Page 1

REV LOW

Engineering Manual

___________________________

Spring Air Systems Inc., Oakville, Ontario

Phone (905) 338-2999, Fax (905) 338-0179, info@springairsystems.com

www.springairsystems.com

Page 2

REV LOW

Engineering Manual

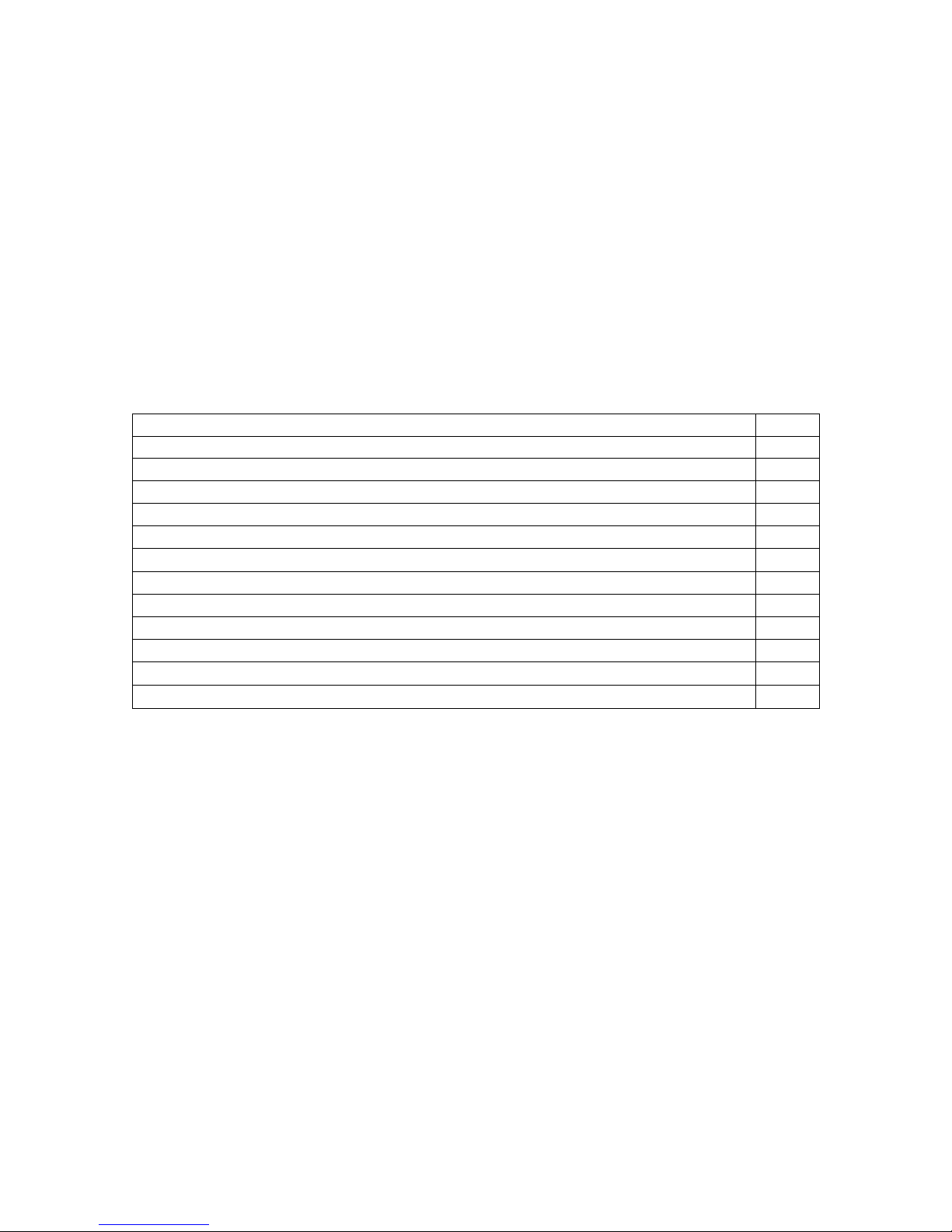

Table of Contents

Introduction 1

Operation 2

Variflow Baffles 3

Model Number Designation 4

Water Wash

Hood and Damper Assemblies 8

Dry

REV LOW

REV LOW

Exhaust Duct Sizes 17

Make Up Air 18

REV LOW

REV LOW

REV LOW

May05

REV LOW

Exhaust Calculations

Systems

Controllers

Work Sheet

5

13

14

19

22

23

Page 3

REV LOW Engineering Manual

Introduction

The Revlow hood is a revolutionary idea in commercial kitchen ventilator design. Revlow allows

the exhaust flow to be field adjusted over each appliance without affecting the overall efficiency of

the grease extractor. Your kitchen will exhaust the lowest minimum required to ventilate the

appliances located under the hood. After your kitchen is complete, appliances can be relocated,

added, or removed from under the hood! It’s a simple adjustment to fine-tune your ventilator to

provide excellent smoke capture with maximum grease extraction.

What is a REV LOW hood?

The REV LOW hood is available in two types; a water wash and dry grease extractor. The water

wash hood is automatically cleaned in place at the end of each cooking day. The REV LOW dry

extractor is manually cleaned the dry extractor has inserts that are removed daily and washed in

your dishwasher or pot sink.

The Spring Air Systems REV LOW hood is fabricated from stainless steel with No. 4 finish on all

exposed surfaces. All edges are ground and polished. All hoods are manufactured to stringent

quality standards and are guaranteed to enhance the appearance of any commercial kitchen.

Why REV LOW ?

REV-LOW VALUABLE FUEL DOLLAR SAVINGS:

minimizes the total exhaust by adjusting the

hood to suit individual appliances.

REV-LOW CLEANER DUCTWORK:

maximizes your extraction at all exhaust airflows to

capture more grease in hood. It’s not a filter hood!

REV-LOW FLEXIBILITY:

add, remove or move appliances anytime. VARIFLOW

baffles are easily adjusted without special tools to

balance any cooking bank.

REV-LOW MULTIPLE HOOD BALANCING:

Multiple hoods connected to a single exhaust fan can

be easily balanced.

______________________________________________________________________

_

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

REV LOW

1

Page 4

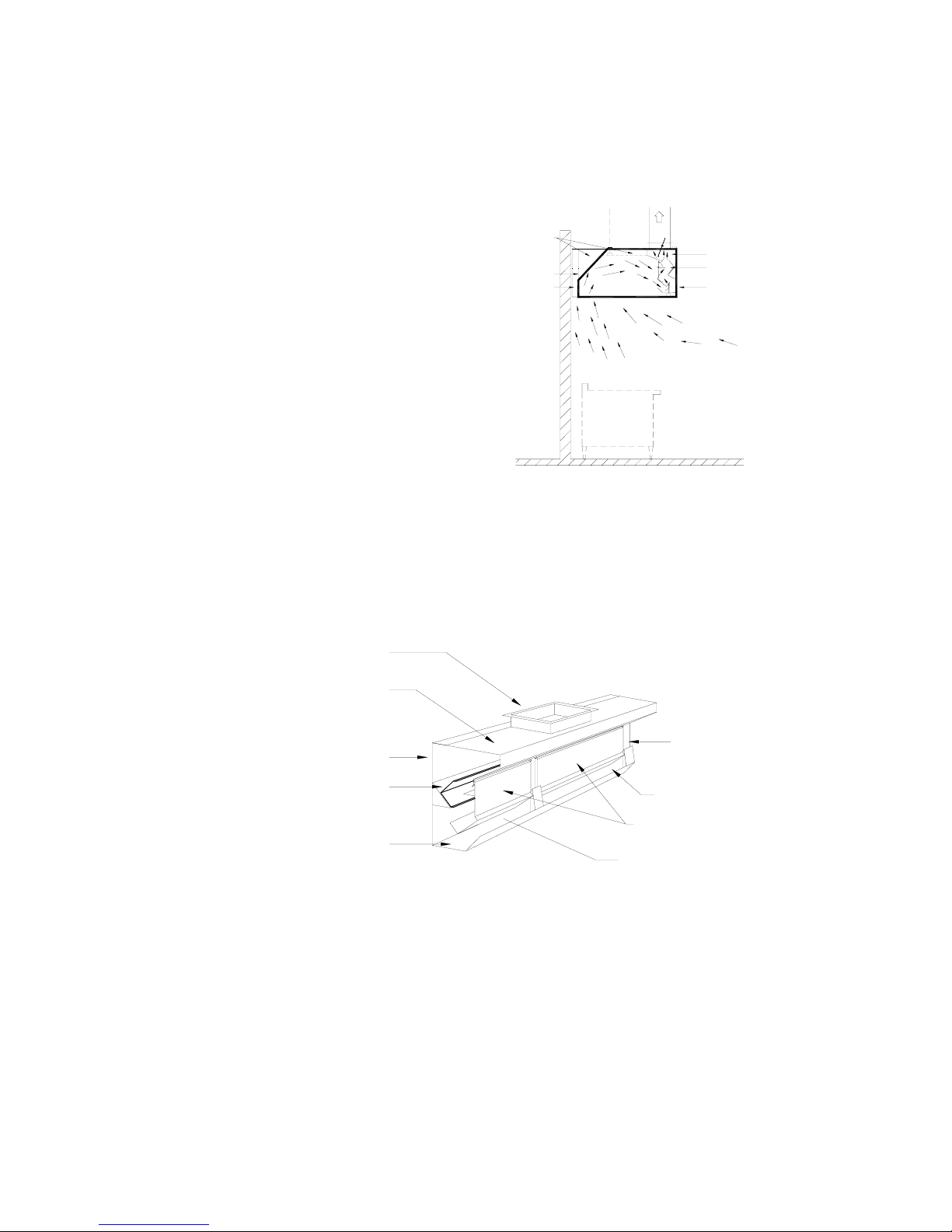

Operation

A commercial kitchen cooking line consists of many different appliances depending on the type of

restaurant or institution. In every commercial kitchen the cooking vapours, which comprise of

grease, smoke, and products of

combustion rise off the cooking surface.

Natural convection forces drive the

cooking vapours up towards the back wall

Roof of hood

as shown in figure 1 below. The kitchen

dilution air is entrained into the cooking

vapours and the air mixture generally

Back wall of hood

Optional 3" aiir space

follows the profile of the back and top of

the hood. The mixture of grease, smoke,

products of combustion, lint, dirt and

kitchen dilution air proceed along the roof

Vapours from appliances

of the hood and follow a path down

towards the core extractor slot (the core

extractor slot extends along the length of

APPLIANCES

the hood). Most of the air mixture enters

the slot and a small amount rolls back into

the hood canopy to meet the main air

stream again.

The REV LOW Hood Model DD-B-F

Figure 1

Optimizing the amount of air mixture that enters the core extractor slot is the key to the REV LOW

system. The REV LOW hood must incrementally maximumize the amount of the air mixture that

enters the slot and minimize the amount of roll back into the canopy as the total amount of the air

mixture deviates along the length of the cooking lineup.

Exhaust Air

Core Extractor

Variflow baffle

Front of hood

Kitchen dilution air

Exhaust duct collar

Top of core extractor

End mullion

Front of core extractor

Variflow Baffle

Shown in full open position

Core extractor slot

Removable Inserts

Grease trough

Core extractor slot

Section View of Core Extractor for DD-B-F REV LOW Hood

Figure 2

The REV LOW accomplishes this complicated process with a unique core extractor profile that

contains a series of specially designed VARIFLOW baffles located along length of the core

extractor. See Figure 2 above. The VARIFLOW baffles are adjusted prior to shipment to allow the

optimum amount of the air mixture to enter the core extractor slot and thereby minimize roll back

into the hood canopy. For instance the VARIFLOW baffles located above a charbroiler are

opened to the maximum 450 CFM/ft position and the VARIFLOW baffles located above ovens or

steamers are closed to the minimum 100 CFM/ft position. This variable adjustment along the

length of each hood provides an exhaust system that truly minimizes the amount of exhaust air to

properly ventilate any kitchen line up.

______________________________________________________________________

2

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

_

Page 5

VARIFLOW Baffles

The most important component for the successful operation of a REV LOW hood is the core

extractor that contains the VARIFLOW baffles. The core extractor profile has been designed to

facilitate the smooth flow of cooking vapours and dilution air from the roof of the hood, down

along the front of the core extractor and into the core extractor slot. The VARIFLOW baffles are

located inside the core extractor along the entire length. The VARIFLOW baffles are adjustable

to provide between a 100 CFM/ft to 450 CFM/ft flow rate into the core extractor slot. The

VARIFLOW baffles are adjustable without any special tools by lifting off the core extractor

removable insert and hand adjusting the position of the baffle. Just set the position of the

VARIFLOW baffle to match the appliance located below. See Figure 3 for isometric view of

Roof of hood

Back of hood

Baffle Closed Baffle OpenedBaffle Partially Closed

Exhaust duct collar

Core extractor

Variflow Baffle

Front of hood

Drain connection

VARIFLOW baffles.

Section View of REV LOW Water Wash Hood with Detail of Variflow Baffle

Figure 3

Benefits

A Spring Air Systems Inc. REV LOW Hood system provides numerous benefits to the

owners/operator of a commercial or institutional restaurant.

1. More comfortable kitchen environment.

2. Lower annual heating cost with little or no capital cost increase.

3. Lower annual air conditioning costs and possible reduced capital cost for air conditioning

equipment.

More Comfortable Kitchen Environment

The Spring Air REV LOW Hood System provides excellent smoke capture using the absolute

minimum net exhaust air from the restaurant. The system can be interlocked with the kitchen

makeup air unit and the building air conditioning units to energize the economizers and provide a

balanced supply and exhaust system. Reduced drafts will provide more comfortable

temperatures throughout the kitchen.

Low Heating Costs

The Spring Air REV LOW Hood System is designed to minimize the net exhaust air from the

building. Less net exhaust means less heating of fresh air or supply air into the building.

Lower Air Conditioning Costs

The Spring Air REV LOW Hood System is designed to minimize the amount of conditioned supply

air required in the store. By reducing the conditioned air into the store, the required air

conditioning load is reduced and the air conditioning operating cost will consequently decrease.

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

3

_

Page 6

Model Number Designation

The Spring Air Systems REV LOW Hood is available in three basic types

1. Continuous cold water spray/hot water wash - “C”

2. Hot water wash - “H”

3. Dry Ventilator - “D”

Each type of hood provides varying degrees of grease extraction efficiency, automatic/manual

wash, and exhaust fire dampers. For a more detailed description of the types of hood exhaust fire

dampers and wash systems refer to the Spring Air Systems “Ventilator Engineering Manual”.

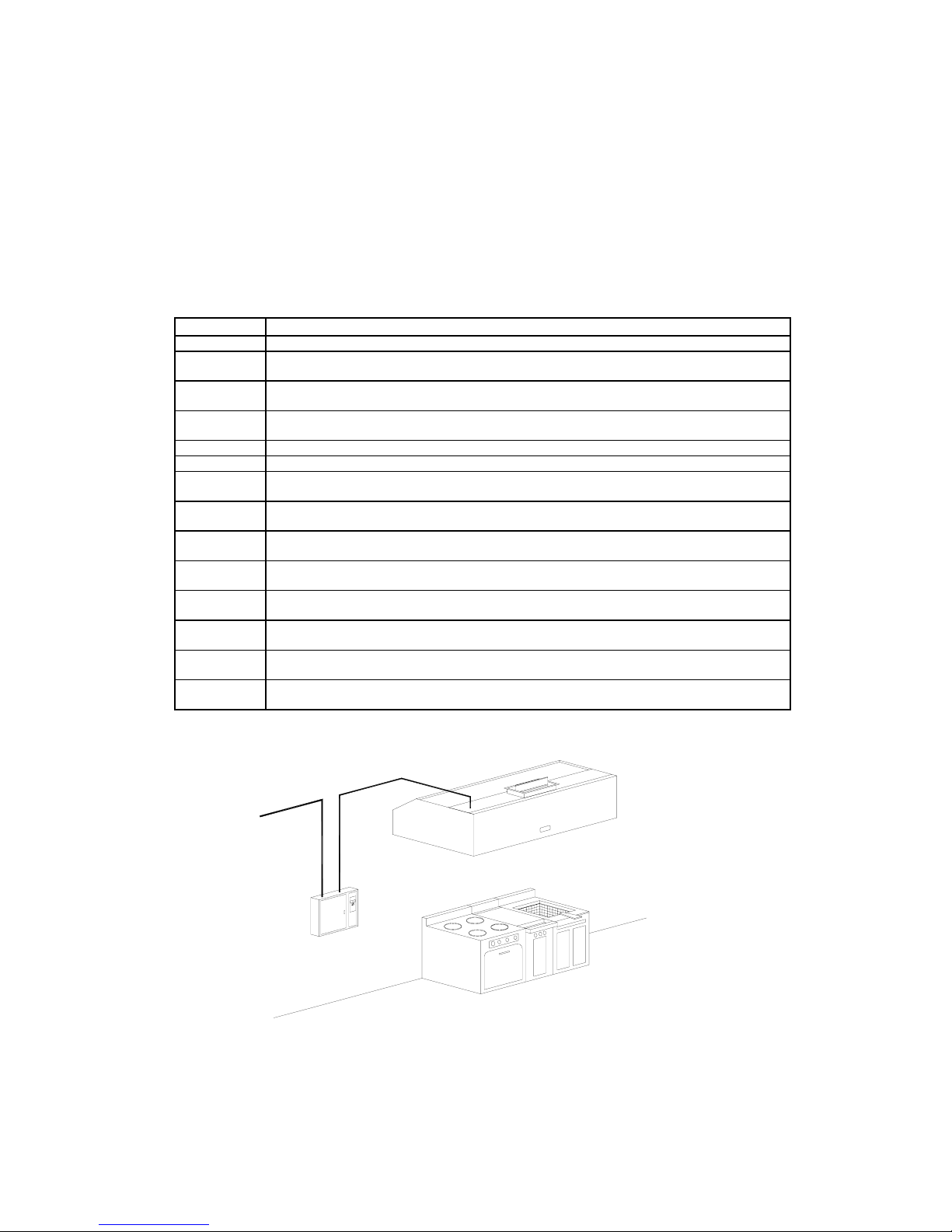

Model No. Description

DD-B-F Single row box canopy, dry extractor with fusible link dead weight fire damper

CD-B-F Single row box canopy, continuous cold water spray/hot water wash ventilator with fusible

CF-B-F Single row box canopy, continuous cold water spray/hot water wash ventilator with fusible

CT-B-F Single row box canopy, continuous cold water spray/hot water wash ventilator with

HD-B-F Single row box canopy, hot water wash ventilator with fusible link dead weight fire damper

HF-B-F Single row box canopy, hot water wash ventilator with fusible link spring loaded fire damper

HT-B-F Single row box canopy, hot water wash ventilator with thermostatic activated spring loaded

DD-BI Island box canopy, dry extractor with fusible link dead weight fire damper, installed back to

CD-BI Island box canopy, continuous cold water spray/hot water wash ventilator with fusible link

CF-B-FI Island box canopy, continuous cold water spray/hot water wash ventilator with fusible link

CT-B-FI Island box canopy, continuous cold water spray/hot water wash ventilator with thermostatic

HD-BI Island box canopy, hot water wash ventilator with fusible link dead weight fire damper,

HF-B-FI Island box canopy, hot water wash ventilator with fusible link spring loaded fire damper,

HT-B-FI Island box canopy, hot water wash ventilator with thermostatic activated spring loaded fire

link dead weight fire damper

link spring loaded fire damper

thermostatic activated spring loaded fire damper

fire damper

back with another Rev-Low hood

dead weight fire damper, installed back to back with another Rev-Low hood

spring loaded fire damper, installed back to back with another Rev-Low hood

activated spring loaded fire damper, installed back to back with another Rev-Low hood

installed back to back with another Rev-Low hood

installed back to back with another Rev-Low hood

damper, installed back to back with another Rev-Low hood

Chart No. 1

Typical Water Wash Application Single Row Wall Mounted REV LOW

______________________________________________________________________

4

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

Model HD-B-F

Figure 4a

_

Page 7

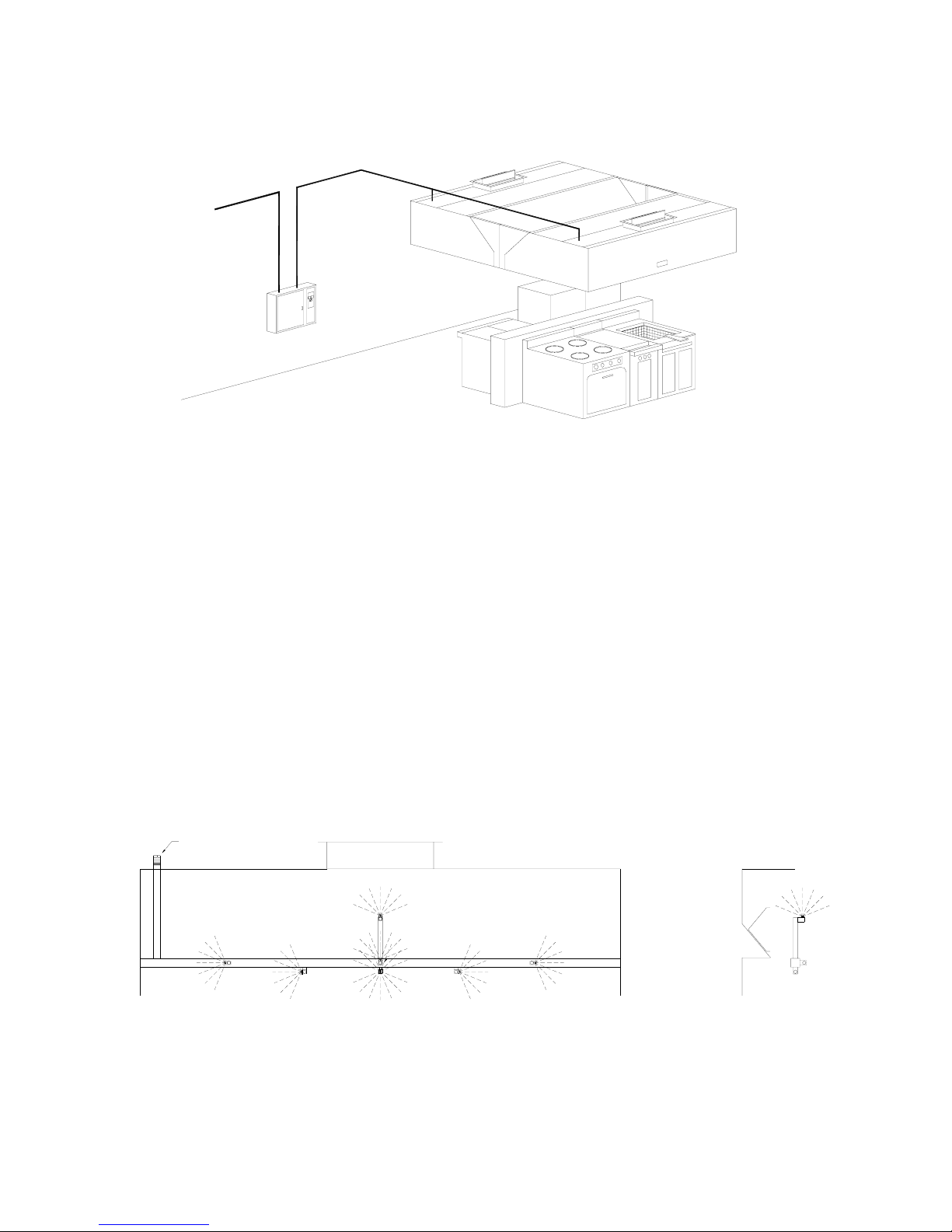

Typical Water Wash Application Island REV LOW

Two Model HD-BI

Figure 4b

The type “H” and “C” ventilators require a water wash control panel. Consult the “Ventilator

Engineering Manual” or individual water wash panel specification sheets for the proper water

wash control panel. The water wash control panel is supplied to provide operation of the exhaust

fan, supply unit (Spring Air SFA series), time wash cycle, and fire suppression system.

Water Wash REV LOW Hoods

Automatic Wash: Type “C” and “H:” Ventilators

SPRING AIR SYSTEMS ventilators are available with either automatic or manual wash systems.

All water wash ventilators must be interconnected with a water wash control panel.

The “C” and “H” ventilators have incorporated a water wash manifold into the high efficiency

extractor. Spray nozzles are spaced evenly along the wash manifolds. The hot detergent-water

NOZZLE TO WASH EXHAUST

HOT WATER INLET

DUCT AND FIRE DAMPER

TOP OF GREASE EXTRACTOR

TOP OF HOOD

FRONT VIEW OF MANIFOLD

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

Water wash Manifold

Figure 5

_

END OF

GREASE

EXTRACTOR

SECTION VIEW

5

Page 8

mixture enters the hot water inlet pipe, and travels into the interconnecting pipe to the MANIFOLD

E. The water detergent mixture is sprayed uniformly within the interior of the extractor.

The water/detergent mixture washes the grease, lint and dirt into the

sloping VORTEX BAFFLE that carries the mixture to the end of the

ventilator and into the grease trough.

The mixture travels along the grease trough to the drain. The drain

may be located at either end of the ventilator. Multiple ventilators

may have individual drains factory manifolds to one common drain.

The wash time is adjustable from 0 to 10 minutes. The type “C” is

normally set at 2 minutes while the type “H” is set at 3 minutes.

Depending on the type of cooking equipment the type “C” usually

requires less hot water wash time because of the continuous coldwater spray. During fan and cooking operation, the spray

continuously carries grease, dirt and lint down the drain, which

reduces the daily grease build-up.

The hot water required is approximately .9 gpm/ft. of ventilator at 40

psig (see Chart No.2). The cold-water continuous spray requires

approximately 1.0 gph/ft. of ventilator at 15 psig (see Chart No.3)

Type “C” and “H” Wash

Figure 6

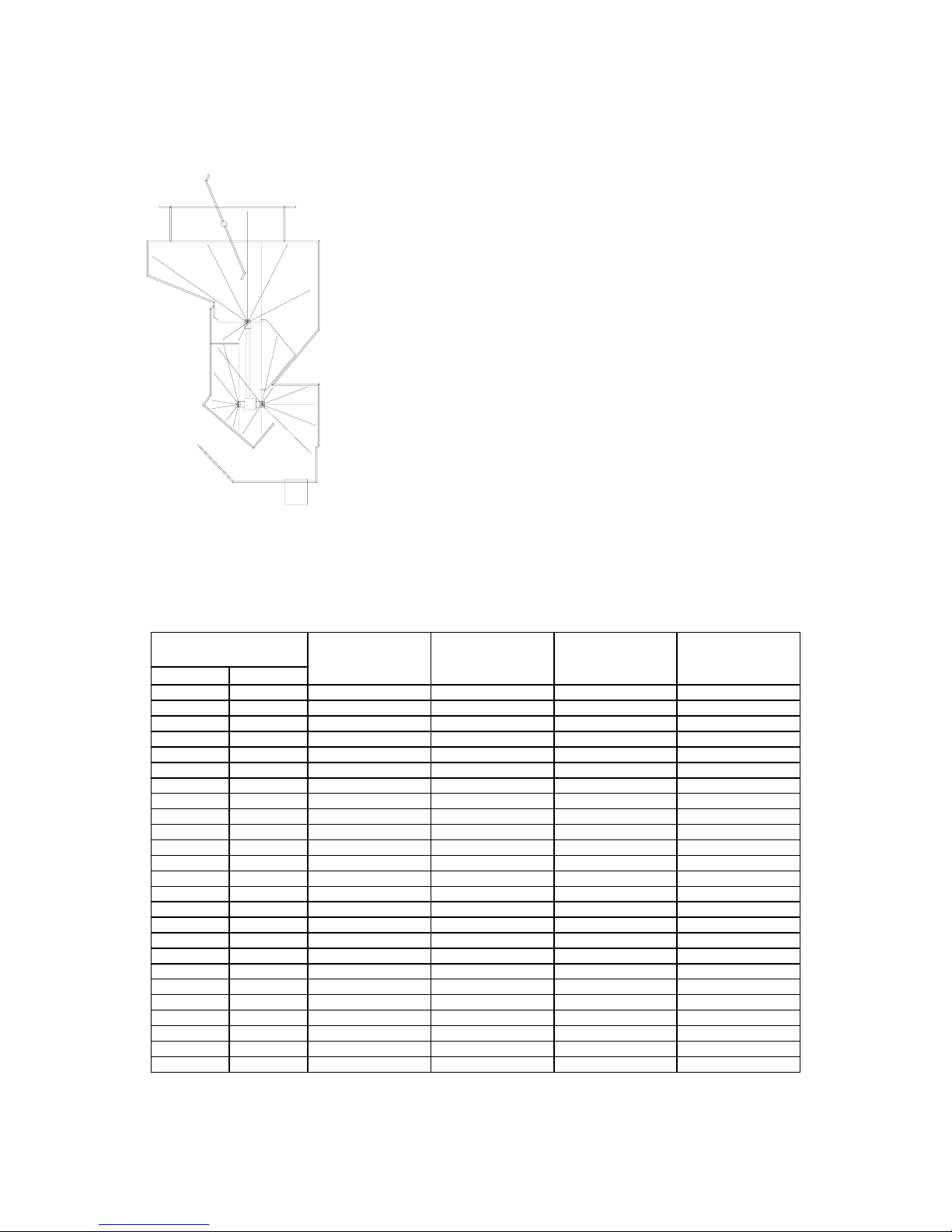

Hot Water Flow Required Model

Ventilator

Length

ft mm @ 40 psi @ 60 psi @ 2.76Kpa @413 Kpa

3.0 914 2.4 2.8 0.14 0.17

3.5 1067 3.1 3.8 0.19 0.23

4.0 1279 3.1 3.8 0.19 0.23

4.5 1372 3.1 3.8 0.19 0.23

5.0 1524 3.1 3.8 0.19 0.23

5.5 1676 3.7 4.5 0.22 0.27

6.0 1829 3.7 4.5 0.22 0.27

6.5 1981 4.3 5.3 0.26 0.32

7.0 2131 4.3 5.3 0.26 0.32

7.5 2286 4.9 6.0 0.30 0.36

8.0 2438 4.9 6.0 0.30 0.36

8.5 2591 5.5 6.7 0.33 0.41

9.0 2743 5.5 6.7 0.33 0.41

9.5 2896 6.7 8.2 0.41 0.50

10.0 3048 6.7 8.2 0.41 0.50

10.5 3200 7.3 8.9 0.44 0.54

11.0 3353 7.3 8.9 0.44 0.54

11.5 3505 7.9 9.7 0.48 0.59

12.0 3658 7.9 9.7 0.48 0.59

12.5 3810 8.5 10.4 0.52 0.63

13.0 3962 8.5 10.4 0.56 0.63

13.5 4115 9.2 11.3 0.56 0.69

14.0. 4207 9.2 11.3 0.56 0.69

14.5 4420 9.8 12.0 0.60 0.73

15.0 4772 9.8 12.0 0.60 0.73

Hot Water Flow

USGPM

Hot Water Flow

USGPM

Hot Water Flow

l/s

Hot Water Flow

l/s

Chart No.2

______________________________________________________________________

6

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

_

Page 9

Cold Water Flow Required Model B

Ventilator

Length

feet mm @ 20 psi @ 138 Kpa feet mm @ 20 psi @ 138 Kpa

3.0 914 0.35 0.02 9.5 2896 0.91 0.05

3.5 1067 0.35 0.02 10.0 3048 0.98 0.06

4.0 1279 0.42 0.02 10.5 3200 1.05 0.06

4.5 1372 0.49 0.03 11.0 3353 1.05 0.06

5.0 1524 0.49 0.03 11.5 3505 1.12 0.07

5.5 1676 0.56 0.03 12.0 3658 1.19 0.07

6.0 1829 0.63 0.04 12.5 3810 1.19 0.07

6.5 1981 0.63 0.04 13.0 3962 1.26 0.08

7.0 2131 0.70 0.04 13.5 4115 1.33 0.08

7.5 2286 0.77 0.05 14.0. 4207 1.33 0.08

8.0 2438 0.77 0.05 14.5 4420 1.40 0.08

8.5 2591 0.84 0.05 15.0 4772 1.47 0.09

9.0 2743 0.91 0.05

Cold

Water

Flow

USGPM

Cold

Water

Flow

l/s

Ventilator

Length

Cold

Water

Flow

USGPM

Cold

Water

Flow

l/s

Chart No. 3

NOTES:

a) All types “C” and “H” water wash ventilators have 3/4” (19 mm) hot water connections.

b) Hot water pressure required is 40 to 60 psi (276 to 413 Kpa).

c) Hot water temperature required is 120F to 180F (49 to 82C).

d) All type “C” ventilators have 1/2” (13 mm) cold water inlet connection.

e) All drain connections are 2” (52 mm) diameter and recommended piped to an open hub drain.

Water Wash

TYPE “C” Core Extractors - Water Wash

The SPRING AIR SYSTEMS type “C” core extractor has the highest grease extraction efficiency

available in a water wash ventilator.

Type “C” Extractor

Figure 7

The cold-water spray extends from the entrance to the exit of the VORTEX CHAMBER B, which

provides a secondary coverage as the exhaust air enters the secondary grease extraction

chamber. The exhaust air continues into the secondary extraction chamber, which contains an

additional baffle, F. Residual grease is deposited on the secondary baffle as the exhaust air

REV LOW Hoods

The contaminated exhaust air enters the extractor slot A and flows

through a transition zone to the VORTEX CHAMBER B. The coldwater spray manifold D sprays a fine cold-water mist into the path

of the exhaust air. The cold-water spray causes the grease

particles to cool, congeal and coagulate forming larger grease

globules. The larger heavier globules are more readily removed

through centrifugal force as the exhaust air accelerates through a

complete 270-degree turn around the VORTEX BAFFLE C. The

grease, dirt and lint are deposited on the VARIFLOW BAFFLE G

and the VORTEX BAFFLE C. The VARIFLOW BAFFLE D is also

adjustable along the length of the grease extractor to provide

varying exhaust airflows. The sloping VORTEX BAFFLE C drains

the collected grease to the end of the ventilator into a grease

trough.

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

7

_

Page 10

gyrates through the secondary chamber. After leaving the secondary chamber the exhaust air

enters the ventilator fire damper and duct collar and discharges into the ductwork.

TYPE “H” Core Extractors - Water Wash

The SPRING AIR SYSTEMS type “H” core extractor is a high efficiency water wash grease

extractor.

The contaminated air enters the extractor slot A and flows through

the transition zone to the VORTEX CHAMBER B. The exhaust air

accelerates through a complete 270-degree turn around the

VORTEX BAFFLE C. Centrifugal force causes the grease, dirt and

lint particles to deposit on the PRIMARY VARIABLE FLOW

BAFFLE G and the VORTEX BAFFLE C. The VARIFLOW BAFFLE

D adjustable for varying exhaust flows along the length of the

extractor. The sloping VORTEX BAFFLE C drains the collected

liquid grease to the end of the ventilator and into the grease trough.

The exhaust air continues into the secondary extraction chamber,

which contains an additional baffle, F. Residual grease is

deposited on the secondary baffle as the exhaust air gyrates

through the secondary chamber. After leaving the secondary

chamber the exhaust air enters the ventilator fire damper and duct

collar and discharges into the exhaust ductwork.

Type “H” Extractor

Figure 8

Hood and Damper Assemblies

THE SURFACE FIRE SUPPRESSION SYSTEM is always installed in commercial kitchens.

They are required by national and local code. The surface fire suppression system is a wet

chemical or a water sprinkler system. In the event of a fire on the cooking surface electric

thermostat or fusible links activates the system. These systems must be UL/ULC listed.

NOTE: The exhaust fan should remain on after a surface fire suppression system has activated.

A properly designed hood and damper assembly is UL/ULC listed to impede the spread of fire

from the kitchen hood into the exhaust duct. The UL/ULC listed hood and damper assembly is

an important part of the kitchen ventilation system.

SPRING AIR SYSTEMS has three (3) arrangements of hood and damper assemblies available,

arrangement “T”, “F”, and “D”, thermostatic or fusible link activated systems respectively.

Arrangement “T” : Thermostat Activated

The arrangement “T” hood and fire damper assembly consists of a thermostatically activated

spring loaded fire damper electrically connected to the water wash control panel by three wires.

______________________________________________________________________

8

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

_

Page 11

DAMPER RESET

HANDLE

END VIEW

SOLENOID

SOLENOID PIN

DAMPER RETAINING

CLIP

PIN BACK BACK STOP

DAMPER ROD

TERMINAL BLOCKS

DAMPER RETAINING

CLIP - DOWN

POSITION.

DAMPER CLOSURE

SPRING

FIRE DAMPER PIN

(DAMPER OPEN POSITION)

SIDE VIEW DAMPER OPEN POSITION

BX CONDUIT

TO J-BOX

ON TOP OF

VENTILATOR

SPRING

RETAINING

POST

DAMPER RETAINING CLIP

IN UP POSITION

SIDE VIEW DAMPER CLOSED POSITION

SOLENOID IN ENERGIZED POSITION

80 DEGREE PIN

ROTATION TO DAMPER

CLOSED POSITION.

FIRE DAMPER PIN

(DAMPER CLOSED POSITION)

TERMINAL

BLOCK

DAMPER

CLOSURE

SPRING

ACCESS DOOR LOCATION FOR DAMPER RESET

DAMPER RESET

HANDLE

DUCT COLLAR

ACCESS DOOR FOR DA MPER RESET ON

MODELS CT-B-F & HT-B-F

12 in X 18 in .

TOP OF THE

VENTILATOR

THERMOSTAT J-BOX

FIRE DAMPER RESET HANDLE

DAMPER OPEN POSITION.

FIRE DAMPER RESET HANDLE

DAMPER CLOSED POSITION.

SIDE VIEW RESET HANDLE POSITIONS

Arrangement “T” Fire Damper SOE Enclosure

Figure 9

1

FENWALL DETECTOR

2

DAMPER SOLENOID

4

ARRANGEMENT "T" FIRE DAMPER:

E

THREE (3) WIRES TO EACH SOE ENCLOSURE LOCATED

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

O

120V/1/60 - 3 AMPS - WIRE EACH SOE IN PARALLEL.

S

“T” Electrical Wiring at SOE Enclosure

Figure 10

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

9

_

Page 12

In the event of a fire within the core extractor the thermostat will

activate at 360F (182C). The thermostat energizes a solenoid,

which pulls the fire damper pin releasing the fire damper. The

spring loaded fire damper closes tight against the blade stops.

As the fire damper shuts an electric signal is sent to the water

wash control panel. Once the signal reaches the water wash

control panel the exhaust fan shuts off, shunt trip contacts

close, and the hot water solenoid valve energizes to flood the

interior of the grease extractor. The hot water spray and closed

fire damper provide an effective fire barrier to impede the

spread of fire into the exhaust ductwork.

After the fire has been extinguished, rotating a lever on the

outside of the SOE, FIRE DAMPER JUNCTION BOX, manually

resets the fire damper.

Arrangement “T” & “F” Activated

Figure 11

The arrangement “T” has three advantages:

1. The damper is spring loaded to provide a positive closure and seal when closed.

2. The thermostat set at 360F (182C) responds quickly to activate the spring in the event of a

fire.

3. Pushing the fire test button in the control panel can periodically test the fire damper. The

damper will activate as if in a fire condition and can be manually reset.

Arrangement “F”: Fusible Link Activated, Spring Loaded.

The arrangement “F” hood and fire damper assembly consists of a fusible link fire damper and a

damper end switch interlocked electrically to the water wash control panel with two wires.

In the event of a fire within the core extractors, the fusible link melts, closing the fire damper

against the force of a spring. When the fire damper completely closes, the microswitch is

activated and an electrical signal is sent to the water wash control panel.

MICRO SWITCH

MICRO SWITCH

FIRE DAMPER PIN

10

END VIEW

______________________________________________________________________

SUPPORT BRACKET

FIRE DAMPER PIN

BACK STOP

DAMPER ROD

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

MICRO SWITCH N/0 POSITION

WHEN DAMPER OPEN

FIRE DAMPER

CLOSURE SPRING

FIRE DAMPER PIN

(DAMPER OPEN)

SIDE VIEW DAMPER OPEN POSITION

TERMINAL BLOCK

BX CONDUIT

TO J-BOX

ON TOP OF

VENTILATOR

SPRING

RETAINING

POST

Arrangement “F” Fire Damper

Figure 12

_

MICRO SWITCH N/C POSITION

WHEN DAMPER CLOSED

80 DEGREE PIN

ROTATION TO

DAMPER CLOSED

POSITION.

FIRE DAMPER PIN

(DAMPER CLOSED)

SIDE VIEW DAMPER CLOSED POSITION

FIRE DAMPER

CLOSURE SPRING

TERMINAL

BLOCK

ENCLOSURE

Page 13

When the signal reaches the control panel the exhaust fan is shut off, the building fire alarm

contact close and the hot water solenoid valve is energized, flooding the interior of the grease

extractor with water. The water spray and closed fire damper provide an effective barrier to

impede the spread of fire into the exhaust ductwork.

After the fire has been extinguished, the fire damper must be reset. Open the front access door

of the grease extractor and replace the fusible link.

1

DAMPER END SWITCH

2

Arrangement “F” Fire Damper ENS Enclosure

Figure 13

ARRANGEMENT "F" FIRE DAMPERS:

S

TWO (2) WIRES TO EACH ENS ENCLOSURE LOCATED

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

N

120V/1/60 - 1 AMPS. WIRE EACH ENS IN PARALLEL.

E

Arrangement “D”: Fusible Link Activated, Dead Weight.

The arrangement “D” hood and damper assembly system consists of a fusible link damper

mounted in the exhaust duct collar.

In the event of a fire within the grease extractor the fusible link melts closing the fire damper

against the force of a dead weight mounted on the damper blade. The closed damper impedes

the spread of fire into the exhaust ductwork. After the fire has been extinguished the fire damper

must be reset. To reset the fire damper the fusible link is replaced. Open the access door on the

front of the ventilator. Pull the fire damper open and replace the fusible link to secure the damper

in place. The fusible link should be examined periodically in accordance with the NFPA-96

(SPRING AIR SYSTEMS recommends inspection every six months.)

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

Arrangement “D” Fire Damper cross Section

Figure 13B

11

_

Page 14

EXHAUST FAN

BY OTHERS

4

5

EXHAUST UNIT

MOTOR STARTER

BY OTHERS

3

7

8

9

WATER WASH REV-LOW HOOD

MODEL CD-B-F-6.0/4.0

1

2

N O T E S :

19mm HOT WATER INLET - 0.8 l/s @2.8 kg/cm2

1.

BACKFLOW PREVENTOR SUPPLIED AND INSTALLED

2.

6

BY MECHANICAL CONTRACTOR

3.

19mm HOT WATER LINE TO EACH VENTILATOR SECTION.

4.

POWER SUPPLY TO EXHAUST FAN MOTOR STARTER

(BY OTHERS)

5.

POWER FROM EXHAUST FAN MOTOR STARTER TO

EXHAUST FAN DISCONNECT SWITCH - BY OTHERS

6.

INTERLOCK FROM WATER WASH PANEL MODEL SB10H

TO EXHAUST FAN MOTOR STARTER - 120V/1/60, 5 AMPS.

POWER SUPPLY TO WATER WASH PANEL MODEL SB10H

7.

120V/1/60, 15 AMPS., 24 HOURS/DAY

INTERLOCK TO WET CHEMICAL CYLINDER HEAD FROM8.

WATER WASH PANEL - 120V/1/60 - 2 AMPS

51mm DRAIN CONNECTION TO OPEN HUB DRAIN.9.

SPRING

AIR

SYSTEMS

FAN

ON/OFF

WASH

APPLIANCES

WET CHEMICAL

FIRE SUPPRESSION

CYLINDER

Typical Water Wash Rev-Low Schematic

Figure 14

Figure 14 above shows a water wash Rev-low field piping and wiring schematic. The hood is a

HD-B; a hot water wash hood with a dead weight fusible link fire damper. The water wash panel

is mounted about 42” (1067 mm) off the finished floor. A water line from a hot water tank is

connected to the inlet of the water wash panel. An interconnecting water line is piped from the

outlet of the wash panel to the 3/4” (19 mm) inlet of the REV LOW hood. A 2” (52 mm) drain on

the hood is connected to an open hub drain and then to a grease interceptor. The panel is

powered by 120V/1/60 - 15-amp service. Interconnecting wiring includes power to the remote

motor starter, interlock to the wet chemical cylinder head, and optional power to the supply fan

and supply fresh air damper. All control wiring is 120V/1/60.

The water wash hood washes in place at the end of each cooking day. For more detail

information covering the water wash control panels available please refer to the Spring Air

Systems “Ventilator Engineering Manual” or the individual water wash panel specification sheets.

______________________________________________________________________

12

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

_

Page 15

Dry REV LOW Hoods - DD-B-F

Manual Wash: Type “D” Ventilator

The type “D” incorporates a core extractor similar to type

“H” but without the wash manifolds. The type “D” is

recommended for light to medium cooking applications

where grease is minimal.

The liquefied grease collects on internal baffles as

described in the “Grease Extractor” section of the

manual. The baffles are designed to drain the liquefied

grease to the end of the ventilator and into the grease

trough and grease cup.

To clean the grease extractor, the front access door and

grease cup are removed and manually washed in a

kitchen sink.

The two interior baffles and grease trough should be

wiped down with a damp cloth soaked in a water and

mild detergent mixture. If the cooking application

generates high temperatures, the grease trough may

require additional cleaning and/or scraping to remove

baked-on solidified grease.

Type “D” Grease Extractor

Figure 15

TYPE “D” GREASE EXTRACTOR

The SPRING AIR SYSTEMS type “D” core extractor is a high efficiency extractor. The type “D”

core extractor removes grease, dirt and lint through centrifugal force. Removing the front access

door and wiping the interior with a damp cloth manually wash the core extractor chamber.

The contaminated exhaust air enters the slot A and flows through the transition zone to the

VORTEX CHAMBER B. The exhaust air

accelerates through a complete 270degree turn around the VORTEX

BAFFLE C. Centrifugal force causes the

grease, dirt and lint particles to deposit

on the PRIMARY VARIABLE FLOW

BAFFLE G and VORTEX BAFFLE C.

The sloping VORTEX BAFFLE C drains

collected grease to the end of the

ventilator into the grease cup H.

The exhaust air continues into the

secondary extraction chamber, which

contains an additional baffle, F.

Residual grease is deposited on the

secondary baffle as the exhaust air

gyrates through the secondary chamber.

Type “D” Extractor

Figure 16

______________________________________________________________________

_

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

13

Page 16

REV LOW Exhaust Air Calculations

Single Row Wall Mount

The Revlow Hood exhaust air formula is as follows:

Once the cooking line up has been established, the TOTAL EXHAUST (TEX) is calculated by

adding each individual NEV valve.

TEX = (NEV of appliance No. 1 + NEV of appliance No. 2 + NEV of appliance No. 3 +....)

Refer to Chart No. 4 for EXHAUST FLOW RATE (EFR) for the various types of Spring Air

Systems hoods.

The TOTAL EXHAUST (TEX) is determined by adding the NET EXHAUST VOLUME (NEV) CFM

(l/s) for each individual cooking appliance. The NET EXHAUST VOLUME (NEV) for individual

appliances varies depending on the amount of smoke, particulate, and grease generated, the

surface temperature and whether the appliance is gas or electric. Gas appliances require higher

NEV because of the high flue gas temperatures. Chart No. 4 includes typical “NEV” values for

most cooking applications. Consult the factory if an appliance is not listed.

It is important to know the dimensions of each appliance. The NET EXHAUST VOLUME (NEV)

decreases and increases proportionally to the length of some appliances. These appliances are

indicated in Chart No. 4 with length dimensions. For lengths other than indicated prorate the

value in the chart.

WARNING

The REV LOW method is an excellent guide to assist in calculating the TOTAL

EXHAUST (TEX) volumes, but consideration must be made for the conditions

within the kitchen. i.e. location of the hood to doors, windows, and pass through

which might create a draft. Consult the factory when unusual site conditions

exist.

The total exhaust must correspond to the minimum allowable per the Spring Air

Systems UL and ULC listing. Check with factory or go directly to the UL web site

www.ul.com

The complete kitchen ventilation system must be balanced, such that a minimum

of 80% continuous heated makeup air is provided through a dedicated makeup

air system or the kitchen A/C units. It is good engineering practice to provide

this heated fresh air into the kitchen space. The heated fresh air should not

exceed 90 percent of the total exhaust volume.

Determining REV LOW Hood Dimensions

Hood Length:

The hood length should equal the width of all the cooking appliances to be covered by the hood

plus allow and additional 6” (152 mm) overhang on either end of the cooking line up.

______________________________________________________________________

14

_

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

Page 17

Hood Width: Single Row Wall Mounted

The hood width should be equal the depth of the largest appliance from the wall plus allow for an

additional 12” (305 mm) overhang from the front of the appliance. The hood should be a

minimum 47” (1194).

Net Exhaust Air (NEV)Volume Chart for All RevLow hoods

Cooking Appliances Net Exhaust Volume

Description Length (in) Electric CFM Gas CFM

Charbroiler 24 24 900 1125

Charbroiler 30 30 1100 1325

Charbroiler 34 34 1300 1600

Charbroiler 36 36 1440 1800

Charbroiler 48 48 1600 2000

Charbroiler 60 60 1800 2250

Charbroiler 72 72 2250 2800

Chicken broaster 20 20 200 200

Chicken broaster 30 30 300 300

Conveyor Oven one deck 90 90 325 430

Conveyor Oven two deck 90 90 430 575

Combi Oven 51 850 880

Comb. Wood/Gas Brick Oven 48 48 - 1200

Comb. Wood/Gas Brick Oven 48 48 - 1200

Donut Fryer 32 32 285 430

Donut Fryer 72 72 320 480

Fry Top 36 36 300 340

Fryer Pitco model 14 17 - 150

Fryer 15 15 - 190

Fryer 16 16 100 200

Fryer 18 18 125 250

Fryer 24 24 150 300

Griddle 24 24 200 225

Griddle 36 36 250 275

Gyro 18 18 - 175

Hot Top Range 48 48 700 880

Induction Cookers 18 72 n/a

Kettle one with stand 28 28 130 130

Kettle Single 45 45 250 250

Microwave 24 24 30 -

Oven 38 38 180 225

Pasta Cooker 18 18 150 150

Pizza Oven 60 60 260 325

Rotisserie Oven 42 42 550 750

Rotisserie Oven 66 66 960 1250

Range stock pot 24 24 255 300

Range two burner regular duty 12 12 180 225

Range four burner regular duty 24 24 275 315

Range six burner regular duty 36 36 415 475

Salamander Broiler 36 36 270 350

Spreader 12 12 10 10

Steamer 30 30 150 Solid Fuel 36” 36 - 1800

Solid Fuel – 60” 60 - 2400

Tilting Skillet 42 42 370 500

Toaster 18 18 50 50

Wok – one hole 30 30 - 500

Wok – two hole 60 60 - 850

Wok –three hole 90 90 - 1400

Woodstone Oven 64 64 - 400

Upright Broiler 2 shelf 36 36 540 700

Upright Broiler 3 shelf 36 36 810 1050

Warming Lamp 18 18 30 30

Chart No. 4

______________________________________________________________________

Spring Air Systems RevLow Engineering Manual Revision 2.0 -021902

15

_

Page 18

Island REV LOW Hoods

The Island Revlow Hood exhaust air formula is as follows:

Once the cooking line up has been established, the TOTAL EXHAUST (TEX) is calculated by

adding each individual NEV valve.

TEX = (NEV of appliance No. 1 + NEV of appliance No. 2 + NEV of appliance No. 3 +..)x 1.10

Refer to Chart No. 4 for NEV of various appliances.

The TOTAL EXHAUST (TEX) is determined by adding the NET EXHAUST VOLUME (NEV) CFM

(l/s) for each individual cooking appliance and then multiplying by a factor of 1.1. The NET

EXHAUST VOLUME (NEV) for individual appliances varies depending on the amount of smoke,

particulate, and grease generated, the surface temperature and whether the appliance is gas or

electric. Gas appliances require higher NEV because of the high flue gas temperatures. Chart

No.4 includes typical “NEV” values for most cooking applications. Consult the factory if an

appliance is not listed.

It is important to know the dimensions of each appliance. The NET EXHAUST VOLUME (NEV)

decreases and increases proportionally to the length of some appliances. These appliances are

indicated in Chart No. 4 with length dimensions. For lengths other than indicated prorate the

value in the chart.

Determining REV LOW Island Hood Dimensions

Hood Length:

The hood length should equal the width of all the cooking appliances to be covered by the hood

plus allow and additional 9” (230 mm) overhang on either end of the cooking line up.

NOTE 3

41.00

(1041)

APPLIANCES

10.00 (254)

3.00 (76)

NOTE 5

NOTE 2

NOTE 2

NOTE 7

NOTES:

EXHAUST DUCT COLLAR WITH 1" (25mm) PERIMETER FLANGE.

1.

MINIMUM WIDT H 54" (13 72mm).

2.

MAXIMUM LENGT H 14'- 0" (426 7mm). FOR GREA TER LENGTH

3.

USE MULTIPLE UNITS.

HANGER ROD BY INSTALLER.

4.

RECOMMENDED MOUNTING HEIGHT 6'6" (1980) FROM FINISHED FLOOR.

5.

6.

TYPICAL HANGER ROD BRACKET LOCATION - 4 SUPPLIED.

7.

DUCT LENGTH TO SUIT EXHAUST VOLUME.

8.

STAINLESS STEEL GREASE CUP.

9.

REMOVEABLE GREASE INSERT.

10.

VARIFLOW BAFFL ES.

PLAN VIEW

NOTE 6

NOTE 4

NOTE 9

NOTE 10

NOTE 8

APPLIANCES

SECTION VIEW

Typical Island REV LOW dimensional drawing model DD-B-F-I

Two Hoods shown Figure 17

______________________________________________________________________

16

_

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

23.00

(584)

3.00(76)

Page 19

Hood Width: Island REV LOW

The hood width should be equal the depth of the largest appliance from the wall plus allow for an

additional 12” (305 mm) overhang from the front of the appliance. Each hood should be a

minimum 54” (1372mm).

REV LOW Exhaust Volume Vs Exhaust Duct Size

Exhaust

Volume

CFM l/s

450 212 10 x 4 254 x 102 3500 1652 10 x 33.5 254 x 851

500 236 10 x 4.5 254 x 114 3625 1711 10 x 34.5 254 x 876

625 295 10 x 6.0 254 x 152 3750 1770 10 x 36.0 254 x 914

750 354 10 x 7.0 254 x 178 3875 1829 10 x 37.0 254 x 940

875 413 10 x 8.0 254 x 203 4000 1888 14 x 27.0 356 x 686

1000 472 10 x 9.5 254 x 241 4125 1947 14 x 28.0 356 x 711

1125 531 10 x 10.5 254 x 267 4250 2006 14 x 29.0 356 x 737

1250 590 10 x 12.0 254 x 305 4375 2065 14 x 30.0 356 x 762

1375 649 10 x 13.0 254 x 330 4500 2124 14 x 30.5 356 x 775

1500 708 10 x 14.0 254 x 356 4625 2183 14 x 31.5 356 x 800

1625 767 10 x 15.5 254 x 394 4750 2242 14 x 32.5 356 x 826

1750 826 10 x 16.5 254 x 419 4875 2301 14 x 33.0 356 x 838

1875 885 10 x 18.0 254 x 457 5000 2360 14 x 34.0 356 x 864

2000 944 10 x 19.0 254 x 483 5125 2419 14 x 35.0 356 x 889

2125 1003 10 x 20. 254 x 508 5250 2475 14 x 36.0 356 x 914

2250 1062 10 x 21.5 254 x 546 5375 2537 14 x 36.5 356 x 927

2375 1121 10 x 22.5 254 x 572 5500 2596 14 x 37.5 356 x 953

2500 1180 10 x 24.0 254 x 610 5625 2655 14 x 38.5 356 x 978

2625 1239 10 x 25.0 254 x 635 5750 2714 14 x 39.0 356 x 991

2750 1298 10 x 26.0 254 x 660 5875 2773 14 x 40.0 356 x 1016

2875 1357 10 x 27.5 254 x 699 6000 2832 14 x 41.0 356 x 1041

3000 1416 10 x 28.5 254 x 724 6125 2891 14 x 42.0 356 x 1067

3125 1475 10 x 30.0 254 x 762 6250 2950 14 x 42.5 356 x 1080

3250 1534 10 x 31.0 254 x 787 6375 3008 16 x 38.0 406 x 965

3375 1593 10 x 32.0 254 x 813 6500 3067 16 x 39.0 406 x 991

1. If exact exhaust volume is not indicated use duct size closest to required exhaust.

2. Model B water wash hoods and dry extractors have 1.5” W.C. (0.38kPa) for exhaust

flow rates from 90 to 450 CFM/ft (140 to 700 l/s/m)

Duct Collar Size Exhaust

Volume

W x L

in x in

W x L

mm x mm

CFM l/s

Chart No. 5

Duct Collar Size

W x L

in x in

W x L

mm x mm

Make Up Air/Supply Air

Introducing fresh air back into the kitchen is generally recommended as good engineering

practice. The amount of make up air should not exceed the total exhaust to maintain a negative

pressure within the kitchen. Inadequate amounts of fresh replacement air will result in cold

drafts, hot spots, poor hood smoke capture and generally uncomfortable working conditions

within the kitchen and uncomfortable environment in the dining room for the customers.

One excellent method of introducing makeup air is through a make up air plenum built into the

ventilator. SPRING AIR SYSTEMS has two optional make up air arrangements; MP and MC.

Directing the make up air through the exhaust hood ensures the correct quantity of make up air

and good air distribution.

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

17

_

Page 20

MP

Model DD-B-F-MP

Figure 18

MC

Model DD-B-F-MC

Figure 19

The make up air is discharged into the kitchen through

a perforated panel located on the front of the Rev-Low

ventilator. This method provides very low discharge

velocity. The fresh air is heated to 55F (13C). The

total supply is 80% to 90% of the total exhaust air

volume. The make up air plenums have 1/2” foam

insulation on the interior surfaces for sound attention

and insulation. A fire damper is located at the supply

air inlet on top of the ventilator.

The make up air is discharged into the kitchen down

through a perforated panel located on the front of the

Rev-Low ventilator. The fresh air is directed down

toward the floor in front of the cooking appliances.

This method is best suited for warm climates. The

fresh air is tempered to 55F (13C) and between 70%

to 80% of the total exhausts air volume. A fire

damper is located at the supply air inlet on top of the

ventilator.

______________________________________________________________________

18

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

Two Models DD-B-F-I-MC

Figure 20

_

Page 21

The REV LOW System Approach

The Spring Air Systems REV LOW Hood does not work alone. A good commercial kitchen

exhaust fan, supply unit, and hood controller are required.

Spring Air Systems Inc. designs a supply unit especially for the REV LOW hoods; the SFA series.

The SFA is available in a vertical or horizontal arrangement, indoor or outdoor and with integral

gas reheat and remote gas and electric reheat.

SFA-OV Unheated Makeup Air Unit

The SFA-V unit is designed and constructed

specifically for commercial kitchen applications.

The SFA-V is a vertical supply unit that introduces

unheated fresh air directly into a duct-mounted

electric or gas-heating unit. The vertical

arrangement requires minimum roof space. The

roof mounted SFA-V is complete with filters, supply

fan motorized discharge damper and end switch,

fan motor, belts, drives and perimeter curb. Supply

air capacities range from 500 to 8,000 CFM. The

SFA-OV is used in conjunction with a remote indoor

gas fired duct heater or electric heating coil.

SFA-OV

Figure 21

SFA-OH Unheated Makeup Air Unit

The SFA-OH unit is designed and constructed

specifically for commercial kitchen applications.

The SFA-OH is a horizontal supply unit that

introduces unheated fresh air directly into a ductmounted electric or gas-heating unit. The roof

mounted SFA-OH is complete with filters, supply fan

motorized inlet damper and end switch, fan motor,

belts, drives and perimeter curb. Supply air

capacities range from 500 to 8,000 CFM. The SFAOH is used in conjunction with a remote indoor gas

fired duct heater or electric heating coil.

SFA-OH

Figure 22

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

19

_

Page 22

FRESH AIR UNIT MODEL SFA10-OV

750 CFM @ 0.50" W.C.

C/W 0.25 HP, 120V/1/60 MOTOR

5

10'0" MINIMUM

EF-1 - MODEL PNU135 -RG

C/W 1.0 HP, 120V/1/60 MOTOR

2

EXHAUST FAN

1515 CFM @ 1.75" W.C.

3

1

EXHAUST FAN EF -1

MOTOR STARTER

N O T E S :

POWER SUPPLY TO EXHAUST FAN MOTOR STARTER - 120V/1/60, 8.8 FLA

1.

POWER FROM EXHAUST FAN MOTOR STARTER TO EXHAUST FAN

2.

DISCONNECT SWITCH - 120V/1/60, 8.8 FLA

POWER FROM RPD20 CONTROLLER TO EXHAUST FAN MOTOR

3.

STARTER COIL - 120V/1/60.

POWER SUPPLY TO SFA10-OV MOTOR STARTER - 120V/1/60, 8.8 FLA

4.

POWER FROM SFA10-OV MOTOR STAR TER TO SFA10-OV

5.

DISCONNECT SWITCH - 120V/1/60, 8.8 FLA

POWER FROM RPD20 CONTROLLER TO SFA10-OV MOTOR

6.

STARTER COIL - 120V/1/60.

9.

POWER FROM RPD20 CONTROLLER TO SUPPLY FRESH AIR

SFA10-OV UNIT MOTORIZED DISCHARGE DAMPER 120V/1/60

10.

POWER SUPPLY TO RPD11 CONTROLLER - 120V/1/60, 15 AMPS.

11.

INTERLOCK TO SHUNT TRIP - DRY CONTACT - 5 AMPS. MAX.

(SHUNT TRIP SUPPLIEND BY ELECTRICAL CONTRACTOR)

TO WET CHEMICAL FIRE SUPPRESSION CYLINDER HEAD MICRO SWITCH

12.

120V/1/60, 2 AMPS. - CONNECT TO N/O CONTACT.

POWER SUPPLY TO THE 20 KW ELECTRIC DUCT HEATER - 208V/3/60 - 55 FLA

13.

CONTROL WIRING TO ELECTR IC DUCT HEATER THERMOSTAT

14.

INTERLOCK TO ELECTRIC DUCT HEATER FROM RPD20 CONTROL - 120V/1/60

15.

15

750 CFM FRESH AIR

HEATED TO 70°F

DISCHARGED INTO

THE KITCHEN AREA

ELECTRIC DUCT HEATER

20 KW WITH SCR CONTROL

13

14

WET CHEMICAL

FIRE SUPPRESSION

CYLINDER

9

12

EXHAUST SUPPLY

FAN

OCCUPIED/UNOCCUPIED

SUMMER/WINTER

SUPPLY UNIT MAU-1

MOTOR STARTER

6

4

10

11

MODEL DD-B-F-6.0/3.92

RPD11

REV-LOW

HOOD

CONTROLLER

FAN

APPLIANCES

Typical REV LOW Hood Schematic with electric heating

Figure 23

The kitchen and dining room must be balanced to provide a proper system. The schematic

shows a typical 100% exhaust, with 80% fresh air supplied directly to the kitchen through some

type of heating unit. A electric duct heater as shown above or gas, steam or hot water can

supply this heat. The remaining 20% required to balance the restaurant must be supplied through

the dining room air conditioning unit(s) economizer or through some other makeup air unit. (Such

as a Spring Air Systems SFA-IGO Unit)

SLAB

NFPA-96

ALL WELDED

DUCT

HANGER

RODS

FINISHED CEILING

FINISHED FLOOR

______________________________________________________________________

20

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

_

Page 23

SFA-IGO Heated Makeup Air Unit

General

The SFA-IGO is an indirect, gas-fired

make-up air unit for commercial

applications. The unit is designed to

introduce 100% fresh air into a

commercial building. When the amount of

heated makeup air required exceed the air

conditioning unit capacity use the SFAIGO. The SFA-IGO is roof-mounted on a

perimeter curb or sleeper with optional

turndown plenum. Supply air capacities

range from 500 to 8000 CFM with burners

from 80,000 to 600,000 BTU/hr output.

Typical SFA-IGO

Figure 24

Heating Capacity:

The total heating required is equal to the following:

Heating Capacity (BTU/hr) = Supply Volume (CFM) x 1.09 x (TI - TO)

Where: TI = Supply discharge temperature required (F)

TO = winter design temperature for the area (F)

Use the Chart No. 6 below for selection of burner required.

SFA-IGO BURNER ENGINEERING DATA

HEATER

SIZE

INPUT OUTPUT (IN) (SCFH)

100

150

200

250

300

350

400

(1)

Not available with power vent.

(2)

112,500 BTU/hr with power vent.

(3)

150,000 BTU/hr with power vent.

(4)

All units require the following clearances: Front: 48” Bottom: 0” Sides: 24” Rear: 6”

(1)

100,000

(2)

150,000

200,000

250,000

300,000

350,000

400,000

BTU/HR GAS PIPE

CONNECTION

80,000

120,000

(3)

160,000

187,000

225,000

262,500

300,000

3/4

3/4

3/4

3/4

3/4

3/4

3/4

Chart No. 6

NATURAL

GAS FLOW

100

150

200

250

300

350

400

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

21

_

Page 24

950 CFM @ 1.75" W.C.

EXHAUST FAN ROOF CURB

EXHAUST DUCT SUPPLIED

AND INSTALLED PER NFPA-96

EXHAUST DUCT ENCLOSURE

FROM BOTTOM OF CURB TO

BELOW ROOF JOIST 24" TYPICAL

EXHAUST FAN

MODEL PNU120-RG

C/W 120V/1/60

3/4 HP MOTOR

24.00

10" DIA FLEX DUCT

10'0" MINIMUM

SPRING AIR SYSTEMS MAKEUP AIR UNIT

MODEL SFA10-IGOD

750 CFM @ 0.50" W.C.

0.33 HP 120V/1/60

10"X 24" DUCT DROP FROM SFA10

EXTERNALLY INSULATED

HANGER RODS

EXHAUST DUCT COLLAR C/W

1" PERIMETER FLANGE AND

ARRANGEMENT "D" FIRE DAMPER

10" X 8" - 950 CFM @ 1.25" W.C.

SPRING AIR SYSTEMS

MODEL DD-B-F 6.0/3.92

APPLIANCES

FINISHED CEILING

24" X 24" DIFFUSER

375 CFM EACH

FROM HEATED MAKEUP

Typical REV LOW Hood Schematic with SFA-IGO

Figure 25

REV LOW Hood Controllers

Spring Air Systems Inc. manufacturers a

REV LOW Hood Controller model RPD-P

(For use with gas or electric duct

heaters) for complete single switch

operating of the exhaust/supply system.

The operator rotates the selector switch

to the occupied position and the exhaust

and supply fans energize, the fresh air

damper opens, and the air conditioning

unit economizers open (optional). In

addition, the panels may be interlocked

10"

SPRING AIR SYSTEMS INC.

MODEL RPD20

EXHAUST SUPPLY

OCCUPIED / UNOCCUPIED

SUMMER/WINTER

to the shunt trip, surface fire suppression

system or building management system.

Spring Air Systems can also supply the

motor starters from stock.

6.5"

4"

RPD11 Controllers

Figure 26

FINISHED FLOOR

MODEL RPD11

EXHAUST SUPPLY

OCCUPIED/UNOCCUPIED

SUMMER/WINTER

______________________________________________________________________

22

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

_

Page 25

Specification

Refer to individual specification sheets for the model and type of REV LOW hood selected. See

Chart No. 1 for a list of the various alternatives available. Refer to the individual specification

sheets for SFA models and REV LOW hood controllers available.

REV LOW Work Sheet

Date Job Name

Representative Job Location

Engineering Food Service

Item

No.

Description of Appliance Gas/

Electric

Length

(in)

NEV*

(CFM)

Totals

*See chart No. 4 in REV LOW Engineering Manual

Hood Length (Total Length above + 12” for single row +18” for Island)

Minimum CFM (100 CFM/ft x length (ft) or total NEV above)

Exhaust Duct Collar (from Chart No. 5 in Engineering Manual)

______________________________________________________________________

Spring Air Systems REV LOW Engineering Manual Revision 2.0 -021902

23

_

Page 26

Other Fine Products From

SPRING AIR SYSTEMS...

• Water Wash Ventilators

♦ Hot Water Wash

♦ Cold Water Spray/Hot Water Wash

♦ Water Wash Control Panels

• Dry Extractor Hoods

• REV-LOW Hoods

• Cartridge Hoods

• Filter Hoods

• Surface Fire Suppression

• Commercial Kitchen Exhaust Fans

• Kitchen Enviro Systems

♦ KES - 100% Exhaust

• Commercial Kitchen Supply Units

• Compensating Hoods

• Exhaust Fans

• Supply Fans

• Commercial Kitchen Control Panels

• Variable Speed Exhaust/Supply Systems

Phone: 905-338-2999, FAX: 905-338-1079, e-mail info@springairsystems.com

www.springairsystems.com

Loading...

Loading...