkens

(27) Stutzen des Saugschlauchs

44 Halteblech des Saugbalkens

Foto I

45 Halterung des Saugbalkens

(27) Stutzen des Saugschlauchs

44 Halteblech des Saugbalkens

Foto L

44 Halteblech des Saugbalkens

Foto M

(24) Steckschraube der Sauglippen

(29) Hintere Sauglippen

(30) Befestigungsleiste Sauglippe

(31) Rändelschraube

5.4 BATTERIE

Die gelieferten Gel-Batterien werden teilgeladen

angeliefert. Vor Inbetriebnahme sind die Batterien

vollständig auf zu laden.

5.5 BATTERIELADEGERÄT

Wenn geliefert, ist Bezug auf das entsprechende

Handbuch zu nehmen.

5.6 KONFIGURATION DES

LADEGERÄTES

Bei Auslieferung ist das Ladegät bereits für die

mitgelieferten Batterien eingestellt.

5.7 ZUBEHÖR

Weiteres Zubehör zu Ihrer Camira können Sie über

den Fachhandel erwerben.

6. VOR DER INBETRIEBNAHME

6.1 BATTER IE

Die Maschine ist für den Einsatz mit Gelbatterien

kofiguriert. Der Einsatz von nicht den Vorschriften

entsprechenden Batterien kann zu schweren Maschinenschäden führen und ein häufigeres Aufladen erforderlich machen.

6.2 INSTALLATION UND ANSCHLUSS

DER BATTERIE

Diese Eingriffe müssen von Fachleuten durchgeführt werden.

Schmutzwasserbehälter anheben. (FotoB-17)

Den Anderson-Stecker des Batteriekabels vom

Anderson-Verbinder des Maschinenkabels trennen. Ziehen sie den Stecker nicht am Kabel aus

der Dose.

Schließen sie die Batterieklemmen an die

mit dem gleichen Symbol gekennzeichneten Pole der Batterie an. (rotes Kabel “+”,

schwarzes Kabel “-”)! Ein eventueller

Kurzschluss der Batterie kann zu Explosionen führen !

Sicherstellen, dass alle Bedienelemente auf “0”

oder auf “Aus” stehen. Nun kann der Batteriestecker (18) wieder verbunden werden.

Das Batteriefach schließen und dabei aufpassen,

dass kein Kabel gequetscht wird.

6.3 KONFIGURATION DES LADEGERÄTS

Dieser Vorgang muss von geschulten Technikern

durchgeführt werden. Beim Kauf der Scheuersaugmaschine ist das eingebaute Batterieladegerät für

den Betrieb mit GEL-Batterien konfiguriert.

6.4 VORBEREITUNG DER MASCHINE

Bevor mit der Arbeit begonnen wird sind rutschfeste Schuhe, Handschuhe und alle anderen vom

Hersteller der verwendeten Reinigungsmittel angegebenen oder von der Arbeitsumgebung geforderten persönlichen Schutzausrüstungen anzuwenden.

16

☞ Vor Arbeitsbeginn sind folgende Eingriffe vorzunehmen. Für eine detaillierte Beschreibung dieser Phasen ist Bezug auf die entsprechenden Abschnitte in der Bedienungsanleitung zu nehmen:

Den Ladestand der Batterie überprüfen und die

Batterie falls erforderlich laden.

Installieren Sie die Bürsten oder den Padtreibteller

(mit entsprechenden Pads) die für die zu bearbeitende Oberfläche geeignet sind. Den Saugbalken

montieren und überprüfen, dass er gut befestigt

und an den Saugschlauch angeschlossen ist. Die

Gummilippen auf Abnutzung kontrollieren und

sicherstellen dass der Schmutzwasserbehälter leer

ist.

Füllen Sie den Frischwasserbehälter mit einer

Wasser-/Reinigungsmittellösung mit dem vorgeschriebenen Mischverhältnis. Verwenden sie

ausschließlich nicht schäumende Reinigungsmittel.

☞ Zur Vermeidung von Gefahren sollte man sich

mit der Maschine auf einer großen, hindernisfreien

Fläche vertraut machen.

Für beste Resultate hinsichtlich Reinigung und Lebensdauer des Geräts beachten sie bitte folgende

Hinweise:

Den Arbeitsbereich begutachten und eventuelle

Hindernisse entfernen. Wenn die zu reinigende

Fläche sehr groß ist, ist sie in aneinanderliegende,

parallel zueinander verlaufende rechteckige Flächen zu unterteilen.

- Eine geradlinige Arbeitsspur wählen und die Arbeit im hinteren Bereich des Raumes beginnen,

damit man nicht über bereits gereinigte Bereiche

fahren muss.

7 BEDIENUNG

7.1 LADEN DER BATTERIEN

Das Batterieladegerät wie beschieben vorbereiten

und überprüfen.

Die im Gebrauchs- und Sicherheitshandbuch

des Batterieherstellers enthaltenen Anleitungen

befolgen.

7.2 EIN- UND AUSBAU DER BÜRSTE

Stellen Sie stets sicher, dass die Bürsten oder

der Padtreibteller einwandfrei montiert sind.

Einbau:

Stellen Sie die Bürste auf den Boden; Heben Sie

den Saugbalken mit dem Hebel an (Foto B-19).

Lenker nach unten drücken (Foto A-1) und somit

den vorderen Teil der Maschine anheben, so dass

die Maschine auf die hintere Rolle steht (Foto

C-20). Positionieren Sie die Maschine über den

Bürsten so dass der Halterungsansch der Bürste

sich unter der Bajonettkupplung der Antriebswelle

bendet. Schalten Sie die Maschine mit (Foto E-32)

dem Hauptschalter auf dem Bedienpanel ein (Foto

E-13) . Wählen sie durch die Taste „Smart Run“

(E-33) den Betrieb der Bürste sowie der Absaugung. Starten sie den Betrieb mit dem (Foto A-2).

Die Bürste/Padtreibteller rastet automatisch ein.

Die Mindestlänge der Borsten beträgt 1 cm.

Die Mindeststärke der Pads beträgt 1 cm.

Zu stark abgenutzte Bürsten oder zu dünne Pads

können die Maschine und den Boden beschädigen.

Überprüfen sie den Verschleißzustand des Zubehörs bevor die Arbeit aufgenommen wird.

Bürsten- /Padtreibtellerabwurf:

Sicherstellen, dass sowohl der Motor der Bürste als

auch der Motor der Absaugung ausgeschaltet sind

(entsprechende Kontrollleuchten müssen erloschen

sein).

Heben Sie den Saugbalken an (Foto B-19).

Lenker nach unten drücken (Foto A-1) und somit

den vorderen Teil der Maschine anheben, so dass

die Maschine auf die hintere Rolle steht (Foto

C-20). Einen Einschalter (A-2) betätigen und gleichzeitig die Taste (E-35) drücken.

Auf dieser Weise wird die Bürste automatisch

abgeworfen.

7.3 ABSTELLEN DER MASCHINE

Um die Maschine im Ruhezustand abzustellen,

gehen Sie wie folgt vor: Schalten Sie die Maschine

(Foto E-32) am Hauptschalter des Bedienpanels ab

(Foto E-13). Heben Sie den Saugbalken mit dem

Hebel an (Foto B-19). Lenker nach unten drücken

(Foto A-1) und somit den vorderen Teil der Maschine anheben, so dass die Maschine auf der hinteren Rolle steht (Foto C-20).

7.4 EINBAU DES SAUGBALKENS

Senken sie den Saugbalken durch Betätigen des

Fußebels (Foto B-19).

Die beiden Knebelschrauben (Foto G-28) am

Saugbalken leicht festziehen (Foto G-44).

Den Saugbalken in seinen Sitz an die Saugbalkenhalterung einsetzen (Foto H-45) und durch Festziehen der beiden Knebelschrauben befestigen.

Den Saugschlauch der Absaugung (Foto H-27) auf

den Anschlussstutzen des Saugbalkens schieben.

7.5 AUSBAU DES SAUGBALKENS

Den Saugbalken durch Betätigen des Fußhebels

(Foto B-19) senken.

Den Saugschlauch vom Saugbalken trennen

(Foto I-27).

Die beiden Knebelschrauben (Foto I-45)

etwas lockern.

Die Halterung des Saugbalkens anheben

(Foto I-45) und den Saugbalken entnehmen.

17

7.6 WECHSELN DER SAUGLIPPEN

Den Saugbalken von seiner Halterung lösen

(siehe 7.5). Die Knebelschrauben (D-31) komplett abschrauben und Schlosserschrauben (D-24)

entfernen bis sich die (D-30) entfernen lässt .

Die Sauglippen aus der Halterung entnehmen.

Die neue Sauglippe in die Kunststohalterung einsetzen, indem die Kunststozapfen in die entspre-

chenden Öffnungen am Saugbalken gedrückt

werden. Die Befestigungsleiste wieder in den

Saugbalken einsetzen und durch Festschrauben der

Knebelschrauben (D-30) befestigen.

Den Saugbalken wieder an seiner Halterung anbringen (D-31).

7.7 EINSETZEN UND ABNAHME DES

SPRITZSCHUTZES

- Die 2 Schrauben des Spritzschutzes (A-12) lösen.

- Die Schraube des Abweiser-Rades (A-11) lösen.

- Den Verriegelung am Spritzschutz (A-12) önen.

- Den Spritzschutz abnehmen.

7.8 BEFÜLLEN UND ENTLEEREN DES

FRISCHWASSERBEHÄLTERS

Die Temperatur des einzufüllenden Was-

sers oder Reinigungsmittels darf nicht über

50°C liegen.

☞ Bei jedem Befüllen des Frischwasserbehälters ist

der Schmutzwasserbehälter immer zu entleeren.

Befüllen:

- Den Deckel des Einfüllstutzens (A-9) abnehmen.

- Den Tank nicht randvoll befüllen.

- Die erforderliche Menge des Reinigungsmittels

hinzugeben, wobei die vom Hersteller angegebene

Konzentration zu beachten ist. Der Frischwasserbehälter ihrer Camira fasst 30 Liter.

- Achten Sie bei der Verwendung der Reinungsmittel

darauf, dass diese für den jeweiligen Boden geeignet sind.

Verwenden sie die Camira ausschließlich

mit modernen, nicht schäumenden Reinigungsmitteln. Die Verwendung anderer

chemischer Produkte, wie z. B. Ätznatron,

Oxydantien, Lösemittel oder Kohlenwasserstoffe kann zu einer Beschädigung oder Zerstörung der Maschine führen.

- Kontaktieren Sie im Zweifelsfall den Reinigungsmittelhersteller oder Sprintus um die Eignung des

Reinigungsmittels sicher zu stellen.

- Das Reinigungsmittel immer in den bereits mit

Wasser gefüllten Behälter geben, damit sich kein

Schaum bildet.

Den Wasserschlauch zum Befüllen des Behälters mit Wasser nicht unbeaufsichtigt lassen und

vollständig in den Behälter einführen. Ansonsten

besteht die Gefahr, dass Wasser zu den elektrischen

Teilen dringt und diese Schaden nehmen.

Entleeren des Frischwassertanks:

Öffnen sie den an der Unterseite der Maschine

gelegenen Ablass-Stutzen (B-46) und entleeren sie

den Behälter vollständig.

- Schließen Sie den Ablass-Stutzen wieder.

7.9 ENTLEEREN DES

SCHMUTZWASSERTANKS

Beim Entsorgen des Schmutzwassers sind die Vorschriften des jeweiligen Anwendungslandes zu

befolgen. Der Anwender haftet für das Beachten

dieser Gesetze.

Wenn die Reinigungslösung aufgebraucht ist, muss

der Schmutzwasserbehälter vor dem Wiederbefüllen des Frischwasserbehälters vollständig entleert

werden.

Im Allgemeinen kann der Schmutzwasserbehälter

so oft wie gewünscht und auch in den Zwischenphasen des Arbeitszyklus entleert werden.

Das Fassungsvermögen des Sammelbehälters

ist größer als das Fassungsvermögen des Reinigungslösungsbehälters, weshalb eine potentielle

Gefährdung des Saugmotors ausgeschlossen sein

sollte. Trotzdem ist zur Sicherheit ein Schwim-

mer vorhanden (F-43) , der den Saugstrom unterbricht, sobald der Schmutzwasserstand zu hoch

ist.

Wenn eine Wasser- oder Schaumleckage unter

den Behältern festgestellt wird, ist der Saugmotor

sofort abzustellen und der Schmutzwasserbehälter

zu entleeren.

Entleeren des Behälters:

Die Maschine an einen zum Ablassen des

Schmutzwassers geeigneten Ort fahren, d.h. möglichst in die Nähe eines WC oder eines Abwassergullys (es sind die im jeweiligen Anwendungsland

der Maschine geltenden Gesetze zur Entsorgung

von Abwasser zu befolgen).

Sicherstellen, dass der Hauptschalter am Bedienpanel ausgeschaltetet ist (E-32).

Den Ablassschlauch (A-7/A-8) aus seiner Halterung

nehmen, den Schlauch hochhalten und den Verschlussstopfen öffnen.

Den Ablassschlauch in Ablassposition bringen.

Der Entleerungsvorgang kann jederzeit unterbrochen werden, indem der Schlauch hochgehalten

wird.

Die Schmutzrückstandmenge im Behälter überprüfen und den Behälterinnenraum gegebenenfalls

durch die Inspektionsöffnung reinigen.

Nach dem Entleeren des Behälters den Ablassschlauch verschließen und wieder an seiner

Halterung an der Maschinenrückseite befestigen.

18

☞ Der Ablassschlauch muss immer korrekt verschlossen sein. Ansonsten kann es durch Lufteintritt zu einem Unterdruckverlust kommen, was den

Trocknungsvorgang beeinträchtigt.

7.10 DOSIERUNG DES FRISCHWASSERS

Es ist möglich, den Frischwasserzuuss mittels des

Hahns (B-22) an den Bürsten zu regulieren.

Das Ventil kann wie folgt eingestellt werden:

Ventil geschlossen

Ventil teilweise geönet

Ventil teilweise geönet

7.11 BETRIEB DER MASCHINE

Netzvariante 230V

Das Netzkabel (B-16) mittels eines Verlängerungskabels an das Stromnetz anschließen.

Den Hauptschalter (E-32) auf ON stellen. Den

Taster „Smart Run“ (E-33) betätigen, dann wird

sowohl der Bürstenmotor als auch der Motor der

Absaugung aktiviert und die entsprechenden Kontrollleuchten leuchten auf.

Zum Aktivieren des Energiesparmodus „Eco“ der

Bürste muss die Taste (E-33) 2 Sekunden lang gedrückt werden. Die entsprechende Kontrollleuchte

wird blinken. Um wieder in den normalen Modus

zurückzukehren, die Taste so lange gedrückt halten, bis die entsprechende Kontrollleuchte wieder

durchgehend leuchtet.

Zum Aktivieren des Energiesparmodus „Eco“ der

Saugfunktion muss die Taste (E-34) 2 Sekunden

lang gedrückt werden, die entsprechende Kontrollleuchte wird dann blinken. Um wieder in den normalen Modus zurückzukehren, die Taste so lange

gedrückt halten, bis die entsprechende Kontrollleuchte wieder durchgehend leuchtet.

die Bürste beginnt sich erst zu drehen,

wenn der Bedienhebel (A-2) betätigt wird.

Die Frischwasserregulierung durch Drehen des

Dosierhebels des (C-22) önen. Soll keine Reinigungsmittellösung aufgebracht werden, muss die

Taste (E-35) gedrückt werden, bis die entsprechende Kontrollleuchte erlischt. Den Saugbalken

durch Betätigen des Fußhebels des Saugbalkens

(B-19) senken.

Starten Sie den Arbeitsmodus mit dem Einschalter (A-2). Bewegen sie die Maschine während des

Betriebs langsam vorwärts. Beim Loslassen des

Bedienhebels wird die Drehung der Bürste nach

einigen Sekunden unterbrochen.

Vergessen sie nicht den Saugbalken vor

dem Rückwärtsfahren anzuheben, um ihn

nicht zu beschädigen.

Soll die Bürste nicht verwendet werden, muss die

Taste (E-33) gedrückt werden und die entsprechende Kontrollleuchte erlischt.

Soll die Absaugung nicht verwendet werden,muss

die Taste (E-34) gedrückt werden und die entsprechende Kontrollleuchte erlischt.

7.12 ARBEITSWEISE

7.12.1 VORBEREITUNG UN D

WARNHINWEISE

Die zu reinigende Fläche muss vor Arbeitsbeginn

mit Staubsaugern, Kehrmaschinen, usw. von grobem Schmutz befreit werden. Wenn die vorbereitende Reinigung nicht vorgenommen wird, könnten

die Schmutzpartikel den einwandfreien Betrieb der

Saugbalkens und somit das ideale Trocknen beeinträchtigen. Die Camira darf nur durch ausgebildetes Personal betrieben werden.

7.12.2 PRÜFUNG DES

BATTERIELADEZUSTANDS

Die LED’s des Batterieladezustands (E-36) zeigen

den Verbrauch der Batterieladung an. Sobald die

rote LED aueuchtet (E-39), ist der Bürstenmotor abzustellen, die Zufuhr der Reinigungslösung

zu unterbrechen, die gegebenenfalls noch nasse

Fläche abzusaugen und die Maschine zum Batterieladegerät zu fahren, wo die Batterie geladen wird.

Die Batterien können irreparabel

beschädigt werden, wenn die Restladung

zu stark absinkt. Die Batterie nicht durch

wiederholtes Ein- und Ausschalten oder

auf andere Art und Weise über die durch

die Sicherheitsvorrichtungen vorgegebenen

Grenzwerte hinaus entladen.

7.12.3 REINIGEN VON LEICHT

VERSCHMUTZTEN FLÄCHEN

Waschen und Trocknen in einem einzigen Durchgang. Die Maschine wie zuvor beschrieben vorbereiten und wie in Abschnitt 7.12 verwenden.

☞ Die Maschine nie ohne Reinigungslösung betreiben, da der Boden beschädigt werden könnte.

19

7.12.4 REINIGEN VON STARK

VERSCHMUTZTEN FLÄCHEN

Waschen und Trocknen in mehreren Durchgängen.

Die Maschine wie zuvor beschrieben vorbereiten.

Erster Arbeitsgang: Erster Arbeitsgang: Den Waschvorgang wie in Abschnitt 7.11 beschrieben durchführen, ohne den Boden zu trocknen.

Beachten sie die auf dem Reinigungsmittel

angegebene Einwirkzeit.

Zweiter Arbeitsgang:

Wie im vorhergehenden Abschnitt “Reinigen von

leicht verschmutzen Flächen” (7.13.3)beschrieben

vorgehen, um den Boden auch zu trocknen.

☞ Die Maschine nie ohne Reinigungsmittel betreiben, da der Boden beschädigt werden könnte.

7.12.5 NACH DEM REINIGEN

Die Frischwasserversorgung unterbrechen.

Schalten sie den Bürstenmotor ab.

Nachdem eventuelle Wasserspuren auf der Fläche

vollständig getrocknet wurden einige Sekunden

warten, bis auch die Saugschläuche komplett entleert sind. Nun heben sie den Saugbalken an und

stellen den Saugmotor ab.

Die Maschine an einen zum Entleeren der Behälter geeigneten Ort fahren und die Behälter entleeren und reinigen (siehe Abschnitt 7.10). Den

Hauptschalter (E-32) auf OFF "0" stellen (Maschine

ausgeschaltet).

Falls erforderlich die Batterie laden (siehe entsprechender Abschnitt).

7.13 GEBRAUCHSANWEISUNG FÜR

DIE 230 VOLT NETZVARIANTE

Die Netzvariante 230V darf nur eingeschaltet werden, wenn die auf dem Leistungsschild angegebene

Spannung mit der des Stromnetzes übereinstimmt

und wenn die Netzsteckdose geerdet ist.

Das Netzkabel nicht beschädigen, nicht quetschen

und nicht daran ziehen.

Nicht mit der Maschine über das Netzkabelfahren.

Das Kabel könnte sich in den sich bewegenden

Maschinenteilen aufwickeln und einen Kurzschluss

hervorrufen.

ACHTUNG!!! - Die Netzvariante 230V besitzt unter Spannung stehende Bauteile. Das

Berühren dieser Teile kann zu schweren Verletzungen und auch zum Tod führen.

- Vor jeglichem Eingri an der Maschine muss die-

selbe vom Stromnetz getrennt werden.

- Beschädigte oder verschlissene Netzkabel niemals

berühren.

- Vor dem Einschalten der elektrischen Anlage ist

die Maschine auszuschalten und der Netzstecker

ist zu ziehen.

- Wenn beschädigte Kabel, andere Schäden oder

Risse festgestellt werden, sind die defekten Teile

umgehend durch Originalersatzteile zu ersetzen.

- Die Anschlüsse an das Stromnetz müssen gegen

Spritzwasser geschützt werden.

- Für den Anschluss an das Stromnetz sind

ausschließlich den geltenden Sicherheitsvorschriften entsprechende Verlängerungskabel zu verwenden.

- Die Netzsteckdose, an die die Maschine angeschlossen ist, muss mit einem FehlerstromSchutzschalter ausgestattet sein.

- Es ist strikt verboten, die Maschine in der Nähe

von Schwimmbädern oder Gewässern zu verwenden.

NOTSITUATIONEN

In Notfällen:

- Die Maschine umgehend vom Stromnetz

trennen.

- Bei Bedarf umgehend die Erste-HilfeMaßnahmen einleiten.

Bei Unfällen darf die Maschine nicht wieder in

Betrieb gesetzt werden, bevor sie durch einen

vom Hersteller autorisierten Techniker untersucht

wurde.

8. WARTUNG

Sicherstellen, dass der Hauptschalter am Bedienpanel sich in der ausgeschalteten Position "0"

befindet. Den Verbinder der Batterie von der Verkabelung der Maschine trennen (B-17/B-18).

☞ Die Eingrie an den elektrischen Komponenten

wie auch alle Wartungs- und Reparaturarbeiten

(ins- besondere nicht ausdrücklich im vorliegenden

Handbuch beschriebene Arbeiten) nur in autorisierten Kundendienstcentern oder durch kompetentes Fachpersonal durchführen lassen, das mit

den anwendbaren Sicherheitsvorschriften vertraut

ist. Die regelmäßige Wartung der Maschine unter

Beachtung der Bedienungsanleitung trägt dazu

bei, eine bessere Leistung und eine längere Lebensdauer der Maschine zu gewährleisten.

8.1 BEHÄLTER

Die beiden Behälter wie in den entsprechenden

Abschnitten beschrieben entleeren.

Reinigen Sie die Behälter am Besten mit handelsüblichen Reinigungsmitteln in Kombination mit

einem Wasserschlauch.

Über 50°C heißes Wasser oder Hochdruckreiniger können die Behälter und die Maschine beschädigen.

Die Behälterdeckel bei Nichtgebrauch geönet las-

20

sen, damit die Behälter trocknen können und keine

unangenehmen Gerüche entstehen.

8.2 FRISCHWASSERFILTER

Um den Frischwasserlter zu säubern, werden die

durchsichtige Abdeckung (C-23) und das Filterelement abgenommen. Nach der Reinigung wird das

Filterelement wieder eingesetzt und die transparente Abdeckung des Filters wieder geschlossen.

8.3 SAUGSCHLAUCH

Den Saugschlauch vom Saugbalken trennen (H-27).

Jetzt kann der Saugschlauch gewaschen und von

Verstopfungen befreit werden.

Den Saugschlauch wieder korrekt am Saugbalken

anbringen.

8.4 SAUGBALKEN

Den Saugbalken nicht mit bloßen Händen anfassen, sondern Handschuhe und alle anderen für den

jeweiligen Eingri erforderlichen Schutzausrüstungen anwenden.

Den Saugbalken von der Maschine abbauen und

mit einem Schwamm oder einer Bürste unter

ießendem Wasser reinigen.

Die Wirksamkeit und den Abnutzungsgrad der Sauglippen überprüfen. Der einwandfreie Zustand

der Sauglippen ist für ein gutes Absaugergebnis

zwingend notwendig. Im Laufe der Zeit rundet sich

die Kante der Sauglippe ab und verschleißt, was

die Wirksamkeit des Trocknungsvorgangs beeinträchtigt. In diesem Fall sind die Sauglippen zuersetzen.

Zum Ersetzen der abgenutzten Sauglippen sind die

im entsprechenden Abschnitt enthaltenen Anleitungen zu befolgen. Die Sauglippen umdrehen, um

die anderen scharfen Kanten zu nutzen oder neue

Sauglippen einsetzen.

8.5 ZUBEHÖR

Die Bürsten oder die Haltescheiben abbauen und

reinigen.

Sorgfältig überprüfen, dass das Zubehör nicht

durch Fremdkörper, wie Metallteile, Schrauben,

Späne, Seile oder Ähnliches verunreinigt ist, damit

der Boden und die Maschine nicht beschädigt

werden.

Kontrollieren, dass die Bürsten eben sind (Bürsten

und Schleifscheiben auf unregelmäßige Abnutzung

überprüfen).

Es ist nur von Sprintus empfohlenes Zubehör zu

verwenden. Andere Produkte können die Sicherheit

beeinträchtigen.

8.6 MASCHINE REINIGEN

Zur Außenreinigung der Maschine ist ein Schwamm

oder ein Tuch zu verwenden. Gegebenenfalls kann

eine weiche Bürste zum Entfernen von hartnäckigem Schmutz verwendet werden.

Der Einsatz von Dampfreinigern, Wasserschläuchen oder Hochdruckreinigern ist verboten.

8.7 BATTERIEN

Bei Ihrer Camira kommen wartungsfreie Gelbatte-

rien zum Einsatz. Eingrie an den Batterien dürfen

nicht vorgenommen werden. Nur Original Sprintus

Batterien/Batterieladegeräte verwenden.

8.8 REGELMÄSSIGE WARTUNG

Für alle hier beschriebenen Eingriffe ist Bezug auf die

detaillierten Anleitungen und Warnhinweise in den

entsprechenden Abschnitten dieses Handbuchs zu

nehmen.

8.9 EMPFOHLENE ERSATZTEILE

Es wird empfohlen, immer ausreichend Verbrauchsmaterial vorrätig zu haben und die Wartungsarbeiten regelmäßig durch zu führen.

9 REINIGUNG / WARTUNG

siehe Tabelle auf Seite 21

9.1 STÖRUNGEN

9.1.1 DIE MASCHINE FUNKTIONIERT

NICHT

Der Batterieverbinder ist getrennt oder falsch an

den Verbinder des Hauptkabels angeschlossen.

Beide Verbinder korrekt anschließen.

Die Maschine wird geladen.

Ladevorgang beenden.

Die Batterien sind leer.

Batterien laden.

Der Bürst- oder Saugmotor ist überhitzt.

Die Motoren verfügen über Thermoschutzsicherun-

gen und schalten bei Überhitzung aus. Lassen sie die

Maschine 30 Minuten abkühlen. Zu rauher Boden bzw.

aggressive Bürsten/Pads können zu Überlastung des

Bürstenmotors führen. Bei Abschalten des Saugmotors evtuelle Verstopfungen entfernen.

9.1.2 FEHLERANZEIGEN AM DISPLAY

Bürsten-LED brennt dauerhaft:

Wenn sich die Bürste nicht dreht, prüfen ob sich

etwas um die Antriebswelle gewickelt hat. Beheben

sie die Fehlerursache.

Saugmotor LED blinkt:

Der Saugmotor läuft nicht. Saugmotor prüfen und

sicherstellen dass der Schmutzwassertank leer ist.

Bürsten-LED und Saugmotor-LED blinken schnell:

Die Thermoschutzsicherung des Bürstenmotors

oder des Saugmotors hat ausgelöst. Prüfen ob sich

etwas um die Antriebswelle gewickelt hat. Saugmotor

prüfen und sicherstellen dass der Schmutzwassertank

leer ist.

21

9.1.3 DIE BÜRSTEN DREHEN SICH NICHT

Der Bürstenmotorschalter wurde nicht eingeschaltet.

Den Schalter zum Einschalten der Bürsten drücken.

Der Thermoschutzschalter des Bürstenmotors hat

angesprochen, der Motor ist überhitzt.

Der Bürstenmotor verfügt über eine Thermoschutzsicherungen und schaltet bei Überhitzung aus.

Lassen sie die Maschine 30 Minuten abkühlen. Zu

rauher Boden bzw. aggressive Bürsten/Pads können

zu Überlastung führen

Das Relais des Motors oder der Bürstenmotor ist

defekt.

Durch einen Fachmann ersetzen lassen.

9.1.4 ES TRITT KEINE ODER NUR WENIG

REINIGUNGSLÖSUNG AUS

Der Lösungsbehälter ist leer.

Den Lösungsbehälter füllen, nachdem der Schmutz-

wasserbehälter entleert wurde.

Die Bürsten oder die Maschine sind nicht eingeschaltet.

Die Bürsten einschalten.

Der Frischwasserregulierung ist geschlossen oder

fast geschlossen.

Stellen sie die Wasserzufuhr wie gewünscht ein

Der Frischwasserfilter ist verstopft.

Filter reinigen.

Die Schläuch der Wasserzufuhr sind verstopft.

Verstopfung entfernen.

Das Magnetventil ist durchgebrannt.

Magnetventil durch einen Fachmann ersetzen lassen.

9.1.5 KEIN SAUGBETRIEB

Der Saugschlauch ist nicht an den Saugbalken angeschlossen.

Korrekt anschließen.

Der Saugschlauch ist verstopft.

Die Verstopfung beheben.

Der Saugmotor ist abgeschaltet.

Den Motor einschalten.

Der Schmutzwasserbehälter ist voll.

Behälter entleeren.

9.1.6 ZU GERINGE SAUGKRAFT

Der Sammelbehälterdeckel wurde nicht korrekt

festgeschraubt.

Korrekt festschrauben.

Der Ablassschlauchstopfen des Sammelbehälters ist

nicht vollständig geschlossen.

Korrekt schließen.

Der Saugschlauch verstopft.

Verstopfung entfernen.

9.1.7 DER BÜRSTENMOTOR ODER DER

SAUGMOTOR schalten nicht ab

Die Maschine stoppen, indem sie die Hauptstromversorgung durch Ziehen des Hauptverbinders der

Batterie unterbrochen wird. Den technischen Kundendienst kontaktieren.

REINIGUNG / WARTUNG

Wenn

notwendig

Nach jeder

Verwendung

Wöchentlich Monatlich

Abnahme und Reinigung des Saugbalkens X

Leerung des Sammelbehälters X

Entleerung, Ausspülen oder Desinfektion des Sammelbehälters X

Aufladen der Batterie X X

Kontrolle der Flüssigkeitsmenge in den Batterien X

Entnahme der Bürsten und Kontrolle ihrer Abnutzung.

Vergewissern Sie sich, dass keine Fremdkörper die Bewegung

oder die Leistung der Reinigungsorgane beeinträchtigen.

X

Sichtkontrolle des Allgemeinzustands der Maschine X

Vergewissern Sie sich, das die Schläuche oder Leitungen nicht

versperrt oder verstopft sind

X

Kontrolle der Abnutzung der Saugblätter X

Entnahme und Reinigung des Filters der Reinigungslösung X

Allgemeine Reinigung der Bürstenplatte, der Halterung und des

Squeegees

X

Die Hebe- und Senkbewegungen des Squeegees kontrollieren X

Schmierung der beweglichen Teile X

Den Hahn der Reinigungslösung kontrollieren. X

Reinigung der Schläuche mit Entkalkungsmittel X

22

9.1.8 DER SAUGBALKEN REINIGT ODER

TROCKNET NICHT GUT

Die Sauglippen sind abgenutzt oder schleppen zu

viel festen Schmutz mit sich.

Die Sauglippen ersetzen oder reinigen.

Der Saugbalken ist nicht richtig eingestellt.

Den Saugbalken so einstellen, dass er eben

aufliegt.

Der Saugschlauch verstopft.

Verstopfung entfernen.

9.1.9 DAS BATTERIELADEGERÄT

FUNKTIONIERT NICHT

Der Batterieladevorgang setzt nicht ein.

Kontrollieren, dass das Batterieladegerät richtig an

die Batterie angeschlossen ist.

9.2 DIE BATTERIEN WERDEN NICHT

GELADEN ODER ENTLADEN SICH

ZU SCHNELL

Die Batterien sind neu und erreichen nicht die erwartete Leistung von 100%.

Die Akkus erreichen ihre maximale Ladekapazität

erst nach 20-30 kompletten Ladezyklen.

Wenn die LED’s am Ladegerät blinken, muss ein

Fachmann das Ladegerät überprüfen.

SPRiNTUS kann NICHT bei der Lösung von

Problemen behilflich sein, die auf nicht direkt

gelieferte Batterien oder Batterieladegeräte

zurückzuführen sind.

Für Batterien und Ladegeräte die nicht original von

Sprintus sind, kann Sprintus keine Gewährleistung

übernehmen.

10. GARANTIE

In jedem Land gelten die von unserer zuständigen

Vertriebsgesellschaft herausgegebenen Garantiebedingungen. Etwaige Störungen an Ihrem Gerät

beseitigen wir innerhalb der Garantiefrist kostenlos, sofern ein Material- oder Herstellungsfehler

die Ursache sein sollte. Im Garantiefall wenden Sie

sich bitte mit Kaufbeleg an Ihren Händler oder die

nächste autorisierte Kundendienststelle.

10.1 ENTSORGUNG

Elektrogeräte nicht mit dem Hausmüll

entsorgen. In Übereinstimmung mit der

Europäischen Richtlinie 2012/19/EU über

Elektro- Elektronik- Altgeräte (WEEE) und

ihrer Einführung in das Landesrecht, müssen

Elektro-Altgeräte getrennt gesammelt und einer

umweltfreundlichen Entsorgung übergeben werden.

Altgeräte enthalten wertvolle recyclingfähige

Materialien, die einer Verwertung zugeführt

werden sollten. Batterien, Öl und ähnliche Stoe

dürfen nicht in die Umwelt gelangen. Bitte entsorgen Sie Altgeräte deshalb über geeignete Sammelsysteme

.

0,26 m/s² am Steuer

Effektivbeschleunigung Vibrationswert

Schalleistungsniveau garantiert

Schalleistungsniveau gemessen

LpA 71,23 dB(A) LwA 80 dB(A) LwA 79 dB(A)

K (uncertainty) ±1dB (A)

Schalldruckpegel

23

1. TABLE OF CONTENTS

2. GENERAL INFORMATION

2.1 PURPOSE OF THE MANUAL

2.2 TERMINOLOGY AND SYMBOL LEGEND

2.3 PRODUCT INFORMATION

2.4 INTENDED USE

2.5 CONFORMITY WITH STANDARDS

3. SAFETY INFORMATION

3.1 IMPORTANT INSTRUCTIONS

3.2 BODY STRESS

4. HANDLING INFORMATION

4.1 TRANSPORT OF THE MACHINE

4.2 CHECKS ON DELIVERY

4.3 UNPACKING

4.4 ASSEMBLY AND ADJUSTMENT OF THE PUSH

BAR

4.5 TRANSPORT OF THE MACHINE,

BATTERY AND BATTERY CHARGER

5. TECHNICAL INFORMATION

5.1 BATTERY

5.2 BATTERY CHARGER

5.3 CONTROLS AND FUNCTIONS

5.4 BATTERY

5.5 BATTERY CHARGER

5.6 CONFIGURATION OF THE CHARGER

5.7 ACCESSORIES

6. BEFORE COMMISSIONING

6.1 BAT TERY

6.2 INSTALLATION AND CONNECTION OF THE

BATTERY

6.3 CONFIGURATION OF THE CHARGER

6.4 PREPARATION OF THE MACHINE

7. SE RVIC E

7.1 CHARGING THE BATTERY

7.2 ASSEMBLY AND REMOVAL OF THE BRUSH

7.3 SWITCHING OFF THE MACHINE

7.4 ASSEMBLY OF THE SQUEEGEE

7.5 DISASSEMBLY OF THE SQUEEGEE

7.6 CHANGING THE SQUEEGEE LIPS

7.7 INSERTING AND REMOVING THE SPLASH

GUARD

7.8 FILLING AND EMPTYING THE FRESH WATER

TANK

7.9 EMPTYING THE WASTE WATER TANK

7.10 DOSING OF FRESH WATER

7.11 RUNNING THE MACHINE

7.12 DRIVING THE MACHINE

7.12 MODE OF OPERATION

7.12.1 PREPARATION AND WARNING

INSTRUCTIONS

7.12.2 THE BATTERY CHARGE CHECKING STATUS

7.12.3 CLEANING LIGHTLY SOILED SURFACES

7.12.4 CLEANING HEAVILY SOILED SURFACES

7.12.5 AFTER CLEANING

7.13 USER INSTRUCTIONS FOR THE 230 VOLTS

NETWORK VERSION

8. MAINTENANCE

8.1 TANK

8.2 FRESH WATER FILTER

8.3 SUCTION HOSE

8.4 SQUEEGEE

8.5 ACCESSORIES

8.6 CLEANING THE MACHINE

8.7 BATTERIES

8.8 REGULAR MAINTENANCE

8.9 RECOMMENDED SPARE PARTS

9. CLEANING / MAINTENANCE

9.1 FAULTS

9.1.1 THE MACHINE DOES NOT WORK

9.1.2 ERROR DISPLAYS ON THE DISPLAY

9.1.3 THE BRUSHES ARE NOT TURNING

9.1.4 THERE IS NO OR ONLY A SMALL AMOUNT OF

CLEANING SOLUTION

9.1.5 NO SUCTION OPERATION

9.1.6 TOO LOW SUCTION POWER

9.1.7 THE BRUSH MOTOR OR SUCTION MOTOR

WILL NOT SWITCH OFF

9.1.8 THE CLEANER DOES NOT PROPERLY CLEAN

OR DRY

9.1.9 THE BATTERY CHARGER DOES NOT WORK

9.2 THE BATTERIES WILL NOT CHARGE OR

DISCHARGE TOO RAPIDLY

10. WARRANTY

10.1 DISPOSAL

24

2. GENERAL INFORMATION

2.1 PURPOSE OF THE MANUAL

For easier reference and reading of the required information please use the list of contents.

This manual forms an additional part of the product. The manual must therefore be carefully stored

throughout the operating life of the machine.

The customer must ensure that the personnel have

read the manual and understood its contents so that

they can follow the instructions described here.

To ensure the best results of safety, performance,

efficacyand service life of your product the instructions of this manual have to be followed. Failure to

follow these instructions may pose a potential hazard

to the user, the machine, the cleaned surface and the

environment. The manufacturer cannot be held liable

for any resulting damage.

The batteries and the battery charger are important

components to ensure the performance of the machine.

Only the correct combination of battery and charger

ensures optimal performance and prevents costly

damage. For more detailed information, refer to the

specific manuals of the batteries and battery chargers.

The original battery charger in combination with the

original battery ensures optimal functioning.

2.2 EXPLANATION OF SYMBOLS USED

To better understand and emphasise the various aspects of the instructions manual, terms and symbols

have been used, which are defined and depicted

below:

- Machine. This term replaces the trade name to

which this manual refers.

- Operator. Person or persons who normally operate

the machine and are familiar with its operation, but do

not have the specific technical competence necessary

to carry out any special interventions.

- Technician. Person with experience, technical

training, knowledge of the laws and regulations required to carry out repairs. The technician is able to

detect and avoid hazards that may occur during installation, use, and maintenance of the machine.

- INSTRUCTION SYMBOL ( ☞ ) This information

is especially important to avoid machine malfunction.

- ATTENTION SYMBOL ( ) Very important infor-

mation to avoid serious damage to the machine and

to the environment in which it operates.

- CAUTION SYMBOL (

) This information is

especially important to avoid serious machinery and

environmental damage.

- HAZARD SYMBOL ( ) This information

is especially important to avoid personal, machine and

environmental damage

2.3 PRODUCT INFORMATION

The rating plate attached under the control panel

contains the following information:

- Information of the manufacturer

- EC-Mark

- Model number

- Model

- Total output

- Serial number (identification number)

- Construction year

- Weight at max. loading

2.4 INTENDED USE

The Camira is a scrubber-dryer.

The machine can be used for scrubbing and suctioning of flat and obstacle-free floors in office buildings

and industrial buildings. Any other use is prohibited.

We ask you to strictly follow the safety instructions in

this manual. The scrubber-dryer distributes an adjustable amount of cleaning solution and detergent, while

the brushes remove the dirt from the floor. By properly combining the cleaning agents with the various

available brush types (or grinding wheels), the machine can be adapted to all floors and levels of soiling.

2.5 CONFORMITY WITH STANDARDS

This machine has been designed and manufactured

in compliance with the relevant EU standards for the

safety and health of the user and is therefore supplied

with the EC mark on the rating plate. The EU standards that the machine complies with are listed in this

instruction manual in the certificate of conform-

ity. This certificate loses its validity if safety-related

changes are made to the machine.

The manufacturer reserves the right, at any time

and without notice, to make technical changes to the

product in order to update or technically improve the

product. The machine you have purchased may therefore differ slightly in minor details from the information and illustrations contained in our catalogues or

this manual, without this causing any impairment to

safety and the corresponding information.

3. SAFETY INFORMATION

3.1 IMPORTANT INSTRUCTIONS

☞ The “Operating Instructions” are to be

carefully read before switching on, using, performing maintenance, performing ordinary

maintenance and any intervention on the machine.

All instructions contained in this manual

and the manuals of the battery and the battery

charger must be strictly followed (especially

the caution and hazard instructions).

The manufacturer is not liable for personal injury and / or property damage resulting from

non-compliance with the above-mentioned

regulations.

☞ Before using the machine, it is important to

make sure all components are correctly assembled.

25

The machine may only be used by persons who

have been trained in the use of the same, who are

capable of operating the machine and who have been

expressly authorised to use the machine.

The use of the machine is only permitted for persons of legal age.

The machine must not be used for a purpose

other than that expressly intended. When using the

machine, the respective building type must be taken

into account and the safety conditions valid therein

must be strictly observed.

The machine must not be used in poorly lit places,

in potentially explosive atmospheres, in connection

with waste harmful to health (dust, gas, etc.), on

public roads and paths and outdoors.

The machine was developed for use at an ambient temperature between + 4 °C and + 35 °C; When

not in use, the machine should be stationed in a dry,

non-corrosive environment at a temperature between + 10 °C and + 50 °C.

The humidity allowed for operation and storage of

the machine is between 30% and 95%.

No suction flammable or explosive liquids,

gases, dry powders, acids and solvents (e.g.

solvents for paint, acetone, etc.) or benzine,

oil, fuel, etc., even if diluted. No suction any

burning or glowing objects.

Do not use the machine on a slope of more than

10% or on ramps with a slope of more than 10%. The

machine must not be used transverse to the slope.

On downhill sections always be careful to manoeuvre and not turn. When transporting on ramps or

on steep slopes, the utmost attention must be paid

to avoid overturning and uncontrolled acceleration.

Only use on ramps and downhill slopes with brushes

and squeegee raised.

Never station the machine on slopes.

When using the machine, attention must be paid

to the presence of third parties in the operational

environment, especially to children.

Do not use the machine to transport persons/

things or to tow objects. Do not tow the machine.

☞ Do not use the machine as storage for objects.

Do not cover or block the ventilation and cooling

holes.

Do not remove, modify or bypass the safety devices.

Always use the personal protective equipment required for the safety of the operator. Before starting

to work, remove bracelets, chains, watches, ties and

other objects that pose a potential hazard and can

lead to serious accidents.

Do not reach between moving machine parts with

your hands.

☞ Only use the intended cleaning agent

and observe the precautionary measures and regulations contained in the respective safety data sheets.

We recommend keeping the cleaning agents in a

place where children are unable to access them. In

case of contact with eyes, rinse immediately with

plenty of water. If swallowed, seek medical attention

immediately.

Ensure that the battery charger power supply sock

ets are grounded and fused.

The instructions of the battery manufacturer and

the relevant standards must be followed. Always

keep the batteries clean and dry to avoid leakage

current. Protect the batteries from soiling, such as

metal dust.

Do not place tools on the batteries: Short circuit

and explosion hazard.

When using battery acid, the appropriate safety

regulations must be strictly observed. In the presence of magnetic fields, the effects on the appliance electronics must be checked. Never clean the

machine with a water jet.

☞ The absorbed liquids contain cleaning agent, disinfectant agent, water, and organic and inorganic materials that have been dissolved while working: These

fluids must therefore be disposed of in accordance

with applicable laws.

In the event of defects and / or malfunctions, the

machine must be switched off immediately (disconnected from the power supply and / or the batteries).

Do not try to repair the machine yourself; contact a

Sprintus dealer.

All maintenance must be performed in well-lit surroundings after the machine has been disconnected

from the power supply by disconnecting the battery

connector and / or the power plug.

☞ All interventions on the electrical system as well

as all maintenance and repair work (especially

those not expressly described in this manual) must

be carried out in authorised service centres or by

technicians with product-specific experience and in

compliance with applicable safety regulations.

☞ Only the original

approved spare parts available from Sprintus are to

be used. Only original spare parts ensure a correct

and safe operation of the machine. If the machine is

no longer to be used, the batteries must be removed

and disposed of in accordance with the provisions

of EU standard 91/157 / EEC or handed over to an

authorised battery collection centre.

When disposing of the machine, the laws applicable

in the country of use must be followed:

- Disconnect the machine from the main power supply, drain the liquids and clean the machine;

-The machine is then dismantled in order to dispose

of the different materials sorted by type. Each group

of materials is disposed of in accordance with the

recycling laws.

To avoid hazard, especially to children, it is recommended that any components of the machine that

may pose a hazard are rendered harmless.

☞ The machine must be checked before each use.

In particular, check that the battery charging cable

and connector are in perfect condition to ensure safe

operation. If these parts are not in perfect condition,

26

the machine must undergo further commissioning by

an authorised specialist before being used again.

☞ When spilling foam or liquids the suction motor

must be switched off immediately.

☞ Do not use the machine on textile floors, such as

carpets etc. The use of waxes or foaming cleaning

agents as well as leaks can lead to serious malfunctions of the machine as well as blockage of the hoses.

3.2 BODY STRESS MEASUREMENTS

Noise and vibration data on page 34.

4. HANDLING INFORMATION

4.1 TRANSPORT OF THE MACHINE

During lifting and transport, make sure that the packaged machine has been securely anchored to prevent

it from tipping over or falling. When loading / unloading

the machine onto / off vehicles, suitable lighting must

be provided.

When handling the packaged machine, appropriate

means should be used; Care must be taken to ensure

that the packaging is not exposed to shocks and is not

damaged. Do not turn the packaged machine upside

down and place it gently onto the floor.

☞ These instructions also apply to the batteries

and the battery charger.

4.2 CHECK ON DELIVERY

☞ At delivery of the goods (machine, battery,

battery charger) by the freight forwarder it must be

checked that the packaging and its contents are not

damaged. If the contents of the package are damaged, the freight forwarder must be informed accordingly and a claim for damages must be submitted

in writing. In this case, the machine must only be

accepted under reserve.

4.3 UNPACKING

When unpacking the machine proceed as follows:

For box packaged machine:

- Cut the plastic strapping with a pair of scissors or

a knife.

- Lift up the box and remove it.

- Take the bags out of the compartment and check

their contents (operating and maintenance manual,

connectors for connection to the battery charger).

- Remove the metal straps or plastic straps that secure the machine to the pallet.

- Remove the brushes and squeegee from the packaging.

- Push the machine backwards off the pallet, using a

tilted board well secured to the pallet and floor.

After all the packaging material has been removed,

the accessories and batteries can be installed according to the instructions given in the specific section.

It is recommended that all the packaging elements

be retained, as they will protect the machine and

accessories from further transportation to another

location or can be used by an authorised customers

service centre. Otherwise, the applicable laws must

be followed when disposing of the packaging material.

4.4 ASSEMBLY AND ADJUSTMENT OF

THE PUSH BAR

- Insert the handle into its place.

- Set the handle at the desired height and tighten the

2 knobs (photo B-21).

- Insert the suction tube into its place on the waste

water collecting tank (photo B-3.

- Plug the Anderson Safety Connector (photo B-18)

into its connector (photo B-17).

4.5 TRANSPORT OF THE MACHINE,

BATTERY, BATTERY CHARGER

Do not lift the machine with a pallet truck

as the machine is not intended for this:

- Empty the waste water tank and the cleaning solution tank.

- Remove the squeegee and brushes.

- Disconnect and remove the batteries.

Move the machine to the original pallet (or other underlay appropriate to the machine weight and dimensions) using a suitable lifting device.

Firmly anchor the machine and squeegee to the pallet.

Lift the pallet with the machine and load it onto the

means of transport.

Secure the machine and the pallet with ropes and

fasten onto the transport vehicle.

If you have a loading ramp, you can also push the

machine directly without a pallet onto the back of

the transport vehicle. However, care must be taken

to ensure that the machine and all components are

protected from shocks, moisture, jolting and sudden

movements during transport.

5. TECHNICAL INFORMATIONS

5.1 BATTERY

Regardless of the type of construction, the capacity

of a battery is expressed in amperes per hour (Ah).

The machine is equipped with gel batteries. This

type of battery is maintenance-free and does not require any special charging facilities (since no harmful

gases are released).

In no case can it be assumed that non-

original batteries and battery chargers

guarantee the product features warranted by

SPRiNTUS. Only perfect compatibility of battery and charger ensures first-class performance, long life, safety and cost-effectiveness.

5.2 BATTERY CHARGER

The built-in high-frequency battery charger ensures

optimal charging of the battery with high battery life.

For non-original batteries and battery charg-

ers SPRiNTUS cannot guarantee the warranted

product features. Only perfect compatibility of

the battery and charger ensures first-class performance, long service life, safety and economy.

27

5.3 CONTROLS AND SYMBOLS

PHOTO A

1

Handlebars

2

Switch (dead man)

3

Suction Hose

4

Cover of waste water tank

5

Waste water tank

6

Fresh water tank

7

Closing cap for drain hose

8

Waste water drain hose

9

Filler neck of fresh water tank

10

Button to adjust

11

Deflector wheel

12

Splash guard

PHOTO B

13

Control panel

14

Cover of the electronics

15

Built-in charger

16

B

AC power plug of the charger

16

power cable (power supply AC230V)

17

Socket of battery cable

18

Battery connector (Anderson)

19

Foot lever of squeegy

20

Rear wheel

21

Adjustment knobs of drawbar

22 Fresh water adjustment

23 Fresh water filter

46 Drain cap of fresh water tank

PHOTO C

20 Rear wheel

22

Fresh water adjustment

23

Fresh water filter

PHOTO D

24

Socket screws of squeegy lips

25

Mounting strip of squeegy lips

26

Front squeegy lips

27

Suction adapter

28

Suction nozzle

29

Rear squeegy lips

30

Mounting strip

PHOTO E

13 Control panel

32 ON / OFF Main switch Indicator light on =

ON

33 Pushbutton brush motor: Indicator light on

= ON

Flashing Indicator = Eco Function

Indicator light off = OFF

34 Pushbutton suction motor: Indicator light

on = ON

Flashing Indicator = Eco Function

Indicator light off = OFF

35 ushbutton fresh water supply: Indicator

light on = fresh water supply indicator light

off = no fresh water Press pushbutton 35

+ power switch 2 = Brush drop

36 Indicator battery charge

37 LED green = battery charged

38 LED yellow = battery 50% charged

39 LED red = battery discharged

PHOTO F

40 Suction adaptor

41 Battery compartment

42 Connection sketch of batteries

43 Float switch

PHOTO G

28 Holding plate of squeegee

44 Squeegee holder

PHOTO H

27 Nozzle of suction hose

44 Holding plate of squeegee

45 Squeegee holder

PHOTO I

27 Adaptor of suction hose

44 Holding plate of squeegee

45 Squeegee holder

PHOTO L

44 Holding plate of squeegee

PHOTO M

24 Screw of squeegy

29 Rear squeegy lips

30 Mounting of squeegy lips

31 Knurled screw

28

5.4 BATTERY

The supplied gel batteries are delivered partially

charged. Before use, the batteries must be fully

charged.

5.5 BATTERY CHARGER

When delivered, reference should be made to the appropriate manual.

5.6 CONFIGURATION OF THE CHARGER

At delivery, the charger is already set for the

accompanying batteries.

5.7 ACCESSORIES

Further accessories for your Camira can be purchased

through the specialised trade outlets.

6. BEFORE COMMISSIONING

6.1 BATTERY

The machine is configured for use with gel batteries. Use of non-compliant batteries can cause serious

machine damage and require more frequent recharging.

6.2 INSTALLATION AND CONNECTION

OF THE BATTERY

These interventions must be carried out by spe-

cialists.

Lift out the waste water tank. (Photo B-17) Disconnect the Anderson connector of the battery cable from

the Anderson connector of the machine cable. Do not

pull the plug out of the socket by the cable.

Connect the battery terminals to the battery

terminal marked with the same symbol. (red

cable “+”, black cable “-”)! A possible short circuit of the battery can lead to explosions!

Make sure all controls are set to “0” or “Off”. Now the

battery connector (18) can be reconnected.

Close the battery compartment, taking care not

to squeeze any cable.

6.3 CONFIGURATION OF THE CHARGER

This procedure must be performed by trained technicians. When purchasing the scrubber-dryer, the

built-in battery charger is configured for operation

with GEL batteries.

6.4 PREPARATION OF THE MACHINE

Before starting work, wear non-slip shoes,

gloves and any other personal protective equipment specified by the manufacturer for the cleaning agents or required by the working environment.