KES Enviro

Maintenance Manual

___________________________

Spring Air Systems Inc., Oakville, Ontario

Phone (905) 338-2999, Fax (905) 338-0179, info@springairsystems.com

KES Enviro Maintenance Manual

Table of Contents

Introduction....................................................................................... 1

The System...................................................................................... 1

Control System: Water Wash Ventilator SB, SBA Panels............... 2

Control System: Water Wash Ventilator AP, MP Panels.................. 4

Filter Hood or Dry Grease Extractor................................................. 5

Control Circuit.................................................................................. 7

Setting the Day and Time................................................................ 13

Setting the Weekday Fan “ON” and “OFF” Times............................ 14

Setting Weekend Operation............................................................. 15

Odor Spray Systems........................................................................ 15

Where to Purchase Filters................................................................ 19

Replacement Filter Equivalents........................................................ 19

Trouble Shooting.............................................................................. 20

KES Maintenance Sch edule............................................................ 22

KES Enviro Start-Up Report............................................................. 24

Filter Frequency Chart...................................................................... 26

KES OPERATIONS AND MAINTENANCE MANUAL

INTRODUCTION

The SPRING AIR SYSTEMS INC. kitchen Enviro system (KES), Exhaust Cleaning Assembly for Kitchen

Exhaust Duct, “Enviro Unit” is ULC and UL listed for use in a commercial kitchen exhaust system. KES

units are available in sizes ranging from 1,000 CFM to 40,000 CFM for indoor or outdoor applications.

The primary function of a KES Enviro unit is to filter the grease, lint and dust particles and remove the odor

from the exhaust air.

The Underwriters’ Laborato ries of Canada Limited (ULC) listing allows the use of non-NFPA-96 exhaust

ductwork after the exhaust air is discharged from the KES unit. In other words the discharge ductwork can

be treated similar to standard HVAC ducting. Also after the kitchen exhaust air has been treated with the

KES unit the exhaust can be discharged outdoors at low levels.

The Underwriters Laboratories Inc. (UL) listing allows the kitchen exhaust air to be discharge to atmosphere

at low levels.

Prior to any installation the installer must seek approval from the authorities having jurisdiction.

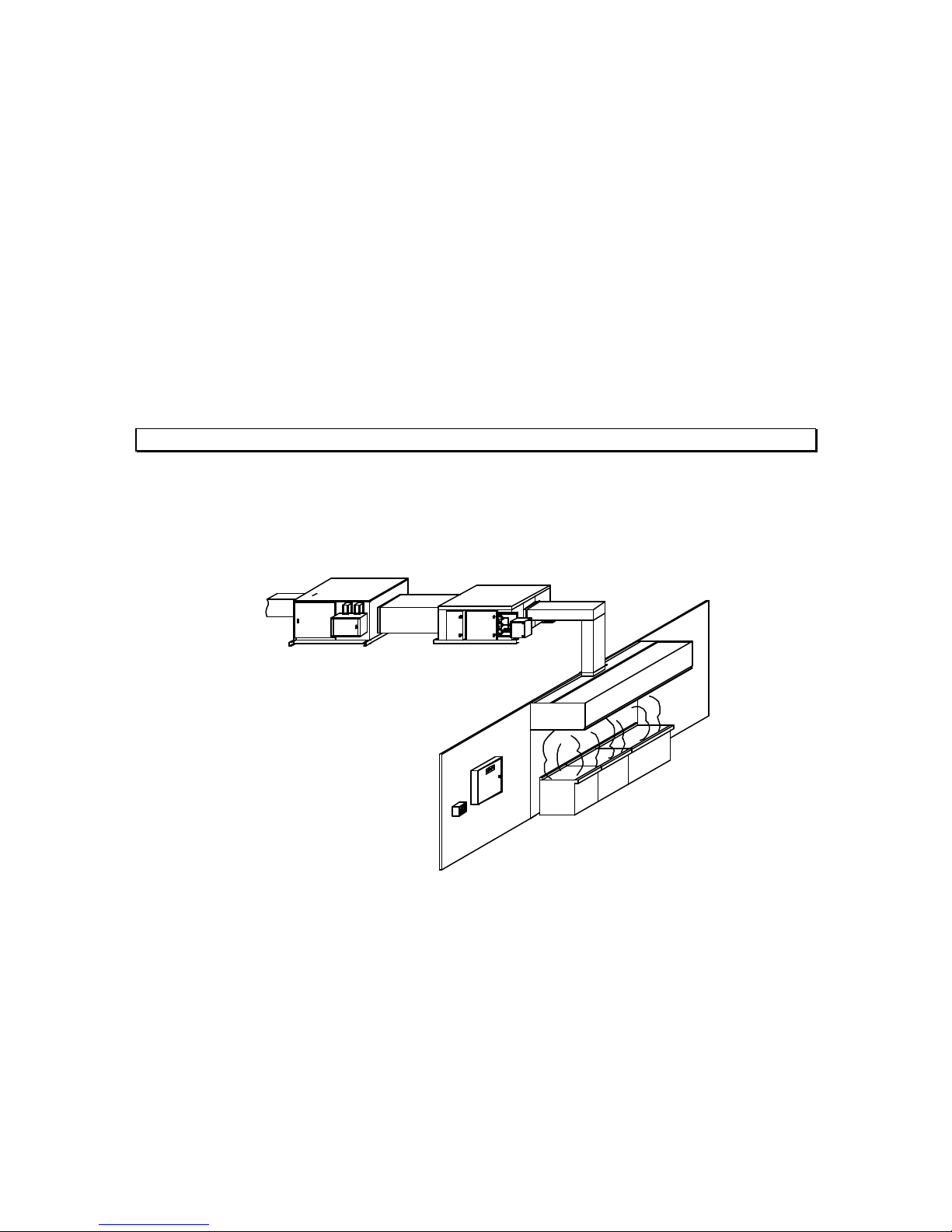

THE SYSTEM

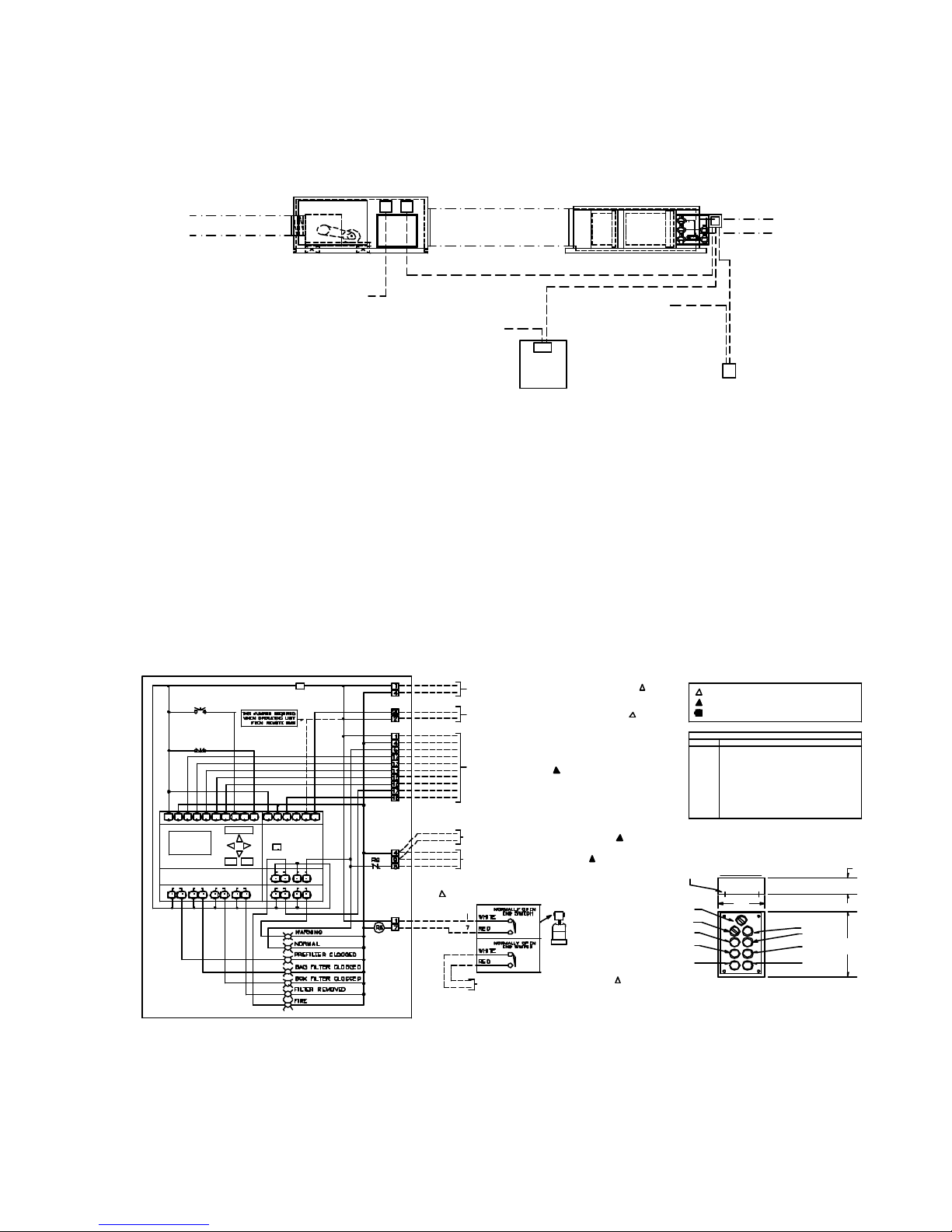

The grease -laden air rises from the cooking equipment into a UL or ULC exhaust hood. The exhaust hood

removes some of the airborne grease particulate. Typically most micron and submicron particles escape

Exhaust to

atmophere at

low level

Discharge Ductwork

KESF Fan Box

Interconnecting Ductwork

KES-ISH Filter Box

Water Wash

Panel

Remote

RPW(D) Panel

NFPA-96 Ductwork

Listed Exhaust Hood

Appliance Line-up

into the exhaust ductwork. The exhaust ducting is connected from the hood to the inlet of the KES Enviro

unit. This exhaust ductwork must be supplied and installed in accordance with the NFPA -96 code.

KES System Schematic

Figure 1

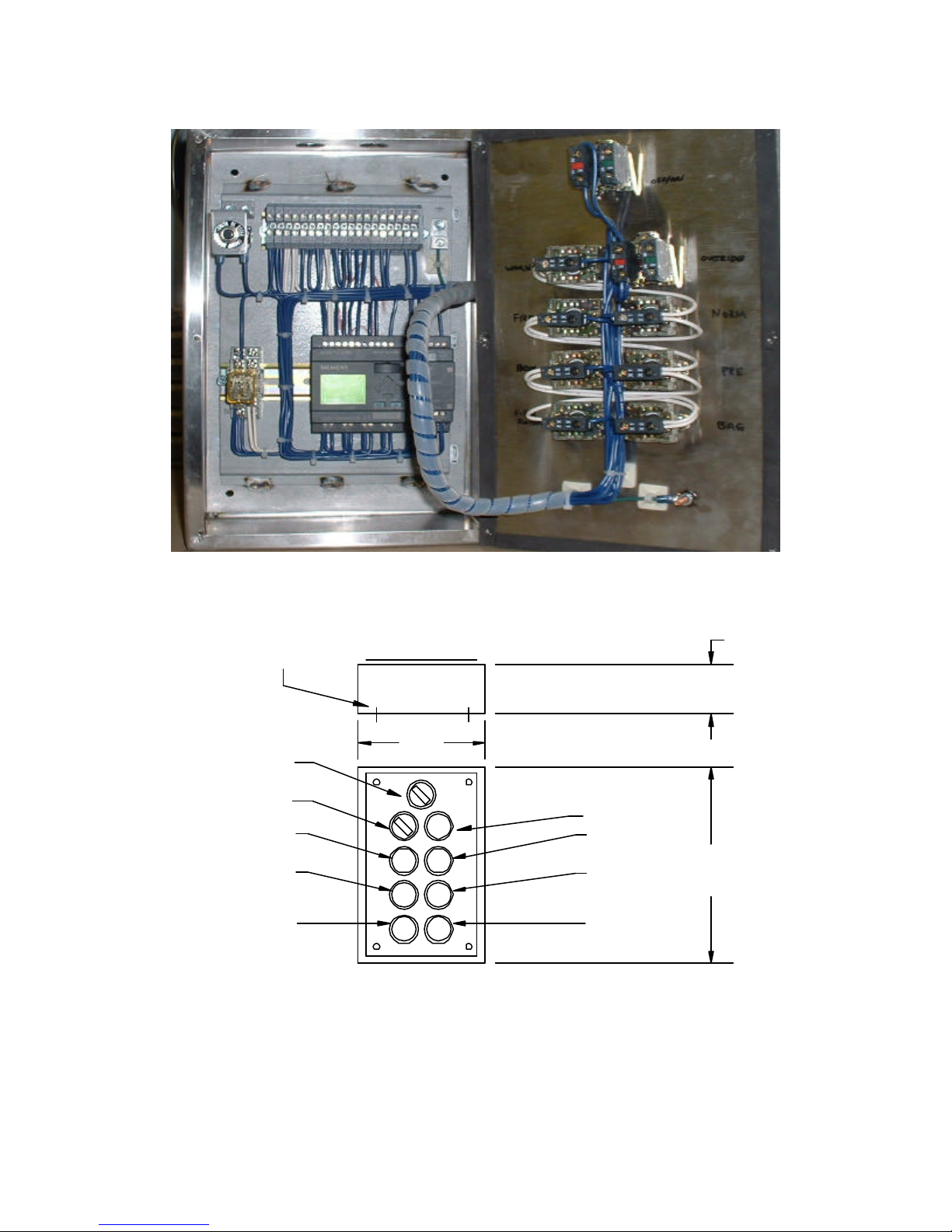

Within the KES unit the exhaust air travels through three stages of particulate filters:

1Two (2) inches pleated - 30 percent ASHRAE 52-76 prefilters.

2Twenty-one (21) to twenty -two (22) inch bag - 90 percent ASHRAE 52-76 filters.

3Twelve (12) inches box - 95 percent DOP filters.

Enviro Maintenance Manual 2004

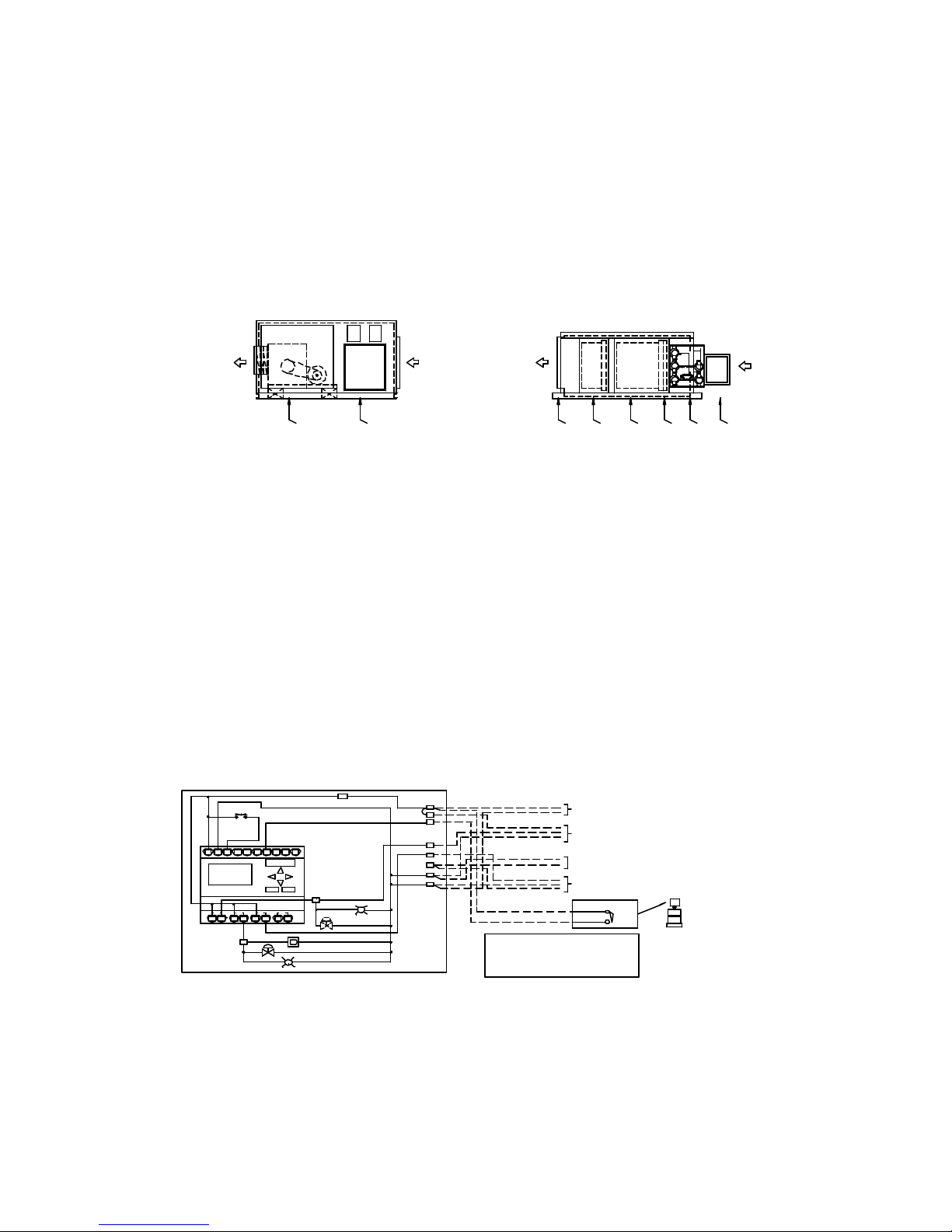

KES-ISH

KESF

Once through the particulate filter sections the exhaust air enters the optional odor removal section. The

odor section is only required when discharging cooking smells may be offensive. This section consists of

two optional odor removal systems.

1.Odor Cells filled with activated alumina impregnated with potassium permanganate. The odor is controlled

through a combination of sorption and the chemical modification of the gaseous contaminates. The

odor media is non-toxic and non-flammable.

1.Odor spray solution. The odor is control by spraying an odor reducer into the exhaust air stream

intermittently during the operation of the cooking systems.

EXHAUST OUTLET

TO THE OUTDOORS

Exhaust Fan

Odour Removal Section

EXHAUST OUTLET

TO THE KESF FAN

Fire Damper

Box Filter

Bag Filter

2 inch prefilter

Pressure switches

LV-10 Panel

2.

KES-ISH and KESF Enviro components

Figure 2

The exhaust air is discharged from the KES unit through a single width, single inlet (SWSI) or double width,

double inlet (DWDI) exhaust fan. The discharge ductwork transfers the exhaust air outdoors.

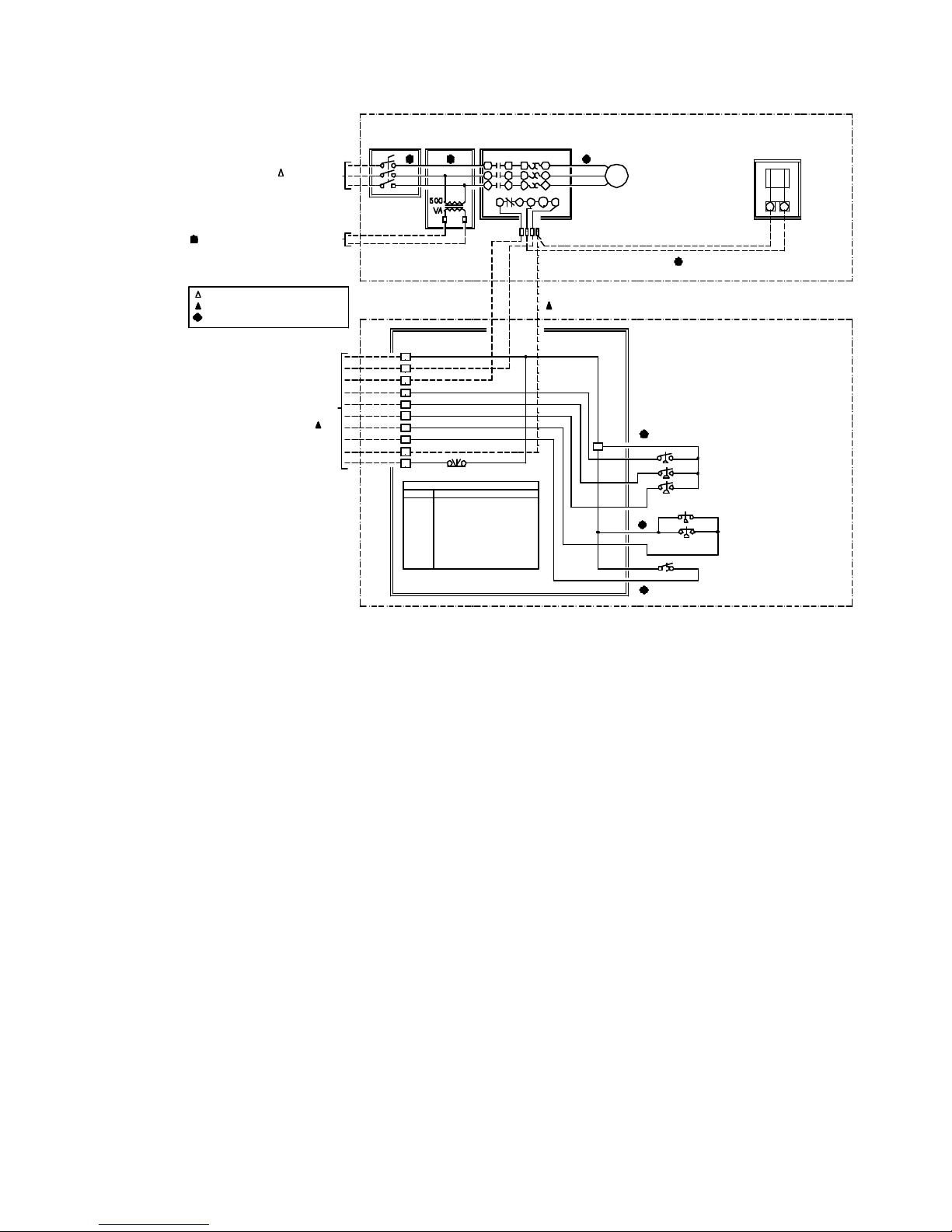

CONTROL SYSTEM

Water Wash Ventilator System: SB, SBA Panels

The KES unit off/on operation is controlled from the SB, or SBA water wash ventilator control panel. Power

is fed to the RPW10 panel through terminals 1 & 4. When the fan selector switch on the water wash control

panel closes a signal is sent through terminal 3 to the RPW10 panel to activate the KES unit.

INTERNAL WIRING BY SPRING AIR

FAN SWITCH

OFF/ON

L N

Mo 09:00

01. 20. 03

LOGO!

Q1

Q2

1 2

1 2 1 2Q31 2

H

I4I1 I2 I3 I5 I6 I7

ESC OK

HOT WATER SOLENOID

CURCUIT BREAKER

I8

Q4

B

DETERGENT

PUMP

WASH PILOT

C

FAN PILOT

OPTIONAL COLD

WATER SOLENOID

1

1

7

3

8

9

4

4

G

ALL REMOTE ELECTRIAL WIRING

SHALL CONFORM TO ALL LOCAL

AND NATIONAL CODE REQUIREMENTS

REMOTE WIRING BY TRADES

1

POWER SUPPLY TO THE SB10H/C PANEL

4

24 HOURS/DAY - 120V/1/60 - 15 AMPS

1

THREE (3) WIRES TO THE KES UNIT RPW10 CONTROL

3

PANEL - 120V/1/60 - 5 AMPS MAXIMUM.

4

4

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

9

MOTOR STARTER - 120V/1/60 - 2 AMPS MAXIMUM

8

(OPTIONAL) THREE (3) WIRES TO SUPPLY AIR MOTORIZED

4

SHUTOFF DAMPER AND END SWITCH 120V/1/60

9

2 AMPS MAXIMUM.

NORMALLY OPEN

END SWITCH

1

WHITE

RED

7

NOTE 1:

TWO (2) WIRES TO THE

WET CHEMICAL CONTROL

HEAD 120V/1/60 - 1A.

EXHAUST INLET

FROM THE HOOD

Typical KES wiring to SB10C water wash panel

Figure 3

Enviro Maintenance Manual 2004

The “NORMAL” operation pilot energizes on the RPW10 remote kitchen annunciation panel. After 30

seconds the RPW10 control circuit is activated. The RPW10 is a stainless steel panel located remote from

the SB or SBA panel. See Figure 5 for RPW10 wiring and dimensions. The KES exhaust fan motor is

energized through the terminals 5 & 4 to the LV10 J-Box located on the KESF fan section. See figure 11 for

internal wiring of the LV10 J-box. See figure 3 or 5 for a SB water wash panel.

Mo 09:00

01. 20. 03

LOGO!

Typical KES wiring to SBA10C water wash panel

Figure 4

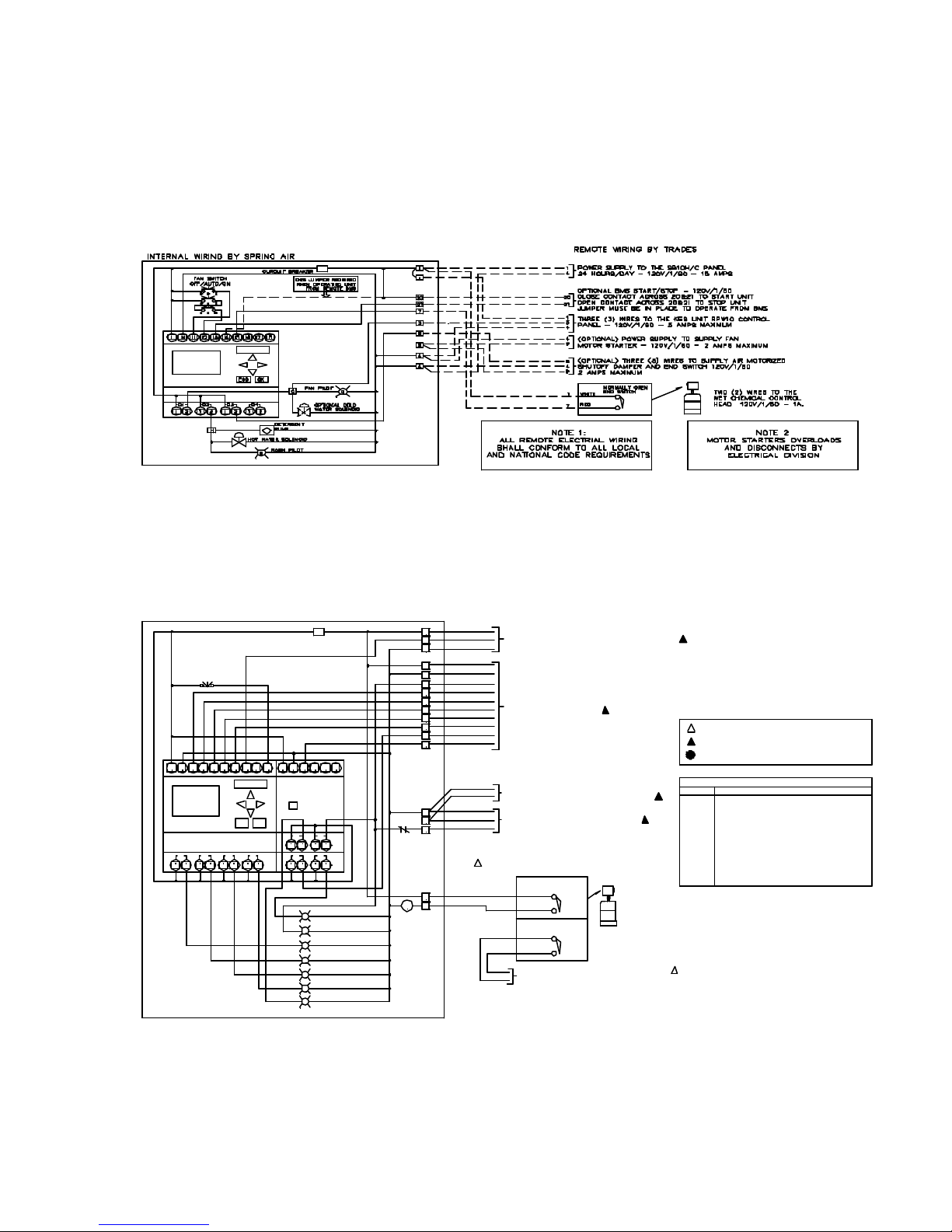

RPW10 ELECTRICAL DATA

OVERIDE SWITCH

I3I2NL I1

I4

Mo 09:00

01. 20. 03

LOGO!

1 2Q121 1

15 AMP CURCUIT BREAKER

I7 I8I6I5

L

AUX!

OKESC

Q3

Q4Q2

2Q312

I4I3I1N I2

RUN/STOP

Q2Q1

21

21

Q4

21

21

WARNING

NORMAL

PREFILTER CLOGGED

BAG FILTER CLOGGED

BOX FILTER CLOGGED

FILTER REMOVED

FIRE

1

3

4

1

4

5

12

13

14

15

16

17

18

4

9

R6

8

1

7R6

THREE (WIRES) TO THE WATER WASH CONTROL

PANEL - 120V/1/60 - 10 AMPS

TO KES UNIT LV10 PANEL ON FILTER

BOX - TEN (10) WIRES

120V/1/60 - 10 AMPS.

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

MOTOR STARTER, 120V/1/60 - 2 AMPS

(OPTIONAL) THREE (3) WIRES TO

MOTORIZED INLET DAMPER AND END

SWITCH, 120V/1/60 - 1 AMP

TWO (2) WIRES TO THE WET CHEMICAL

CONTROL HEAD, 120V/1/60 - 1AMP

NORMALLY OPEN

END SWITCH

1

WHITE

7

RED

NORMALLY OPEN

END SWITCH

WHITE

RED

DRY CONTACT FOR BUILDING FIRE ALARM

FIRE ANUNCIATION, 5 AMPS MAXIMUM, N/O

RPW10 Wiring Schematic

Figure 5

POWER WIRING BY GENERAL CONTRACTOR

CONTROL WIRING BY MECHANICAL CONTACTOR

FACTORY WIRING BY SPRING AIR SYSTEMS

TERMINAL DESCRIPTION

1&4

5

12

13

14

15

16

17

18

20&21

LEGEND

POWER SUPPLY FROM BREAKER PANEL

KES FAN/NORMAL OPERATION

PREFILTER CLOGGED

BAG FILTER CLOGGED

BOX FILTER CLOGGED

FILTER OUT/LOW AIR

FIRESTAT - HIGH LIMIT

0DOR SPRAY UNIT

LV10 RESET

BMS START/STOP

Enviro Maintenance Manual 2004

PANEL MOUNTING

HOLES LOCATED

IN PANEL BACK.

8.0"

5.0"

FILTER

OVERIDE

NORMAL

PREFILTER

CLOGGED

BAG FILTER

CLOGGED

WARNING

FIRE

BOX FILTER

CLOGGED

FILTER

REMOVED

14.0"

Remote RPW10 Panel Dimensions

Figure 6

Water Wash Ventilator System: AP, MP Panels

The KES unit off/on operation is controlled from the MP or AP water wash ventilator control panel. The fan

selector switch on the water wash control panel closes and sends power through terminals 3 & 4 to the

RPW10 remote panel to energize the exhaust fan through terminals 5 & 4 in the LV -10 J-Box. (The LV10 JBox is mounted on the KES-ISH filter section).

The “NORMAL” operation pilot energizes on the RPW10. After 30 seconds the KES control circuit within the

RPW10 remote panel is activated. See Figure 5 for RPW10 internal wiring. The exhaust fan motor is

energized through the terminals 9 & 4 to the motor starter located on the KESF fan section. See figure 11

for internal wiring of LV10 J-Box with RPW10 remote panel.

Mo 09:00

01. 20. 03

LOGO!

Typical KES wiring to AP20C water wash panel

AUX!

Figure 7

Enviro Maintenance Manual 2004

KESF

EXHAUST DISCHARGE

DUCTWORK DUCTWORK AS REQUIRED

POWER SUPPLY

TO KESF FAN UNIT

FIELD INTERCONNECTING

INTERLOCK BETWEEN KES-ISH LV10 AND KESF MOTOR STARTER

THREE (3) WIRES TO

RPW10 PANEL FROM

WATER WASH PANEL

POWER SUPPLY

TO SB10 WASH PANEL

120V/1/60

KES-ISH

POWER SUPPLY

TO RPD10 REMOTE

WATER WASH

PANEL MODEL

SB10C OR SB10H

TEN (10) WIRES FROM

THE RPW10 CONTROLLER

FROM THE KES-ISH LV10

J-BOX - 120V/1/60

CONTROLLER

EXHAUST INLET

RPW10

DUCTWORK

Remote wiring of KES Enviro units with Water Wash Hood and Panel

Figure 8

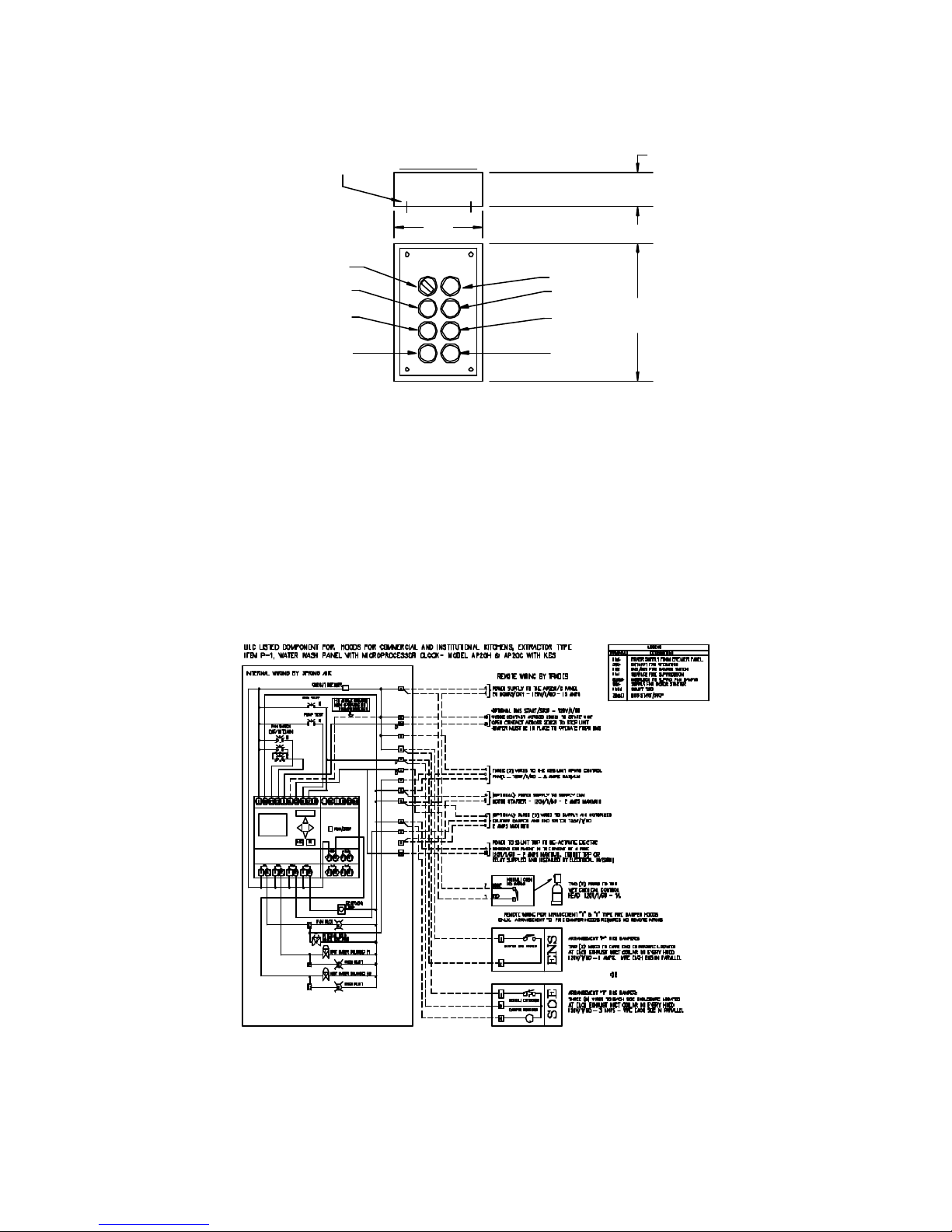

Filter Hood or Dry Grease Extractor: RPD10 Remote Panel

The KES unit off/on operation is controlled from RPD10 remote annunciation panel. The fan selector switch

on the RPD10 remote panel closes and sends power through terminals 5 & 4 to the LV10 J-Box to energize

the exhaust fan circuit. (The LV10 J-Box is mounted on the KES-ISH filter section). The “NORMAL”

operation pilot on the RPD10 remote kitchen annunciation panel energizes and after 30 seconds the KES

control circuit within the RPD10 remote panel is activated. The exhaust fan motor is energized through the

terminals 5 & 4 to the motor starter. See fi gure 8 for the RPD10 remote panel wiring and figure 9 for

dimensions.

RPD10A ELECTRICAL DATA

FAN SWITCH

OFF/ON

OVERIDE SWITCH

I4I2L N I1 I3

I5 I6 I7 I8 L N

Mo 09:00

01. 20. 03

LOGO!

Q3Q1

1 2Q21 2 1 2Q41 2

15 AMP CURCUIT BREAKER

AUX!

ESC OK

I1 I2 I3 I4

RUN/STOP

Q1

2

1

Q3

2

1

POWER SUPPLY TO THE KES UNIT

RPD10 CONTROL PANEL - 120V/1/60 - 15 AMPS

OPTIONAL BMS START/STOP - 120V/1/60

CLOSE CONTACT ACROSS 20&21 TO START UNIT

OPEN CONTACT ACROSS 20&21 TO STOP UNIT

JUMPER MUST BE IN PLACE AS NOTED TO OPERATE FROM BMS

TO KES UNIT LV10 PANEL ON FILTER

BOX - TEN (10) WIRES

120V/1/60 - 10 AMPS.

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

MOTOR STARTER, 120V/1/60 - 2 AMPS

(OPTIONAL) THREE (3) WIRES TO

MOTORIZED INLET DAMPER AND END

Q2

1 2

Q4

1 2

SWITCH, 120V/1/60 - 1 AMP

TWO (2) WIRES TO THE WET CHEMICAL

CONTROL HEAD, 120V/1/60 - 1AMP

DRY CONTACT FOR BUILDING FIRE ALARM

FIRE ANUNCIATION, 5 AMPS MAXIMUM, N/O

OVERIDE

POWER WIRING BY GENERAL CONTRACTOR

CONTROL WIRING BY MECHANICAL CONTACTOR

FACTORY WIRING BY SPRING AIR SYSTEMS

TERMINAL

POWER SUPPLY FROM BREAKER PANEL

1&4

KES FAN/NORMAL OPERATION

5

PREFILTER CLOGGED

12

BAG FILTER CLOGGED

13

14 BOX FILTER CLOGGED

FILTER OUT/LOW AIR

15

FIRESTAT - HIGH LIMIT

16

0DOR SPRAY UNIT

17

18

LV10 RESET

BMS START/STOP

20&21

PANEL MOUNTING

HOLES LOCATED

IN PANEL BACK.

KES

OFF/ON

FILTER

NORMAL

PREFILTER

CLOGGED

BAG FILTER

CLOGGED

8.0"

RPD10 DIMENSIONAL DATA

LEGEND

DESCRIPTION

WARNING

FIRE

BOX FILTER

CLOGGED

FILTER

REMOVED

5"

14.0"

RPD10 Wiring Schematic

Figure 9

Enviro Maintenance Manual 2004

RPD10 Internal Wiring

Figure 10

PANEL MOUNTING

HOLES LOCATED

IN PANEL BACK.

5"

KES

OFF/ON

FILTER

OVERIDE

NORMAL

PREFILTER

CLOGGED

BAG FILTER

CLOGGED

8.0"

RPD10 Remote Panel Dimensions

Figure 11

Enviro Maintenance Manual 2004

WARNING

FIRE

BOX FILTER

CLOGGED

FILTER

REMOVED

14.0"

KESF

KES-ISH

EXHAUST DISCHARGE

DUCTWORK

POWER SUPPLY

TO KESF FAN UNIT

FIELD INTERCONNECTING

DUCTWORK AS REQUIRED

INTERLOCK BETWEEN KES-ISH LV10 AND KESF MOTOR STARTER

POWER SUPPLY

TO RPD10 REMOTE

EXHAUST INLET

TEN (10) WIRES FROM

THE RPD10 CONTROLLER

FROM THE KES-ISH LV10

J-BOX - 120V/1/60

RPD10

CONTROLLER

DUCTWORK

Remote wiring of KES Enviro units with Dry Hood

Figure 12

CONTROL CIRCUIT

Filter Clogged:

During normal operation of the KES unit three-filter stages collect grease, dust, and lint particulate. The type

of cooking equipment and the hours of operation determines the useful life of the individual filt ers.

P1 - PLEATED FILTER

CLOGGED SWITCH

(SET AT 1.0 in. W.C.)

P2 - BAG FILTER

CLOGGED SWITCH

(SET AT 1.0 in. W.C.)

P3 - BOX FILTER

CLOGGED SWITCH

(SET AT 1.2 in. W.C.)

PRESSURE SWITCHES LOCATED ON KES-ISH FILTER

SECTION TO RIGHT OF BOX FILTER ACCESS DOOR

P3 P2

P5

BOX

P4

BAG

FILTERFILTER

P1

PREFILTER

Pressure Switch Locations

Figure 13

P4 - BAG FILTER

REMOVED SWITCH

(SET AT 0.25 in. W.C.)

P5 - BOX FILTER

REMOVED SWITCH

(SET AT 0.25 in. W.C.)

COPPER TUBING

Enviro Maintenance Manual 2004

POWER SUPPLY

____V/3/60

____ FLA

POWER WIRING BY GENERAL CONTRACTOR

CONTROL WIRING BY MECHANICAL CONTACTOR

FACTORY WIRING BY SPRING AIR SYSTEMS

30 AMP DISCONNECT

IN EEMAC12 ENCLOSURE

MOUNTED ON FAN UNIT

KES TELE MOTOR STARTER

IN EEMAC12 ENCLOSURE

MOUNTED ON FAN UNIT

M1

O/L

T1L1

L1

T2T3L2

L2

L3

T2

L3T1T3

G1

95

96

M1

1

63 7

OPTIONAL ODOUR CONTROL PANEL

LOCATED ON KES FAN SECTION

EXHAUST FAN MOTOR

____ HP

A1A2

WIRING HARNESS IN

MOTOR STARTER

WIRING FROM EXHAUST FAN MOTOR STARTER

TO THE ODOUR CONTROL UNIT 120V/1/60

4.2 AMPS. MAXIMUM. WIRES BY SPRING AIR

THREE WIRES FROM LV10 PANEL TO EXHAUST FAN MOTOR STARTER BY

MECHANICAL WHEN KES FAN AND FILTER SECTIONS ARE SPLIT 120V/1/60, 5 AMPS

KES-ISH FILTER SECTION

KESF FAN SECTION

417

TEN (10) WIRES TO THE

TO REMOTE CONTROL STATION LOCATED IN

IN THE KITCHEN AREA MODEL RPD10 OR

RPW10 - 120V/1/60 - 10 AMPS.

1

4

5

12

13

14

15

16

17

18

TERMINAL

1&4 POWER FROM RPD10

KES FAN/NORMAL OPERATION

5

PREFILTER CLOGGED12

13

BAG FILTER CLOGGED

14

BOX FILTER CLOGGED

15

FILTER OUT/LOW AIR

16

FIRESTAT - HIGH LIMIT

17

0DOR SPRAY UNIT

18

LV10 RESET

RESET

LEGEND

DESCRIPTION

LV10 J-BOX

LOCATED ON

KES FILTER

UNIT

1

FILTER CLOGGED PRESSURE SWITCHES

P1

P1 - PREFILTER (SET AT 1.0" W.C.)

P2

P2 - BAG FILTER (SET AT 1.0" W.C.)

P3

P3 - BOX FILTER (SET AT 1.2" W.C.)

FILTER REMOVED SWITCHES

P4

P4 - BAG FILTERS (SET AT 0.25" W.C.)

P5

P5 - BOX FILTERS (SET AT 0.25" W.C.)

TH1

HI TEMP STAT LOCATED IN THE

EXHAUST INLET SET AT 225 °F

Typical indoor KES, motor starter, LV10 J-Box with odor spray wiring schematic

Figure 14

Pressure switches have been installed to determine when the filters are totally used and must be replaced.

As the filter reaches the grease loading capacity the static pressure across each filter increases. When the

maximum static pressure is reached the pressure switch is activated. The exhaust fan shuts off, the

“NORMAL” pilot energizes, and the kitchen remote panel annunciates a filter-clogged condition. (The

remote panel indicates which stage of filters has clogged; PREFILTER, BAG FILTER, or BOX FILTER.) In

addition the screen of the LOGO controller in the RPD10 or RPW10 has a text mes sage also indicating

which filter is clogged.

RPD10 or RPW10 LOGO controller indicating Box Filter clogged text messages

Change

Prefilter

LOGO!

AUX!

Change

Box Filter

LOGO!

LOGO!

Figure 15

Enviro Maintenance Manual 2004

Change

Bag Filter

AUX!

AUX!

The clogged filter must be replaced and the system reset to resume normal operation. If this condition

occurs during normally operating hours rotate the OVERRIDE selector switch and the fan will come back on.

The systems can run in the OVERRIDE position for about 4 hours. (See the section the OVERRIDE switch)

If the system runs longer than 4 hours the fan will shut down. The filters must be changed and the system

reset. It is recommended that the filters be changed prior to the filter clogged light energizing. A filter usage

chart is attached to record when the filters are being changed. Using this chart a regular maintenance

schedule can be set up to ensure constant uninterrupted operation of the commercial kitchen.

Filter Removed:

Should the bag or box filters be removed during normal operation the KES unit is automatically shut down.

A pressure switch across the bag filters and box filters monitors a minimum pressure drop of 0.25” W.C.

When the filter is removed the pressure differential falls and the pressure switch is activated. The exhaust

fan shuts off, the “FILTER REMOVED” pilot light on the RPD10 or RPW10 energizes and the screen of the

LOGO controller in the RPD10 or RPW10 has a text message indicating “FILTER REMOVED/LOW

EXHAUST. To resume normal operation the filter must be replaced and the system reset. (See the section

the OVERRIDE switch)

Filters

Removed

or Low

Exhaust

LOGO!

AUX!

RPD10 or RPW10 LOGO controller indicating filter removed text message

Figure 16

Fire:

In the event of a high temperature in the ductwork leading to the KES unit or within the KES unit a firestat

located at the inlet of the KES filter section is activated. When the exhaust air reaches 160 F the firestat is

energized. The exhaust fan shuts off, the “NORMAL” pilot goes off, and a “FIRE” pilot energizes on the

remote RPD10 or RPW10 panel. Should the exhaust temperature continue to rise the fusible link melts and

closes the fire damper in the exhaust discharge of the KES filter section. This fire damper is always located

between the fan and filter section. The fire damper fusible link is rated at 165 F. Shut off all cooking

equipment and notify the fire department. To resume normal operation, replace the fusible link and reset the

system. An authorized SPRING AIR SYSTEM INC. service technician should be called to inspect the unit.

Override Switch: (located on RPW10 or RPD10 panel)

In the event that the filter clogged annunciation shuts off the KES unit during a peak cooking time rotate the

OVERRIDE SWITCH located on the RPW10 panel clockwise. The WARNING pilot light will energize and

the FILTER CLOGGED and NORMAL lights will turn off. This is a temporary override to allow for the

cooking equipment to be shut off prior to changing the filters. The systems can run in the OVERRIDE

position for 4 hours. If the system runs longer than 4 hours the fan will shut down. The filters must be

changed and the system reset. It is recommended that the filters be changed prior to the filter clogged light

energizing. A filter usage chart is attached to record when the filters are being changed. Using this chart a

regular maintenance schedule can be set up to ensure constant uninterrupted operation of the commercial

kitchen.

Once the dirty filter has been replaced rotate the OVERRIDE SWITCH to counter clock wise to resume

normal operation.

Enviro Maintenance Manual 2004

Service

Filters

Within

4 hours

AUX!

LOGO!

RPD10 or RPW10 LOGO with Override selector in on position

Figure 17

System Reset:

After any of the safety circuit annunciation, the system must be reset. The system is reset by toggling the

“RESET” switch in the LV10 J-box, or switching the OVERRIDE SWITCH on the RPW10 or RPD10, or

turning the fan selector switch to the “OFF” and then to the “ON” position.

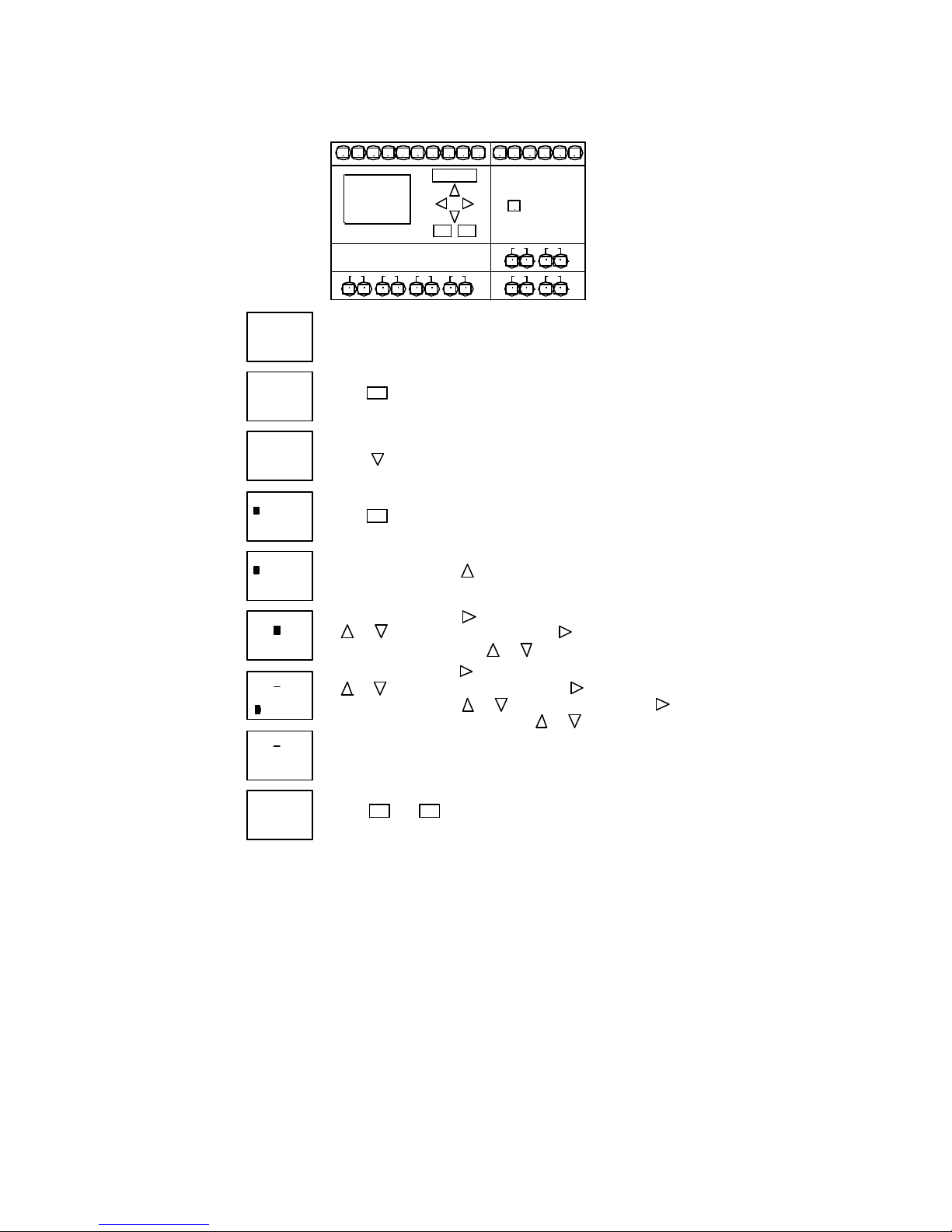

Logo Processor

Figure 18

Enviro Maintenance Manual 2004

RPD10 Face Plate

Figure 19

RPW10 Face Plate

Figure 20

Enviro Maintenance Manual 2004

POWER SUPPLY

____V/3/60

____ FLA

TO FACTORY MOUNTED BASEBOARD HEATER

WITH THERMOSTAT FOR SPRAY ENCLOSURE

POWER WIRING BY GENERAL CONTRACTOR

CONTROL WIRING BY MECHANICAL CONTACTOR

FACTORY WIRING BY SPRING AIR SYSTEMS

30 AMP

EEMAC3R

DISCONNECT

EEMAC4

TRANSFORMER

ENCLOSURE

XXXV

120V

KES TELE MOTOR STARTER

IN EEMAC4 ENCLOSURE

MOUNTED ON FAN UNIT

M1T1O/L

L1

L1

L3

95G196T3A2L3A1

M1

71 3 6

OPTIONAL ODOUR CONTROL PANEL

T1

T2L2T2L2

T3

WIRING HARNESS IN

MOTOR STARTER

THREE WIRES FROM LV10 PANEL TO EXHAUST FAN MOTOR STARTER BY

MECHANICAL WHEN KES FAN AND FILTER SECTIONS ARE SPLIT 120V/1/60, 5 AMPS

EXHAUST FAN MOTOR

____ HP

LOCATED ON KES FAN SECTION

WIRING FROM EXHAUST FAN MOTOR STARTER

TO THE ODOUR CONTROL UNIT 120V/1/60

4.2 AMPS. MAXIMUM. WIRES BY SPRING AIR

KES-ISH FILTER SECTION

KESF FAN SECTION

17

4

TEN (10) WIRES TO THE

TO REMOTE CONTROL STATION LOCATED IN

IN THE KITCHEN AREA MODEL RPD10 OR

RPW10 - 120V/1/60 - 10 AMPS.

1

4

5

12

13

14

15

16

17

18

TERMINAL

1&4

5

12

13

14

15

16

17

18

RESET

LEGEND

DESCRIPTION

POWER FROM RPD10

KES FAN/NORMAL OPERATION

PREFILTER CLOGGED

BAG FILTER CLOGGED

BOX FILTER CLOGGED

FILTER OUT/LOW AIR

FIRESTAT - HIGH LIMIT

0DOR SPRAY UNIT

LV10 RESET

LV10 PANEL

LOCATED ON

KES FILTER

UNIT

1

Wiring diagram for Outdoor KES, motor starter, LV10 J-Box, and odor unit

Figure 21

FILTER CLOGGED PRESSURE SWITCHES

P1

P1 - PREFILTER (SET AT 1.0" W.C.)

P2

P2 - BAG FILTER (SET AT 1.0" W.C.)

P3

P3 - BOX FILTER (SET AT 1.2" W.C.)

FILTER REMOVED SWITCHES

P4

P4 - BAG FILTERS (SET AT 0.25" W.C.)

P5

P5 - BOX FILTERS (SET AT 0.25" W.C.)

TH1

HI TEMP STAT LOCATED IN THE

EXHAUST INLET SET AT 225 °F

Enviro Maintenance Manual 2004

Setting the Day and Time

ESC

I6

AUX!

RUN/STOP

OK

2

Q4

1Q11Q22

Q4

221

1Q31 2

L N I2I1 I3 I4 I5 I7 I8 L N I2I1 I3 I4

Su 00:00

01.01.00

LOGO!

Q1 Q2

1 2

1 2Q31 2

Su 00:00

01.01.00

>Stop

Set Parma

Set Clock

Prg Name

Stop

Set Parma

>Set Clock

Prg Name

Set Clock

Su 00:00

MM.DD.YY

01. 01. 00

Set Clock

Th 00:00

MM.DD.YY

01. 01. 00

Set Clock

Th 00:00

MM.DD.YY

01. 01. 00

Set Clock

Su 06:16

MM.DD.YY

01. 01. 00

Set Clock

Su 06:16

MM.DD.YY

01. 06. 03

1. When power is first applied to the RPD10 panel the following display will blink

If the SERVICE FILTERS WITHIN 4 HOURS displays instead the OVERRIDE

switch is on. Just rotate the switch and the correct display will blink.

OK

2. Press and the following screen will appear.

3. Press twice.

4. Press and the following screen will appear.

OK

5. To change the day press

6. To change the time press once. The hour will be highlighted. Press

Adjust the minutes by pressing

7. To change the date press again. The month will be highlighted. Press

Adjust the day by pressing

move to year. Adjust the year by pressing

8. You have finished setting the clock.

until the correct hour appears.

or

until the correct month appears.

or

until the correct day appears.

Press to move to minutes.

or

until correct minutes appears.

Press to move to day.

until correct day appear. Press to

or

or

until correct year appears.

Su 06:16

01. 06. 03

Setting the clock on RPD10A automatic panels

OK ESC

7. Press and

to return to the operating screen.

Figure 22

Enviro Maintenance Manual 2004

Setting the Weekend Fan "ON" and "OFF" times

Su 06:16

01. 06. 03

>Stop

Set Parma

Set Clock

Prg Name

Stop

>Set Parma

Set Clock

Prg Name

B04: No1

D =MTWTFSS

On = 06: 00

Off = 23: 00

B04: No1

D =MTWTFSS

On = 06: 00

Off = 23: 00

B04: No1

D =MTWTFSS

On = 06: 00

Off = 23: 00

B04: No1

D = MTWTF-S

On = 06: 00

Off = 23: 00

B04: No1

D = - TWTF- -

On = 06: 00

Off = 23: 00

1. Press

2. Press once.

3. Press

4. Press

5. The clock has been factory set to turn the fan on at 6:00 a.m. and off

6. To change the above settings press

7. Press to remove Monday from the weekly schedule. The - dash indicates

8. Press to move to the next day of the week. Press each time the fan is

ESC

OK

time setting for start and stop each weekday.

at 23:00 hours or 11:00 p.m.

the fan will not start automatically any given day.

not required to operate on that given day. The screen on the left indicates the

fan will not automatically operate on Monday, Saturday or Sunday.

until the B04: No1 timer appears. This is the

OK

The cursor will move to M = Monday.

B04: No1

D = - TWTF- -

On = 0 6: 00

Off = 23: 00

B04: No1

D = - TWTF- -

On = 06: 30

Off = 2 3: 00

B04: No1

D = MTWTF- -

On = 06: 30

Off = 22: 30

Su 06:16

01. 06. 03

9. Press to move to the hour that the fan will start in the morning. Press

to change the hour you want the fan to start in each morning. Press to move

to the minute the the fan will start in the morning. Press to change the minutes.

10. Press to move to the hour that the fan will stop in the evening. Press

to change the hour you want the fan to stop each evening. Press to move

to the minute the fan stop in the evening. Press to change the minutes.

11.Press

OK

12. If your selection is complete press and to return to the operating screen.

You have completed programming one weekly fan "On" and "Off" cycling. If you wish

to program a second (Weekend Operation) or third weekly setting go the the section

"Setting Weekend Operation"

ESC ESC

Setting the Week Day Fan On and Off Timers on RPD10A automatic panels

Figure 23

Enviro Maintenance Manual 2004

Setting Weekend Operation

Su 06:16

01. 06. 03

>Stop

Set Parma

Set Clock

Prg Name

Stop

>Set Parma

Set Clock

Prg Name

B04: No2

D = - - - - - - -

On = - - : - Off = - - : - -

B04: No2

D = - - - - - - -

On = - - : - Off = - - : - -

B04: No2

D = - - - - - SS

On = - - : - Off = - - : - -

B04: No2

D = - - - - - SS

On = - - : - Off = - - : - -

1. Press

2. Press once.

3. Press

4. Press

5. Press to program the weekend operation.

6. Press five times to move to Saturday. Press to turn fan on Saturday.

7. Press to move to the hour that the fan will start in the morning. Press

ESC

OK

until the B04: No1 timer appears. This is the

time setting for start and stop each weekday.

OK

Press once to move to Sunday. Press to turn fan on Sunday.

to change the hour you want the fan to start in each morning. Press to move

to the minute the the fan will start in the morning. Press to change the minutes.

B04: No2

D = - - - - - SS

On = 10: 00

Off = - - : - -

B04: No2

D = - - - - - SS

On = 10: 00

Off = 23: 30

Su 06:16

01. 06. 03

Setting the and Weekend Fan On and Off Timers on RPD10A automatic panels

8. Press to move to the hour that the fan will stop in the evening. Press

to change the hour you want the fan to stop each evening. Press to move

to the minute the fan stop in the evening. Press to change the minutes.

9. Press

operating screen.

10. You have completed programming weekend fan "On" and "Off" cycling.

If your selection is complete press and to return the

OK

ESC ESC

Figure 24

Enviro Maintenance Manual 2004

ODOR SPRAY SYSTEM

Operating and Maintenance

The Spring Air Systems Inc. odor spray unit has a one-year warranty from startup. The two timers, cyc le

timer B01, and spray timer B02, are factory set (5 minute cycle and 2 second spray) and then adjusted

during startup to the odor reducing intensity required for the application. The B01 cycle timer is generally set

between 5 to 10 minutes. The B02 spray timer is generally set between 2 to 60 seconds.

How does it Work?

The odor spray setting is a qualitative measurement. The spray timers are field set to provide adequate

odor reduction for the installation. This is completely subject to what a particular person feel is an

acceptable discharge odor.

During the spray timer activation the combination air compressor and air-atomizing nozzle injects a volume

of odor solution into the exhaust discharge. This solution is carried along the discharge duct and vented to

atmosphere. The spray solution chemically activates with the kitchen exhaust air to reduce the kitchen

exhaust odors. As the solution is carried down the duct some adheres to the duct walls. We will call this the

spray residue. During the cycle time when the spray is not activated this spray residue continues the odor

reducing process as the exhaust air passes. Therefore installation with longer discharge ducts can normally

use a longer cycle time because there will be more spray residue. A shorter run of discharge duct usually

results in shorter cycle time.

A. When adjusting the timers the object is to use as little spray solution as possible to provide adequate

odor reduction:

1. First adjust the spray cycle, B01 timer.

2. Reduce this setting by ½ of the original cycle setting and check the operation. If ½ proves

adequate, increase the cycle back to ¾ of the original cycle setting. If this is adequate increase to

7/8 of the original setting and so forth.

3. If reducing the setting by ½ is not adequate decrease the cycle to ¼ of the original setting. If this is

not adequate adjust the spray timer B02.

a. Increase the spray time B02 in increments of 5 seconds. After each 5 second increase

evaluate the quality of the exhaust discharge air to determine if it is acceptable to the user.

b. When the spray timer setting equals the cycle timer settings the spray will be continuous.

The maximum setting of B02 should not exceed the cycle timer B01.

The odor spray bottle must be changed regularly depending on the length of time set on timers B01 and

B02. The odor spray line from the spray bottle to the spray nozzle must be cleaned every 6 months in a

water and detergent mixture. The compressed air gauge should read between 10 and 15 psi. When the air

gauge is reading below 10 psi clean out the compressed air line. If the pressure is still low proceed to the

next step compressor maintenance.

When there is odor in adjoining floors or office spaces

A kitchen located in the interior of an office building must be very negative to keep the kitchen odor within

the kitchen. We recommend the kitchen be a minimum 20% negative. The fresh air supply is 80% of the

total exhaust air from the kitchen space. When there is odor in adjoining spaces check the following.

1. The kitchen is not negative enough to keep the smell of the kitchen in the kitchen. If this is the

case the odor is usually present all the time, even when there is no cooking. Reduce the amount of

fresh air to the kitchen by adjusting the supply fan volume.

2. The kitchen may be connected to the same building A/C unit as the rest of the floor. If this is the

case the return air grilles in the kitchen draws the kitchen odor to the main A/C unit and disperses

the odor throughout the floor. The main A/C return must be blocked from the kitchen and put on a

separate A/C unit.

3. The floor above the kitchen have odor. There are three possibilities.

a. The exhaust shaft is not sealed and the kitchen exhaust is leaking out onto the floors

above the kitchen. Either adjust the amount of odor spray per section "A" above or install

Enviro Maintenance Manual 2004

an exhaust fan on the roof to draw the kitchen exhaust to the roof and maintain a negative

pressure in the discharge duct.

b. The odor may escape when the kitchen is not operating during the night. After the kitchen

is shut off kitchen odor may migrate up the exhaust duct and leak out into the adjoining

floors. This can be solved by operating the kitchen exhaust for a couple hours after the

cooking has stopped for the day and starting the kitchen exhaust fan an hour before

cooking starts in the morning.

Setting the cycle and spray times

ESC

Su 06:16

01. 06. 03

>Stop

Set Parma

Set Clock

Prg Name

Stop

>Set Parma

Set Clock

Prg Name

B01: T

T = 05:00m

Ta = 05:00m

B01: T

T = 05:00m

Ta = 00:00m

B01: T

T = 05:00m

Ta = 00:00m

1. Press

2. Press once.

3. Press

OK

4. Press

or the time period between sprays.

5. To change the cycle time press

6. The first two digits are minutes and the two digits to the right are seconds.

Press to change the cycle length in minutes. Press to move to the

the cycle length in seconds. Press to change the seconds.

until the B01 timer appears. This is the cycle timer

OK

B01: T

T = 04:30m

Ta = 00:00m

B02: T

T = 03:00s

Ta = 00:00m

B02: T

T = 03:00s

Ta = 00:00s

B02: T

T = 03:00s

Ta = 00:00s

B02: T

T = 02:30s

Ta = 00:00s

Su 06:16

01. 06. 03

7. Press if the cycle time is correct.

8. Press

9. To change spray time press

10. The first two digits are seconds and the two digits to the right are 0.1 and 0.01

11. Press if the cycle time is correct.

12. Press and to return to the operating screen.

OK

or the length of the odor sprays.

the spray time in fractions of a second. Press to change the 0.1 and 0.01 seconds.

until the B02 timer appears. This is the spray timer

OK

seconds. Press to change the spray in seconds. Press to move to the

OK

ESC

ESC

Setting the Cycle and Spray Timer

Figure 25

Enviro Maintenance Manual 2004

Compressor Maintenance

WARNING

-

Do not, at any time lubricate any of the parts with oil, grease, or petroleum products nor clean with acids,

caustics or chlorinated solvents. Be very careful to keep the diaphragm from contacting any petroleum

product of hydrocarbons. It can affect the service life of the pump.

To clean or replace the filters and/or rubber gasket, remove the five screws in the top of the unit. The filters

and gaskets are located beneath this top plate. Remove the filters and wash then in a solvent and/or blow

off with air and replace. The gasket may be cleaned with water. Replace the filters in proper position and

replace the gasket. Note that the gasket and top plate will fit in one position only.

To replace the diaphragm, remove the socket cap screws from the head of the pump. The diaphragm is

held in place by two Philip head screws. Remove screws, retainer plate, and diaphragm. The diaphragm

will fit in any position on the connecting rod. Replace the plate and the two Phillips head screws. Torque to

30 inch-pounds on DOA and DAA.

Caution: Do not raise any burrs or nicks on the heads of these screws. These burrs could cause damage

to the inlet valve.

For replacing the inlet and outlet valve, remove the slotted machine screw that holds each valve in place.

The stainless steel inlet and outlet valves are interchangeable. Clean them with water. When replacing the

outlet valve, place the new valve in location and note there is a retaining bar near the machine screw hole.

This retaining bar holds the valve in position. When replacing the inlet valve, note that the valve holder is

marked with an X in one corner. This X should be in the lower right hand corner toward the inlet of the air

chamber. Replace the head and tighten the socket head screws to 90-100 inch-pounds or torque on DOA

and DAA.

The motor is

thermally

protected

and can

automaticall

y restart

when the

protector

resets.

ALWAYS

disconnect

KES fan

power

source

before

servicing.

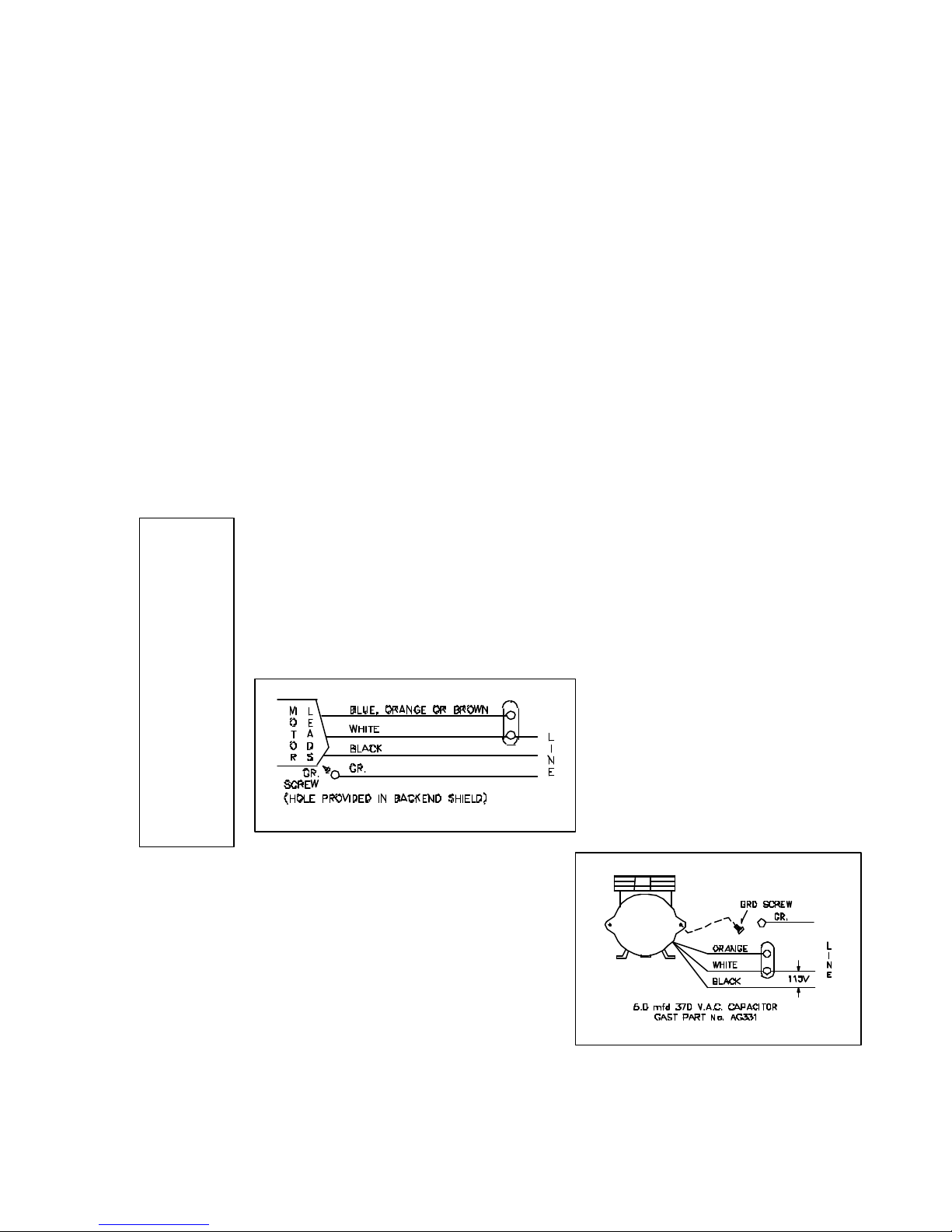

For any permanent split capacitor for DOA & DAA motor,

which has three (3) leads is as follows:

Do not attempt to replace the connecting rod or motor bearings. If after cleaning the unit

and/or installing a new service kit, the unit still does not operate properly, contact your

representative, the factory, or return the pump to one of our authorized Service Centers.

IF YOUR PUMP IS EQUIPPED WITH PLASTIC PLUGS IN THE EXHAUST AND/OR

INTAKE POTS, REMOVE BEFORE STARTING THE UNIT

Wiring Information

For any permanent split

capacitor motor, which has four

(4) leads is as follows:

Brown leads to capacitor.

Black-leads to Power Source.

IMPORTANT NOTICE:

DO NOT AT ANY TIME ATTEMPT TO REMOVE THE CONNECTING ROD

OR COMPLETELY DISASSEMBLE THE PUMP. IF IT DOES NOT GIVE

YOU THE PROPER SERVICE EVEN AFTER INSTALLING A NEW

SERVICE KIT, PLEASE RETURN IT TO ONE OF THE AUTHORIZED

SERVICE CENTERS

Enviro Maintenance Manual 2004

WHERE TO PURCHASE FILTERS:

Spring Air Systems Inc.

1388 Cornwall Rd., Oakville Ont., L6J 7W5

(905) 338-2999

Airguard Industries

125 Buttermill Rd., Concord, Ontario, L4K 3X5

905-669-9876

Airguard Corp.

4806 Strong Rd., Crystal Lake, IL, 60014

888-324-5665

Camfil Farr Filters

67 Steelecase Rd. W., Markham Ont., L3R 2M4

RECOMMENDATION

TO ENSURE TROUBLE FREE OPERATION FOR

YOUR KITCHEN EXHAUST SYSTEM A PROPER

PREVENTATIVE MAINTENANCE PROGRAM IS A

NECESSITY.

SPRING AIR SYSTEMS RECOMMENDS THAT A

YEARLY SERVICE CONTRACT BE SET UP WITH A

REPUTABLE SERVICE ORGANIZATION. THIS WILL

REDUCE UNEXPECTED DOWN TIME TO A MINIMUM.

(905) 415-3030

Camfil Farr

2201 Park Place, El Segundo, CA, 90245

310-727-6300

REPLACEMENT FILTER EQUIVALENTS

PREFILTERS: 30% ASHRAE 52-76 - ULC Class II

Airguard: 24” x 24” x 2” - DP40 Class II

12” x 24” x 2” - DP40 Class II

American Air Filter:

24” x 24” x 2” - AM-AIR Class II

12” x 24” x 2” - AM-AIR Class II

Farr Filters: 24” x 24” x 2” - 30% ASHRAE 52-76 Class II

12” x 24” x 2” - 30% ASHRAE 52-76 Class II

BAG FILTERS: 90 - 95% ASHRAE 52 - 76 - ULC Class II

Airguard: 24” x 24” x 22” - V9-4M Class II

12” x 24” x 22” - V9-4M Class II

American Air Filter:

24” x 24” x 21” - DRI-PAK - Class II

12” x 24” x 21” - DRI-PAK - Class II

Farr Filters: 24” x 24” x 22” - 90% ASHRAE 52-76 Class II

12” x 24” x 22” - 90% ASHRAE 52-76 Class II

BOX FILTERS: 95% DOP/99% ASHRAE 52-76 ULC Class II

Airguard: 24” x 24” x 12” - VMB- 904 Class II

12” x 24” x 12” - VMB-904 Class II

American Air Filter:

24” x 24” x 12” - BIOCELL Class II

12” x 24” x 12” - BIOCELL Class II

Farr Filter:

24” x 24” x 12” - 6 pocket - 95% DOP Class II

12” x 24” x 12” - 6 pocket - 95% DOP Class II

ODOR MEDIA: 1/8” Activated alumina pellets impregnated with potassium permanganate.

Airguard: Barneby-Cheney CP-2

American Air Filter:

Permasorb

Farr Filters: Unisorb.

Odor Spray: Spring Fresh, Spring Air Systems

Enviro Maintenance Manual 2004

TROUBLE SHOOTING

I. Exhaust fan does not run.

Reset the system once. Press the reset button in the LV10 J-Box or turn the fan selector switch

to “OFF” and “ON”. Observe the sequence that follows.

1.The fan does not start and there is no indication on remote panel.

a)Check power from the breaker to the RPD10.

b)Check the three wiring connection from the wash panel to the RPW10 panel.

2.The fan does not start but the green normal pilot energizes for 30 seconds goes

out and “Filter removed” pilot energizes.

a)Check wiring between KES filter box LV10 J-box terminals 5 & 4 and the KESF fan motor

starter.

b)Check wiring between the RPD10 or RPW10 remote and the KES-ISH LV10 J-Box

c)Reset the exhaust fan overload in the exhaust fan motor starter on the KESF fan section.

d)Check three phase power to the KESF fan section disconnect.

e)Check if exhaust duct access door is open between the KES filter section and hood.

f)Check that all filters on in place.

g)Check if the prefilter or box filter access door on the KES unit is open

h)Check the Filter Removed pressure switch. The switch must make and close after 30

seconds of operation. Adjust the pressure setting or replace switch.

i)If all the filters are in place check if pressure tips on the end of the pressure switch

manifolds are plugged. There is a pressure tip in front and behind each filter.

j)Measure Exhaust air volume. If low increase fan RPM to within FLA of fan motor

k)Check KESF exhaust fan motor starter coil. Replace or repair.

l)Check KESF fan belts if loose or broken.

m)Check KESF exhaust fan motor. Replace or repair.

3.The exhaust fan runs for 30 seconds then shuts off and one of the Filter

Clogged pilots energizes.

a.Check the wiring from the LV10-J-Box to the pressure switch

b.Check pressure switch operation P1, P2 & P3. These switches should remain open after

30 seconds operation. Calibrate the pressure setting or replaced switch.

c.Check the wiring between the RPD10 or RPW10 panel and the LV10 J-Box.

II. Low Exhaust Air

1.Exhaust fan is running but exhaust air is low.

a)Check if fan belts are slipping. Tighten if necessary.

b)Check if fusible link fire damper has closed in the KES filter section. Replace fusible link.

c)Check if filters are dirty but have not activated the “Filter Clogged” pilot. Replace dirty

filters.

d)Check for correct fan rotation.

Enviro Maintenance Manual 2004

III. Filter Clogged Pilot On.

1.Filter clogged pilot indicates which filter section has plugged. Replace filter and reset

system.

IV. Filter Removed Pilot On.

1.A filter has been removed or access door left open. Replace if necessary.

V. Fire Pilot On.

1.The fire stat in the KES filter section exhaust outlet has activated and shut the KES system

down. If a fire is not present check calibration of firestat TH1. Firestat should be set at

160F.

If operation problems persist check the individual the connection between the RPD10 or RPW10

panel and the LV10 J-Box. If problems still exist contact an authorized SPRING AIR SYSTEMS

service technician.

Enviro Maintenance Manual 2004

KES MAINTENANCE SCHEDULE

Every two weeks:

1.Inspect the prefilters. Replace if necessary. It is important to maintain clean

prefilters. Replacing the inexpensive prefilters often extends the life of the bag

and box filters and reduces unnecessary down time due to clogged filter

shutdowns. The RPD or RPW annunciation panel will indicate separately when

the “prefilter”, “bag” and “box” filters are clogged. When this occurs the unit

shuts down. Rotate the override switch to energize the system for about 4 hours.

This provides time to change the filters after the day of cooking. This is a final

dirty filter warning. The filter life of all the filters is constant for each operation.

Once the approximate filter life for your application is determined we recommend

that a regular filter change schedule be set up before the filter out switches

activate.

Every Month:

1.Complete the two -week list.

2.Inspect the exhaust fan belt for correct tension and wear. All belts usually require

adjustment at this time. Failure to tighten may result in the belt falling off and no

airflow.

3.Inspect the bag filters (2nd stage filtration). Replace if necessary. The life of the

bag filter depends on the type of cooking equipment and exhaust hood system.

For heavy cooking applications the bag filters may require replacement every

month.

4.(Odor Spray Option) Inspect the odor spray bottle. Refill if necessary. At startup

the odor spray is adjusted to the desired level. The amount of odor spray used

varies with this initial setting. It is important to inspect the level in the bottle every

two weeks until the normal rate of use is determined.

Every Three Months:

1.Complete the two -week and monthly checklist.

2.Inspect the exhaust fan belt for correct tension and wear. Adjust if necessary.

3.Inspect the box filters (3rd stage filtration). Replace if necessary. Once again the

life of the box filter depends on the type of cooking equipment and exhaust hood

system. The box filter may provide one year of service on most applications with

high efficiency water wash ventilators.

4.Inspect all electrical connections. Tighten if necessary.

5.Test the filter-removed circuit. Open the prefilter access door while the KES unit is

in operation. The unit should shut down and indicate a filter-removed condition.

Every Six Months

1.Complete the two -week, monthly and three month check list.

2.Open the fan wheel access door or hatch on the KES fan section. Inspect the fan

wheel for grease build up. Clean as required.

3.Inspect the exhaust inlet fire damper and fusible link. Replace link annually.

4.Check the motor and fan bearings for noise or overheating.

5.(Odor Pellet Option) Inspect the condition of odor media.

Enviro Maintenance Manual 2004

6.The odor media pellets can be checked for remaining life by sending a sample to

an accredited test laboratory. Most major filter suppliers have access to such

service. Replace media if required. To replace the media remove the cells from

the KES unit. Open the side panel on each odor cell and pour out the used

media. Refill the cells with new media. Shake cells while filling to allow pellets to

settle evenly in the cell. Note: Do not allow odor media to come in contact with

water, as this will immediately render the pellets useless.

Fan Bearings

1.STY and FYC bearings are factory pre-lubricated lifetime sealed and require no

further lubrication.

2.SY and FY bearings are pre-lubricated and equipped with pressure grease fittings

for re-greasing.

3.Under normal service conditions grease after six months of operation.

Motor Bearings:

1.All motors leave the factory with bearings custom greased for many years of

service under most conditions.

2.Re-greasing of motors depends on the application and is best left to trained service

technicians.

3.Periodically check if motor is running hotter then normal.

Centrifugal Exhaust Fan:

1.Make sure the wheel rotates freely before startup.

2.Inspect and clean the wheel periodically.

3.If dirt is allowed to build up the wheel could become out of balance and cause

premature bearing wear.

4.A noisy fan is a typical sign of a fan out of balance.

V-Belt Drives:

1.ALWAYS KEEP SPARE SET OF BELTS. Periodically check the belt tension and

adjust if necessary.

2.Some slack should be left in the belt, typically 1/4” per foot of belt from the fan to

the motor sheave.

3.Always replace the complete set of belts to ensure even tension and wear. When

replacing belts loosen the motor mounts.

4.Do not force belts over sheaves.

RECOMMENDATION

TO ENSURE TROUBLE FREE OPERATION FOR YOUR KITCHEN EXHAUST

SYSTEM A PROPER PREVENTATIVE MAINTENANCE PROGRAM IS NECESSARY.

SPRING AIR RECOMMENDS THAT A YEARLY SERVICE CONTRACT BE SET UP

WITH A REPUTABLE SERVICE ORGANIZATION. THIS WILL REDUCE

UNEXPECTED DOWN TIME TO A MINIMUM.

Enviro Maintenance Manual 2004

KES ENVIRO START-UP REPORT

96

-

Turn on the Override switch in the RPD10 or RPW10 remote panel. The LOGO text message “Service

” switch in the wash panel or remote RPD10 panel to the OFF position. Observe the fan

RPD10 or RPW10 to the original position. The text message will

Job Name Date

Location File No.

KES No. Motor HP

S/N Voltage

Item Description Y / N

1

2

2a

3

4

5

6

7

Check if all filters are in the unit

Type of Filter Size Qty

8

9

10

11

12

13

Check all electrical connections. Tighten as necessary

(RPD10 panels only) Check for power to the RPD10 panel on terminals 1 & 4

Check all remote wiring to ensure it has been connected

(RPW10 panels only) Check wiring to terminals 1, 3 & 4 from water wash panel to RPW10 remote

LV10 J-Box wiring to terminal 1, 4 & 5 from RPD10- or RPW10 remote

LV10 J-Box wiring to terminal 4 & 5 to exhaust fan motor starter

LV10 J-Box wiring to odor spray 4 & 17 (Optional for odor spray units)

Power wiring to disconnect switch

Prefilter 12” x 24” x 2”

Prefilter 24” x 24” x 2”

Bag Filter 12” x 24” x 22”

Bag Filter 24” x 24” x 22”

Box Filter 12” x 24” x 12”

Box Filter 24” x 24” x 12”

Item Decryption Y / N

14

15

16

17

Check of the inlet exhaust ductwork to the KES unit from the kitchen exhaust hood is all welded NFPACheck if clearance to top, sides, and ends of KES filter box is available: 18” to combustible or 6” to non

combustibles

Check power at disconnect switch 3/60/ V

Check fan rotation as follows:

Turn on the main disconnect to the KESF fan motor starter

Turn “FAN ON” switch in the wash panel or remote RPD10 panel to the ON position

Filters within 4 hours” will appear.

Turn “FAN OFF

rotation. Change one of L1, L2 or L3 if fan is rotating backwards

Item Description Y / N

18

19

20

Safety Circuit Check

21

22

23

24

Switch P1

25

26

27

28

Switch P2

29

30

31

32

Switch P3

33

34

35

36

Turn “FAN ON” switch in the wash panel or remote RPD10 panel to the ON position

Check the FLA L1 L2 L3

Adjust the overload setting on motor starter to FLA rating of motor

Turn “FAN OFF” switch in the wash panel or remote RPD10 panel to the OFF position

Rotate the OVERRIDE switch on the

disappear once the fan is turned back on.

Remove the front covers from all the pressure switches on the KES-ISH filter box.

Turn “FAN ON” switch in the wash panel or remote RPD10 panel to the ON position

Jumper switch P1– terminals 1 & 12

KES unit shuts off Yes No

Prefilter clogged light on and LOGO text message “Change Prefilter” Yes No

Reset unit at LV10 J-Box reset switch by turning on and off

Jumper switch P2– terminals 1 & 13

KES unit shuts off Yes No

Bag clogged light on and LOGO text message “Change Bag filter” Yes No

Reset unit at LV10 J-Box reset switch by turning on and off

Jumper switch P3– terminals 1 & 14

KES unit shuts off Yes No

Box clogged light on and LOGO text message “Change Box Filter” Yes No

Reset unit at LV10 J-Box reset switch by turning on and off

Enviro Maintenance Manual 2004

KES ENVIRO STARTUP REPORT page 2

Filter removed light on and LOGO text message “Filter Out or Low Exhaust”

GO text message “Filter Out or Low Exhaust”

Replace pressure switch covers and turn of the unit and remove all the bag filters. Shut the access door and turn the

Filter removed light on and LOGO text message “Filter Out or Low Exhaust”

vers and turn of the unit and remove all the box filters. Shut the access door and turn the

Filter removed light on and LOGO text message “Filter Out or Low Exhaust”

If the unit does not shut off and the filter clogged light does not come on for this test the pressure switch setting must

he LOGO text message “Prefilter Clogged”

Warning light turns on and the LOGO text message “Service Filters within 4

or RPD10 remote panel to the OFF position. The Warning light goes off

Switch P4

33

34

35

36

Switch P5

33

34

35

36

Filter Out Test #1

33

34

35

36

Filter Out Test #2

37

38

39

40

Fire Switch Test

41

42

43

44

Check override switch

45

46

47

48

49

50

51

52

53

54

55

56

Jumper switch P4

KES unit shuts off Yes No

Reset unit at LV10 J-Box reset switch by turning on and off

Jumper switch P5

KES unit shuts off Yes No

Filter removed light on and LO

Reset unit at LV10 J-Box reset switch by turning on and off

unit on. Wait for 30 sec.

KES unit shuts off Yes No

Reset unit at LV10 J-Box reset switch by turning on and off

Replace pressure switch co

unit on. Wait for 30 sec.

KES unit shuts off Yes No

Reset unit at LV10 J-Box reset switch by turning on and off

be adjusted. With the filters out rotate the pressure adjustment screw slowly clock wise until the unit shuts off.

Jumper terminals 1 & 16 in the LV10 J-Box.

KES unit shuts off Yes No

Fire light on Yes No

Reset unit at LV10 J-Box reset switch by turning on and off

Turn “FAN OFF” switch in the wash panel or remote RPD10 panel to the OFF position

Jumper terminals 1 & 12

Turn “FAN ON” switch in the wash panel or remote RPD10 panel to the ON position

After 30 seconds the KES shuts off, the Prefilter Clogged light turns on and t

will appear.

Rotate the OVERRIDE switch on the RPW10 or RPD10 remote panel to the ON position.

KES unit turns on Yes No

hours” will appear.

Turn “FAN OFF” switch in the wash panel or remote RPD10 panel to the OFF position

Remove the jumper

Turn “FAN ON” switch in the wash panel or remote RPD10 panel to the ON position

Rotate the OVERRIDE switch on the RPW10

and the LOGO text message disappears.

Measure the exhaust air volume at each hood

Use hood start up form for this

Yes No

Yes No

Yes No

Yes No

Yes No

Comments:

Service Technician:_____________________________________________________________

Yes I have received a set of Spring Air Systems Inc. maintenance manuals.

Signature ___________________ Print Name ____________________

Enviro Maintenance Manual 2004

FILTER FREQUENCY CHART

Enter the date of each filter change

Startup date

Change No. Prefilter Bag Filter Box Filter Odor

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Enviro Maintenance Manual 2004

Other Fine Products From

SPRING AIR SYSTEMS...

Water Wash Ventilators

•Hot Water Wash

•Cold Water Spray/Hot Water Wash

•Water Wash Control Panels

Dry Ventilators

REV-LOW Hood

Filter Hoods

Surface Fire Suppression

Commercial Kitchen Exhaust Fans

Kitchen Enviro Systems

•KES - 100% Exhaust

Commercial Kitchen Supply Units

Bio Spray Hoods

Compensating Hoods

Loading...

Loading...